Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment

Abstract

1. Introduction

2. Drivers to BIM-Enabled Sustainable CMM: Literature Review

2.1. Knowledge Gaps

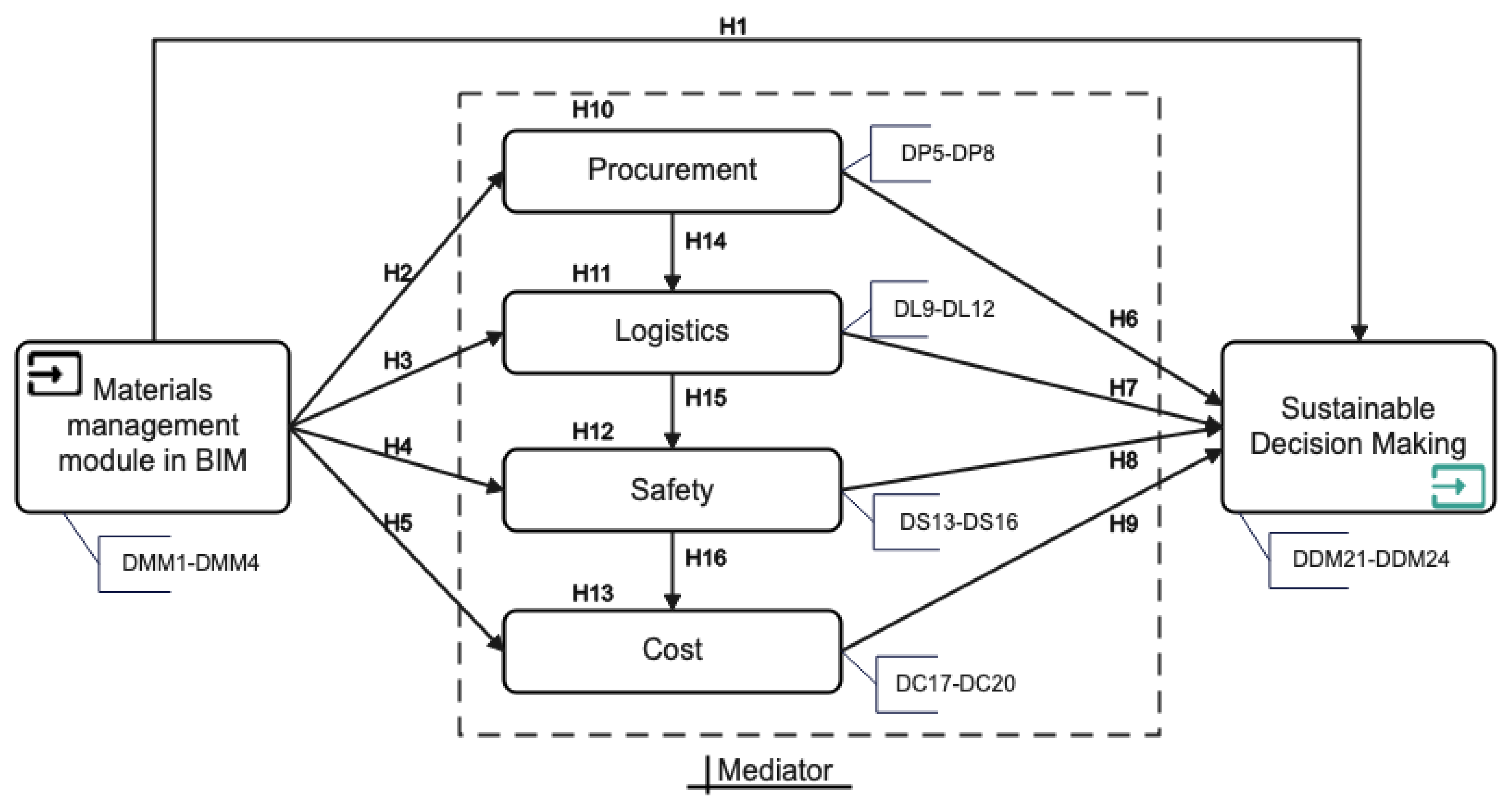

2.2. BIM-Enabled Materials Management towards Sustainable Decision Making

2.3. BIM-Enabled Materials Management’s Link to Procurement, Logistics, Safety, and Cost

2.4. Procurement, Logistics, Safety, and Cost towards Sustainable Decision-Making

2.5. Mediating Effects in the BIM-Enabled Materials Management and Sustainable Decision Making Linkage

2.6. Interrelationship between Procurement, Logistics, Safety, and Cost

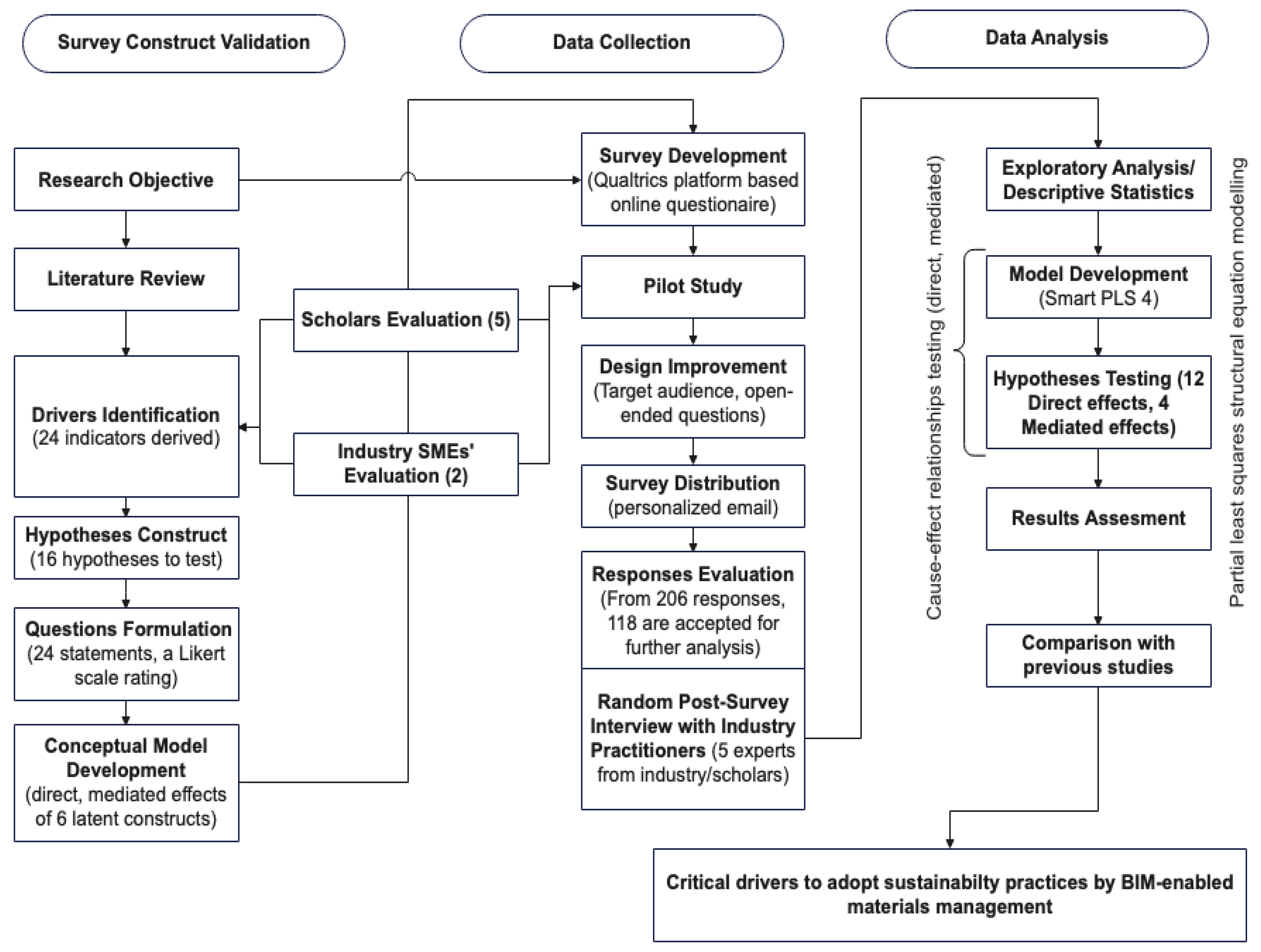

3. Research Design

3.1. Study Measures

3.2. Sample Justification

4. Data Analysis

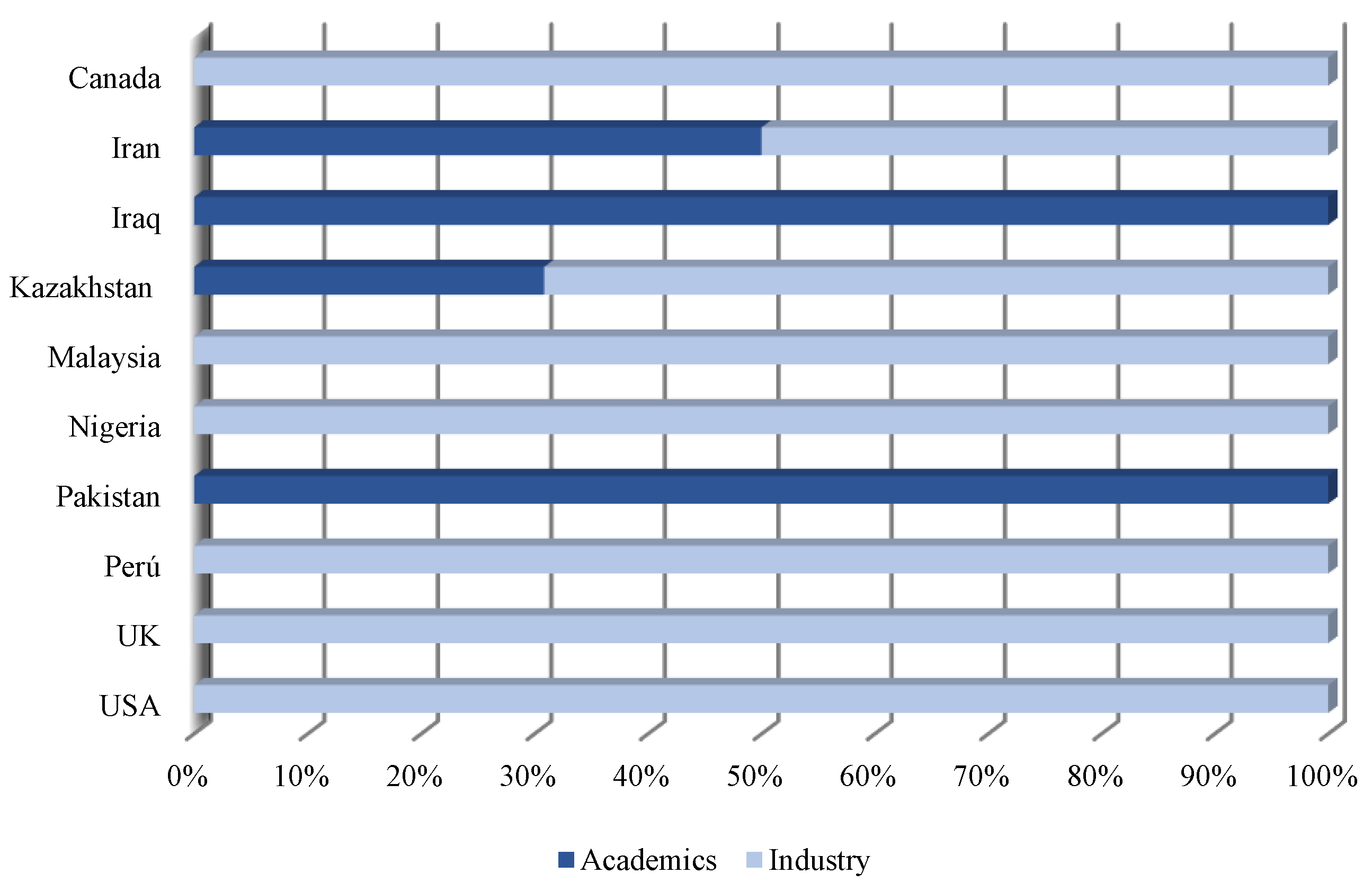

4.1. Respondent Profile

4.2. Descriptive Statistics

4.3. Reliability and Validity

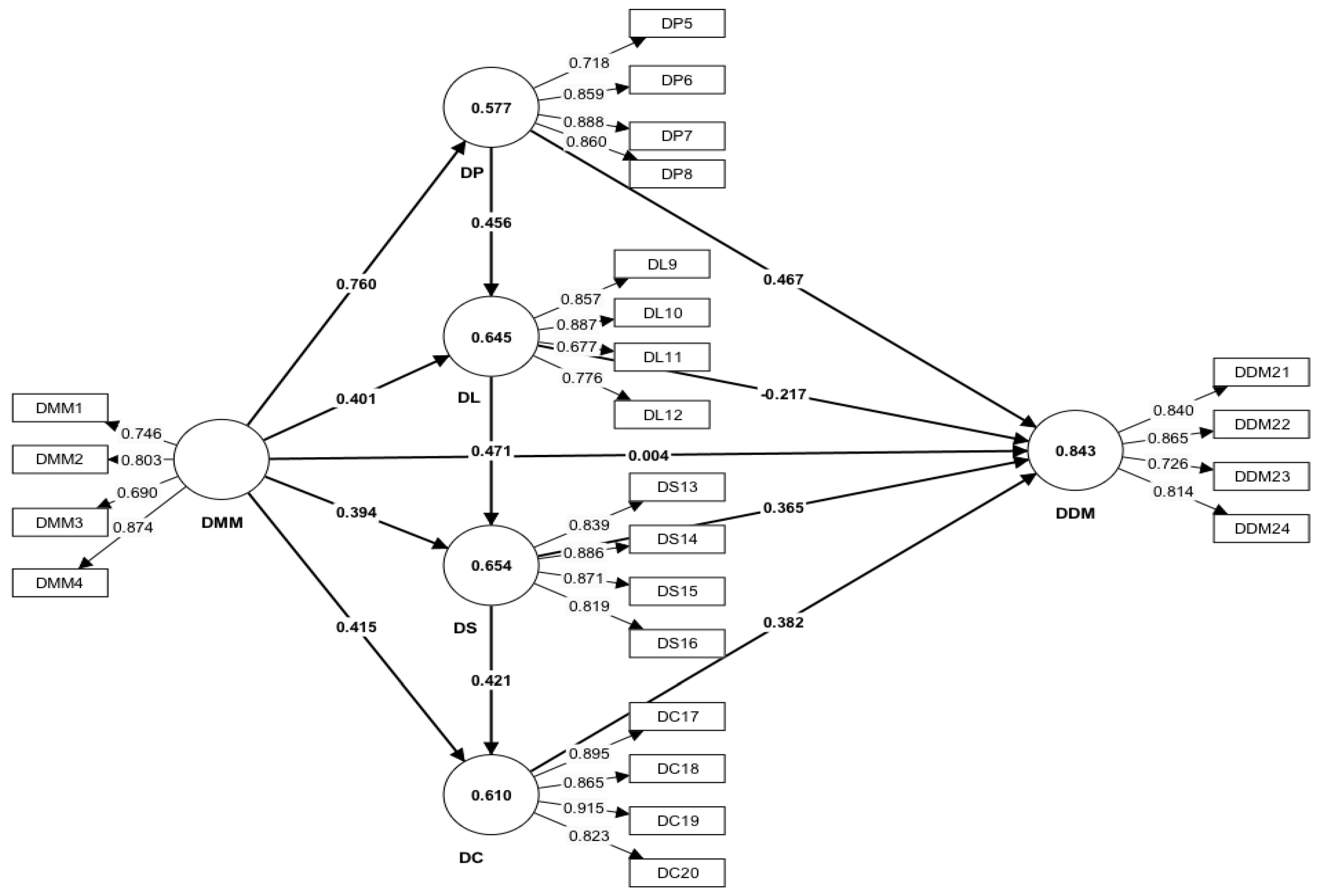

4.4. Structural Model

5. Discussion

5.1. Materials Management

5.2. Procurement

5.3. Logistics

5.4. Safety

5.5. Cost

5.6. Implications

5.7. Research Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Primeminister.kz. Kazakhstan Has Set a Target to Construct 103 Million Square Metres of Housing by 2025. 2021. Available online: https://primeminister.kz/ru/news/v-kazahstane-do-2025-goda-planiruetsya-postroit-103-mln-kv-metrov-zhilya-2811175 (accessed on 10 September 2023).

- GlobalData Plc. Kazakhstan Construction Market Size, Trend Analysis by Sector, Competitive Landscape and Forecast to 2027. 2023. Available online: https://www.globaldata.com/store/report/kazakhstan-construction-market-analysis/ (accessed on 10 September 2023).

- Atta, I.; Bakhoum, E.S.; Marzouk, M.M. Digitizing material passport for sustainable construction projects using BIM. J. Build. Eng. 2021, 43, 103233. [Google Scholar] [CrossRef]

- Rodríguez, R.C.; Lepe, J.A.D.; Torrez, L.F.J. Current situation of construction material management at international Level. Rev. Ing. Constr. 2022, 37, 79–90. [Google Scholar] [CrossRef]

- Soni, H.; Pitroda, J.; Bhavshar, J.J. Analyzing inventory material management control technique on residential construction. Int. J. Adv. Res. Innov. Ideas Educ. 2016, 2, 41–53. [Google Scholar]

- Dakhli, Z.; Lafhaj, Z. Considering Materials Management in Construction: An Exploratory Study. Logistics 2018, 2, 7. [Google Scholar] [CrossRef]

- Rathnasinghe, A.P.; Wijewickrama, M.K.C.S.; Kulatunga, U.; Jayasena, H.S. Integration of BIM and Construction Supply Chain through Supply Chain Management; An Information Flow Model. In Lecture Notes in Civil Engineering; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Papadonikolaki, E. The Digital Supply Chain. In Successful Construction Supply Chain Management, 2nd ed.; Pryke, S., Ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2020; pp. 13–41. ISBN 9781119450535. [Google Scholar]

- Thöni, A.; Tjoa, A.M. Information technology for sustainable supply chain management: A literature survey. Enterp. Inf. Syst. 2015, 11, 828–858. [Google Scholar] [CrossRef]

- Amade, B.; Akpan, P.O.E.; Amaeshi, F.U.; Okorocha, K.A.; Ogbonna, C.A. Delineating Supply Chain Management (SCM) Features in Construction Project Delivery: The Nigerian Case. Int. J. Constr. Supply Chain Manag. 2017, 7. [Google Scholar] [CrossRef]

- Hijazi, A.A.; Perera, S.; Calheiros, R.N.; Alashwal, A. Rationale for the Integration of BIM and Blockchain for the Construction Supply Chain Data Delivery: A Systematic Literature Review and Validation through Focus Group. J. Constr. Eng. Manag. 2021, 147, 103798. [Google Scholar] [CrossRef]

- Celik, Y.; Petri, I.; Barati, M. Blockchain supported BIM data provenance for construction projects. Comput. Ind. 2023, 144, 103768. [Google Scholar] [CrossRef]

- Celik, Y.; Petri, I.; Rezgui, Y. Integrating BIM and Blockchain across construction lifecycle and supply chains. Comput. Ind. 2023, 148, 103886. [Google Scholar] [CrossRef]

- Van Nieuwenhuyse, I.; De Boeck, L.; Lambrecht, M.; Vandaele, N.J. Advanced resource planning as a decision support module for ERP. Comput. Ind. 2011, 62, 1–8. [Google Scholar] [CrossRef][Green Version]

- Mathews, M.; Bowe, B.; Robles, D. BIM+Blockchain: A Solution to the Trust Problem in Collaboration? CITA BIM Gathering 2017, November 23rd–24th November 2017. Available online: https://arrow.tudublin.ie/bescharcon/26/ (accessed on 19 November 2023).

- Penzes, B. Blockchain Technology in the Construction Industry—Digital Transformation for High Productivity; Institution of Civil Engineers (ICE): London, UK, 2018. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Concept for a BIM-based Material Passport for buildings. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Brussels, Belgium, 2019; Volume 225, p. 012073. [Google Scholar] [CrossRef]

- Getuli, V.; Ventura, S.M.; Capone, P.; Ciribini, A.L. A BIM-based Construction Supply Chain Framework for Monitoring Progress and Coordination of Site Activities. Procedia Eng. 2016, 164, 542–549. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Khan, M.A. Integrating BIM with ERP Systems towards an Integrated Multi-user Interactive Database: Reverse-BIM Approach. In Proceedings of the Lecture Notes in Civil Engineering, Singapore, 24–26 March 2023; Volume 260. [Google Scholar]

- Junussova, T.; Nadeem, A.; Kim, J.R.; Azhar, S.; Khalfan, M.; Kashyap, M. Sustainable Construction through Resource Planning Systems Incorporation into Building Information Modelling. Buildings 2022, 12, 1761. [Google Scholar] [CrossRef]

- Christopher, K.; Matthias, G. Blockchain Technology How the Inventions behind Bitcoin are Enabling a Network of Trust for the Built Environment; ARUP: London, UK, 2017; Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwixgvapmZ-DAxVS2SoKHQPmCI0QFnoECAsQAQ&url=https%3A%2F%2Fwww.arup.com%2F-%2Fmedia%2Farup%2Ffiles%2Fpublications%2Fb%2Farup--blockchain-technology-report_comp.pdf&usg=AOvVaw24ey2gv46C3Y_fnrsbfR1L&opi=89978449 (accessed on 10 September 2023).

- Bella, N.; Volker, B.; Will, C.; David, G.; Santo, L.; Agnieszka, K.; Rick, R.; John, B.; Matthew, P.; Kevin, O.; et al. Blockchain and the Built Environment; ARUP: London, UK, 2019; Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwizqL3hmp-DAxVmEhAIHRozDnIQFnoECAsQAQ&url=https%3A%2F%2Fwww.arup.com%2F-%2Fmedia%2Farup%2Ffiles%2Fpublications%2Fb%2Fblockchain-and-the-built-environment.pdf&usg=AOvVaw0CrHTcPQ15jistKmBnRS0N&opi=89978449 (accessed on 10 September 2023).

- Elghaish, F.; Hosseini, M.R.; Kocaturk, T.; Arashpour, M.; Ledari, M.B. Digitalised circular construction supply chain: An integrated BIM-Blockchain solution. Autom. Constr. 2023, 148, 104746. [Google Scholar] [CrossRef]

- Lamb, K. 11-Blockchain and Smart Contracts: What the AEC Sector Needs to Know; Centre for Digital Built Britain: Cambridge, UK, 2018. [Google Scholar] [CrossRef]

- Eze, C.E.; Awodele, I.A.; Adegboyega, A.A.; Onyeagam, O.P.; Guto, J. Assessment of the triggers of inefficient materials management practices by construction SMEs in Nigeria. Int. J. Real Estate Stud. 2020, 14, 38–56. [Google Scholar]

- Deng, Y.; Gan, V.J.L.; Das, M.; Cheng, J.C.P.; Anumba, C. Integrating 4D BIM and GIS for Construction Supply Chain Management. J. Constr. Eng. Manag. 2019, 145, 04019016. [Google Scholar] [CrossRef]

- Magill, L.J.; Jafarifar, N.; Watson, A.; Omotayo, T. 4D BIM integrated construction supply chain logistics to optimise on-site production. Int. J. Constr. Manag. 2020, 22, 2325–2334. [Google Scholar] [CrossRef]

- Na, Z.; Bin, Y.; Zhixuan, Z.; Meijie, W. Application of BIM in green building materials management. In Proceedings of the 2021 7th International Conference on Mechanical Engineering, Bristol, UK, 11 August 2021; Volume 1986. [Google Scholar] [CrossRef]

- Le, P.L.; Chaabane, A.; Dao, T.-M. BIM contributions to construction supply chain management trends: An exploratory study in Canada. Int. J. Constr. Manag. 2019, 22, 66–84. [Google Scholar] [CrossRef]

- Chen, P.-H.; Nguyen, T.C. A BIM-WMS integrated decision support tool for supply chain management in construction. Autom. Constr. 2018, 98, 289–301. [Google Scholar] [CrossRef]

- Özaşkın, A.; Görener, A. An integrated multi-criteria decision-making approach for overcoming barriers to green supply chain management and prioritizing alternative solutions. Supply Chain Anal. 2023, 3, 100027. [Google Scholar] [CrossRef]

- Ma, X. Research on green building materials management system based on BIM. Chem. Eng. Trans. 2018, 66. [Google Scholar] [CrossRef]

- Toyin, J.O.; Mewomo, M.C.; Joanna, M.I.; Oyewole, M.D. An Overview of BIM as a Material Management Tool in the Construction Industry. In Proceedings of the International Conference on Construction in the 21st Century, Arnhem, The Netherlands, 8–11 May 2023; Volume 2023. [Google Scholar]

- Porwal, A.; Hewage, K.N. Building Information Modeling–Based Analysis to Minimize Waste Rate of Structural Reinforcement. J. Constr. Eng. Manag. 2012, 138, 943–954. [Google Scholar] [CrossRef]

- Wu, X. Assembly Building Material Management Method Based on BIM Technology. Prepr. Version 1 Available Res. Sq. 2020. Available online: https://www.researchsquare.com/article/rs-72285/v1 (accessed on 10 September 2023). [CrossRef]

- Marcelline, T.R.S.; Chengang, Y.; Ny Avotra, A.A.R.; Hussain, Z.; Zonia, J.E.; Nawaz, A. Impact of Green Construction Procurement on Achieving Sustainable Economic Growth Influencing Green Logistic Services Management and Innovation Practices. Front. Environ. Sci. 2022, 9, 815928. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M.; Khosravi, Y. Factors influencing safety performance on construction projects: A review. Saf. Sci. 2018, 109, 382–397. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). 2018–2022. Organization and Digitization of Information about Buildings and Civil Engineering Works, Including Building Information Modelling (BIM). ISO 19650:2018–2022 (All Parts). ISO: Geneva, Switzerland. Available online: https://www.iso.org/obp/ui (accessed on 10 September 2023).

- ISO 10845; Construction Procurement. ISO: Geneva, Switzerland, 2020.

- ISO 20400; Sustainable Procurement. ISO: Geneva, Switzerland, 2017.

- Zhineng, T. Application of BIM technology in green building material management system. Proc. E3S Web Conf. 2018, 38, 02017. [Google Scholar] [CrossRef]

- Ruparathna, R.; Hewage, K. Sustainable procurement in the Canadian construction industry: Challenges and benefits. Can. J. Civ. Eng. 2015, 42, 417–426. [Google Scholar] [CrossRef]

- Walker, H.; Miemczyk, J.; Johnsen, T.; Spencer, R. Sustainable procurement: Past, present and future. J. Purch. Supply Manag. 2012, 18, 201–206. [Google Scholar] [CrossRef]

- Machete, R.; Silva, J.R.; Bento, R.; Falcão, A.P.; Gonçalves, A.B.; de Carvalho, J.M.L.; Silva, D.V. Information transfer between two heritage BIMs for reconstruction support and facility management: The case study of the Chalet of the Countess of Edla, Sintra, Portugal. J. Cult. Herit. 2021, 49, 94–105. [Google Scholar] [CrossRef]

- Kinnunen, J.; Saunila, M.; Ukko, J.; Rantanen, H. Strategic sustainability in the construction industry: Impacts on sustainability performance and brand. J. Clean. Prod. 2022, 368, 133063. [Google Scholar] [CrossRef]

- Pero, M.; Moretto, A.; Bottani, E.; Bigliardi, B. Environmental Collaboration for Sustainability in the Construction Industry: An Exploratory Study in Italy. Sustainability 2017, 9, 125. [Google Scholar] [CrossRef]

- Worford David. Green Construction Technology Investments Surge. Environment Energy Leader. 2022. Available online: https://www.environmentenergyleader.com/2022/11/green-construction-technology-investments-surge/ (accessed on 10 September 2023).

- Beorkrem, C. Material Strategies in Digital Fabrication, 1st ed.Routledge: New York, NY, USA, 2012; pp. 174–200. ISBN 9780203100677. [Google Scholar]

- Beorkrem, C. BIM, Materials, and Fabrication. In Building Information Modeling: BIM in Current and Future Practice; Kensek, K.M., Noble, D., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 211–224. ISBN 9781119174752. [Google Scholar]

- Kar, S.; Jha, K.N. Exploring the Critical Barriers to and Enablers of Sustainable Material Management Practices in the Construction Industry. J. Constr. Eng. Manag. 2021, 147, 04021102. [Google Scholar] [CrossRef]

- Bajomo, M.; Ogbeyemi, A.; Zhang, W. A systems dynamics approach to the management of material procurement for Engineering, Procurement and Construction industry. Int. J. Prod. Econ. 2021, 244, 108390. [Google Scholar] [CrossRef]

- Islam, M.; Murad, W.; McMurray, A.J.; Abalala, T.S. Aspects of sustainable procurement practices by public and private organisations in Saudi Arabia: An empirical study. Int. J. Sustain. Dev. World Ecol. 2016, 24, 289–303. [Google Scholar] [CrossRef]

- Tang, Y.; Xia, N.; Lu, Y.; Varga, L.; Li, Q.; Chen, G.; Luo, J. BIM-based safety design for emergency evacuation of metro stations. Autom. Constr. 2021, 123, 103511. [Google Scholar] [CrossRef]

- Chatzimichailidou, M.; Ma, Y. Using BIM in the safety risk management of modular construction. Saf. Sci. 2022, 154, 105852. [Google Scholar] [CrossRef]

- Xie, Y.; Zhao, Y.; Chen, Y.; Allen, C. Green construction supply chain management: Integrating governmental intervention and public–private partnerships through ecological modernisation. J. Clean. Prod. 2021, 331, 129986. [Google Scholar] [CrossRef]

- Nadeem, A.; Wong, A.K.D.; Akhanova, G.; Azhar, S.; Wong, S.N. Application of building information modeling (BIM) in site management—Material and progress control. In Proceedings of the 21st International Symposium on Advancement of Construction Management and Real Estate, Kowloon, Hong Kong, 14–17 December 2016. [Google Scholar] [CrossRef]

- Dickson, T.; Pavía, S. Energy performance, environmental impact and cost of a range of insulation materials. Renew. Sustain. Energy Rev. 2021, 140, 110752. [Google Scholar] [CrossRef]

- Cohen, L.; Lawrence, M.; Morrison, K. Research Methods in Education, 8th ed.; Routledge: London, UK, 2017; pp. 323–333. [Google Scholar]

- Hoxley, M. Questionnaire design and factor analysis. In Advanced Research Methods in the Built Environment; Knight, A., Ruddock, L., Eds.; Wiley-Blackwell: Chichester, UK, 2008; pp. 122–134. [Google Scholar]

- Latif, K.F.; Pérez, A.; Sahibzada, U.F. Corporate social responsibility (CSR) and customer loyalty in the hotel industry: A cross-country study. Int. J. Hosp. Manag. 2020, 89, 102565. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107. [Google Scholar] [CrossRef]

- Silva, A.; Rosano, M.; Stocker, L.; Gorissen, L. From waste to sustainable materials management: Three case studies of the transition journey. Waste Manag. 2017, 61, 547–557. [Google Scholar] [CrossRef]

- EPA Sustainable Materials Management. Available online: https://www.epa.gov/smm/sustainable-materials-management-basics (accessed on 10 September 2023).

- Goh, C.S.; Chong, H.-Y.; Jack, L.; Faris, A.F.M. Revisiting triple bottom line within the context of sustainable construction: A systematic review. J. Clean. Prod. 2019, 252, 119884. [Google Scholar] [CrossRef]

- Abbasnejad, B.; Nepal, M.P.; Ahankoob, A.; Nasirian, A.; Drogemuller, R. Building Information Modelling (BIM) adoption and implementation enablers in AEC firms: A systematic literature review. Arch. Eng. Des. Manag. 2020, 17, 411–433. [Google Scholar] [CrossRef]

- Gulghane, A.A.; Khandve, P.V. Management for Construction Materials and Control of Construction Waste in Construction Industry: A Review. J. Eng. Res. Appl. 2015, 5, 59–64. [Google Scholar]

- Čuš-Babič, N.; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-chain transparency within industrialized construction projects. Comput. Ind. 2014, 65, 345–353. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2019, 111, 103063. [Google Scholar] [CrossRef]

- Yu, A.T.W.; Yevu, S.K.; Nani, G. Towards an integration framework for promoting electronic procurement and sustainable procurement in the construction industry: A systematic literature review. J. Clean. Prod. 2019, 250, 119493. [Google Scholar] [CrossRef]

- Okpala, I.; Nnaji, C.; Karakhan, A.A. Utilizing Emerging Technologies for Construction Safety Risk Mitigation. Pr. Period. Struct. Des. Constr. 2020, 25, 0000468. [Google Scholar] [CrossRef]

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean. Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Ogundipe, K.; Owolabi, J.; Ogbebor, C. Factors Militating against Effective Building Materials Management (Ebmm) in Construction Projects. Proceedings of the International Structural Engineering and Construction. 2020, Volume 7. Available online: https://d1wqtxts1xzle7.cloudfront.net/69610276/CON-19-libre.pdf?1631606855=&response-content-disposition=inline%3B+filename%3DFactors_Militating_Against_Effective_Bui.pdf&Expires=1703131720&Signature=fFKwT8IK8KyImQel02szLtvsfZDCacmin66enb4p9kDY5L485vdp9~k6Owv6aINjb3fGrkl6xFgRL0Ldw7vIkqTpxO2BzoGlddfXxpRei0LquLJURoEaMFxMzKigV-nf14DClHrwcCM06MGH42-YhSVQaDoBPgSERHZcWwxf1fBs0kfyPZLYj-91gT6R6I88vUZ2Ssseol7yaWzjYwK2OdtNXdrlmymIDb72g53aYQmgrYpuM76eH6X6NH0xSdudcwqtfFh54BSHTChDiEK5rybfFTdQce~bBv57QNecTASsfZvnMyEQH8vNIkLEhyViuPg3hEe1D9Dk2G3OE8DgmQ__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 19 November 2023).

- Jusoh, Z.M.; Kasim, N. A Review on Implication of Material Management to Project Performance. MATEC Web Conf. 2016, 87, 01012. [Google Scholar] [CrossRef]

| Abbreviation | Definition |

|---|---|

| AEC | Architecture Engineering and Construction |

| AVE | Average Variance Extracted |

| BIM | Building Information Modelling |

| CMM | Construction Material Management |

| GDP | Gross domestic product |

| GIS | Geographic information system |

| HTMT | Heterotrait–Monotrait Ratio |

| ISO | International Organization for Standardization |

| NFI | Normed Fit Index |

| PLS | Partial Least Squares |

| SEM | Structural Equation Modelling |

| SRMR | Standardized root mean square residual |

| VIF | Variance Inflation Factor |

| Scales Items | How Much Do You Agree That the Following Drivers Improve Sustainability in Construction Due to BIM-Enabled Materials Management? Drivers: Positive Results (Output) of the Process (BIM-Enabled Materials Management) | |||

|---|---|---|---|---|

| Statement | Explanation | Derived Based on Studies | ||

| I Materials Management | DMM1 | Material traceability and transparency | To mitigate the environmental impact of the construction materials’ lifecycle cost-effectively. To optimize materials consumption: governance through materials lot and serial traceability and transparency | Elghaish et al. [24], Zhineng [42], and Ruparathna and Hewage [43] |

| DMM2 | Inventory management visibility | To promote usage of project leftovers and surplus materials (use/reuse/maintenance) | Zhu Na et al. [29] and Islam et al. [44] | |

| DMM3 | Fewer, less toxic, and more durable materials usage | To improve materials planning and enable commodity re-design so they are manufactured using different, fewer, less toxic, and more durable materials (waste management) | Elghaish et al. [24] | |

| DMM4 | Materials specifications for facility management | To facilitate transferring construction to facility management: greater control over replacements, refurbishments, and renewals (cost reduction) | Machete et al. [45] and Zhineng [42] | |

| II Procurement | DP5 | Material planning and ordering | To enhance data-sharing with manufacturers/suppliers, to improve procurement reliability via consistent use of data for better material planning and ordering | Zhu Na et al. [29] and Le et al. [30] |

| DP6 | Market differentiation for construction companies that adopt sustainable practices | To increase the inventory management system’s visibility for proper tracking of project resources and project leftovers to reduce over-ordering | Walker et al. [44], Jorma Kinnunen et al. [46], and Pero et al. [47] | |

| DP7 | Material and corporate sustainability assessment | To cooperate with local manufacturers/suppliers as alternative sources and, therefore, minimize embodied carbon material purchasing | Elghaish et al. [24] | |

| DP8 | Investment in sustainable construction technologies and materials | To create shared value approaches with manufacturers/suppliers and facilitate the assessment of product and corporate sustainability in general | David Worford [48], Beorkrem [49,50], and Kar and Jha [51] | |

| III Logistics | DL9 | Delivery Scheduling | To improve material delivery scheduling by having real-time data on material characteristics and properties | Xiaoqiu Ma [33] and Bajomo et al. [52] |

| DL10 | Shipping routes and mode selection optimization | To optimize the shipping routes and mode selection by having real-time data on material characteristics and properties | Getuli et al. [18] and Zhineng [42] | |

| DL11 | Emissions reduction | To reduce emissions by distributing the load in each vehicle by having real-time data on material characteristics, properties, and locations | Thöni et al. [9] and Walker et al. [44] | |

| DL12 | Delivery cost decrease | To reduce the cost of delivery by enhancing shipment track and transporting goods from one place to another | Getuli et al. [18] and Xiaoqiu Ma [33] | |

| IV Safety | DS13 | Hazard-based design choices | To evaluate the likelihood of hazard-based design choices for making safety-conscious decisions (e.g., material selection and clash detection) | Deng et al. [27] |

| DS14 | Workplace, operation, and maintenance safety | To reduce the production of waste on construction sites (e.g., material cut-offs) to improve workplace safety performance | Getuli et al. [18], Ruparathna and Hewage [43], and Islam et al. [53] | |

| DS15 | Building evacuation performance | To improve evacuation performance of building layout design under various fire scenarios | Tang et al. [54] and Chatzimichailidou and MA [55] | |

| DS16 | Innovation and competition in sustainable construction practices | To facilitate transferring construction projects to facility management: greater control over replacements, refurbishments, and renewals | Ying Xie et al. [56] | |

| V Cost | DC17 | Cost savings through streamlined processes | To cut operational costs through time and resource optimization and increase net profit from the construction materials supply chain by minimizing risks and errors | Xiaoqiu Ma [33] |

| DC18 | Supply-demand planning, work order scheduling | To reduce cost by improving supply–demand planning, work order scheduling, and forecasting | Nadeem et al. [57], Magill et al. [28], and Le et al. [30] | |

| DC19 | Resource management cost reduction | To reduce the additional cost of purchasing, inventory, and disposal associated with over-purchasing materials | Zhu Na et al. [29] and Porwal and Hewage [35] | |

| DC20 | Process waste cost decrease | To decrease process waste by letting resource planning systems sustainably process operational activities, while BIM efficiently improves sustainability at the design stage | Xiaoqiu Ma [33] and Zhineng [42] | |

| VI Decision Making | DDM21 | Streamlining data workflow for decision-making | To optimize, streamline, and automate data workflow and improve decision-making by providing real-time data | Getuli et al. [18], Papadonikolaki [8], and Bajomo et al. [52] |

| DDM22 | Stakeholders’ collaboration and data sharing | To enhance dialogue and data sharing among stakeholders | Getuli et al. [18], Papadonikolaki [8], and Atta et al. [3] | |

| DDM23 | Sustainability awareness and education | To improve data workflow efficiency by implementing integrated solutions rather than adopting a fragmented solution | Atta et al. [3], Magill et al. [28], and Ruparathna and Hewage [43] | |

| DDM24 | Building’s performance and life-long environmental impact tracking | To analyse a building’s performance and quantify a building’s life-long environmental impact before construction | Dickson and Pavía [58] | |

| Experience/Education | BSc | MSc | PhD | Other |

|---|---|---|---|---|

| 0–10 years | 36 | 22 | 6 | 5 |

| 11–20 years | 21 | 14 | 3 | 1 |

| Above 20 years | 3 | 4 | 3 |

| Indicator | Mean | SD | Excess Kurtosis | Skewness | Indicator | Mean | SD | Excess Kurtosis | Skewness |

|---|---|---|---|---|---|---|---|---|---|

| DMM1 | 4.472 | 0.942 | 4.744 | −2.206 | DS13 | 4.361 | 0.822 | 0.928 | −1.229 |

| DMM2 | 4.528 | 0.849 | 4.524 | −2.103 | DS14 | 4.333 | 0.913 | 0.274 | −1.169 |

| DMM3 | 4.306 | 0.876 | −0.924 | −0.774 | DS15 | 4.264 | 0.986 | 0.616 | −1.18 |

| DMM4 | 4.542 | 0.763 | 3.294 | −1.871 | DS16 | 4.444 | 0.815 | 3.892 | −1.785 |

| DP5 | 4.583 | 0.777 | 7.641 | −2.55 | DC17 | 4.403 | 0.892 | 1.386 | −1.497 |

| DP6 | 4.125 | 0.815 | −0.467 | −0.552 | DC18 | 4.472 | 0.816 | 1.731 | −1.553 |

| DP7 | 4.389 | 0.792 | 0.703 | −1.169 | DC19 | 4.361 | 0.855 | 2.934 | −1.599 |

| DP8 | 4.472 | 0.745 | 0.709 | −1.242 | DC20 | 4.222 | 0.931 | 1.152 | −1.202 |

| DL9 | 4.333 | 0.913 | 0.703 | −1.281 | DDM21 | 4.403 | 0.877 | 3.319 | −1.781 |

| DL10 | 4.333 | 0.882 | 0.121 | −1.089 | DDM22 | 4.528 | 0.745 | 2.323 | −1.642 |

| DL11 | 4.208 | 0.942 | −0.811 | −0.74 | DDM23 | 4.472 | 0.763 | 0.557 | −1.244 |

| DL12 | 4.028 | 1 | −0.373 | −0.653 | DDM24 | 4.417 | 0.795 | 0 | −1.075 |

| Extraction Sums of Squared Loadings | ||

|---|---|---|

| Total | % of Variance | Cumulative % |

| 28.221 | 47.037 | 47.034 |

| Extraction Method: Principal Axis Factoring. a. 1 factor extracted. 3 iterations required. | ||

| Drivers | |||||

|---|---|---|---|---|---|

| Outer Loading | Cronbach’s Alpha | CR (rho_c) | AVE | VIF | |

| Materials management | 0.784 | 0.862 | 0.610 | ||

| DMM1 | 0.746 | 1.543 | |||

| DMM2 | 0.803 | 1.707 | |||

| DMM3 | 0.690 | 1.348 | |||

| DMM4 | 0.874 | 2.065 | |||

| Procurement | 0.851 | 0.901 | 0.696 | ||

| DP5 | 0.718 | 1.395 | |||

| DP6 | 0.859 | 2.483 | |||

| DP7 | 0.888 | 2.632 | |||

| DP8 | 0.860 | 2.386 | |||

| Logistics | 0.812 | 0.878 | 0.645 | ||

| DL9 | 0.857 | 2.537 | |||

| DL10 | 0.887 | 2.531 | |||

| DL11 | 0.677 | 1.413 | |||

| DL12 | 0.776 | 1.830 | |||

| Safety | 0.876 | 0.915 | 0.729 | ||

| DS13 | 0.839 | 2.086 | |||

| DS14 | 0.886 | 2.913 | |||

| DS15 | 0.871 | 2.691 | |||

| DS16 | 0.819 | 1.801 | |||

| Cost | 0.898 | 0.929 | 0.766 | ||

| DC17 | 0.895 | 3.406 | |||

| DC18 | 0.865 | 2.447 | |||

| DC19 | 0.915 | 3.901 | |||

| DC20 | 0.823 | 2.208 | |||

| Decision Making | 0.828 | 0.886 | 0.661 | ||

| DDM21 | 0.840 | 2.355 | |||

| DDM22 | 0.865 | 2.443 | |||

| DDM23 | 0.726 | 1.667 | |||

| DDM24 | 0.814 | 1.936 | |||

| Drivers | ||||||

|---|---|---|---|---|---|---|

| DMM | DP | DL | DS | DC | DDM | |

| DMM1 | 0.746 | 0.564 | 0.457 | 0.446 | 0.539 | 0.507 |

| DMM2 | 0.803 | 0.522 | 0.535 | 0.634 | 0.643 | 0.657 |

| DMM3 | 0.690 | 0.630 | 0.591 | 0.565 | 0.368 | 0.488 |

| DMM4 | 0.874 | 0.661 | 0.724 | 0.662 | 0.695 | 0.660 |

| DP5 | 0.703 | 0.718 | 0.553 | 0.538 | 0.647 | 0.640 |

| DP6 | 0.604 | 0.859 | 0.664 | 0.593 | 0.500 | 0.663 |

| DP7 | 0.623 | 0.888 | 0.698 | 0.643 | 0.677 | 0.755 |

| DP8 | 0.603 | 0.860 | 0.610 | 0.526 | 0.559 | 0.704 |

| DL9 | 0.624 | 0.667 | 0.857 | 0.671 | 0.686 | 0.647 |

| DL10 | 0.685 | 0.612 | 0.887 | 0.688 | 0.644 | 0.602 |

| DL11 | 0.607 | 0.560 | 0.677 | 0.589 | 0.477 | 0.496 |

| DL12 | 0.459 | 0.597 | 0.776 | 0.485 | 0.631 | 0.522 |

| DS13 | 0.608 | 0.547 | 0.597 | 0.839 | 0.546 | 0.702 |

| DS14 | 0.643 | 0.599 | 0.671 | 0.886 | 0.680 | 0.680 |

| DS15 | 0.549 | 0.514 | 0.692 | 0.871 | 0.601 | 0.661 |

| DS16 | 0.735 | 0.691 | 0.650 | 0.819 | 0.657 | 0.698 |

| DC17 | 0.612 | 0.638 | 0.710 | 0.609 | 0.895 | 0.726 |

| DC18 | 0.666 | 0.632 | 0.732 | 0.741 | 0.865 | 0.753 |

| DC19 | 0.566 | 0.602 | 0.616 | 0.584 | 0.915 | 0.676 |

| DC20 | 0.694 | 0.631 | 0.596 | 0.604 | 0.823 | 0.703 |

| DDM21 | 0.639 | 0.642 | 0.735 | 0.802 | 0.796 | 0.840 |

| DDM22 | 0.653 | 0.656 | 0.535 | 0.648 | 0.787 | 0.865 |

| DDM23 | 0.632 | 0.711 | 0.469 | 0.517 | 0.512 | 0.726 |

| DDM24 | 0.496 | 0.712 | 0.542 | 0.614 | 0.528 | 0.814 |

| DC | DDM | DL | DMM | DP | DS | |

|---|---|---|---|---|---|---|

| DC | 0.875 | 0.933 | 0.889 | 0.854 | 0.818 | 0.815 |

| DDM | 0.809 | 0.813 | 0.854 | 0.919 | 0.997 | 0.932 |

| DL | 0.762 | 0.710 | 0.803 | 0.923 | 0.915 | 0.900 |

| DMM | 0.729 | 0.746 | 0.747 | 0.781 | 0.936 | 0.889 |

| DP | 0.717 | 0.831 | 0.760 | 0.760 | 0.834 | 0.797 |

| DS | 0.730 | 0.803 | 0.765 | 0.745 | 0.692 | 0.854 |

| Hypotheses | Beta (B) | T-Value | p Value | Results | |

|---|---|---|---|---|---|

| H1 | Materials Management -> Sustainable Decision Making (DMM -> DDM) | 0.004 | 0.035 | 0.972 | Not Accepted |

| H2 | Materials Management -> Procurement (DMM -> DP) | 0.760 | 9.254 | 0.000 | Accepted |

| H3 | Materials Management -> Logistics (DMM -> DL) | 0.401 | 2.814 | 0.005 | Accepted |

| H4 | Materials Management -> Safety (DMM -> DS) | 0.394 | 2.534 | 0.011 | Accepted |

| H5 | Materials Management -> Cost (DMM -> DC) | 0.415 | 2.837 | 0.005 | Accepted |

| H6 | Procurement -> Sustainable Decision Making (DP -> DDM) | 0.467 | 4.281 | 0.000 | Accepted |

| H7 | Logistics -> Sustainable Decision Making (DL -> DDM) | −0.217 | 2.378 | 0.017 | Accepted |

| H8 | Safety -> Sustainable Decision Making (DS -> DDM) | 0.365 | 3.370 | 0.001 | Accepted |

| H9 | Cost -> Sustainable Decision Making (DC -> DDM) | 0.382 | 2.915 | 0.004 | Accepted |

| H14 | Procurement -> Logistics (DP -> DL) | 0.456 | 3.242 | 0.001 | Accepted |

| H15 | Logistics -> Safety (DL -> DS) | 0.471 | 3.200 | 0.001 | Accepted |

| H16 | Safety -> Cost (DS -> DC) | 0.421 | 3.082 | 0.002 | Accepted |

| H10 | Materials Management -> Procurement -> Sustainable Decision Making (DMM -> DP -> DDM) | Accepted | ||||

| H11 | Materials Management -> Logistics -> Sustainable Decision Making (DMM -> DL -> DDM) | Not Accepted | ||||

| H12 | Materials Management -> Safety -> Sustainable Decision Making (DMM -> DS -> DDM) | Accepted | ||||

| H13 | Materials Management -> Cost -> Sustainable Decision Making (DMM -> DC -> ODM) | Accepted | ||||

| Hypothesis | Indirect Effect | BI 2.5–97.5% | ||||

| Beta (B) | T-Value | p-Value | ||||

| H10 DMM -> DP -> DDM | 0.355 | 3.817 | 0.000 | 0.182 | 0.545 | |

| H11 DMM -> DL -> DDM | −0.087 | 1.608 | 0.108 | −0.225 | −0.013 | |

| H12 DMM -> DS -> DDM | 0.144 | 2.049 | 0.041 | 0.031 | 0.311 | |

| H13 DMM -> DC -> DDM | 0.159 | 1.983 | 0.047 | 0.039 | 0.381 | |

| Beta (B) | Mean | SD | T-Value | p Value | |

|---|---|---|---|---|---|

| DMM -> DP -> DDM | 0.355 | 0.350 | 0.093 | 3.817 | 0.000 |

| DMM -> DP -> DL -> DDM | −0.075 | −0.079 | 0.042 | 1.793 | 0.073 |

| DMM -> DP -> DL -> DS -> DDM | 0.059 | 0.065 | 0.043 | 1.383 | 0.167 |

| DMM -> DP -> DL -> DS -> DC -> DDM | 0.026 | 0.024 | 0.015 | 1.744 | 0.081 |

| DMM -> DP -> DL | 0.346 | 0.346 | 0.117 | 2.951 | 0.003 |

| DMM -> DP -> DL -> DS | 0.163 | 0.162 | 0.079 | 2.077 | 0.038 |

| DMM -> DP -> DL -> DS -> DC | 0.069 | 0.072 | 0.045 | 1.539 | 0.124 |

| DMM -> DL -> DDM | −0.087 | −0.093 | 0.054 | 1.608 | 0.108 |

| DMM -> DL -> DS -> DDM | 0.069 | 0.068 | 0.036 | 1.908 | 0.056 |

| DMM -> DL -> DS -> DC -> DDM | 0.030 | 0.028 | 0.018 | 1.642 | 0.101 |

| DMM -> DL -> DS | 0.189 | 0.186 | 0.089 | 2.116 | 0.034 |

| DMM -> DL -> DS -> DC | 0.079 | 0.076 | 0.038 | 2.068 | 0.039 |

| DMM -> DS -> DDM | 0.144 | 0.147 | 0.070 | 2.049 | 0.041 |

| DMM -> DS -> DC -> DDM | 0.063 | 0.062 | 0.042 | 1.495 | 0.135 |

| DMM -> DS -> DC | 0.166 | 0.172 | 0.094 | 1.760 | 0.078 |

| DMM -> DC -> DDM | 0.159 | 0.148 | 0.080 | 1.983 | 0.047 |

| DP -> DL -> DS | 0.215 | 0.217 | 0.103 | 2.093 | 0.036 |

| DP -> DL -> DS -> DC | 0.090 | 0.096 | 0.058 | 1.561 | 0.119 |

| DP -> DL -> DS -> DDM | 0.078 | 0.087 | 0.057 | 1.379 | 0.168 |

| DP -> DL -> DS -> DC -> DDM | 0.034 | 0.032 | 0.020 | 1.729 | 0.084 |

| DP -> DL -> DDM | −0.099 | −0.104 | 0.053 | 1.867 | 0.062 |

| DL -> DS -> DDM | 0.172 | 0.179 | 0.084 | 2.051 | 0.040 |

| DL -> DS -> DC -> DDM | 0.076 | 0.070 | 0.036 | 2.078 | 0.038 |

| DL -> DS -> DC | 0.198 | 0.199 | 0.086 | 2.314 | 0.021 |

| DS -> DC -> DDM | 0.161 | 0.153 | 0.072 | 2.228 | 0.026 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junussova, T.; Nadeem, A.; Kim, J.R.; Azhar, S. Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment. Buildings 2024, 14, 84. https://doi.org/10.3390/buildings14010084

Junussova T, Nadeem A, Kim JR, Azhar S. Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment. Buildings. 2024; 14(1):84. https://doi.org/10.3390/buildings14010084

Chicago/Turabian StyleJunussova, Tokzhan, Abid Nadeem, Jong R. Kim, and Salman Azhar. 2024. "Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment" Buildings 14, no. 1: 84. https://doi.org/10.3390/buildings14010084

APA StyleJunussova, T., Nadeem, A., Kim, J. R., & Azhar, S. (2024). Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment. Buildings, 14(1), 84. https://doi.org/10.3390/buildings14010084