Investigation of Surface Modification of Bagasse Fibers: Performance of Asphalt Binders/Mixtures with Bagasse Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Preparation of Bagasse Fibers

2.1.2. Surface Modification

2.1.3. Preparation of Asphalt Binders with Fibers

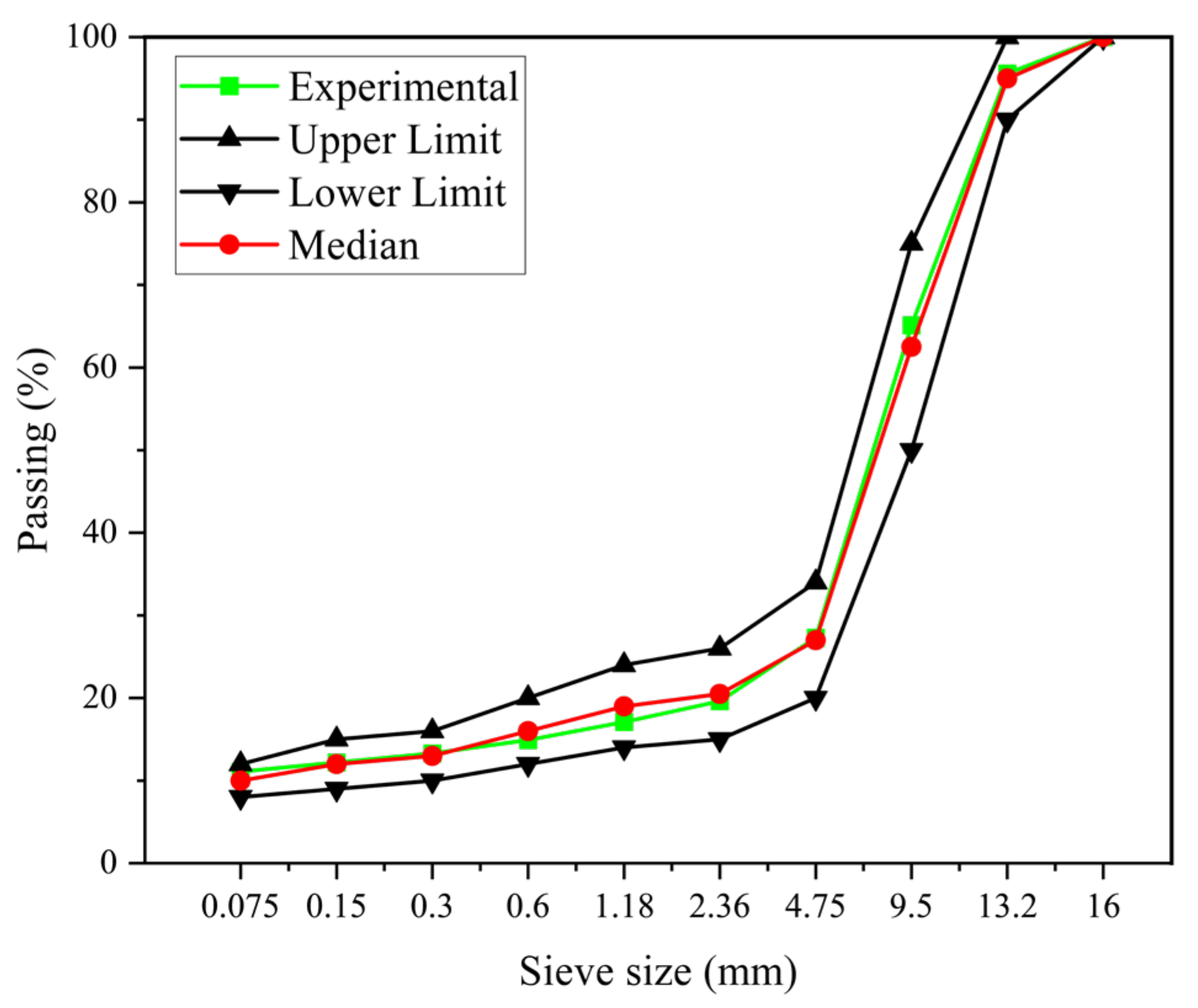

2.1.4. Preparation of Asphalt Mixtures with Fibers

2.2. Methods

2.2.1. SEM Test

2.2.2. FTIR Test

2.2.3. Oil Absorbing Test

2.2.4. Rheological Test

3. Results

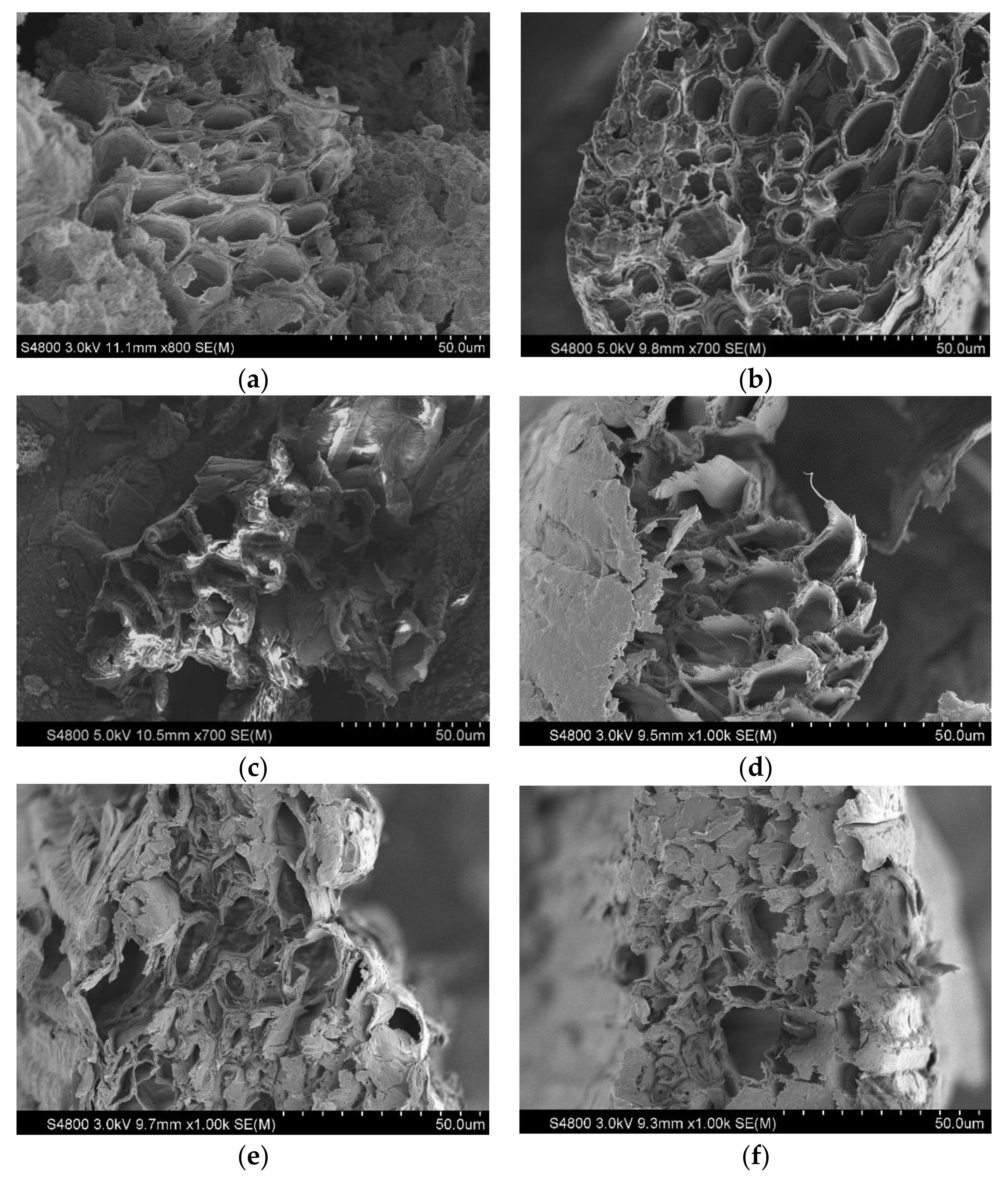

3.1. SEM Analysis

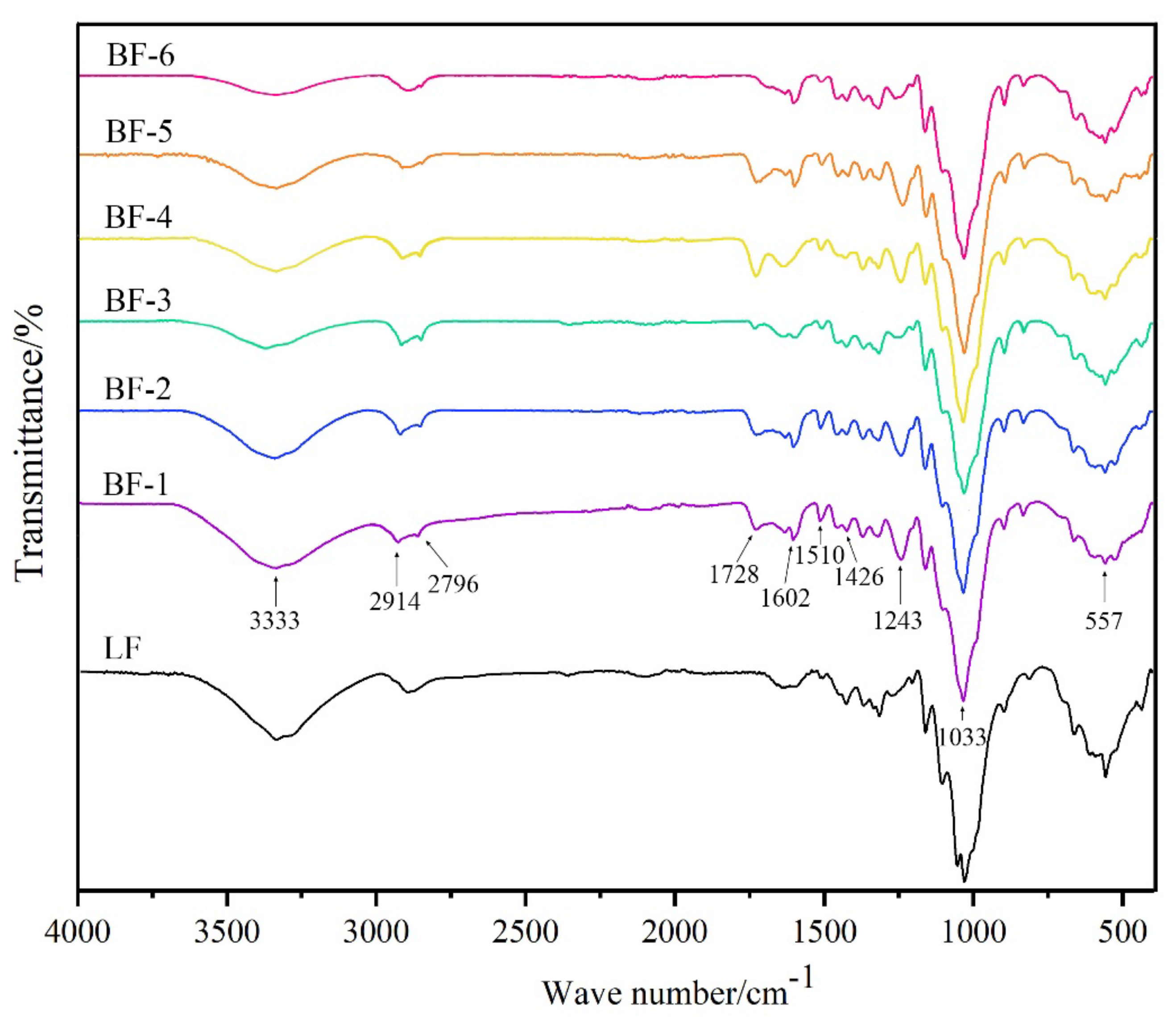

3.2. FTIR Analysis

3.3. Oil Absorption Analysis

3.4. Rheological Property Analysis

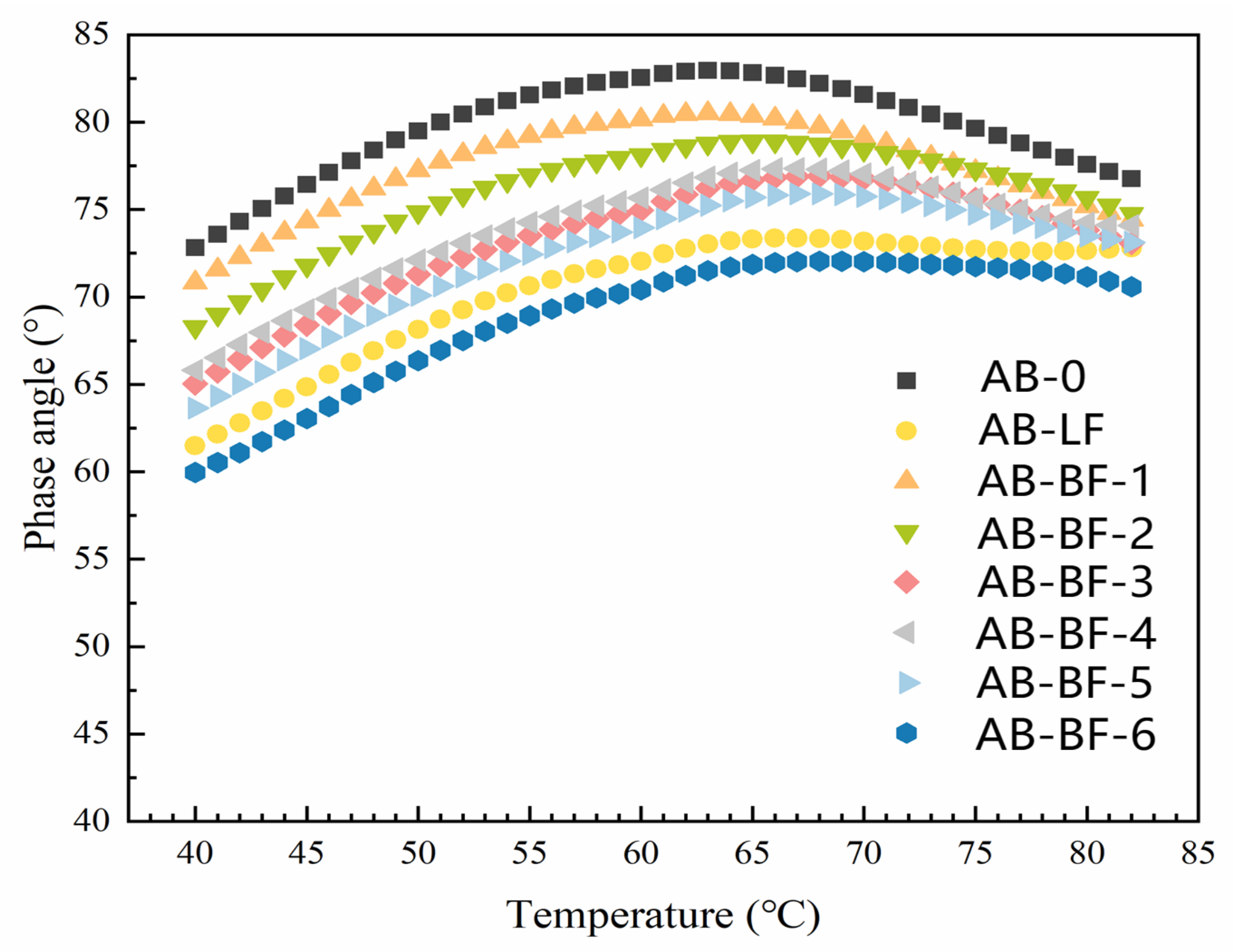

3.4.1. Temperature Sweep

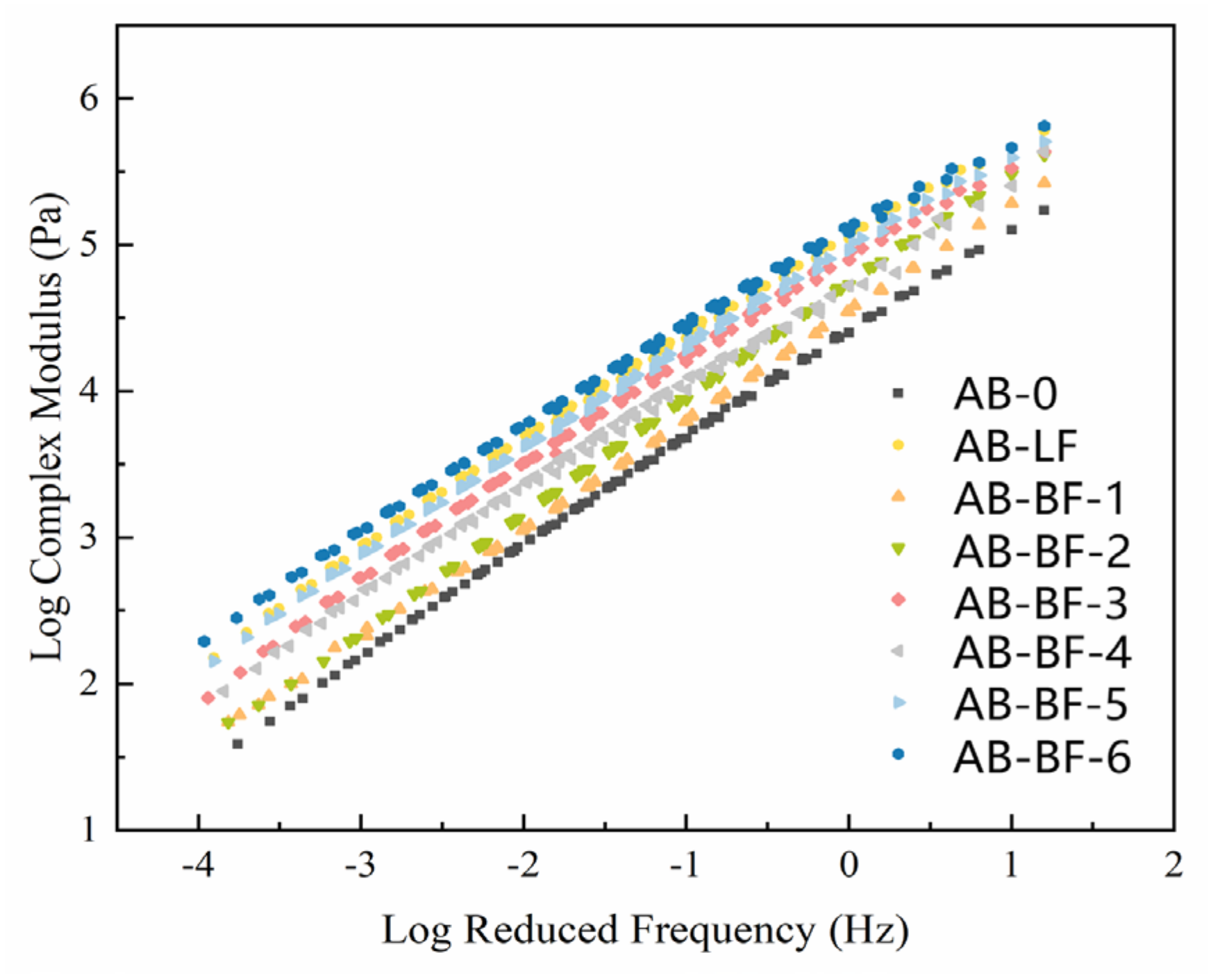

3.4.2. Master Curve and CAM Model

3.4.3. BBR

3.5. Performance of Asphalt Mixtures with Bagasse Fibers

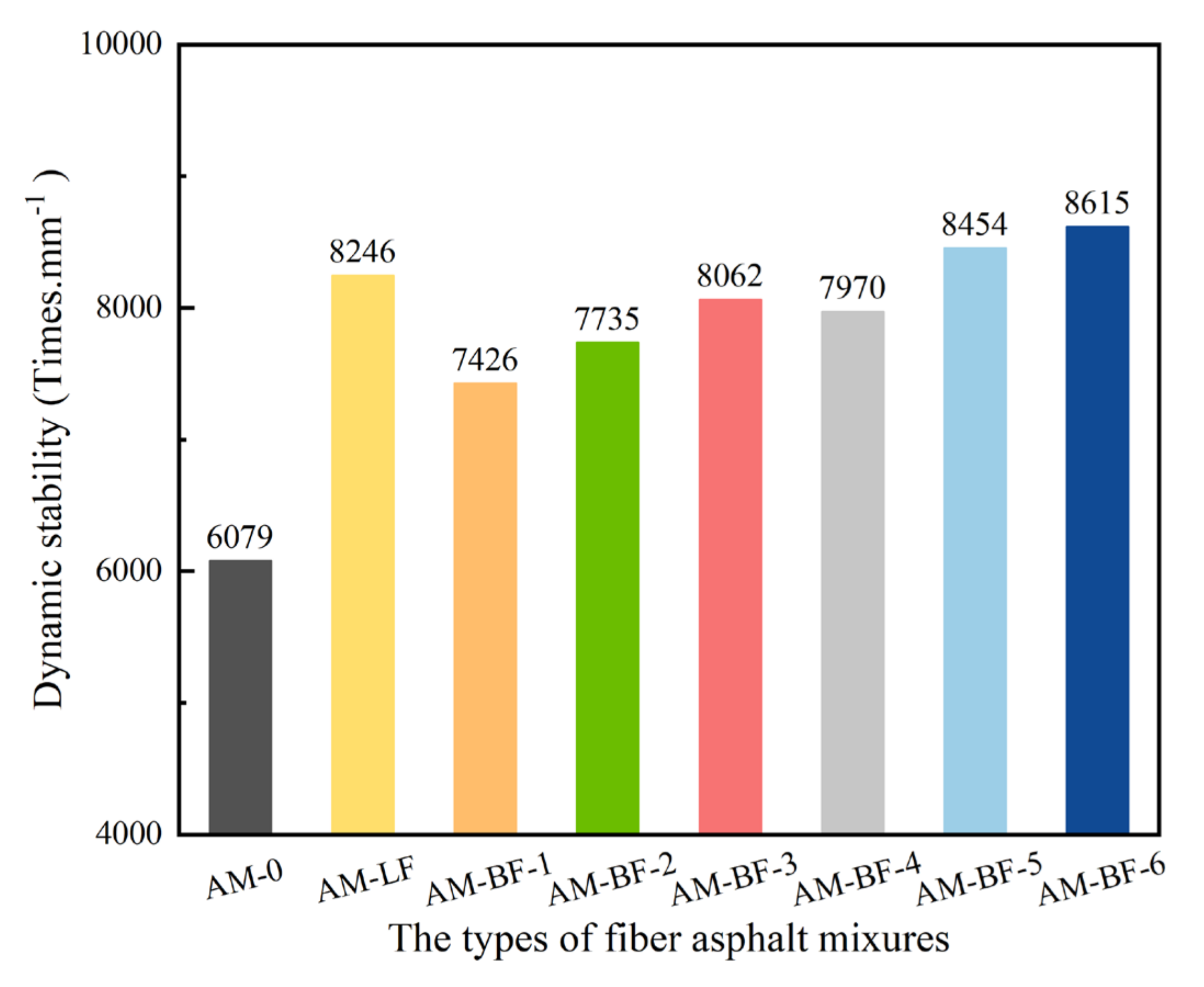

3.5.1. Rutting Resistance at a High Temperature

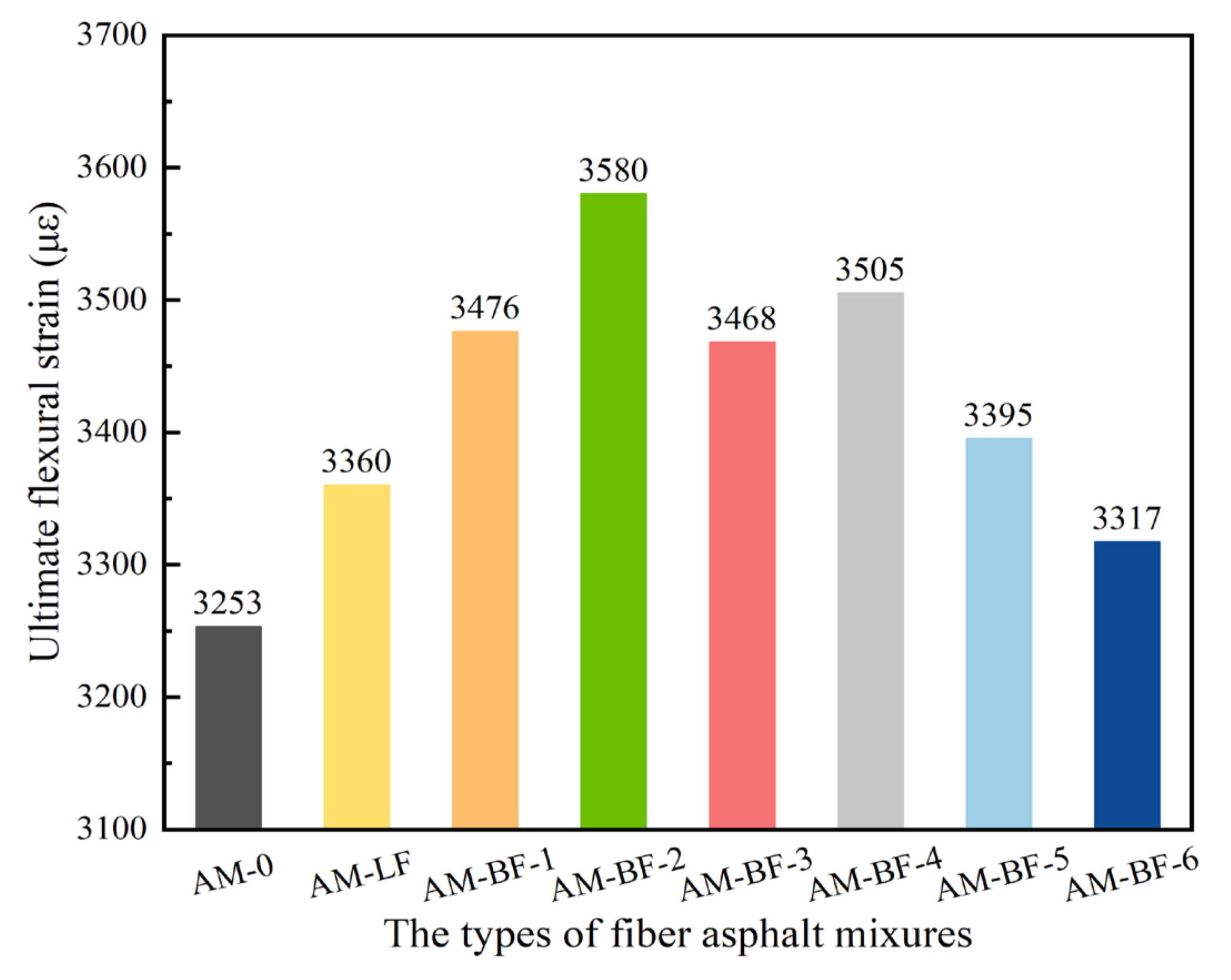

3.5.2. Cracking Resistance at a Low Temperature

3.5.3. Water Stability

4. Conclusions and Future Trends

- In accordance with the SEM images, it was verified that chemical modification could remove impurities on the surface of fibers, promote fibrillation, and make the fibers flexible. In addition, it was speculated that long-term heating may also damage the fiber structure and weaken the supporting function of the cell wall.

- The result of FTIR revealed that sodium hydroxide had a significant impact on delignification, resulting in the presence of a cleaner cellulose phase with a high degree of polymerization, thus promoting the formation of a looser structure. Moreover, all the modification schemes could remove hydrophilic functional groups.

- The result attained by the oil absorbing test showed that the five types of modified bagasse fibers exceed BF-1 regarding the value of the oil absorption ratio, which was caused by the loose structure of the fibers and partial removal of major components (i.e., cellulose, hemicellulose, and lignin). The increments were 15.0% for BF-2, 42.4% for BF-3, 31.6% for BF-4, 59.5% for BF-5, and 68.5% for BF-6.

- In accordance with the DSR test, the asphalt binder with and without fibers, in terms of performance at a high temperature, ranked as follows: AB-BF-6 > AB-LF > AB-BF-5 > AB-BF-3 > AB-BF-4 > AB-BF-2 > AB-BF-1 > AB-0. The three-dimensional network comprised of fibers, and the SBS copolymer could hinder the fluidity of the asphalt. Meanwhile, the fibers could increase the stiffness of the asphalt binder by absorbing many asphalt components, enhancing the high-temperature deformation resistance of the asphalt binder, and the modification of fibers could also cause the promotion of comprehensive performance. The variation in the result of the BBR test was based on the same reason.

- The road performance of the asphalt mixtures was significantly improved by bagasse fibers, confirmed by a series of comparative analyses. Modified bagasse fibers led to a much more significant enhancement in high-temperature performance compared to their impact on low-temperature performance. Furthermore, the ternary composite modification of bagasse fibers could effectively balance rutting resistance at a high temperature, cracking resistance at a low temperature, and the water stability of the asphalt mixtures. Overall, the performance of the asphalt mixtures with bagasse fibers by the ternary composite modification was close to that of lignin fibers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, M.; Peng, C.; Cheng, C. Study on the Rheological Properties of Formic Acid Lignin Modified Asphalt. Buildings 2023, 13, 655. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Fa, C.; Zhang, Y.; Xiong, J.; Chen, H. Investigation on characteristics and properties of bagasse fibers: Performances of asphalt mixtures with bagasse fibers. Constr. Build. Mater. 2020, 248, 118648. [Google Scholar] [CrossRef]

- Li, J.; Luo, C.; Jie, J.; Cui, H. Rheological Properties and Microscopic Morphology Evaluation of UHMWPE-Modified Corn Stover Oil Bio-Asphalt. Buildings 2023, 13, 2167. [Google Scholar] [CrossRef]

- Safirzadeh, S.; Chorom, M.; Karimi, R.; Ariz, A.; Behravan, H.R.; Fadami, M. Effects of alkaline pretreatments on chemical composition of sugarcane bagasse for easy degradation in soil. Sugar Tech 2017, 19, 89–94. [Google Scholar] [CrossRef]

- Caro, S.; Vega, N.; Husserl, J.; Alvarez, A.E. Studying the impact of biomodifiers produced from agroindustrial wastes on asphalt binders. Constr. Build. Mater. 2016, 126, 369–380. [Google Scholar] [CrossRef]

- Bilba, K.; Arsène, M.-A.; Ouensanga, A. Sugar cane bagasse fibre reinforced cement composites. Part I. Influence of the botanical components of bagasse on the setting of bagasse/cement composite. Cem. Concr. Compos. 2003, 25, 91–96. [Google Scholar] [CrossRef]

- de Sá, L.R.V.; de Oliveira Faber, M.; da Silva, A.S.A.; Cammarota, M.C.; Ferreira-Leitão, V.S. Biohydrogen production using xylose or xylooligosaccharides derived from sugarcane bagasse obtained by hydrothermal and acid pretreatments. Renew. Energy 2020, 146, 2408–2415. [Google Scholar] [CrossRef]

- Cardona, C.; Quintero, J.; Paz, I. Production of bioethanol from sugarcane bagasse: Status and perspectives. Bioresour. Technol. 2010, 101, 4754–4766. [Google Scholar] [CrossRef]

- Bhardwaj, N.K.; Kaur, D.; Chaudhry, S.; Sharma, M.; Arya, S. Approaches for converting sugarcane trash, a promising agro residue, into pulp and paper using soda pulping and elemental chlorine-free bleaching. J. Clean. Prod. 2019, 217, 225–233. [Google Scholar] [CrossRef]

- Cabral, M.R.; Nakanishi, E.Y.; Dos Santos, V.; Palacios, J.H.; Godbout, S.; Savastano, H.; Fiorelli, J. Evaluation of pre-treatment efficiency on sugarcane bagasse fibers for the production of cement composites. Arch. Civ. Mech. Eng. 2018, 18, 1092–1102. [Google Scholar] [CrossRef]

- Ali, M.A.S.S.; Jimat, D.N.; Nawawi, W.M.F.W.; Sulaiman, S. Antibacterial, mechanical and thermal properties of PVA/starch composite film reinforced with cellulose nanofiber of sugarcane bagasse. Arab. J. Sci. Eng. 2022, 47, 5747–5754. [Google Scholar] [CrossRef]

- Mansor, S.; Zainuddin, N.; Aziz, N.; Razali, M.; Joohari, M. Sugarcane Bagasse Fiber—An Eco-Friendly Pavement of SMA. AIP Conf. Proc. 2018, 2020, 020032. [Google Scholar]

- Buritatum, A.; Suddeepong, A.; Akkharawongwhatthana, K.; Horpibulsuk, S.; Yaowarat, T.; Hoy, M.; Arulrajah, A.; Rashid, A.S.A. Hemp fiber-modified asphalt concretes with reclaimed asphalt pavement for low-traffic roads. Sustainability 2023, 15, 6860. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L. Interface and bonding mechanisms of plant fibre composites: An overview. Compos. Part B Eng. 2016, 101, 31–45. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patino, W.; Cardenas, J. Physical-mechanical properties of bamboo fibers-reinforced biocomposites: Influence of surface treatment of fibers. J. Build. Eng. 2020, 28, 101058. [Google Scholar] [CrossRef]

- Laluce, C.; Roldan, I.U.; Pecoraro, E.; Igbojionu, L.I.; Ribeiro, C.A. Effects of pretreatment applied to sugarcane bagasse on composition and morphology of cellulosic fractions. Biomass Bioenergy 2019, 126, 231–238. [Google Scholar] [CrossRef]

- Seki, Y.; Kılınç, A.Ç.; Dalmis, R.; Atagür, M.; Köktaş, S.; Göktaş, A.A.; Çelik, E.; Seydibeyoğlu, M.Ö.; Önay, A.B. Surface modification of new cellulose fiber extracted from Conium maculatum plant: A comparative study. Cellulose 2018, 25, 3267–3280. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, Z.; Yi, J.; Feng, D. Preparation method of corn stalk fiber material and its performance investigation in asphalt concrete. Sustainability 2019, 11, 4050. [Google Scholar] [CrossRef]

- Ranganagowda, R.P.G.; Kamath, S.S.; Bennehalli, B.; Muddanna, A.; Sampathkumar, D.; Venkateshappa, S.C. Spectral studies on chemically modified single areca fibre. Mater. Today Proc. 2018, 5, 28018–28025. [Google Scholar] [CrossRef]

- Sanjay, M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Kalia, S.; Thakur, K.; Celli, A.; Kiechel, M.A.; Schauer, C.L. Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: A review. J. Environ. Chem. Eng. 2013, 1, 97–112. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, B.; Feng, D.; Li, G. Adsorption mechanism between corn stalk fiber and asphalt. Sustainability 2022, 14, 12863. [Google Scholar] [CrossRef]

- Boumediri, H.; Bezazi, A.; Del Pino, G.G.; Haddad, A.; Scarpa, F.; Dufresne, A. Extraction and characterization of vascular bundle and fiber strand from date palm rachis as potential bio-reinforcement in composite. Carbohydr. Polym. 2019, 222, 114997. [Google Scholar] [CrossRef] [PubMed]

- Moubarik, A.; Grimi, N.; Boussetta, N. Structural and thermal characterization of Moroccan sugar cane bagasse cellulose fibers and their applications as a reinforcing agent in low density polyethylene. Compos. Part B Eng. 2013, 52, 233–238. [Google Scholar] [CrossRef]

- Qiang, X.; Lei, L.; Yi-jun, C. Study on the action effect of pavement straw composite fiber material in asphalt mixture. Constr. Build. Mater. 2013, 43, 293–299. [Google Scholar] [CrossRef]

- Sheng, Y.; Zhang, B.; Yan, Y.; Li, H.; Chen, Z.; Chen, H. Laboratory investigation on the use of bamboo fiber in asphalt mixtures for enhanced performance. Arab. J. Sci. Eng. 2019, 44, 4629–4638. [Google Scholar] [CrossRef]

- Wu, M.; Li, R.; Zhang, Y.; Wei, J.; Lv, Y.; Ding, X. Reinforcement effect of fiber and deoiled asphalt on high viscosity rubber/SBS modified asphalt mortar. Pet. Sci. 2014, 11, 454–459. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Bellatrache, Y.; Ziyani, L.; Dony, A.; Taki, M.; Haddadi, S. Effects of the addition of date palm fibers on the physical, rheological and thermal properties of bitumen. Constr. Build. Mater. 2020, 239, 117808. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, J.; Chen, Z.; Feng, D. Properties of asphalt binder modified by corn stalk fiber. Constr. Build. Mater. 2019, 212, 225–235. [Google Scholar] [CrossRef]

- ASTM D6114; Standard Specification for Asphalt-Rubber Binder. ASTM International: West Conshohocken, PA, USA, 2023.

- Ministry of Transport of the People’s Republic of China. JT/T533-2020: Fiber for Asphalt Pavements; China Communication Press: Beijing, China, 2020.

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D6648-08; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer. ASTM International: West Conshohocken, PA, USA, 2008.

| Method | Chemical Reagent | Proportion | Temperature | Time | Code Name |

|---|---|---|---|---|---|

| % | °C | min | |||

| Single modification | Hydrochloric acid | 1.5 | 60 | 100 | BF-2 |

| Sodium hydroxide | 1.5 | 30 | 100 | BF-3 | |

| Sodium chlorite | 0.5 | 80 | 80 | BF-4 | |

| Binary composite modification | Sodium chlorite | 0.5 | 80 | 80 | BF-5 |

| + hydrochloric acid | 1.5 | 60 | 100 | ||

| Ternary composite modification | Sodium hydroxide | 1.5 | 30 | 100 | BF-6 |

| + sodium chlorite | 0.5 | 80 | 80 | ||

| + hydrochloric acid | 1.5 | 60 | 100 |

| Tested Property | Units | Value | Standard [33] |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 69 | ASTM D5-13 |

| Softening point | °C | 82.5 | ASTM D36-76 |

| Ductility (5 °C) | cm | 48 | ASTM D113-99 |

| Viscosity (135 °C) | Pa·s | 2.2 | ASTM D2170 |

| Flash point | °C | 265 | ASTM D92 |

| Solubility | % | 99.4 | ASTM D2042 |

| Separation difference | °C | 1.0 | ASTM D5976 |

| Matrix | Reinforcement | Code Name |

|---|---|---|

| SBS-modified asphalt binder | / | AB-0 |

| Lignin fiber | AB-LF | |

| BF-1 | AB-BF-1 | |

| BF-2 | AB-BF-2 | |

| BF-3 | AB-BF-3 | |

| BF-4 | AB-BF-4 | |

| BF-5 | AB-BF-5 | |

| BF-6 | AB-BF-6 |

| Wave Number (cm−1) | Functional Groups | Polymer |

|---|---|---|

| 3333 | O-H from complex vibrational stretching | Cellulose |

| 2914–2796 | C-H asymmetric and symmetric stretching vibration | Lignin and hemicellulose |

| 1728 | Stretching vibration of carbonyl group (-C=O) | Hemicellulose and lignin |

| 1602 | Aromatic symmetrical vibration | Lignin |

| 1510 | C=C stretching of aromatic symmetrical vibration | Lignin |

| 1426 | C-H deformation (asymmetric) and aromatic ring stretching | Lignin |

| 1243 | C-O stretching vibration of acetyl ester group | Hemicellulose |

| 1033 | The stretching of the C–O–C group | Lignin, cellulose, and hemicellulose |

| 557 | O-H groups stretching outside of the plane | Cellulose and hemicellulose |

| Fibers | LF | BF-1 | BF-2 | BF-3 | BF-4 | BF-5 | BF-6 |

|---|---|---|---|---|---|---|---|

| Oil absorption ratio (multiple) | 6.4 | 6.20 | 7.13 | 8.83 | 8.16 | 9.89 | 10.45 |

| Sample | me | R | R2 |

|---|---|---|---|

| AB-0 | 1.63063 | 0.9162 | 0.9995 |

| AB-LF | 1.34596 | 0.6023 | 0.9988 |

| AB-BF-1 | 1.66661 | 0.7916 | 0.9998 |

| AB-BF-2 | 1.53518 | 0.6581 | 0.9998 |

| AB-BF-3 | 1.34732 | 0.6161 | 0.9983 |

| AB-BF-4 | 1.56308 | 0.7311 | 0.9955 |

| AB-BF-5 | 1.35245 | 0.6211 | 0.9987 |

| AB-BF-6 | 1.30164 | 0.6007 | 0.9966 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Jia, Y.; Zhu, C.; Liu, W.; Li, Z.; Huang, Z. Investigation of Surface Modification of Bagasse Fibers: Performance of Asphalt Binders/Mixtures with Bagasse Fibers. Buildings 2024, 14, 1352. https://doi.org/10.3390/buildings14051352

Xie H, Jia Y, Zhu C, Liu W, Li Z, Huang Z. Investigation of Surface Modification of Bagasse Fibers: Performance of Asphalt Binders/Mixtures with Bagasse Fibers. Buildings. 2024; 14(5):1352. https://doi.org/10.3390/buildings14051352

Chicago/Turabian StyleXie, Haiwei, Yixuan Jia, Chunsheng Zhu, Weidong Liu, Zuzhong Li, and Zhipeng Huang. 2024. "Investigation of Surface Modification of Bagasse Fibers: Performance of Asphalt Binders/Mixtures with Bagasse Fibers" Buildings 14, no. 5: 1352. https://doi.org/10.3390/buildings14051352

APA StyleXie, H., Jia, Y., Zhu, C., Liu, W., Li, Z., & Huang, Z. (2024). Investigation of Surface Modification of Bagasse Fibers: Performance of Asphalt Binders/Mixtures with Bagasse Fibers. Buildings, 14(5), 1352. https://doi.org/10.3390/buildings14051352