Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO

Abstract

1. Introduction

2. Materials and Methods of Testing

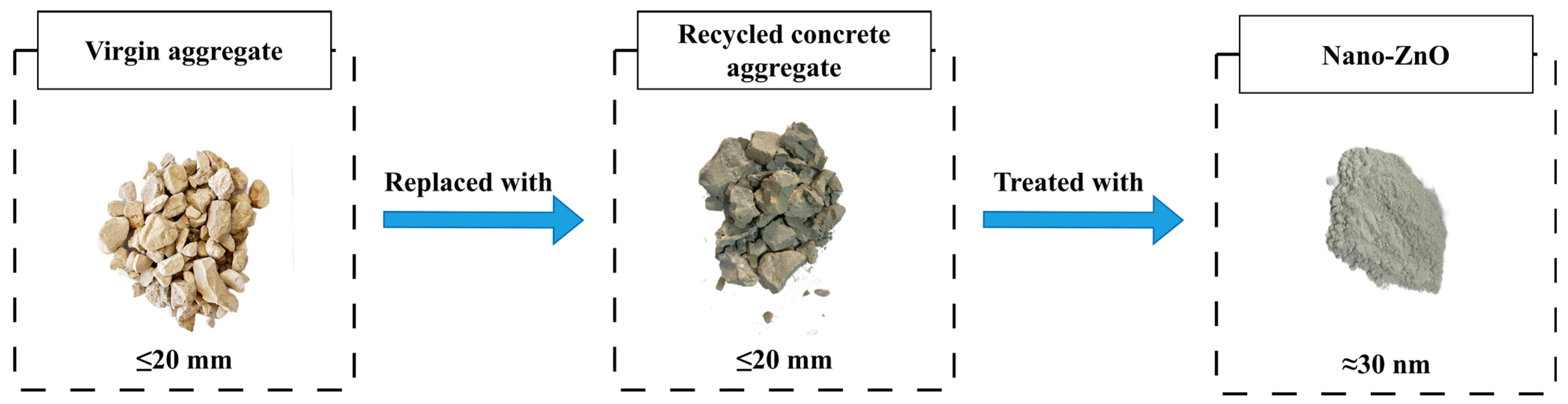

2.1. Materials and Specimens

2.2. Experimental Setup

3. Results and Discussion

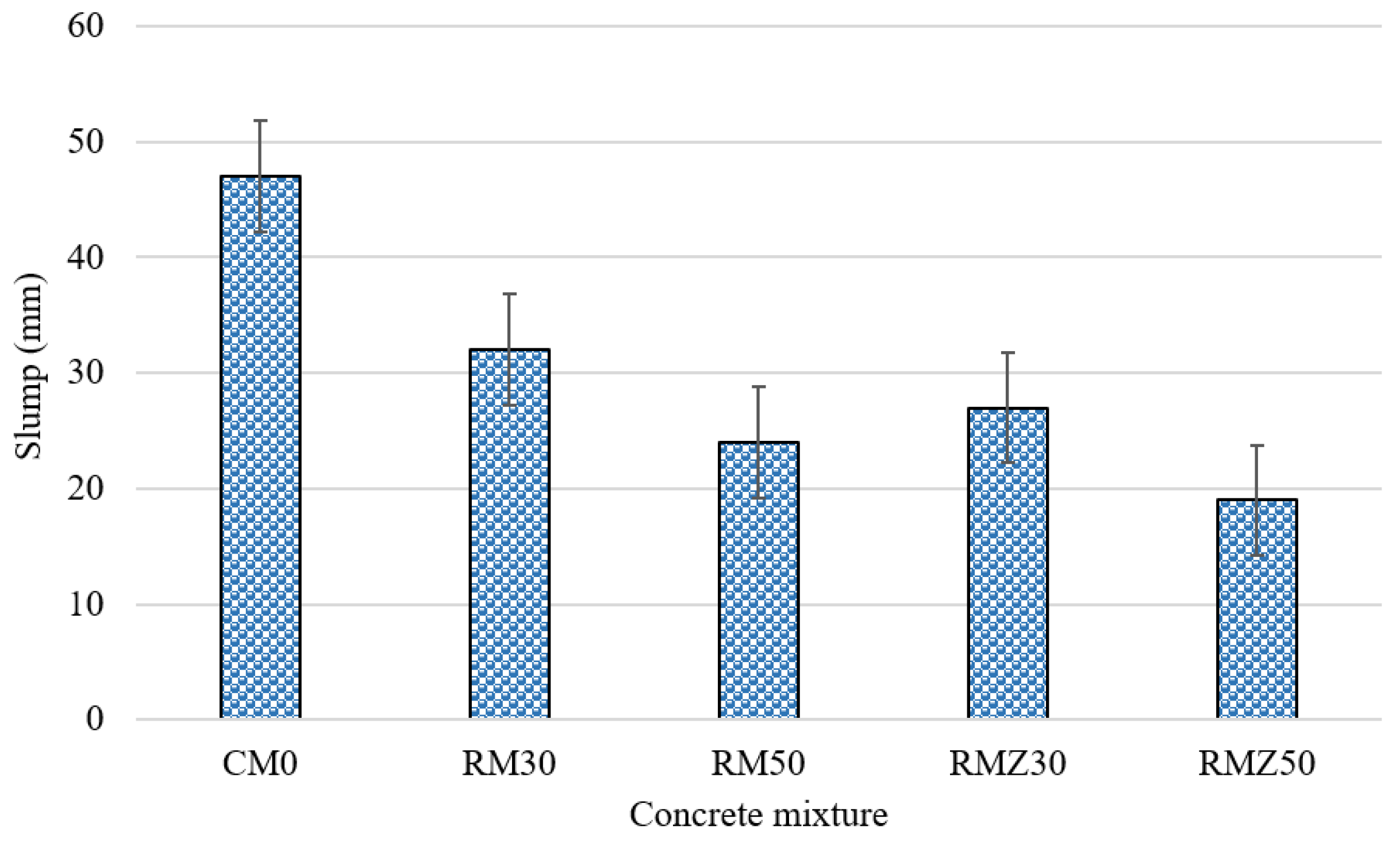

3.1. Workability Assessment

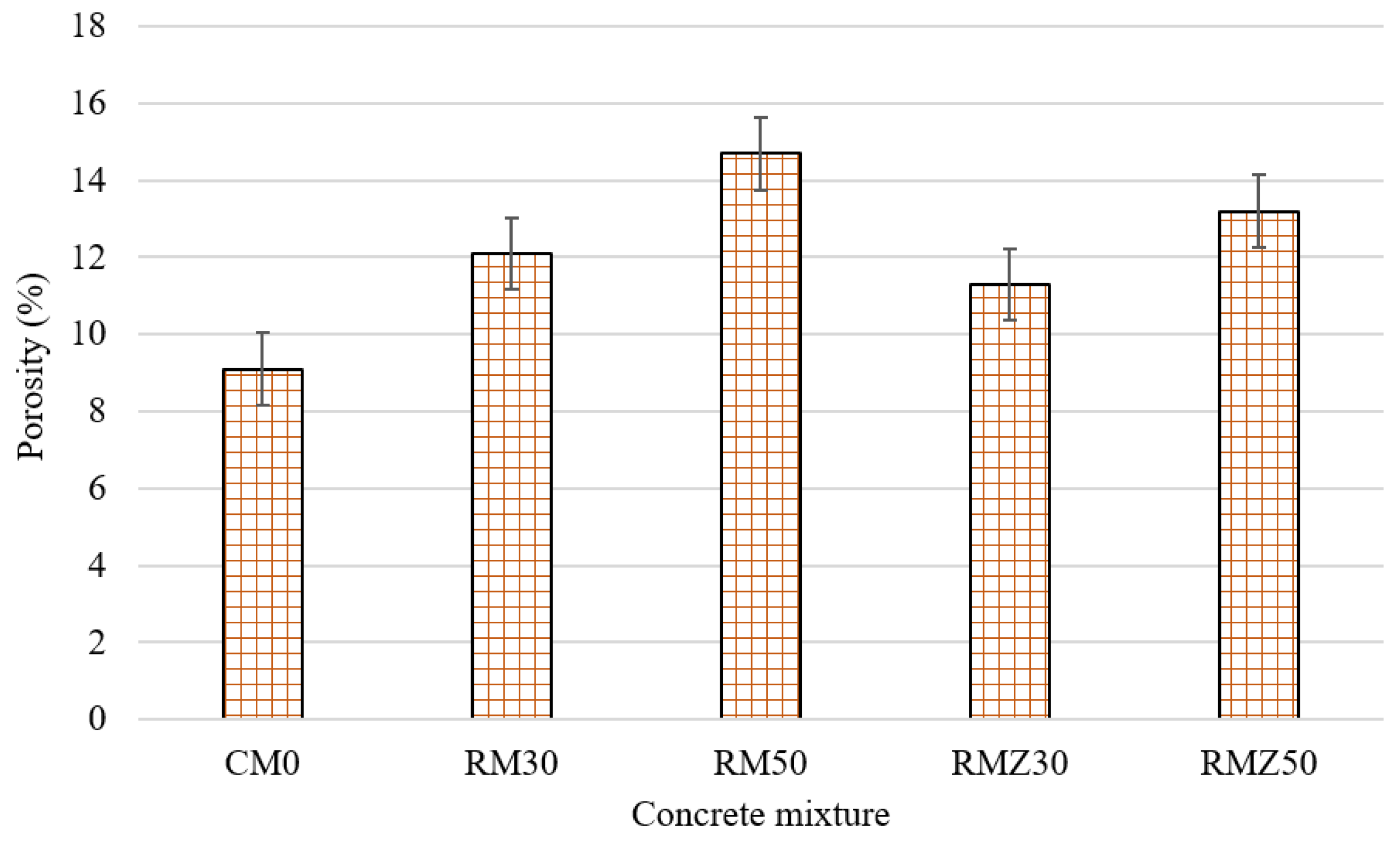

3.2. Porosity of Concrete

3.3. Water Absorption Assessment

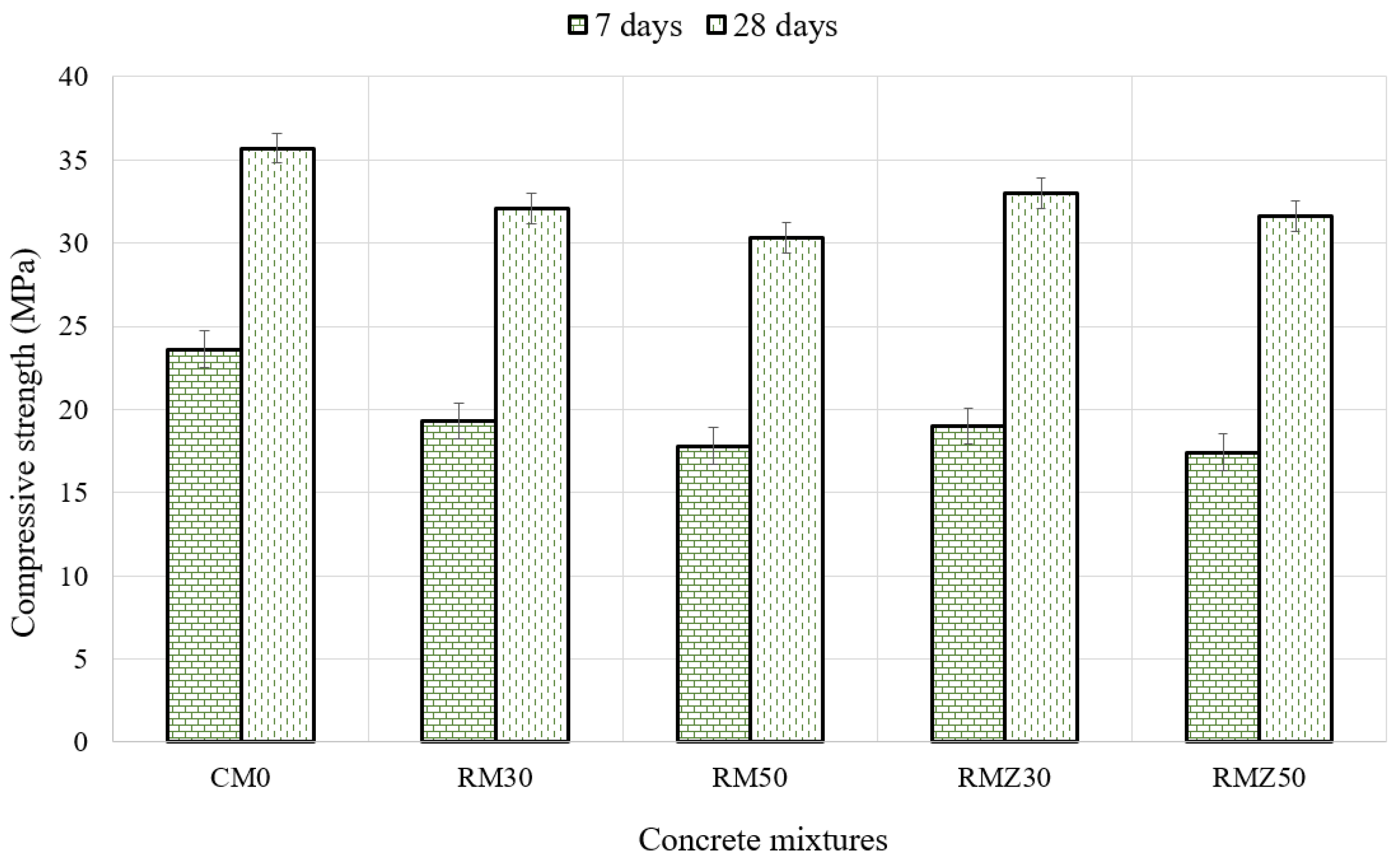

3.4. Compressive Strength of the Mixtures

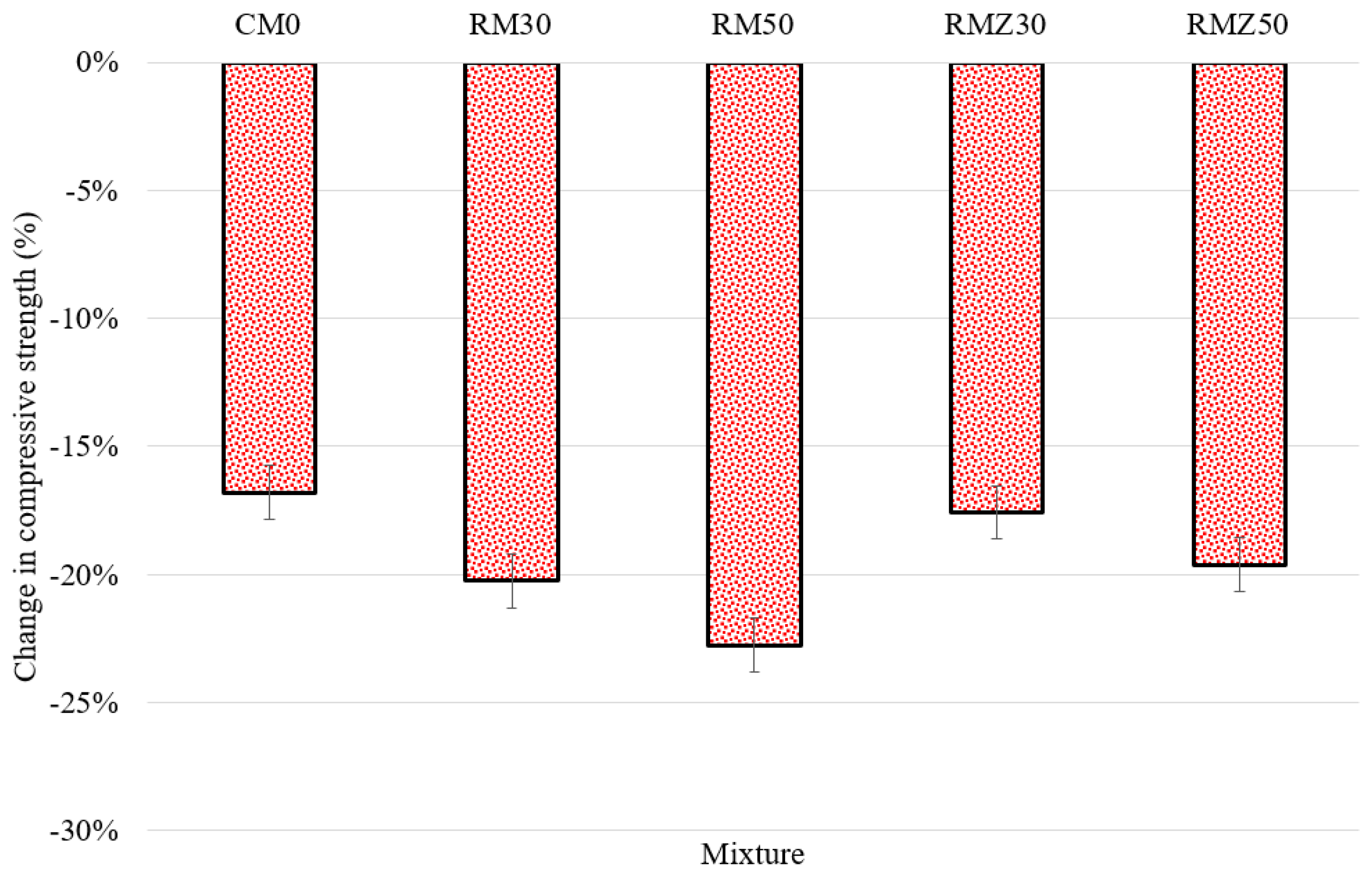

3.5. Acid Attack Assessment

4. Practical Applications

5. Conclusions

- Replacing coarse aggregates with 30 wt.% and 50 wt.% RCA reduced the workability of concrete by 32% and 49% compared to control due to the high absorption of RCA in water. Moreover, the addition of nano-ZnO particles to mixtures with 30 wt.% and 50 wt.% RCA further reduced their workability by 43% and 60% due to the high surface area of ZnO particles.

- The porosity of concrete with 30 wt.% and 50 wt.% RCA increased by 33% and 62%, respectively, owing to the porous nature of RCA. However, using nano-ZnO particles in those mixtures refined their pore structure, resulting in their porosity dropping by 7% and 10%, respectively.

- The replacement of natural aggregate with 30 wt.% and 50 wt.% RCA increased the permeability of concrete, achieving absorption rates of 6% and 7.2%, respectively, whereas the control mixture achieved an absorption rate of 2.9%. However, treating RCA mixtures with nan-ZnO managed to reduce their absorption rate by 14.5% and 18%, respectively.

- The 28-day compressive strength of RCA mixtures exhibited a 10% and 15% drop (for mixtures with 30 wt.% and 50 wt.% RCA) compared to the control mixture, which is due to the inferior mechanical properties of the old mortar attached to RCA. However, using nano-ZnO particles to treat RCA-concrete mixtures worked on enhancing their compressive strength by 2.8% and 4%.

- All concrete mixtures exhibited a drop in their compressive strength after exposure to the H2SO4 solution, with the control mixture being the least affected. Mixtures with 30 wt.% and 50 wt.% RCA showed 20.2% and 22.8% loss in their compressive strength, respectively, due to their porous nature. However, the drop in the compressive strength of concrete with 30 wt.% and 50 wt.% RCA and treated with nano-ZnO was 17.6% and 19.6%, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Raqeb, H.; Ghaffar, S.H.; Al-Kheetan, M.J.; Chougan, M. Understanding the Challenges of Construction Demolition Waste Management towards Circular Construction: Kuwait Stakeholder’s Perspective. Clean. Waste Syst. 2023, 4, 100075. [Google Scholar] [CrossRef]

- El-Seidy, E.; Sambucci, M.; Chougan, M.; Al-Kheetan, M.J.; Biblioteca, I.; Valente, M.; Ghaffar, S.H. Mechanical and Physical Characteristics of Alkali-Activated Mortars Incorporated with Recycled Polyvinyl Chloride and Rubber Aggregates. J. Build. Eng. 2022, 60, 105043. [Google Scholar] [CrossRef]

- Poon, C.S.; Shen, P.; Jiang, Y.; Ma, Z.; Xuan, D. Total Recycling of Concrete Waste Using Accelerated Carbonation: A Review. Cem. Concr. Res. 2023, 173, 107284. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Byzyka, J.; Ghaffar, S.H. Sustainable Valorisation of Silane-Treated Waste Glass Powder in Concrete Pavement. Sustainability 2021, 13, 4949. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental Impacts and Decarbonization Strategies in the Cement and Concrete Industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Chougan, M.; Al-kheetan, M.J.; Yio, M.H.N.; Wong, H.S.; Ghaffar, S.H. Upcycling End-of-Life Bricks in High-Performance One-Part Alkali-Activated Materials. Dev. Built Environ. 2023, 16, 100231. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the Cement and Concrete Industry: A Systematic Review of Socio-Technical Systems, Technological Innovations, and Policy Options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Al-Awabdeh, F.W.; Al-Kheetan, M.J.; Jweihan, Y.S.; Al-Hamaiedeh, H.; Ghaffar, S.H. Comprehensive Investigation of Recycled Waste Glass in Concrete Using Silane Treatment for Performance Improvement. Results Eng. 2022, 16, 100790. [Google Scholar] [CrossRef]

- Chinzorigt, G.; Lim, M.K.; Yu, M.; Lee, H.; Enkbold, O.; Choi, D. Strength, Shrinkage and Creep and Durability Aspects of Concrete Including CO2 Treated Recycled Fine Aggregate. Cem. Concr. Res. 2020, 136, 106062. [Google Scholar] [CrossRef]

- Bai, G.; Wang, L.; Ma, G.; Sanjayan, J.; Bai, M. 3D Printing Eco-Friendly Concrete Containing under-Utilised and Waste Solids as Aggregates. Cem. Concr. Compos. 2021, 120, 104037. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Zheng, J.; Ling, T.-C. Carbon Dioxide Sequestration on Recycled Aggregates. In Carbon Dioxide Sequestration in Cementitious Construction Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 247–277. [Google Scholar]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of Fine Recycled Concrete Aggregate on the Mechanical Behavior of Self-Compacting Concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Ouyang, K.; Liu, J.; Liu, S.; Song, B.; Guo, H.; Li, G.; Shi, C. Influence of Pre-Treatment Methods for Recycled Concrete Aggregate on the Performance of Recycled Concrete: A Review. Resour. Conserv. Recycl. 2023, 188, 106717. [Google Scholar] [CrossRef]

- Xie, T.; Gholampour, A.; Ozbakkaloglu, T. Toward the Development of Sustainable Concretes with Recycled Concrete Aggregates: Comprehensive Review of Studies on Mechanical Properties. J. Mater. Civ. Eng. 2018, 30, 04018211. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance Enhancement of Recycled Concrete Aggregate—A Review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Adessina, A.; Ben Fraj, A.; Barthélémy, J.-F.; Chateau, C.; Garnier, D. Experimental and Micromechanical Investigation on the Mechanical and Durability Properties of Recycled Aggregates Concrete. Cem. Concr. Res. 2019, 126, 105900. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of Recycled Aggregate on Interfacial Transition Zone, Strength, Chloride Penetration and Carbonation of Concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality Improvement of Recycled Concrete Aggregate by Removal of Residual Mortar: A Comprehensive Review of Approaches Adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Santos, W.F.; Quattrone, M.; John, V.M.; Angulo, S.C. Roughness, Wettability and Water Absorption of Water Repellent Treated Recycled Aggregates. Constr. Build. Mater. 2017, 146, 502–513. [Google Scholar] [CrossRef]

- Shaban, W.M.; Yang, J.; Su, H.; Liu, Q.; Tsang, D.C.W.; Wang, L.; Xie, J.; Li, L. Properties of Recycled Concrete Aggregates Strengthened by Different Types of Pozzolan Slurry. Constr. Build. Mater. 2019, 216, 632–647. [Google Scholar] [CrossRef]

- Pu, Y.; Li, L.; Wang, Q.; Shi, X.; Luan, C.; Zhang, G.; Fu, L.; El-Fatah Abomohra, A. Accelerated Carbonation Technology for Enhanced Treatment of Recycled Concrete Aggregates: A State-of-the-Art Review. Constr. Build. Mater. 2021, 282, 122671. [Google Scholar] [CrossRef]

- Wu, C.-R.; Hong, Z.-Q.; Zhang, J.-L.; Kou, S.-C. Pore Size Distribution and ITZ Performance of Mortars Prepared with Different Bio-Deposition Approaches for the Treatment of Recycled Concrete Aggregate. Cem. Concr. Compos. 2020, 111, 103631. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A Comprehensive Review on the Use of Recycled Concrete Aggregate for Pavement Construction: Properties, Performance, and Sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of Concrete Prepared with PVA-Impregnated Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Yaowarat, T.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M.; A Rashid, A.S. Compressive and Flexural Strength of Polyvinyl Alcohol–Modified Pavement Concrete Using Recycled Concrete Aggregates. J. Mater. Civ. Eng. 2018, 30, 04018046. [Google Scholar] [CrossRef]

- Lim, A.E.; Goh, S. Effect of Microchannel Diameter on Electroosmotic Flow Hysteresis. Energies 2023, 16, 2154. [Google Scholar] [CrossRef]

- Bîrcă, A.C.; Gherasim, O.; Niculescu, A.-G.; Grumezescu, A.M.; Neacșu, I.A.; Chircov, C.; Vasile, B.Ș.; Oprea, O.C.; Andronescu, E.; Stan, M.S.; et al. A Microfluidic Approach for Synthesis of Silver Nanoparticles as a Potential Antimicrobial Agent in Alginate–Hyaluronic Acid-Based Wound Dressings. Int. J. Mol. Sci. 2023, 24, 11466. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Bansal, M.; Garg, R. An Overview of Beneficiary Aspects of Zinc Oxide Nanoparticles on Performance of Cement Composites. Mater. Today Proc. 2021, 43, 892–898. [Google Scholar] [CrossRef]

- Al-saffar, F.Y.; Wong, L.S.; Paul, S.C. An Elucidative Review of the Nanomaterial Effect on the Durability and Calcium-Silicate-Hydrate (C-S-H) Gel Development of Concrete. Gels 2023, 9, 613. [Google Scholar] [CrossRef] [PubMed]

- Arbabi, A.; Kolahchi, R.; Bidgoli, M.R. Experimental Study for ZnO Nanofibers Effect on the Smart and Mechanical Properties of Concrete. Smart Struct. Syst. 2020, 25, 97–104. [Google Scholar]

- Reshma, T.V.; Manjunatha, M.; Bharath, A.; Tangadagi, R.B.; Vengala, J.; Manjunatha, L. Influence of ZnO and TiO2 on Mechanical and Durability Properties of Concrete Prepared with and without Polypropylene Fibers. Materialia 2021, 18, 101138. [Google Scholar] [CrossRef]

- Nayak, C.B.; Taware, P.P.; Jagadale, U.T.; Jadhav, N.A.; Morkhade, S.G. Effect of SiO2 and ZnO Nano-Composites on Mechanical and Chemical Properties of Modified Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 1237–1247. [Google Scholar] [CrossRef]

- Nochaiya, T.; Sekine, Y.; Choopun, S.; Chaipanich, A. Microstructure, Characterizations, Functionality and Compressive Strength of Cement-Based Materials Using Zinc Oxide Nanoparticles as an Additive. J. Alloy. Compd. 2015, 630, 1–10. [Google Scholar] [CrossRef]

- Silatikunsatid, T.; Jaitanong, N.; Narksitipan, S. A Study on Influence of Zinc Oxide in Cement Composite Materials. Key Eng. Mater. 2018, 772, 95–99. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Lu, Z.; Chen, J. Properties and Hydration Mechanism of Cement Pastes in Presence of Nano-ZnO. Constr. Build. Mater. 2021, 289, 123080. [Google Scholar] [CrossRef]

- BS EN 196-1:2016; Methods of Testing Cement—Determination of Strength. British Standards Institution: London, UK, 2016.

- BS EN 12350-2:2019; TC: Testing Fresh Concrete—Slump Test. British Standards Institution: London, UK, 2019.

- Al-Kheetan, M.J.; Rahman, M.M.; Ghaffar, S.H.; Al-Tarawneh, M.; Jweihan, Y.S. Comprehensive Investigation of the Long-Term Performance of Internally Integrated Concrete Pavement with Sodium Acetate. Results Eng. 2020, 6, 100110. [Google Scholar] [CrossRef]

- BS 1881-122:2011+A1:2020; Testing Concrete—Method for Determination of Water Absorption. British Standards Institution: London, UK, 2020.

- BS EN 12390-3:2019; Testing Hardened Concrete—Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2019.

- ASTM C1898-20; Standard Test Methods for Determining the Chemical Resistance of Concrete Products to Acid Attack. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Kox, S.; Vanroelen, G.; Van Herck, J.; de Krem, H.; Vandoren, B. Experimental Evaluation of the High-Grade Properties of Recycled Concrete Aggregates and Their Application in Concrete Road Pavement Construction. Case Stud. Constr. Mater. 2019, 11, e00282. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M. Porosity of Recycled Concrete with Substitution of Recycled Concrete Aggregate. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and Macro-Porosity of Dry- and Saturated-State Recycled Aggregate Concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Arefi, M.R.; Rezaei-Zarchi, S. Synthesis of Zinc Oxide Nanoparticles and Their Effect on the Compressive Strength and Setting Time of Self-Compacted Concrete Paste as Cementitious Composites. Int. J. Mol. Sci. 2012, 13, 4340–4350. [Google Scholar] [CrossRef]

- Yang, J.; Mohseni, E.; Behforouz, B.; Khotbehsara, M.M. An Experimental Investigation into the Effects of Cr2O3 and ZnO2 Nanoparticles on the Mechanical Properties and Durability of Self-Compacting Mortar. Int. J. Mater. Res. 2015, 106, 886–892. [Google Scholar] [CrossRef]

- Vazinram, F.; Jalal, M.; Foroushani, M.Y. Effect of Nano ZnO2 and Lime Water Curing on Strength and Water Absorption of Concrete. Int. J. Mater. Prod. Technol. 2015, 50, 356. [Google Scholar] [CrossRef]

- Agamuthu, P. Challenges in Sustainable Management of Construction and Demolition Waste. Waste Manag. Res. J. A Sustain. Circ. Econ. 2008, 26, 491–492. [Google Scholar] [CrossRef] [PubMed]

- Nivethitha, D.; Dharmar, S. Influence of Zinc Oxide Nanoparticle on Strength and Durability of Cement Mortar. Int. J. Earth Sci. Eng. 2016, 9, 175–181. [Google Scholar]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alsubari, B.; Alqedra, M.A.; Mo, K.H. Effect of Aggressive Chemicals on Durability and Microstructure Properties of Concrete Containing Crushed New Concrete Aggregate and Non-Traditional Supplementary Cementitious Materials. Constr. Build. Mater. 2018, 163, 482–495. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Effect of Recycled Aggregate Treatment Techniques on the Durability of Concrete: A Comparative Evaluation. Constr. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Sahoo, S.; Das, B.B.; Rath, A.K.; Kar, B.B. Acid, Alkali and Chloride Resistance of High Volume Fly Ash Concrete. Indian J. Sci. Technol. 2015, 8, 12. [Google Scholar] [CrossRef]

| Purity (%) | ≥99 |

| Average diameter (nm) | 30 |

| Density (g/cm3) | 4.8 |

| Average specific surface area (m2/g) | 34.2 |

| Colour | White |

| Mixture | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Water (kg/m3) | Cement (kg/m3) | Coarse RCA (kg/m3) | Nano-ZnO (kg/m3) |

|---|---|---|---|---|---|---|

| CM0 | 1074 | 812 | 196 | 446 | 0 | 0 |

| RM30 | 752 | 812 | 196 | 446 | 322 | 0 |

| RM50 | 537 | 812 | 196 | 446 | 537 | 0 |

| RMZ30 | 752 | 812 | 196 | 443.8 | 322 | 2.2 |

| RMZ50 | 537 | 812 | 196 | 443.8 | 537 | 2.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Kheetan, M.J.; Jweihan, Y.S.; Rabi, M.; Ghaffar, S.H. Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO. Buildings 2024, 14, 353. https://doi.org/10.3390/buildings14020353

Al-Kheetan MJ, Jweihan YS, Rabi M, Ghaffar SH. Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO. Buildings. 2024; 14(2):353. https://doi.org/10.3390/buildings14020353

Chicago/Turabian StyleAl-Kheetan, Mazen J., Yazeed S. Jweihan, Musab Rabi, and Seyed Hamidreza Ghaffar. 2024. "Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO" Buildings 14, no. 2: 353. https://doi.org/10.3390/buildings14020353

APA StyleAl-Kheetan, M. J., Jweihan, Y. S., Rabi, M., & Ghaffar, S. H. (2024). Durability Enhancement of Concrete with Recycled Concrete Aggregate: The Role of Nano-ZnO. Buildings, 14(2), 353. https://doi.org/10.3390/buildings14020353