Experimental Study on the Effects of Straight and Ring-Type Steel Fibres on the Bond Behaviour of Steel Bars in Rubber-Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Experimental Programme

2.1. Materials Properties

2.2. Mix Proportions

2.3. Design and Preparation of Pull-Out Specimens

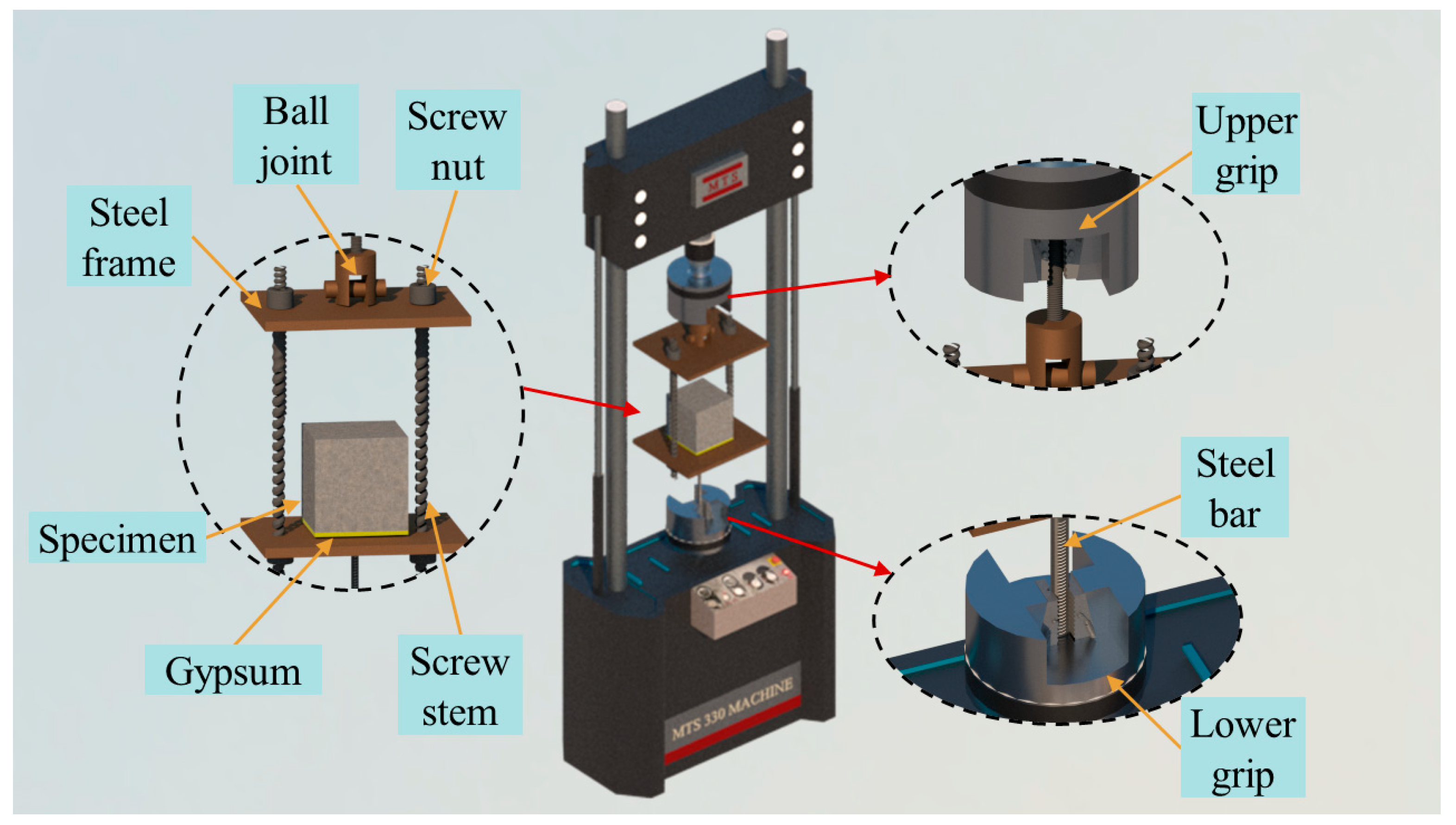

2.4. Test Setup and Machine

3. Results and Discussion

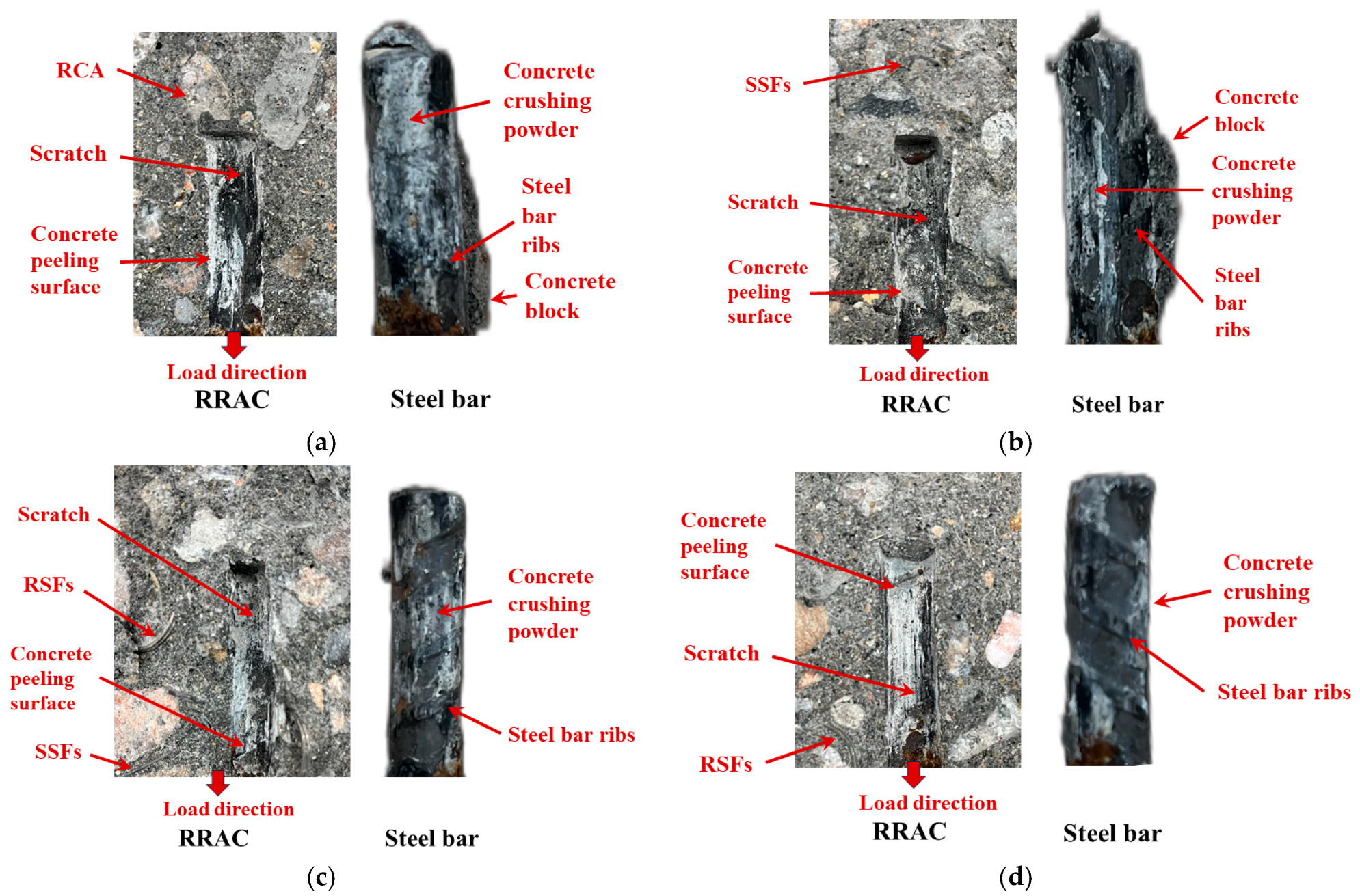

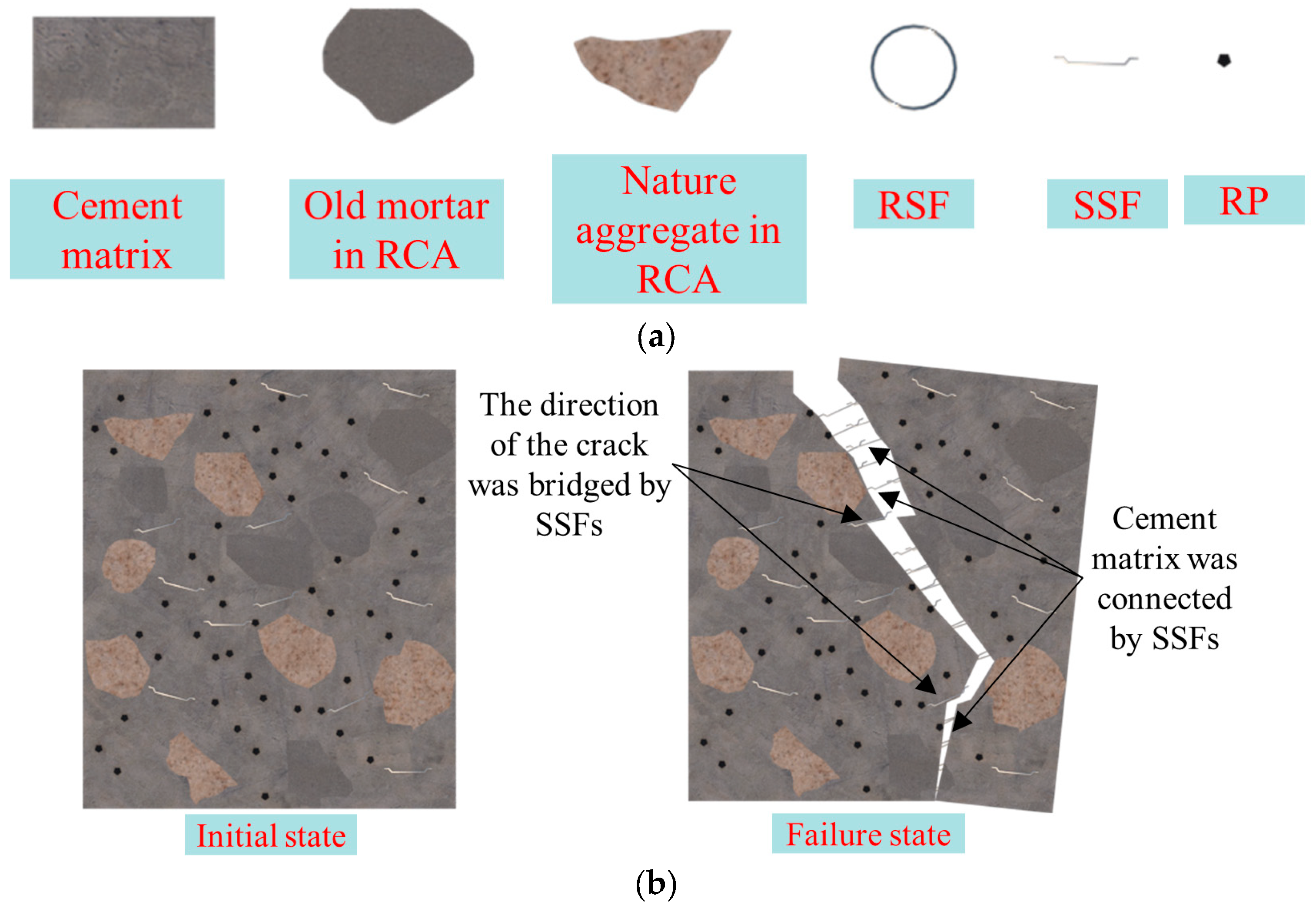

3.1. Bond Interface Damage and Bond Mechanism

3.2. Effects of SSFs and RSFs on Bond Mechanism

3.3. Bond Stress–Slip Curves

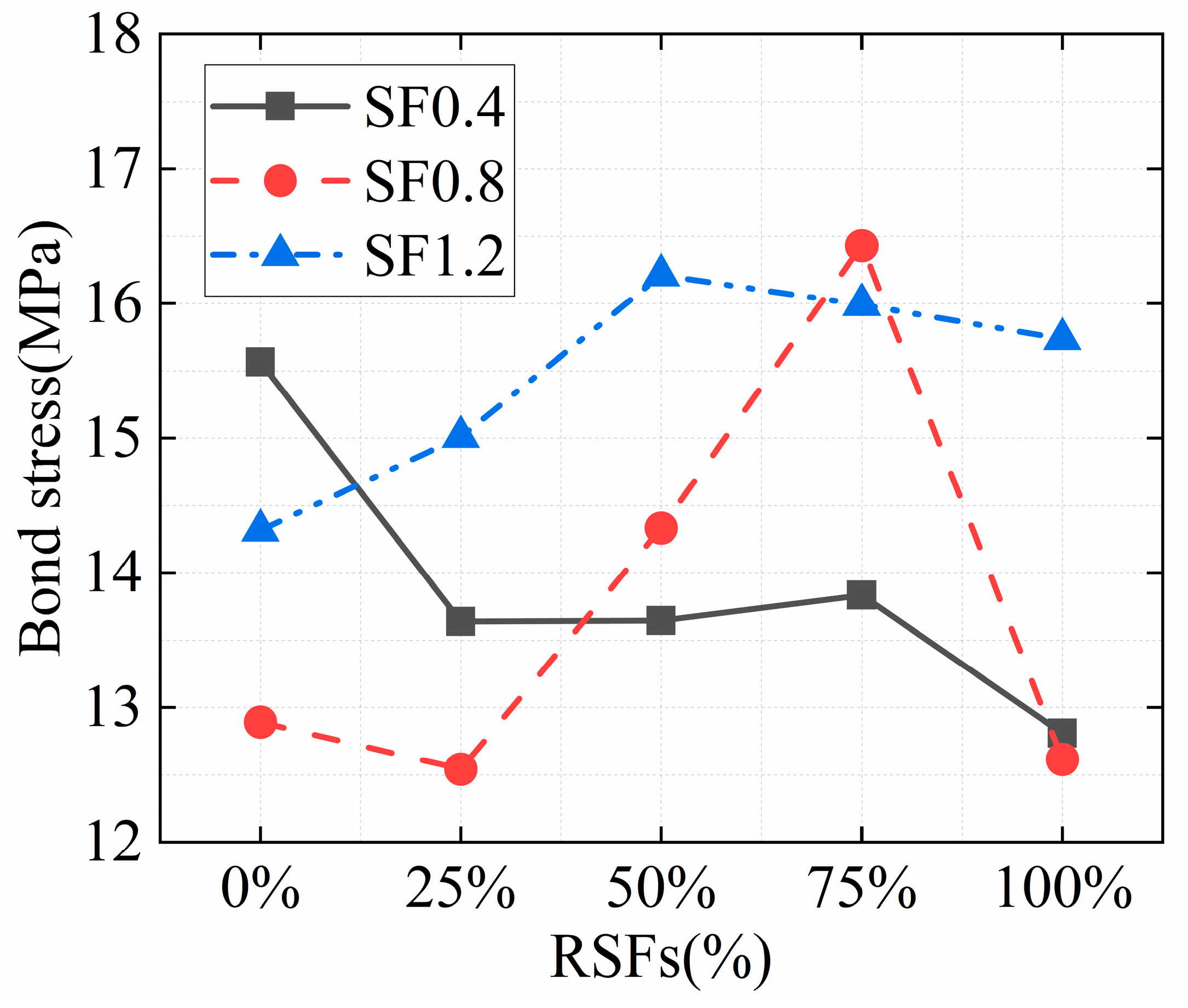

3.4. Bond Strength

3.5. Bond Stiffness

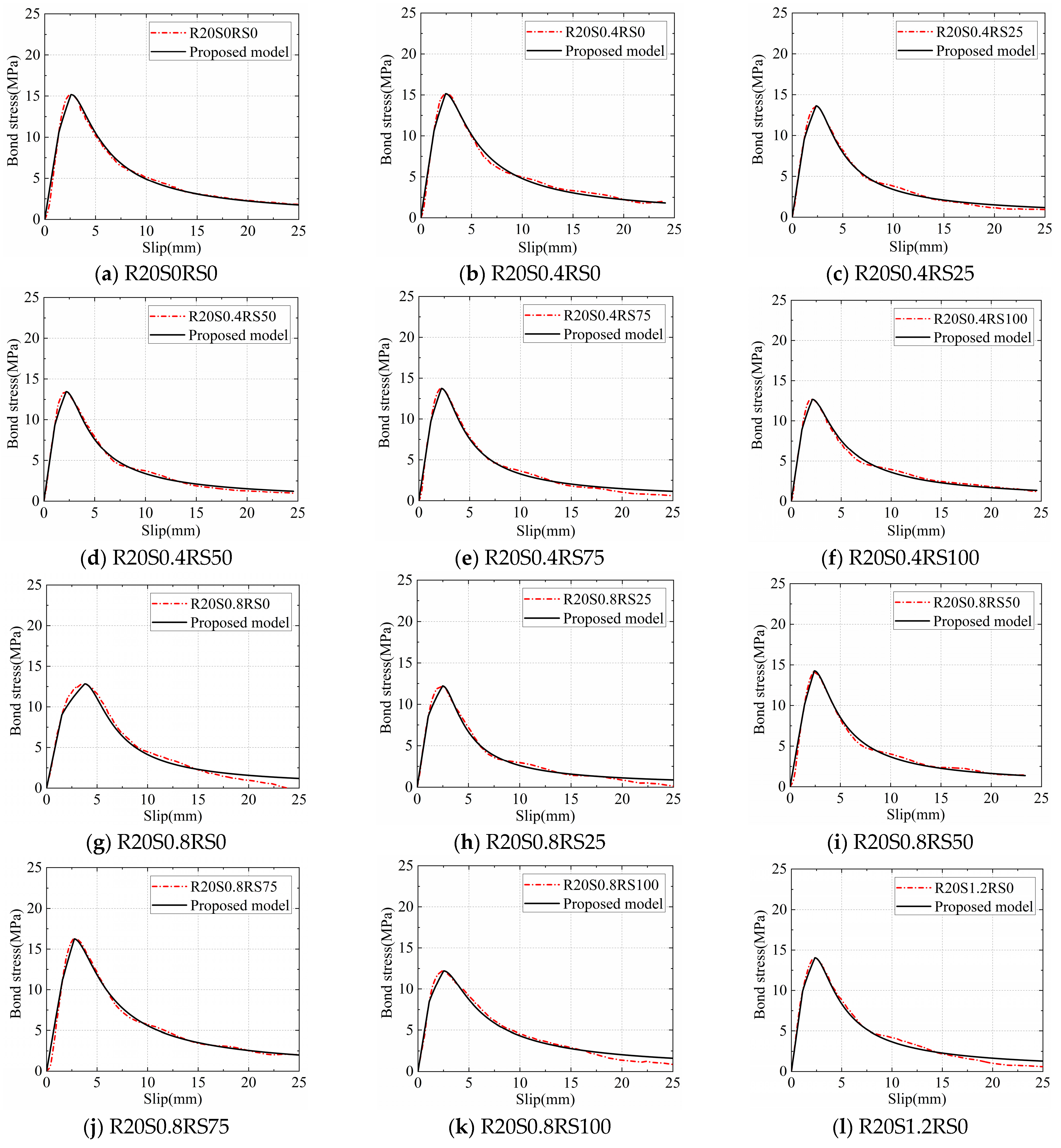

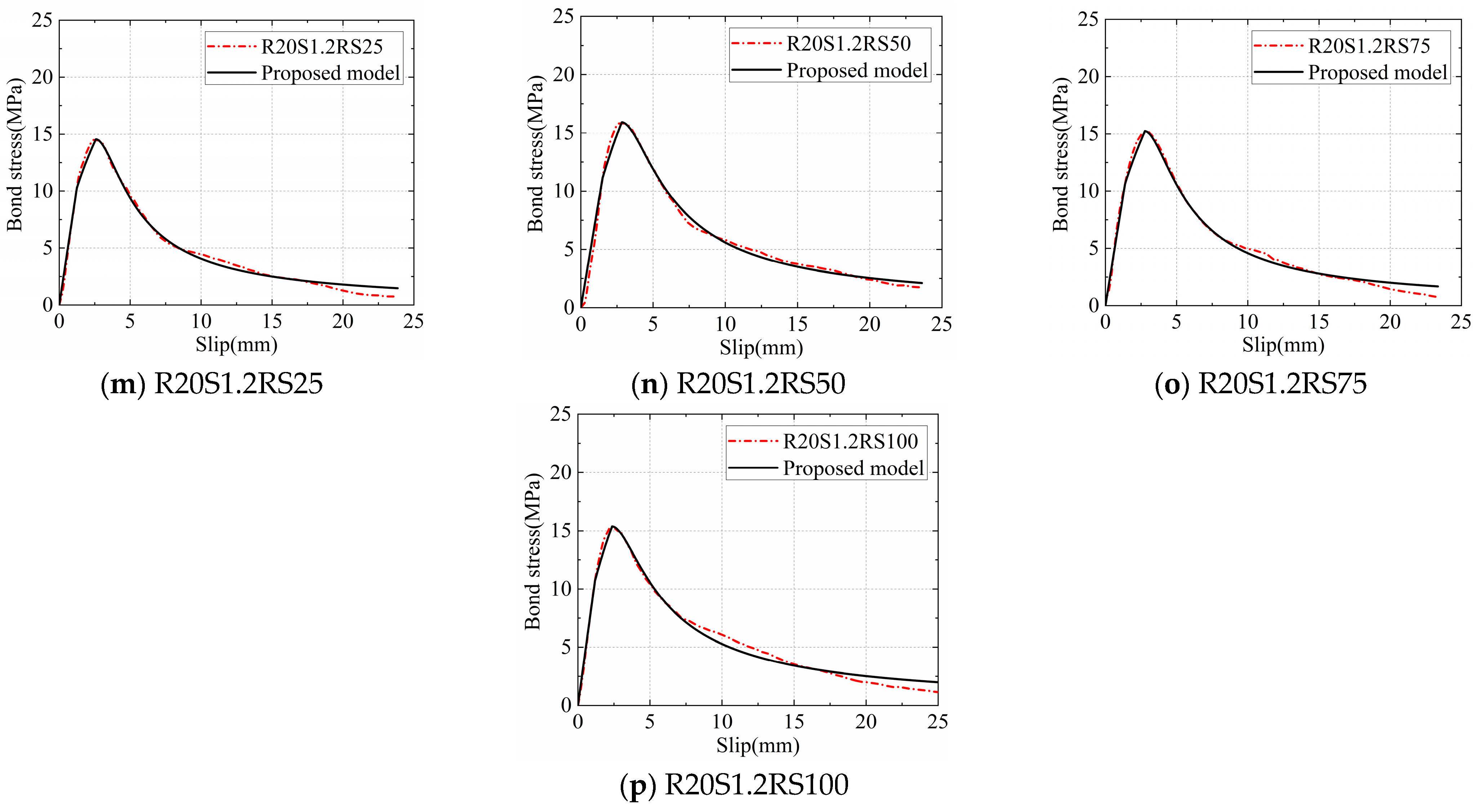

4. Bond–Slip Constitutive Model

5. Conclusions

- (1)

- The failure of reinforced inter-rib concrete after extrusion is crucial for the failure of RRAC and steel bar bonding. The combined use of SSFs and RSFs inhibits crack development of RRAC, delays damage to the inter-ribbed concrete matrix, and enhances the bonding effect between RRAC and steel bars. However, excessive SFs can reduce the compactness of concrete and create a weak layer at the interface between SFs and concrete, which negatively affects the bonding effect. In practical applications, it is recommended to limit the steel fibre content to below 1.2% and control the water–cement ratio of concrete.

- (2)

- After the addition of 20% RPs, the bond strength experienced a decrease of 32.87%. When only SSFs or RSFs were added, the bond strength showed improvement with the addition of 0.4% SSFs or 1.2% RSFs, while other dosages resulted in varying degrees of bond-strength decrease. There is a synergistic effect between SSFs and RSFs, and the best improvement in bond strength is achieved through their combined use. When the SF content is 0.8% and the RSF ratio is 75%, the bond strength reaches its maximum value, which is 6.55% higher than that of specimen R20S0RS0.

- (3)

- The bonding stiffness decreased by 37.26% after adding 20% RPs. However, the bonding stiffness improved when SFs were added, regardless of changes in content. The improvement effect becomes more apparent as the SF content increases. The bonding stiffness reaches its maximum at a 1.2% SF content and a 75% RSF ratio, which is 53.88% higher than that of the R20S0RS0 specimen. Considering both bonding strength and bonding stiffness, the optimal mix ratio to enhance the bonding effect between RRAC and steel bars is a 1.2% SF total content and a 75% RSF ratio.

- (4)

- The bond–slip constitutive model of RRAC and steel bars was established based on the characteristics of the bond stress–slip curve. The model shows excellent agreement with the experimental data and can accurately predict the bond stress–slip relationship between RRAC and steel bars.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mai, G.H.; Li, L.J.; Lin, J.W.; Wei, W.; He, S.H.; Zhong, R.K.; Xiong, Z. Bond durability between BFRP bars and recycled aggregate seawater sea-sand concrete in freezing-thawing environment. J. Build. Eng. 2023, 70, 106422. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Jiang, Z.M. Reuse of waste rubber in pervious concrete: Experiment and DEM simulation. J. Build. Eng. 2023, 71, 106452. [Google Scholar] [CrossRef]

- Xiong, Z.; Wei, W.; Liu, F.; Cui, C.Y.; Li, L.J.; Zou, R.; Zeng, Y. Bond behaviour of recycled aggregate concrete with basalt fibre-reinforced polymer bars. Compos. Struct. 2021, 256, 113078. [Google Scholar] [CrossRef]

- Wang, W.D.; Lu, C.X.; Zhu, Z.M.; Zhang, Z.Y.; Liu, S.Y.; Ji, Y.C.; Xing, Z.Q. Mechanical performance of recycled aggregate concrete in green civil engineering: Review. Case Stud. Constr. Mat. 2023, 19, e02384. [Google Scholar] [CrossRef]

- Formela, K. Waste tire rubber-based materials: Processing, performance properties and development strategies. Adv. Ind. Eng. Polym. Res. 2022, 5, 234–247. [Google Scholar] [CrossRef]

- Tang, Y.C.; Feng, W.H.; Feng, W.X.; Chen, J.M.; Bao, D.J.; Li, L.J. Compressive properties of rubber-modified recycled aggregate concrete subjected to elevated temperatures. Constr. Build. Mater. 2021, 268, 121181. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Xiong, Z.; Song, Y.Y.; Zhou, K.T.; Su, Y. Effect of expansion agent and glass fiber on the dynamicsplitting tensile properties of seawater–sea-sand concrete. Buildings 2024, 14, 217. [Google Scholar] [CrossRef]

- Pan, Z.Z.; Liu, F.; Li, H.W.; Li, X.H.; Wang, D.C.; Ling, Z.; Zhu, H.Y.; Zhu, Y.H. Performance evaluation of thermal insulation rubberized mortar modified by fly ash and glass fiber. Buildings 2024, 14, 221. [Google Scholar] [CrossRef]

- Zhen, H.; Xiong, Z.; Song, Y.Y.; Li, L.J.; Qiu, Y.; Zou, X.Z.; Chen, B.; Chen, D.G.; Liu, F.; Ji, Y.D. Early mechanical performance of glass fibre-reinforced manufactured sand concrete. J. Build. Eng. 2024, 83, 108440. [Google Scholar] [CrossRef]

- El-Zohairy, A.; Sanchez, M.; Abediniangerabi, B.; Moler, P. Performance of rubberized concrete and the effect of temperature and stainless steel fibers. Buildings 2023, 12, 280. [Google Scholar] [CrossRef]

- Eisa, A.S.; Elshazli, M.T.; Nawar, M.T. Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Constr. Build. Mater. 2020, 252, 119078. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhanng, J.H.; Chen, G.; Chen, G.M.; Xie, Z.H. Fracture behaviors of a new steel fiber reinforced recycled aggregate concrete with crumb rubber. Constr. Build. Mater. 2014, 53, 32–39. [Google Scholar] [CrossRef]

- Chen, A.J.; Han, X.Y.; Chen, M.; Wang, X.Y.; Wang, Z.H.; Guo, T.T. Mechanical and stress-strain behavior of basalt fiber reinforced rubberized recycled coarse aggregate concrete. Constr. Build. Mater. 2020, 260, 119888. [Google Scholar] [CrossRef]

- Mohseni, E.; Koushkbaghi, M. Recycling of landfill waste tyre in construction materials: Durability of concrete made with chipped rubber. Constr. Build. Mater. 2023, 409, 134114. [Google Scholar] [CrossRef]

- Xiong, Z.; Fang, Z.; Feng, W.H.; Liu, F.; Yang, F.; Li, L.J. Review of dynamic behaviour of rubberised concrete at material and member levels. J. Build. Eng. 2021, 38, 102237. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.H.; Chen, G.M.; Xie, Z.H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Shahjalal, M.; Islam, K.; Batool, F.; Tiznobaik, M.; Hossain, Z.F.M.; Ahmed, K.S.; Alam, S.M.; Ahsan, R. Fiber-reinforced recycled aggregate concrete with crumb rubber: A state-of-the-art review. Constr. Build. Mater. 2023, 404, 133233. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T.; Hassanli, R. Behavior of rubberized concrete under active confinement. Constr. Build. Mater. 2017, 138, 372–382. [Google Scholar] [CrossRef]

- Chen, F.; Wu, K.; Ren, L.J.; Xu, J.N.; Zheng, H.M. Internal curing effect and compressive strength calculation of recycled clay brick aggregate concrete. Materials 2019, 12, 1815. [Google Scholar] [CrossRef]

- Zrar, Y.J.; Younis, K.H.; Sherwani, A.F.H. Properties of sustainable self-compacted concrete with recycled concrete and waste tire crumb rubber aggregates. Constr. Build. Mater. 2023, 407, 133524. [Google Scholar] [CrossRef]

- Liu, F.; Meng, L.Y.; Ning, G.F.; Li, L.J. Fatigue performance of rubber-modified recycled aggregate concrete (RRAC) for pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Saberian, M.; Tajaddini, A.; Li, J.; Zhang, G.M.; Wang, L.; Sun, D.A.; Maqsood, T.; Roychand, R. Mechanical properties of polypropylene fibre reinforced recycled concrete aggregate for sustainable road base and subbase applications. Constr. Build. Mater. 2023, 405, 133352. [Google Scholar] [CrossRef]

- Peng, S.; Wu, B.; Du, X.Q.; Zhao, Y.F.; Yu, Z.P. Study on dynamic splitting tensile mechanical properties and microscopic mechanism analysis of steel fiber reinforced concrete. Structures 2023, 58, 105502. [Google Scholar] [CrossRef]

- Han, J.H.; Zhao, M.M.; Chen, J.Y.; Lan, X.F. Effects of steel fiber length and coarse aggregate maximum size on mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2019, 209, 577–591. [Google Scholar] [CrossRef]

- Li, Q.Y.; Shi, Z.M.; Zhao, F.; Yu, S.B.; Xie, K.L. Mechanical performance evaluation of steel fiber-reinforced concrete (FRC) based on multi-mechanical indicators from split hopkinson pressure bar (SHPB) test. J. Build. Eng. 2023, 79, 107898. [Google Scholar] [CrossRef]

- Olivito, R.S.; Zuccarello, F.A. An experimental study on the tensile strength of steel fiber reinforced concrete. Compos. Part B-Eng. 2010, 41, 246–255. [Google Scholar] [CrossRef]

- Xie, J.H.; Li, J.L.; Lu, Z.Y.; Li, Z.J.; Fang, C.; Huang, L.; Li, L.J. Combination effects of rubber and silica fume on the fracture behaviour of steel-fibre recycled aggregate concrete. Constr. Build. Mater. 2019, 203, 164–173. [Google Scholar] [CrossRef]

- Xue, G.J.; Wang, C.L.; Zhang, J.M.; Liu, Z.P.; Zhang, T.T.; Zhang, Y.X. Influence of steel fiber shape on the performance of high-performance concrete. Acta Mater. Compos. Sin. 2021, 38, 43413–44324. [Google Scholar]

- Lee, C.; Kim, H. Orientation factor and number of fibers at failure plane in ring-type steel fiber reinforced concrete. Cement Concrete Res. 2010, 40, 810–819. [Google Scholar] [CrossRef]

- Choia, O.C.; Lee, C. Flexural performance of ring-type steel fiber-reinforced concrete. Cem. Concr. Res. 2003, 33, 841–849. [Google Scholar] [CrossRef]

- He, S.H.; Li, L.J.; Xiong, Z.; Zhang, H.Q.; Zheng, J.H.; Su, Y.; Huang, J.; Liu, F. Effects of ring-type and straight steel fibres on the compressive performance of rubber-recycled aggregate concrete. J. Build. Eng. 2023, 76, 107148. [Google Scholar] [CrossRef]

- Zheng, Y.X.; Fang, C.C.; Ma, J.J.; Wang, S.Q. Review of research on Bond-Slip of reinforced concrete structures. Constr. Build. Mater. 2023, 385, 131437. [Google Scholar] [CrossRef]

- Li, L.G.; Chen, Z.P.; Ouyang, Y.; Zhu, J.; Chu, S.H.; Kwan, A.K.H. Synergistic effects of steel fibres and expansive agent on steel bar-concrete bond. Cem. Concr. Comp. 2019, 104, 103380. [Google Scholar] [CrossRef]

- Vedernikov, A.; Gemi, L.; Madenci, E.; Onuralp Özkılıç, Y.; Yazman, Ş.; Gusev, S.; Sulimov, A.; Bondareva, J.; Evlashin, S.; Konev, S.; et al. Effects of high pulling speeds on mechanical properties and morphology of pultruded GFRP composite flat laminates. Compos. Struct. 2022, 301, 116216. [Google Scholar] [CrossRef]

- Vedernikov, A.; Tucci, F.; Carlone, P.; Gusev, S.; Konev, S.; Firsov, D.; Akhatov, I.; Safonov, A. Effects of pulling speed on structural performance of L-shaped pultruded profiles. Compos. Struct. 2021, 255, 112967. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, Z.F. Experimental study of the bonding behavior between coarse aggregate ultra-high performance concrete and steel rebar. Eng. Struct. 2023, 288, 116253. [Google Scholar] [CrossRef]

- Gao, K.; Li, H.; Liu, G.G.; Huang, Z.Y.; Wu, G.B. Bonding properties between steel-basalt hybrid fibers reinforced cementitious composites and existing concrete at high temperatures. J. Build. Eng. 2023, 70, 106371. [Google Scholar]

- Garcia-Taengua, E.; Martí-Vargas, J.R.; Serna, P. Bond of reinforcing bars to steel fiber reinforced concrete. Constr. Build. Mater. 2016, 105, 275–284. [Google Scholar] [CrossRef]

- Dancygier, A.N.; Katz, A.; Wexler, U. Bond between deformed reinforcement and normal and high-strength concrete with and without fibers. Mater. Struct. 2010, 43, 839–856. [Google Scholar] [CrossRef]

- Bao, S.H.; Zhang, Y.F.; Li, C.B.; Zhang, W.J.; Zeng, K. Interfacial bonding behavior of steel fibers when using fine glass powder as partial substitution of silica fume/cement. Constr. Build. Mater. 2024, 411, 134516. [Google Scholar] [CrossRef]

- Majain, N.; Rahman, A.B.A.; Adnan, A.; Mohamed, R.N. Bond behaviour of deformed steel bars in steel fibre high-strength self-compacting concrete. Constr. Build. Mater. 2022, 318, 125906. [Google Scholar] [CrossRef]

- Xiong, Z.; Zeng, Y.; Li, L.G.; Kwan, A.K.H.; He, S.H. Experimental study on the effects of glass fibres and expansive agent on the bond behaviour of glass/basalt FRP bars in seawater sea-sand concrete. Constr. Build. Mater. 2021, 274, 122100. [Google Scholar] [CrossRef]

- Mo, K.H.; Visintin, P.; Alengaram, U.J.; Jumaat, M.Z. Bond stress-slip relationship of oil palm shell lightweight concrete. Eng. Struct. 2016, 127, 319–330. [Google Scholar] [CrossRef]

- Guo, Z.H. The Strength and Deformation Test Basis and Constitutive Relationship of Concrete; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

| Fibre Type | Raw Material | Shape Feature | Tensile Strength fst (MPa) | Apparent Density ρ (kg/m3) | Elastic Modulus Es (GPa) |

|---|---|---|---|---|---|

| SSFs | Carbon steel | Hooked-end steel fibre | 1000 | 7436 | 200 |

| RSFs | Stainless steel | Ring-shape steel fibre | 960 | 7600 | 193 |

| Mix Number | Cement (kg/m3) | Water (kg/m3) | Sand (kg/m3) | RCA (kg/m3) | RPs (kg/m3) | RSFs (kg/m3) | SSFs (kg/m3) | Compressive Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| R0S0RS0 | 596.20 | 228.30 | 791.33 | 742.87 | 0.00 | 0.00 | 0.00 | 45.73 |

| R20S0RS0 | 596.20 | 228.01 | 633.06 | 742.87 | 59.28 | 0.00 | 0.00 | 37.07 |

| R20S0.4RS0 | 596.20 | 227.88 | 628.84 | 737.92 | 58.88 | 0.00 | 29.74 | 35.89 |

| R20S0.4RS25 | 596.20 | 227.88 | 628.84 | 737.92 | 58.88 | 7.60 | 22.31 | 36.86 |

| R20S0.4RS50 | 596.20 | 227.88 | 628.84 | 737.92 | 58.88 | 15.20 | 14.87 | 40.08 |

| R20S0.4RS75 | 596.20 | 227.88 | 628.84 | 737.92 | 58.88 | 22.80 | 7.44 | 32.44 |

| R20S0.4RS100 | 596.20 | 227.88 | 628.84 | 737.92 | 58.88 | 30.40 | 0.00 | 38.30 |

| R20S0.8RS0 | 596.20 | 227.75 | 624.62 | 732.96 | 58.49 | 0.00 | 59.49 | 40.26 |

| R20S0.8RS25 | 596.20 | 227.75 | 624.62 | 732.96 | 58.49 | 15.20 | 44.62 | 43.17 |

| R20S0.8RS50 | 596.20 | 227.75 | 624.62 | 732.96 | 58.49 | 30.40 | 29.74 | 39.83 |

| R20S0.8RS75 | 596.20 | 227.75 | 624.62 | 732.96 | 58.49 | 45.60 | 14.87 | 36.18 |

| R20S0.8RS100 | 596.20 | 227.75 | 624.62 | 732.96 | 58.49 | 60.80 | 0.00 | 33.03 |

| R20S1.2RS0 | 596.20 | 227.62 | 620.40 | 728.01 | 58.09 | 0.00 | 89.23 | 41.25 |

| R20S1.2RS25 | 596.20 | 227.62 | 620.40 | 728.01 | 58.09 | 22.80 | 66.92 | 38.76 |

| R20S1.2RS50 | 596.20 | 227.62 | 620.40 | 728.01 | 58.09 | 45.60 | 44.62 | 38.67 |

| R20S1.2RS75 | 596.20 | 227.62 | 620.40 | 728.01 | 58.09 | 68.40 | 22.31 | 37.42 |

| R20S1.2RS100 | 596.20 | 227.62 | 620.40 | 728.01 | 58.09 | 91.20 | 0.00 |

| Concrete Mix No. | Bond Strength (MPa) | |||

|---|---|---|---|---|

| Specimen 1 | Specimen 2 | Specimen 3 | Mean | |

| R0S0RS0 | 22.15 | 24.67 | 22.10 | 22.97 |

| R20S0RS0 | 13.85 | 17.31 | 15.10 | 15.42 |

| R20S0.4RS0 | 15.57 | 15.76 | 15.36 | 15.56 |

| R20S0.4RS25 | 13.59 | 13.36 | 13.97 | 13.64 |

| R20S0.4RS50 | 12.83 | 13.32 | 14.68 | 13.64 |

| R20S0.4RS75 | 15.28 | 13.75 | 12.47 | 13.83 |

| R20S0.4RS100 | 13.24 | 12.46 | 12.73 | 12.81 |

| R20S0.8RS0 | 13.02 | 13.98 | 11.68 | 12.89 |

| R20S0.8RS25 | 13.06 | 11.86 | 12.71 | 12.54 |

| R20S0.8RS50 | 13.53 | 14.57 | 14.90 | 14.33 |

| R20S0.8RS75 | 16.51 | 18.38 | 14.41 | 16.43 |

| R20S0.8RS100 | 12.12 | 13.17 | 12.55 | 12.61 |

| R20S1.2RS0 | 12.50 | 14.93 | 15.51 | 14.32 |

| R20S1.2RS25 | 13.70 | 15.11 | 16.21 | 15.01 |

| R20S1.2RS50 | 15.79 | 16.65 | 16.19 | 16.21 |

| R20S1.2RS75 | 15.42 | 16.81 | 15.75 | 15.99 |

| R20S1.2RS100 | 16.17 | 16.88 | 14.16 | 15.74 |

| Concrete Mix No. | Bond Stiffness (MPa/mm) | |||

|---|---|---|---|---|

| Specimen 1 | Specimen 2 | Specimen 3 | Mean | |

| R0S0RS0 | 10.81 | 10.72 | 8.02 | 9.85 |

| R20S0RS0 | 5.05 | 6.64 | 6.85 | 6.18 |

| R20S0.4RS0 | 7.63 | 7.69 | 7.13 | 7.49 |

| R20S0.4RS25 | 7.60 | 6.50 | 7.99 | 7.36 |

| R20S0.4RS50 | 7.27 | 6.84 | 7.80 | 7.30 |

| R20S0.4RS75 | 7.34 | 7.03 | 6.67 | 7.01 |

| R20S0.4RS100 | 6.86 | 7.32 | 7.05 | 7.08 |

| R20S0.8RS0 | 8.12 | 7.72 | 7.61 | 7.82 |

| R20S0.8RS25 | 6.68 | 9.48 | 7.69 | 7.95 |

| R20S0.8RS50 | 8.44 | 8.10 | 7.43 | 7.99 |

| R20S0.8RS75 | 7.88 | 7.89 | 8.18 | 7.98 |

| R20S0.8RS100 | 7.39 | 7.18 | 9.00 | 7.85 |

| R20S1.2RS0 | 7.90 | 8.58 | 8.05 | 8.18 |

| R20S1.2RS25 | 7.90 | 8.75 | 8.44 | 8.36 |

| R20S1.2RS50 | 8.52 | 9.30 | 8.55 | 8.79 |

| R20S1.2RS75 | 9.77 | 9.18 | 9.57 | 9.51 |

| R20S1.2RS100 | 7.45 | 8.68 | 8.44 | 8.19 |

| Concrete Mix No. | K | α | β | R2 | SE |

|---|---|---|---|---|---|

| R20S0RS0 | 6.18 | 0.5798 | 0.9920 | 0.9972 | 0.0024 |

| R20S0.4RS0 | 7.49 | 0.5650 | 0.9231 | 0.9935 | 0.0033 |

| R20S0.4RS25 | 7.36 | 0.5218 | 1.2194 | 0.9935 | 0.0051 |

| R20S0.4RS50 | 7.30 | 0.5166 | 1.0699 | 0.9947 | 0.0043 |

| R20S0.4RS75 | 7.01 | 0.5506 | 1.1753 | 0.9911 | 0.0058 |

| R20S0.4RS100 | 7.08 | 0.5243 | 0.8547 | 0.9916 | 0.0034 |

| R20S0.8RS0 | 7.82 | 0.3858 | 2.0587 | 0.9633 | 0.0235 |

| R20S0.8RS25 | 7.95 | 0.4259 | 1.6187 | 0.9833 | 0.0116 |

| R20S0.8RS50 | 7.99 | 0.6701 | 1.2044 | 0.9943 | 0.0042 |

| R20S0.8RS75 | 7.98 | 0.6772 | 0.9801 | 0.9971 | 0.0025 |

| R20S0.8RS100 | 7.85 | 0.4456 | 0.8229 | 0.9812 | 0.0053 |

| R20S1.2RS0 | 8.18 | 0.4720 | 1.1265 | 0.9796 | 0.0086 |

| R20S1.2RS25 | 8.36 | 0.4769 | 1.2101 | 0.9885 | 0.0064 |

| R20S1.2RS50 | 8.79 | 0.5664 | 1.0161 | 0.9948 | 0.0033 |

| R20S1.2RS75 | 9.51 | 0.5152 | 1.2332 | 0.9900 | 0.0061 |

| R20S1.2RS100 | 8.19 | 0.5246 | 0.7804 | 0.9782 | 0.0054 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Li, H.; Zheng, J.; Wei, W.; He, S.; Tian, X.; Li, X.; Liu, F. Experimental Study on the Effects of Straight and Ring-Type Steel Fibres on the Bond Behaviour of Steel Bars in Rubber-Recycled Aggregate Concrete. Buildings 2024, 14, 504. https://doi.org/10.3390/buildings14020504

Ma H, Li H, Zheng J, Wei W, He S, Tian X, Li X, Liu F. Experimental Study on the Effects of Straight and Ring-Type Steel Fibres on the Bond Behaviour of Steel Bars in Rubber-Recycled Aggregate Concrete. Buildings. 2024; 14(2):504. https://doi.org/10.3390/buildings14020504

Chicago/Turabian StyleMa, Honglong, Huawei Li, Jinhu Zheng, Wei Wei, Shaohua He, Xiaopeng Tian, Xiaohui Li, and Feng Liu. 2024. "Experimental Study on the Effects of Straight and Ring-Type Steel Fibres on the Bond Behaviour of Steel Bars in Rubber-Recycled Aggregate Concrete" Buildings 14, no. 2: 504. https://doi.org/10.3390/buildings14020504