Enhancing the Thermal and Energy Performance of Clay Bricks with Recycled Cultivated Pleurotus florida Waste

Abstract

1. Introduction

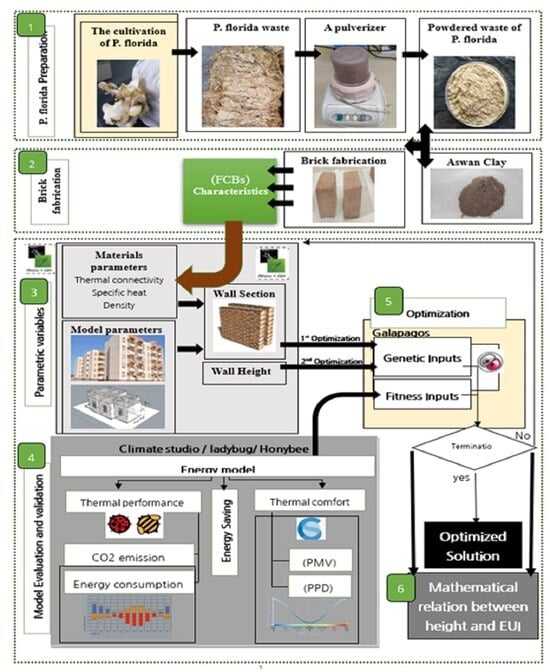

2. Materials and Methods

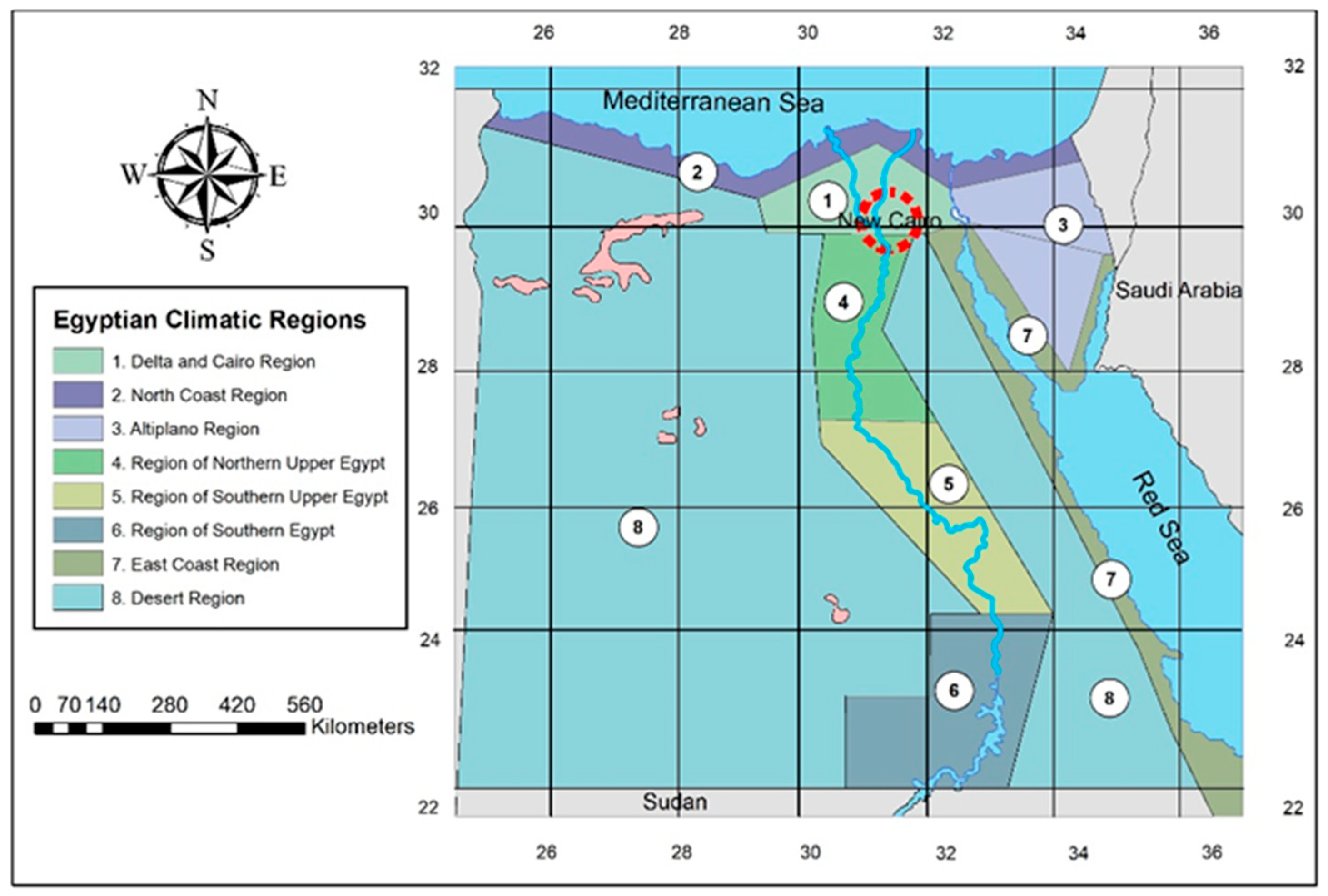

2.1. Study Area

2.2. Materials and Fabrication Methods

2.2.1. Raw Materials

2.2.2. The Production of P. florida Wastes

2.2.3. Samples Preparation

2.3. Laboratory Characterization

- ▪

- Compressive Strength

- ▪

- Water Absorption, Density, and Porosity

- ▪

- Thermal Conductivity

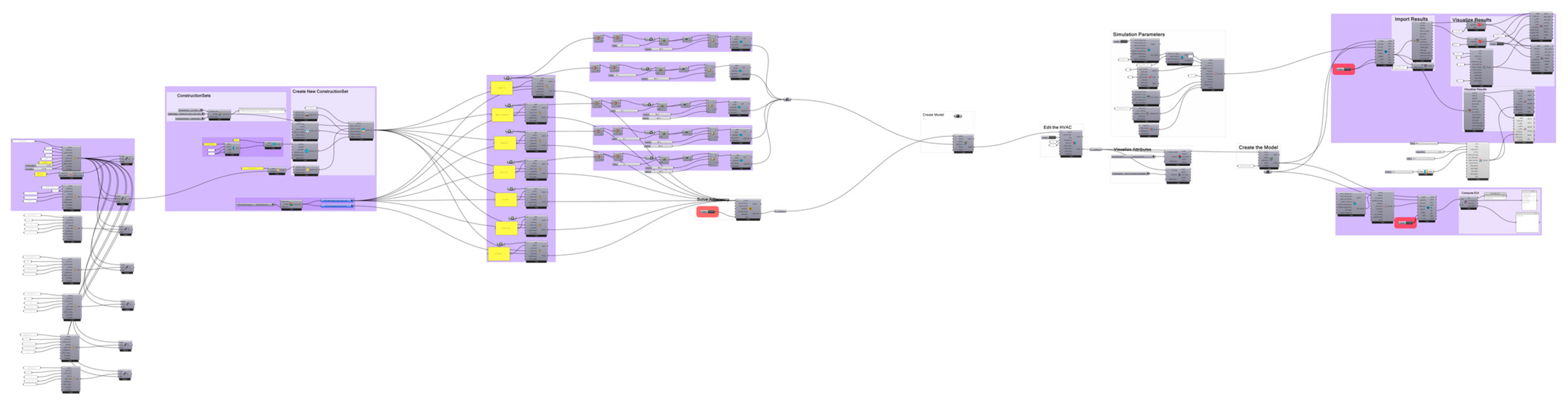

2.4. Simulation Process

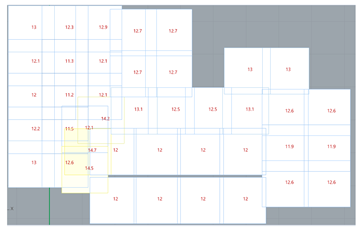

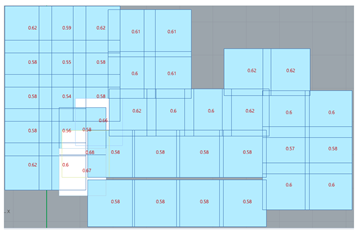

2.4.1. Description of the Model (Case Study)

2.4.2. Thermal Performance and Optimization

3. Results and Discussion

3.1. Mechanical Properties

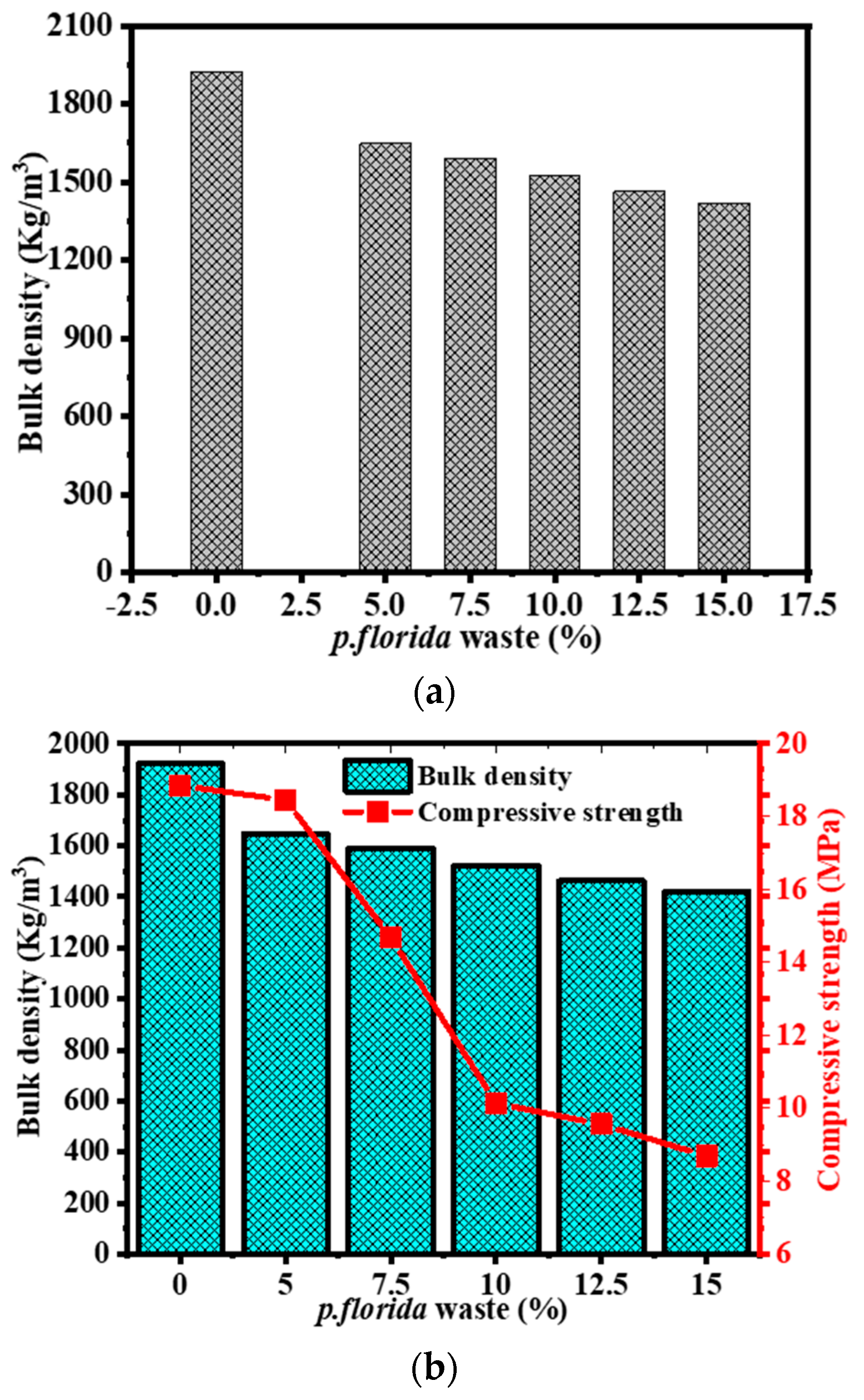

3.1.1. Compressive Strength

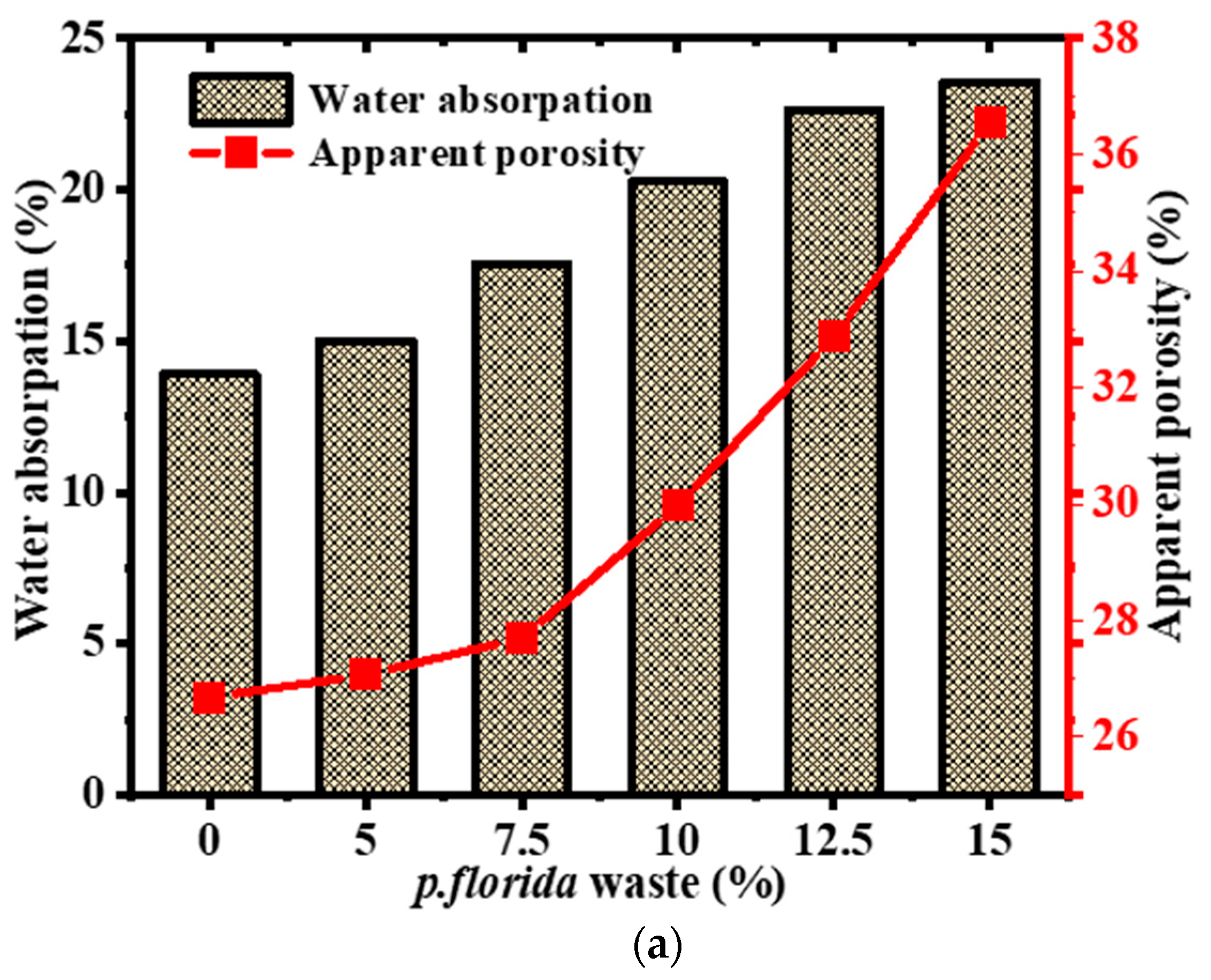

3.1.2. Water Absorption

3.2. Physical Properties

3.2.1. Bulk Density

3.2.2. Apparent Porosity

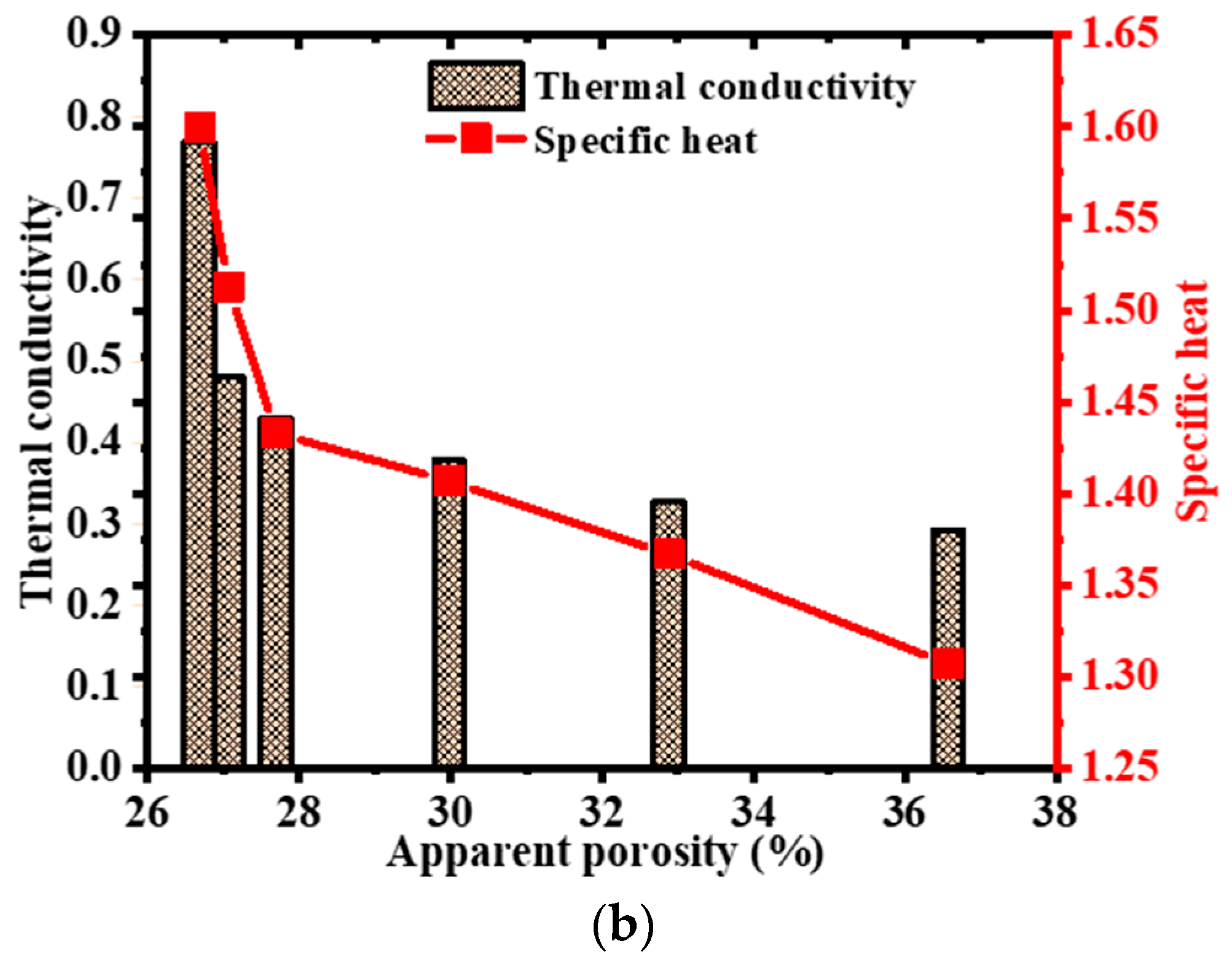

3.3. Thermal Performance

3.3.1. Thermal Conductivity

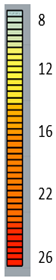

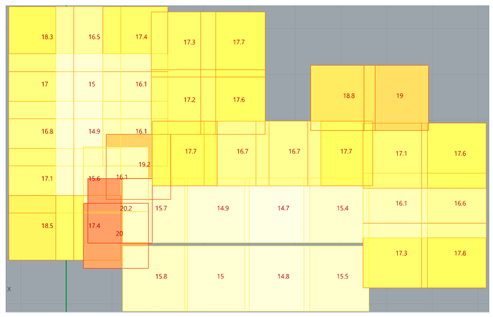

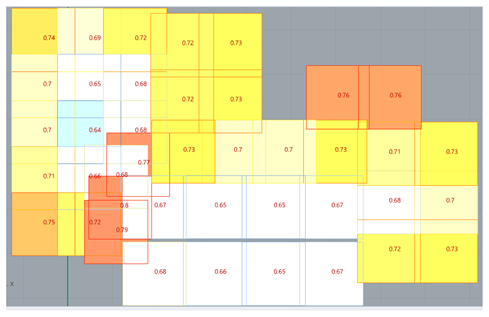

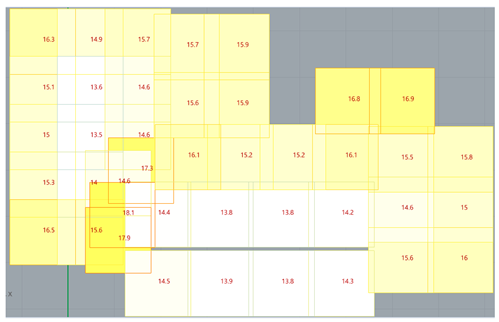

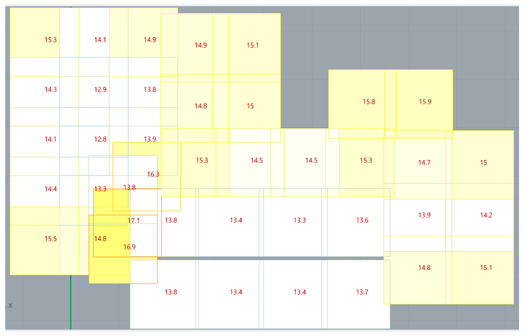

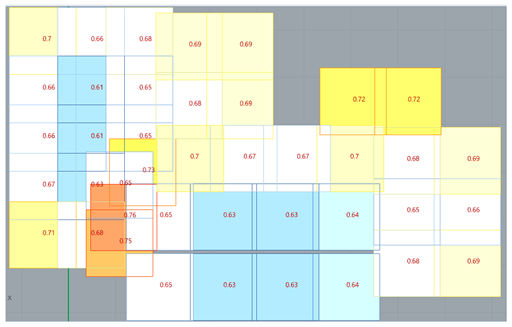

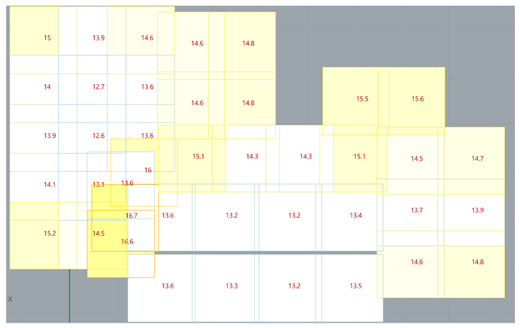

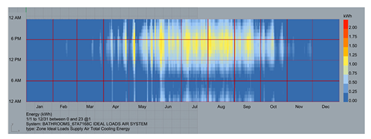

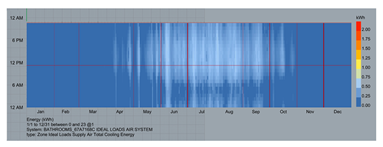

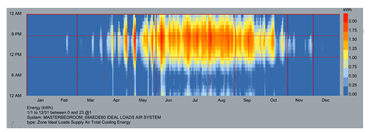

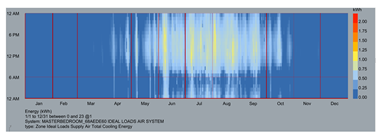

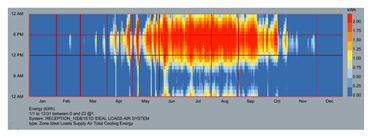

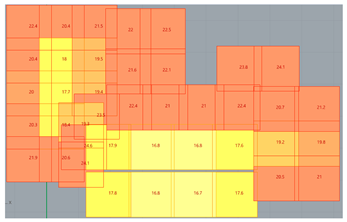

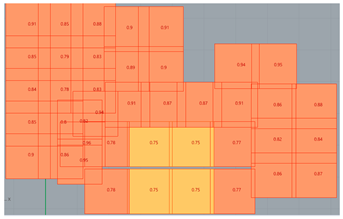

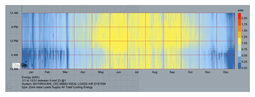

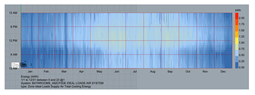

3.3.2. Thermal Comfort

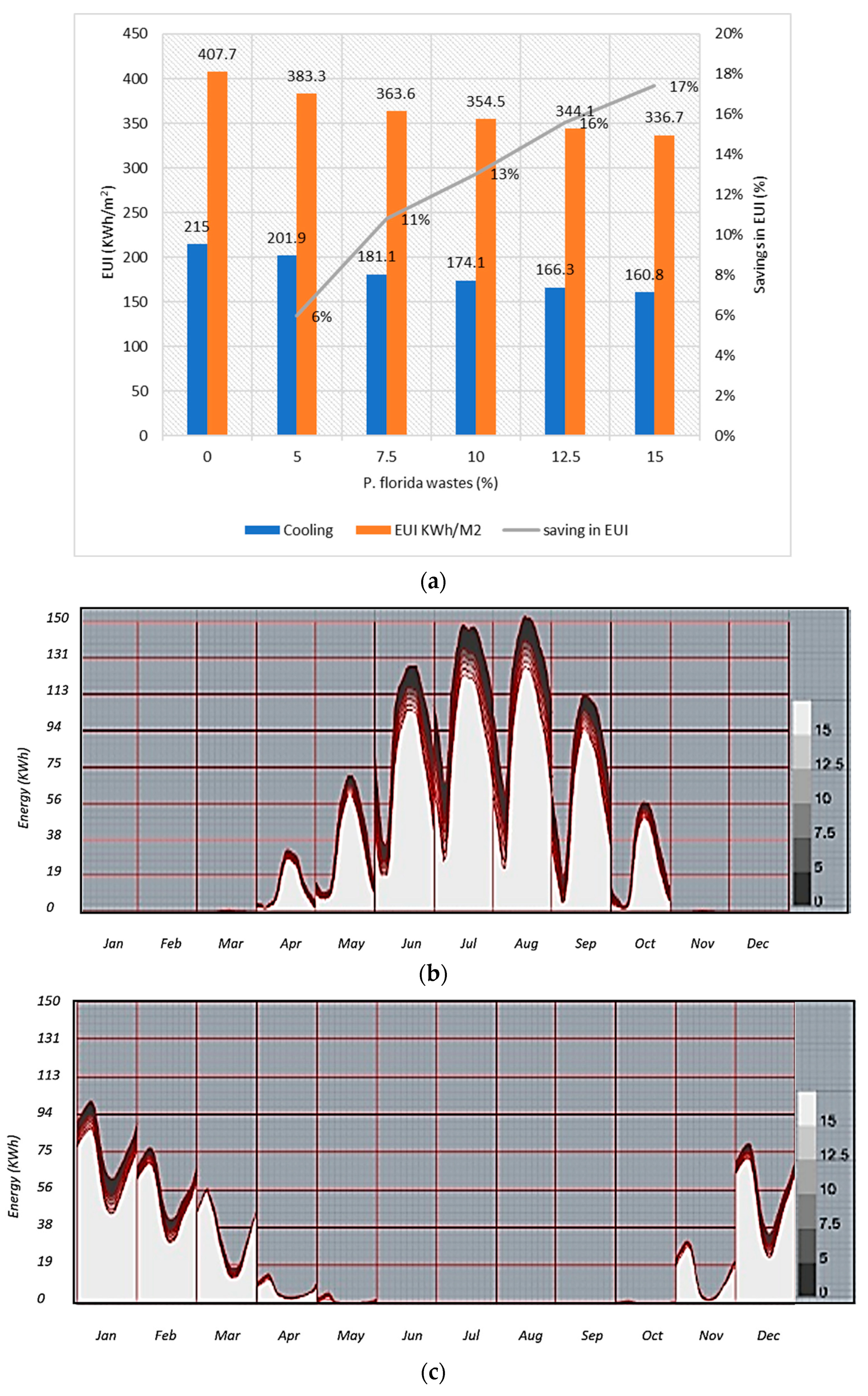

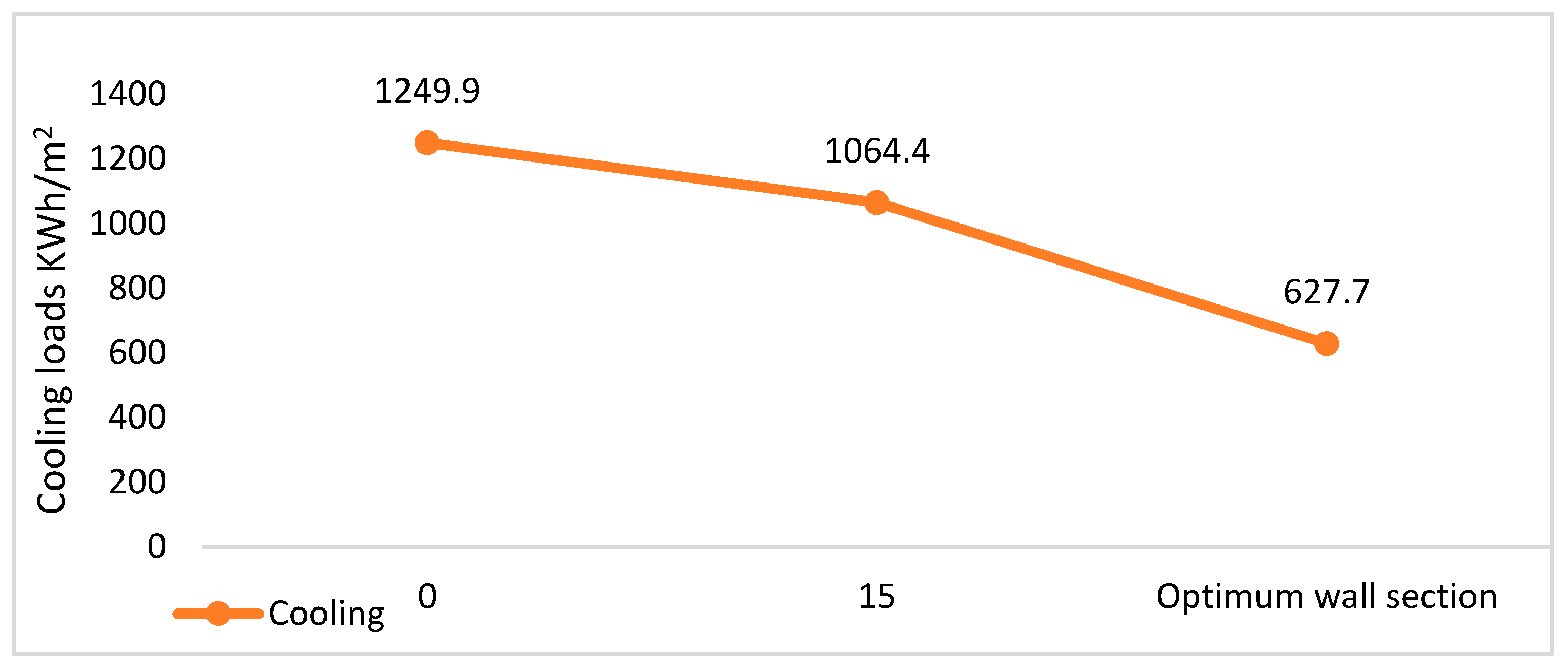

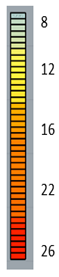

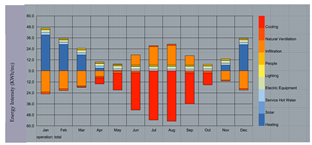

3.3.3. Energy Consumption

3.3.4. Best EUI Values

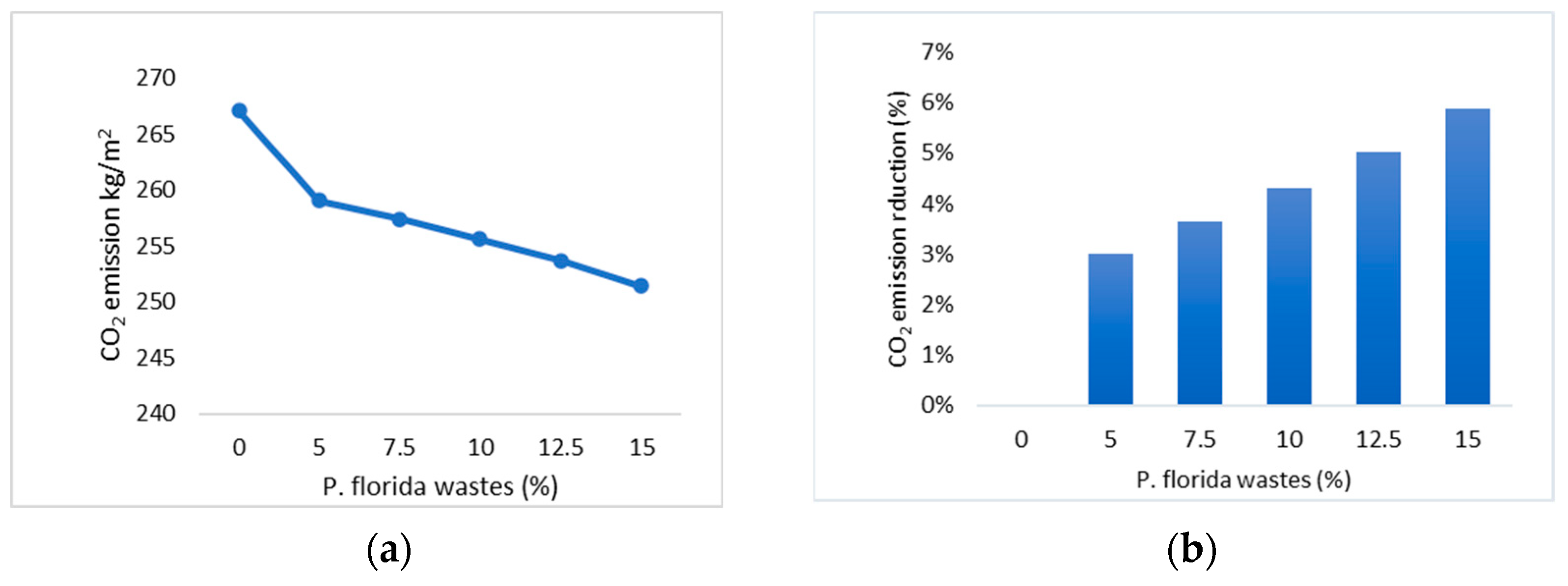

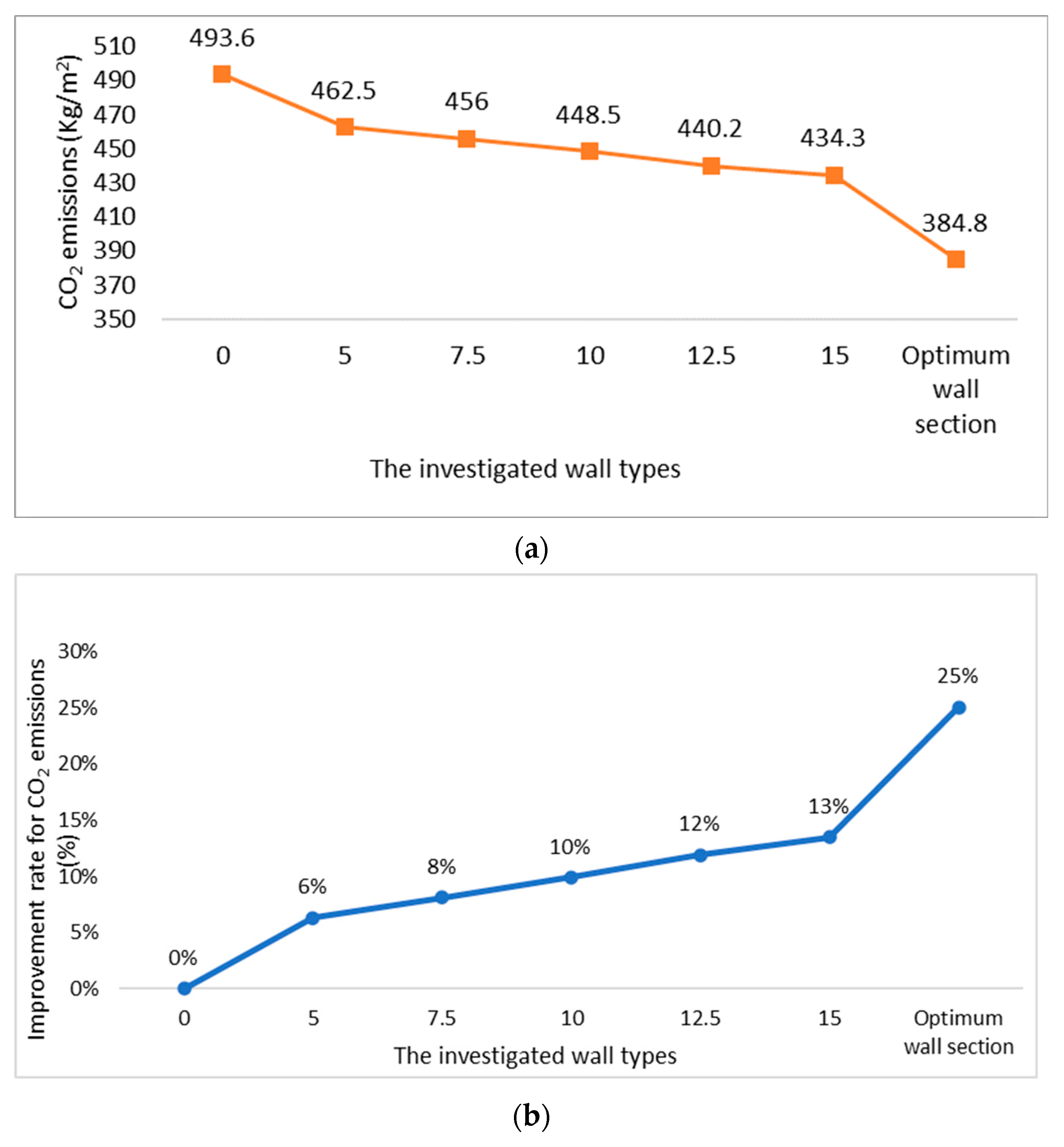

3.3.5. Decreased CO2 Emissions

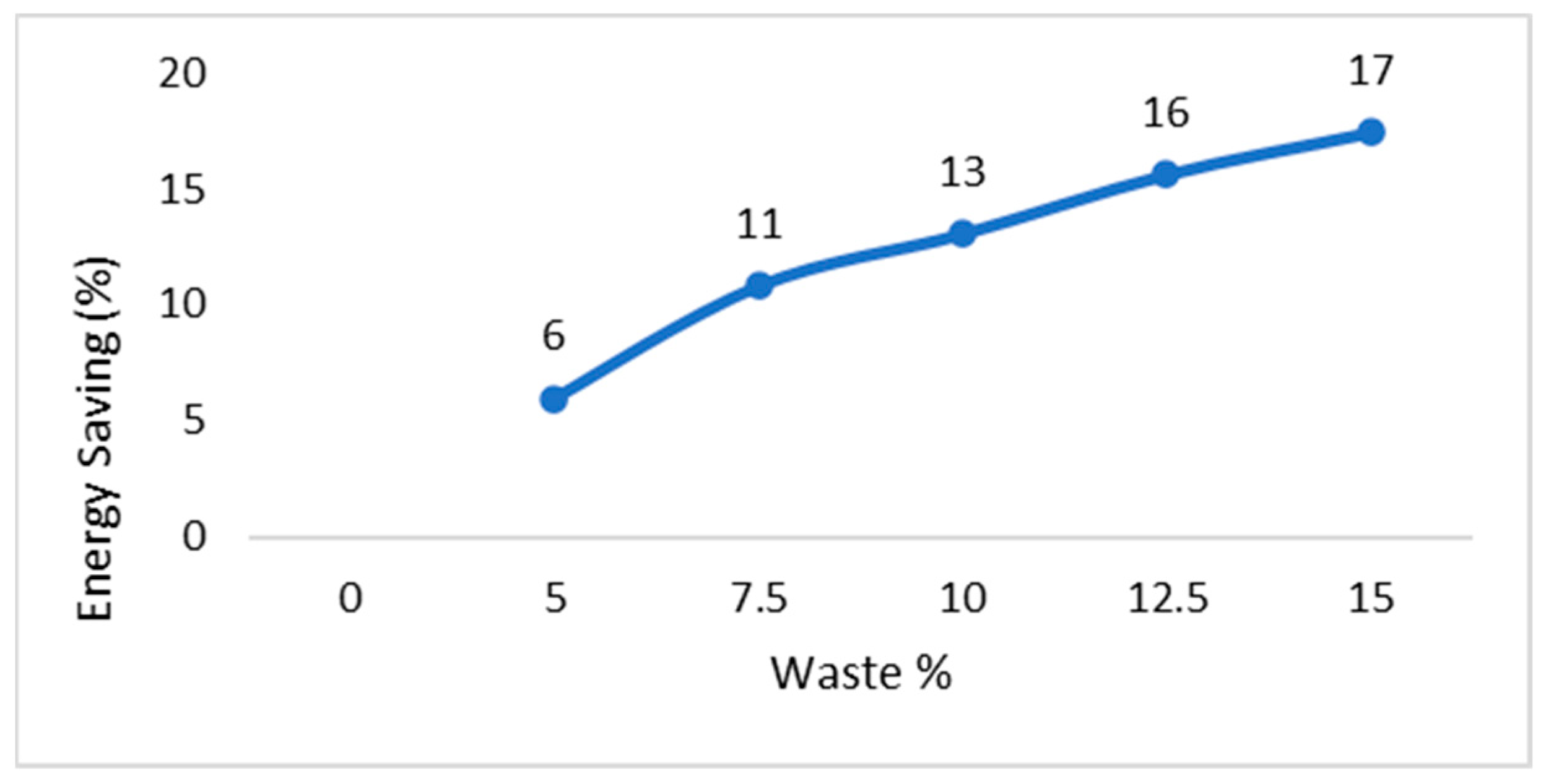

3.3.6. Energy Saving

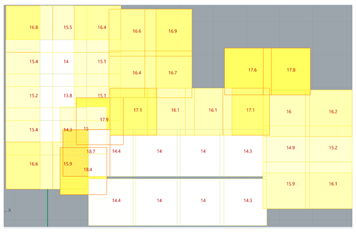

3.4. Optimum Wall Design

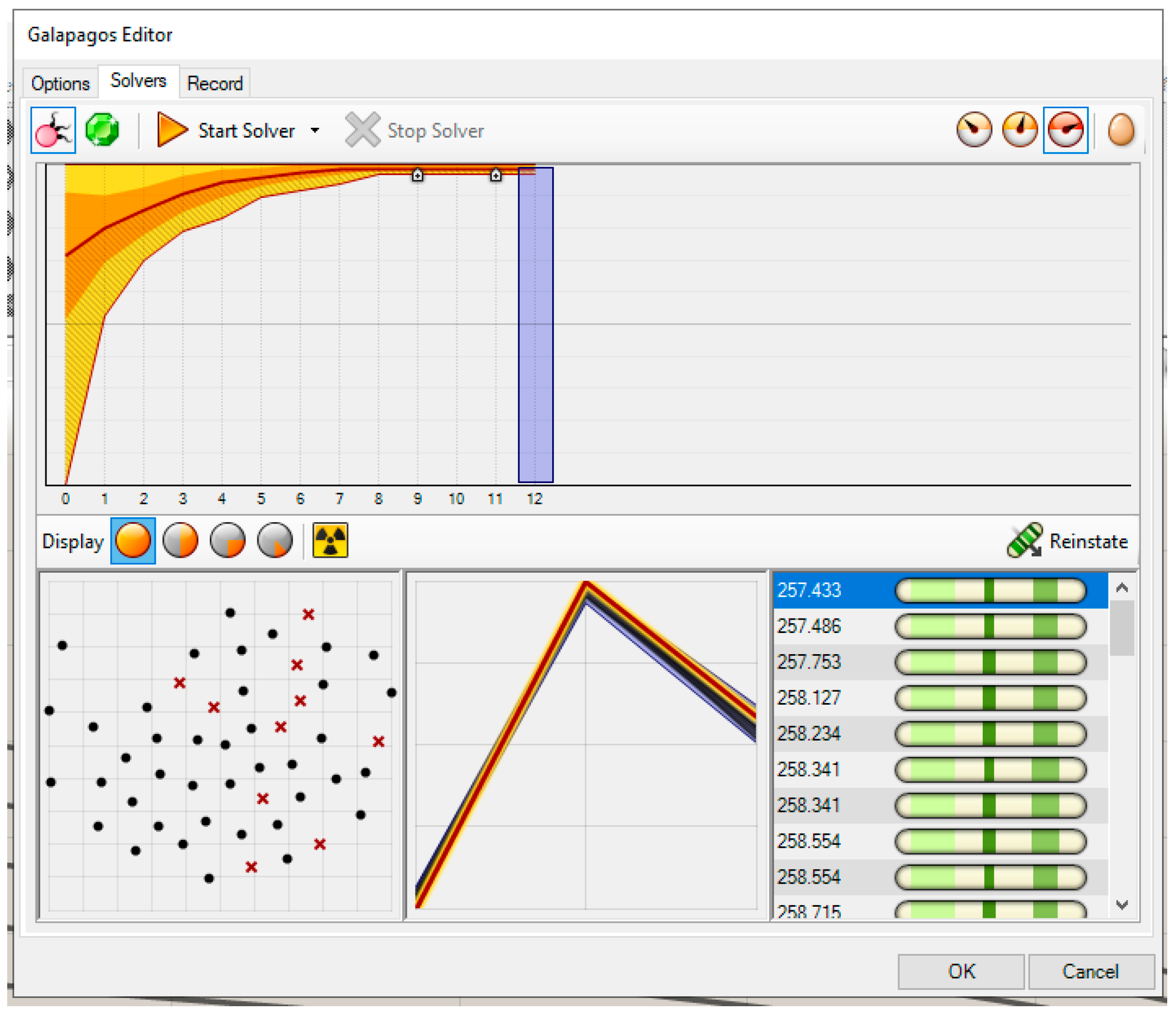

3.4.1. Wall Section Optimization

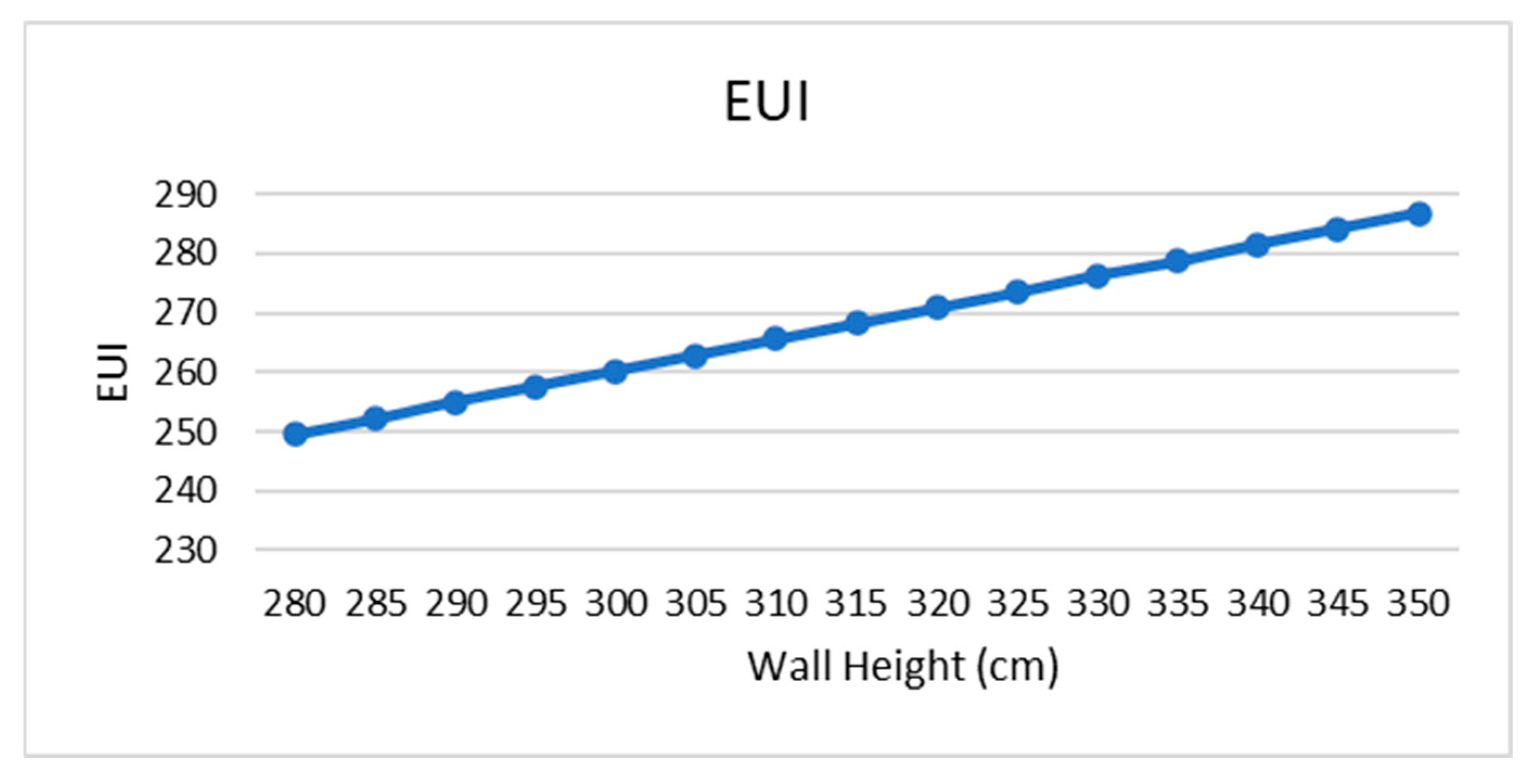

3.4.2. Wall Height Impact

3.4.3. Mathematical Relationship between Height and EUI

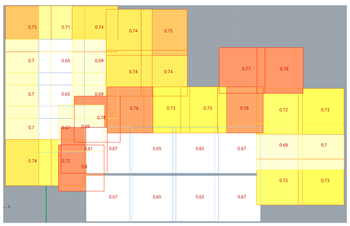

3.5. Applying the Optimum Wall Design in Jazan City

3.5.1. Thermal Comfort for Jazan City

3.5.2. CO2 Reduction for Jazan City

3.5.3. EUI, Cooling, and Heating Loads

4. Discussion

5. Conclusions

- ▪

- In terms of mechanical properties, the compressive strength of fired clay bricks was observed to decrease with higher levels of Pleurotus florida waste content and improve with increasing firing temperature, indicating that a smaller amount of Pleurotus florida waste and higher firing temperatures can enhance the bricks’ compressive strength.

- ▪

- Regarding physical properties, the bulk density of fired clay bricks exhibited a decrease with higher levels of Pleurotus florida waste content, while it increased with firing temperature. This implies that increasing the Pleurotus florida waste content reduces the overall density of the bricks, whereas higher firing temperatures lead to denser bricks. Similarly, the apparent porosity of fired clay bricks showed an increase with higher levels of Pleurotus florida waste content and a decrease as firing temperature increased, indicating a denser structure resulting from incorporating less Pleurotus florida waste and subjecting the bricks to higher firing temperatures.

- ▪

- The study also revealed that bricks containing Pleurotus florida waste demonstrated lower thermal conductivity compared to conventional bricks, making them more energy-efficient. For instance, using 15% of Pleurotus florida waste resulted in a significant 61.94% reduction in thermal conductivity compared to conventional bricks. Moreover, bricks with Pleurotus florida waste were found to enhance indoor thermal comfort, with an optimal waste ratio of 15%.

- ▪

- The energy performance of the building was evaluated, the results showed that bricks with higher waste ratios led to greater energy savings. For example, the brick with a waste ratio of 5% achieved a 6% energy saving, while the brick with 15% waste demonstrated the best energy saving of 17%. Furthermore, bricks with higher waste ratios exhibited lower CO2 emissions, with a nearly 6% reduction in CO2 emissions compared to the base case with no incorporated waste.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khani, A.; Khakzand, M.; Faizi, M. Multi-objective optimization for energy consumption, visual and thermal comfort performance of educational building (case study: Qeshm Island, Iran). Sustain. Energy Technol. Assess. 2022, 54, 102872. [Google Scholar] [CrossRef]

- Delgarm, N.; Sajadi, B.; Delgarm, S.; Kowsary, F. A novel approach for the simulation-based optimization of the buildings energy consumption using NSGA-II: Case study in Iran. Energy Build. 2016, 127, 552–560. [Google Scholar] [CrossRef]

- Rizi, R.A.; Eltaweel, A. A user detective adaptive facade towards improving visual and thermal comfort. J. Build. Eng. 2021, 33, 101554. [Google Scholar] [CrossRef]

- Eze, V.H.U.; Tamball, J.S.; Uzoma, O.F.; Sarah, N.I.; Robert, O.; Wisdom, O.O. Advancements in Energy Efficiency Technologies for Thermal Systems: A Comprehensive Review. INOSR Appl. Sci. 2024, 12, 1–20. [Google Scholar] [CrossRef]

- Abd Elrady, A.; Hassan, M. Conservation of morphological characters as an approach to thermal comfort. In Vernacular Architecture: Towards a Sustainable Future; CRC Press: London, UK, 2015; p. 15. [Google Scholar] [CrossRef]

- Mamajonova, N.; Oydin, M.; Usmonali, T.; Olimjon, A.; Madina, A.; Marguba, M. Parametric Design: Enhancing Architectural Environments through Computational Innovatio. Hold. Reason. 2024, 2, 334–345. [Google Scholar]

- González-Torres, M.; Pérez-Lombard, L.; Coronel, J.F.; Maestre, I.R.; Yan, D. A review on buildings energy information: Trends, end-uses, fuels and drivers. Energy Rep. 2022, 8, 626–637. [Google Scholar] [CrossRef]

- Labaran, Y.H.; Mathur, V.S.; Muhammad, S.U.; Musa, A.A. Carbon footprint management: A review of construction industry. Clean. Eng. Technol. 2022, 9, 100531. [Google Scholar] [CrossRef]

- Tsay, Y.-S.; Yeh, Y.-C.; Jheng, H.-Y. Study of the tools used for early-stage carbon footprint in building design. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 4, 100128. [Google Scholar] [CrossRef]

- Tarek, N.; Aly, A.M.M.; Ragab, A. Energy-Efficient Passive Cooling Design for Residential Buildings in Hot and Arid Climates: A Parametric Study. Aswan Univ. J. Sci. Technol. 2024, 4, 80–95. [Google Scholar] [CrossRef]

- Mahmoud, A.R. Investigating the Impact of Different Glazing Types on the Energy Performance in Hot Arid Climate. J. Adv. Eng. Trends 2022, 42, 69–84. [Google Scholar] [CrossRef]

- Abdelrady, A.; Abdelhafez, M.H.H.; Ragab, A. Use of insulation based on nanomaterials to improve energy efficiency of residential buildings in a hot desert climate. Sustainability 2021, 13, 5266. [Google Scholar] [CrossRef]

- Langbehn, R.K.; Michels, C.; Soares, H.M. Antibiotics in wastewater: From its occurrence to the biological removal by environmentally conscious technologies. Environ. Pollut. 2021, 275, 116603. [Google Scholar] [CrossRef] [PubMed]

- Miao, Y.; Ye, T.; Xiao, J.; Lau, S.S.Y.; Zhou, Z. Investigation on alkali-activated insulation mortar containing high-volume recycled concrete powder for energy-efficient buildings. Energy Build. 2024, 303, 113825. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Rabczuk, T.; Olofsson, T.; Lu, W. Multi-scale modeling in thermal conductivity of Polyurethane incorporated with Phase Change Materials using Physics-Informed Neural Networks. Renew. Energy 2024, 220, 119565. [Google Scholar] [CrossRef]

- Nasri, W.; Djebali, R.; Chamkha, A.J.; Bezazi, A.; Mechighel, F.; Reis, P.; Driss, Z. Thermal behavior of mesoporous Aramid fiber reinforced silica aerogel composite for thermal insulation applications: Microscale modeling. J. Appl. Comput. Mech. 2024, 10, 140–151. [Google Scholar]

- Rashad, A.M.; Mosleh, Y.A.; Mokhtar, M. Thermal insulation and durability of alkali-activated lightweight slag mortar modified with silica fume and fly ash. Constr. Build. Mater. 2024, 411, 134255. [Google Scholar] [CrossRef]

- Mezaien, A.; Baltazar, J.-C. Evaluating the Performance of a Passive Architectural Element in a Hot-Dry Climate Through Natural Ventilation and Thermal Impact Analysis. In Proceedings of the American Solar Energy Society National Conference, Boulder, CO, USA, 8–11 August 2023; pp. 171–183. [Google Scholar]

- Cantor, D.M.; Manea, D.L. Innovative building materials using agricultural waste. Procedia Technol. 2015, 19, 456–462. [Google Scholar]

- Zeyad, A.M. Sustainable concrete Production: Incorporating recycled wastewater as a green building material. Constr. Build. Mater. 2023, 407, 133522. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Tayeh, B.A.; de Azevedo, A.R.G.; Abutaleb, A.; Hussain, Q. Production of geopolymer concrete by utilizing volcanic pumice dust. Case Stud. Constr. Mater. 2022, 16, e00802. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Johari, M.A.M.; Abadel, A.; Abutaleb, A.; Mijarsh, M.; Almalki, A. Transport properties of palm oil fuel ash-based high-performance green concrete subjected to steam curing regimes. Case Stud. Constr. Mater. 2022, 16, e01077. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Shubaili, M.; Abutaleb, A. Using volcanic pumice dust to produce high-strength self-curing concrete in hot weather regions. Case Stud. Constr. Mater. 2023, 18, e01927. [Google Scholar] [CrossRef]

- Korpayev, S.; Bayramov, M.; Durdyev, S.; Hamrayev, H.; Baymyradova, D.; Nurmuhammedov, A. Effect of stone wool waste from greenhouse agriculture in brick production. J. Build. Eng. 2023, 63, 105340. [Google Scholar] [CrossRef]

- Hassan, A.M.S.; Abdeen, A.; Mohamed, A.S.; Elboshy, B. Thermal performance analysis of clay brick mixed with sludge and agriculture waste. Constr. Build. Mater. 2022, 344, 128267. [Google Scholar] [CrossRef]

- Ya-bin, C.; Xing-wang, P.; Bing-zheng, H. Thermal performance analysis of building construction with insulated walls in summer days and nights. J. Cent. South Univ. 2021, 28, 3613–3625. [Google Scholar]

- Ravelo, B.; Rajaoarisoa, L.; Maurice, O. Thermal modelling of multilayer walls for building retrofitting applications. J. Build. Eng. 2020, 29, 101126. [Google Scholar] [CrossRef]

- François, A.; Ibos, L.; Feuillet, V.; Meulemans, J. Estimation of the thermal resistance of a building wall with inverse techniques based on rapid active in situ measurements and white-box or ARX black-box models. Energy Build. 2020, 226, 110346. [Google Scholar] [CrossRef]

- Flores-Ales, V.; Alducin-Ochoa, J.M.; Martín-del-Río, J.J.; Torres-Gonzalez, M.; Jimenez-Bayarri, V. Physical-mechanical behaviour and transformations at high temperature in a cement mortar with waste glass as aggregate. J. Build. Eng. 2020, 29, 101158. [Google Scholar] [CrossRef]

- Al-Sanea, S.A.; Zedan, M. Improving thermal performance of building walls by optimizing insulation layer distribution and thickness for same thermal mass. Appl. Energy 2011, 88, 3113–3124. [Google Scholar] [CrossRef]

- Ahmed, S.; El Attar, M.E.; Zouli, N.; Abutaleb, A.; Maafa, I.M.; Ahmed, M.; Yousef, A.; Ragab, A. Improving the Thermal Performance and Energy Efficiency of Buildings by Incorporating Biomass Waste into Clay Bricks. Materials 2023, 16, 2893. [Google Scholar] [CrossRef]

- Ragab, A.; Zouli, N.; Abutaleb, A.; Maafa, I.M.; Ahmed, M.; Yousef, A. Environmental and Economic Benefits of Using Pomegranate Peel Waste for Insulation Bricks. Materials 2023, 16, 5372. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, W.; Luan, X.; Gao, W.; Geng, X.; Xue, Y. Thermal performance enhancement of hollow brick by agricultural wastes. Case Stud. Constr. Mater. 2022, 16, e01047. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.; Selvakumar, K.K.; Jyothi, M.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar]

- Khalil, A.; Tolba, O.; Ezzeldin, S. Optimization of an office building form using a lattice incubate boxes method. Adv. Eng. Inform. 2023, 55, 101847. [Google Scholar] [CrossRef]

- Jasińska, A. Spent mushroom compost (SMC)–retrieved added value product closing loop in agricultural production. Acta Agrar. Debreceniensis 2018, 150, 185–202. [Google Scholar] [CrossRef]

- Bakmohammadi, P.; Noorzai, E. Optimization of the design of the primary school classrooms in terms of energy and daylight performance considering occupants’ thermal and visual comfort. Energy Rep. 2020, 6, 1590–1607. [Google Scholar] [CrossRef]

- Singh, A.D.; Vikineswary, S.; Abdullah, N.; Sekaran, M. Enzymes from spent mushroom substrate of Pleurotus sajor-caju for the decolourisation and detoxification of textile dyes. World J. Microbiol. Biotechnol. 2011, 27, 535–545. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.; Pelletier, M. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017, 29, 04017030. [Google Scholar] [CrossRef]

- Xing, Y.; Brewer, M.; El-Gharabawy, H.; Griffith, G.; Jones, P. Growing and testing mycelium bricks as building insulation materials. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; p. 022032. [Google Scholar]

- Wimmers, G.; Klick, J.; Tackaberry, L.; Zwiesigk, C.; Egger, K.; Massicotte, H. Fundamental studies for designing insulation panels from wood shavings and filamentous fungi. BioResources 2019, 14, 5506–5520. [Google Scholar] [CrossRef]

- Satbaev, B.; Yefremova, S.; Zharmenov, A.; Kablanbekov, A.; Yermishin, S.; Shalabaev, N.; Satbaev, A.; Khen, V. Rice husk research: From environmental pollutant to a promising source of organo-mineral raw materials. Materials 2021, 14, 4119. [Google Scholar] [CrossRef] [PubMed]

- Grimm, D.; Wösten, H.A. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef] [PubMed]

- Phan, C.-W.; Sabaratnam, V. Potential uses of spent mushroom substrate and its associated lignocellulosic enzymes. Appl. Microbiol. Biotechnol. 2012, 96, 863–873. [Google Scholar] [CrossRef] [PubMed]

- Jabi, W. Parametric Design for Architecture; Hachette: London, UK, 2013. [Google Scholar]

- Eltaweel, A.; Yuehong, S. Parametric design and daylighting: A literature review. Renew. Sustain. Energy Rev. 2017, 73, 1086–1103. [Google Scholar] [CrossRef]

- Fahmy, M.K. Applying Urban Parametricism in the Design of Dynamic Neighborhoods. In Transformations and Challenges [9th ASCAAD Conference Proceedings ISBN 978-1-907349-20-1] Cairo (Egypt), Virtual Conference. pp. 2–4. Available online: https://papers.cumincad.org/cgi-bin/works/paper/ascaad2021_028 (accessed on 27 December 2023).

- Fahmy, M.K.; Eltaweel, A.; Rizi, R.A.; Imani, N. Integrated Kinetic Fins for Western Facades in Territories with Low Solar Altitudes. Buildings 2023, 13, 782. [Google Scholar] [CrossRef]

- Okigbo, R.; Muonyelu, N.; Egwu, A. Effect of using rice husk for cultivation of Pleurotus tuberregium (FR.) SINGER. J. Basic Appl. Res. Int. 2021, 27, 1–10. [Google Scholar]

- Al-Jabri, K.; Shoukry, H.; Mokhtar, M.M.; Morsy, M.S. Thermo-physical, mechanical and microstructural properties of cementless lightweight mortar. Adv. Cem. Res. 2021, 33, 74–83. [Google Scholar] [CrossRef]

- Phonphuak, N. Application of dry grass for clay brick manufacturing. Key Eng. Mater. 2017, 757, 35–39. [Google Scholar] [CrossRef]

- Gencel, O.; Munir, M.J.; Kazmi, S.M.S.; Sutcu, M.; Erdogmus, E.; Velasco, P.M.; Quesada, D.E. Recycling industrial slags in production of fired clay bricks for sustainable manufacturing. Ceram. Int. 2021, 47, 30425–30438. [Google Scholar] [CrossRef]

- ASTM: D5334-08; Standard Test Method for Determination of Thermal Conductivity of Soil Soft Rock by Thermal Needle Probe Procedure. ASTM International: West Conshohocken, PA, USA, 2008.

- Chen, R.; Tsay, Y.-S. Carbon emission and thermal comfort prediction model for an office building considering the contribution rate of design parameters. Energy Rep. 2022, 8, 8093–8107. [Google Scholar] [CrossRef]

- Zou, Y.; Zhan, Q.; Xiang, K. A comprehensive method for optimizing the design of a regular architectural space to improve building performance. Energy Rep. 2021, 7, 981–996. [Google Scholar] [CrossRef]

- Ministry of Housing and Works, Government of Pakistan Lahore. Building Code of Pakistan—Seismic Hazard Evaluation Studies; Ministry of Housing and Works, Government of Pakistan Lahore: Islamabad, Pakistan, 2007.

- Bureau of Indian Standards (BIS). Specifications for Common Burnt Clay Building Bricks; 5th Revision; IS: 3495 (Part-I to IV); BIS: New Delhi, India, 1992.

- NBR-6064; Ceramic soft-mud brick—Assessment of compressive strength—Assay method. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 1983.

- IS1077-1992; Common Burnt Clay Building Bricks-Specification. Bureau of Indian Standards, N.D.: New Delhi, India, 2007. Available online: https://law.resource.org/pub/in/bis/S03/is.1077.1992.pdf (accessed on 27 December 2023).

- CNS382-R2002; Building with Ordinary Brick. National Standard Republic of China: Beijing, China, 2002. Available online: https://www.confinedmasonry.org/wp-content/uploads/2009/09/China_Code_seismic_design_buildings.pdf (accessed on 27 December 2023).

- ES4763; Building of Brick Masonry Units Made from Clay. Egyptian Organization for Standardization & Quality: Cario, Egypt, 2006. Available online: https://law.resource.org/pub/eg/ibr/es.4763.2006.pdf (accessed on 27 December 2023).

- ASTM C62; Standard Specification for Building Brick (Solid Masonry Units Made from Clay or Shale). ASTM: Philadelphia, PA, USA, 2012. Available online: http://www.masonryinstitute.com/wp-content/uploads/ASTM_C216-10.pdf (accessed on 27 December 2023).

- ASTM C90; Standard Specification for Loadbearing Concrete Masonry Units. ASTM: Philadelphia, PA, USA, 2014. Available online: https://spectraglaze.com/wp-content/uploads/2018/04/ASTM-C90-122117.pdf (accessed on 27 December 2023).

- Maza-Ignacio, O.T.; Jiménez-Quero, V.G.; Guerrero-Paz, J.; Montes-García, P. Recycling untreated sugarcane bagasse ash and industrial wastes for the preparation of resistant, lightweight and ecological fired bricks. Constr. Build. Mater. 2020, 234, 117314. [Google Scholar] [CrossRef]

- Ölmez, H.; Erdem, E. The effects of phosphogypsum on the setting and mechanical properties of Portland cement and trass cement. Cem. Concr. Res. 1989, 19, 377–384. [Google Scholar] [CrossRef]

- Rashad, A.M.; Gharieb, M.; Shoukry, H.; Mokhtar, M.M. Valorization of sugar beet waste as a foaming agent for metakaolin geopolymer activated with phosphoric acid. Constr. Build. Mater. 2022, 344, 128240. [Google Scholar] [CrossRef]

is deleted Genomes,

is deleted Genomes,  remaining Genomes.

remaining Genomes.

is deleted Genomes,

is deleted Genomes,  remaining Genomes.

remaining Genomes.

is deleted Genomes,

is deleted Genomes,  remaining Genomes.

remaining Genomes.

| Samples | The Percentage of P. florida Wastes (%) | Firing Temperature °C |

|---|---|---|

| P. florida wastes—5% | 5 | |

| P. florida wastes—7.5% | 7.5 | |

| P. florida wastes—10% | 10 | 900 |

| P. florida wastes—12.5% | 12.5 | |

| P. florida wastes—15% | 15 |

| Composition | Clay wt. (%) | P. florida Wastes wt. (%) |

|---|---|---|

| Al2O3 | 32.906 | 0.07 |

| SiO2 | 48.931 | 30.2 |

| Na2O | 0.094 | 0.38 |

| K2O | 0.014 | 0.66 |

| CaO | 0.505 | 1.58 |

| MgO | 0.09 | - |

| TiO2 | 5.918 | - |

| Fe2O3 | 1.193 | 0.1 |

| SO3 | 0.291 | - |

| F | - | - |

| Cl | 0.011 | - |

| Cr2O3 | 0.138 | - |

| ZrO2 | 0.465 | - |

| LOI | 9.2 | 32 |

| TOTAL | 99.756 | 64.99 |

| P. florida Waste (%) | Thermal Cond. (W/m·K) | Specific Heat (MJ/m3·K) | Density (Kg/m3) |

|---|---|---|---|

| 0 | 0.77 | 1.6 | 1922.027 |

| 5 | 0.481 | 1.513 | 1646.172 |

| 7.5 | 0.43 | 1.433 | 1589.453 |

| 10 | 0.379 | 1.407 | 1523.376 |

| 12.5 | 0.327 | 1.367 | 1462.963 |

| 15 | 0.293 | 1.307 | 1419.981 |

| Wastes (%) | PMV | PPD | ||

|---|---|---|---|---|

| 0 |  |  |  |  |

| 5 |  |  | ||

| 7.5 |  |  |  |  |

| 10 |  |  | ||

| 12.5 |  |  |  |  |

| 15 |  |  | ||

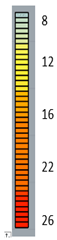

| Waste % | Energy Balance | Waste % | Energy Balance |

|---|---|---|---|

| Legend bar |  | ||

| 0% |  | 15% |  |

| Cooling Loads Per Months | |||

|---|---|---|---|

| Base Case Model | Waste 15% | ||

| Bathroom |  |  |

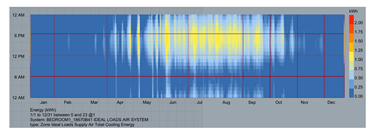

| Bedroom1 |  |  | |

| Bedroom2 |  |  | |

| Corridor |  |  | |

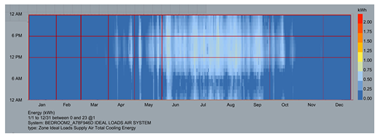

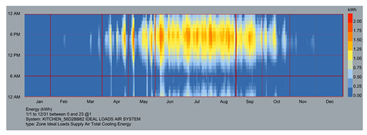

| Kitchen |  |  | |

| master bedroom |  |  | |

| Reception |  |  | |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 | Case 11 | Case 12 | Case 13 | Case 14 | Case 15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Brick Thickness in cm | 12.5 | 11.7 | 7.5 | 11.3 | 8.4 | 12.2 | 11.2 | 9.6 | 8.8 | 12.3 | 10.4 | 10 | 11.6 | 10.2 | 11.5 |

| Gap Spacing in cm | 12.5 | 12.3 | 12.5 | 12.1 | 12.5 | 12.5 | 11.5 | 11.3 | 12 | 11.4 | 11.5 | 12 | 12.4 | 12.2 | 12 |

| EUI In kWh/m2 | 258.127 | 258.605 | 260.21 | 259.142 | 259.783 | 258.074 | 260.263 | 261.278 | 260.477 | 259.889 | 260.637 | 259.676 | 258.554 | 259.462 | 258.982 |

| Enhancement Ratio | 36.7% | 36.6% | 36.2% | 36.4% | 36.3% | 36.7% | 36.2% | 35.9% | 36.1% | 36.3% | 36.1% | 36.3% | 36.6% | 36.4% | 36.5% |

| Case 16 | Case 17 | Case 18 | Case 19 | Case 20 | Case 21 | Case 22 | Case 23 | Case 24 | Case 25 | Case 26 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Brick Thickness, cm | 7.7 | 7.5 | 8 | 7 | 8 | 9.5 | 7.2 | 7.6 | 9 | 10 | 10 |

| Gap Spacing. cm | 12.5 | 12.5 | 12.5 | 12.5 | 12 | 11 | 12.5 | 12 | 12 | 11 | 11.5 |

| EUI, kWh/m2 | 280 | 280 | 280 | 280 | 280 | 280 | 285 | 280 | 280 | 280 | 285 |

| Wall height | 249.477 | 249.53 | 249.317 | 249.744 | 250,171 | 251.239 | 249.637 | 250.331 | 249.69 | 251.025 | 252.841 |

| Enhancement ration | 38.8% | 38.8% | 38.8% | 38.7% | 38.5% | 38.4% | 38.8% | 38.6% | 38.8% | 38.4% | 38.0% |

| Wall Height (cm) | 280 | 285 | 290 | 295 | 300 | 305 | 310 | 315 | 320 | 325 | 330 | 335 | 340 | 345 | 350 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EUI, kWh/m2 | 249.53 | 252.36 | 254.87 | 257.54 | 260.21 | 262.826 | 265.55 | 268.166 | 270.836 | 273.507 | 276.229 | 278.792 | 281.516 | 284.186 | 286.802 |

| Enhancement ration | 38.8% | 38.1% | 37.5% | 36.8% | 36.2% | 35.5% | 34.9% | 34.2% | 33.6% | 32.9% | 32.2% | 31.6% | 31.0% | 30.3% | 29.7% |

| PMV | PPD | |||

|---|---|---|---|---|

| Base case |  |  |  |  |

| 15% Waste ratio |  |  | ||

| Optimum wall section |  |  | ||

| 0% | 15% | Optimum | |

|---|---|---|---|

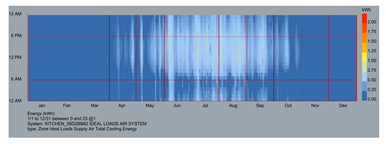

| Bathroom |  |  |  |

| Bedroom |  |  |  |

| Bedroom2 |  |  |  |

| Corridor |  |  |  |

| Kitchen |  |  |  |

| Master Bedroom |  |  |  |

| Reception |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fahmy, M.K.; Ahmed, M.M.; Ali, S.A.; Tarek, D.; Maafa, I.M.; Yousef, A.; Ragab, A. Enhancing the Thermal and Energy Performance of Clay Bricks with Recycled Cultivated Pleurotus florida Waste. Buildings 2024, 14, 736. https://doi.org/10.3390/buildings14030736

Fahmy MK, Ahmed MM, Ali SA, Tarek D, Maafa IM, Yousef A, Ragab A. Enhancing the Thermal and Energy Performance of Clay Bricks with Recycled Cultivated Pleurotus florida Waste. Buildings. 2024; 14(3):736. https://doi.org/10.3390/buildings14030736

Chicago/Turabian StyleFahmy, Marwa Kamal, M. M. Ahmed, Sally A. Ali, Dalia Tarek, Ibrahim M. Maafa, Ayman Yousef, and Ayman Ragab. 2024. "Enhancing the Thermal and Energy Performance of Clay Bricks with Recycled Cultivated Pleurotus florida Waste" Buildings 14, no. 3: 736. https://doi.org/10.3390/buildings14030736

APA StyleFahmy, M. K., Ahmed, M. M., Ali, S. A., Tarek, D., Maafa, I. M., Yousef, A., & Ragab, A. (2024). Enhancing the Thermal and Energy Performance of Clay Bricks with Recycled Cultivated Pleurotus florida Waste. Buildings, 14(3), 736. https://doi.org/10.3390/buildings14030736