Steel Beam-to-Column Friction Joint under a Column Loss Scenario

Abstract

1. Introduction

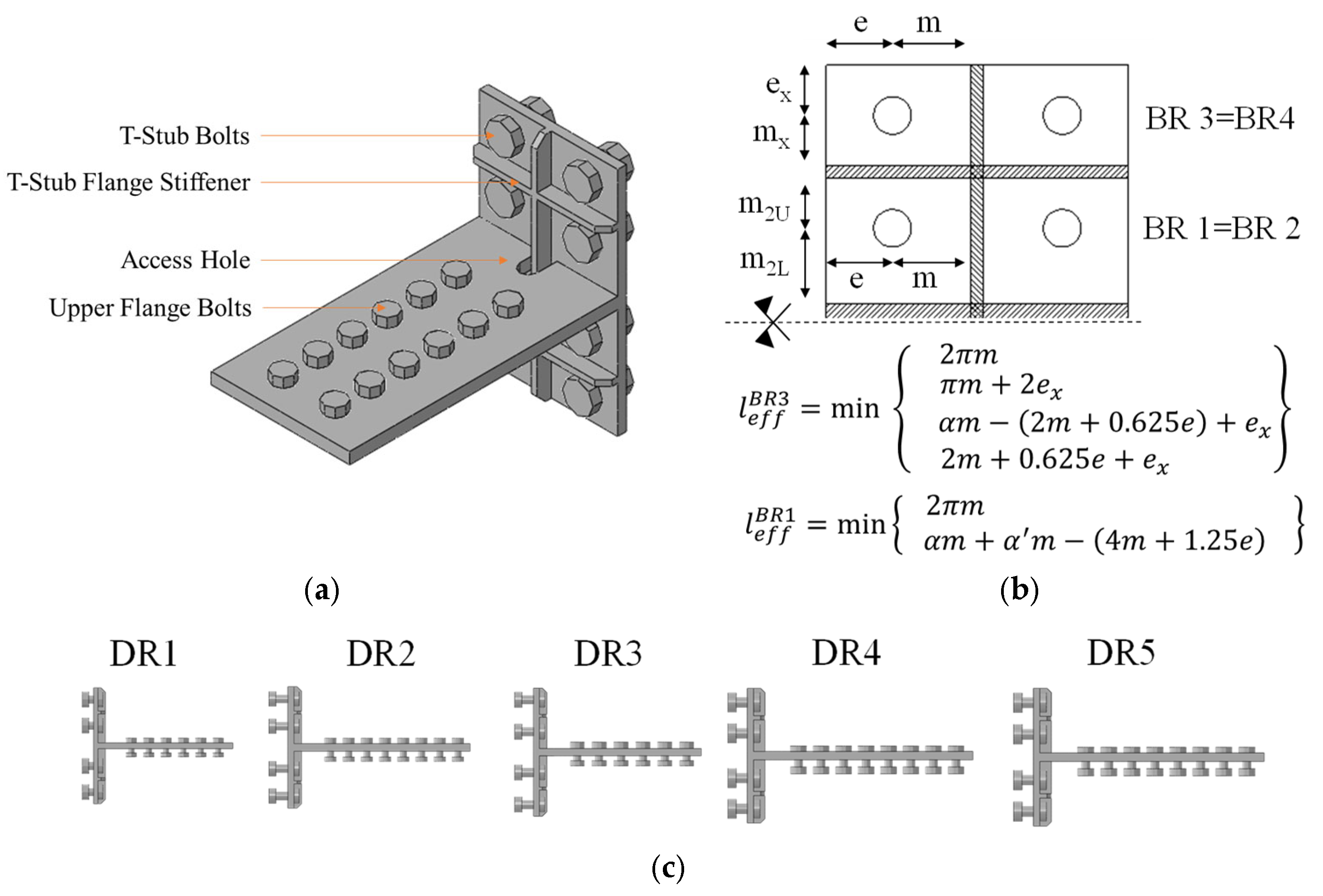

2. The Investigated Beam-to-Column Joints

2.1. The Seismically Prequalifed FREEDAM Joints

2.2. The Revised Detail to Enhance the Ductility of the Joint

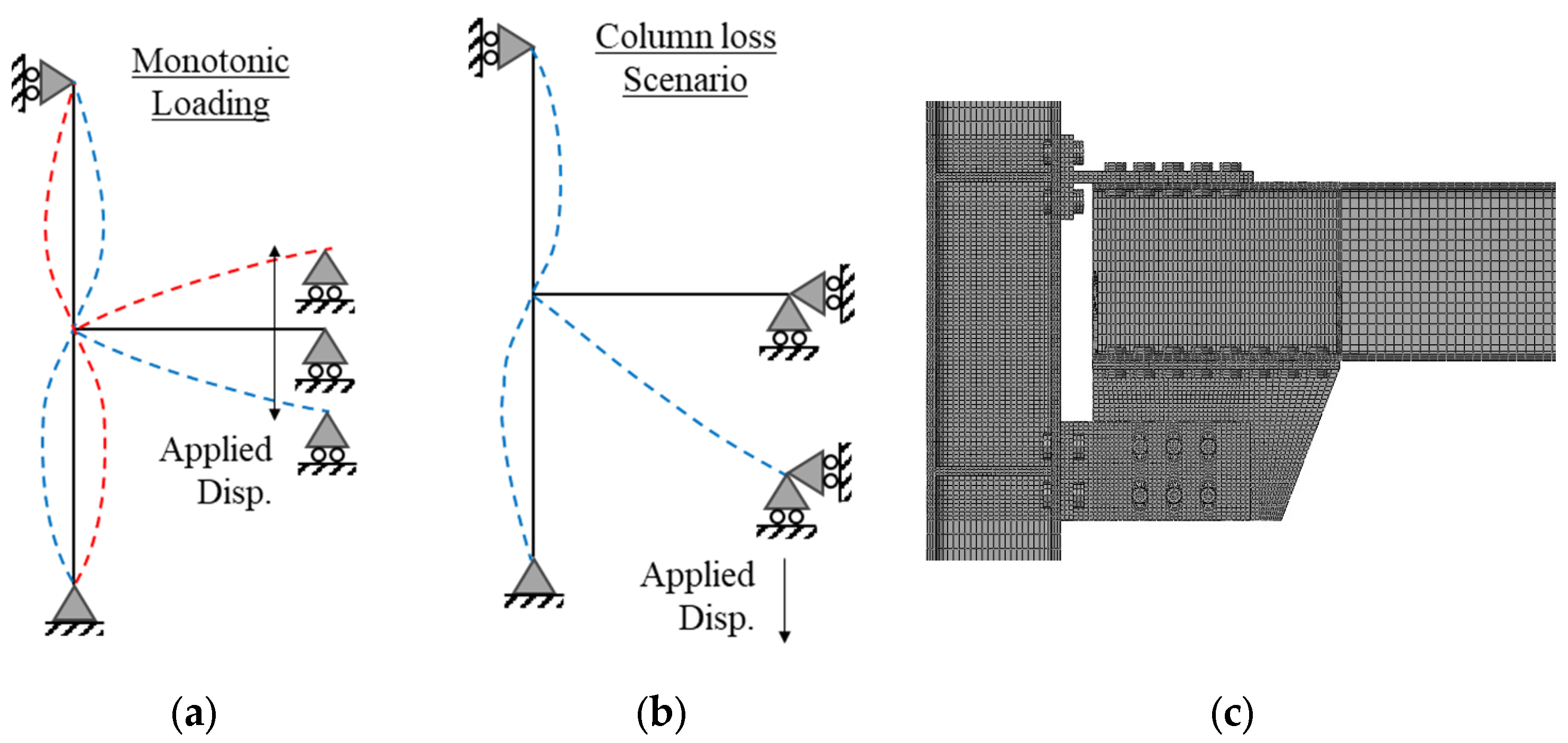

3. Finite-Element Modelling

3.1. Modelling Assumptions

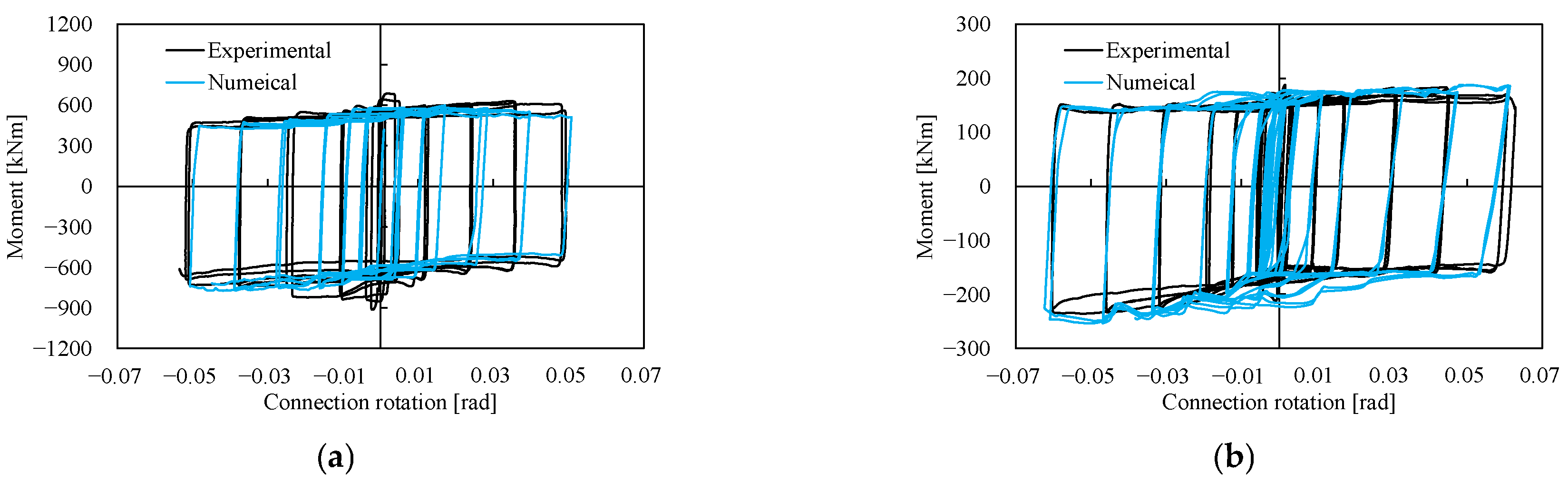

3.2. Validation of the FE Model

- Experimental specimen 1: with IPE 270 as beam and HE 220 M as column;

- Experimental specimen 2: with IPE 450 as beam and HE 500 B as column.

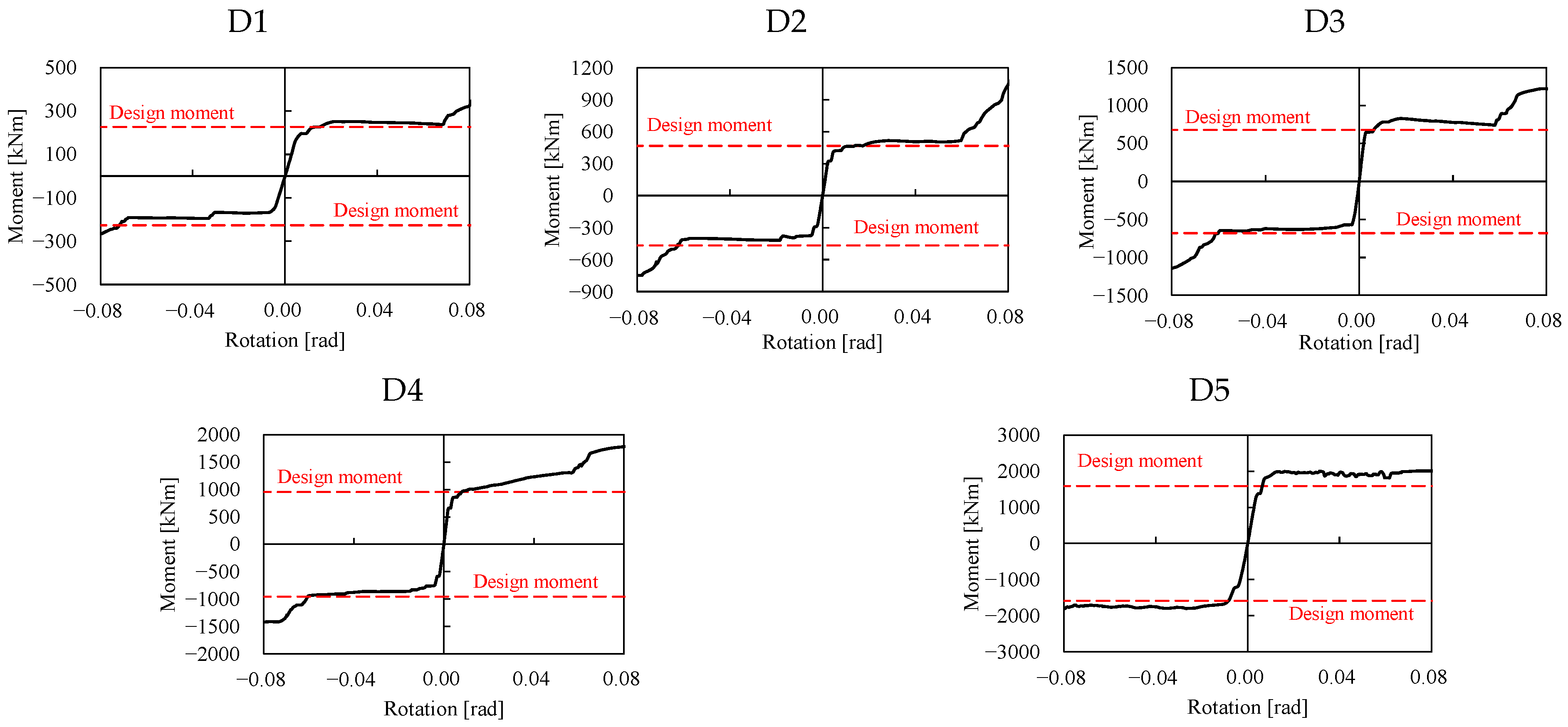

4. Results of Parametric FE Simulations

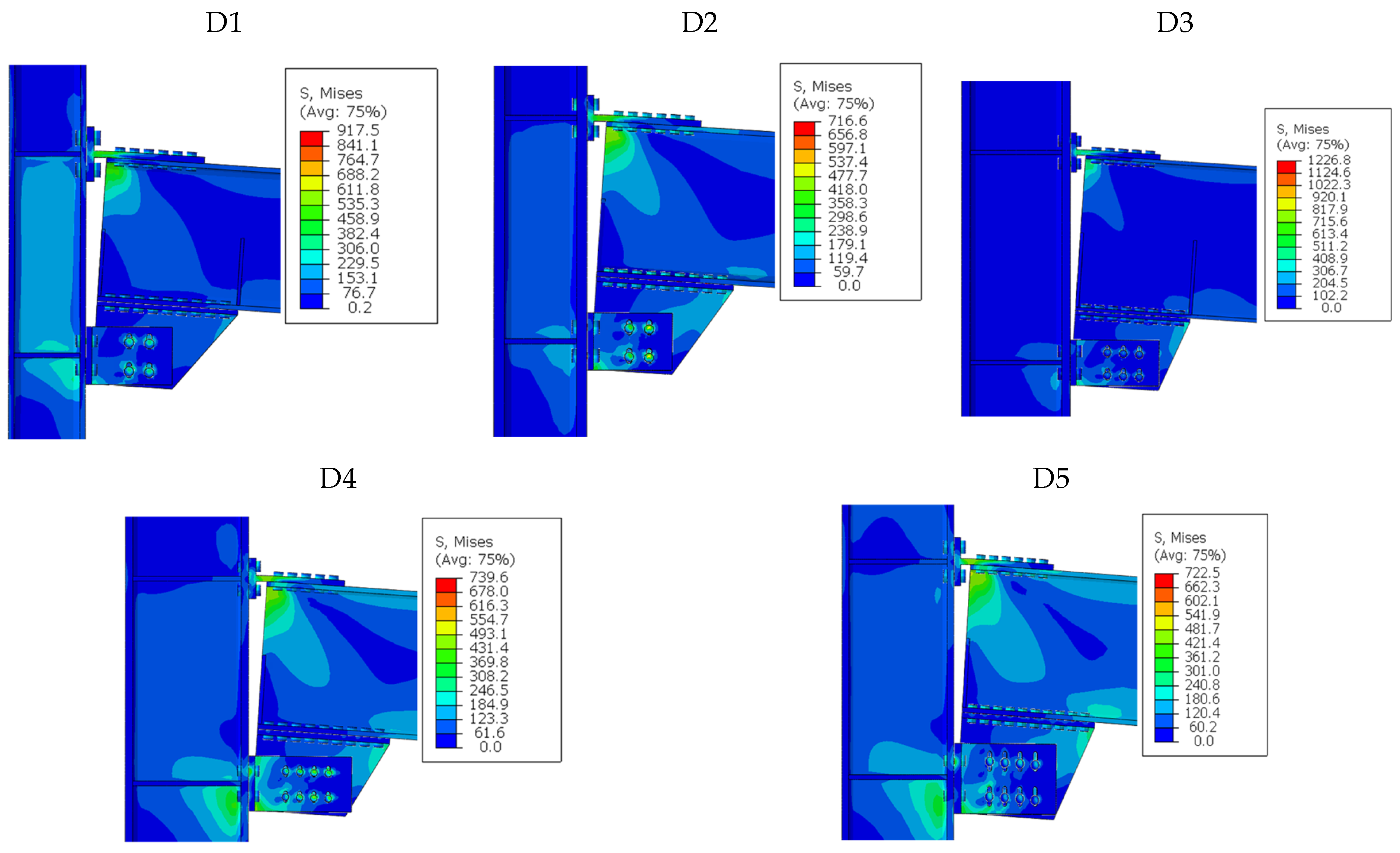

4.1. Performance of the Reference FREEDAM Joints

4.1.1. Response under Monotonic Loading

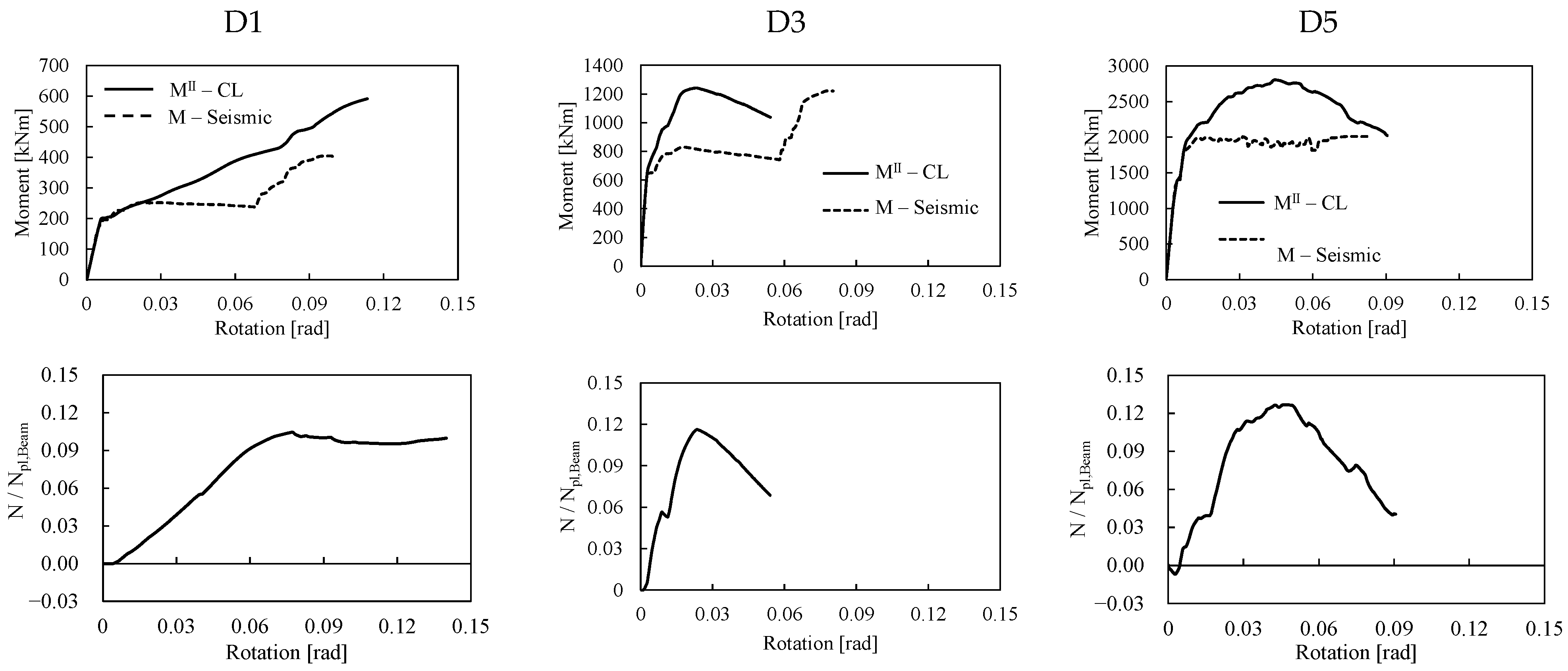

4.1.2. Response under Column Loss Scenario

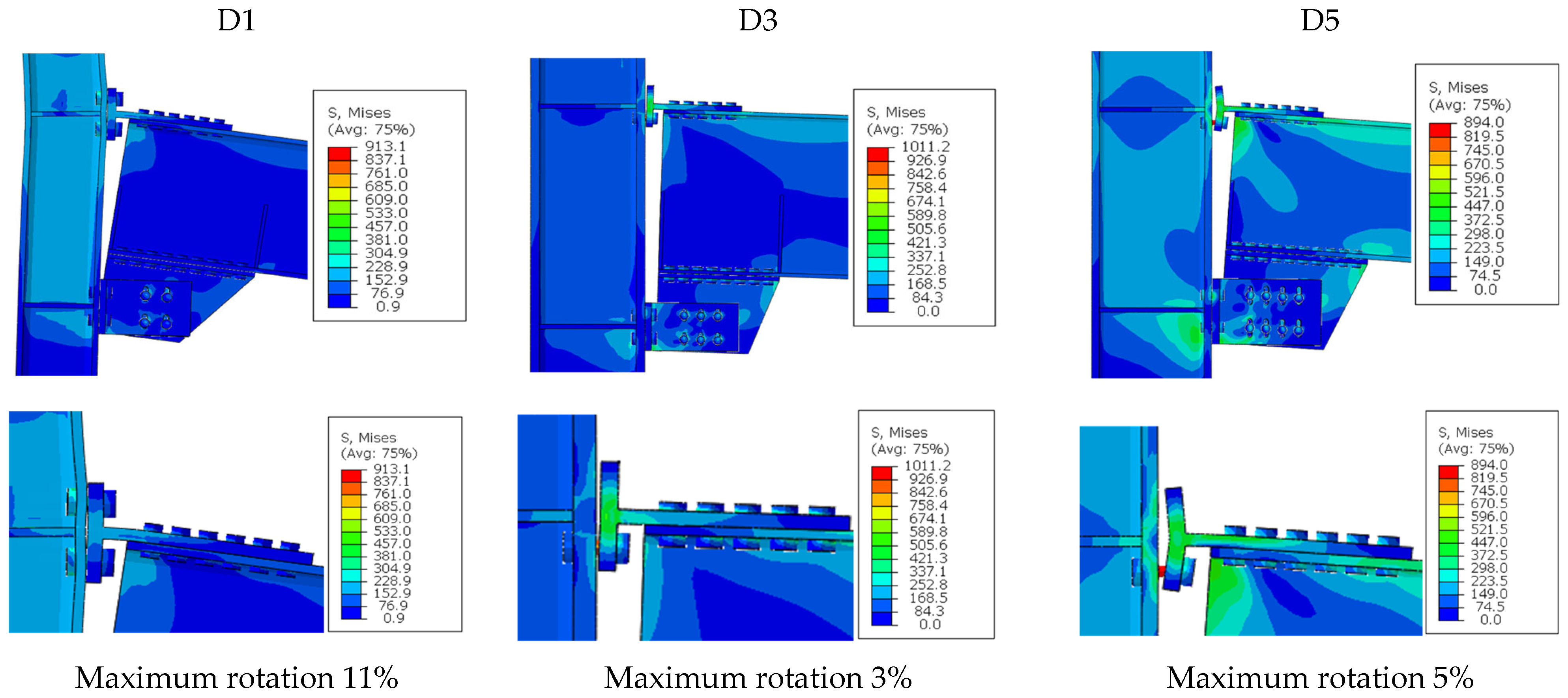

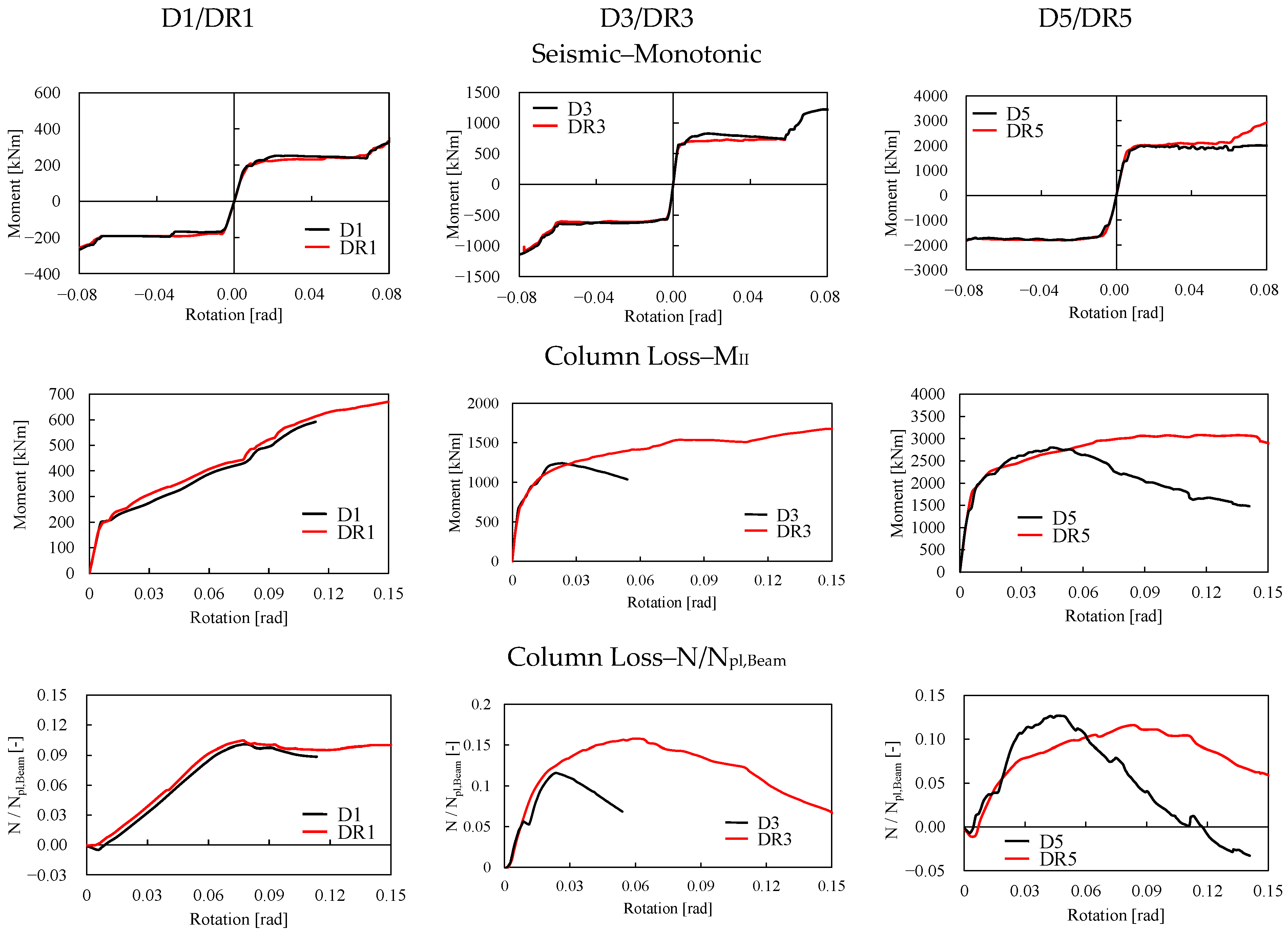

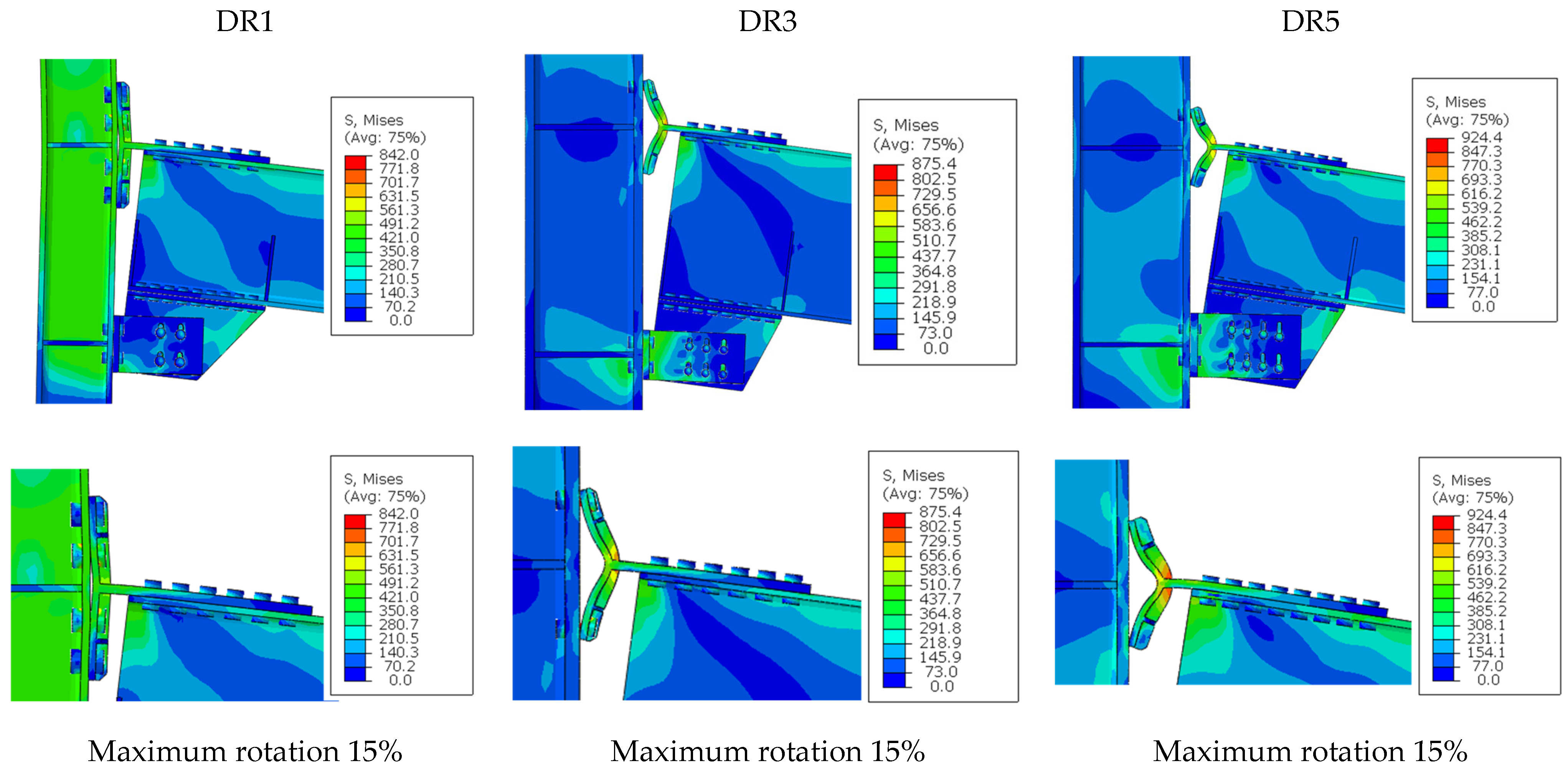

4.2. Performance of the Joints with the Enhanced Details

5. Conclusions

- Under column-loss loading conditions, the ductility of FREEDAM joints is limited by the brittle failure of the bolts of the upper T-stub connection. The catenary action developing in the beam induces significant tensile forces in the upper T-stub connection, which exceed the resistance of the bolts.

- To enhance the response of the joints, the details of the flange of the upper T-stub were ameliorated by introducing two additional bolt rows (one-per-side of the stem) and a grid of stiffeners to restrain the pattern of the yield line and to promote failure mode 1 of the flange.

- The finite-element analyses showed that the ductility and ultimate rotation of the joints with the designed details can exceed a rotation of 0.15 rad, thus substantially improving the response of the considered beam–column joints under column loss conditions.

- In the case of seismic-like loading, the response of the joints with the ameliorated details is substantially the same as the original FREEDAM joints.

- Additional experimental and numerical studies should be performed to assess the improvement of the contribution to the resisting mechanism of the additional bolt rows in the function of the local detailing of the stiffeners.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elghazouli, A.Y. Assessment of European seismic design procedures for steel framed structures. Bull. Earthq. Eng. 2010, 8, 65–89. [Google Scholar] [CrossRef]

- Nastri, E. Design and assessment of steel structures in seismic areas: Outcomes of the last Italian conference of steel structures. Ing. Sismica 2018, 35, 1–4. [Google Scholar]

- Tartaglia, R.; D’Aniello, M.; Landolfo, R. Seismic performance of Eurocode-compliant ductile steel MRFs. Earthq. Eng. Struct. Dyn. 2022, 51, 2527–2552. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Qiu, C.; Hu, S.; MacRae, G.A.; Eatherton, M.R. Seismic resilient steel structures: A review of research, practice, challenges and opportunities. J. Constr. Steel Res. 2022, 191, 107172. [Google Scholar] [CrossRef]

- Pampanin, S.; Ciurlanti, J.; Bianchi, S.; Perrone, D.; Granello, G.; Palmieri, M.; Grant, D.N.; Palermo, A.; Costa, A.C.; Candeias, P.X.; et al. Triaxial shake table testing of an integrated low-damage building system. Earthq. Eng. Struct. Dyn. 2023, 52, 2983–3007. [Google Scholar] [CrossRef]

- Lignos, D.G.; Paronesso, M. Low-damage steel structures for enhanced life-cycle seismic performance. Stahlbau 2022, 91, 315–325. [Google Scholar] [CrossRef]

- Grigorian, C.E.; Yang, T.S.; Popov, E.P. Slotted bolted connection energy dissipators. Earthq. Spectra 1993, 9, 491–504. [Google Scholar] [CrossRef]

- Butterworth, J.W.; Clifton, G.C. Performance of hierarchical friction dissipating joints in moment resisting steel frames. In Proceedings of the 12th World Conference on Earthquake Engineering (WCEE2000), Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Borzouie, J.; MacRae, G.A.; Chase, J. Cyclic performance of asymmetric friction connections with grade 10.9 bolts. Bridg. Struct. Eng. 2015, 45, 53–62. [Google Scholar]

- Khoo, H.-H.; Clifton, G.C.; Butterworth, J.; MacRae, G.A. Experimental study of full-scale self-centering sliding hinge joint connections with friction ring springs. J. Earthq. Eng. 2013, 17, 972–997. [Google Scholar] [CrossRef]

- Khoo, H.-H.; Clifton, G.C.; MacRae, G.A.; Zhou, H.; Ramhormozian, S. Proposed design models for the asymmetric friction connection. Earthq. Eng. Struct. Dyn. 2014, 44, 1309–1324. [Google Scholar] [CrossRef]

- Khoo, H.-H.; Clifton, G.C.; Butterworth, J.; MacRae, G.A.; Ferguson, G. Influence of steel shim hardness on the sliding hinge joint performance. J. Constr. Steel Res. 2012, 72, 119–129. [Google Scholar] [CrossRef]

- Khoo, H.-H.; Clifton, G.C.; Butterworth, J.; MacRae, G.A.; Gledhill, S.; Sidwell, G. Development of the self-centering Sliding Hinge Joint with friction ring springs. J. Constr. Steel Res. 2012, 78, 201–211. [Google Scholar] [CrossRef]

- MacRae, G.A.; MacKinven, H.; Clifton, G.C.; Walpole, W.; Butterworth, J. Tests of sliding hinge joints for steel moment frames. In Proceedings of the 8th Pacific Structural Steel Conference (PSSC2007), Waikarei, New Zealand, 13–16 March 2007. [Google Scholar]

- Lee, C.-H.; Ryu, J.; Oh, J.; Yoo, C.-H.; Ju, Y.K. Friction between a new low-steel composite material and milled steel for SAFE Dampers. Eng. Struct. 2016, 122, 279–295. [Google Scholar] [CrossRef]

- Lee, C.-H.; Kim, J.; Kim, D.-H.; Ryu, J.; Ju, Y.K. Numerical and experimental analysis of combined behavior of shear-type friction damper and non-uniform strip damper for multi-level seismic protection. Eng. Struct. 2016, 114, 75–92. [Google Scholar] [CrossRef]

- Zhai, Z.; Liu, Y.; Ma, Y.; Zhang, M.; Zhou, F. Seismic performance assessment of metal-friction hybrid damper linked steel frame considering extremely rare earthquakes. J. Build. Eng. 2024, 84, 108638. [Google Scholar] [CrossRef]

- Qian, H.; Ye, J.; Shi, Y.; Ye, Y.; Gao, J.; Deng, E. Development and investigation of a novel precast beam-column friction hinge joint enhanced with Cu–Al–Mn SMA-plate-based self-centring buckling-restrained devices. J. Build. Eng. 2023, 79, 107825. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, X.; Zhou, Q.; Guo, W.; Huang, W. Development and experimental validation of a novel friction-type energy dissipation steel truss. J. Constr. Steel Res. 2023, 211, 108150. [Google Scholar] [CrossRef]

- Piluso, V.; Rizzano, G.; Latour, M.; Francavilla, A.; Di Benedetto, S.; Landolfo, R.; D’Aniello, M.; Simoes da Silva, L.; Santiago, A.; Santos, A.; et al. Informative Documents of the Dissemination Project FREEDAM-PLUS. GA 899321-2020. Available online: https://www.steelconstruct.com/eu-projects/freedam-2/documents/ (accessed on 5 November 2023).

- Latour, M.; D’Aniello, M.; Zimbru, M.; Rizzano, G.; Piluso, V.; Landolfo, R. Removable friction dampers for low-damage steel beam-to-column joints. Soil Dyn. Earthq. Eng. 2018, 115, 66–81. [Google Scholar] [CrossRef]

- Ferrante Cavallaro, G.; Francavilla, A.; Latour, M.; Piluso, V.; Rizzano, G. Cyclic response of friction materials for low yielding connections using different friction materials. Soil Dyn. Earthq. Eng. 2018, 114, 404–423. [Google Scholar] [CrossRef]

- Latour, M.; Piluso, V.; Rizzano, G. Free from damage beam-to-column joints: Testing and design of DST connections with friction pads. Eng. Struct. 2015, 85, 219–233. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; Campiche, A.; Latour, M. Symmetric friction dampers in beam-to-column joints for low-damage steel MRFs. J. Constr. Steel Res. 2021, 184, 106791. [Google Scholar] [CrossRef]

- Tartaglia, R.; D’Aniello, M.; Landolfo, R. FREEDAM connections: Advanced finite element modelling. Ing. Sismica 2022, 39, 24–38. [Google Scholar]

- D’Antimo, M.; Latour, M.; Demonceau, J.F. Drop-weight impact tests on free from damage beam to column connections. J. Constr. Steel Res. 2022, 192, 107215. [Google Scholar] [CrossRef]

- D’Antimo, M.; Latour, M.; Rizzano, G.; Demonceau, J.F. Experimental and numerical assessment of steel beams under impact loadings. J. Constr. Steel Res. 2019, 158, 230–247. [Google Scholar] [CrossRef]

- Golea, T.; Tartaglia, R.; Latour, M.; D’Aniello, M.; Demonceau, J.F.; Landolfo, R.; Piluso, V. Design for robustness of a pilot building equipped with dissipative free from damage steel connections. In Proceedings of the 9th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering (COMPDYN2023), Athens, Greece, 12–14 June 2023. [Google Scholar]

- Golea, T.; Santos, A.F.; Jaspart, J.-P.; Latour, M.; Santiago, A.; Demonceau, J.-F. Design for robustness of steel structures with dissipative freedam joints. Ing. Sismica 2022, 39, 40–55. [Google Scholar]

- EN 1993-1-8; Design of Steel Structures—Part 1-8: Design of Joints. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- Latour, M.; Rizzano, G.; Santiago, A.; Da Silva, L.S. Experimental analysis and mechanical modeling of T-stubs with four bolts per row. J. Constr. Steel Res. 2014, 101, 158–174. [Google Scholar]

- Demonceau, J.F.; Jaspart, J.-P.; Weynand, K.; Oerder, R.; Müller, C. Connections with four bolts per horizontal row. In Proceedings of the 6th European Conference on Steel and Composite Structures (EUROSTEEL2011), Budapest, Hungary, 31 August–2 September 2011. [Google Scholar]

- SCI. Joints in Steel Construction—Moment Resisting Joints to Eurocode 3; Publication 398; The Steel Construction Institute (SCI): Berkshire, UK, 2013. [Google Scholar]

- Tartaglia, R.; D’Aniello, M.; Zimbru, M.; Landolfo, R. Finite element simulations on the ultimate response of extended stiffened end-plate joints. Steel Compos. Struct. 2018, 27, 727–745. [Google Scholar]

- Dassault. Abaqus 6.14—Abaqus Analysis User’s Manual; Dassault Systèmes Simulia Corp.: Johnston, RI, USA, 2014. [Google Scholar]

- EN 1993-1-1; Eurocode 3—Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- D’Aniello, M.; Cassiano, D.; Landolfo, R. Simplified criteria for finite element modelling of European preloadable bolts. Steel Compos. Struct. 2017, 24, 643–658. [Google Scholar]

| ID | Beam/Column | T-Stub | Friction Device | |||

|---|---|---|---|---|---|---|

| Bolts | Flange Thickness | Bolts | Lever Arm | m | ||

| [-] | [mm] | [-] | [mm] | [-] | ||

| D1 | IPE450/HE240B | 4 × M24 | 25 | 4 × M16 | 170 | 0.3 |

| D2 | IPE600/HE320M | 4 × M24 | 25 | 4 × M20 | 250 | 0.3 |

| D3 | IPE750 × 147/HE500M | 4 × M27 | 30 | 6 × M20 | 250 | 0.3 |

| D4 | IPE750 × 196+/HE650M | 4 × M30 | 40 | 8 × M20 | 250 | 0.3 |

| D5 | IPE750 × 196+/HE650M | 4 × M36 | 40 | 8 × M24 | 330 | 0.3 |

| ID | Beam/Column | T-Stub | |||

|---|---|---|---|---|---|

| Bolts | Flange Thickness | Thickness of the Stiffener | Depth of the Stiffener | ||

| [-] | [mm] | [mm] | [mm] | ||

| DR1 | IPE450/HE240B | 8 × M27 | 15 | 15 | 25 |

| DR2 | IPE600/HE320M | 8 × M27 | 20 | 15 | 25 |

| DR3 | IPE750 × 147/HE500M | 8 × M30 | 20 | 15 | 25 |

| DR4 | IPE750 × 196+/HE650M | 8 × M36 | 20 | 15 | 40 |

| DR5 | IPE750 × 196+/HE650M | 8 × M36 | 22 | 15 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tartaglia, R.; Carlevaris, R.; D’Aniello, M.; Landolfo, R. Steel Beam-to-Column Friction Joint under a Column Loss Scenario. Buildings 2024, 14, 784. https://doi.org/10.3390/buildings14030784

Tartaglia R, Carlevaris R, D’Aniello M, Landolfo R. Steel Beam-to-Column Friction Joint under a Column Loss Scenario. Buildings. 2024; 14(3):784. https://doi.org/10.3390/buildings14030784

Chicago/Turabian StyleTartaglia, Roberto, Roberto Carlevaris, Mario D’Aniello, and Raffaele Landolfo. 2024. "Steel Beam-to-Column Friction Joint under a Column Loss Scenario" Buildings 14, no. 3: 784. https://doi.org/10.3390/buildings14030784

APA StyleTartaglia, R., Carlevaris, R., D’Aniello, M., & Landolfo, R. (2024). Steel Beam-to-Column Friction Joint under a Column Loss Scenario. Buildings, 14(3), 784. https://doi.org/10.3390/buildings14030784