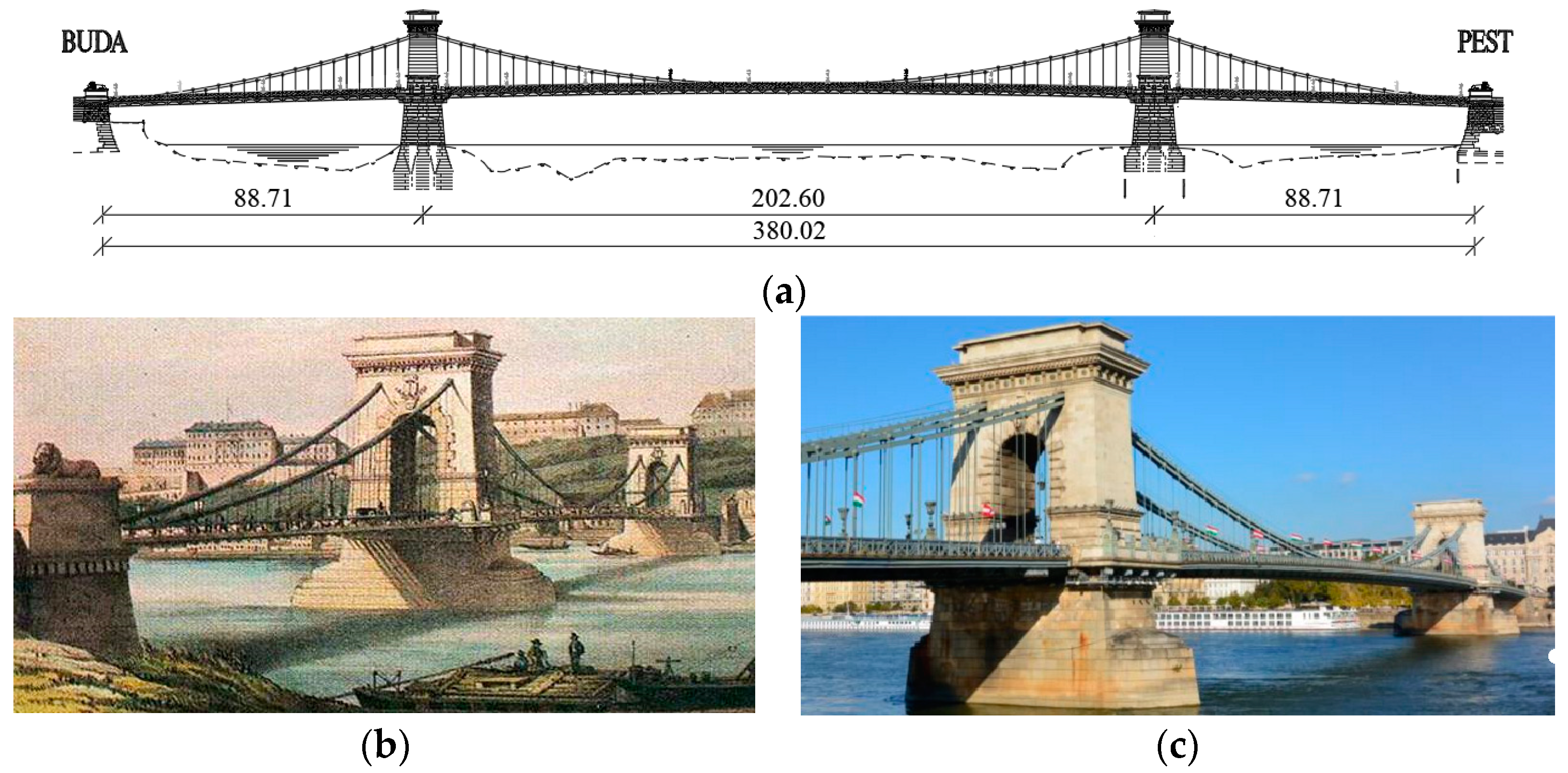

Temporary Structural Health Monitoring of Historical Széchenyi Chain Bridge

Abstract

:1. Introduction

- Evaluating the measurement results of a proof load test, which was carried out in 2018, to conclude whether fixed or partly fixed pins would start rotating due to a live load on the bridge;

- Assessing the temporary measurement results during reconstruction to conclude whether pins would start rotating due to reducing self-weight (dead load), which is mostly dominant for chain bridges.

2. Literature Review

3. Proof Load Test

3.1. Configuration and Measurement Locations

3.2. Load Cases

- Unloaded bridge;

- Three trucks in one lane in the middle span of the inflow side;

- Six trucks in one lane in the middle span of the inflow side;

- Nine trucks in one lane in the middle span of the inflow side;

- Twelve trucks in one lane in the middle span of the inflow side;

- Unloaded bridge (evaluating the effect of ΔT);

- Six trucks in the middle span of the outflow side;

- Twelve trucks in the middle span of the outflow side.

- Unloaded bridge (evaluating the effect of ΔT);

- Ten trucks, five in each side span, on the inflow side;

- Unloaded bridge (evaluating the effect of ΔT);

- Ten trucks, five on each side span, on the outflow side;

- Unloaded bridge (evaluating the effect of ΔT).

3.3. Measurement Results

4. Temporary Monitoring System

4.1. Configuration and Measurement Locations

4.2. Reconstruction Stages

- The crane runway is built on the superstructure (15 July 2021);

- Suspended scaffolding is installed, while the reinforced concrete slab is demolished in the main span (1 August 2021);

- Old steel stingers are dismantled in the main span, a new orthotropic deck is installed on half of the main span, and suspended scaffolding is installed in the side spans (3 November 2021);

- The old concrete slab and steel stringers are dismantled from the entire bridge, the new orthotropic deck is installed between the pylons, the sidewalks in the main span are dismantled, and the suspended scaffolding is dismantled (3 January 2022).

4.3. Measurement Results

5. Summary and Conclusions

- All the measured pins are stuck, so no rotations were expected due to the live load (proof test load), temperature change, or the removal of the concrete deck during the bridge reconstruction.

- The internal forces resulting from daily and/or seasonal temperature changes can equal or exceed the magnitude of the internal forces resulting from the design traffic load; the largest normal force and bending moment changes compared to the characteristic resistances from the proof load test are 3% and 10%, respectively, whereas they are 5% and 15%, respectively, for temperature changes.

- The effect of reconstruction was dominant, with the largest normal force and bending moment changes reaching 13% of the tensile resistance and 33% of the bending resistance, respectively, but these significant internal force changes could not cause the pins to rotate.

- Normal stresses due to bending within the chain elements are significant, and therefore, the bending component should always be considered in the static verification of the chain elements.

- Half-a-year-long monitoring of data could significantly contribute to the understanding of the structural behaviour of the Széchenyi Chain Bridge and its specialties, including (i) the error in the pin rotation capacity and (ii) significant internal forces due to temperature change, which were not previously considered significant issues during the design process.

- The change in normal force has a significant effect on the geometric stiffness of the chain system, as shown by the analysis of the monitoring system data. This effect can also be caused by temperature change, which warrants attention from the designers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Åesson, B. Understanding Bridge Collapses, 1st ed.; CRC Press: London, UK, 2008. [Google Scholar]

- Kövesdi, B.; Kollár, D.; Dunai, L.; Horváth, A. Reliability analysis-based investigation of the historical Széchenyi Chain Bridge deck system. Results Eng. 2022, 15, 100555. [Google Scholar] [CrossRef]

- Neves, A.C.; González, I.; Leander, J.; Karoumi, R. Structural health monitoring of bridges: A model-free ANN-based approach to damage detection. J. Civ. Struct. Health Monit. 2017, 7, 689–702. [Google Scholar] [CrossRef]

- Neves, A.C.; Leander, J.; González, I.; Karoumi, R. An approach to decision-making analysis for implementation of structural health monitoring in bridges. Struct Control Health Monit. 2019, 26, 1. [Google Scholar] [CrossRef]

- Li, H.; Ou, J.P. Design approach of health monitoring system for cable-stayed bridges. In Proceedings of the 2nd International Conference of Structural Health Monitoring for Intelligent Infrastructure, Shenzhen, China, 16–18 November 2005. [Google Scholar]

- Hovhanessian, G. Health monitoring of cable stayed structures experience and implementation. In Proceedings of the 24th Conference and Exposition on Structural Dynamics, St. Louis, MO, USA, 30 January–2 February 2006. [Google Scholar]

- Dacol, V.; Caetano, E.; Correia, J.R. Modal identification and damping performance of a full-scale GFRP-SFRSCC hybrid footbridge. Struct. Control Health Monit. 2022, 29, e3137. [Google Scholar] [CrossRef]

- Nicoletti, V.; Quarchioni, S.; Tentella, L.; Martini, R.; Gara, F. Experimental Tests and Numerical Analyses for the Dynamic Characterization of a Steel and Wooden Cable-Stayed Footbridge. Infrastructures 2023, 8, 100. [Google Scholar] [CrossRef]

- Degrauwe, D.; De Roeck, G.; Lombaert, G. Uncertainty quantification in the damage assessment of a cable-stayed bridge by means of fuzzy numbers. Comput. Struct. 2009, 87, 1077–1084. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Ou, J.; Li, H. Modal identification of bridges under varying environmental conditions: Temperature and wind effects. Struct. Control Health Monit. 2010, 17, 495–512. [Google Scholar] [CrossRef]

- Xiao, F.; Hulsey, J.L.; Balasubramanian, R. Fiber optic health monitoring and temperature behavior of bridge in cold region. Struct. Control Health Monit. 2017, 24, e2020. [Google Scholar] [CrossRef]

- Ding, Y.; Xiao, F.; Zhu, W.; Xia, T. Structural health monitoring of the scaffolding dismantling process of a long-span steel box girder viaduct based on BOTDA technology. Adv. Civ. Eng. 2019, 2019, 5942717. [Google Scholar] [CrossRef]

- Xiao, F.; Hulsey, J.L.; Chen, G.S.; Xiang, Y. Optimal static strain sensor placement for truss bridges. Int. J. Distrib. Sens. Netw. 2017, 13, 1550147717707929. [Google Scholar] [CrossRef]

- Okasha, N.M.; Frangopol, D.M. Integration of structural health monitoring in a system performance based life-cycle bridge management framework. Struct. Infrastruct. Eng. 2012, 18, 316–333. [Google Scholar] [CrossRef]

- Li, D.; Hu, Q.; Ou, J. Fatigue damage evolution and monitoring of carbon fiber reinforced polymer bridge cable by acoustic emission technique. Int. J. Distrib. Sens. Netw. 2012, 8, 282139. [Google Scholar] [CrossRef]

- Li, D.; Ou, J.; Lan, C.; Li, H. Monitoring and failure analysis of corroded bridge cables under fatigue loading using acoustic emission sensors. Sensors 2012, 12, 3901–3915. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Lan, C.M.; Ju, Y.; Li, D.S. Experimental and Numerical Study of the Fatigue Properties of Corroded Parallel Wire Cables. J. Bridg. Eng. 2011, 17, 211–220. [Google Scholar] [CrossRef]

- Li, H.; Li, S.; Ou, J.; Li, H. Reliability assessment of cable-stayed bridges based on structural health monitoring techniques. Struct. Infrastruct. Eng. 2012, 8, 829–845. [Google Scholar] [CrossRef]

- Li, H.; Ou, J. The state of the art in structural health monitoring of cable-stayed bridges. J. Civ. Struct. Health Monit. 2016, 6, 43–67. [Google Scholar] [CrossRef]

- Al-Hijazeen, A.Z.O.; Fawad, M.; Gerges, M.; Koris, K.; Salamak, M. Implementation of digital twin and support vector machine in structural health monitoring of bridges. Arch. Civ. Eng. 2023, 69, 31–47. [Google Scholar] [CrossRef]

- Barros, B.; Conde, B.; Cabaleiro, M.; Riveiro, B. Deterministic and probabilistic-based model updating of aging steel bridges. Structures 2023, 54, 89–105. [Google Scholar] [CrossRef]

- Borlenghi, P.; Gentile, C.; Pirrò, M. Vibration-Based Structural Health Monitoring of a Historic Arch Bridge. In Proceedings of the Experimental Vibration Analysis for Civil Engineering Structures, EVACES 2023, Milan, Italy, 30 August–1 September 2023; Lecture Notes in Civil Engineering; Limongelli, M.P., Giordano, P.F., Quqa, S., Gentile, C., Cigada, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2023; Volume 432. [Google Scholar]

| Fibre | Chain | P1 | P2 | P3 | P4 |

|---|---|---|---|---|---|

| Top | Upper | 110–125 | 85–110 | 105–120 | 80–105 |

| Lower | 100–125 | 110–135 | 100–140 | 95–140 | |

| Neutral | Upper | 60–80 | 35–80 | 60–80 | 40–80 |

| Lower | 55–70 40–50 | 35–80 | 65–85 | 25–80 | |

| Bottom | Upper | 85–120 | 45–50 | 115–125 | |

| Lower | 40–110 | 115–115 | 45–110 | 95–140 |

| Chain | Quantity | P1 | P2 | P3 | P4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PLT | REC | ΔT | PLT | REC | ΔT | PLT | REC | ΔT | PLT | REC | ΔT | ||

| Upper | ΔN [kN] | 1206 | 1517 | 1904 | 1036 | 1682 | 1439 | 1482 | 4568 | 1768 | 1042 | 2379 | 1426 |

| ΔM [kNm] | 147 | 702 | 151 | 146 | 359 | 268 | 228 | 457 | 142 | 141 | 366 | 285 | |

| Lower | ΔN [kN] | 998 | 2996 | 1215 | 801 | 2943 | 1134 | 1305 | - | 1316 | 959 | 2565 | 1132 |

| ΔM [kNm] | 17 | 560 | 197 | 23 | 263 | 270 | 27 | - | 220 | 21 | 347 | 326 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kövesdi, B.; Kollár, D.; Dunai, L. Temporary Structural Health Monitoring of Historical Széchenyi Chain Bridge. Buildings 2024, 14, 535. https://doi.org/10.3390/buildings14020535

Kövesdi B, Kollár D, Dunai L. Temporary Structural Health Monitoring of Historical Széchenyi Chain Bridge. Buildings. 2024; 14(2):535. https://doi.org/10.3390/buildings14020535

Chicago/Turabian StyleKövesdi, Balázs, Dénes Kollár, and László Dunai. 2024. "Temporary Structural Health Monitoring of Historical Széchenyi Chain Bridge" Buildings 14, no. 2: 535. https://doi.org/10.3390/buildings14020535

APA StyleKövesdi, B., Kollár, D., & Dunai, L. (2024). Temporary Structural Health Monitoring of Historical Széchenyi Chain Bridge. Buildings, 14(2), 535. https://doi.org/10.3390/buildings14020535