1. Introduction

Wind power has emerged as a critical component of the future energy landscape. Simultaneously, it plays a pivotal role in accelerating the adjustment of the Chinese energy structure and achieving the ambitious goal of carbon neutrality by 2060 [

1]. Due to the relatively late development of the Chinese wind power industry, several associated technologies exhibit noticeable hysteresis phenomena, including foundation fatigue damage [

2,

3] and the cracking of foundation ring concrete gap [

4].

Given these challenges concerning wind turbine foundations, research on the mechanisms of foundation damage and rehabilitation techniques for damaged foundations has attracted growing attention from scholars. Guo et al. [

5] discovered that torque load is most sensitive to changes in bottom flange size but less responsive to variations in the buried depth of the foundation ring or the strength of the foundation concrete. Velarde et al. [

6] investigated the sensitivity of fatigue load for a 5 MW offshore wind turbine installed on a gravity base with respect to major structural, geotechnical, and marine parameters. They found that turbulence intensity and wave load uncertainty significantly influence fatigue load uncertainty, while soil property uncertainties exhibit nonlinear or interactive behavior. Amponsah et al. [

7] proposed an analytical expression for the ultimate bending moment bearing capacity based on stress distribution and failure mode under observed ultimate loads for embedded steel ring-foundation connections. McAlorum et al. [

8] employed an ultra-long fiber optic strain sensor to monitor crack development and changes in foundation concrete over time. Sun et al. [

9] suggested using finite element method simulations to compare the effectiveness of different reinforcement schemes and determine the best method during the reinforcement design process.

In summary, research methods for wind turbine foundation deformation mainly focus on numerical simulation, which has drawbacks such as lengthy modeling time, complex analysis, and limited simulation applicability. In recent years, with the continuous advancement of artificial intelligence, machine learning models have been applied in finance, healthcare, transportation, environmental research, and other fields [

9,

10,

11]. There is also abundant research on the application of machine learning models for prediction in the civil engineering industry, such as the seismic damage assessment of structures and analysis of material performance indicators [

12,

13]. Of course, in geotechnical engineering problems, machine learning is used to predict ground settlement in tunnel excavation and pipeline excavation instead of simulation [

14,

15]. Machine learning has been extensively studied in foundation settlement methods. Samui [

16] used support vector machines to predict settlement in and out of shallow foundations with cohesionless soils, and concluded that SVM can serve as a practical tool for predicting foundation settlement. Scott Kirts et al. [

17] also utilized support vector machines to make pertinent predictions of foundation settlement and demonstrated positive outcomes. In addition to the SVM method, Raja et al. [

18] employed the Multivariate Adaptive Regression Splines (MARS) model to predict the deformation of reinforced foundations, while Deng et al. [

19] proposed a prediction interval for the settlement of building foundations using an Extreme Learning Machine (ELM). Moreover, artificial neural networks are commonly employed in foundation settlement studies [

20]. Currently, numerous studies have focused on the health monitoring of wind turbine foundations [

21,

22]. However, few studies have utilized machine learning models to predict foundation deformation under cyclic dynamic loads following the rehabilitation of fan foundations in mountainous areas. The applicability of machine learning models to predict wind turbine foundation deformation post-rehabilitation remains uncertain.

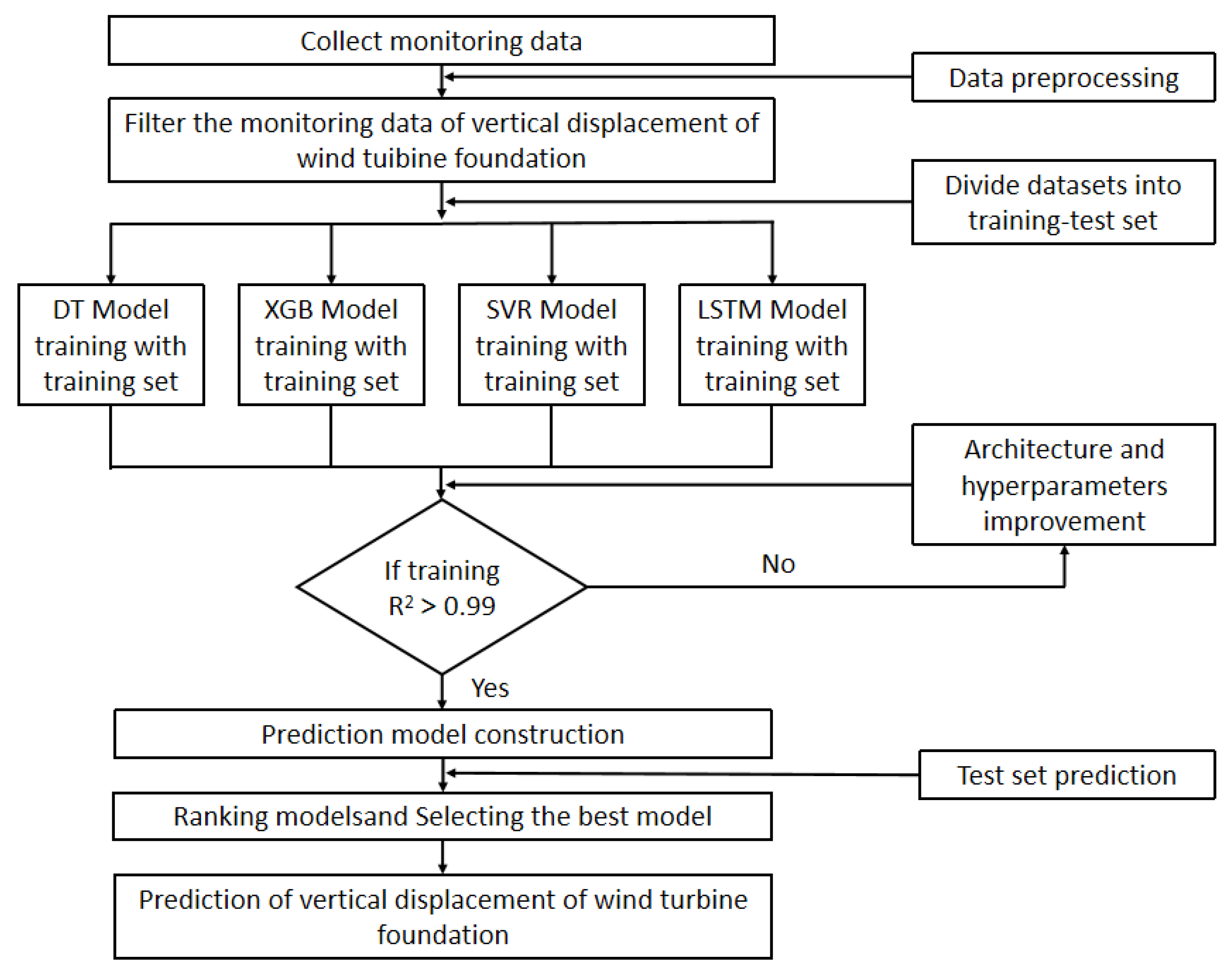

This study primarily analyzes the stability of damaged wind turbine foundations after rehabilitation and the predictive efficacy of machine learning on future foundation deformation. Firstly, the field deformation data following the rehabilitation of the mountainous wind turbine foundation are analyzed, and the stability of the wind turbine foundation deformation after rehabilitation is discussed. Subsequently, we investigate the applicability of machine learning in predicting wind turbine foundation displacement, establish a prediction model for wind turbine foundation vertical displacement deformation, assess the predictive performance of four machine learning models, and employ the best model to predict wind turbine foundation displacement. Furthermore, machine learning models are explored for the long-term prediction of wind turbine foundation deformation. The practical significance lies in the capability of the constructed model to accurately predict the vertical displacement of wind turbine foundations, offering data support for subsequent maintenance and serving as a reference for monitoring and predicting foundation deformations after rehabilitation.

4. Results and Discussion

Table 2,

Table 3,

Table 4 and

Table 5 summarize the R

2, MSE, and MAE of the four developed models under different parameter combinations. The models are sorted according to their R

2 scores on the test set, and the best combination of parameters for each model is shown in bold.

By comparing the optimal parameter combination model, it can be seen that the MAE function and MSE function of DT model test set and XGB model are 0.082, 0.144, 0.083, and 0.142, respectively, which are significantly higher than the other models, and the performance is the worst. The MAE and MSE values of the SVR model and LSTM model test sets are 0.004, 0.049, and 0.004, 0.046, respectively, achieving the best performance.

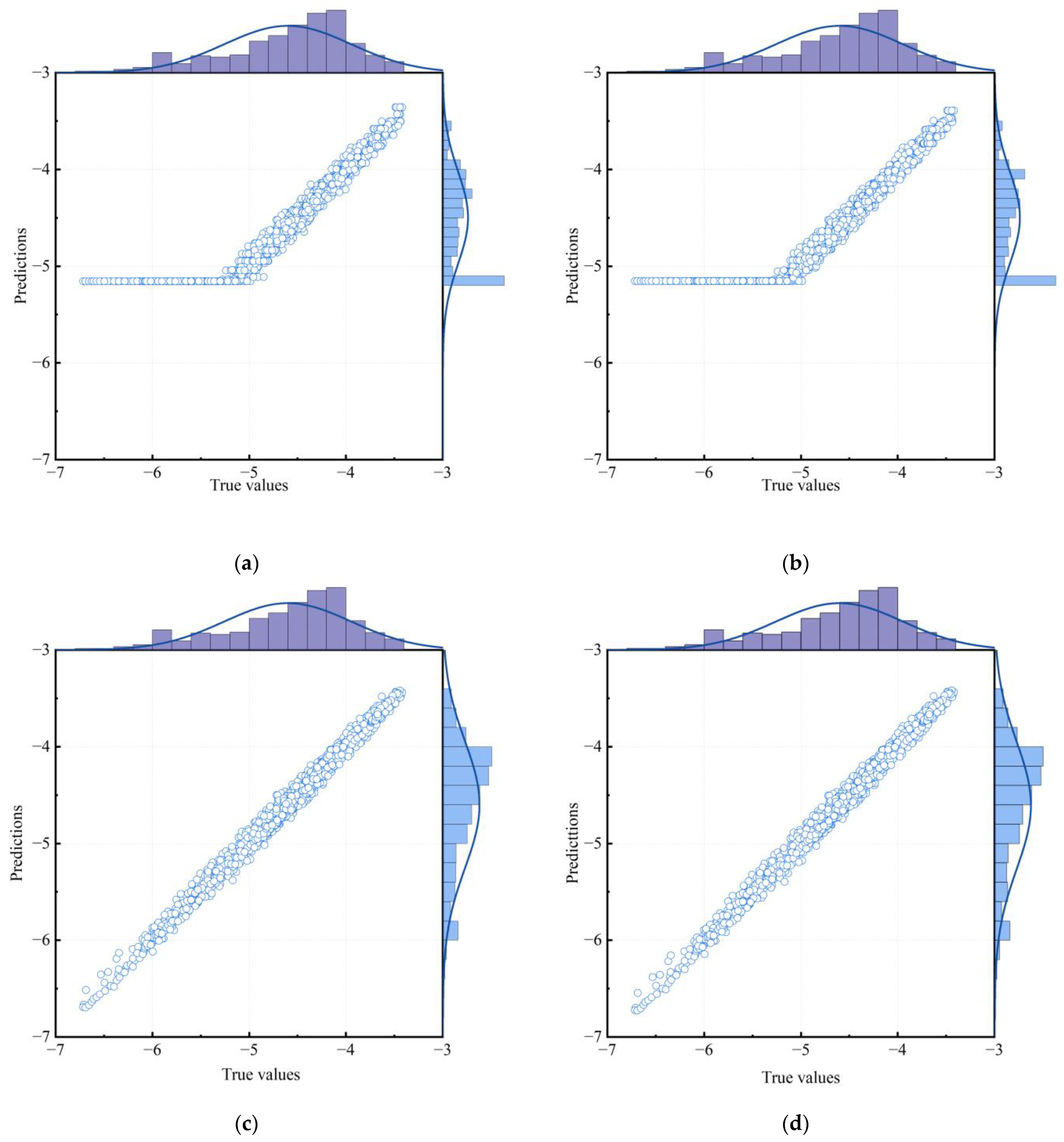

Marginal Histogram were developed by combining the predicted values from the model test set with the optimal parameters of the four models to further observe the performance of the models in predicting the vertical deformation of the wind turbine foundations, as shown in

Figure 14. The middle section is a scatter plot of the true and predicted values, and the edge section is a histogram of the distribution of the true and predicted values and a normal distribution curve.

As can be seen from the tables and graphs, the DT and XGB models are the worst at predicting deformations, with a coefficient of determination of 0.810 on the test set. When the value of deformation is large, the predictions of both the DT model and the XGB model reach a critical phenomenon. This is due to the fact that both the XGB model and the DT model are essentially tree models, and when there is a certain range of data in the test set that is not involved in the training process, the unknown data enter the tree model to predict the clustering of the results, and the model will experience serious overfitting problems [

38]. In addition, it can be learnt from the table and figure that the SVR model and LSTM model fit the data in the test set very well, and the coefficient of determination is as high as 0.992, which is the best prediction effect among all models.

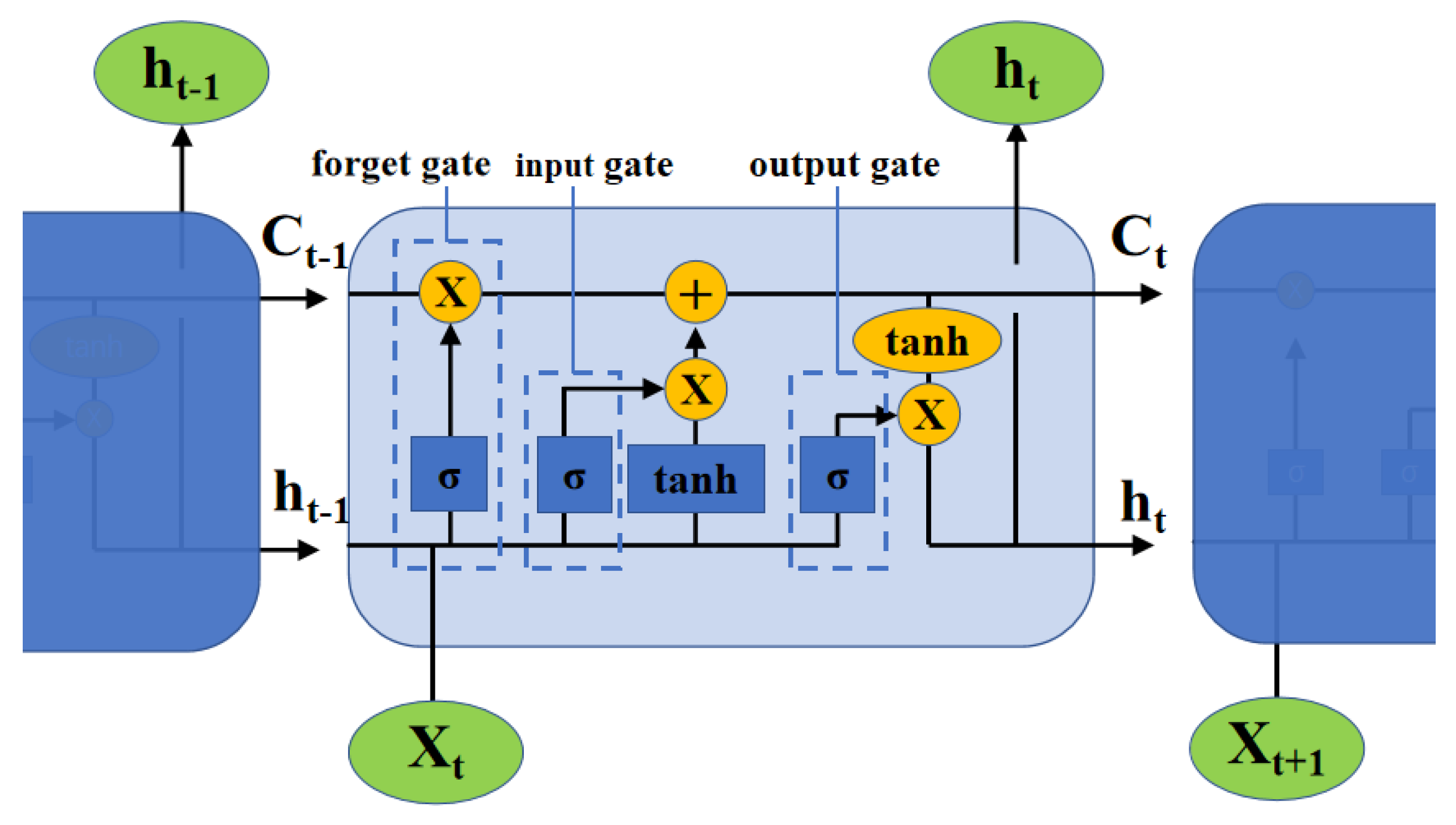

As mentioned before, among all the developed models, the SVR model with hyperparameters C = 1, epsilon = 0.001, gamma = 0.01, and the LSTM model with hyperparameters activation = tanh, hidden_size = 128, epochs = 256 exhibit the best performance, efficiently predicting wind turbine settlement data with the highest R2 value and the lowest MAE and MSE values.

While R

2 and other statistical measures can provide an overall picture of the performance of the model being developed, they do not provide information about the distribution and extent of errors. To compare more specifically the performance of the four models in predicting wind turbine foundation deformation, probability density distributions and function plots were plotted using Equation (15), as shown in

Figure 15.

Figure 15a shows the probability density distribution plots of the four machine learning models, showing the centralized distribution of the predicted/true values of the models, and

Figure 15b shows the probability density cumulative plots of the four machine learning models, showing the cumulative probability share of the predicted/true values of the models.

where

represents the kernel,

is the smoothing parameter, and

represents the number of sample data points.

As shown in

Figure 15, the ratios of predicted values to actual values for the four models are distributed between 0.85 and 1.05. Among them, the SVR and LSTM models are the most stable, reaching a maximum value at a ratio of 1.0, which is higher than the other two models. On the other hand, the mean and standard deviation of the ratio between the predicted values and the actual values for the SVR model are 0.9991 and 0.0127. For the LSTM model, they are 1.0006 and 0.0128. These two models have the best prediction effect on foundation settlement. Moreover, it can be found from

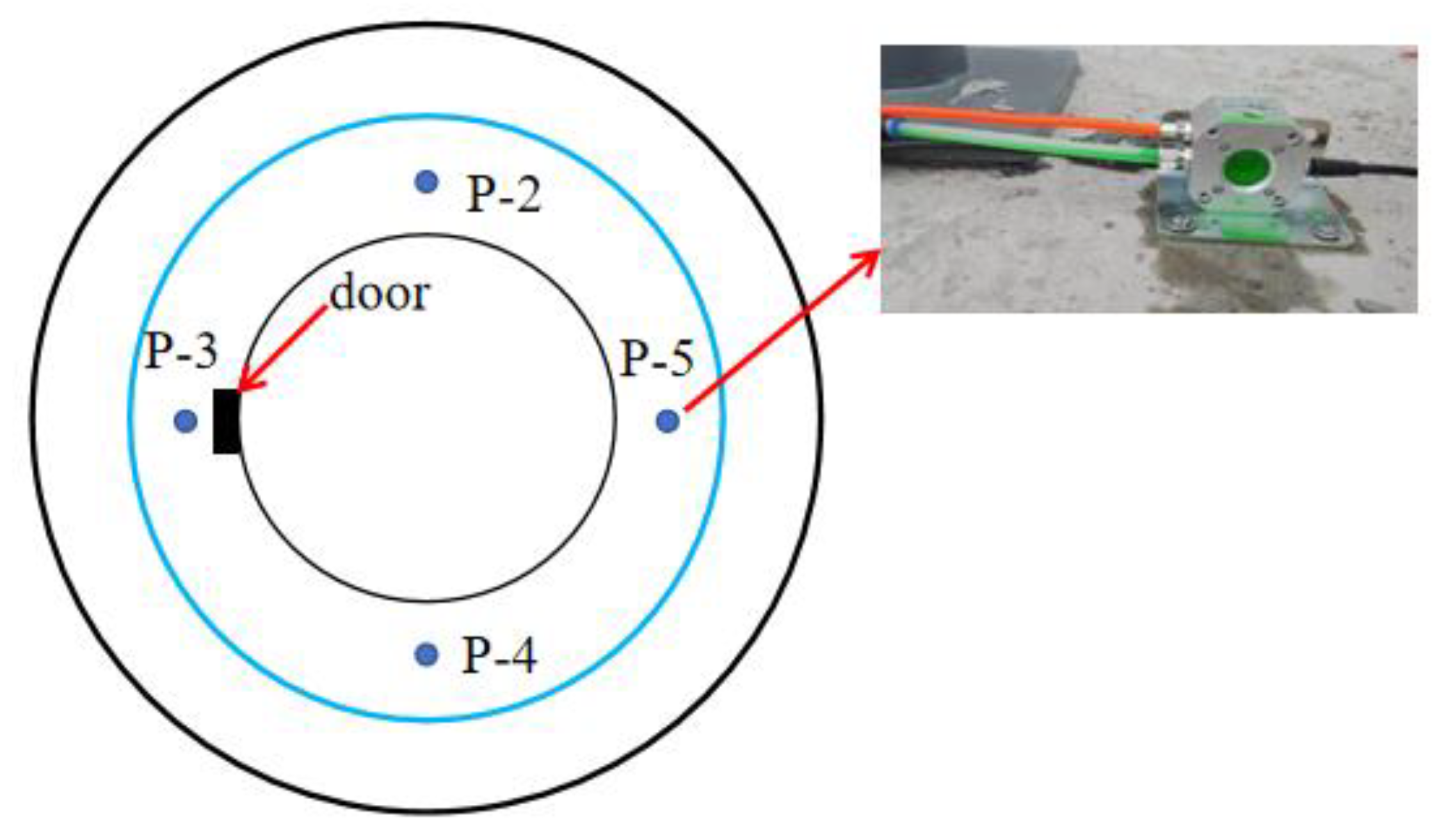

Figure 15a that the peak of the SVR model is concentrated at 1.0, implying that the predicted values are closer to the real values. In order to further observe the adaptability of the SVR and LSTM models in predicting the settlement of wind turbines foundation, the data of measuring points P-3, P-4 and P-5 were imported into the above two models for verification, and the prediction results are shown in

Table 6.

From the data in the table, it can be seen that the MAE and MSE values predicted by the SVR model for P-3, P-4, and P-5 measuring points are smaller than those predicted by the LSTM model, and the R

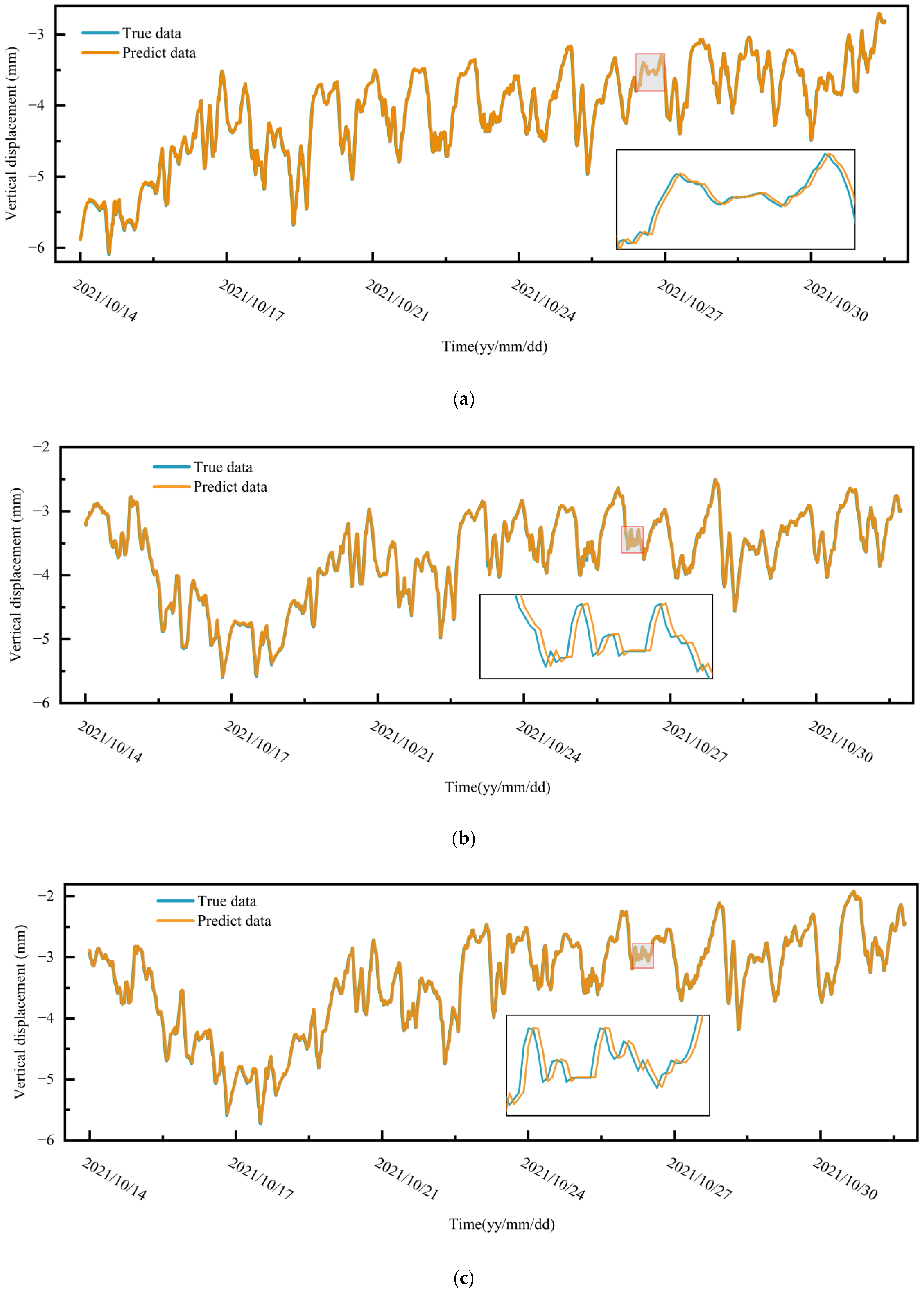

2 values predicted by the P-4 and P-5 measuring points are higher than those predicted by the LSTM model. This indicates that the comprehensive prediction performance of the SVR model is better than that of the LSTM model for all measurement points. The SVR model has stronger applicability in predicting wind turbine foundation deformation. The prediction performance of the SVR model for other measurement points is shown in

Figure 16.

On this basis, we discuss the prediction of the measured points of the wind turbine foundation using the better-performing LSTM model and the SVR model, and here, the two models are used to quantitatively compare the multi-time-step prediction of the vertical displacement of the wind turbine foundation. The 5-time-step, 10-time-step, 20-time-step, and 50-time-step prediction tests are performed on the vertical displacement data of the wind turbine foundation. The performance of the two models for the prediction of wind turbine foundation displacement is further identified by comparing the multi-time-step prediction results.

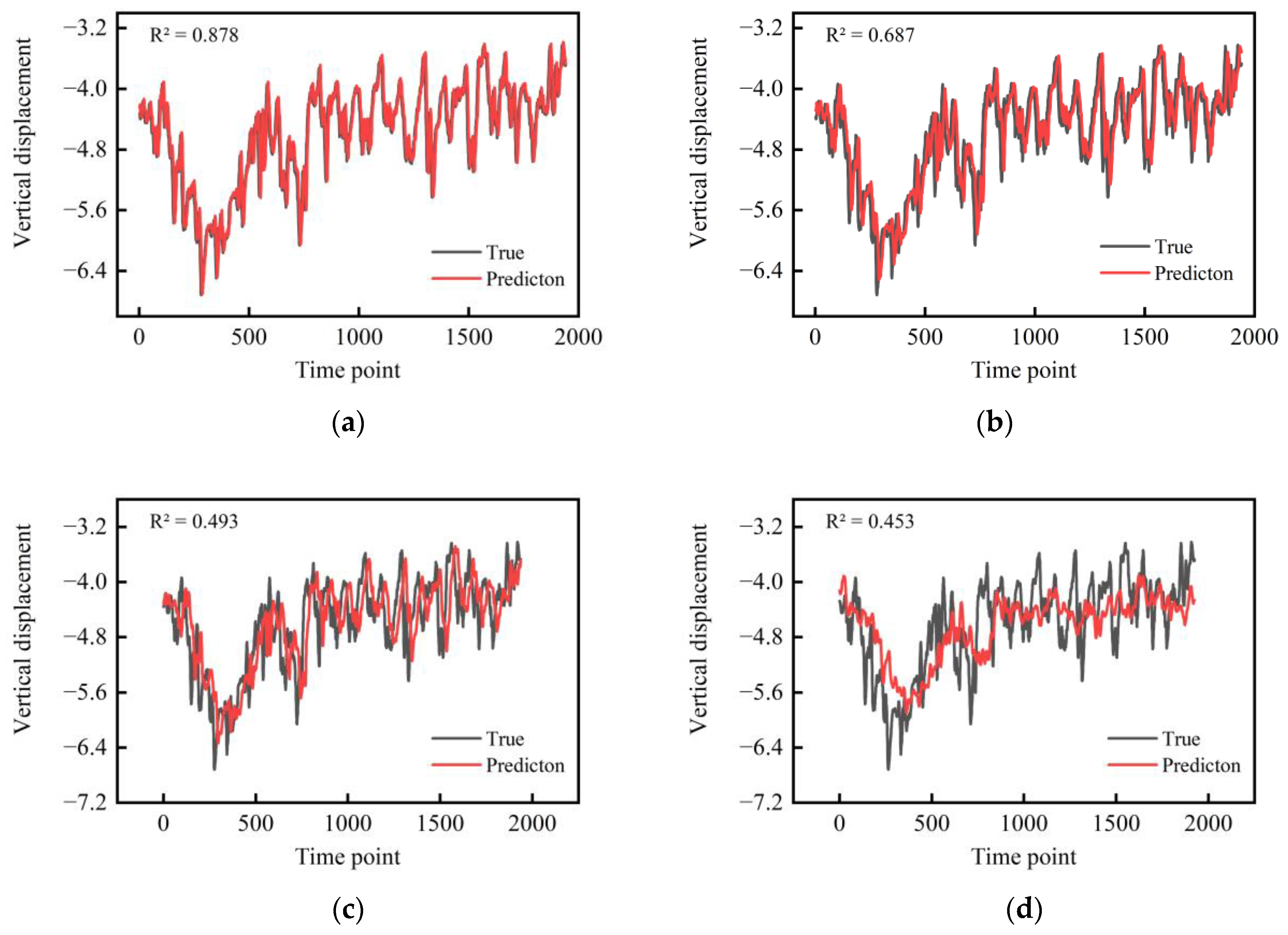

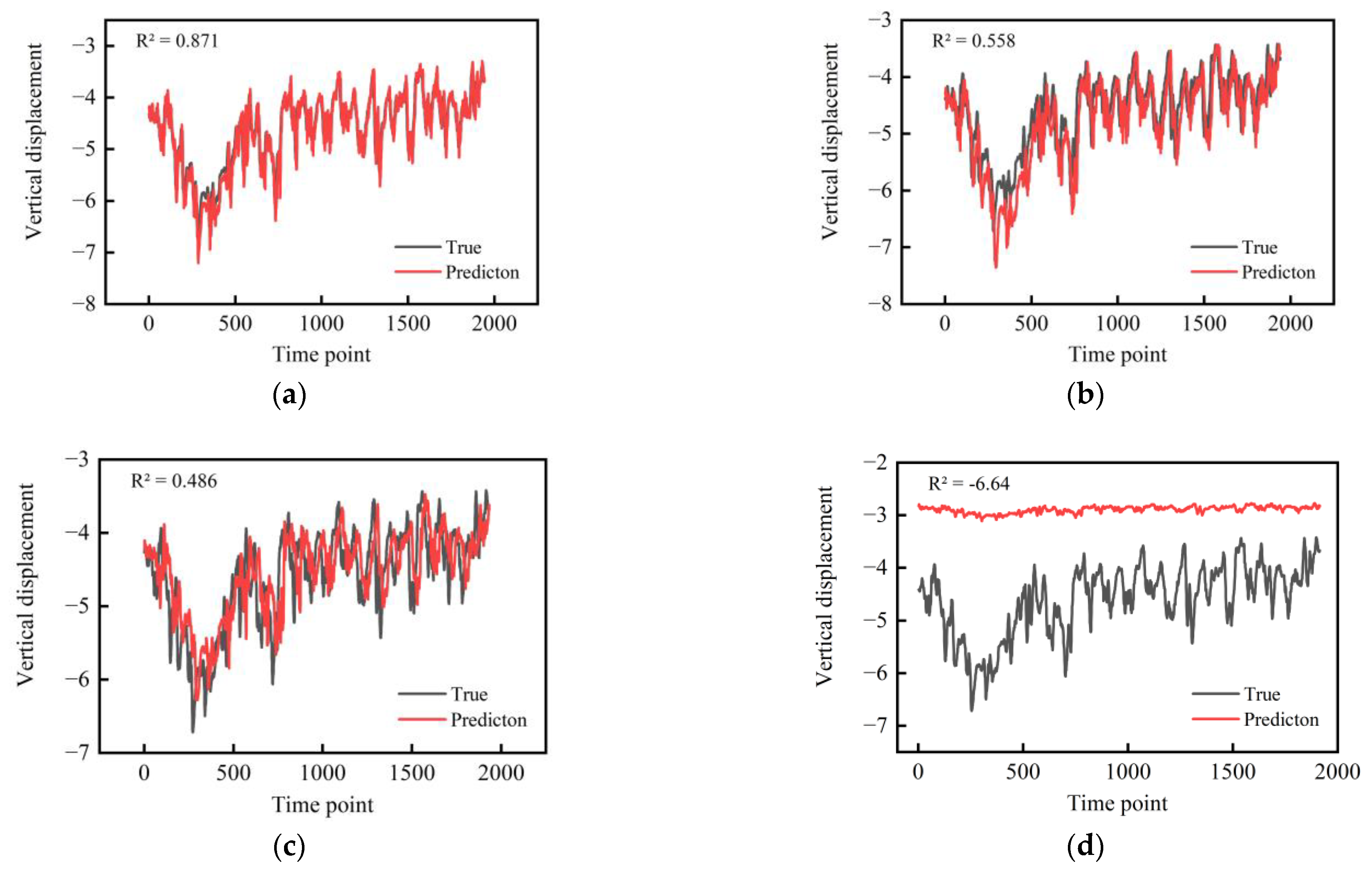

The multi-time-step test results of the SVR model and LSTM model for the prediction of vertical displacement of wind turbine foundation are shown in

Figure 17 and

Figure 18, respectively. Firstly, comparing the two models with the same prediction step length, it can be found that both the SVR model and LSTM model perform well in the prediction of 5-time-step length, and at the same time, the R

2 value can reach 0.87, which indicates that the two models are more effective in the prediction of shorter time-step lengths. Secondly, in 10-time-step prediction, the LSTM model is slightly less effective than the SVR model, with a significant deviation in peak prediction around 300 Time point, which is less effective. In terms of 20-time-step prediction, both models perform poorly, with R

2 = 0.5 or less, and fail to achieve effective prediction of the base deformation. Finally, by comparing the 50-time-step prediction, it can be clearly found that the LSTM model has deviated from learning and predicting the base deformation law of the wind turbine, and the prediction of SVR can still fluctuate within the real interval in comparison, but the effect is still poor. The prediction effect of the model decreases significantly after 10 time steps, and the prediction effect of the subsequent 20 time steps and 50 time steps is poor. Such a phenomenon is due to the fact that the model only learns the short-term change characteristics of the wind turbine vertical displacement deformation during training, which yields a more accurate prediction for the next moment and shorter moments, however, it is difficult to get a long-term accurate prediction in the face of data spanning a large period of time. Multi-step prediction is still an open challenge in time series prediction [

39].

Then, by comparing the experimental results of the SVR model with different step sizes, it can be found that the SVR model can still effectively learn and predict the displacement of the wind turbine foundation when it is predicted with shorter time steps (5 time steps and 10 time steps), but when the time step is increased to 20 time steps or 50 time steps when the time step is increased to 20 time steps or 50 time steps, the prediction effect is weakened and the accuracy decreases. By comparing the performance of the above models, it can be concluded that the SVR model and LSTM model have a higher short-time prediction accuracy and poorer long-time prediction effect in terms of wind turbine foundation displacement, while the SVR model is more advantageous in terms of learning the wind turbine foundation displacement data, its prediction effect and prediction accuracy are better than that of the LSTM model, and the trend prediction is closer to that of the LSTM model. The SVR model can be used to predict the future changes of the foundation of wind turbines so as to achieve the goal of predicting the future changes of the foundation of wind turbines. The SVR model can be utilized to predict future changes in wind turbine foundations, facilitating the assessment of the foundation’s future state after rehabilitation. However, the prediction of long-term changes in the base of wind turbines needs further study.