Effects of Shear Characteristics of Anchoring Interface on Bearing Performance of Fully Grouted Bolts Based on Variable Controlling Method

Abstract

:1. Introduction

2. Numerical Methodology

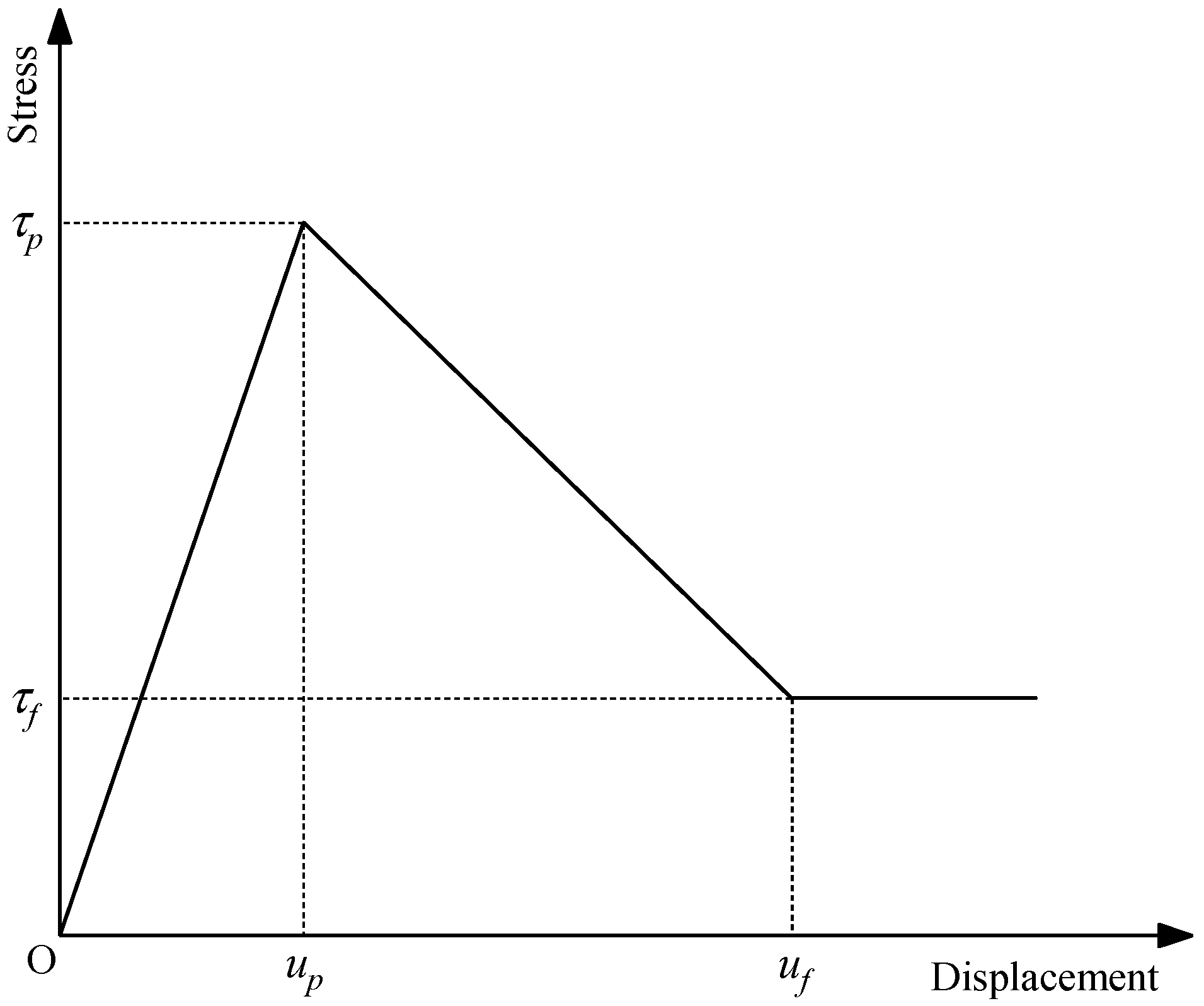

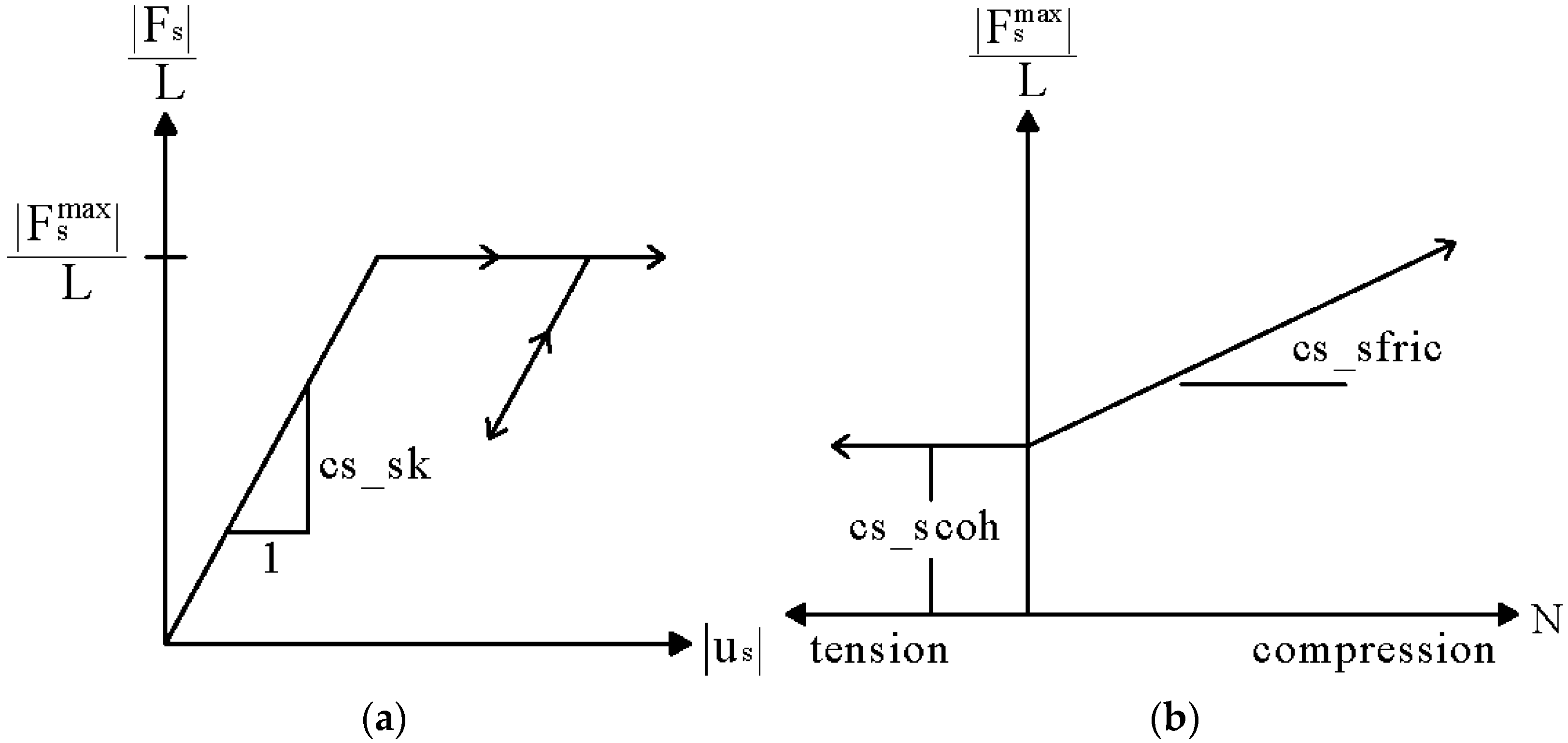

2.1. Realization of Mechanical Behavior of Anchorage Interface

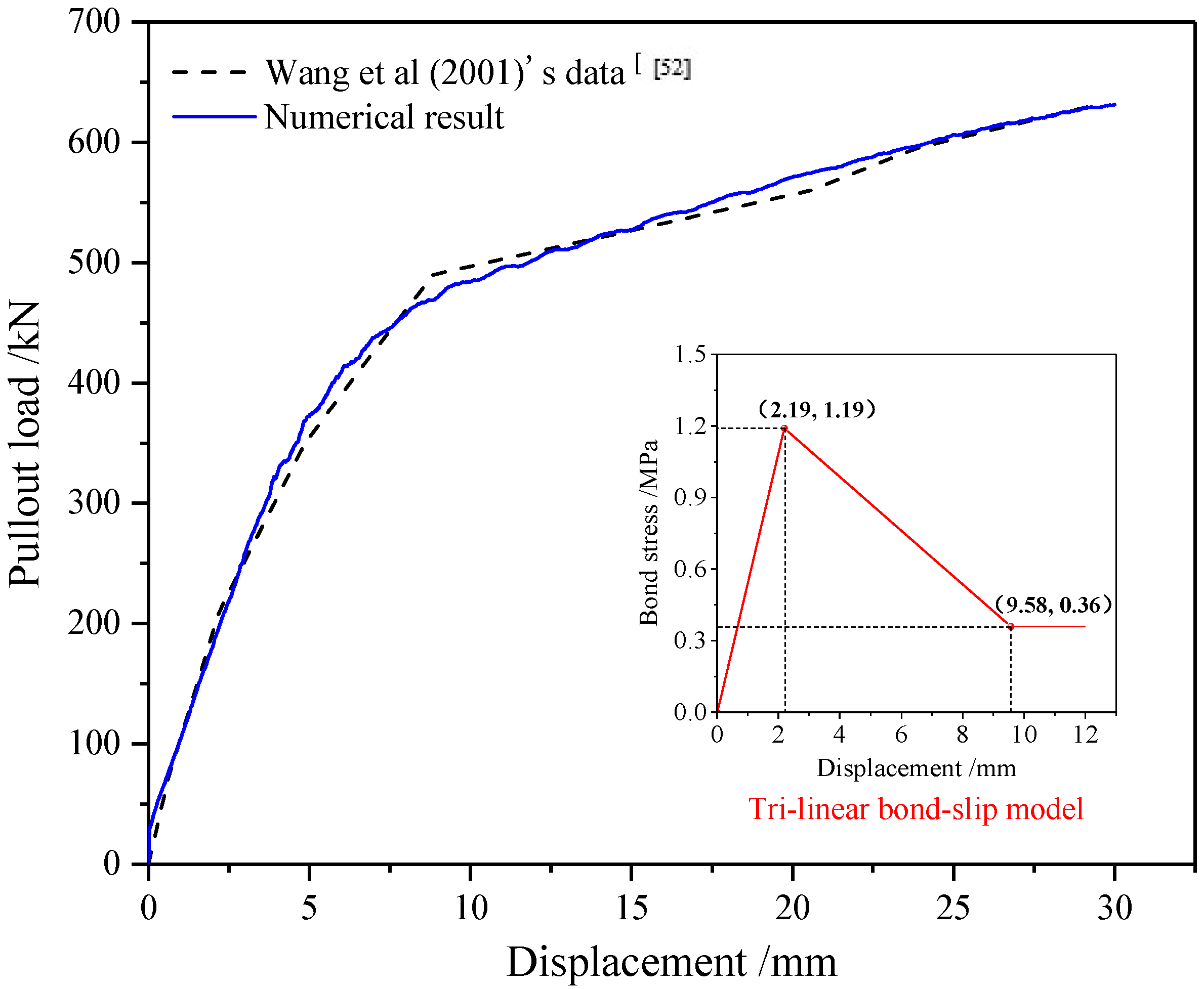

2.2. Model Verification

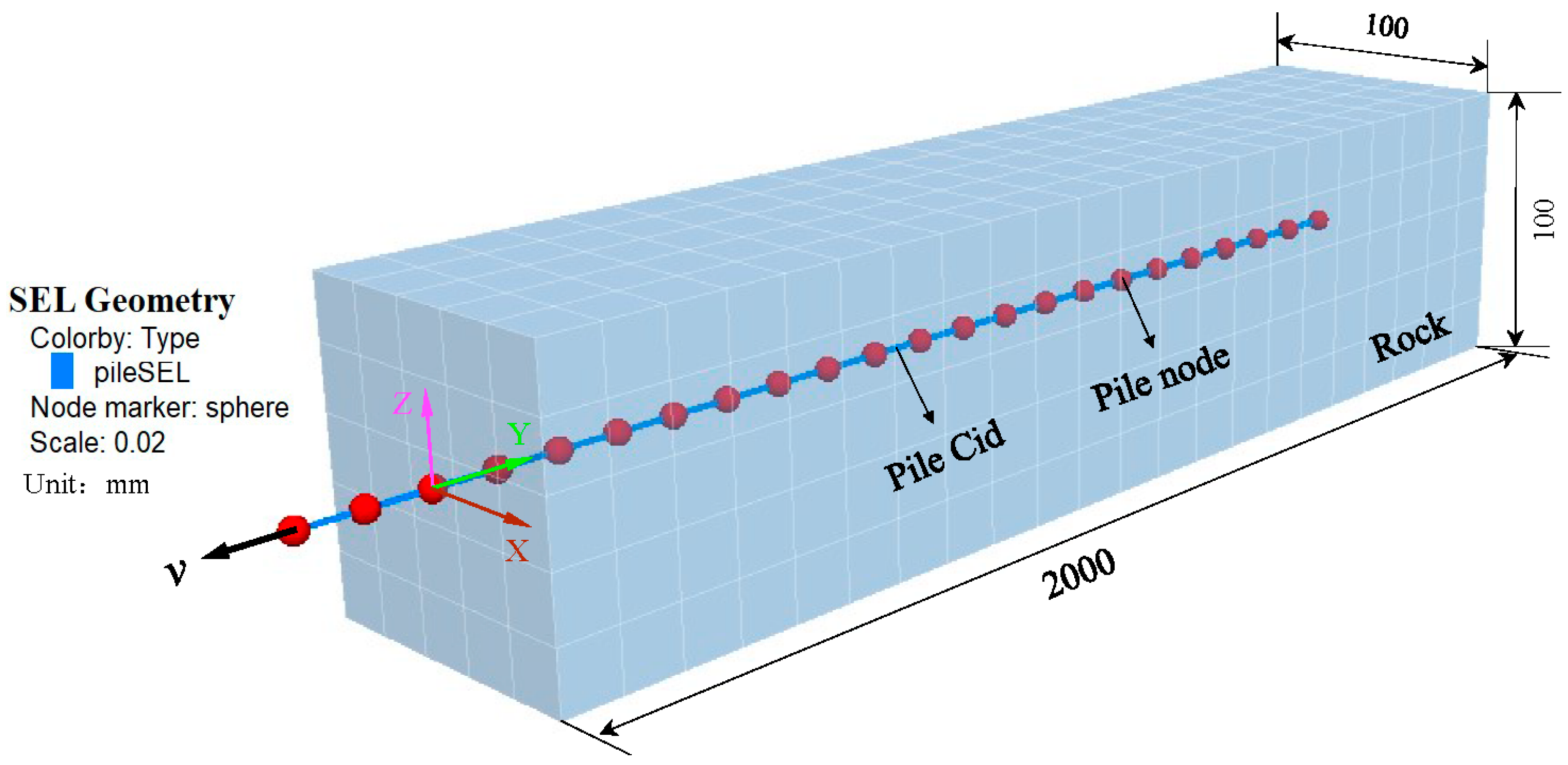

2.3. Pullout Calculation Model and Scheme Design

3. Parameters Analysis

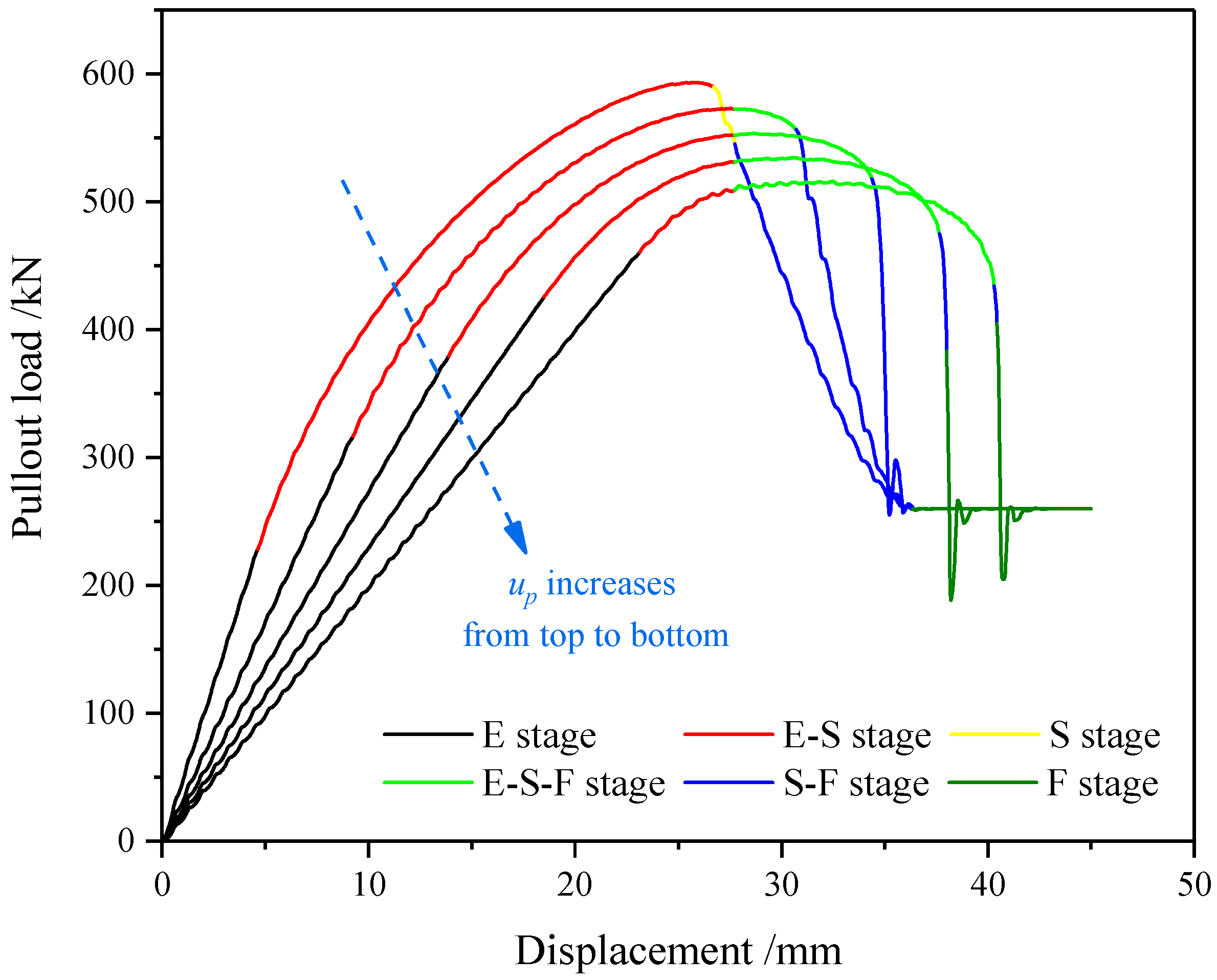

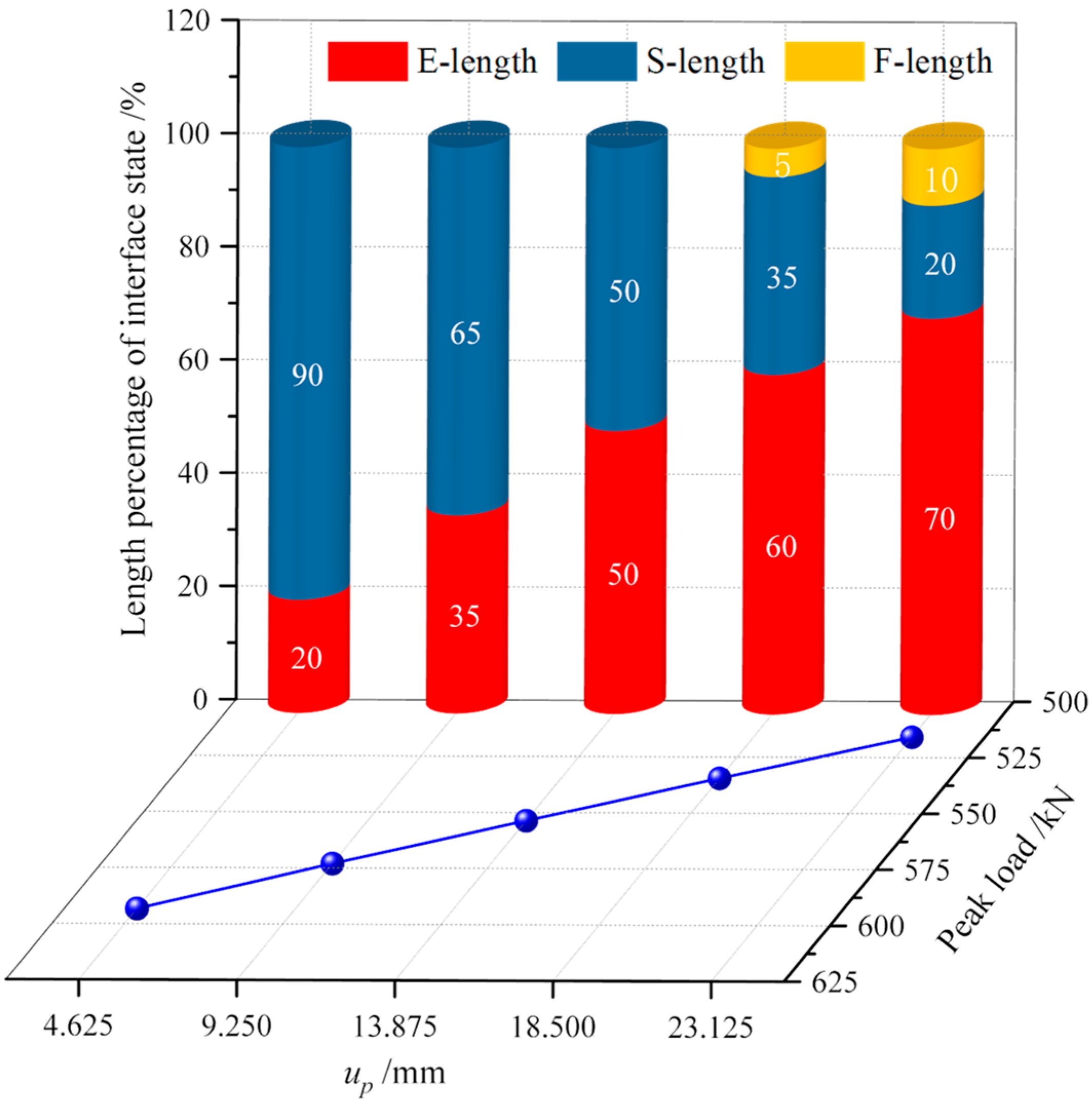

3.1. Displacement at Peak Bonding Stress

3.1.1. Bearing Properties Characteristic

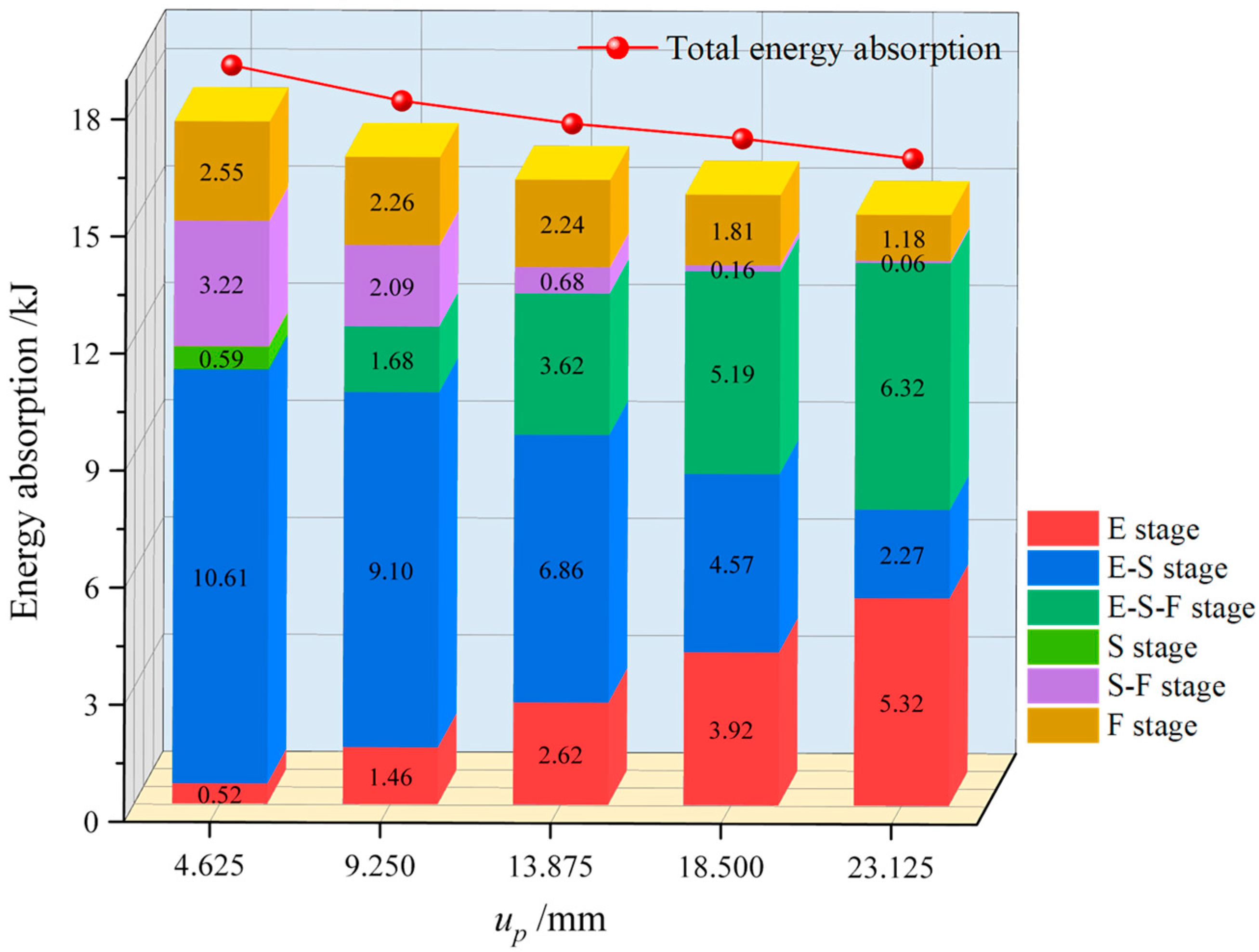

3.1.2. Energy Absorption Characteristic

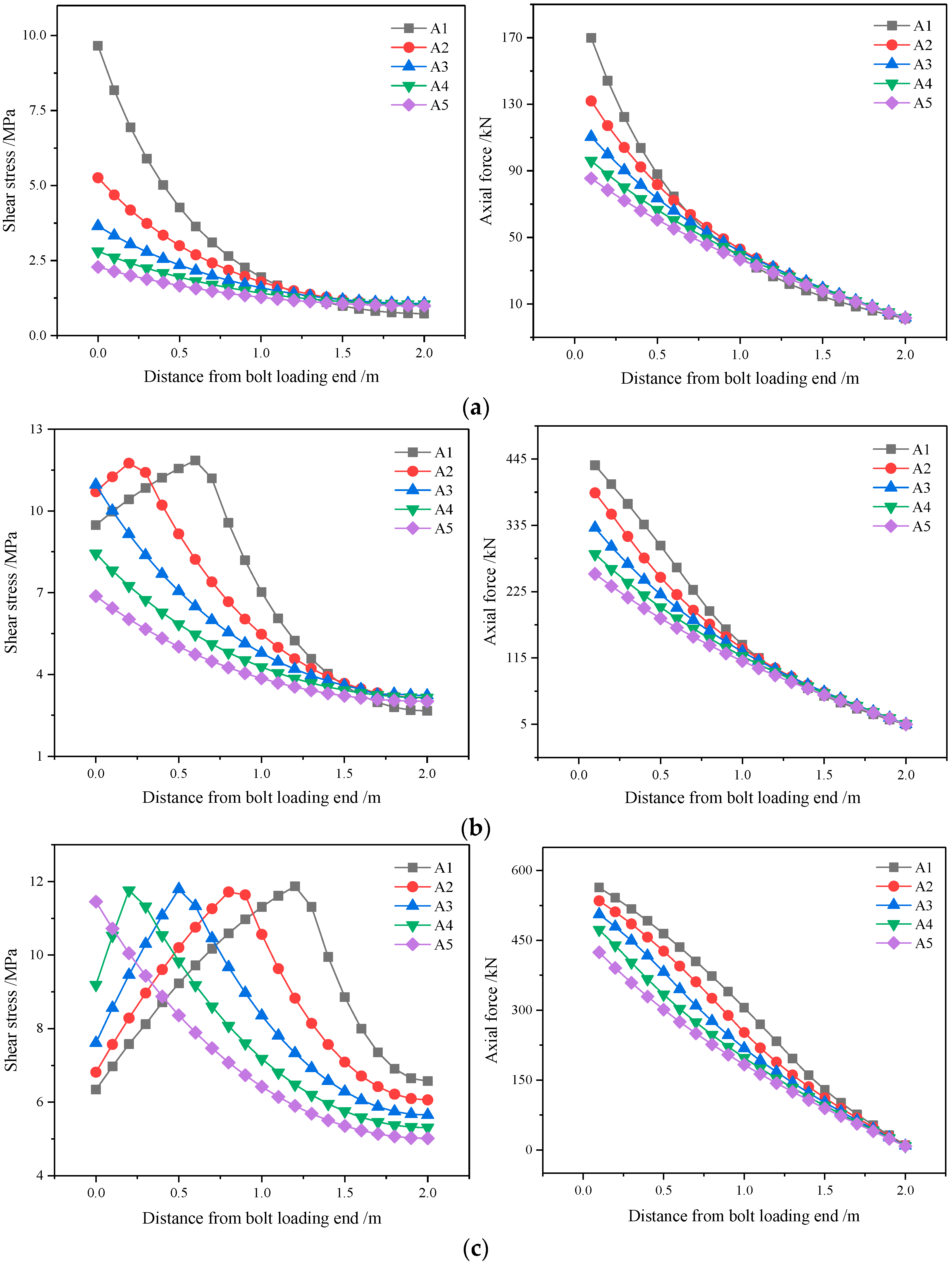

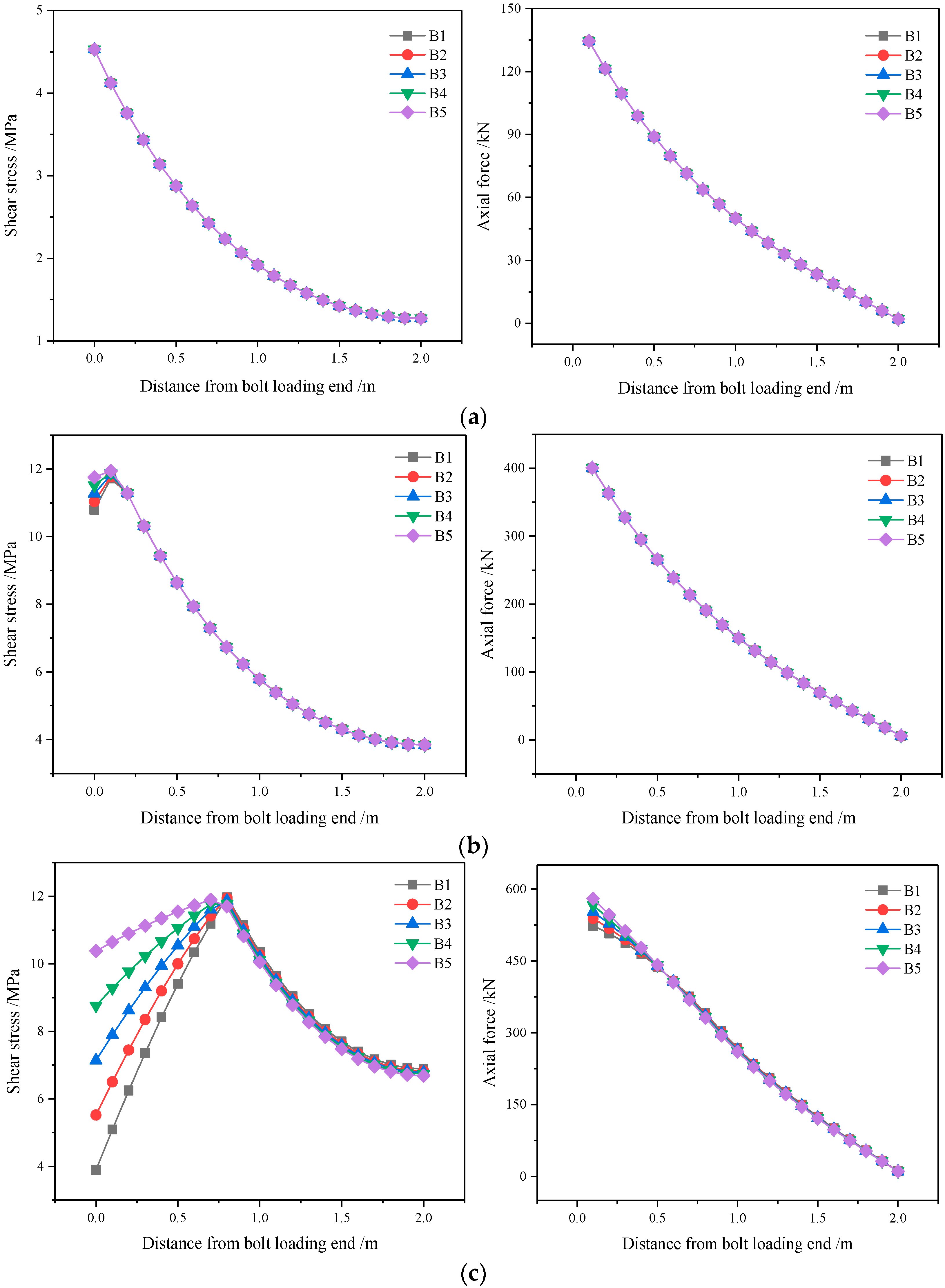

3.1.3. Stress Evolution Characteristic

3.2. Residual Bonding Stress

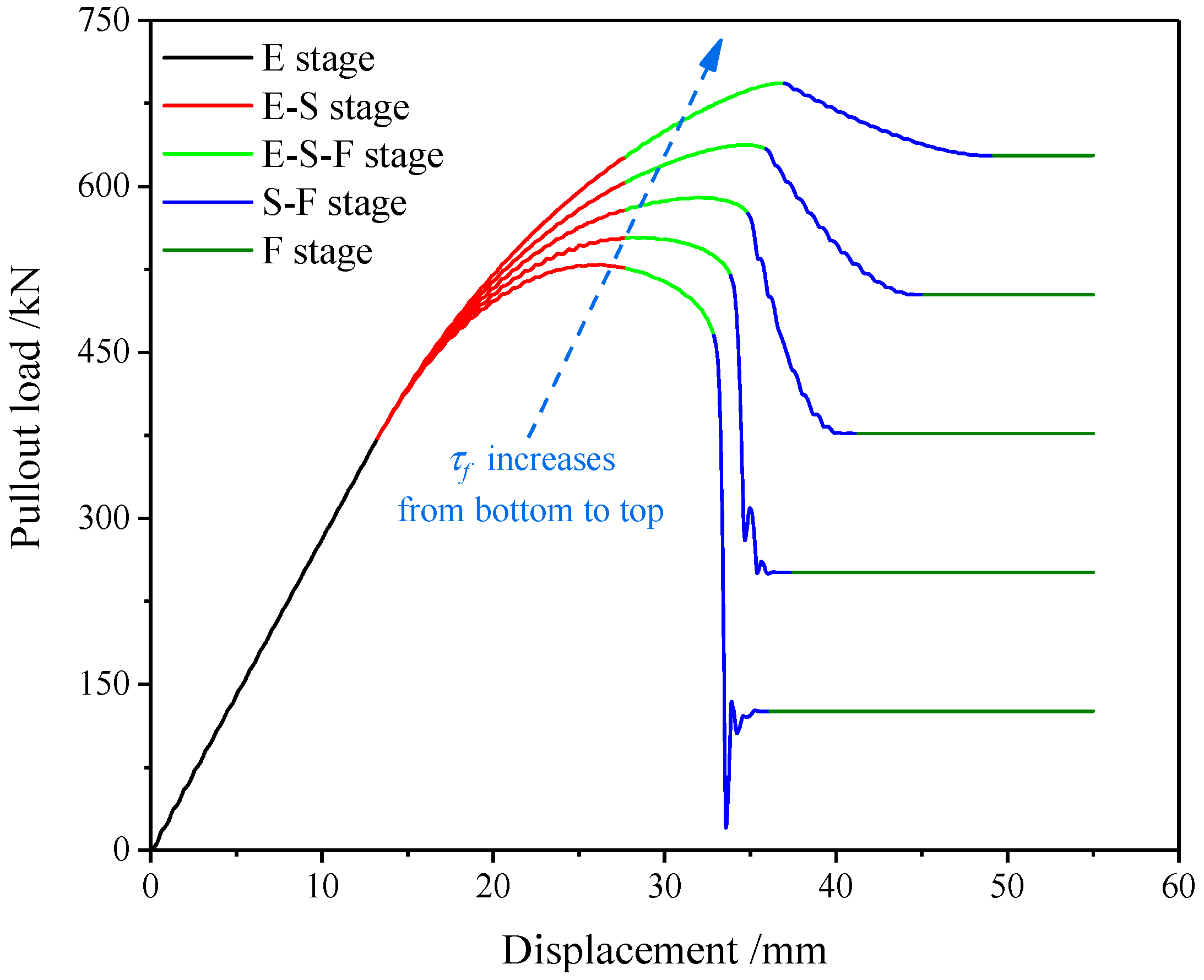

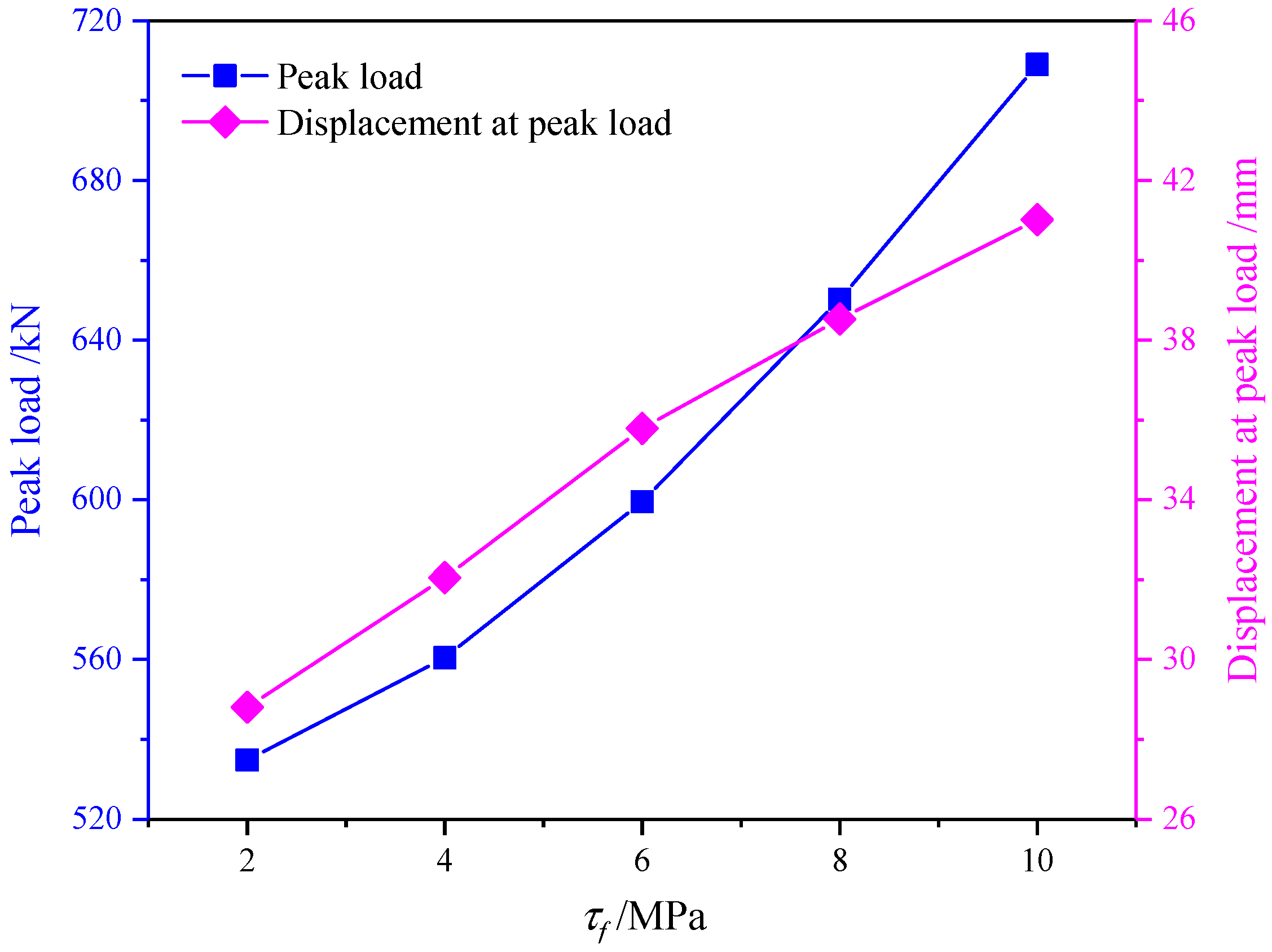

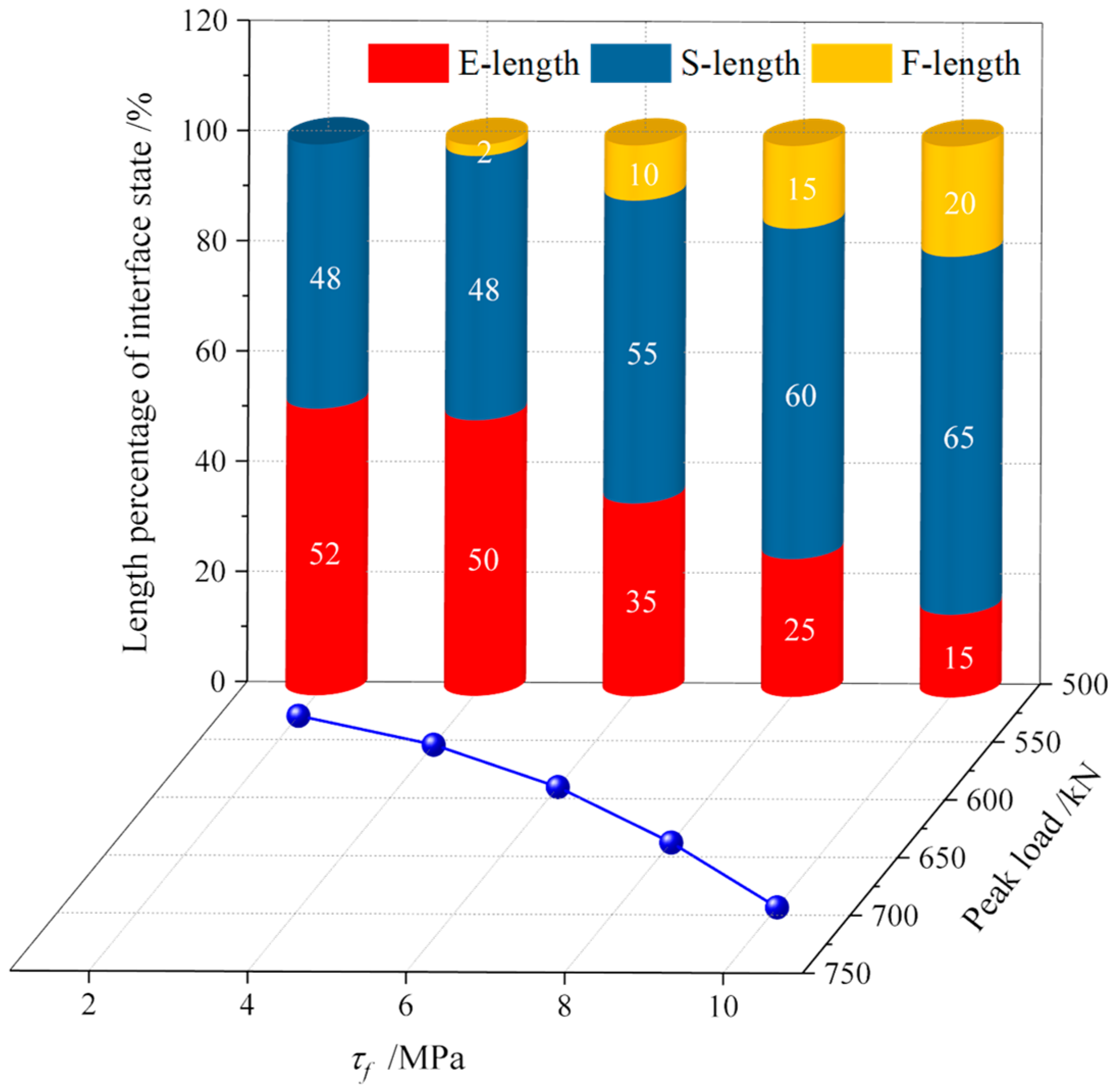

3.2.1. Bearing Properties Characteristic

3.2.2. Energy Absorption Characteristic

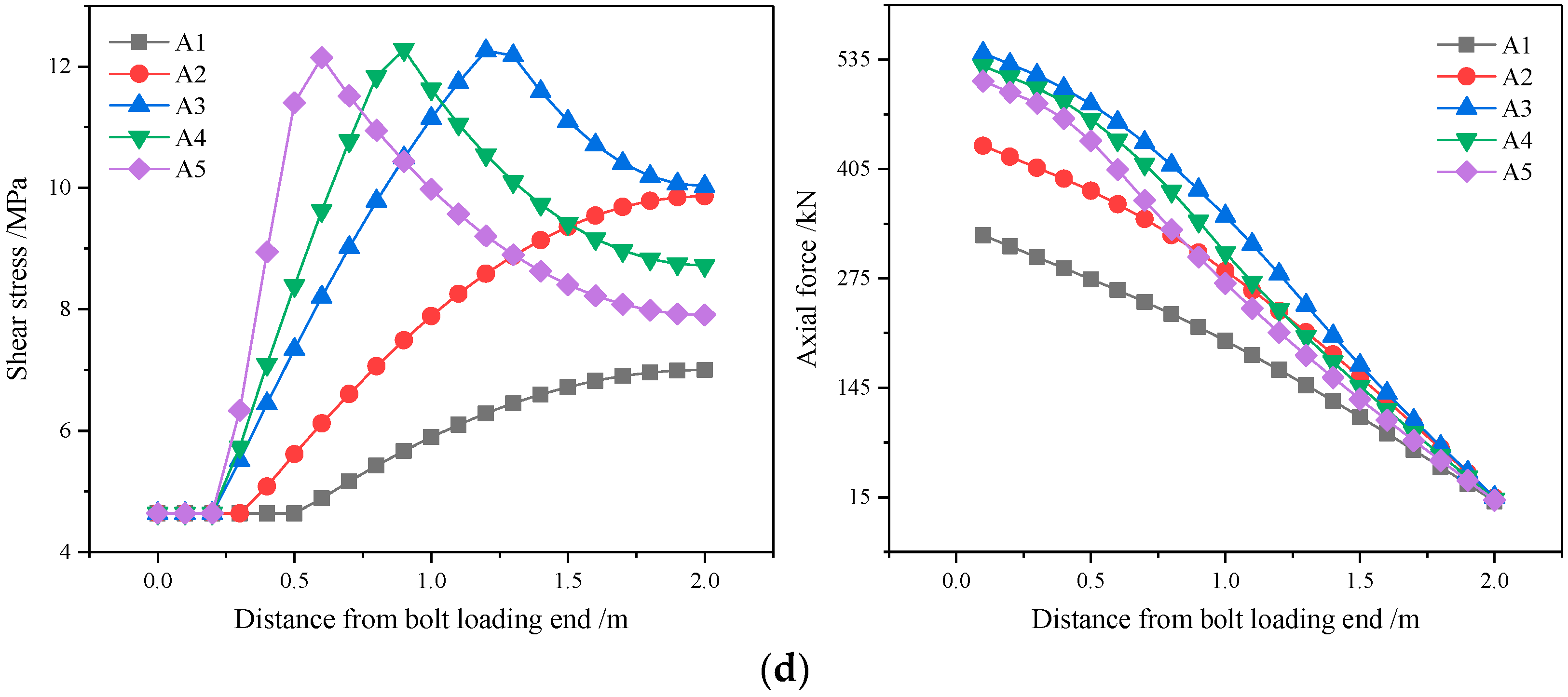

3.2.3. Stress Evolution Characteristic

3.3. Displacement at Residual Bonding Stress

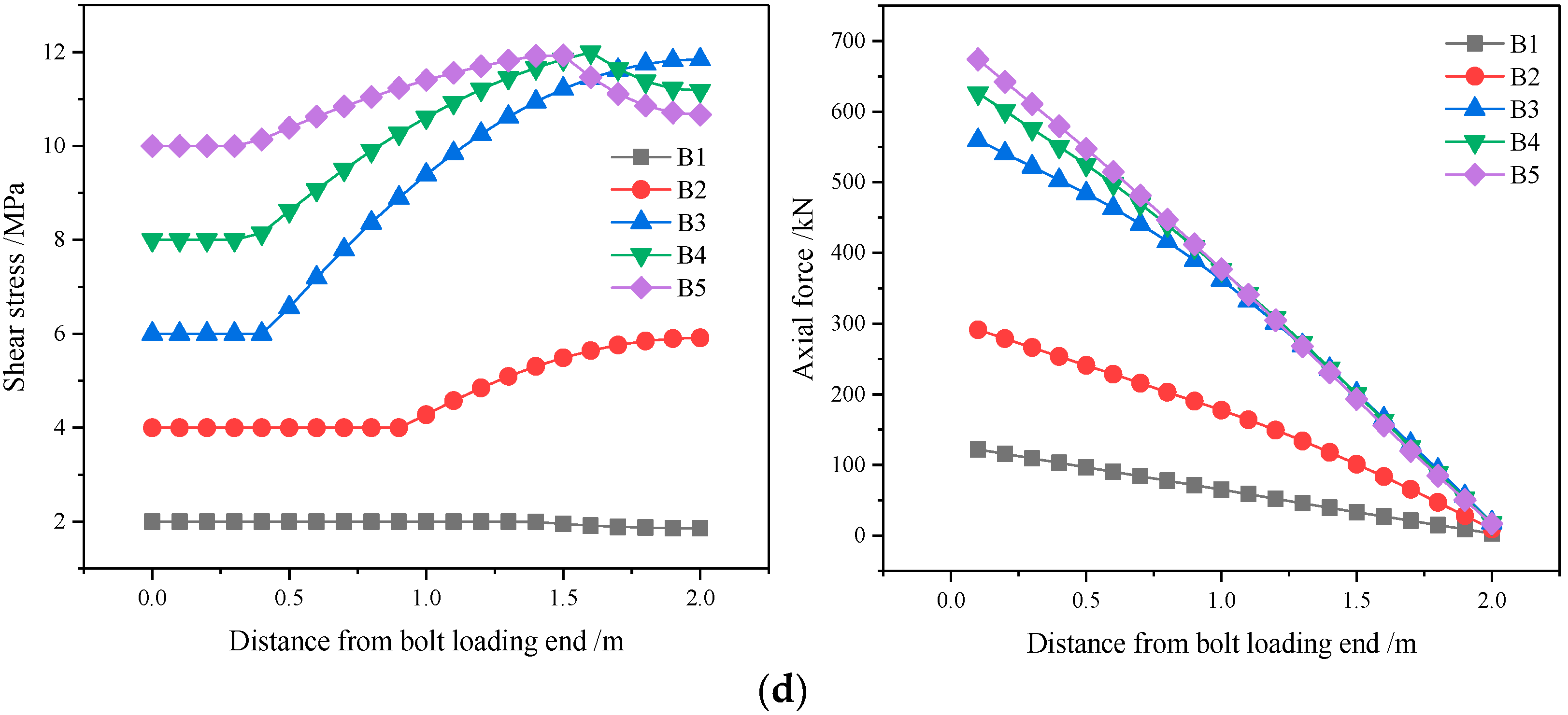

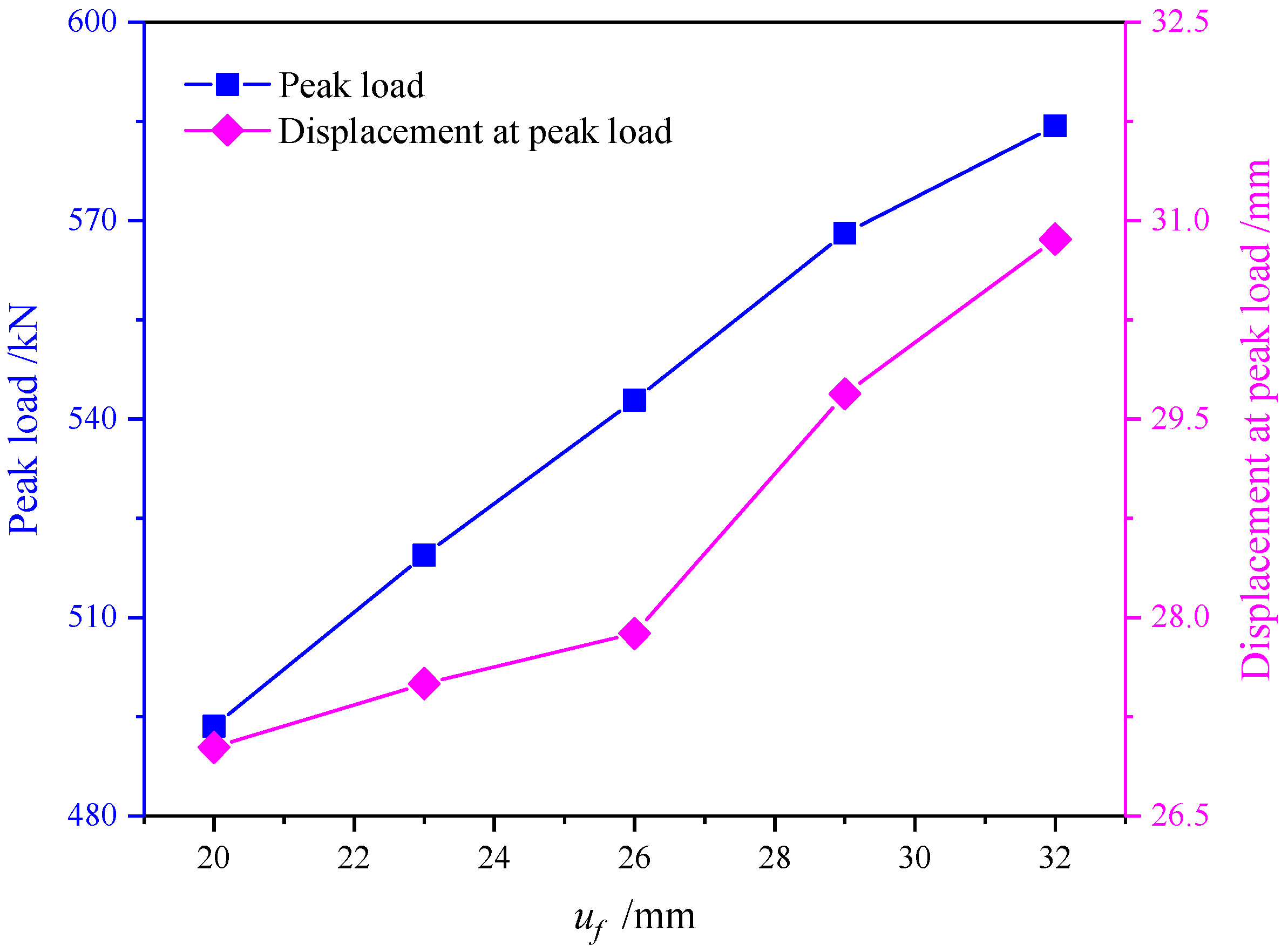

3.3.1. Bearing Properties Characteristic

3.3.2. Energy Absorption Characteristic

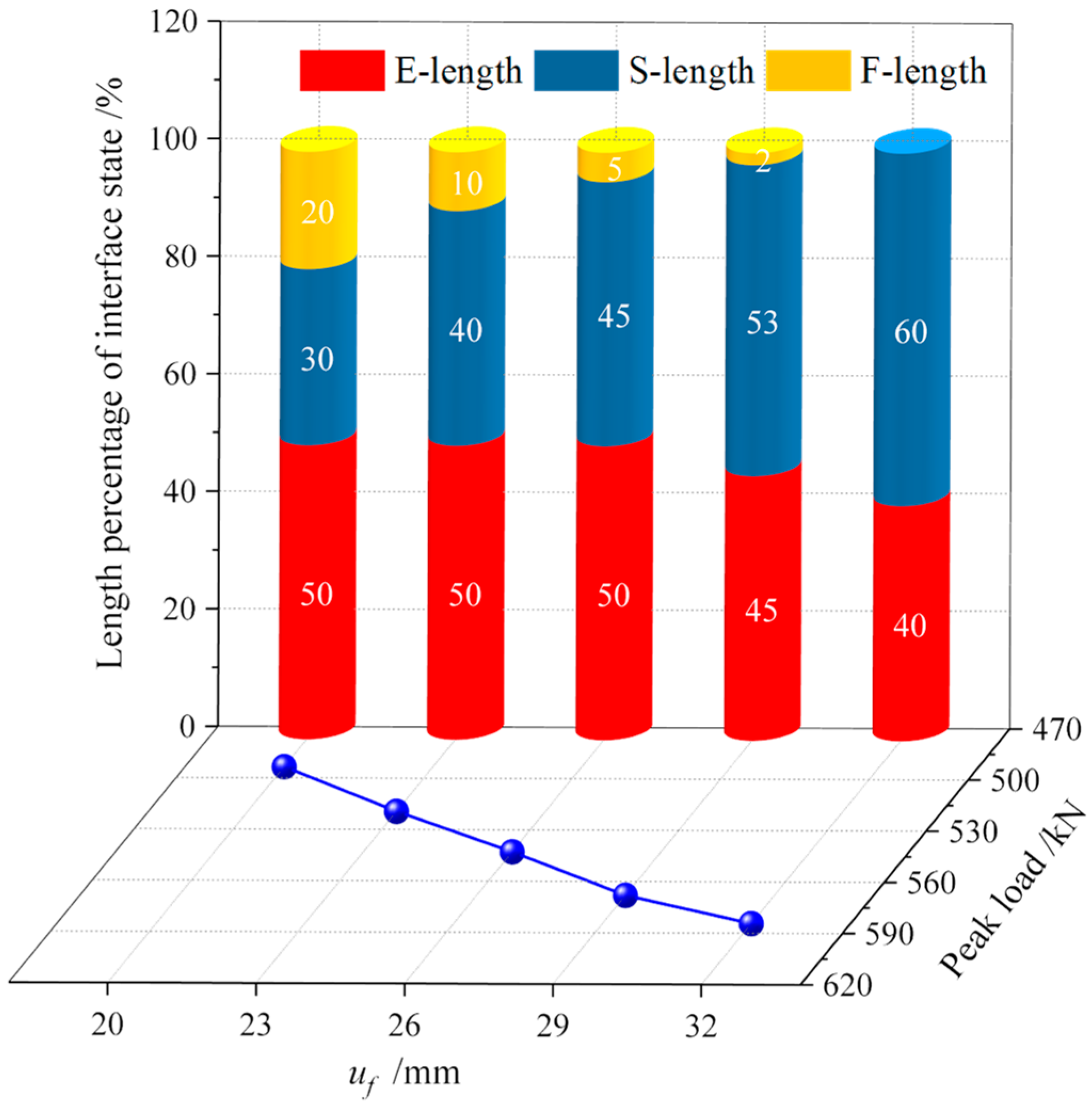

3.3.3. Stress Evolution Characteristic

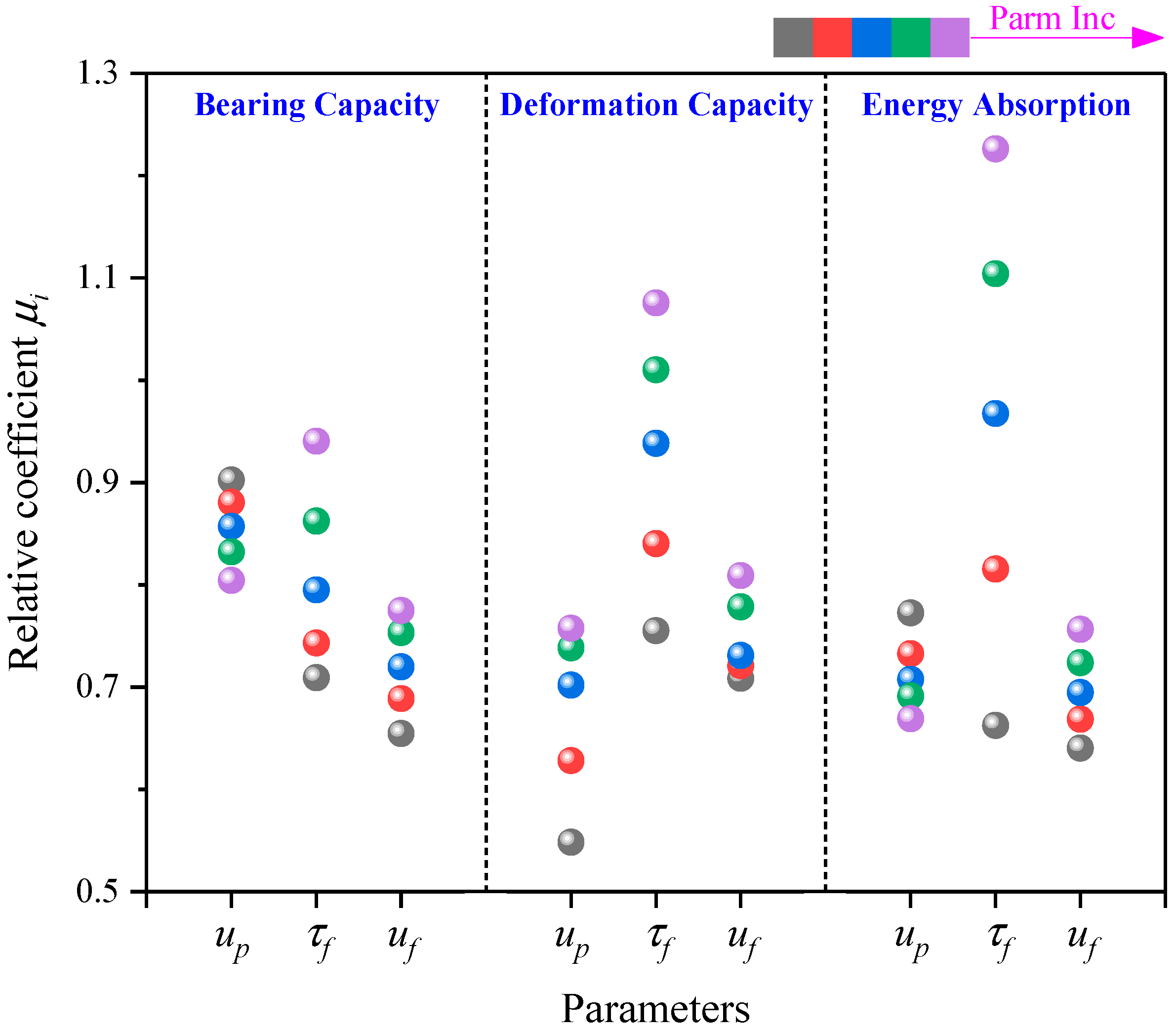

4. Discussion

4.1. Effects on Bearing Characteristics

4.2. Thoughts on the Design of Bolt Support

- (1)

- The shear strength parameters of the anchoring interface have a great influence on the design of bolt support. It is inappropriate to only use the peak shear stress of the anchoring interface for bolt support design, which often overestimates the bearing performance of the anchoring system and brings hidden dangers to roadway safety. Therefore, the shear strength parameters of the anchoring interface must be fully considered when designing bolt support.

- (2)

- Improving the post-peak characteristics of the bond-slip model of the anchoring interface can significantly increase the bearing performance of the anchoring system. Therefore, when designing bolt supports, materials such as gravel or steel fibers can be added to the agent grout [53,54,55], or the roughness of the anchoring interface can be increased to strengthen the shear behavior of the anchoring interface and improve the shear strength parameters of the anchoring interface, thereby enhancing the durability of the anchoring system.

- (3)

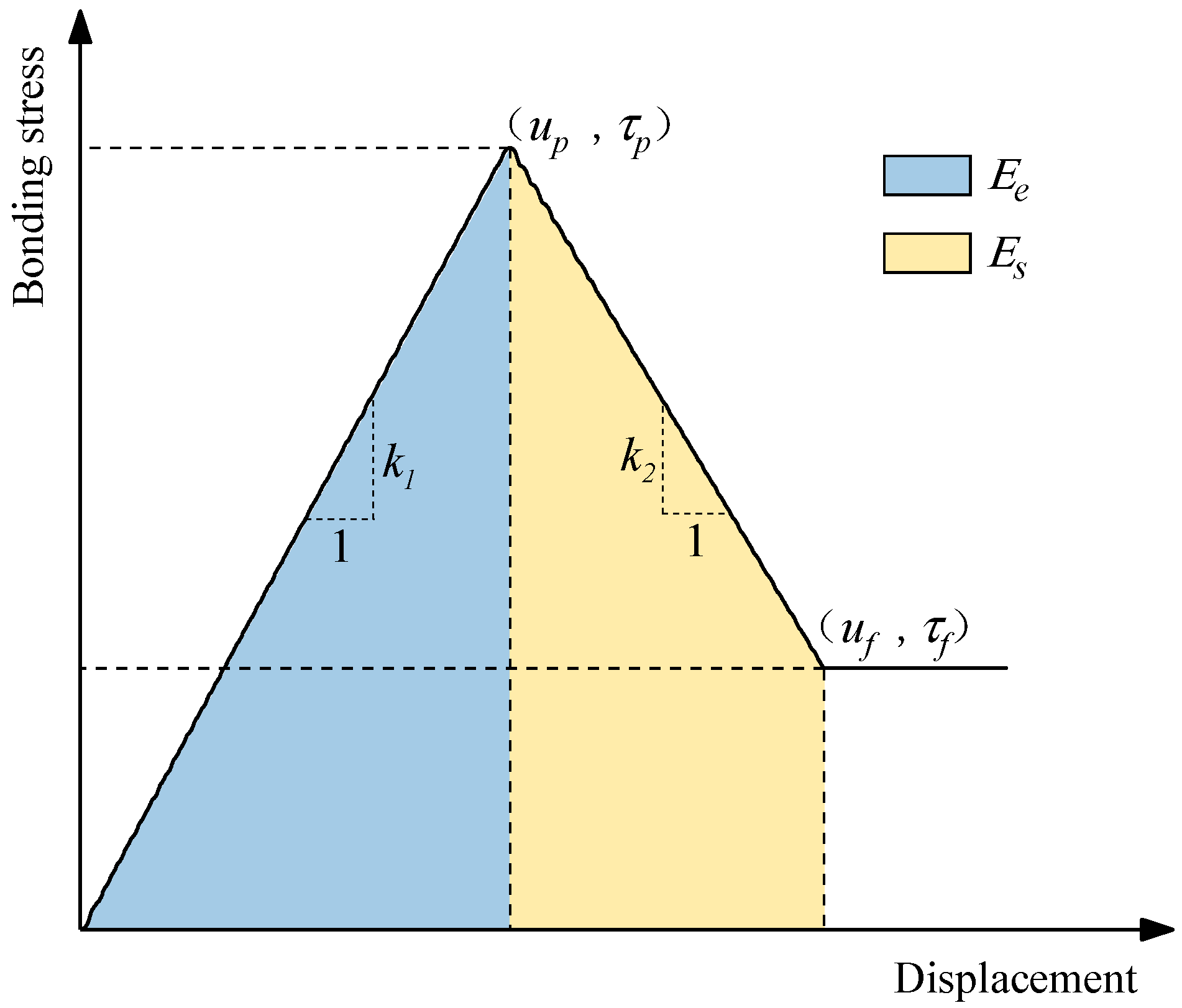

- The bearing process of the anchoring system is the process of energy dissipation at the anchoring interface. Combined with the bond-slip model of the anchoring interface, the energy dissipation ratio of the anchoring interface is defined in this study. The energy dissipation ratio of the anchoring interface is the ratio of softening energy to elastic energy during the bearing process of the anchoring interface (), as shown in Figure 22.

5. Conclusions

- (1)

- The displacement at the peak shear stress will significantly affect the pullout bearing process of fully grouted bolts. With the increase in the displacement at the peak shear stress, the bearing capacity of fully grouted bolts gradually decreases, the energy absorption also decreases and the response rate of the fully grouted anchoring system to external loads weakens. However, the ability of the fully grouted anchoring system to resist failure increases with the increase in the displacement at the peak shear stress, and the durability of the fully grouted anchoring system increases.

- (2)

- The residual shear stress has a great influence on the pullout bearing performance of fully grouted bolts. With the increase in the residual shear stress, the bearing capacity and deformation capacity of fully grouted bolts increase, and the energy absorption also increases. Meanwhile, the increase in residual shear stress gives fully grouted bolts higher residual bearing capacity, which helps the fully grouted anchoring system to better withstand external loads.

- (3)

- With the increase in the displacement at the residual shear stress, the bearing capacity and deformation capacity of fully grouted bolts show an increasing trend, and the energy absorption of fully grouted bolts also increases. The increase in displacement at the residual shear stress enhances the durability of the fully grouted anchoring system, which is beneficial to fully grouted bolts to better exert the support performance.

- (4)

- The shear strength parameters of the anchoring interface will significantly affect the pullout bearing performance of fully grouted bolts. Therefore, when designing bolt support, in addition to considering the peak shear stress of the anchoring interface, it is also necessary to fully consider the post-peak shear strength parameters of the anchoring interface to avoid overestimating or underestimating the bearing capacity of the anchoring system. Meanwhile, measures can be taken to strengthen the post-peak bearing characteristics of the anchoring interface, which is beneficial to the bearing performance of the anchoring system.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, M.; Miao, X.; Xu, J. Green mining of coal resources harmonizing with environment. J. China Coal Soc. 2007, 32, 1–7. (In Chinese) [Google Scholar] [CrossRef]

- Kang, H. Sixty years development and prospects of rock bolting technology for underground coal mine roadways in China. J. Univ. Min. Technol. 2016, 45, 1071–1081. (In Chinese) [Google Scholar] [CrossRef]

- Du, Y.; Feng, G.; Kang, H.; Zhang, X.; Zhang, Y.; Shi, X.; Wen, X. Investigation on the mechanical behavior and failure characteristics of fully grouted bolts under tension. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 10, 1–15. [Google Scholar] [CrossRef]

- Kang, H.; Cui, Q.; Hu, B.; Wu, Z. Analysis on anchorage performances and affecting factors of resin bolts. J. China Coal Soc. 2014, 39, 1–10. (In Chinese) [Google Scholar] [CrossRef]

- Windsor, C. Rock reinforcement systems. Int. J. Rock Mech. Min. Sci. 1997, 34, 919–951. [Google Scholar] [CrossRef]

- Cao, C.; Nemcik, J.; Aziz, N.; Ren, T. Analytical study of steel bolt profile and its influence on bolt load transfer. Int. J. Rock Mech. Min. Sci. 2013, 60, 188–195. [Google Scholar] [CrossRef]

- Benmokrane, B.; Chennouf, A.; Mitri, H. Laboratory evaluation of cement-based grouts and grouted rock anchors. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 633–642. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, S.; Hu, X.; Zheng, J. Analytical method for pullout of anchor from anchor-mortar-concrete anchorage system due to shear failure of mortar. J. Eng. Mech. 2007, 133, 1352–1369. [Google Scholar] [CrossRef]

- Yang, S.; Wu, Z.; Hu, X.; Zheng, J. Theoretical analysis on pullout of anchor from anchor-mortar-concrete anchorage system. Eng. Fract. Mech. 2008, 75, 961–985. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, S.; Wu, Y.; Hu, X. Analytical method for failure of anchor-grout-concrete anchorage due to concrete cone failure and interfacial debonding. J. Struct. Eng. 2009, 135, 356–365. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, S.; Zheng, J.; Hu, X. Analytical solution for the pull-out response of FRP rods embedded in steel tubes filled with cement grout. Mater. Struct. 2010, 43, 597–609. [Google Scholar] [CrossRef]

- Ren, F.; Yang, Z.; Chen, J.; Chen, W. An analytical analysis of the full-range behaviour of grouted rockbolts based on a tri-linear bond-slip model. Constr. Build. Mater. 2010, 24, 361–370. [Google Scholar] [CrossRef]

- Martín, L.; Tijani, M.; Hadj-hassen, F. A new analytical solution to the mechanical behaviour of fully grouted rockbolts subjected to pull-out tests. Constr. Build. Mater. 2011, 25, 749–755. [Google Scholar] [CrossRef]

- Guo, R.; Chen, W.; Duan, J.; Yan, Z. Pullout mechanical analysis of soil anchor based on softening behavior of interface. J. Cent. South Univ. (Sci. Technol.) 2012, 43, 4003–4009. (In Chinese) [Google Scholar]

- Luo, Y.; Shi, S.; Yan, Z. Shear interaction of the anchorage body and rock and soil interface under the action of uplift load. J. China Coal Soc. 2015, 40, 58–64. (In Chinese) [Google Scholar] [CrossRef]

- Cao, C.; Nemcik, J.; Ren, T.; Aziz, N. A study of rock bolting failure modes. Int. J. Min. Sci. Technol. 2013, 23, 79–88. [Google Scholar] [CrossRef]

- Chen, J.; Saydam, S.; Hagan, P. An analytical model of the load transfer behavior of fully grouted cable bolts. Constr. Build. Mater. 2015, 101, 1006–1015. [Google Scholar] [CrossRef]

- Lu, W.; Zhao, D.; Mao, X.; Ai, Y. Experimental study on bond-slip behavior of bamboo bolt-modified slurry interface under pull-out load. Adv. Civ. Eng. 2018, 2018, 1–23. [Google Scholar] [CrossRef]

- Lu, W.; Zhao, D.; Li, D.; Mao, X. Study on the force transfer process of the anchorage interface of bamboo bolt in the rammed earth sites. Chin. J. Theor. Appl. Mech. 2019, 51, 524–539. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z.; Zheng, J.; Zhou, X. Three-dimensional analytical model for the pull-out response of anchor-mortar-concrete anchorage system based on interfacial bond failure. Eng. Struct. 2019, 180, 234–248. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z.; Zheng, J.; Zhou, X. 3D analytical investigation on the overall pullout behavior of grouted anchorages in presence of shear failure of grout. Eng. Fail. Anal. 2020, 109, 104249. [Google Scholar] [CrossRef]

- Zhu, C.; Chang, X.; Men, Y.; Luo, X. Modeling of grout crack of rockbolt grouted system. Int. J. Min. Sci. Technol. 2015, 25, 73–77. [Google Scholar] [CrossRef]

- Chang, X.; Wang, G.; Liang, Z.; Yang, J.; Tang, C. Study on grout cracking and interface debonding of rockbolt grouted system. Constr. Build. Mater. 2017, 135, 665–673. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, Z.; Nie, W.; Gui, Y. A numerical model of fully grouted bolts considering the tri-linear shear bond-slip model. Tunn. Undergr. Space Technol. 2016, 54, 73–80. [Google Scholar] [CrossRef]

- You, C.; Zhan, Y.; Liu, Q.; Sun, L.; Wang, K. Shear lag-debonding model for anchorage section of prestressed anchor cable. Chin. J. Rock Mech. Eng. 2013, 32, 800–806. (In Chinese) [Google Scholar] [CrossRef]

- Cai, Y.; Esaki, T.; Jiang, Y. A rock bolt and rock mass interaction model. Int. J. Rock Mech. Min. Sci. 2004, 41, 1055–1067. [Google Scholar] [CrossRef]

- He, S.; Zhang, X.; Wang, C. Study on mechanism of prestressed anchoring cable based on modified shear lag model. Chin. J. Rock Mech. Eng. 2004, 15, 2562–2567. (In Chinese) [Google Scholar] [CrossRef]

- Xu, H.; Wang, W.; Jiang, M.; Tong, Q. Theoretical analysis of pullout deformation and stiffness of grouted rockbolts. Chin. J. Geotech. Eng. 2011, 33, 1511–1516. (In Chinese) [Google Scholar]

- Zhao, Y.; Yang, M. Pull-out behavior of an imperfectly bonded anchor system. Int. J. Rock Mech. Min. Sci. 2011, 48, 469–475. [Google Scholar] [CrossRef]

- Duan, J.; Yan, Z.; Guo, R.; Liu, Z.; Ren, Z. Failure analysis of soil anchors induced by loose interface under pullout load. Chin. J. Geotech. Eng. 2012, 34, 936–941. (In Chinese) [Google Scholar]

- Zhang, J.; Tang, B. Hyperbolic function model to analyze load transfer mechanism on bolts. Chin. J. Geotech. Eng. 2002, 24, 188–192. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, Y.; Yun, Y. Analytical modeling of the bond-slip relationship at FRP-concrete interfaces for adhesively-bonded joints. Compos. Part B Eng. 2010, 41, 423–433. [Google Scholar] [CrossRef]

- Ma, S.; Nemcik, J.; Aziz, N. An analytical model of fully grouted rock bolts subjected to tensile load. Constr. Build. Mater. 2013, 49, 519–526. [Google Scholar] [CrossRef]

- Ma, S.; Nemcik, J.; Aziz, N.; Zhang, Z. Numerical modeling of fully grouted rockbolts reaching free-end slip. Int. J. Geomech. 2016, 16, 04015020. [Google Scholar] [CrossRef]

- Nemcik, J.; Ma, S.; Aziz, N.; Ren, T.; Geng, X. Numerical modelling of failure propagation in fully grouted rock bolts subjected to tensile load. Int. J. Rock Mech. Min. Sci. 2014, 71, 293–300. [Google Scholar] [CrossRef]

- Li, N.; Ma, Z.; Gong, P.; Qi, F.; Wang, T.; Cheng, S. Simulation research on the load transfer mechanism of anchoring system in soft and hard composite rock strata under tensile loading conditions. Adv. Mater. Sci. Eng. 2020, 2020, 9097426. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Z.; Ou, J. Nonlinear analysis on load transfer mechanism of wholly grouted anchor rod along anchoring section. Chin. J. Rock Mech. Eng. 2014, 33, 3992–3997. (In Chinese) [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Z.; Ou, J. Nonlinear full-range analysis of load transfer in fixed segment of tensile anchors. Chin. J. Rock Mech. Eng. 2014, 33, 2190–2199. (In Chinese) [Google Scholar] [CrossRef]

- Huang, M.; Li, J.; Zhao, M.; Chen, C. Nonlinear analysis on load transfer mechanism of bolts in layered grouns. China J. Highw. Transp. 2019, 32, 12–20+56. (In Chinese) [Google Scholar] [CrossRef]

- Li, D.; Masoumi, H.; Saydam, S.; Hagan, P. A constitutive model for load-displacement performance of modified cable bolts. Tunn. Undergr. Space Technol. 2017, 68, 95–105. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, B.; Liang, C.; Wang, Y. Study on load transfer characteristics of wholly grouted bolt. Chin. J. Rock Mech. Eng. 2017, 36, 3774–3780. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, S.; Zhu, W.; Yu, S. Analysis of load transfer mechanism for fully grouted rockbolts based on the bi-exponential shear-slip model. Chin. J. Rock Mech. Eng. 2018, 37, 3817–3825. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, P. Analytical model of fully grouted bolts in pull-out tests and in situ rock masses. Int. J. Rock Mech. Min. Sci. 2019, 113, 278–294. [Google Scholar] [CrossRef]

- Aghchai, M.; Maarefvand, P.; Rad, H. Analytically determining bond shear strength of fully grouted rock bolt based on pullout test results. Period. Polytech. Civ. Eng. 2020, 64, 212–222. [Google Scholar] [CrossRef]

- Du, Y.; Feng, G.; Kang, H.; Zhang, Y.; Zhang, X. Effects of different pull-out loading rates on mechanical behaviors and acoustic emission responses of fully grouted bolts. J. Cent. South Univ. 2021, 28, 2052–2066. [Google Scholar] [CrossRef]

- Du, Y.; Feng, G.; Kang, H.; Zhang, Y.; Zhang, X. Investigation on the pull-out bearing characteristics of bolts with different bond lengths. J. Min. Strat. Control Eng. 2021, 3, 5–12. (In Chinese) [Google Scholar] [CrossRef]

- Chen, C.; Laing, G.; Tang, Y. Analysis of pull-out mechanical and deformation characteristics for bolts in layered ground. China J. Highw. Transp. 2015, 28, 1–9+17. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, W.; Huang, L.; Juang, C. An analytical model for estimating the force and displacement of fully grouted rock bolts. Comput. Geotech. 2020, 117, 103222. [Google Scholar] [CrossRef]

- Wang, X.; Kang, H.; Zhao, K.; Liu, Y. Numerical analysis of bonding stiffness for support effectiveness of pre-stressed bolts. J. China Coal Soc. 2016, 41, 2999–3007. (In Chinese) [Google Scholar] [CrossRef]

- Du, Y.; Feng, G.; Kang, H.; Zhang, Y.; Zhang, X. Effects of steel fiber grout on the mechanical performance and failure characteristics of fully grouted bolts. Structures 2021, 33, 1096–1106. [Google Scholar] [CrossRef]

- Yin, X.; Zhou, T.; Zhou, C.; Xie, H.; Zhu, J. Rate-and Normal Stress-Dependent Mechanical Behavior of Rock under Direct Shear Loading Based on a Bonded-Particle Model (BPM). Rock Mech. Rock Eng. 2023, 56, 7959–7979. [Google Scholar] [CrossRef]

- Wang, X.; Ye, R.; Zhou, F. Proposals for the selection of failure criteria in soil float-resisting anchor rod test. J. Geol. Hazards Environ. Preserv. 2001, 3, 73–77. (In Chinese) [Google Scholar] [CrossRef]

- Teymen, A. Effect of mineral admixture types on the grout strength of fully-grouted rockbolts. Constr. Build. Mater. 2017, 145, 376–382. [Google Scholar] [CrossRef]

- Liu, R.; Yan, S.; Luo, Q.; Long, W.; Zhou, Y. Research on reinforced anchor with fiber mortar. Chin. J. Geotech. Eng. 2005, 27, 214–218. (In Chinese) [Google Scholar] [CrossRef]

- Cao, C.; Ren, T.; Zhang, Y.; Zhang, L.; Wang, F. Experimental investigation of the effect of grout with additive in improving ground support. Int. J. Rock Mech. Min. Sci. 2016, 85, 52–59. [Google Scholar] [CrossRef]

| Type | Parameters | Values |

|---|---|---|

| Bolt | Perimeter (m) | 9.42 × 10−2 |

| Cross-sectional area (m2) | 3.14 × 10−4 | |

| Elastic modulus (Pa) | 2.00 × 1011 | |

| Poisson’s ratio | 0.25 | |

| Tensile yield strength (N) | 5.00 × 1011 | |

| Rock | Elastic bulk modulus (Pa) | 5.00 × 109 |

| Elastic shear modulus (Pa) | 3.00 × 109 | |

| Density (kg/m3) | 2.80 × 103 |

| Variable | Number | Value | Image |

|---|---|---|---|

| (mm) | A1 | 4.625 |  |

| A2 | 9.250 | ||

| A3 | 13.875 | ||

| A4 | 18.500 | ||

| A5 | 23.125 | ||

| (MPa) | B1 | 2.0 |  |

| B2 | 4.0 | ||

| B3 | 6.0 | ||

| B4 | 8.0 | ||

| B5 | 10.0 | ||

| (mm) | C1 | 20.0 |  |

| C2 | 23.0 | ||

| C3 | 26.0 | ||

| C4 | 29.0 | ||

| C5 | 32.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Zhang, Y.; Feng, G.; He, L.; Zhang, X. Effects of Shear Characteristics of Anchoring Interface on Bearing Performance of Fully Grouted Bolts Based on Variable Controlling Method. Buildings 2024, 14, 874. https://doi.org/10.3390/buildings14040874

Du Y, Zhang Y, Feng G, He L, Zhang X. Effects of Shear Characteristics of Anchoring Interface on Bearing Performance of Fully Grouted Bolts Based on Variable Controlling Method. Buildings. 2024; 14(4):874. https://doi.org/10.3390/buildings14040874

Chicago/Turabian StyleDu, Yunlou, Yujiang Zhang, Guorui Feng, Lujin He, and Xihong Zhang. 2024. "Effects of Shear Characteristics of Anchoring Interface on Bearing Performance of Fully Grouted Bolts Based on Variable Controlling Method" Buildings 14, no. 4: 874. https://doi.org/10.3390/buildings14040874