Structural Design and Technology of Pocket Foundations for Long Precast Concrete Columns in Seismic Areas

Abstract

:1. Introduction

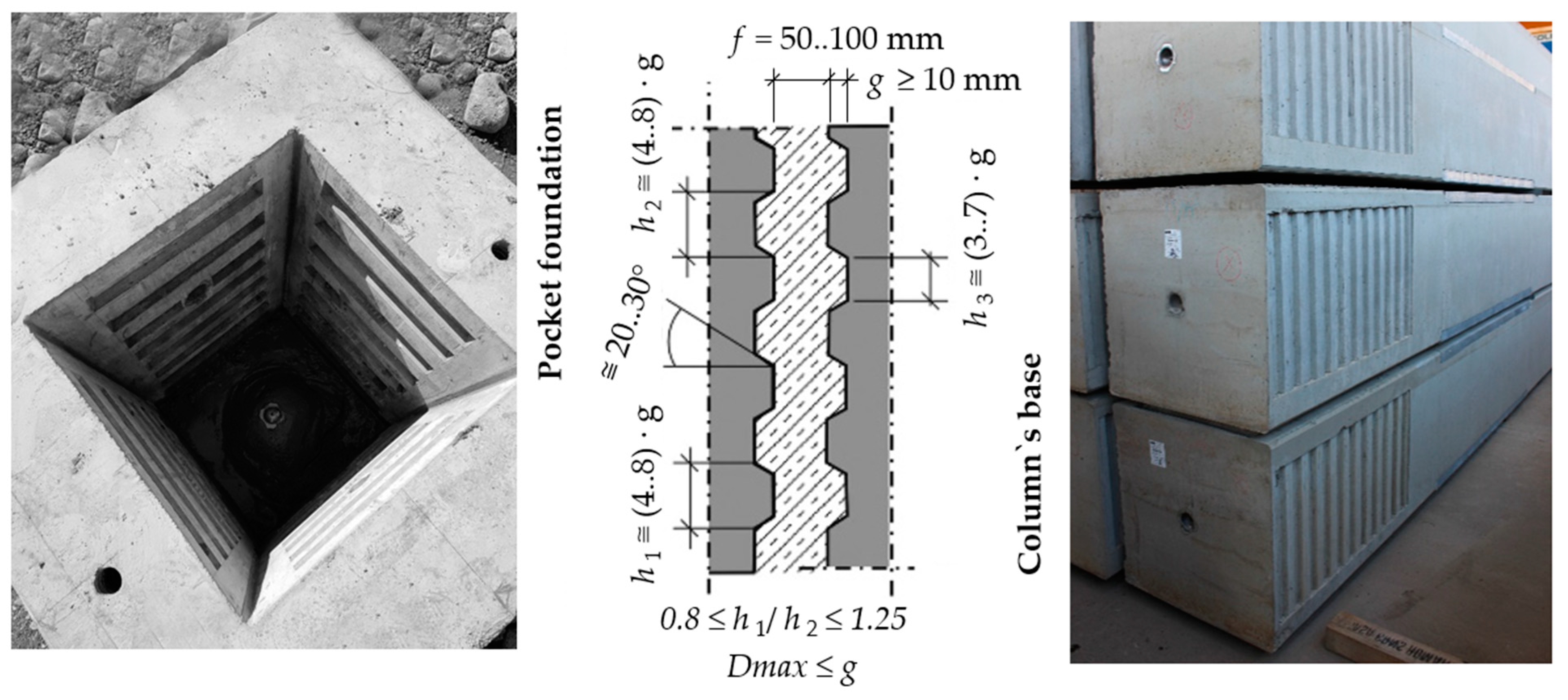

- Pedestal pocket foundation with smooth internal walls;

- Pedestal pocket foundation with rough internal walls;

- Pedestal pocket foundation with keyed internal walls;

- Pad foundation with pocket and keyed internal walls.

- The level at which good soil is located (TBF) in relation to the natural land level (CTN) and the developed land level (CTA), and implicitly compared to the ±0.00 level of the future construction;

- The nature of the soil and the execution technology used for the infrastructure;

- The groundwater level (NAS);

- The reaction forces transmitted by the superstructure and their magnitude;

- The owner’s requirements;

- Quality control in conjunction with building costs.

2. Materials and Technology

- Choosing the materials used (concrete classes, types of reinforcement) and the type of foundation;

- Choosing the technology for mounting the column in the pocket foundation;

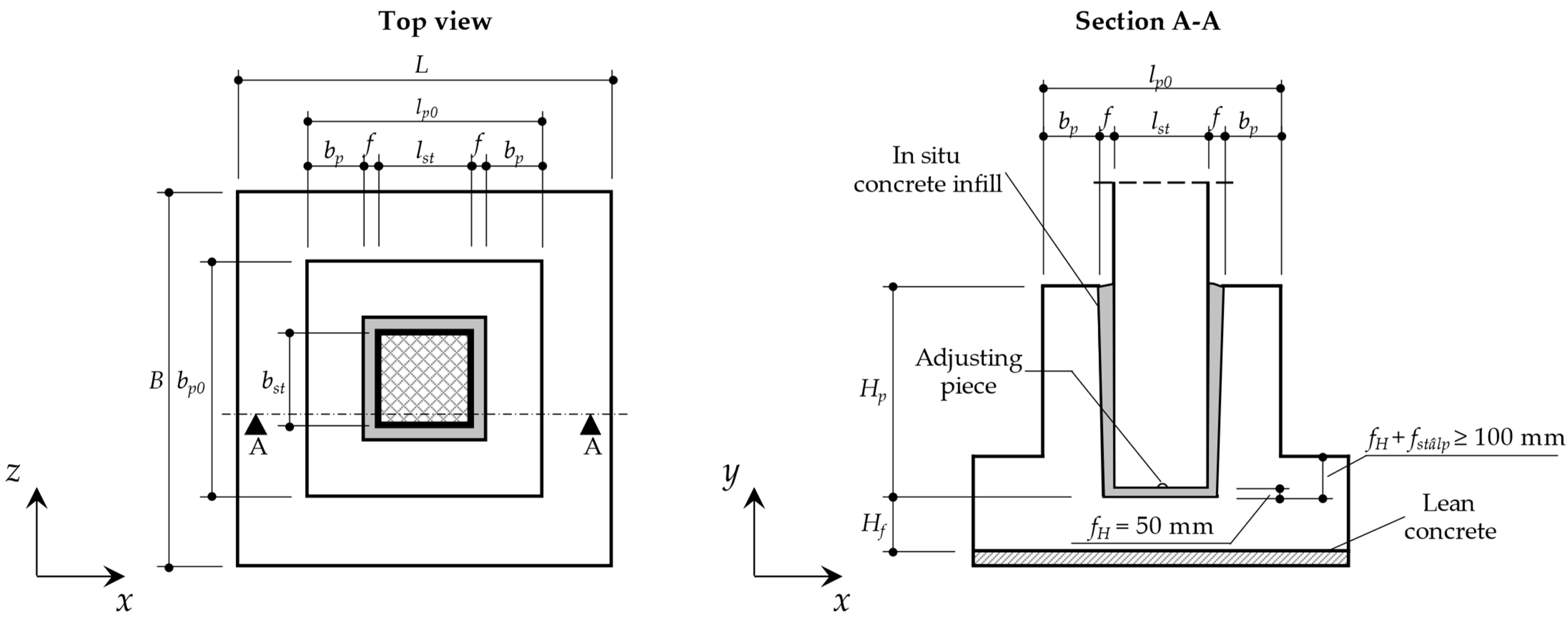

- Pre-dimensioning of the pocket foundation (height of the pocket Hp, wall thickness bp, and concrete infill thickness f, fH and fstâlp);

- Dimensioning of the pocket foundation (checking the concrete cross-section, calculating the amount of reinforcement necessary and reinforcement positioning in the concrete volume);

- Dimensioning of the slab foundation (foundation footing);

- Preparation of technical drawings;

- The inclusion of the construction particularities in the “Technical specifications”.

2.1. Materials and Choosing the Type of Foundation

- (a)

- Compressive strength class: Denotes the characteristic value of the concrete compressive strength determined for a concrete cylinder, respectively, and the characteristic value of the compressive strength determined for a concrete cube, both expressed in MPa. Therefore, a concrete whose characteristic value for compressive strength is at least 30 MPa per cylinder, respectively, at least 37 MPa per cube, will be marked with C30/37 (Figure 2);

- (b)

- Environmental exposure class: This is correlated with the lifetime and maintenance of the structure (usually 50 years). Depending on the environmental conditions to which the structure is exposed (infrastructure, respectively, superstructure, as the case may be), the corresponding exposure classes will be identified. Reinforced concrete elements will be classified in one or more exposure classes, such as XC1..4 (risk of corrosion of steel by carbonation), XA1..3 (risk of a chemical attack on concrete), XD1..3 (risk of corrosion of steel due to chlorides), XS1..3 (risk of corrosion of steel due to chlorides in seawater), XF1..3 (risk of attack on concrete by freeze–thaw), etc. For example, a reinforced concrete foundation in a humid and rarely dry environment corresponds to exposure class XC2, and this implies the use of a minimum class of C25/30 concrete (Figure 2);

- (c)

- Class of chlorides: This is the maximum amount of chlorides contained in fresh concrete with reference to the mass of the cement in its composition. Both the amount of chlorides contained in the aggregates and the amount of chloride ions, Cl−, in the fresh concrete mixture should be considered. For example, for steel-reinforced concrete, the maximum chloride content of the aggregates is 0.04%, and the maximum Cl− content by mass of cement is 0.2% or 0.4%. As a result, reinforced concrete will be marked by Cl 0.20 or Cl 0.40, both classes being accepted;

- (d)

- Consistency class: This denotes the workability of fresh concrete. For example, fluid concrete is denoted by S4;

- (e)

- Density class: This indicates the density of unreinforced (plain) concrete in its dry state. Concrete with a density equal to 2.4 tons/m3 can be marked as D2.4.

- The maximum tension in the concrete for the considered structural member;

- The ductility class of the structure (seismic design);

- The exposure class.

2.2. The Technology of Mounting the Column in the Pocket Foundation

- (a)

- Marking the axes of the foundation and positioning the centering device on the bottom of the pocket on a concrete layer that is approx. 50 mm thick (at least of the same strength class as the infill concrete);

- (b)

- Marking the station points of the mobile crane (by beating poles or painting the ground surfaces) and parking points for the trailer (when the installation is done directly with unloading from the transport equipment) in accordance with the technological project;

- (c)

- Transporting the columns in the vicinity of the final mounting position;

- (d)

- Cleaning the inner surfaces of the pocket and the outer surfaces at the base of the column;

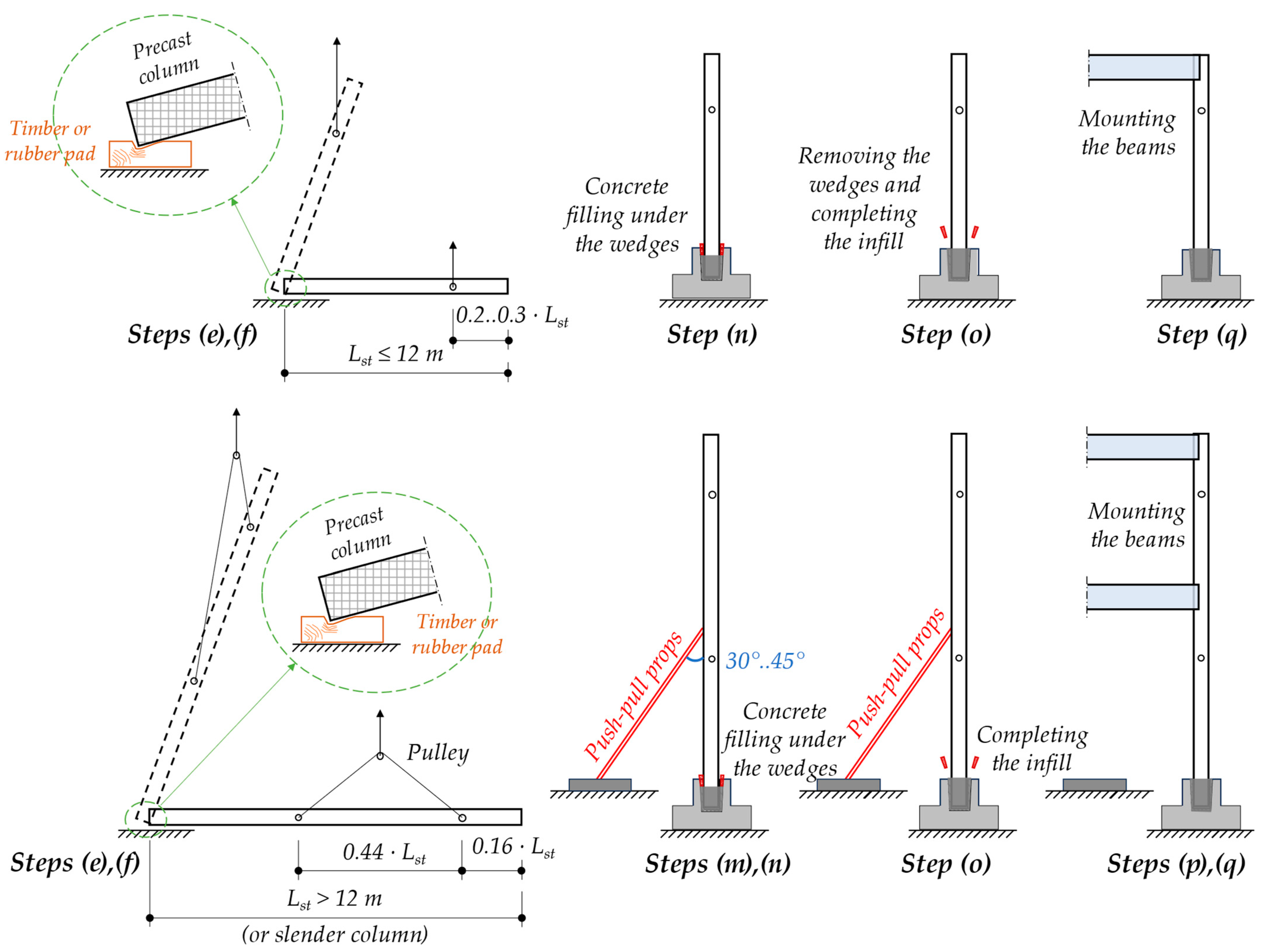

- (e)

- After positioning and centering the mobile crane, the handling device is fixed on its hook and mounting of the columns starts;

- (f)

- After placing the column horizontally on the ground, the column is lifted again to be brought to a vertical position (by crawling, turning or tipping);

- (g)

- Cleaning the column’s leaning areas and marking down the structural axes on the sides;

- (h)

- Fastening the guide ropes to the column;

- (i)

- Slow lowering of the column into the foundation and adjusting its position by workers with the help of ropes and two crowbars so that the axes marked on the column coincide with the position of the axes marked on the foundation;

- (j)

- Verifying the verticality of the precast column on the two orthogonal sides using a plumb line, bubble level (spirit level) or laser level, followed by the initial temporary fixation of the column at the foundation level by hammering special hardwood wedges (e.g., oak, beech, acacia, etc.) on each side (minimum 6 wedges in total, of which on two parallel faces there are at least 2 pieces) [20]. The geometry of a wedge is a quadrilateral prism type, with one of the faces chamfered under an angle of 10 sexagesimal degrees [20], with a length of about 300 mm and a width of about 100 mm (Figure 3). The geometry of the wedge is made in such a way that after hammering, it remains above the pocket foundation by approx. 120 mm. The use of wedges with too large angles, wedges made of soft wood (e.g., spruce, fir, pine, etc.) or overlapping wedges to compensate for their insufficient thickness may lead to the rotation of the columns in the foundation under the wind action or under an accidental action (e.g., the collision of heavy members with columns) and their collapse in the intermediate phases of construction execution (Figures S1–S9, Videos S1 and S2). In the mentioned figures and videos, one can see the domino effect following the rotation of a column in the pocket foundation caused by a gust of wind with a speed of up to 80 km/h. The dynamic action of wind can cause the expulsion of the wooden wedges as a result of the cyclical/balanced movement of the precast column. From a row of 11 precast reinforced concrete columns, the first column did not rotate in the pocket foundation, the second column rotated (the wooden wedges being crushed or expelled), and the deformed shape of the column was large enough to hit the third standing column (Figure S1). Following the impact, the third column rotated in the pocket foundation (by crushing the wooden wedges or by expelling them, Figure S2), hitting the fourth column. After the impact, the fourth rotated at the base and deformed and broke under its own weight. Now broken, in the fall, the fourth column hit the fifth column with amplification from the shock, and the remaining failures happened similarly, ending with a total of 8 prefabricated columns collapsing (Figures S3–S9). It can be noticed that the first fallen columns (the fourth and fifth) developed a single plastic joint each (the cross-section broke at the base), but the next 5 columns developed two plastic joints each (one at the base and one at the middle of the height as a result of the change in the static scheme: from a cantilevering beam to that of a beam hinged in the foundation and supported at the top). The causes of the failure could be one or more of the following: A high wind loading in the intermediate construction phase (the precast column–pocket foundation interspace was not completed); the fixing with wooden wedges was not correctly carried out (insufficient wedges, wedges with a chamfering of only about 20°…30°, the wooden wedges were short, the thickness of the wooden wedges was supplemented by using short ends of wooden slats or softwood was used); and the distance between the pocket foundation internal wall and the precast concrete column (thickness of the concrete infill layer) was excessively large—a situation in which after the expulsion of the wedges, the rotation of the column at the base was so great that its tip collided with the neighboring column;

- (k)

- Checking the verticality of the precast column using more precise equipment (with topometric devices), adjusting the position of the column by loosening/hammering the oak wedges;

- (l)

- For slender precast reinforced concrete columns, as well as for those whose length exceeds 12 m, it is recommended to use tilt props or scaffoldings for additional temporary fixing (Figure 4). The tilt props will be mounted in such a way that they can take compression forces (and tensile forces, if possible), their inclination should be at 30°…45° (the angle measured between the longitudinal axis of the prop and the column) and their arrangement must provide stability in two orthogonal directions in the horizontal plane. In the case of exceptionally long columns, scaffolding or other temporary constructions with a similar effect will be used for temporary support;

- (m)

- Additional topometric verification is required after mounting all columns in both horizontal directions (in-plane) and vertically (in elevation). At the end, the final hammering of the oak wedges is carried out, and if tilt props/scaffolding are used, they will be firmly fixed to the concrete blocks and to the columns;

- (n)

- The concrete surfaces that come into contact with the fresh infill concrete (the base of the column and inner surfaces of the pocket) are sprayed with water. The infill concrete is poured until it reaches the bottom level of the oak wedges. After pouring, the fresh infill concrete is vibrated with a concrete compactor;

- (o)

- The oak wedges are removed after the infill concrete has reached approx. 70% of the compressive strength (approx. 3 days) that the infill concrete has at 28 days. Sprinkling with water (watering) the hardened concrete surfaces that come into contact with the rest of the fresh concrete for filling the remaining column-pocket interspace;The tilt props/scaffolding are removed after the last part of the infill concrete is poured into the interspace and has reached approx. 70% of the compressive strength that the infill concrete has at 28 days;

- (p)

- Mounting the beams is carried out after the concrete filling in the column–pocket interspace is completed (Figure 4), has hardened and has reached the strength class mentioned in the project’s technical documentation (e.g., technical drawings, technical specifications, etc.) unless there are other specifications from the structural engineer.

3. Pre-Dimensioning and Design Method

3.1. Pre-Dimensioning of Socket in Pedestal Pocket Foundation

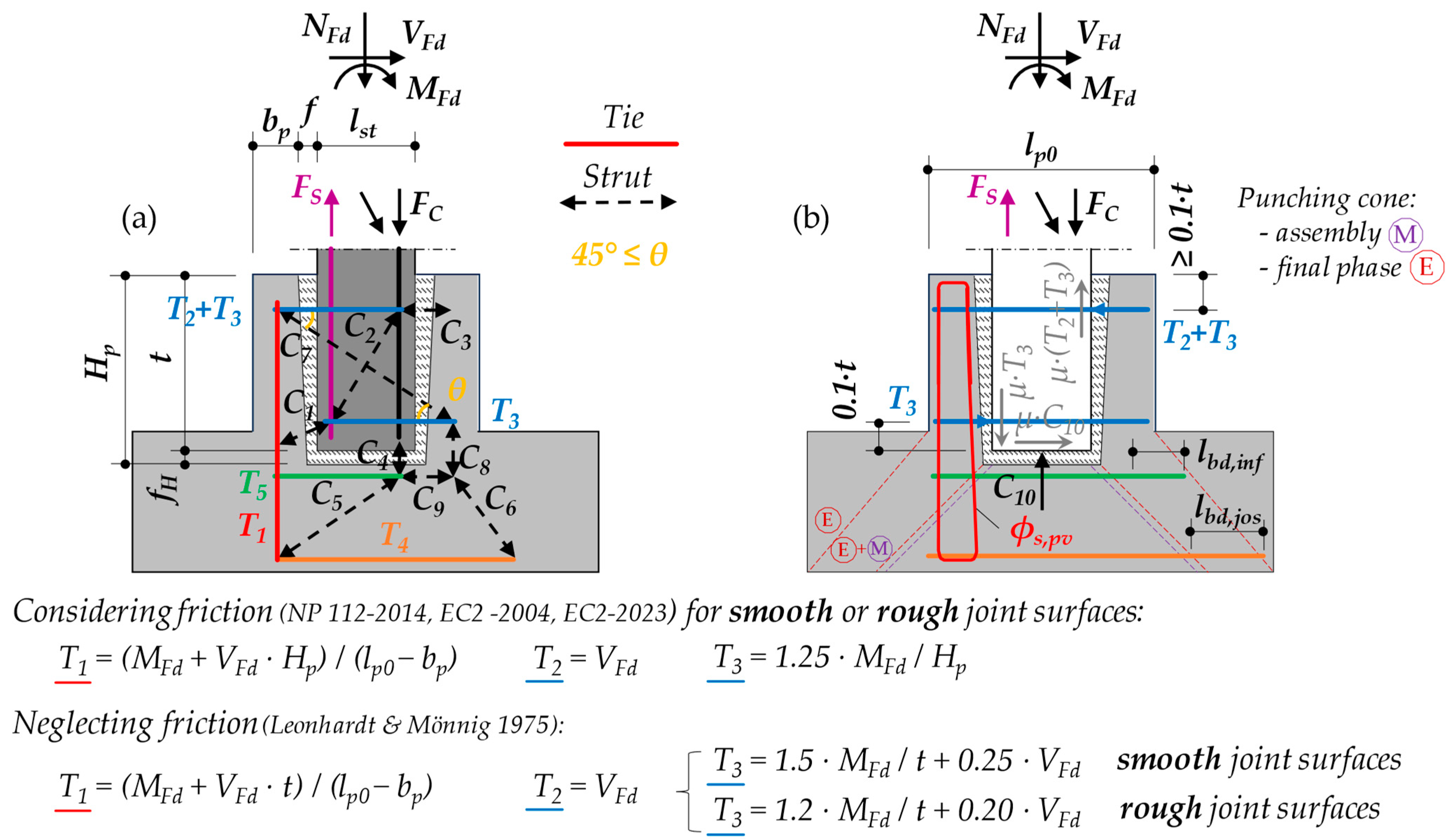

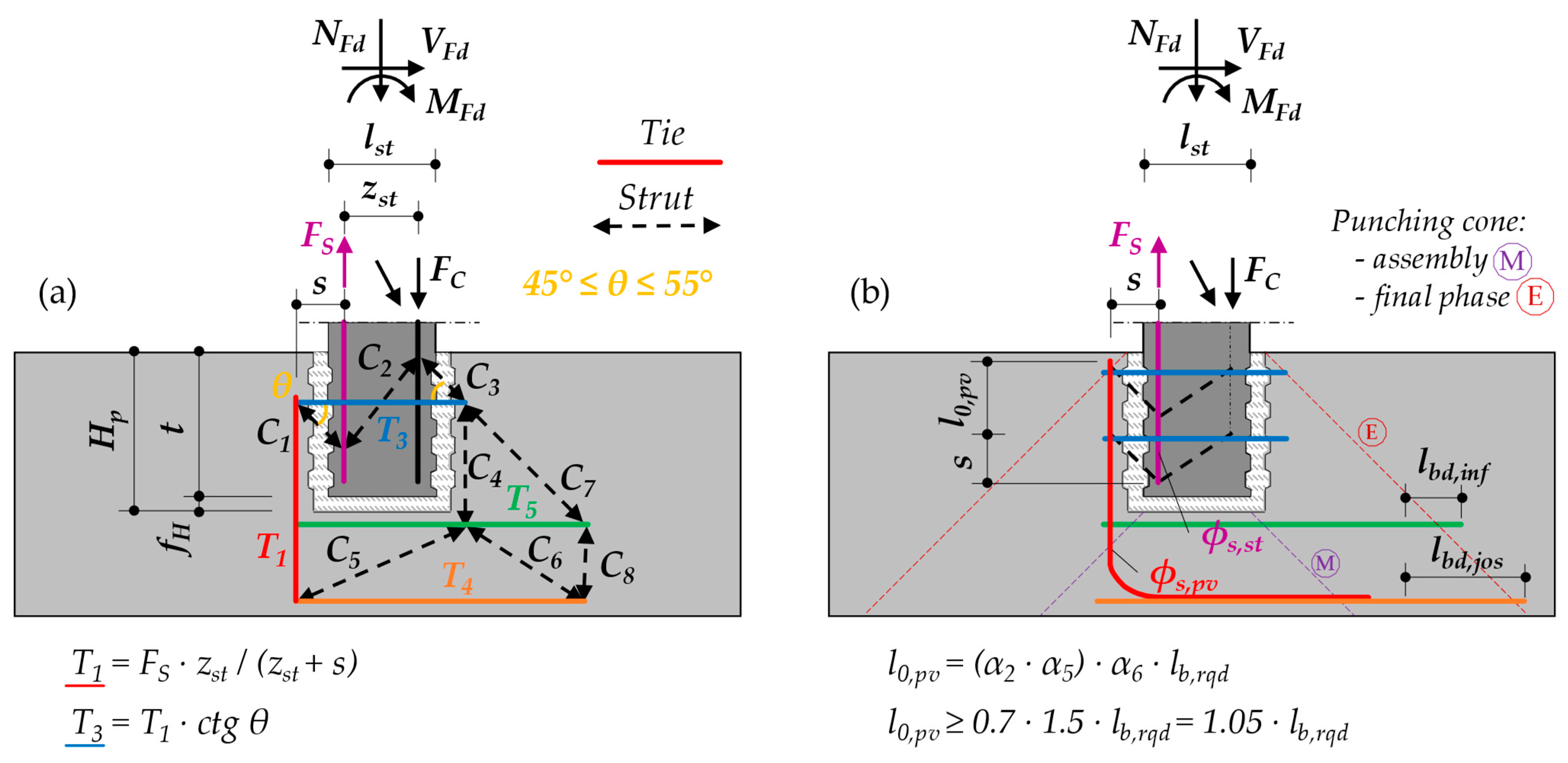

3.2. Sizing the Pocket Foundation Using Strut-And-Tie Models

- (a)

- The vertical reinforcement placed in the pocket foundation shall be properly anchored at both ends. At the bottom end, the vertical rebars will be continued in the slab’s foundation until above the horizontal slab reinforcement layer at the bottom of the footing and anchoring it with a length at least equal to lbd [1], considering the tension in the reinforcement being equal to the design yield strength of the steel rebars, σsd = fyd. While at the top end, it is recommended that the anchorage length be at least equal to lb,min = max(0.3·lb,rqd; 15·ϕ; 250 mm), with the hooks bent at 90°;

- (b)

- (c)

- For columns in structures designed for ductility class high (DCH), the longitudinal reinforcement in the critical region will have the anchorage length increased to lbd,DCH = 5·ϕ + 1.2·lbd (par. 5.7.1(4)) [6]. Columns belonging to structures designed for ductility classes medium (DCM) and low (DCL) will have the longitudinal rebars anchored with the lengths calculated according to EC2 [1], lbd, without increases;

- (d)

- For pocket foundations with keyed internal walls, when the distance between the vertical rebars in the pocket and the ones in the column s is greater than max(50 mm; 4·ϕ), the lapping length will be increased to l0 + s (par. 8.4.4(2) + 10.9.6.2) [1];

- (e)

- (f)

- (g)

- When calculating the anchorage and lapping lengths, not only will the different diameters of the rebars to be anchored/overlapped be considered, but the different classes of concrete will also be considered. The longer anchoring/lapping length will be chosen;

- (h)

- For pocket foundations with keyed internal walls, in the calculation of the lap length, l0, of vertical rebars overlapped with the longitudinal rebars in the column, the design value of the ultimate bond stress, fbd, may be increased by 50% due to the presence of transverse compression at 90° (par. 8.4.4(2)) DIN EN 1992-1-1:2004 + AC:2010 + NA:2011-01, or due to a concrete cover of minimum 6·ϕ EC2 [1];The beneficial effect of normal pressure on the plane of lapping, by preventing concrete splitting and spalling in the vicinity of the overlapping reinforcement, means that the 50% increase in the ultimate bond stress, fbd, can be applied to concrete covers up to 10·ϕ. In EC 2 [1] this increase in bond is introduced in the calculation of the anchorage length by the α2 coefficient (which results in α2 = 0.7 for straight rebars in tension, with a concrete layer around them of minimum 6·ϕsl) or by the coefficient α5 (confinement by transverse pressure), unlike DIN 1045-1:2008 (German edition) and 2010 (English edition), where the design value of the ultimate bond stress is increased to 1.5·fbd. Nevertheless, in DIN EN 1992-1-1:2004 + AC:2010 + NA:2011-01, the German norm that is enforced, along with its national annex, this adhesion increase is introduced by considering the coefficient α2 = 2/3 = 1/1.5 ≅ 0.67;

- (i)

- When columns are horizontally concreted (e.g., precast columns), and external vibrating devices are used, then satisfactory/good bond conditions may be considered over the entire cross-sectional height when lst(bst) ≤ 500 mm (par. 8.4.4(2)) DIN EN 1992-1-1:2004 + AC:2010+ NA:2011-01).

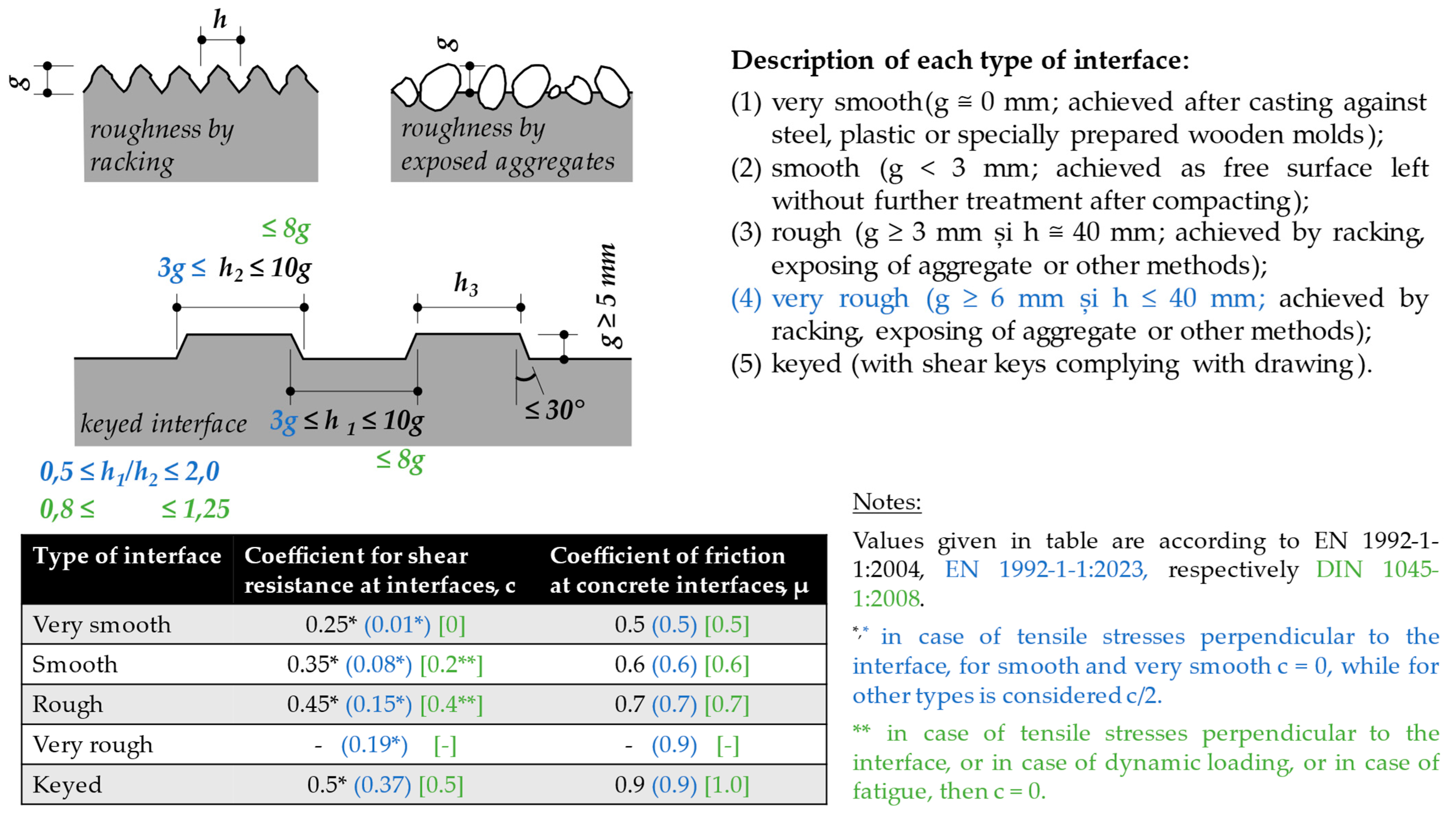

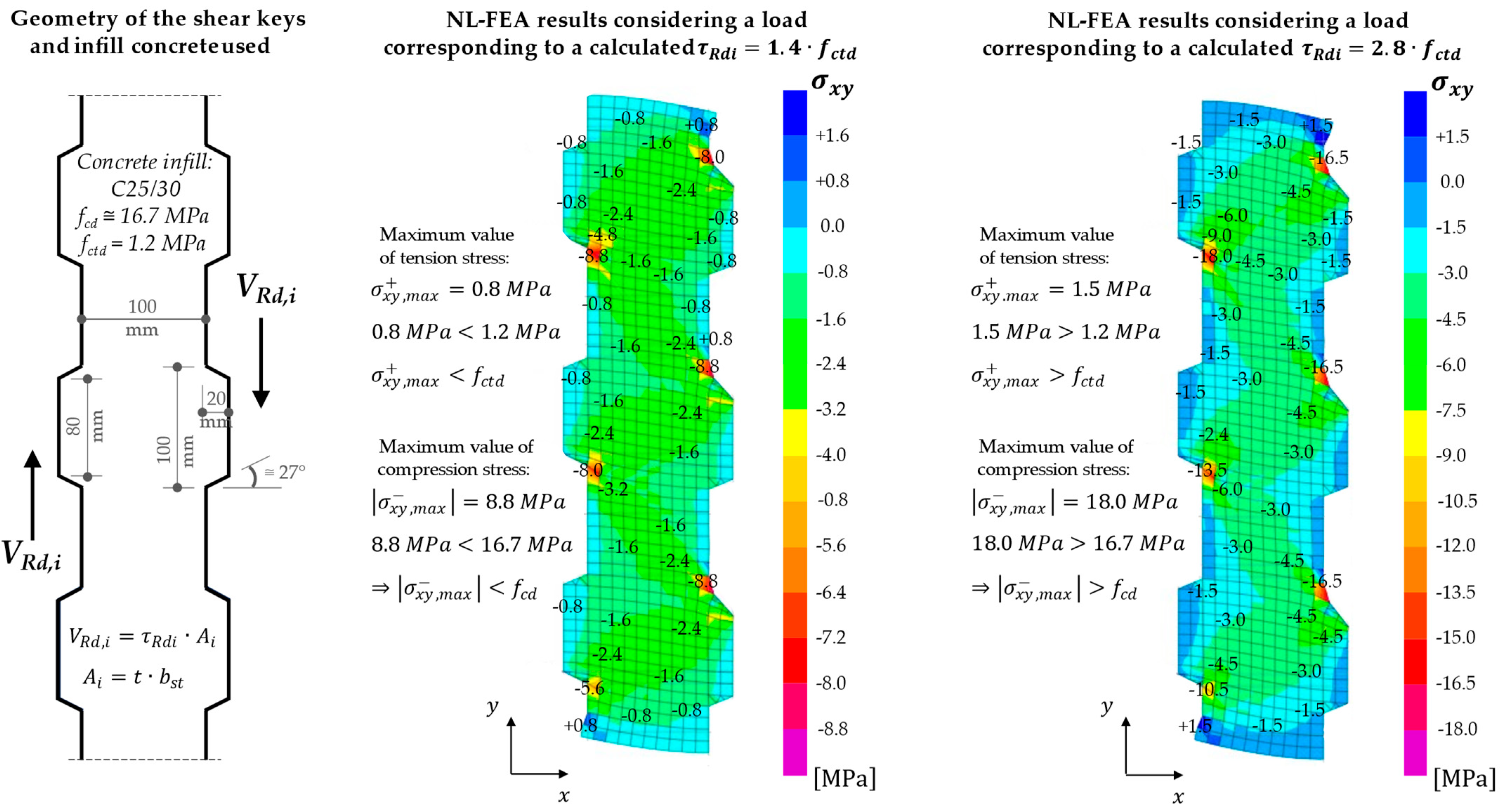

3.3. Calculating the Load-Bearing Capacity of the Concrete Infill in Concrete–Pocket Interfaces

- The coefficient of the shear resistance at interfaces, c, with the values given in the table shown in Figure 9;

- The design value of the tensile strength of concrete, fctd;

- The coefficient of friction at concrete interfaces, µ;

- The compressive stress (with absolute value) acting perpendicular to the plane of the interface, σn ≤ 0.60·fcd, and if the normal stress at the interface surface is tensile, then it is considered in Equation (2) σn = 0.

3.4. Dimensioning of the Slab Foundation (Isolated Footing)

- (a)

- Longitudinal reinforcement (bottom side):

- Minimum reinforcement ratio in each direction: ;

- Minimum diameter of the rebars used: mm;

- Maximum and minimum distances between rebars: and mm;

- (b)

- Longitudinal reinforcement (top side): A minimum of three rebars in each direction, arranged orthogonally next to the column as a grid on the entire slab surface, is required. Foundations that do not detach from the ground are constructively reinforced, and those that work with an active area are reinforced based on the dimensioning to the negative bending moments in the critical cross-sections (in this case, the provisions for bottom reinforcement are also respected) [2].

- (c)

- Transversal reinforcement: If transverse reinforcement is required due to checking for punching, then inclined or vertical reinforcements will be arranged, respecting the reinforcement provisions specified in EC2 [1].

4. Case Study: Results

5. Discussion

- The geometry of the shear keys (castellation) does not comply with the provisions of the design norm;

- The concrete used for filling the joint is not sufficiently fluid in its fresh state or shows shrinkage after hardening and drying;

- The longitudinal reinforcement of the column is meant to be anchored directly in the foundation, and the castellation does not comply with the provisions of the design norm;

- The castellation has been damaged to a great extent (e.g., during removal of the formwork, mounting, handling, etc.);

- The column is subjected to large axial compression force (e.g., ) or when the column is subjected to axial tensile force.

6. Conclusions

- The shear stress resistance, τRd,i, is greater than the design value of shear stress, τEd,i, for all four types of pocket foundations studied. This means that the pre-dimensioning mathematical expressions led to a correct final geometry of each of the pocket foundations. Meanwhile, the ratio of longitudinal reinforcement in the column is 1.2% compared to the maximum permitted value of 4.0% [1,2,6]. It is expected that for heavily reinforced columns, increased pocket heights, Hp, will be required, which means that a pre-dimensioning with consideration of the MEd/NEd ratio, as indicated in the new EC2 standard [3], could provide Hp values closer to those required in the final design;

- The interface area, Ai, was taken as the area of the entire lateral side of the column over the pocket depth for all interface types. In comparison, pocket foundations with rough internal walls exhibited an 18% increase in shear resistance, VRd,i, over those with smooth internal walls, while those with keyed internal walls showed a 26% increase, even though pockets with keyed internal walls are 8% shorter than those with smooth or rough internal walls. The values obtained seem plausible, and when interpreting them from the perspective of the roughness of the column–filled concrete interface, as the roughness increases, so does the shear resistance. However, this conclusion regarding joints with keyed interfaces becomes interpretable according to the text in EC2 [1] (par. 6.2.5(1)) and the one in the new EC2 [3] (par. 8.2.6(4)). Which states that for the area of a joint, Ai, one should consider either the area of all individual shear keys placed on one side or the keyed surface as a whole;

- Pocket foundations with keyed internal walls are more efficient than those with smooth or rough walls. This foundation type requires 30% to 37% less reinforcement area and reduces pocket heights by 8%. Even though in terms of working hours and constructability, the use of castellation is slightly more expensive when compared to smooth joints, when the overall cost is considered (especially the material savings in terms of concrete and reinforcing steel), it is more economical. Furthermore, considering the enhanced structural performance (keyed surfaces are more capable of resisting tension in the column), pocket foundations with keyed internal walls may be the optimal choice, especially for long-term performance.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Comité européen de normalisation (CEN). Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings (Abbreviated EN 1992-1-1, Informally EC2); CEN: Brussels, Belgium, 2004; Available online: https://eurocodes.jrc.ec.europa.eu/EN-Eurocodes/eurocode-2-design-concrete-structures (accessed on 11 October 2024).

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). Normativ privind proiectarea fundațiilor de suprafață (Abbreviated NP 112-2014); MDLPA: București, Romania, 2014; Available online: https://www.mdlpa.ro/userfiles/reglementari/Domeniul_III/III_26_NP_112_2014.pdf (accessed on 11 October 2024).

- Comité européen de normalisation (CEN). Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings, Bridges and Civil Engineering Structures (Second Generation Eurocode 2, Abbreviated EN 1992-1-1, Informally EC2); CEN-CENELEC: Brussels, Belgium, 2023; Available online: https://www.en-standard.eu/bs-en-1992-1-1-2023-eurocode-2-design-of-concrete-structures-general-rules-and-rules-for-buildings-bridges-and-civil-engineering-structures/?srsltid=AfmBOoryekhTQ2PA6WdsiM-Sr8yCvPSKc00BC7Xn_5rTmIZPc9AUJ4Ah (accessed on 11 October 2024).

- Muteb, H.; Hasan, H.; Al-Baghdadi, H. Interaction between Precast Concrete Columns with Socket Foundations Using Different Bonding Interfaces. In Proceedings of the 3rd International Conference on Architectural and Civil Engineering, Cihan University-Erbil Conferences, Erbil, Iraq, 5–6 April 2021. [Google Scholar] [CrossRef]

- Kiss, Z.I. Structuri Prefabricate de Beton Armat. Recomandări Pentru Alcătuirea Constructivă și Dimensionarea Structurilor în Cadre; Abel: Cluj-Napoca, Romania, 2024; Available online: https://www.abelkiado.ro/ro/carte/3715/structuri-prefabricate-de-beton-armat/recomandari-pentru-alcatuirea-constructiva-i-dimensionarea-structurilor-in-cadre (accessed on 11 October 2024).

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). Cod de Proiectare Seismică—Partea 1: Prevederi de Proiectare Pentru Clădiri (Abbreviated P100-1/2013); MDLPA: București, Romania, 2019; Available online: https://www.mdlpa.ro/userfiles/reglementari/Domeniul_I/I_22_P100_1_2013.pdf (accessed on 11 October 2024).

- Tillmann, M. Knotenverbindungen für Betonfertigteile. Hinweise für Bemessung und Konstruktion; Fachvereinigung Deutscher Betonfertigteilbau e.V. 2011. Available online: https://www.bft-international.com/de/news/fdb-fachbroschuere-knotenverbindungen-fuer-betonfertigteile-ueberarbeitet-3429967.html (accessed on 11 October 2024).

- Liu, B.; Zhang, L.; Sun, H.; Feng, M.; Dou, K. Side shear strength and load-transfer mechanism of corrugated steel column–foundation socket connection. Case Stud. Constr. Mater. 2022, 17, e01377. [Google Scholar] [CrossRef]

- Steinle, A.; Bachmann, H.; Tillmann, M. Precast Concrete Structures, 2nd ed.; Ernst & Sohn (Wiley): Berlin, Germany, 2019; Available online: https://www.ernst-und-sohn.de/precast-concrete-structures-ebundle (accessed on 11 October 2024).

- Steinle, A.; Bachmann, H.; Tillmann, M. Bauen mit Betonfertigteilen im Hochbau (BetonKalendar 2016—Kapitel III); Ernst & Sohn (Wiley): Berlin, Germany, 2016; Available online: https://www.ernst-und-sohn.de/beton-kalender-2016 (accessed on 11 October 2024).

- Bachmann, H.; Tillmann, M.; Urban, S. Bauen mit Betonfertigteilen im Hochbau (BetonKalendar 2021); Ernst & Sohn (Wiley): Berlin, Germany, 2021; Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9783433610206.ch2 (accessed on 11 October 2024).

- Comité européen de normalisation (CEN). Design of Structures for Earthquake Resistance—Part 1: General Rules, Seismic Actions and Rules for Buildings (Abbreviated EN 1998, Informally EC8); CEN: Brussels, Belgium, 2004; Available online: https://eurocodes.jrc.ec.europa.eu/EN-Eurocodes/eurocode-8-design-structures-earthquake-resistance (accessed on 11 October 2024).

- DIN Norm. Tragwerke aus Beton, Stahlbeton und Spannbeton—Teil 1: Bemessung und Konstruktion (abbreviated DIN 1045-1), DIN Norm. 2008. Available online: https://www.baunormenlexikon.de/norm/din-1045-1/1ce039fc-a3e6-4f97-a670-38950b599945 (accessed on 11 October 2024).

- Popa, A.; Ilieș, N.-M. Fundații; Casa Cărții de Știință: Cluj-Napoca, Romania, 2013; Available online: https://www.casacartii.ro/editura/carte/fundatii/ (accessed on 11 October 2024).

- Toader, T.-N. Stabilirea Specificației Betonului de Ciment Proaspăt și întărit, Conform SR EN 206-1, 2nd ed.; UTPRESS: Cluj-Napoca, Romania, 2023; Available online: https://biblioteca.utcluj.ro/files/carti-online-cu-coperta/632-6.pdf (accessed on 11 October 2024).

- Ionescu, A. Construcții de Beton Armat I și II—Note de Curs; Specializarea CCIA, Facultatea de Construcții—Universitatea Tehnică din Cluj-Napoca: Cluj-Napoca, Romania, 2007. [Google Scholar]

- Sparowitz, L. Vorlesungsskriptum aus Betonbau; Institut für Betonbau—Technische Universität Graz, Fachbereichs Ingenieurbaukunst (IBK) and der TU Graz: Graz, Austria, 2004. [Google Scholar]

- Zilch, K.; Zehetmeier, G. Bemessung im Konstruktiven Betonbau (2. Auflage), 2nd ed.; Nach Din 1045-1 (Fassung 2008) und EN 1992-1-1 (Eurocode 2); Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Plan_31_Ro. Fotografii din Timpul Execuției Proiectelor Realizate în Colectivul de Proiectare; Arhiva Biroului de proiectare: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Elliot, K.S.; Jolly, C.K. Multi-Storey Precast Concrete Framed Structures; Wiley Blackwell: West Sussex, UK, 2013; Available online: https://www.wiley.com/en-au/Multi-Storey+Precast+Concrete+Framed+Structures%2C+2nd+Edition-p-9781405106146 (accessed on 11 October 2024).

- Bachmann, H.; Steinle, A. Precast Concrete Structures; Ernst & Sohn (Wiley): Berlin, Germany, 2011; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9783433600962 (accessed on 11 October 2024).

- Hierlein, E.; Tillmann, M.; Brandt, J.; Rösel, W.; Schwerm, D.; Stöffler, J. Betonfertigteile im Geschoss- und Hallenbau. Grundlagen für die Planung, 3rd ed.; FDB—Fachvereinigung, Deutscher Betonfertigteilbau e.V.: Bonn, Germany; Verlag Bau + Technik GmbH: Düsseldorf, Germany, 2021; Available online: https://www.fdb-fertigteilbau.de/fileadmin/user_upload/broschueren/FDB_Geschoss-_und_Hallenbau_2021_Webdatei.pdf (accessed on 11 October 2024).

- Ge, J.; Lai, L.; Liu, S.; Yan, X. Ultimate Bearing Capacity Analysis of Pile Caps with New Socket Connections. Buildings 2022, 12, 2034. [Google Scholar] [CrossRef]

- Deutscher Beton- und Bautechnik-Verein E.V. Beispiele zur Bemessung nach Eurocode 2; Band 1: Hochbau; Ernst & Sohn (Wiley): Berlin, Germany, 2012; Available online: https://www.ernst-und-sohn.de/beispiele-zur-bemessung-nach-eurocode-2-band-1 (accessed on 11 October 2024).

- Leonhardt, F.; Mönnig, E. Vorlessungen über Massivbau. Dritter Teil—Grundlagen zum Bewehren im Stahlbetonbau; Springer: Berlin/Heidelberg, Germany, 1975; Available online: https://link.springer.com/book/10.1007/978-3-662-10822-2 (accessed on 11 October 2024).

- Hemamathi, L.; Jaya, K. Behaviour of Precast Column Foundation Connection under Reverse Cyclic Loading. Adv. Civ. Eng. 2021, 2021, 17. [Google Scholar] [CrossRef]

- Aboukifa, M.; Reyad, K.; Saad, F. Behavior and Design of Precast Column/Base Pocket Connections with Smooth Surface Interface. CERM 2017, 39, 191–202. Available online: http://www.azharcermjournal.com/CERMF1707/P17-07-16.pdf (accessed on 11 October 2024).

- Canha, R.; Jaguaribe, K.; El Debs, A.; El Debs, M. Analysis of the behavior of transverse walls of socket base connections. Eng. Struct. 2009, 31, 788–798. [Google Scholar] [CrossRef]

- Hemamathi, A.; Jaya, K.P.; Sukumar, B. Evaluation of Ductility of Precast Column Foundation Connections. Indian J. Sci. Technol. 2023, 16, 1516–1526. [Google Scholar] [CrossRef]

- Tazarv, M.; Saiidi, M.S. Design and Construction of Precast Bent Caps with Pocket Connections for High Seismic Regions; University of Nevada, Reno, Center for Civil Engineering Earthquake Research: Reno, Nevada, 2015; Available online: https://rosap.ntl.bts.gov/view/dot/41828/dot_41828_DS1.pdf (accessed on 11 October 2024).

- Zhiqiang, G.W.; Li, T.; Qu, H.; Wei, H.; Li, Y. Seismic Performance of Precast Bridge Columns with Socket and Pocket Connections Based on Quasi-Static Cyclic Tests: Experimental and Numerical Study. J. Bridge Eng. 2019, 24. [Google Scholar] [CrossRef]

- Jiang, X.; Li, J.; Liu, P.; Qu, H.; Gao, J.; Bao, Z. Seismic performance of precast bridge bents with prestressed piles and new pocket connection design: Experimental and numerical study. Soil Dyn. Earthq. Eng. 2024, 183, 16. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, Y. Experimental and numerical investigations of the impact resistance of socket and pocket connections for precast bridge columns. Structures 2024, 64, 106631. [Google Scholar] [CrossRef]

- Comité européen de normalisation (CEN). EN 206:2013+A2:2021 Concrete Specification, Performance, Production and Conformity; CEN-CENELEC: Brussels, Belgium, 2021; Available online: https://www.en-standard.eu/bs-en-206-2013-a2-2021-concrete-specification-performance-production-and-conformity/?srsltid=AfmBOoqTIJ6Ti1oDN_Ce3bkCDPCahg5kFA-9dgct7gELTIJUL4KC4Gqs (accessed on 11 October 2024).

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). NE 012/1-2022 Normativ Pentru Producerea și Executarea Lucrărilor din Beton, Beton Armat şi Beton Precomprimat—Partea 1: Producerea Betonului; MLPAT: București, Romania, 2023; Available online: https://www.mdlpa.ro/uploads/articole/attachments/63d7c00311fba319161394.pdf (accessed on 11 October 2024).

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). NE 012/2-2022 Normativ Pentru Producerea și Executarea Lucrărilor din Beton, Beton Armat și Beton Precomprimat—Partea 2: Executarea Lucrărilor din Beton; MLPAT: București, Romania, 2023; Available online: https://www.mdlpa.ro/uploads/articole/attachments/63d7c09bb537f654267470.pdf (accessed on 11 October 2024).

- Golewski, G. Specificity of Shaping and Execution of Monolithic Pocket Foundations (PF) in Hall Buildings. Buildings 2022, 12, 192. [Google Scholar] [CrossRef]

- Tomșa, F.; Sima, T.; Gottfried, I. Cartea Montatorului de Prefabricate (Ediția a 3a); Editura Tehnică: București, Romania, 1972. [Google Scholar]

- Kiss, Z.I.; Oneț, T. Proiectarea Structurilor de Beton După SR EN 1992-1-1; Abel: Cluj-Napoca, Romania, 2010; Available online: https://www.abelkiado.ro/ro/carte/1164/proiectarea-structurilor-de-beton-dupa-sr-en-1992-1-ed-ii-revizuita-coperta-subire/curs-universitar (accessed on 11 October 2024).

- Leviat a CRH Company. Modersohn Stainless Steel, www.modersohn.eu. Available online: https://www.modersohn.eu/industrie/detailseite/zentriersysteme-fuer-fertigteile/ (accessed on 5 April 2024).

- Ministerul transporturilor, construcțiilor și turismului (MTCT). Normativ Privind Proiectarea Fundațiilor de Suprafață (Abbreviated NP 112-2004), Monitorul Oficial Al României, Partea I, nr. 451 din 27 mai 2005: București, Romania. 2005. Available online: https://www.academia.edu/29215744/NP_112_04_normativ_fundatii (accessed on 11 October 2024).

- Associação Brasileira de Normas Técnicas. NBR 9062—Design and Execution of Precast Concrete Structures (în Portugheză: Projeto e Execução de Estruturas de Concreto Pré-moldado); ABNT: Sao Paulo, Brazil, 2017; Available online: https://professor.pucgoias.edu.br/sitedocente/admin/arquivosUpload/14026/material/NBR9062_2017.pdf (accessed on 11 October 2024).

- Canha, R.M.F.; El Debs, M.K. Critical Analysis of Models and Recommendations for Designing Column-Base Connection by Socket of Precast Concrete Structures. IBRACON Struct. J. 2006, 2, 95–115. Available online: http://ibracon.org.br/publicacoes/revistas_ibracon/rev_estruturas/pdf/riest%20-%20vol2%20-%20n%C2%BA2%20-%20artigo%201-%20english.pdf (accessed on 11 October 2024).

- Santos, S.P. Connections of Precast Concrete Structures (in Portuguise: Ligações de Estruturas Prefabricadas de Betão); Laboratório Nacional de Engenharia Civil: Lisboa, Portugal, 1985. [Google Scholar]

- Yang, J.; Guo, T.; Zeng, C. Experimental investigation of seismic behavior of precast pier-footing socket connection with different design parameters. Struct. Concr. 2024, 25, 1938–1952. [Google Scholar] [CrossRef]

- Canha, R.; de Cresce El Debs, A.L.H.; El Debs, M. Design model for socket base connections adjusted from experimental results. Struct. Concr. 2007, 8, 3–10. [Google Scholar] [CrossRef]

- Canha, R.M.F.; El Debs, M.K.; Jaguaribe Junior, K.d.B.; El Debs, A.L.H.d.C. Behavior of Socket Base Connections Emphasizing Pedestal Walls. ACI Struct. J. 2009, 106, 268–278. [Google Scholar] [CrossRef]

- Pul, S.; Husem, M.; Arslan, M.E.; Hamzacebi, S. An experimental study on different socket base connections under cyclic loading. Comput. Concr. 2014, 13, 377–387. [Google Scholar] [CrossRef]

- El-Naqeeb, M.H.; Hassanli, R.; Zhuge, Y.; Ma, X.; Manalo, A. Numerical investigation on the behaviour of socket connections in GFRP-reinforced precast concrete. Eng. Struct. 2024, 303, 117489. [Google Scholar] [CrossRef]

- Campos, G.M.; Canha, R.M.F.; El Debs, M.K. Design of precast columns bases embedded in socket foundations with smooth interfaces. IBRACON Struct. Mater. J. 2011, 4. [Google Scholar] [CrossRef]

- Canha, R.; Ebeling, E.; El Debs, A.; El Debs, M. Analysing the base of precast column in socket foundations with smooth interfaces. Mater. Struct. 2009, 42, 725–737. [Google Scholar] [CrossRef]

- Cheng, Z.; Liu, D.; Li, S.; Wang, J.; Zhang, J. Performance characterization and design recommendations of socket connections for precast columns. Eng. Struct. 2021, 242. [Google Scholar] [CrossRef]

- Canha, R.M.F.; Campos, G.M.; El Debs, M.K. Design model and recommendations of column-foundation connection through socket with rough interfaces. IBRACON Struct. J. 2012, 5, 182–218. [Google Scholar] [CrossRef]

- Chen, W.; De Corte, H.; Jiang, H.; Taerwe, L. Experimental study on direct-shear behaviour of narrow joints in socket connections for precast pier-to-pile footing systems. Structures 2024, 61. [Google Scholar] [CrossRef]

- CEN European Committee for Standardization/ASRO. Eurocode 0: Basis of Structural Design/SR EN 1990:2004 + SR EN 1990/NA:2006, CEN/TC250; CEN: Bruxelles, Belgium, 2002; Available online: https://magazin.asro.ro/ro/standard/115449 (accessed on 11 October 2024).

- Albert, A. Bautabellen für Ingenieure mit Berechnungshinweisen und Beispielen, 21st ed.; Bundesanzeiger Verlag GmbH: Cologne, Germany, 2014; Available online: https://books.google.ro/books/about/Bautabellen_f%C3%BCr_Ingenieure.html?id=X0eSoAEACAAJ&redir_esc=y (accessed on 11 October 2024).

- Toader, T.-N. Structural Design of Keyed Surfaces for Precast Concrete Columns Embedded in Pocket Foundations. In Proceedings of the C70 International Conference “Tradition and Innovation—70 Years of Constructions in Transilvania”, Cluj-Napoca, Romania, 8 November 2023; Available online: https://c70.utcluj.ro/wp-content/uploads/2023/12/657-9-Constructii-70-min.pdf (accessed on 11 October 2024).

- Agent, R.; Bănuț, V. Calculul Structurilor din Beton Armat cu Stâlpi Zvelți; Editura Tehnică: București, Romania, 1979. [Google Scholar]

- Mîrșu, O.; Friedrich, R. Construcții din Beton Armat; Editura Didactică și Pedagogică: București, Romania, 1980. [Google Scholar]

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). Cod de Proiectare a Construcțiilor cu Pereți Structurali de Beton Armat; MDLPA: București, Romania, 2013; Available online: https://www.mdlpa.ro/userfiles/reglementari/Domeniul_I/I_21_CR_2_1_1_1_2013_completare.pdf (accessed on 11 October 2024).

- Ministerul Dezvoltării, Lucrărilor Publice și Administrației (MDLPA). Cod de Proiectare a Construcțiilor cu Pereți Structurali de Beton Armat; MDLPA: București, Romania, 2006. [Google Scholar]

- Toader, T.-N.; Mircea, C.-R.; Truta, A. Coniferous Trees as Bioinspiration for Designing Long. Biomimetics 2024, 9, 165. [Google Scholar] [CrossRef]

- Toader, N.; Sobek, W.; Nickel, K. Energy Absorption in Functionally Graded Concrete. J. Bionic Eng. 2017, 14, 369–378. [Google Scholar] [CrossRef]

- Pastrav, M.; Constantinescu, H. Seismic Behavior of Self-Balancing Post-Tensioned Reinforced Concrete Spatial Structure, World Academy of Science, Engineering and Technology. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2016, 10. Available online: https://publications.waset.org/10005784/seismic-behavior-of-self-balancing-post-tensioned-reinforced-concrete-spatial-structure (accessed on 11 October 2024).

- fib Bulletin, No. 27 Seismic Design of Precast Concrete Building Structures; State-of-art Report; fib CEB FIP: Lausanne, Switzerland, 2003. [CrossRef]

- fib Bulletin, No. 43 Structural Connections for Precast Concrete Buildings; Guide to Good Practice; fib CEB FIP: Lausanne, Switzerland, 2008. [CrossRef]

- fib Bulletin, No. 78 Precast-Concrete Buildings in Seismic Areas; State-of-the-art report; fib CEB FIP: Lausanne, Switzerland, 2016. [CrossRef]

- Toader, T.N.; Schmeer, D.; Sobek, W. Concept for an Onshore Tower Structure Made of UHPFRC Segments for Wind Turbines. Acta Tech. Napoc. Civ. Eng. Archit. 2019, 62, 1. Available online: https://oldconstructii.utcluj.ro/ActaCivilEng/download/atn/ATN2019(1)_1.pdf (accessed on 11 October 2024).

- Nickel, K.; Klang, K.; Toader, N.; Sobek, W. The potential of improving building construction materials by a biomimetic approach. In Proceedings of the 10th International Conference on Emerging Materials and Nanotechnology, Vancouver, BC, Canada, 27–29 July 2017. [Google Scholar] [CrossRef]

- Toader, N.; Haase, W.; Sobek, W. Energy Absorption in Functionally Graded Concrete under Compression, Bul. Institutului Politeh. Iasi—Sectia Constr. Arhit. 2018, 64, 9–23. Available online: https://www.bipcons.ce.tuiasi.ro/Content/ArticleInformation.php?ArticleID=654 (accessed on 11 October 2024).

- Butean, C.; Heghes, B. Flexure behavior of a two layer reinforced concrete beam. Procedia Manuf. 2020, 46, 110–115. [Google Scholar] [CrossRef]

- Butean, C.; Heghes, B. Cost efficiency of a two layer reinforced concrete beam. Procedia Manuf. 2020, 46, 103–109. [Google Scholar] [CrossRef]

- Puskas, A.; Zagon, R.; Szilagyi, H.; Corbu, O.; Baerã, C.; Constantinescu, H. Modelling of the bending behaviour of double floor systems for different contact surfaces. Constructii 2014, 15, 46–53. [Google Scholar]

| Type of Surface | Pocket’s Wall Thickness bp | Depth of the Pocket Hp | Bibliographic Source |

|---|---|---|---|

| smooth | Leonhardt and Mönnig (1975) [25] | ||

| rough | |||

| For the intermediate values of the ratio between the value of the bending moment and that of the axial force, a linear interpolation is to be used. | |||

| smooth rough keyed | where, correlated with the direction of VEd.st, we have: or | NP 112-*04 (2004) [41] | |

| smooth | No specification. | EN 1992-1-1:2004 (2004) [1] | |

| keyed | |||

| smooth rough | NP 112-2014 (2014) [2] | ||

| keyed | |||

| For columns subjected to tensile axial force, the use of a column–pocket foundation joint with smooth internal walls is not permitted. The longitudinal reinforcements of the columns subjected to tensile axial force in the seismic combination must be anchored with an anchorage length of 1.50·lbd. (par. 5.7.2.2(1)) [6] and (par. 5.6.2.1(2)) [12]. The longitudinal reinforcement in the critical areas of columns in structures designed for the high ductility class (DCH) requires anchoring to begin at a depth of 5·ϕsl within the element where the anchoring is performed (in the pocket). In addition, the anchorage length for the rebars in tension will be 1.20·lbd, where ϕsl is the diameter of the longitudinal rebars. (par. 5.7.1(4)) [6] (par. 5.6.1(3)) [12]. | P100-1/2013+2019 [6] | ||

| smooth rough | for pedestal pocket foundations for pad foundations with pocket | ABNT NBR -9062:2017 (2017 [42] | |

| keyed | |||

| For the intermediate values of the ratio between the value of the bending moment and that of the axial force, a linear interpolation is to be used. In the dimensioning of the pocket foundation, an overstrength factor for column resistance must be used: . When rough interfaces are used, lower values of Hp can be used if they are validated experimentally. For columns subjected to tensile axial force, it is mandatory to use keyed interfaces and | |||

| smooth rough | No specification. | EN 1992-1-1:2023 (2023) [3] | |

| keyed | |||

| For the intermediate values of the ratio between the value of the bending moment and that of the axial force, a linear interpolation is to be used. | |||

| Parameter | Value | Meaning |

|---|---|---|

| Input | ||

| Geometry | ||

| Hst_0 | 7.0 m | The free height of the column measured vertically from the top of the slab on grade to the bottom of the roof’s main beam |

| Hst_calc | 8.2 m | The design height of the column was measured vertically from the top of the pocket foundation (−0.40 m) to the roof’s center of gravity (0.80 m above the bottom of the roof’s main beam) |

| f | 100 mm | The thickness of the in situ concrete filling around the column |

| fH | 50 mm | The thickness of the in situ concrete filling below the column |

| fstalp | 50 mm | The embedment depth of the column in the footing of the foundation |

| bst, lst | 600 mm | The size of the column’s rectangular cross-section |

| Asl,1_lat,ef | 1390 mm2 | The total cross-sectional area of the longitudinal rebars on one side of the column (2ϕ20 + 3ϕ18) |

| ϕsw | 8 mm | The diameter of the stirrups (with six legs) used as transverse reinforcement in the column |

| cnom,st | 30 mm | The concrete cover for longitudinal rebars (in the column) |

| Materials | ||

| C30/37, C28/35, C25/30 | The strength classes for the concrete in the column, joint and foundation | |

| B500 C | - | The steel grade and ductility class of the steel used as reinforcement |

| Structural design | ||

| DCH | - | The ductility class of the superstructure |

| γRd | 1.15 | The overstrength factor considers the overstrength of the superstructure in DCH. For DCM and DCL, the value of 1.00 can be considered |

| θ | 45° | The inclination of the strut crossing the joint |

| 100 | % | The minimum active area of the foundation footing in all fundamental combinations, according to NP 112-2014 [2] (par. I.6.1.1(3.1). In the previous edition, NP 112-*0 [41] (6.2.5), the acceptance limit was set to 80% |

| 75 | % | The minimum active area of the foundation footing in all seismic combinations, including plastic hinge formation, according to NP 112-2014 [2] (par. I.6.1.1(3.2)). In the previous edition, NP 112-*0 [41] (6.2.6), the acceptance limit was set to 50% |

| Load Combination | NEd (“-” is Compression) | VEd | MEd |

|---|---|---|---|

| Fundamental combination (STR, GEO) | −2400 kN | 51 kN | 415 kN·m |

| Fundamental combination (ECH) | −1100 kN | 51 kN | 415 kN·m |

| Seismic combination (GS) | −1200 kN | 70 kN | 580 kN·m |

| Seismic combination (GS)—plastic hinge | −1200 kN | 76 kN | 620 kN·m |

| Pedestal Socket Foundation | Pad Foundation with Pocket | |||||

|---|---|---|---|---|---|---|

| Having the Internal Walls | ||||||

| Smooth | Rough | Keyed | Keyed | |||

| Parameter | Unit | Value for each foundation type | Meaning | |||

| bp | mm | 200 | 200 | 200 | - | Wall thickness of the pocket foundation |

| lbd,st | mm | 1040 | 1040 | 1000 | 1000 | Anchorage length for the longitudinal rebars in the column |

| l0,pv | mm | - | - | 590 | 590 | Overlapping length for the vertical rebars in the pocket |

| s | mm | - | - | 240 | 180 | Distance between the vertical reinforcement in the internal wall of the foundation and the longitudinal reinforcement in the column |

| Hp | mm | 1200 | 1200 | 1100 | 1100 | Total height of the pocket’s internal walls |

| T1 | kN | 711 | 711 | 494 | 449 | Design value for tension force in tie T1 |

| T1 % | [-] | 100% | 100% | 69% | 63% | Value of T1 compared with the pedestal pocket foundation with smooth internal walls |

| T2 | kN | 76 | 76 | 76 | - | Design value for tension force in tie T2 |

| T2 % | [-] | 100% | 100% | 100% | - | Value of T2 compared with the pedestal pocket foundation with smooth internal walls |

| T3 | kN | 646 | 646 | 414 | 449 | Design value for tension force in tie T3 |

| T3 % | [-] | 100% | 100% | 64% | 70% | Value of T3 compared with the pedestal pocket foundation with smooth internal walls |

| σn | N/mm2 | 1.05 | 1.05 | 0.78 | 0.83 | Compression stress per unit area caused by the normal force across the joint interface column-concrete filling, calculated with Equation (3), as in [57] |

| Ai | mm2 | 690 × 103 | 690 × 103 | 690 × 103 | 690 × 103 | Area of the interface |

| VRd,i | kN | 740 | 900 | 994 | 994 | Shear resistance (strength) at the interface column–concrete filling |

| VEd,i | kN | 605 | 605 | 605 | 605 | Design value of the shear force at the interface, column–concrete filling, VEd,i = Fs |

| τRd,i | N/mm2 | 1.07 | 1.31 | 1.58 | 1.58 | Shear stress resistance (strength) at the interface column–concrete filling |

| τEd,i | N/mm2 | 0.88 | 0.88 | 0.96 | 0.96 | Design value of the shear stress at the interface column–concrete filling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Constantinescu, H.; Toader, T.-N. Structural Design and Technology of Pocket Foundations for Long Precast Concrete Columns in Seismic Areas. Buildings 2024, 14, 3466. https://doi.org/10.3390/buildings14113466

Constantinescu H, Toader T-N. Structural Design and Technology of Pocket Foundations for Long Precast Concrete Columns in Seismic Areas. Buildings. 2024; 14(11):3466. https://doi.org/10.3390/buildings14113466

Chicago/Turabian StyleConstantinescu, Horia, and Traian-Nicu Toader. 2024. "Structural Design and Technology of Pocket Foundations for Long Precast Concrete Columns in Seismic Areas" Buildings 14, no. 11: 3466. https://doi.org/10.3390/buildings14113466

APA StyleConstantinescu, H., & Toader, T.-N. (2024). Structural Design and Technology of Pocket Foundations for Long Precast Concrete Columns in Seismic Areas. Buildings, 14(11), 3466. https://doi.org/10.3390/buildings14113466