A Novel Pervious Concrete Improved by Hexagonal Boron Nitride and Basalt Fiber in Mechanical Properties, Permeability, and Micro-Mechanisms

Abstract

1. Introduction

2. Materials and Methods

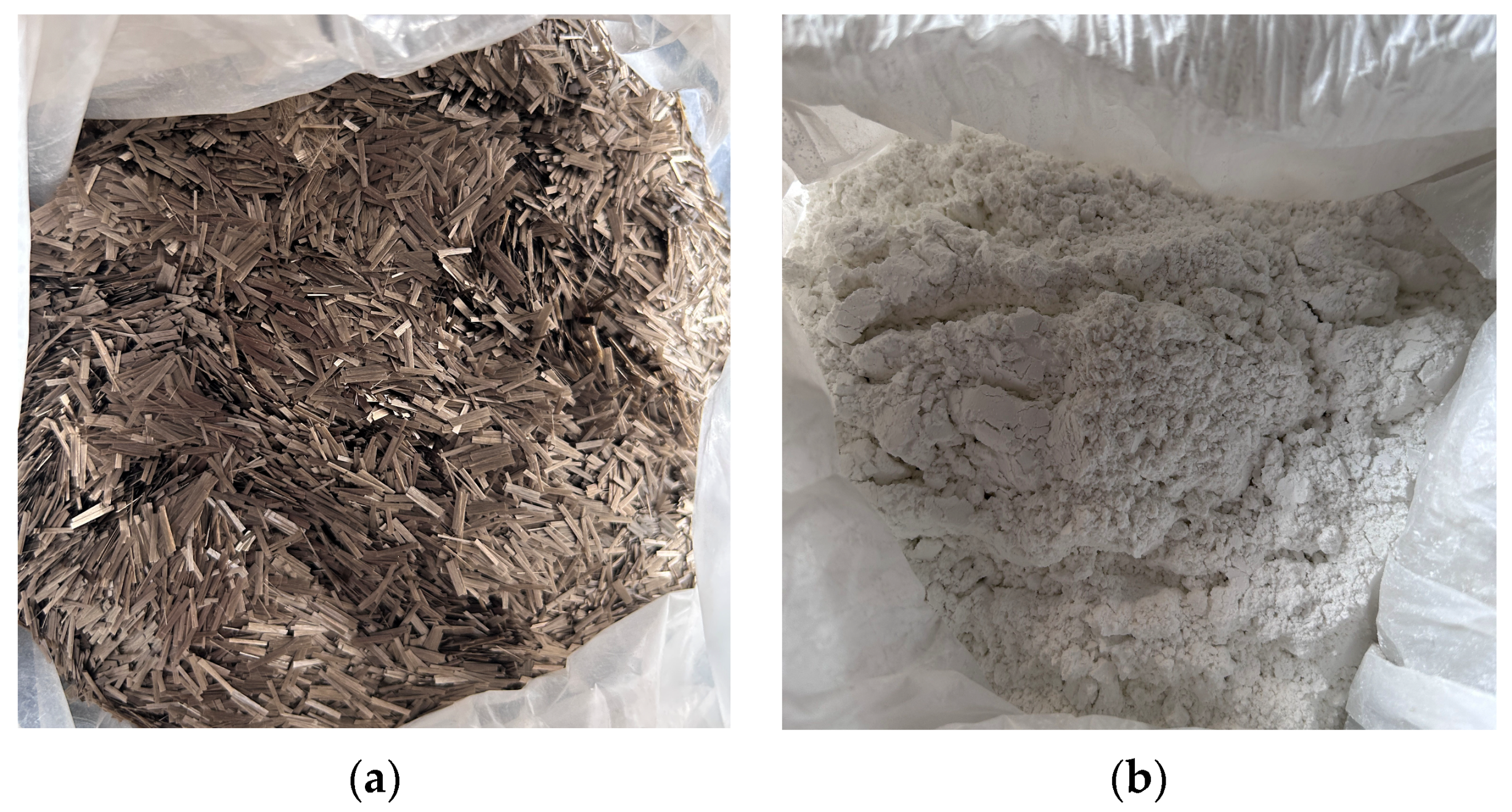

2.1. Materials

2.2. Mixture Proportions

2.3. Preparation of Hexagonal Boron Nitride Dispersions

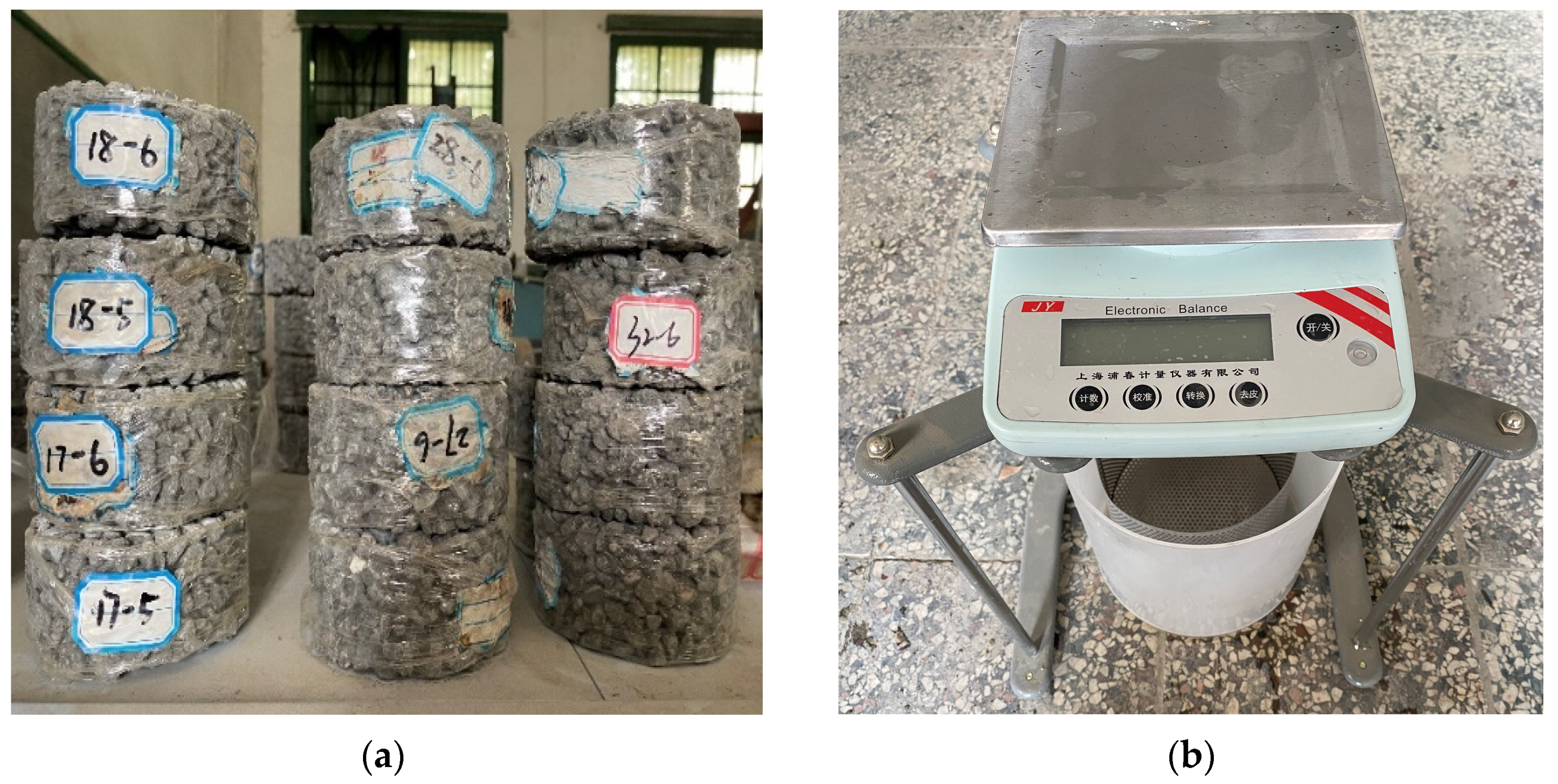

2.4. Testing Methods

3. Results and Discussion

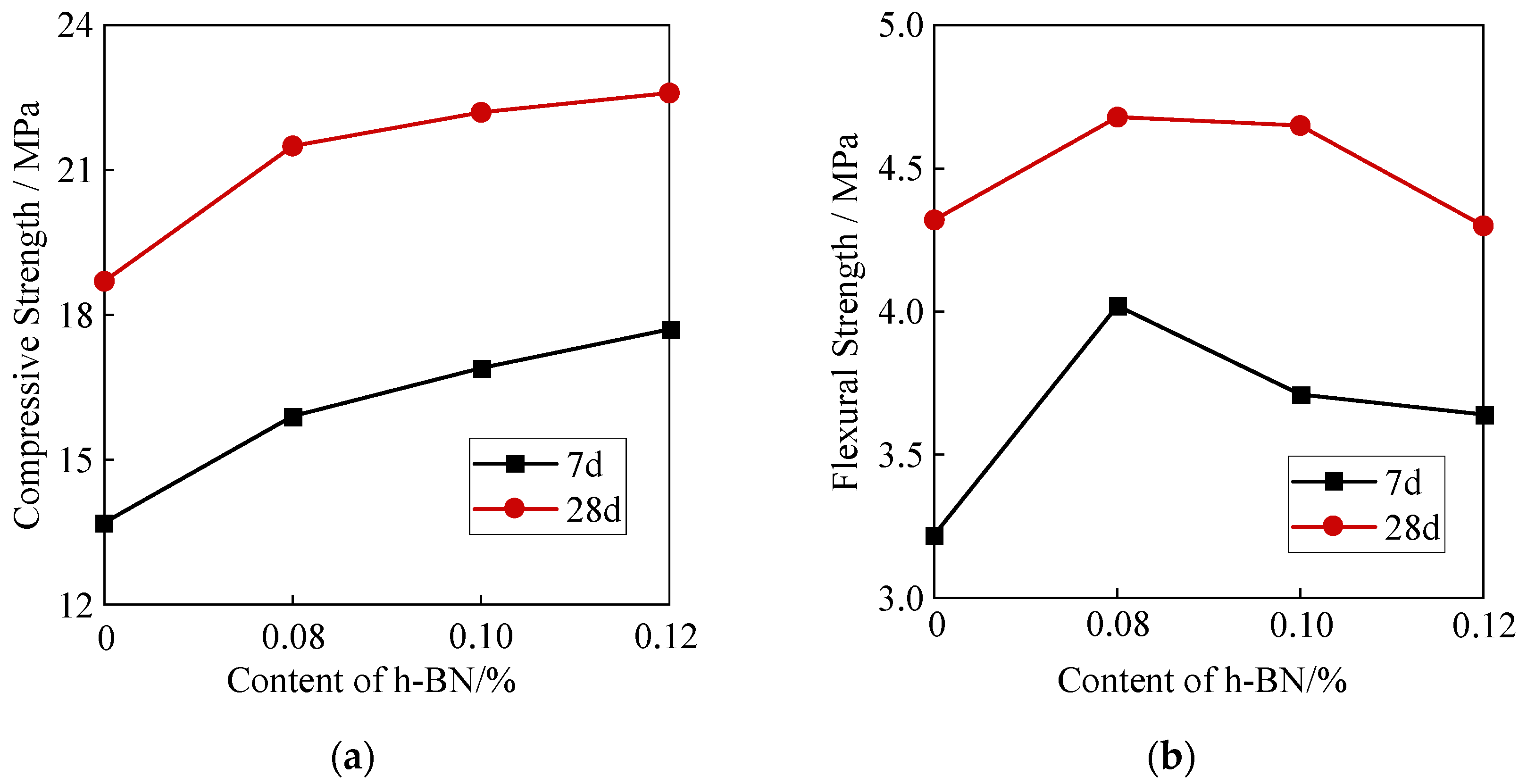

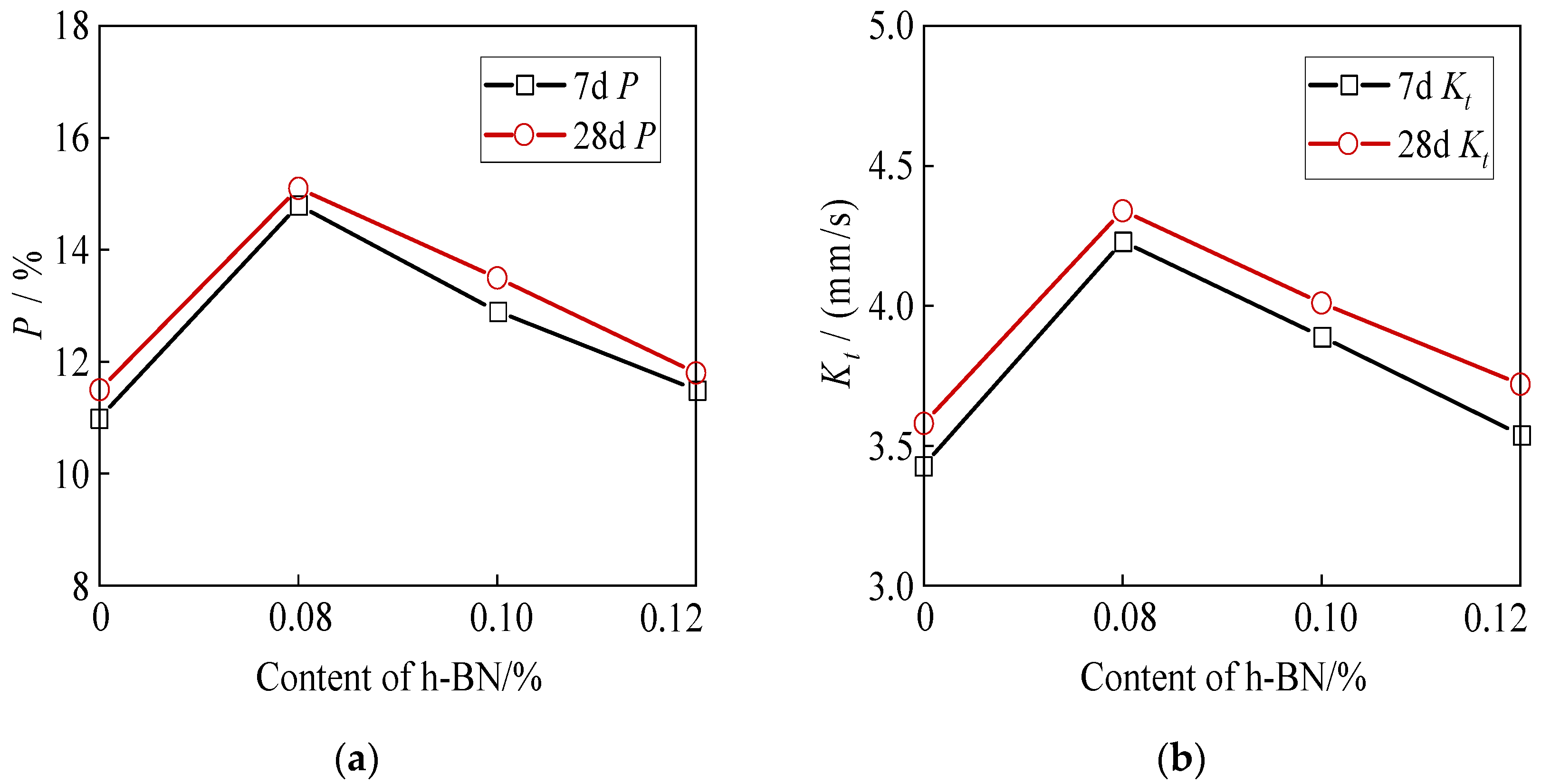

3.1. PC Single-Doped with h-BN

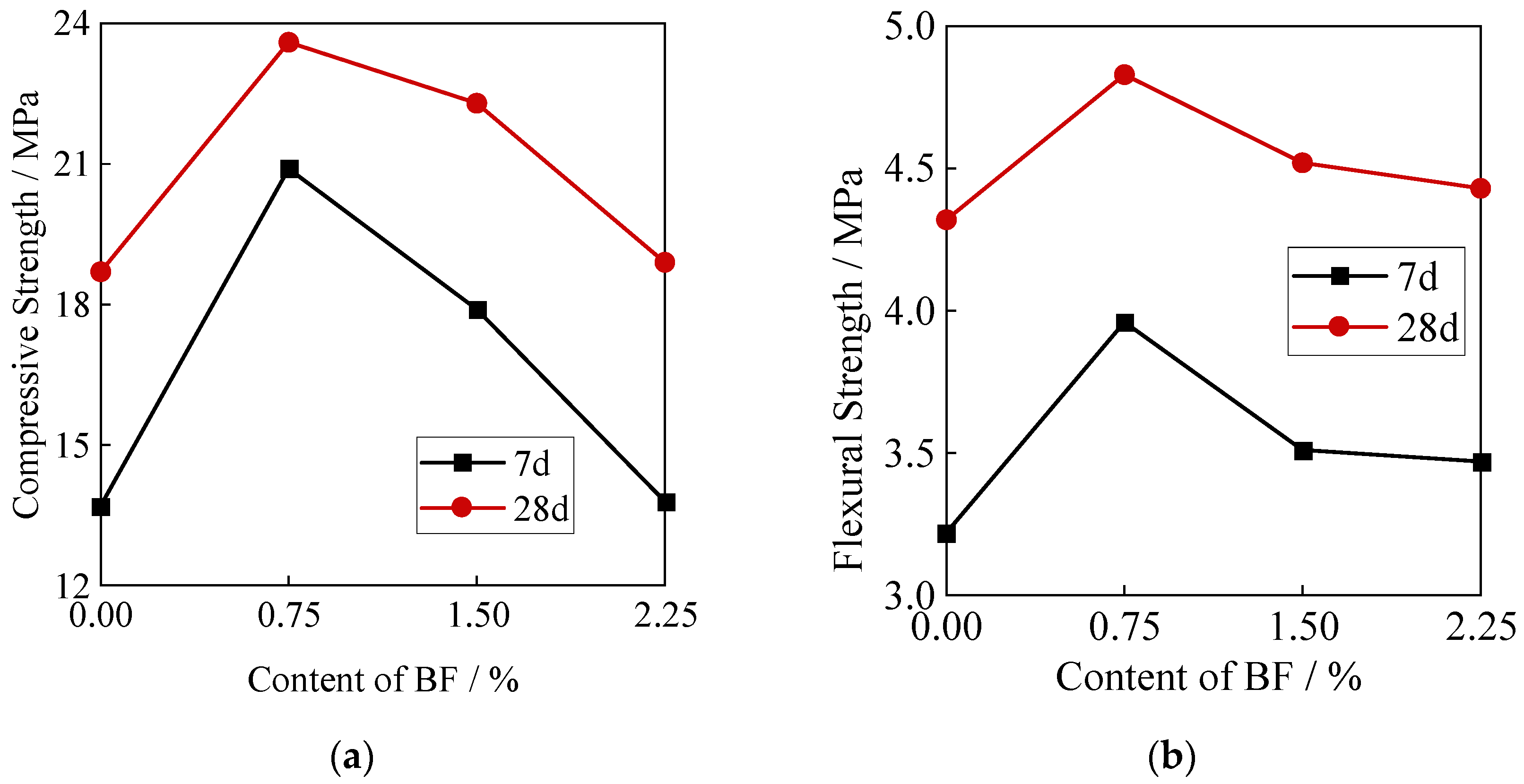

3.2. PC Single-Doped with BF

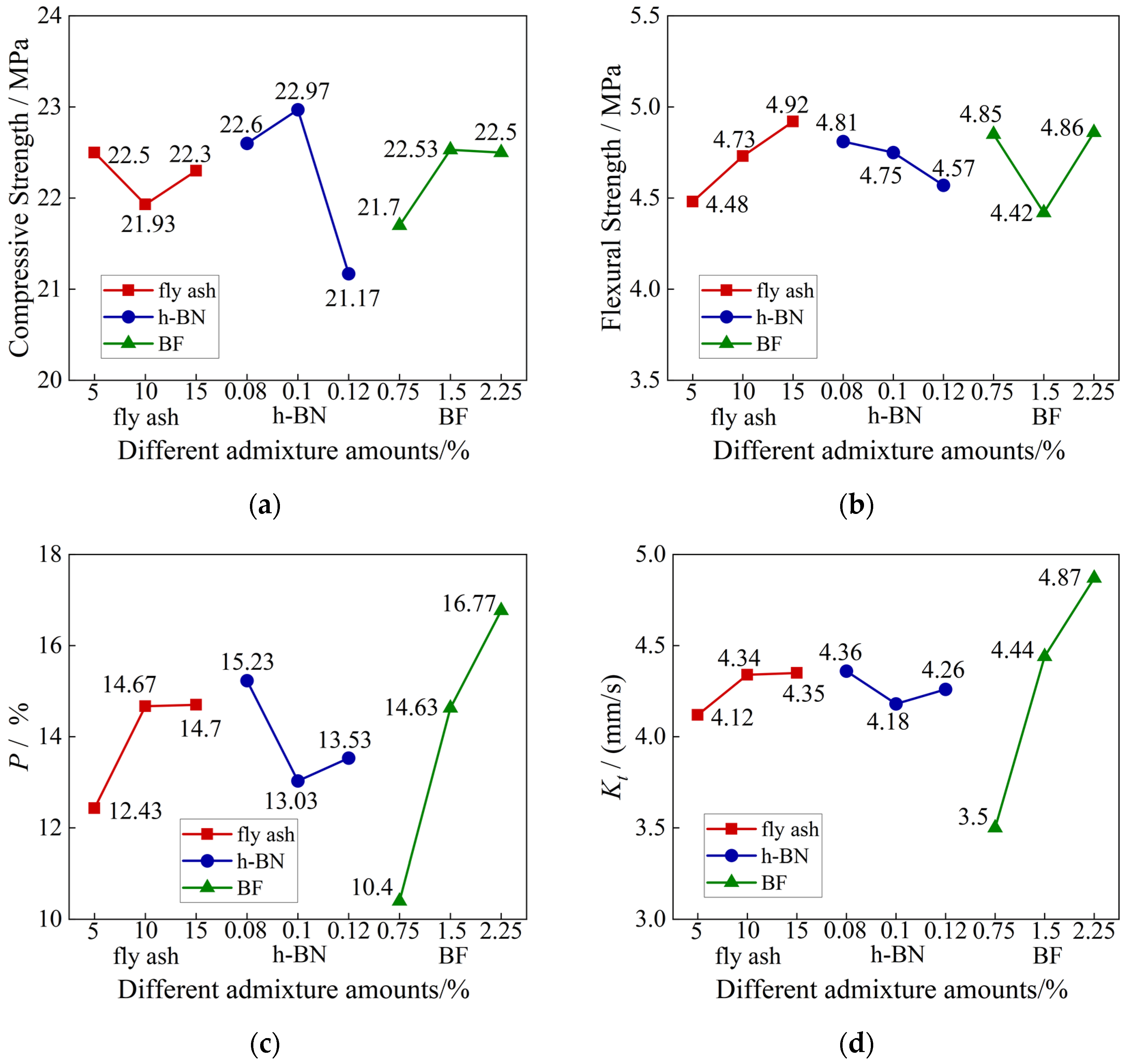

3.3. PC Double-Doped with h-BN and BF

4. Micro-Mechanism Analysis of Pervious Concrete

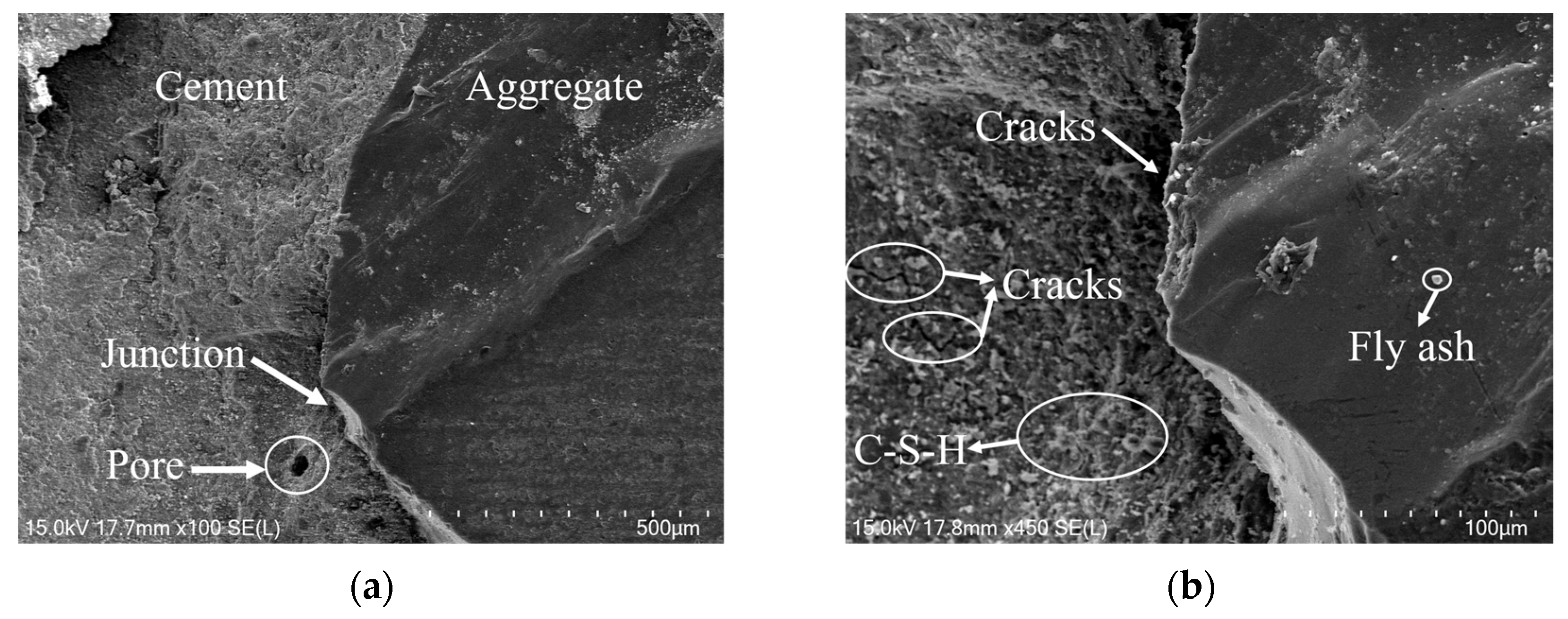

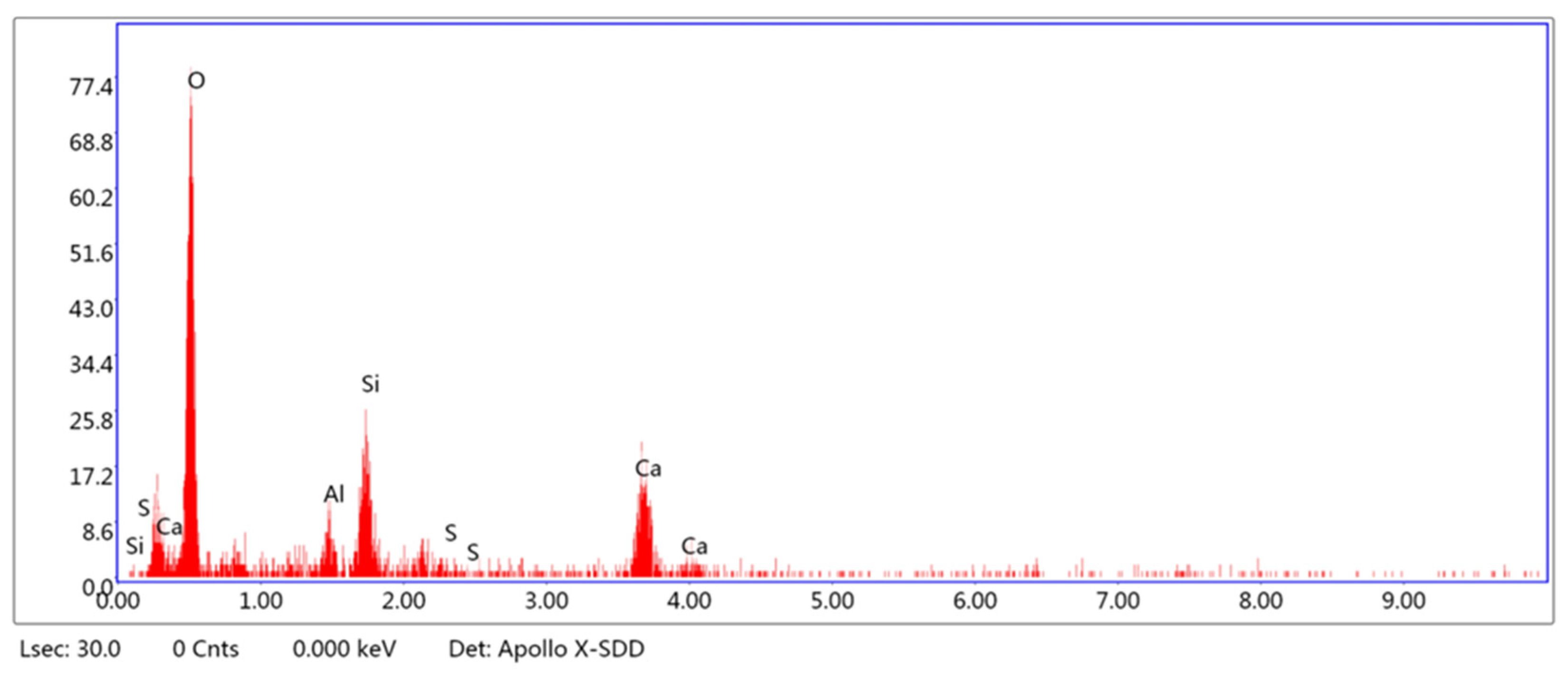

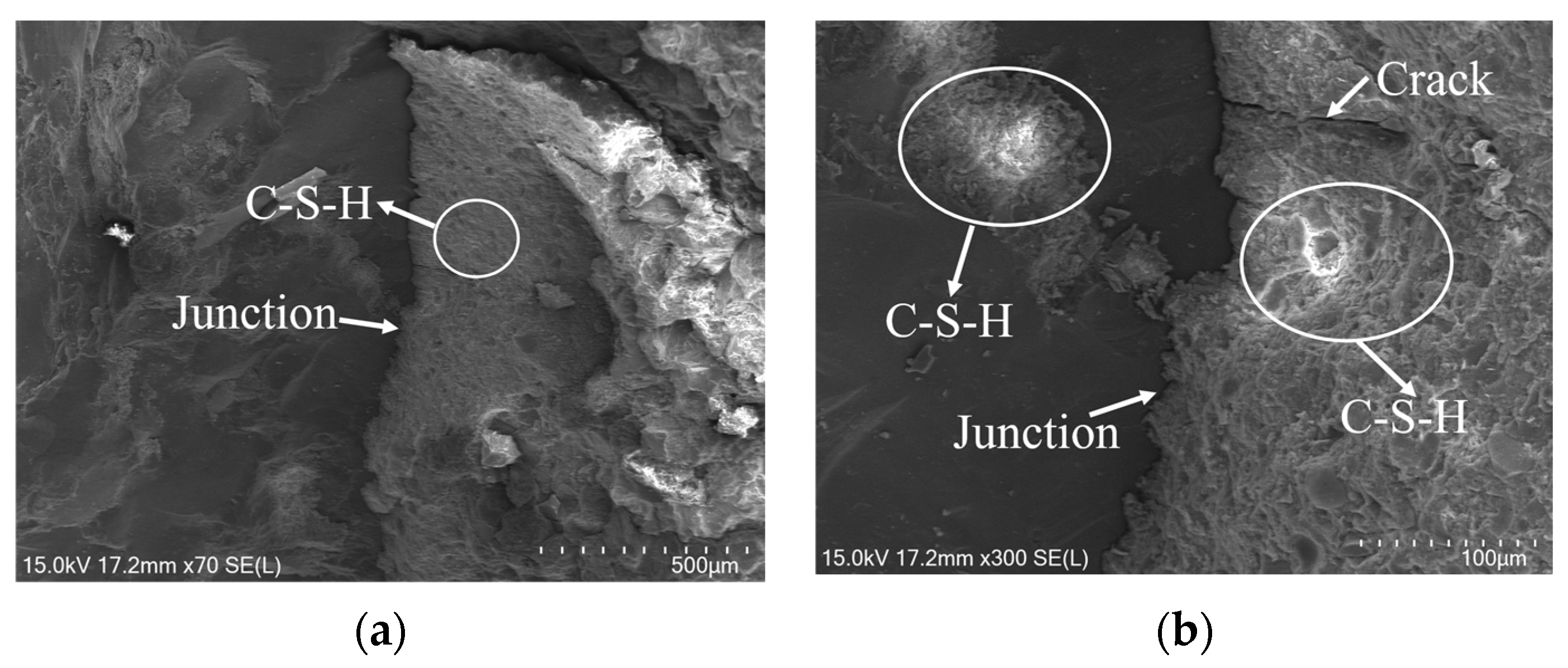

4.1. Micro-Mechanism Analysis of Ordinary Pervious Concrete

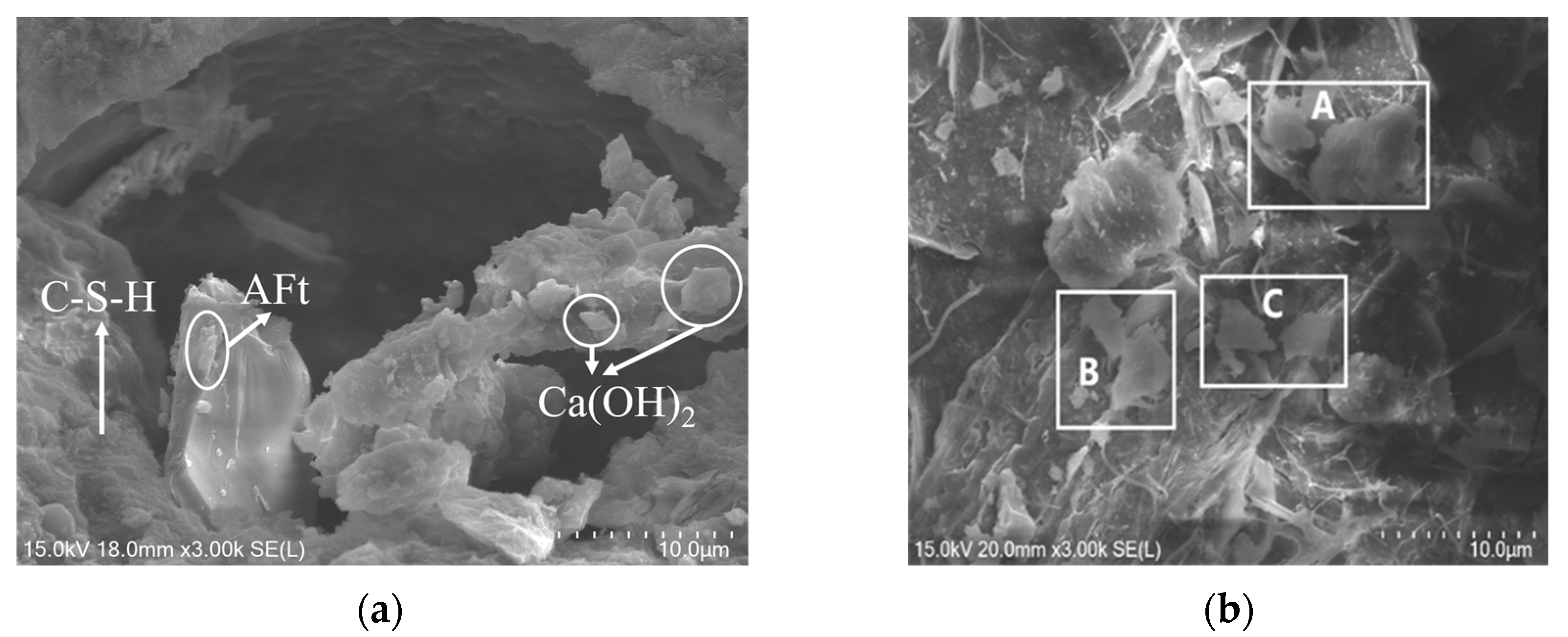

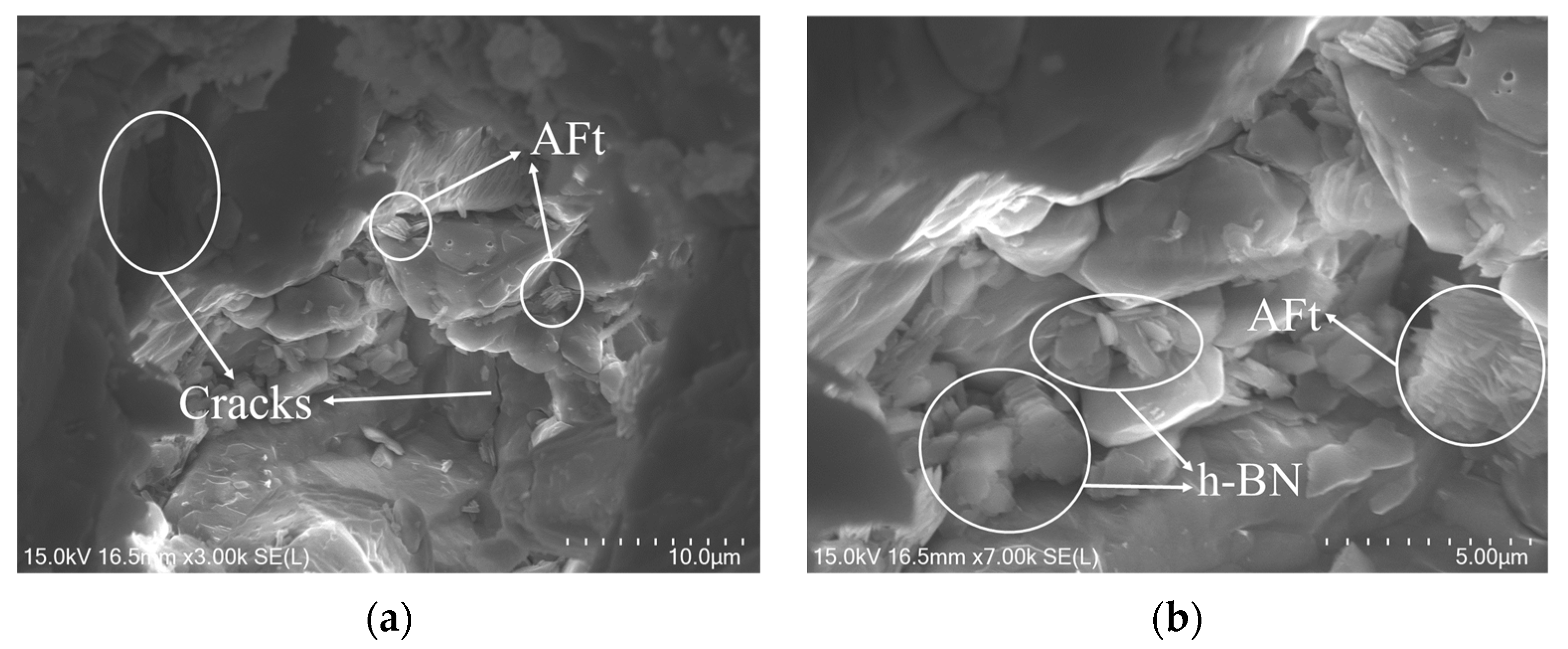

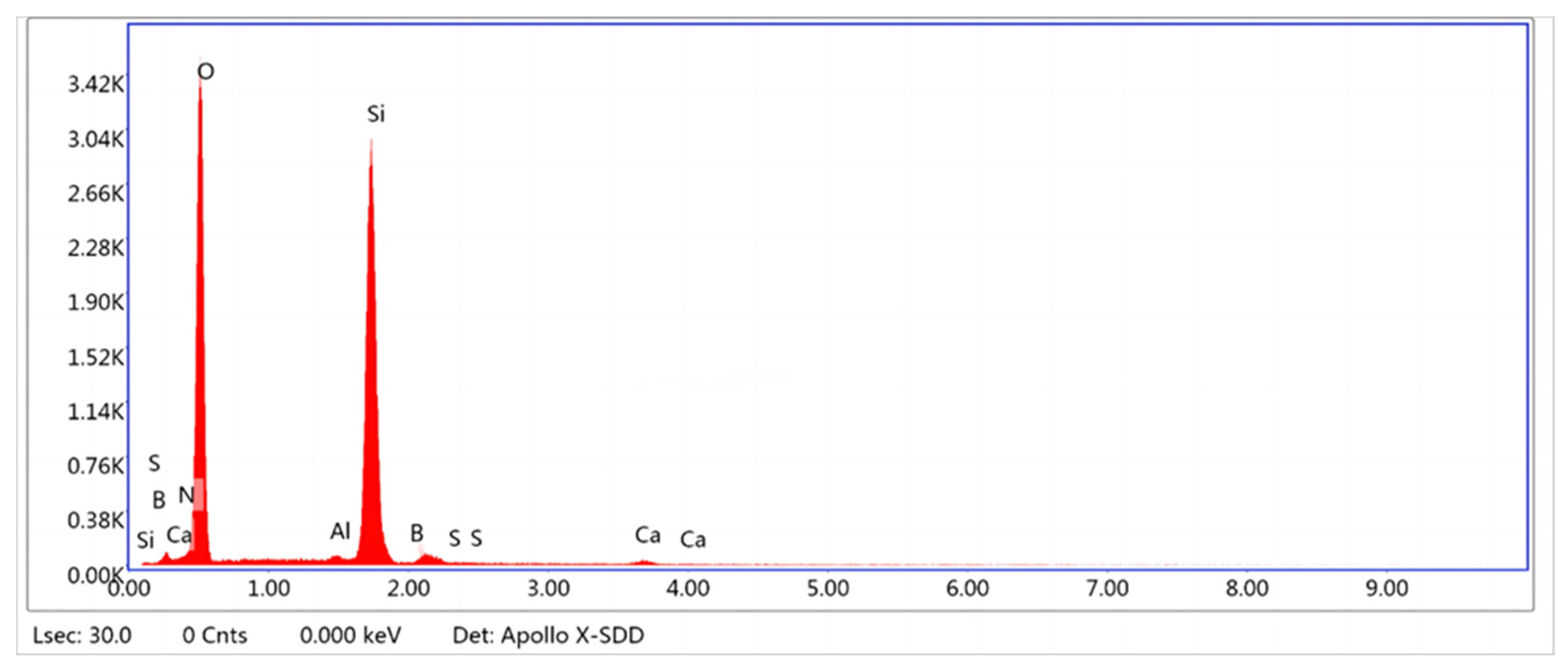

4.2. Micro-Mechanism Analysis of PC Single-Doped with h-BN

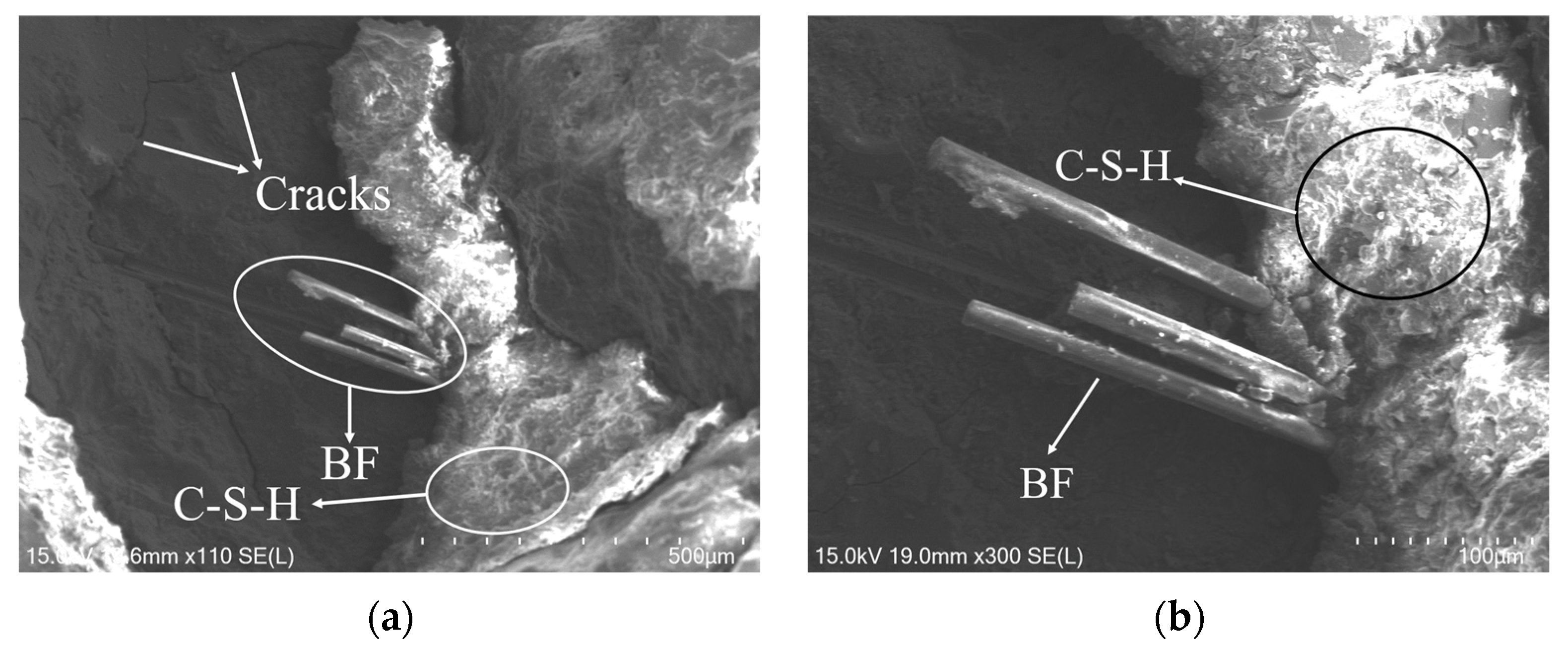

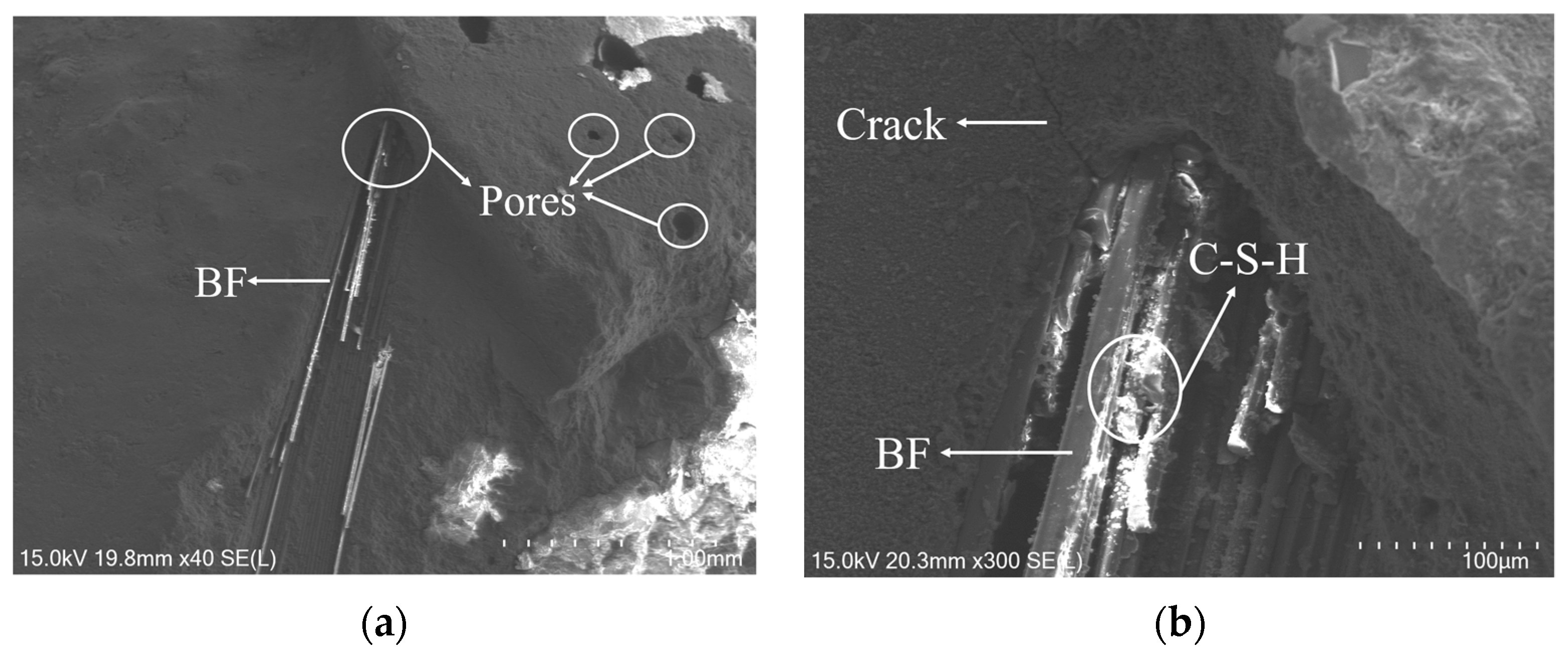

4.3. Micro-Mechanism Analysis of PC Single-Doped with BF

5. Conclusions

- (1)

- In the single-doped experiment, the appropriate amount of hexagonal boron nitride or basalt fibers can improve the mechanical properties and water permeability of permeable concrete, on which the basalt fibers have the most obvious effect. In the double-doped experiment, the optimal combination for the composite pervious concrete was a mixture of 15% fly ash, 0.08% hexagonal boron nitride, and 2.25% basalt fiber. The 28-day compressive strength, flexural strength, porosity, and permeability coefficients were 22.8 MPa, 5.17 MPa, 18.5%, and 5.09 mm/s, respectively, representing increases of 21.9%, 19.7%, 60.9%, and 42.2%, respectively, compared with ordinary pervious concrete.

- (2)

- The significance of the influence of hexagonal boron nitride and basalt fiber on the 28-day compressive strength of composite pervious concrete increased and then decreased with the increase in the content. The trend of the influence of hexagonal boron nitride (h-BN) content on the 28-day permeability of dual-doped pervious concrete was opposite to the trend of the 28-day compressive strength.

- (3)

- The scanning electron microscopy and energy dispersive spectrometer results indicated that hexagonal boron nitride and basalt fiber could promote the degree of cement hydration and increase the contact area between cement and aggregates, thus enhancing the bond strength between cement and aggregates, ultimately improving the mechanical and permeable properties of pervious concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Yang, J.; Jiang, G. Experimental study on properties of pervious concrete pavement materials. Cem. Concr. Res. 2003, 33, 381–386. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wei, H.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef]

- Vu, V.; Tran, B.; Le, B.; Nguyen, H. Prediction of the relationship between strength and porosity of pervious concrete: A micromechanical investigation. Mech. Res. Commun. 2021, 118, 103791. [Google Scholar] [CrossRef]

- Li, L.G.; Feng, J.; Xiao, B.; Chu, S.; Kwan, A.K.H. Roles of mortar volume in porosity, permeability and strength of pervious concrete. J. Infrastruct. Preserv. Resil. 2021, 2, 19. [Google Scholar] [CrossRef]

- Li, J.; Xia, J.; Di Sarno, L.; Gong, G. Fiber utilization in pervious concrete: Review on manufacture and properties. Constr. Build. Mater. 2023, 406, 133372. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Zhao, C.; Zhu, P.; Liu, H. The permeability, mechanical and snow melting performance of graphene composite conductive-pervious concrete. J. Build. Eng. 2023, 79, 107929. [Google Scholar] [CrossRef]

- Tho-in, T.; Sata, V.; Chindaprasirt, P.; Jaturapitakkul, C. Pervious high-calcium fly ash geopolymer concrete. Constr. Build. Mater. 2012, 30, 366–371. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Wu, J.; Pang, Q.; Lv, Y.; Zhang, J.; Gao, S. Research on the mechanical and physical properties of basalt fiber-reinforced pervious concrete. Materials 2022, 15, 6527. [Google Scholar] [CrossRef]

- Kamisetty, A.; Gandhi, I.S.R.; Kumar, A. Combined effect of fly ash and fiber on spreadability, strength and water permeability of foam concrete. J. Build. Eng. 2023, 78, 107607. [Google Scholar] [CrossRef]

- Ying, J.; Xie, Z.; Chen, B.; Jiang, Z.; Tian, Z.; Xiao, J. Multi-scale experimental studies on mechanical properties of three-dimensional porous graphene cementitious composite. Cem. Concr. Compos. 2024, 147, 105412. [Google Scholar] [CrossRef]

- Dimov, D.; Amit, I.; Gorrie, O.; Barnes, M.D.; Townsend, N.J.; Neves, A.I.S.; Withers, F.; Russo, S.; Craciun, M.F. Ultrahigh performance nanoengineered graphene-concrete composites for multifunctional applications. Adv. Funct. Mater. 2018, 28, 1705183. [Google Scholar] [CrossRef]

- Reddy, P.V.R.K.; Prasad, D.R. The role of graphene oxide in the strength and vibration characteristics of standard and high-grade cement concrete. J. Build. Eng. 2023, 63, 105481. [Google Scholar] [CrossRef]

- Chetty, K.; Watson, M.; Raine, T.; McGurgan, T.; Ladislaus, P.; Chen, J.; Zhang, S.; Lin, L.; Jiang, G. Enhancing concrete and mortar properties and durability using pristine graphene particles. Coatings 2022, 12, 1703. [Google Scholar] [CrossRef]

- Tay, R.Y.; Li, H.; Wang, H.; Lin, J.; Ng, Z.K.; Shivakumar, R.; Bolker, A.; Shakerzadeh, M.; Tsang, S.H.; Teo, E.H.T. Advanced nano boron nitride architectures: Synthesis, properties and emerging applications. Nano Today 2023, 53, 102011. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Narayanan, T.N.; Hashim, D.P.; Sakhavand, N.; Shahsavari, R.; Vajtai, R.; Ajayan, P.M. Hexagonal boron nitride and graphite oxide reinforced multifunctional porous cement composites. Adv. Funct. Mater. 2013, 23, 5624–5630. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Thomas, C.M.; Maglogianni, M.E.; Hersam, M.C.; Konsta-Gdoutos, M.S. Functionalized hexagonal boron nitride nanoplatelets for advanced cementitious nanocomposites. Cem. Concr. Compos. 2023, 141, 105127. [Google Scholar] [CrossRef]

- Balendran, R.V.; Martin-Buades, W.H. The influence of high temperature curing on the compressive, tensile and flexural strength of pulverized fuel ash concrete. Build. Environ. 2000, 35, 415–423. [Google Scholar] [CrossRef]

- Kress, N. The use of coal fly ash in concrete for marine artificial reefs in the southeastern mediterranean: Compressive strength, sessile biota, and chemical composition. ICES J. Mar. Sci. 2002, 59, S231–S237. [Google Scholar] [CrossRef][Green Version]

- Nazeer, M.; Kapoor, K.; Singh, S.P. Strength, durability and microstructural investigations on pervious concrete made with fly ash and silica fume as supplementary cementitious materials. J. Build. Eng. 2023, 69, 106275. [Google Scholar] [CrossRef]

- Peng, H.; Yin, J.; Song, W. Mechanical and hydraulic behaviors of eco-friendly pervious concrete incorporating fly ash and blast furnace slag. Appl. Sci. 2018, 8, 859. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Long term mechanical performance of nano-engineered high volume fly ash concrete. J. Build. Eng. 2021, 43, 103168. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Wang, W.; Li, W.; Gong, Y. Laboratory evaluation of eco-friendly pervious concrete pavement material containing silica fume. Appl. Sci. 2019, 9, 73. [Google Scholar] [CrossRef]

- Tang, C.; Cheng, C.; Ean, L. Mix design and engineering properties of fiber-reinforced pervious concrete using lightweight aggregates. Appl. Sci. 2022, 12, 524. [Google Scholar] [CrossRef]

- Chen, S.; Xing, C.; Zhao, M.; Zhang, J.; Wang, L.; He, Q. Recycled aggregate pervious concrete: Analysis of influence of water-cement ratio and fly ash under single action and optimal design of mix proportion. J. Renew. Mater. 2022, 10, 799–819. [Google Scholar] [CrossRef]

- Yan, X.; Wang, X.; Sun, C.; Xin, M.; He, J. Performance analysis and admixture optimization of gbfs-hpmc/fiber pervious concrete. Materials 2023, 16, 6455. [Google Scholar] [CrossRef]

- 28. GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Standard of the People’s Republic of China: Beijing, China, 2002.

- Lin, Y.; Williams, T.V.; Xu, T.; Cao, W.; Elsayed-Ali, H.E.; Connell, J.W. Aqueous dispersions of few-layered and monolayered hexagonal boron nitride nanosheets from sonication-assisted hydrolysis: Critical role of water. J. Phys. Chem. C 2011, 115, 2679–2685. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Zhu, P.; Li, H.; Ling, Q.; Asghar, H.K.; Gang, L.; Jun, W.Z.; Frank, C.; Dan, L.; Wen, H.D.; Ming, C.W. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Dilbas, H.; Çakır, Ö. Influence of basalt fiber on physical and mechanical properties of treated recycled aggregate concrete. Constr. Build. Mater. 2020, 254, 119216. [Google Scholar] [CrossRef]

- Fang, S.; Hong, H.; Zhang, P. Mechanical property tests and strength formulas of basalt fiber reinforced recycled aggregate concrete. Materials 2018, 11, 1851. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, X.; Wang, Y.; Fan, C.; Sang, A.; Fan, L.; Hao, S.; Yan, Z. Significance analysis of the factors influencing the strength of the frozen soil-structure interface and their interactions in different phase transition zones. Case Stud. Therm. Eng. 2023, 50, 103475. [Google Scholar] [CrossRef]

- Newbury, D.E.; Ritchie, N.W.M. Performing elemental microanalysis with high accuracy and high precision by scanning electron microscopy/silicon drift detector energy-dispersive x-ray spectrometry (SEM/SDD-EDS). J. Mater. Sci. 2015, 50, 493–518. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.J.; Ishida, T.; Cho, W.J. Characteristics of micro structure and strength development of alkali activated GGBS-FNS hybrid cement. Constr. Build. Mater. 2023, 408, 133773. [Google Scholar] [CrossRef]

- Chen, X.; Wang, G.; Dong, Q.; Zhao, X.; Wang, Y. Microscopic characterizations of pervious concrete using recycled steel slag aggregate. J. Clean. Prod. 2020, 254, 120149. [Google Scholar] [CrossRef]

- Yao, Y.; Xu, G.; Wu, M.; Zhao, M. Exploring the influence of cement and cement hydration products on strength and interfacial adhesion in emulsified cold recycled mixture: A molecular dynamics and experimental investigation. Constr. Build. Mater. 2023, 409, 134050. [Google Scholar] [CrossRef]

- Yun, J.; Zhao, C.; Li, X.; Zhang, W.; Liu, H.; Liu, B. Rheological properties and early mechanical strength of oil-well cement modified by hybrid nano-silica and nano-hexagonal boron nitride. Constr. Build. Mater. 2022, 356, 129291. [Google Scholar] [CrossRef]

- Liu, J.; Jian, W.; Lau, D. Boron nitride nanosheet as a promising reinforcement for cementitious composites. Appl. Surf. Sci. 2022, 572, 151395. [Google Scholar] [CrossRef]

- Zuo, K.; Zhang, X.; Huang, X.; Oliveira, E.F.; Guo, H.; Zhai, T.; Wang, W.; Alvarez, P.J.J.; Elimelech, M.; Ajayan, P.M.; et al. Ultrahigh resistance of hexagonal boron nitride to mineral scale formation. Nat. Commun. 2022, 13, 4523. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Cheng, X.; Zhu, J.; Jiang, D.; Sun, H.; Liu, S. Experimental study on the performance of basalt fiber modified pervious concrete based on entropy method. Adv. Mater. Sci. Eng. 2022, 2022, 6705354. [Google Scholar] [CrossRef]

- Hari, R.; Mini, K.M. Mechanical and durability properties of basalt-steel wool hybrid fibre reinforced pervious concrete—A box Behnken approach. J. Build. Eng. 2023, 70, 106307. [Google Scholar] [CrossRef]

| Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Fracture Strength (MPa) | Elastic Modulus (GPa) | Fracture Elongation (%) |

|---|---|---|---|---|---|

| 18 | 2.7 | 4200 | 3200 | 89 | 3.2 |

| Property | Specific Surface Area (m2/g) | Tap Density (g/cm3) | Particle Size (μm) | Moisture Content (%) | Carbon Content (%) |

|---|---|---|---|---|---|

| Standard Value | <1.00 | 0.3–0.5 | 5.00–8.00 | <0.50 | <0.0400 |

| Actual Value | 0.95 | 0.42 | 7.04 | 0.41 | 0.0235 |

| Mix Number | Weight of Ingredients (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Cement | Water | Silica Fume | Fly Ash | Water-Reducing Agent | h-BN | |

| S-0-0-2 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 0 |

| BN-1 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 0.25 |

| BN-2 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 0.31 |

| BN-3 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 0.37 |

| Mix Number | Weight of Ingredients (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Cement | Water | Silica Fume | Fly Ash | Water-Reducing Agent | BF | |

| S-0-0-2 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 0 |

| BF-1 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 2.28 |

| BF-2 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 4.56 |

| BF-3 | 1528.8 | 80.5 | 304 | 91.2 | 16 | 30.4 | 4.56 | 6.84 |

| Mix Number | Weight of Ingredients (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Cement | Water | Silica Fume | Fly Ash | BF | h-BN | |

| S-0-0-2 | 1528.8 | 80.5 | 304 | 95.76 | 16 | 30.4 | 0 | 0 |

| Q-1-1-1 | 1528.8 | 80.5 | 304 | 95.76 | 16 | 15.2 | 2.28 | 0.25 |

| Q-2-2-1 | 1528.8 | 80.5 | 304 | 95.76 | 16 | 15.2 | 4.56 | 0.31 |

| Q-3-3-1 | 1528.8 | 80.5 | 304 | 95.76 | 16 | 15.2 | 6.84 | 0.37 |

| Q-1-2-2 | 1528.8 | 80.5 | 304 | 100.32 | 16 | 30.4 | 4.56 | 0.25 |

| Q-2-3-2 | 1528.8 | 80.5 | 304 | 100.32 | 16 | 30.4 | 6.84 | 0.31 |

| Q-3-1-2 | 1528.8 | 80.5 | 304 | 100.32 | 16 | 30.4 | 2.28 | 0.37 |

| Q-1-3-3 | 1528.8 | 80.5 | 304 | 104.88 | 16 | 45.6 | 6.84 | 0.25 |

| Q-2-1-3 | 1528.8 | 80.5 | 304 | 104.88 | 16 | 45.6 | 2.28 | 0.31 |

| Q-3-2-3 | 1528.8 | 80.5 | 304 | 104.88 | 16 | 45.6 | 4.56 | 0.37 |

| Content/% | Compressive Strength/MPa | Flexural Strength/MPa | Porosity/% | Permeability Coefficient/(mm/s) | ||||

|---|---|---|---|---|---|---|---|---|

| 7 d | 28 d | 7 d | 28 d | 7 d | 28 d | 7 d | 28 d | |

| 0 | 13.7 | 18.7 | 3.22 | 4.32 | 11.0 | 11.5 | 3.43 | 3.58 |

| 0.08 | 15.9 | 21.5 | 4.02 | 4.68 | 14.8 | 15.1 | 4.23 | 4.34 |

| 0.10 | 16.9 | 22.2 | 3.71 | 4.65 | 12.9 | 13.5 | 3.89 | 4.01 |

| 0.12 | 17.7 | 22.6 | 3.64 | 4.30 | 11.5 | 11.8 | 3.54 | 3.72 |

| Content/% | Compressive Strength/MPa | Flexural Strength/MPa | Porosity/% | Permeability Coefficient/(mm/s) | ||||

|---|---|---|---|---|---|---|---|---|

| 7 d | 28 d | 7 d | 28 d | 7 d | 28 d | 7 d | 28 d | |

| 0 | 13.7 | 18.7 | 3.22 | 4.32 | 11.0 | 11.5 | 3.43 | 3.58 |

| 0.75 | 20.9 | 23.6 | 3.96 | 4.83 | 16.1 | 16.9 | 4.81 | 5.34 |

| 1.50 | 17.9 | 22.3 | 3.51 | 4.52 | 12.3 | 12.9 | 3.56 | 4.34 |

| 2.25 | 13.8 | 18.9 | 3.47 | 4.43 | 15.6 | 16.1 | 4.63 | 5.05 |

| Group | Compressive Strength (MPa) | Flexural Strength (MPa) | Porosity (%) | Permeability Coefficient (mm/s) |

|---|---|---|---|---|

| S-0-0-2 | 18.7 | 4.32 | 11.5 | 3.58 |

| 1. Q-1-1-1 | 22.3 | 4.76 | 10.6 | 3.47 |

| 2. Q-2-2-1 | 23.4 | 4.23 | 11.9 | 4.26 |

| 3. Q-3-3-1 | 21.8 | 4.46 | 14.8 | 4.64 |

| 4. Q-1-2-2 | 22.7 | 4.51 | 16.6 | 4.53 |

| 5. Q-2-3-2 | 22.9 | 4.95 | 17.0 | 4.87 |

| 6. Q-3-1-2 | 20.2 | 4.72 | 10.4 | 3.61 |

| 7. Q-1-3-3 | 22.8 | 5.17 | 18.5 | 5.09 |

| 8. Q-2-1-3 | 22.6 | 5.07 | 10.2 | 3.42 |

| 9. Q-3-2-3 | 21.5 | 4.53 | 15.4 | 4.53 |

| Test Metrics | Element | K1 | K2 | K3 | R |

|---|---|---|---|---|---|

| Compressive strength (MPa) | Fly ash | 22.50 | 21.93 | 22.30 | 0.57 |

| h-BN | 22.60 | 22.97 | 21.17 | 1.80 | |

| BF | 21.70 | 22.53 | 22.50 | 0.83 | |

| Flexural strength (MPa) | Fly ash | 4.48 | 4.73 | 4.92 | 0.44 |

| h-BN | 4.81 | 4.75 | 4.57 | 0.24 | |

| BF | 4.85 | 4.42 | 4.86 | 0.44 | |

| Porosity (%) | Fly ash | 12.43 | 14.67 | 14.70 | 2.27 |

| h-BN | 15.23 | 13.03 | 13.53 | 2.20 | |

| BF | 10.4 | 14.63 | 16.77 | 6.37 | |

| Permeability coefficient (mm/s) | Fly ash | 4.12 | 4.34 | 4.35 | 0.22 |

| h-BN | 4.36 | 4.18 | 4.26 | 0.18 | |

| BF | 3.50 | 4.44 | 4.87 | 1.37 |

| Performance Indicator | Item | Degree of Freedom | Sum of Squares | Mean Square | F | p | Significance |

|---|---|---|---|---|---|---|---|

| Compressive strength (MPa) | Fly ash | 2 | 0.496 | 0.248 | 6.027 | 0.142 | - |

| h-BN | 2 | 5.429 | 2.714 | 66.027 | 0.015 | ** | |

| BF | 2 | 1.336 | 0.668 | 16.243 | 0.058 | * | |

| Flexural strength (MPa) | Fly ash | 2 | 0.291 | 0.146 | 43.148 | 0.023 | ** |

| h-BN | 2 | 0.096 | 0.048 | 14.155 | 0.066 | * | |

| BF | 2 | 0.373 | 0.186 | 55.188 | 0.018 | ** | |

| Porosity (%) | Fly ash | 2 | 10.127 | 5.063 | 12.25 | 0.075 | * |

| h-BN | 2 | 7.98 | 3.99 | 9.653 | 0.094 | * | |

| BF | 2 | 63.007 | 31.503 | 76.218 | 0.013 | ** | |

| Permeability coefficient (mm/s) | Fly ash | 2 | 0.095 | 0.048 | 3.847 | 0.206 | - |

| h-BN | 2 | 0.049 | 0.024 | 1.972 | 0.336 | - | |

| BF | 2 | 2.933 | 1.467 | 118.177 | 0.008 | *** |

| Element | Weight/% | Atomic/% | Error Rate/% |

|---|---|---|---|

| O | 56.71 | 73.77 | 9.03 |

| Al | 3.64 | 2.81 | 22.59 |

| Si | 11.60 | 8.60 | 12.15 |

| S | 1.97 | 1.28 | 65.50 |

| Ca | 26.07 | 13.54 | 12.91 |

| Element | Weight/% | Atomic/% | Error Rate/% |

|---|---|---|---|

| N | 3.05 | 4.29 | 14.19 |

| O | 52.90 | 65.10 | 3.72 |

| Al | 0.74 | 0.54 | 13.29 |

| Si | 41.73 | 29.25 | 1.96 |

| B | 0.15 | 0.09 | 28.57 |

| S | 0.17 | 0.10 | 95.24 |

| Ca | 1.27 | 0.62 | 18.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, Q.; Yin, C. A Novel Pervious Concrete Improved by Hexagonal Boron Nitride and Basalt Fiber in Mechanical Properties, Permeability, and Micro-Mechanisms. Buildings 2024, 14, 778. https://doi.org/10.3390/buildings14030778

Zhan Q, Yin C. A Novel Pervious Concrete Improved by Hexagonal Boron Nitride and Basalt Fiber in Mechanical Properties, Permeability, and Micro-Mechanisms. Buildings. 2024; 14(3):778. https://doi.org/10.3390/buildings14030778

Chicago/Turabian StyleZhan, Qianqian, and Changjun Yin. 2024. "A Novel Pervious Concrete Improved by Hexagonal Boron Nitride and Basalt Fiber in Mechanical Properties, Permeability, and Micro-Mechanisms" Buildings 14, no. 3: 778. https://doi.org/10.3390/buildings14030778

APA StyleZhan, Q., & Yin, C. (2024). A Novel Pervious Concrete Improved by Hexagonal Boron Nitride and Basalt Fiber in Mechanical Properties, Permeability, and Micro-Mechanisms. Buildings, 14(3), 778. https://doi.org/10.3390/buildings14030778