The Effect of Scrap Tires and Reclaimed Asphalt Pavement on the Behavior of Stone Columns

Abstract

1. Introduction

2. Materials

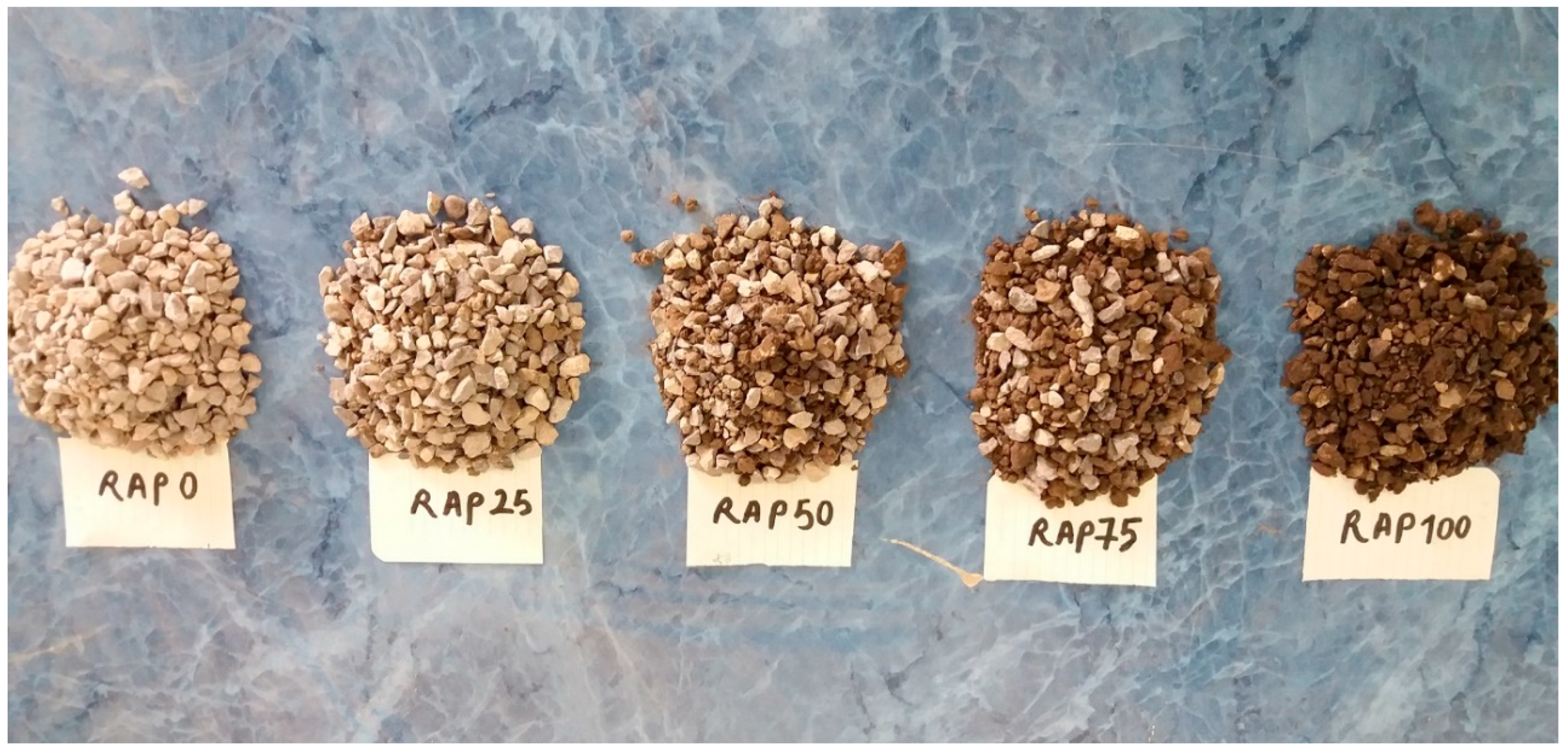

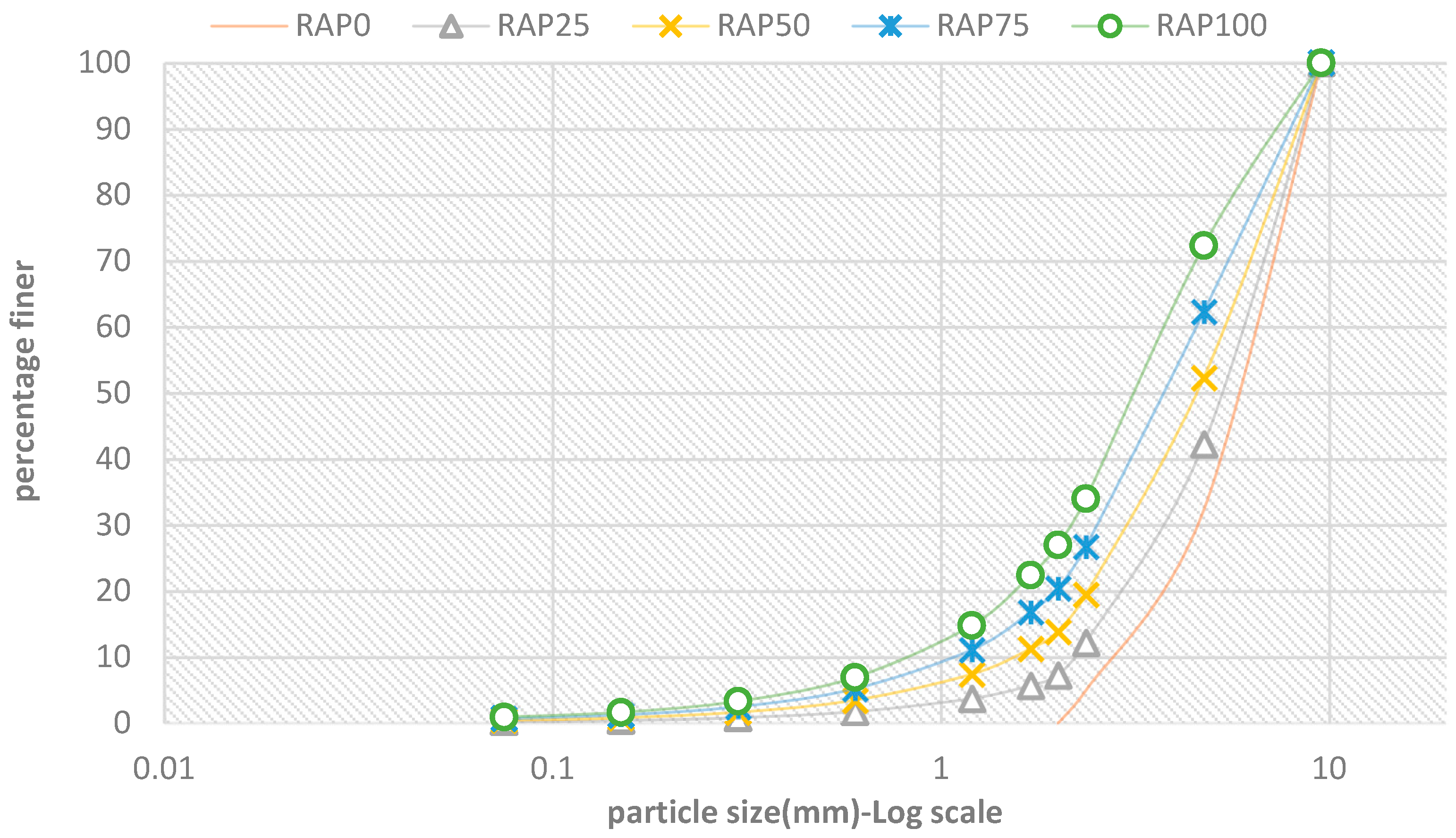

2.1. Soil and Stone Column Material

2.2. Tires

3. Tests

3.1. Loading Capacity Test

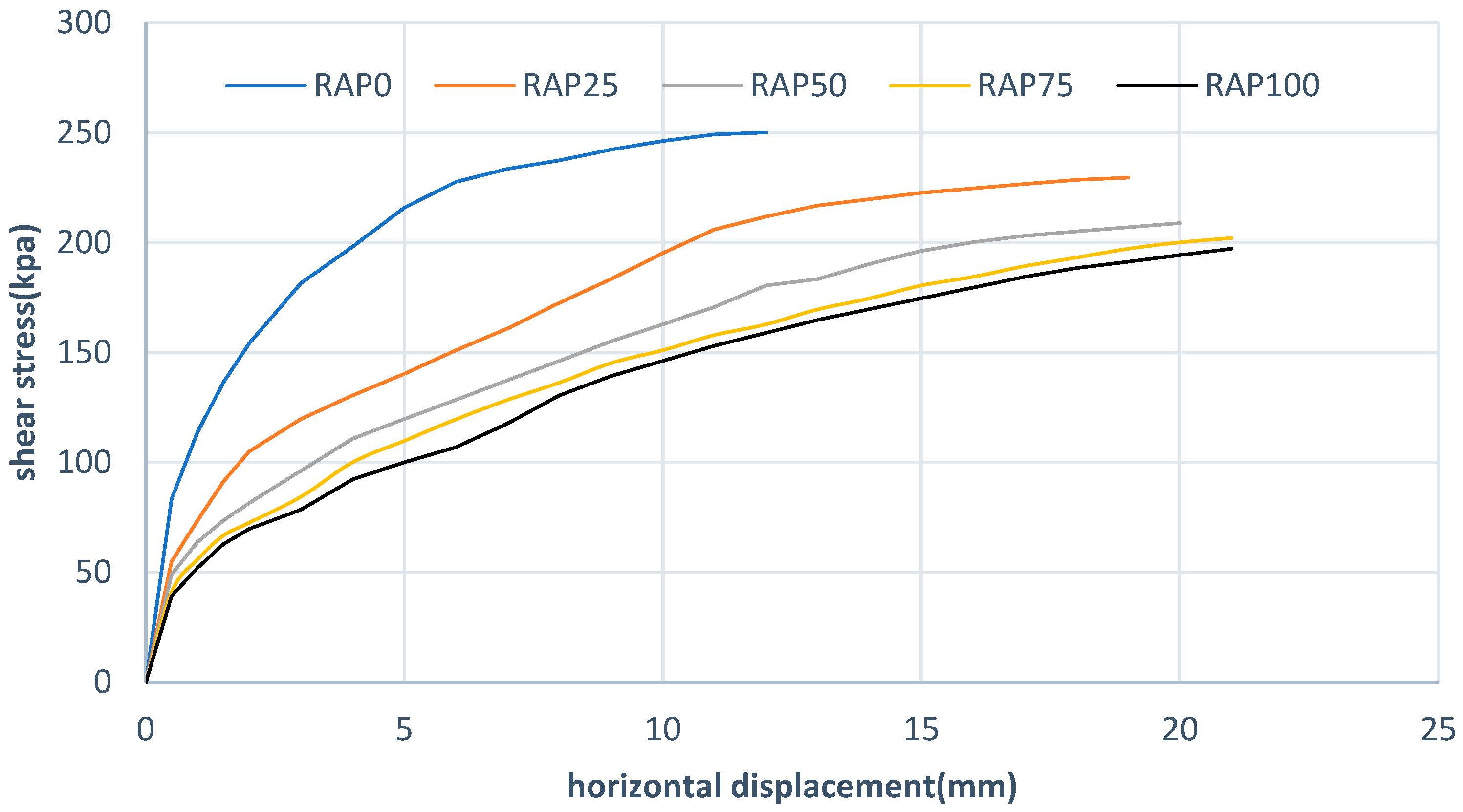

3.2. Direct Shear Test

4. Results and Discussion

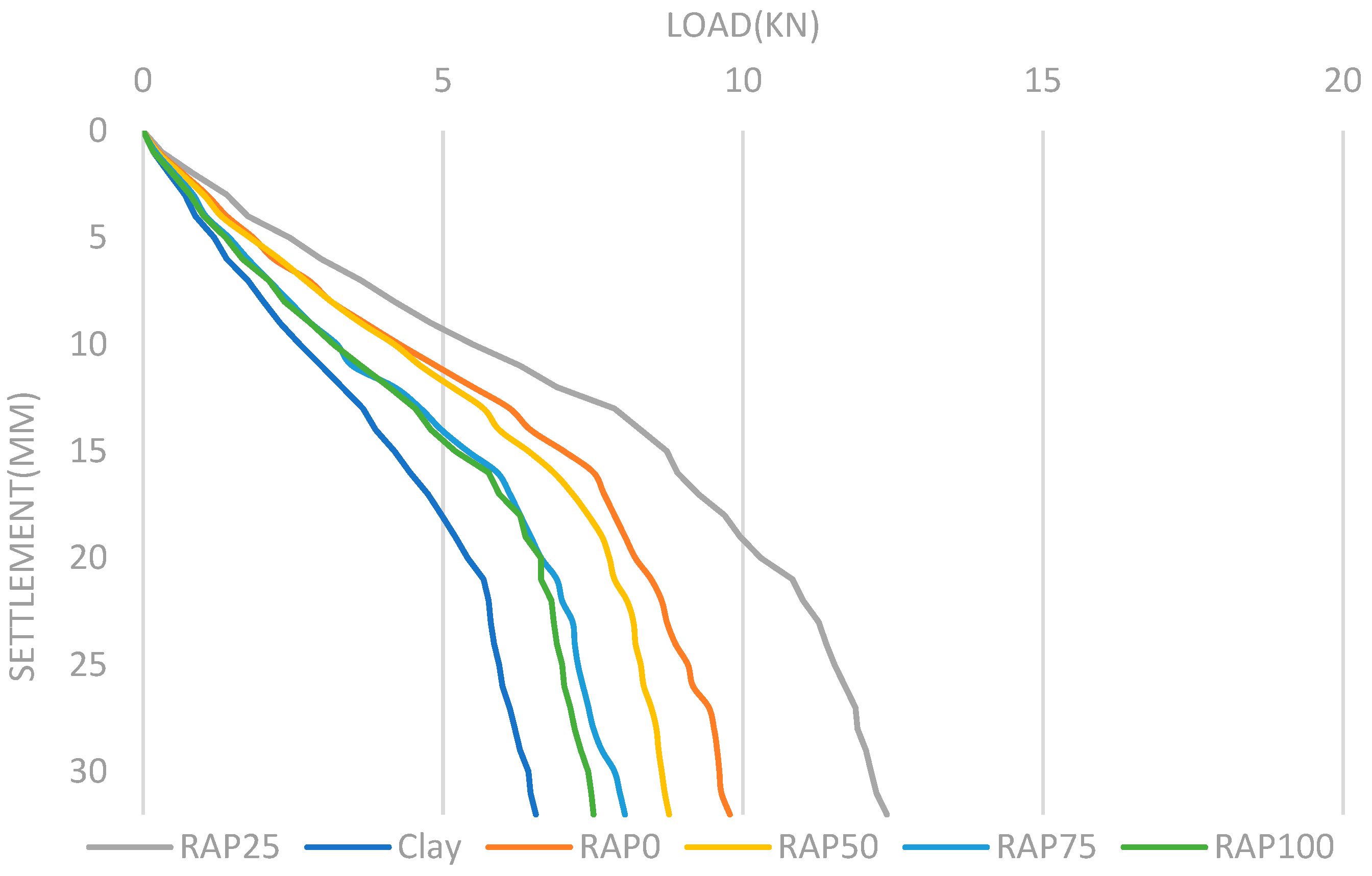

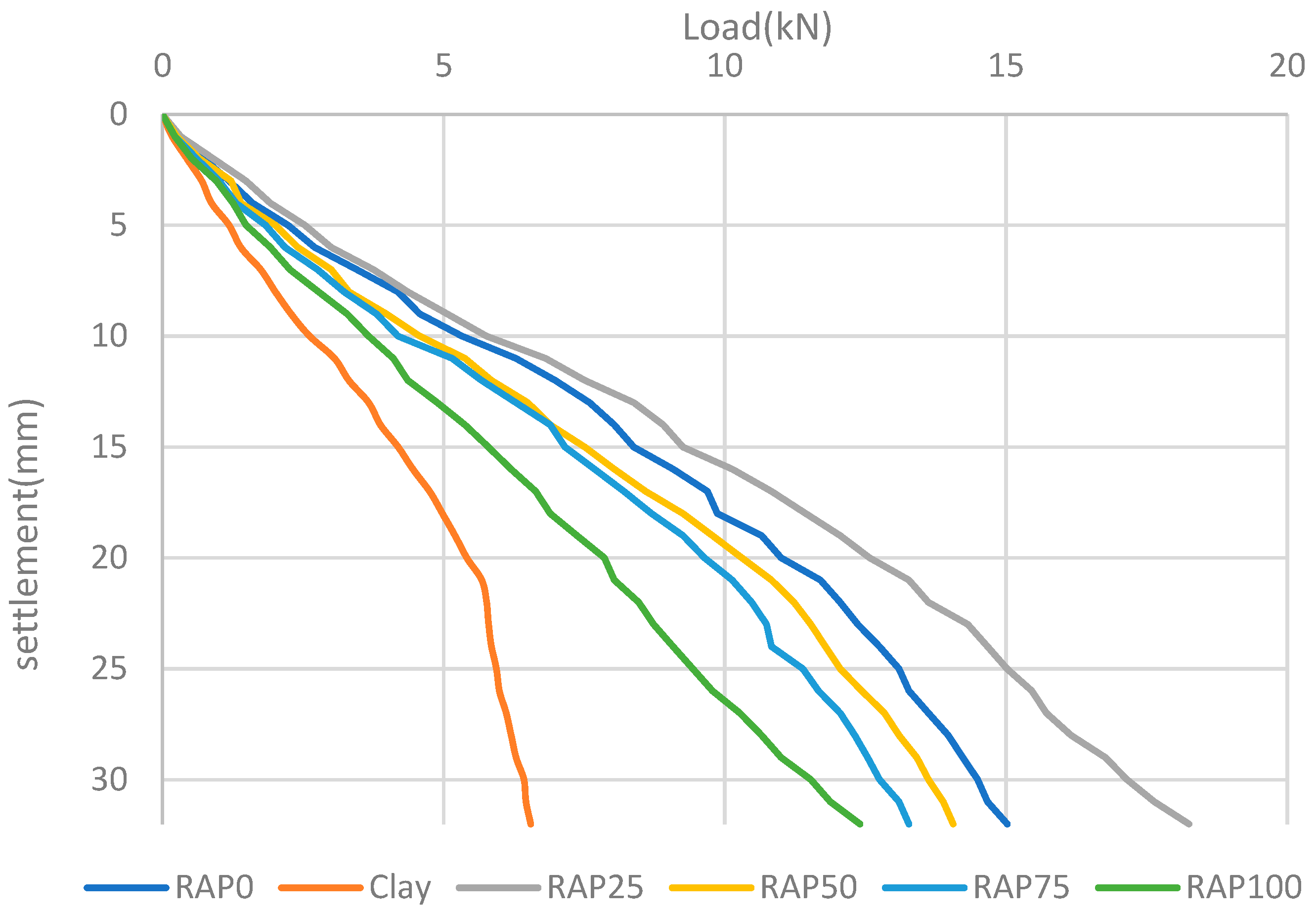

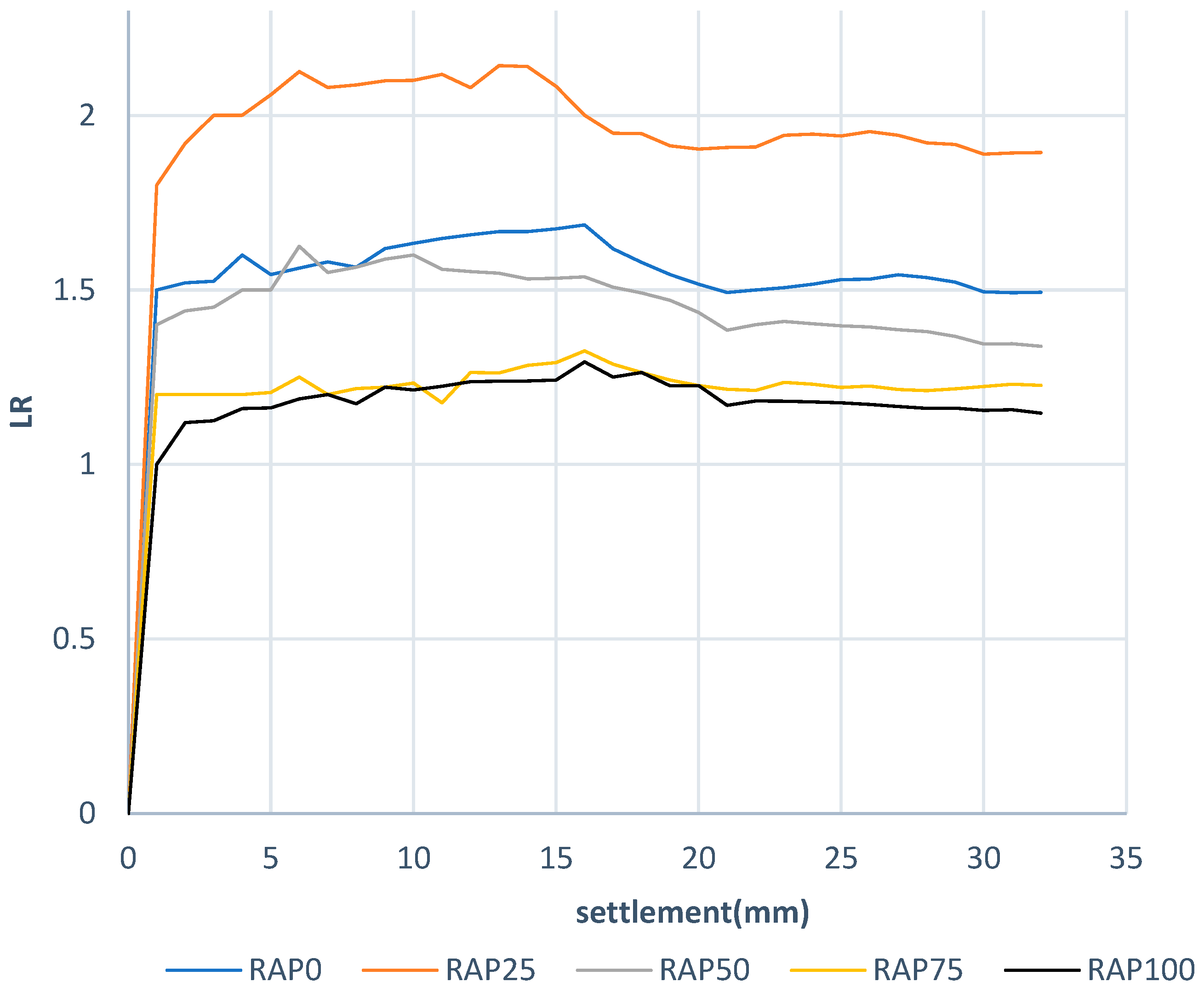

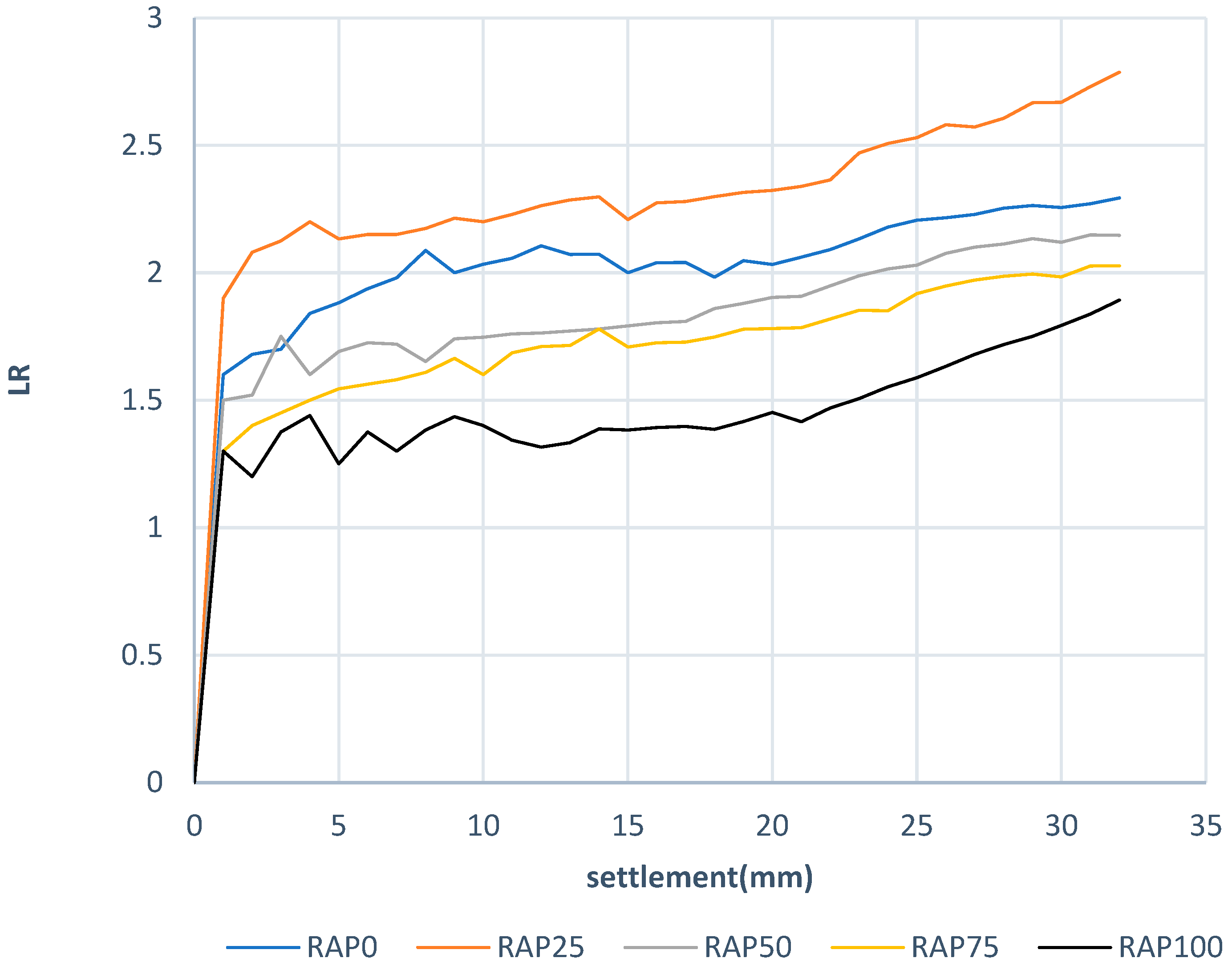

4.1. Charge Capacity

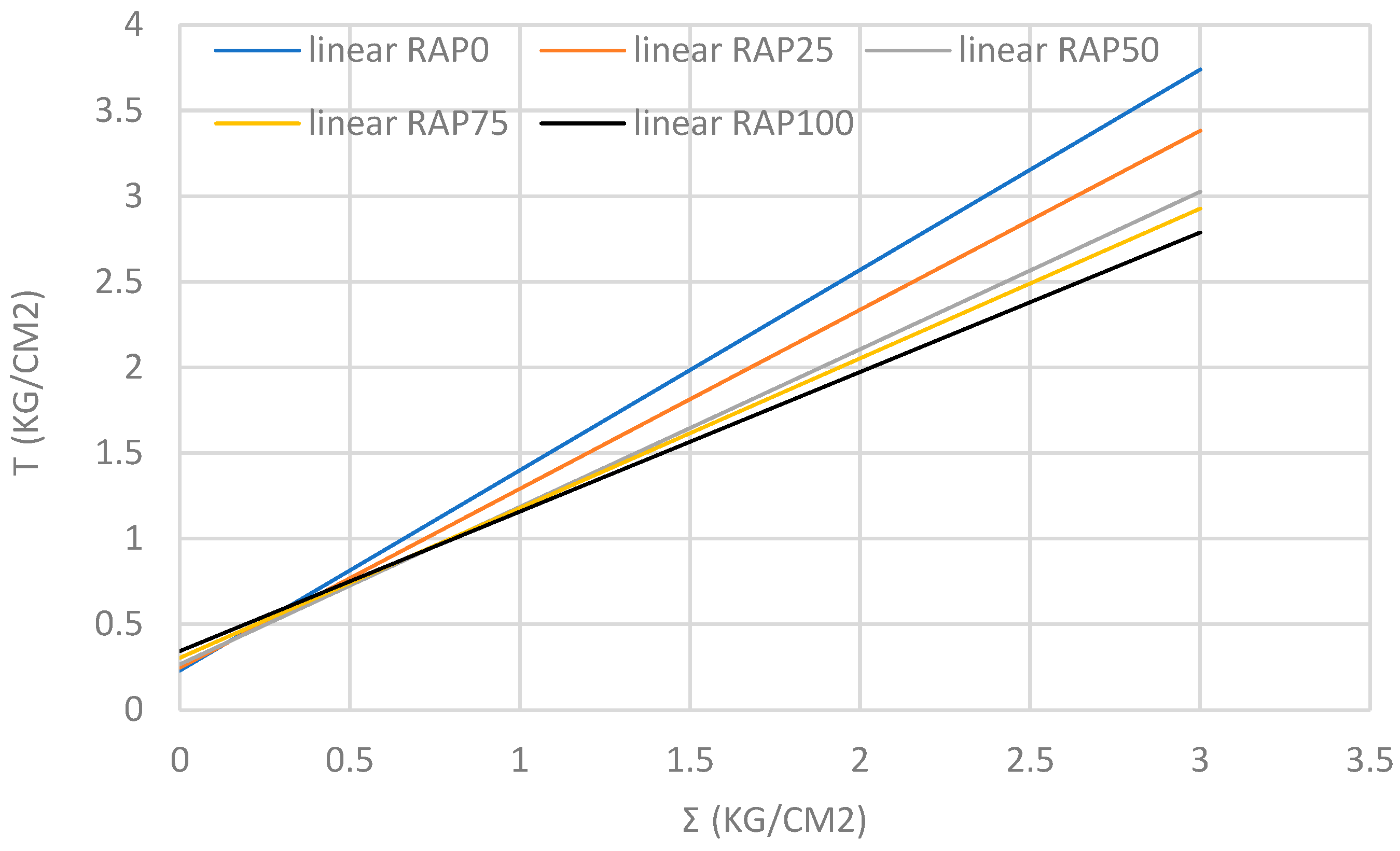

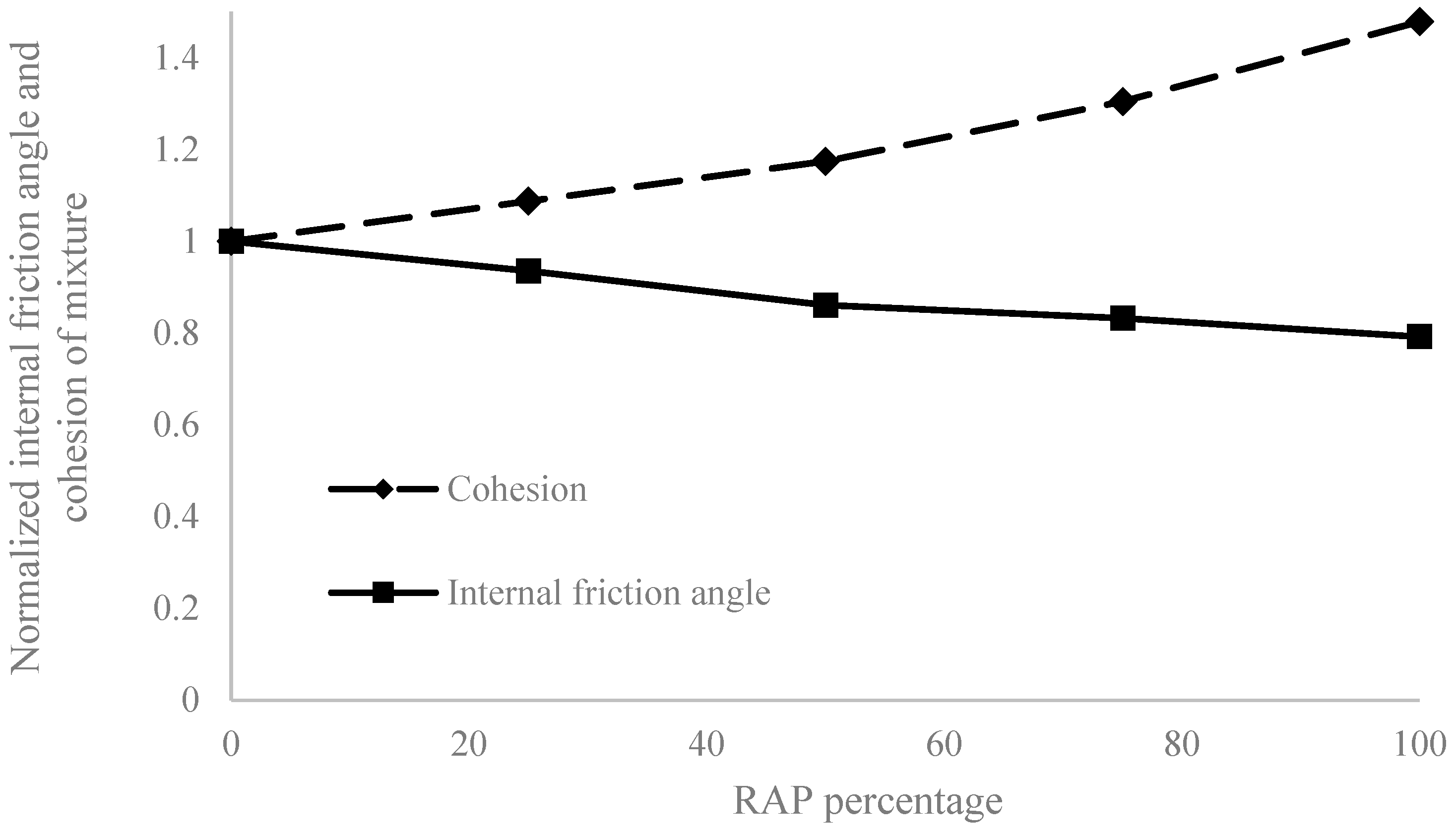

4.2. Shear Strength

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for Road Asphalt Mixtures: A Literature Review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Shariatmadari, N.; Zeinali, S.M.; Mirzaeifar, H.; Keramati, M. Evaluating the Effect of Using Shredded Waste Tire in the Stone Columns as an Improvement Technique. Constr. Build. Mater. 2018, 176, 700–709. [Google Scholar] [CrossRef]

- Afshar, J.N.; Ghazavi, M. Experimental Studies on Bearing Capacity of Geosynthetic Reinforced Stone Columns. Arab. J. Sci. Eng. 2012, 39, 1559–1571. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Al-Neami, M.A.; Shamel Al-Suhaily, A. Estimation of Bearing Capacity of Floating Group of Stone Columns. Eng. Sci. Technol. Int. J. 2017, 20, 1166–1172. [Google Scholar] [CrossRef]

- Ambily, A.P.; Gandhi, S.R. Behavior of Stone Columns Based on Experimental and FEM Analysis. J. Geotech. Geoenviron. Eng. 2007, 133, 405–415. [Google Scholar] [CrossRef]

- Marto, A.; Hasan, M.; Hyodo, M.; Makhtar, A.M. Shear Strength Parameters and Consolidation of Clay Reinforced with Single and Group Bottom Ash Columns. Arab. J. Sci. Eng. 2014, 39, 2641–2654. [Google Scholar] [CrossRef]

- Ayothiraman, R.; Soumya, S. Model Tests on the Use of Tyre Chips as Aggregate in Stone Columns. Proc. Inst. Civ. Eng. Ground Improv. 2015, 168, 187–193. [Google Scholar] [CrossRef]

- Barksdale, R.D.; Bachus, R.C. Design and Construction of Stone Columns Volume II, Appendixes; BiblioGov: Columbus, OH, USA, 1983. [Google Scholar]

- Madhav, M.R.; Vitkar, P.P. Strip footing on weak clay stabilized with a granular trench or pile. Can. Geotech. J. 1978, 15, 605–609. [Google Scholar] [CrossRef]

- Greenwood, D.A. Mechanical Improvement of Soils below Ground Surface; Institution of Civil Engineers: London, UK, 1970. [Google Scholar]

- Wong, H. Vibroflotation-Its Effect on Weak Cohesive Soils. Civ. Eng. 1975, 82, 44–76. [Google Scholar]

- Miranda, M.; Da Costa, A.; Castro, J.; Sagaseta, C. Influence of Geotextile Encasement on the Behaviour of Stone Columns: Laboratory Study. Geotext. Geomembr. 2017, 45, 14–22. [Google Scholar] [CrossRef]

- Debnath, P.; Dey, A.K. Bearing Capacity of Geogrid Reinforced Sand over Encased Stone Columns in Soft Clay. Geotext. Geomembr. 2017, 45, 653–664. [Google Scholar] [CrossRef]

- Siva Gowri Prasad, S.; Harish, Y.; Satyanarayana, P.V.V. Stabilization of Marine Clays with Geotextile Reinforced Stone Columns Using Silica-Manganese Slag as a Stone Column Material. Int. J. Comput. Eng. Res. 2015, 5, 9. [Google Scholar]

- Mazumder, T.; Rolaniya, A.K.; Ayothiraman, R. Experimental Study on Behaviour of Encased Stone Column with Tyre Chips as Aggregates. Geosynth. Int. 2018, 25, 259–270. [Google Scholar] [CrossRef]

- Gharavi, H.; Yazdani, E.; Alidoust, P.; Shariatmadari, N.; Yazdani, F.; Niavol, K.P. Utilization of Shredded Waste Tire as a Substitute for Gravel in Stone Column Groups. KSCE J. Civ. Eng. 2023, 27, 198–206. [Google Scholar] [CrossRef]

- ASTM D4318-00; Standard Test Methods for Liquid Limit, Plasticity Limit, and Plasticity Index of Soils. “Annual Book of ASTM Standards, Section 4, Vol. 04.08, Soil and Rock; Building Stones”; ASTM: Philadelphia, PA, USA, 1988.

- ASTM D698-00; Standard Test Methods for Laboratory Compaction of Soil Standard Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D2166-00; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: Philadelphia, PA, USA, 2010.

- ASTM D2487-06; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2011.

- Bikdeli, H.; Badarloo, B.; Golabchifard, A. Experimental Investigation of Using Reclaimed Asphalt Pavement Aggregate in Scrap Tire Encased Stone Column. Amirkabir J. Civ. Eng. 2021, 53, 4505–4518. [Google Scholar] [CrossRef]

- ASTM D4253-00; Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4254-00; Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2012.

- Baranowski, P.; Bogusz, P.; Gotowicki, P.; Małachowski, J. Assessment of Mechanical Properties of Offroad Vehicle Tire: Coupons Testing and FE Model Development. Acta Mech. Et Autom. 2012, 6, 17–22. [Google Scholar]

- Ghanizadeh, A.R.; Rahrovan, M.; Bafghi, K.B. The Effect of Cement and Reclaimed Asphalt Pavement on the Mechanical Properties of Stabilized Base via Full-Depth Reclamation. Constr. Build. Mater. 2018, 161, 165–174. [Google Scholar] [CrossRef]

- Ekwulo, E.O.; Eme, D.B. Effect of Aggregate Size and Gradation on Compressive Strength of Normal Strength Concrete for Rigid Pavement. Am. J. Eng. Res. 2017, 6, 112–116. [Google Scholar]

| Parameters | Value | Specification |

|---|---|---|

| Liquid limit (%) | 28 | ASTM D4318-00 [17] |

| Plastic limit (%) | 20 | ASTM D4318-00 [17] |

| Plastic index (%) | 8 | ASTM D4318-00 [17] |

| Optimal moisture content (%) | 17 | ASTM D698-00 [18] |

| Maximum dry density (kN/m3) | 17 | ASTM D698-00 [18] |

| Bulk density at 25% water content (kN/m3) | 18 | - |

| Undrained shear strength (kPa) | 7 | ASTM D2166-00 [19] |

| USCS classification symbol | CL | ASTM D2487-06 [20] |

| Specification | Value | Specification | ||||

|---|---|---|---|---|---|---|

| RAP100 | RAP75 | RAP50 | RAP75 | RAP0 | ||

| Maximum dry density (kN/m3) | 17.23 | 17.23 | 16.98 | 16.95 | 16.58 | ASTM D4253-00 [22] |

| Minimum dry density (kN/m3) | 14.85 | 14.71 | 14.56 | 14.52 | 13.95 | ASTM D4254-00 [23] |

| Matrix density for a test at 70% relative density (kN/m3) | 16.44 | 16.39 | 16.17 | 16.14 | 15.69 | - |

| Uniformity coefficient (Cu) | 2.3 | 2.9 | 3.4 | 4.3 | 4.3 | ASTM D2487-06 |

| Curvature coefficient (Cc) | 1.10 | 1.07 | 1.18 | 1.12 | 1.40 | ASTM D2487-06 |

| USCS classification symbol | GP | GP | SP | SP | SP | ASTM D2487-06 |

| Symbol | Factor of Improvement | Symbol | Factor of Improvement |

|---|---|---|---|

| RAP0 | 1 | ERAP0 | 1.54 |

| RAP25 | 1.27 | ERAP25 | 1.87 |

| RAP50 | 0.90 | ERAP50 | 1.44 |

| RAP75 | 0.82 | ERAP75 | 1.36 |

| RAP100 | 0.77 | ERAP100 | 1.27 |

| Sample | Φ (°) | C (kPa) | Normalized φ | Normalized C |

|---|---|---|---|---|

| RAP0 | 49.5 | 22.56 | 1 | 1 |

| RAP25 | 46.3 | 24.52 | 0.93 | 1.09 |

| RAP50 | 42.6 | 26.49 | 0.86 | 1.17 |

| RAP75 | 41.2 | 29.43 | 0.83 | 1.30 |

| RAP100 | 39.2 | 33.35 | 0.79 | 1.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bikdeli, H.; Sharahi, M.J.; Badarloo, B.; Lehner, P. The Effect of Scrap Tires and Reclaimed Asphalt Pavement on the Behavior of Stone Columns. Buildings 2024, 14, 733. https://doi.org/10.3390/buildings14030733

Bikdeli H, Sharahi MJ, Badarloo B, Lehner P. The Effect of Scrap Tires and Reclaimed Asphalt Pavement on the Behavior of Stone Columns. Buildings. 2024; 14(3):733. https://doi.org/10.3390/buildings14030733

Chicago/Turabian StyleBikdeli, Hoora, Morteza Jiryaei Sharahi, Baitollah Badarloo, and Petr Lehner. 2024. "The Effect of Scrap Tires and Reclaimed Asphalt Pavement on the Behavior of Stone Columns" Buildings 14, no. 3: 733. https://doi.org/10.3390/buildings14030733

APA StyleBikdeli, H., Sharahi, M. J., Badarloo, B., & Lehner, P. (2024). The Effect of Scrap Tires and Reclaimed Asphalt Pavement on the Behavior of Stone Columns. Buildings, 14(3), 733. https://doi.org/10.3390/buildings14030733