A Novel Eco-Friendly Thermal-Insulating High-Performance Geopolymer Concrete Containing Calcium Oxide-Activated Materials from Waste Tires and Waste Polyethylene Terephthalate

Abstract

:1. Introduction

- (1)

- To evaluate the performance of sustainable concrete incorporated with SSRS and PE wastes derived from single-use food containers found in Taiwan in terms of the fresh, hardened, and durability properties;

- (2)

- To examine the cost-effectiveness of cement mortar production using SSRS and PE as sustainable building materials; and

- (3)

- To conduct a comparative analysis of the carbon footprint emission of the SSRS– and PE–cement mortar.

2. Materials and Experimental Methods

2.1. Fabrication of SSRS–Cement Mortar Specimens

2.1.1. Materials

2.1.2. Test Mix Proportions and Variables for SSRS-Substituted Cement Mortar

2.2. Fabrication of PE–Cement Mortar Specimens

2.2.1. Materials

2.2.2. Test-Mix Proportions and Variables for PE-Substituted Cement Mortar

2.3. Test Methods for the Evaluation of Mechanical Properties of Cement Mortar

2.3.1. Slump

2.3.2. Flow

2.3.3. Compressive Strength

2.3.4. Flexural Strength

2.3.5. Tensile Strength

2.3.6. Ultrasonic Pulse Velocity

2.3.7. Water Absorption Rate

2.4. Direct Cost Comparison and Cost–Benefit Analysis

2.5. Carbon Footprint Emission Calculations

3. Results and Discussion

3.1. Mechanical Properties (Fresh and Hardened)

3.1.1. Slump

3.1.2. Flow

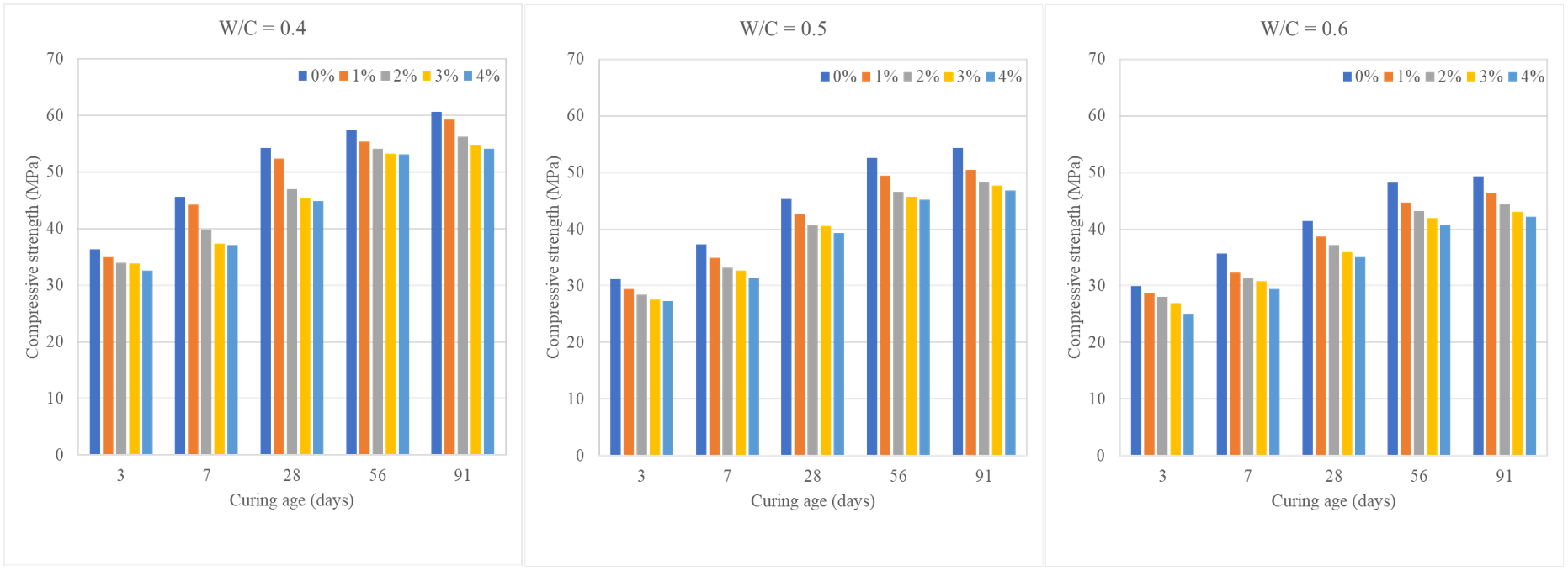

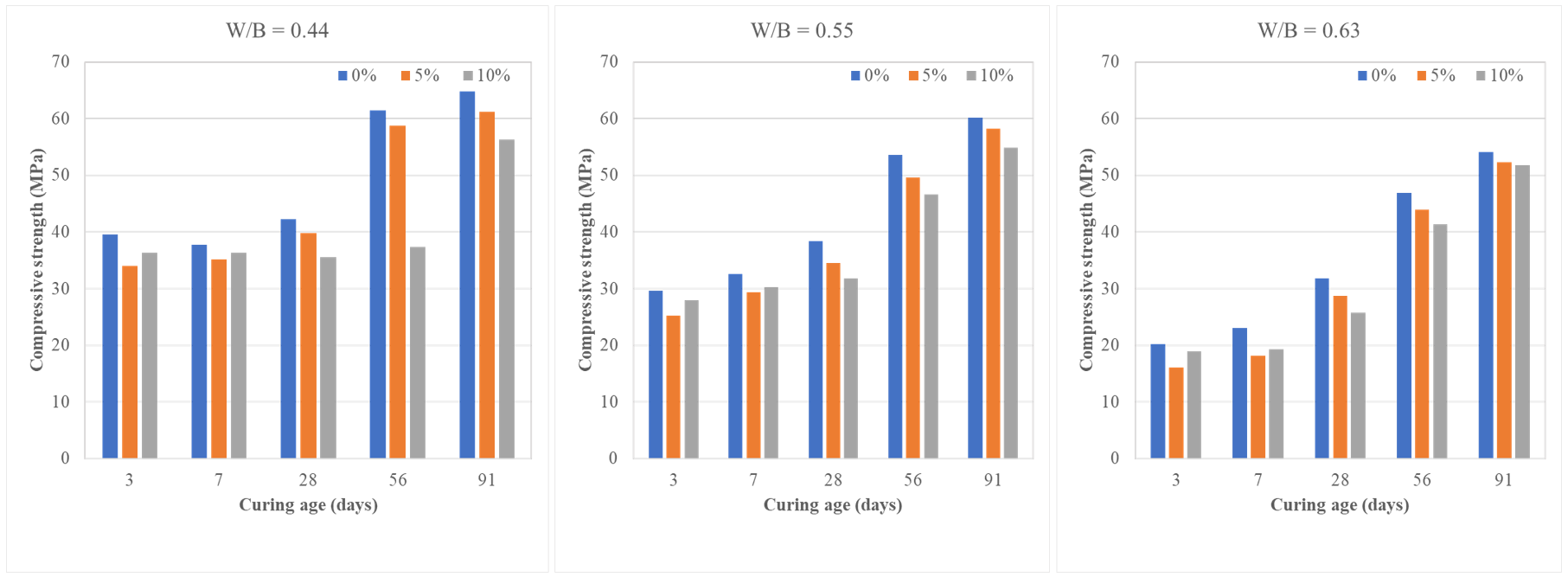

3.1.3. Compressive Strength

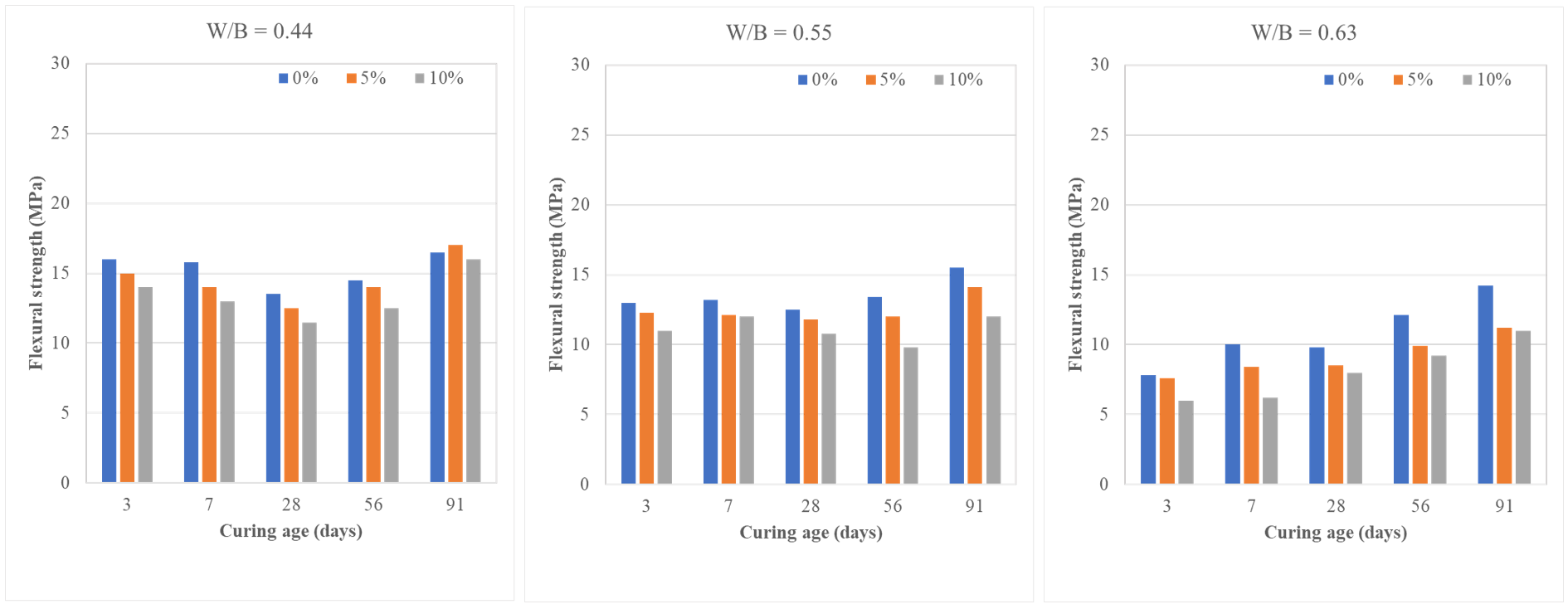

3.1.4. Flexural Strength

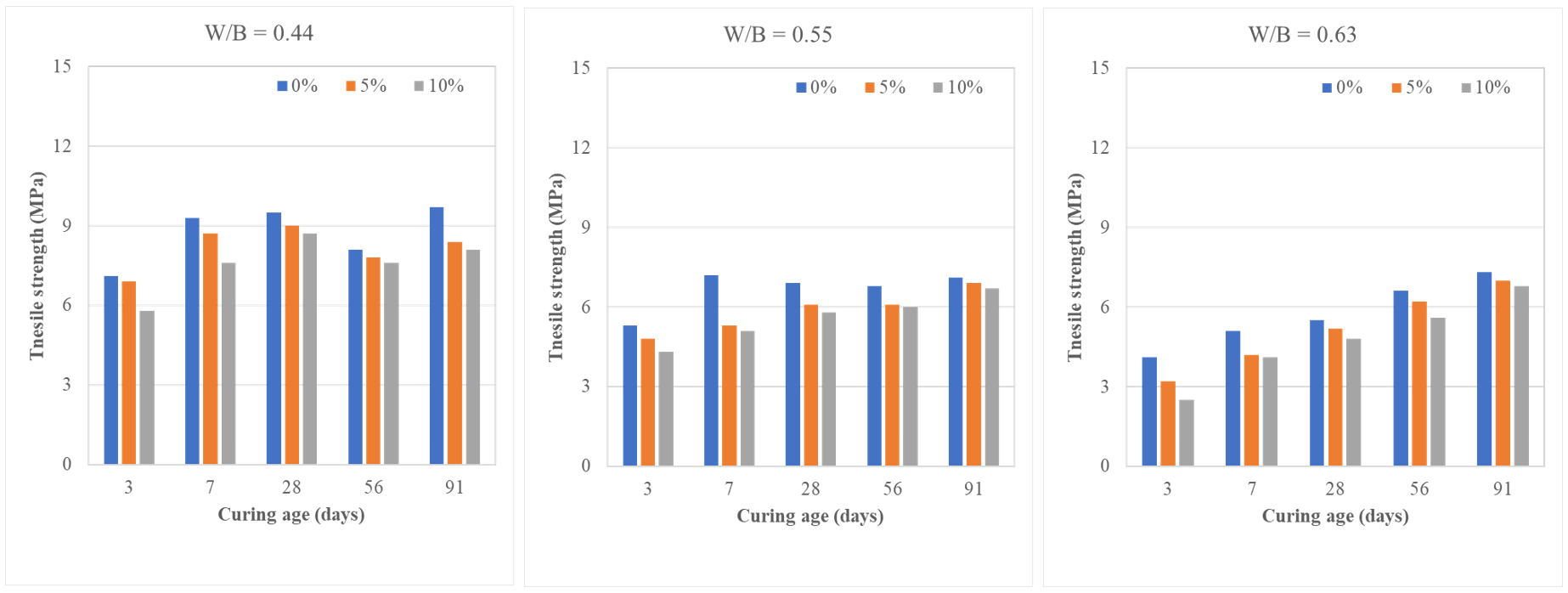

3.1.5. Tensile Strength

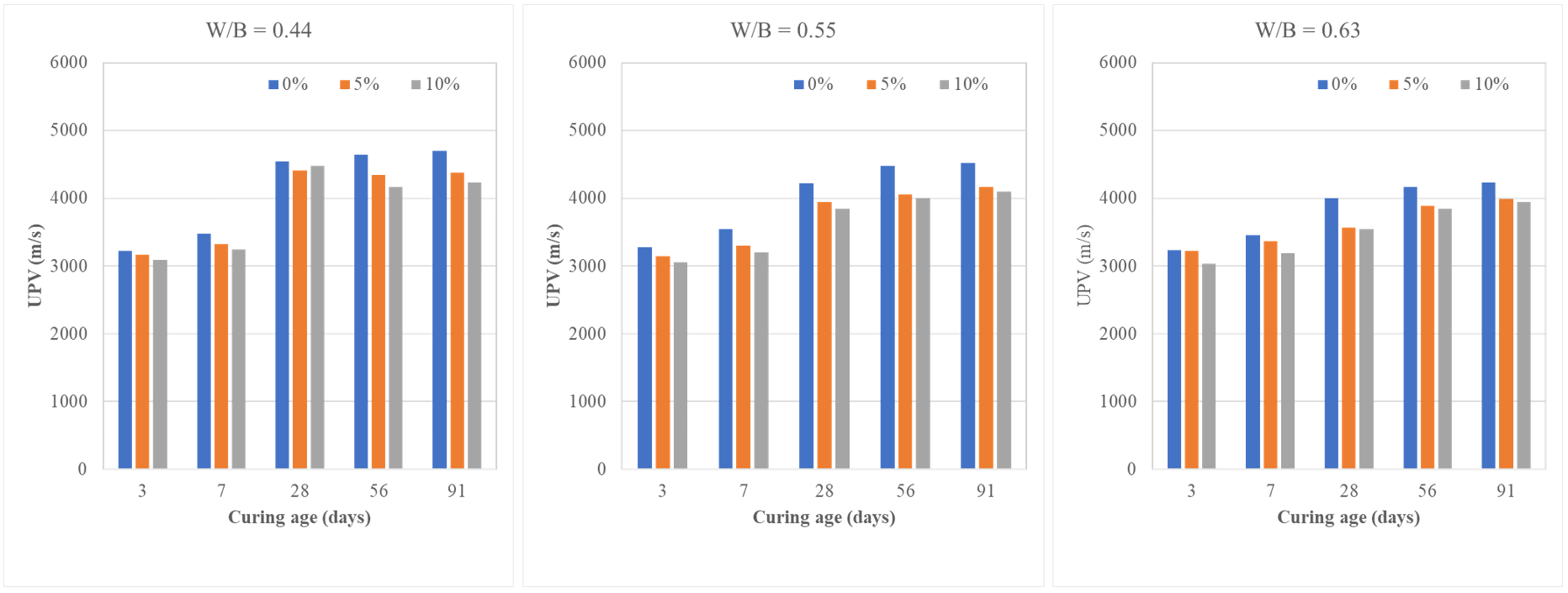

3.1.6. Ultrasonic Pulse Velocity (UPV)

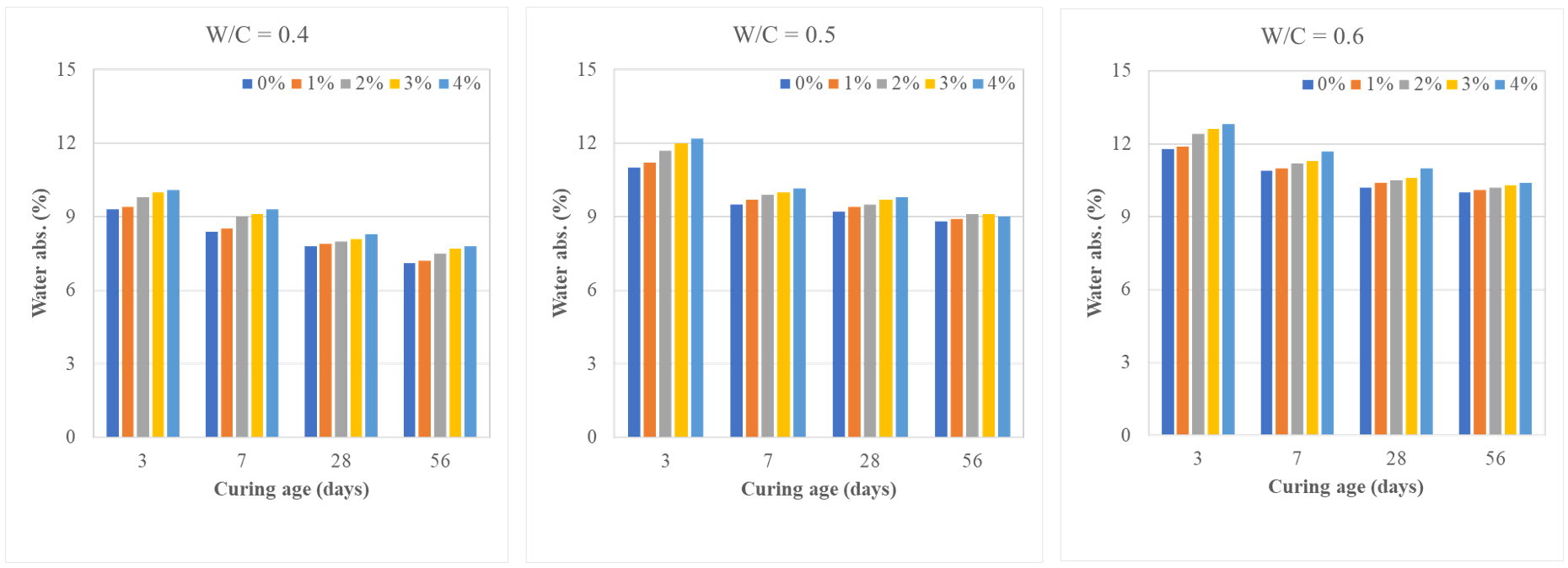

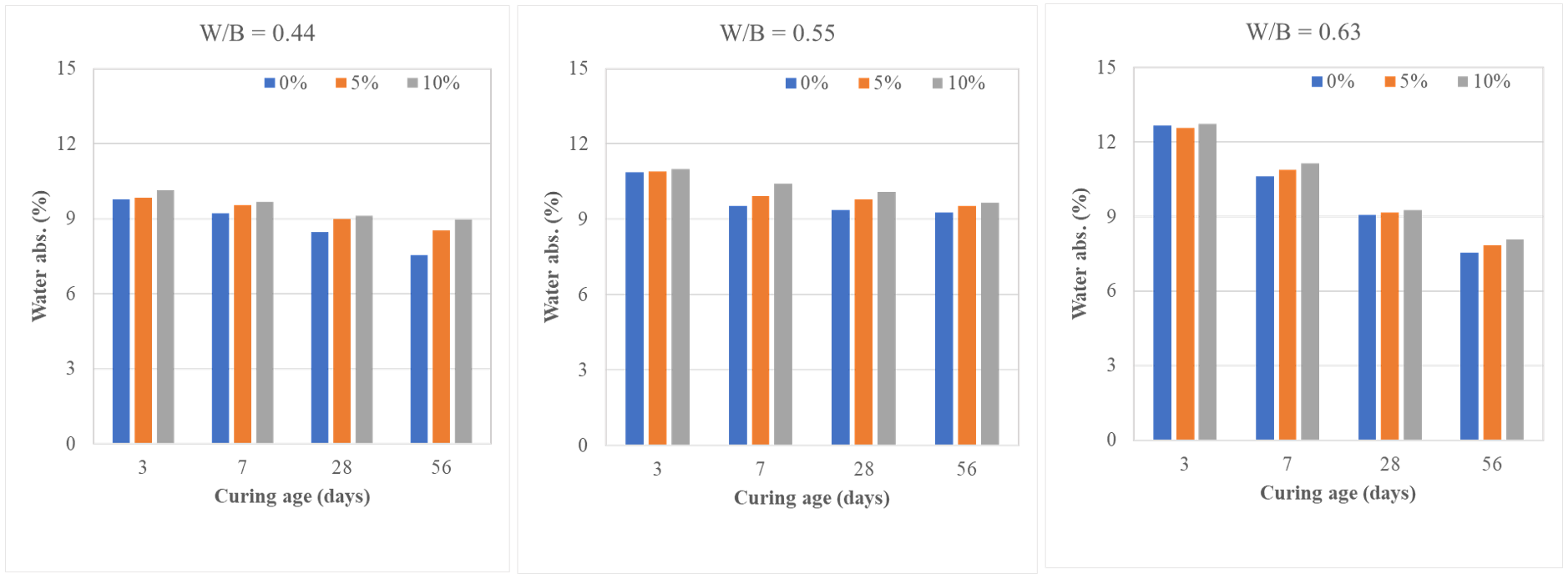

3.1.7. Water Absorption

3.2. Direct Cost Comparison and Cost–Benefit Analysis

3.3. Carbon Footprint Emission

4. Conclusions

- With increasing SSRS substitution amounts, the overall workability (slump and slump flow) of the cement mortar mixture was enhanced. This can be attributed to the more uniform size and shape distribution of SSRS. On the other hand, increasing the PE substitution amount resulted in reduced overall workability. This can be attributed to the non-uniform size distribution and angular shape of the PE aggregates.

- In terms of the mechanical properties (compressive strength, flexural strength, and tensile strength), a similar trend was observed for both cases. Increasing the substitution amount for both SSRS and PE resulted in lower mechanical strength. Similarly, increasing the w/c or w/b ratio also resulted in poor mechanical properties due to the enhanced formation of porosity in the cement mortar samples.

- Ultrasonic pulse velocity (UPV) test results showed that increasing the w/c ratio from 0.4 to 0.6 reduced the UPV by up to 6%. Increasing the PE substitution amount from 0% to 4% also reduced the UPV by 5–8%. Similarly, increasing the w/b ratio reduced the UPV of SSRS–cement mortar samples by up to 12%, while increasing the SSRS substitution amount from 0% to 10% reduced the UPV by up to 11%. The decreasing trend in the UPV is attributed to the increased formation of porosity in the test specimen and the increased number of barriers that attenuated the ultrasonic wave.

- The water absorption results showed that for both the PE–cement mortar and SSRS–cement mortar samples, increasing the w/c or w/b ratio and the substitution amount resulted in increased water absorption due to increased formation of porosity in the test body. These findings are in good agreement with the mechanical tests performed in this study.

- Comparative analysis of the transportation costs and the carbon footprint emission showed that geographical location remains a challenge in the fabrication of cement mortar with PE and SSRS as partial replacements for aggregates. More efforts are needed to make PE and SSRS more accessible to cement mortar manufacturers all over Taiwan to further reduce the cost of fabrication.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resources. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar]

- Nwankwo, C.O.; Bamigboye, G.O.; Davies, I.E.; Michaels, T.A. High volume Portland cement replacement: A review. Constr. Build. Mater. 2020, 260, 120445. [Google Scholar] [CrossRef]

- Dunuweera, S.P.; Rajapakse RM, G. Cement types, composition, uses and advantages of nanocement, environmental impact on cement production, and possible solutions. Adv. Mater. Sci. Eng. 2018, 2018, 4158682. [Google Scholar] [CrossRef]

- World Energy Outlook 2014; International Energy Agency: Paris, France, 2014.

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Zhuang, S. The soundness of steel slag with different free CaO and MgO contents. Constr. Build. Mater. 2017, 151, 138–146. [Google Scholar] [CrossRef]

- Biskri, Y.; Achoura, D.; Chelghoum, N.; Mouret, M. Mechanical and durability characteristics of High Performance Concrete containing steel slag and crystalized slag as aggregates. Constr. Build. Mater. 2017, 150, 167–178. [Google Scholar] [CrossRef]

- Rosales, J.; Agrela, F.; Díaz-López, J.L.; Cabrera, M. Alkali-Activated Stainless Steel Slag as a Cementitious Material in the Manufacture of Self-Compacting Concrete. Materials 2021, 14, 3945. [Google Scholar] [CrossRef]

- Miranda, T.; Leitão, D.; Oliveira, J.; Corrêa-Silva, M.; Araújo, N.; Coelho, J.; Fernández-Jiménez, A.; Cristelo, N. Application of alkali-activated industrial wastes for the stabilisation of a full-scale (sub)base layer. J. Clean. Prod. 2019, 242, 118427. [Google Scholar] [CrossRef]

- Clavier, K.A.; Paris, J.M.; Ferraro, C.C.; Townsend, T.G. Opportunities and challenges associated with using municipal waste incineration ash as a raw ingredient in cement production—A review. Resour. Conserv. Recycl. 2020, 160, 104888. [Google Scholar] [CrossRef]

- Le, D.-H.; Sheen, Y.-N.; Bui, Q.-B. An assessment on volume stabilization of mortar with stainless steel slag sand. Constr. Build. Mater. 2017, 155, 200–208. [Google Scholar] [CrossRef]

- Chang, C.-J. Strategies for Promoting Steelmaking Slag Resourcezation in Taiwan. MATEC Web Conf. 2018, 187, 03001. [Google Scholar] [CrossRef]

- Sheen, Y.-N.; Le, D.-H.; Lam, M.N.-T. Performance of Self-compacting Concrete with Stainless Steel Slag Versus Fly Ash as Fillers: A Comparative Study. Period. Polytech. Civ. Eng. 2021, 65, 1050–1060. [Google Scholar] [CrossRef]

- Liu, S.; Li, L. Influence of fineness on the cementitious properties of steel slag. J. Therm. Anal. Calorim. 2014, 117, 629–634. [Google Scholar] [CrossRef]

- Ducman, V.; Mladenovič, A. The potential use of steel slag in refractory concrete. Mater. Charact. 2011, 62, 716–723. [Google Scholar] [CrossRef]

- Monosi, S.; Ruello, M.L.; Sani, D. Electric arc furnace slag as natural aggregate replacement in concrete production. Cem. Concr. Compos. 2016, 66, 66–72. [Google Scholar] [CrossRef]

- Groh, K.J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P.A.; Lennquist, A.; Leslie, H.A.; Maffini, M.; Slunge, D.; Trasande, L.; et al. Overview of known plastic packaging-associated chemicals and their hazards. Sci. Total. Environ. 2018, 651, 3253–3268. [Google Scholar] [CrossRef] [PubMed]

- De Smet, M. The New Plastics Economy—Rethinking the future of plastics. In Proceedings of the European Conference on Plastics in Freshwater Environments, Berlin, Germany, 21–22 June 2016. [Google Scholar]

- Yearbook of Environmental Protection Statistics; Government Environmental Protection Agency: Taipei, Taiwan, 2021.

- 2020 Sales News for Wholesale, Retail, and Food Services. 2020. Available online: https://www.moea.gov.tw/Mns/dos/bulletin/Bulletin.aspx?kind=9&html=1&menu_id=18808&bull_id=7217 (accessed on 29 October 2023).

- Kulkarni, B.N.; Anantharama, V. Repercussions of COVID-19 pandemic on municipal solid waste management: Challenges and opportunities. Sci. Total. Environ. 2020, 743, 140693. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, M.; Oskoei, V.; Jafari, A.J.; Farzadkia, M.; Firooz, M.H.; Abdollahinejad, B.; Torkashvand, J. Municipal solid waste management during COVID-19 pandemic: Effects and repercussions. Environ. Sci. Pollut. Res. 2021, 28, 32200–32209. [Google Scholar] [CrossRef] [PubMed]

- Sarkodie, S.A.; Owusu, P.A. Impact of COVID-19 pandemic on waste management. Environ. Dev. Sustain. 2020, 23, 7951–7960. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Raheem, D. Application of plastics and paper as food packaging materials ? An overview. Emir. J. Food Agric. 2013, 25, 177. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Rumšys, D.; Bačinskas, D.; Spudulis, E.; Meškėnas, A. Comparison of Material Properties of Lightweight Concrete with Recycled Polyethylene and Expanded Clay Aggregates. Procedia Eng. 2017, 172, 937–944. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Al-Tamimi, A.S.; Al-Tarbi, S.M.; Al-Amoudi, O.S.B.; Al-Awsh, W.A.; Saleh, T.A. Development of sustainable concrete using recycled high-density polyethylene and crumb tires: Mechanical and thermal properties. J. Build. Eng. 2022, 45, 103399. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, M.-J. High energy absorbent ultra-high-performance concrete with hybrid steel and polyethylene fibers. Constr. Build. Mater. 2019, 209, 354–363. [Google Scholar] [CrossRef]

- Coviello, C.G.; Lassandro, P.; Sabbà, M.F.; Foti, D. Mechanical and Thermal Effects of Using Fine Recycled PET Ag-gregates in Common Screeds. Sustainability 2023, 15, 16692. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of steel slag aggregate in portland cement concrete: An overview. J. Clean. Prod. 2020, 282, 124447. [Google Scholar] [CrossRef]

- Fisher, L.V.; Barron, A.R. The recycling and reuse of steelmaking slags—A review. Resources. Conserv. Recycl. 2019, 146, 244–255. [Google Scholar] [CrossRef]

- ASTM C150; Standard Specification for Portland Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM C230; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 1997.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50 mm Cube Specimens). American Society for Testing and Materials: West Conshohocken, PA, USA, 1994.

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic Cement Mortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM C190; Standard Test Method for Tensile Strength of Hydraulic Cement Mortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 1995.

- ASTM C597; Standard Test Method for Pulse Velocity through Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C1585; Standard Test Method for Measurement of the Rate of Absorption of Water by Hydraulic-Cement Concretes. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Jiménez, L.F.; Domínguez, J.A.; Vega-Azamar, R.E. Carbon Footprint of Recycled Aggregate Concrete. Adv. Civ. Eng. 2018, 2018, 7949741. [Google Scholar] [CrossRef]

- ISO 14064-1; Greenhouse Gases—Part 1: Specification with Guidance at the Organization Level for Quantification and Reporting of Greenhouse Gas Emissions and Removals. International Organization for Standardization: Geneva, Switzerland, 2018.

- Instituto Nacional de Ecología. Inventario Nacional de Emisiones de Gases de Efecto Invernadero 1990; Instituto Nacional de Ecología: México, Mexico, 2004. [Google Scholar]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Secretaría del Medio Ambiente y Recursos Naturales. Registro Nacional de Emisiones; Secretaría del Medio Ambiente y Recursos Naturales: México, Mexico, 2015. [Google Scholar]

- Comisión Nacional para el Uso Eficiente de la Energía. Estudio Integral de Sistemas de Bombeo de Agua Potable Mu-nicipal; Comisión Nacional para el Uso Eficiente de la Energía: México, Mexico, 2011. [Google Scholar]

- Al-Hadithi, A.I.; Noaman, A.T.; Mosleh, W.K. Mechanical properties and impact behavior of PET fiber reinforced self-compacting concrete (SCC). Compos. Struct. 2019, 224, 111021. [Google Scholar] [CrossRef]

- Rahim, N.L.; Sallehuddin, S.; Ibrahim, N.M.; Amat, R.C.; Ab Jalil, M.F. Use of Plastic Waste (High Density Polyethylene) in Concrete Mixture as Aggregate Replacement. Adv. Mater. Res. 2013, 701, 265–269. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Lerna, M.; Foti, D.; Petrella, A.; Sabbà, M.F.; Mansour, S. Effect of the Chemical and Mechanical Recycling of PET on the Thermal and Mechanical Response of Mortars and Premixed Screeds. Materials 2023, 16, 3155. [Google Scholar] [CrossRef]

- Foti, D.; Lerna, M. New Mortar Mixes with Chemically Depolymerized Waste PET Aggregates. Adv. Mater. Sci. Eng. 2020, 2020, 8424936. [Google Scholar] [CrossRef]

- Liu, Y.; Su, Y.; Xu, G.; Chen, Y.; You, G. Research Progress on Controlled Low-Strength Materials: Metallurgical Waste Slag as Cementitious Materials. Materials 2022, 15, 727. [Google Scholar] [CrossRef] [PubMed]

- Susanto, A.; Koleva, D.A.; van Breugel, K. The Effect of Water-to-Cement Ratio and Curing on Material Properties of Mortar Specimens in Stray Current Conditions. J. Adv. Concr. Technol. 2017, 15, 627–643. [Google Scholar] [CrossRef]

- ASTM C330; Standard Specification for Lightweight Aggregates for Structural Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Hedjazi, S. Compressive strength of lightweight concrete. In Compressive Strength of Concrete; BoD—Books on Demand: Norderstedt, Germany, 2019; pp. 1–8. [Google Scholar]

- Kodua, J.; Tagbor, T.A.; Berko-Boateng, V.N.; Appiah, K.B. Influence of recycled waste high density polyethylene plastic aggregate on the physico-chemical and mechanical properties of concrete. Int. J. Sci. Eng. Sci. 2018, 2, 22–25. [Google Scholar]

- Lee, Z.H.; Paul, S.C.; Kong, S.Y.; Susilawati, S.; Yang, X. Modification of Waste Aggregate PET for Improving the Concrete Properties. Adv. Civ. Eng. 2019, 2019, 6942052. [Google Scholar] [CrossRef]

- Fathy, S.; Liping, G.; Ma, R.; Chunping, G.; Wei, S. Comparison of Hydration Properties of Cement-Carbon Steel Slag and Cement-Stainless Steel Slag Blended Binder. Adv. Mater. Sci. Eng. 2018, 2018, 1851367. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Steel furnace slag aggregate expansion and hardened concrete properties. Cem. Concr. Compos. 2015, 60, 1–9. [Google Scholar] [CrossRef]

- Martins, A.C.P.; de Carvalho, J.M.F.; Costa, L.C.B.; Andrade, H.D.; de Melo, T.V.; Ribeiro, J.C.L.; Pedroti, L.G.; Peixoto, R.A.F. Steel slags in cement-based composites: An ultimate review on characterization, applications and performance. Constr. Build. Mater. 2021, 291, 123265. [Google Scholar] [CrossRef]

- Aydın, A.C.; Aras, G.H.; Kotan, T.; Öz, A. Effect of Boron Active Belite Cement on the Compressive Strength of Concrete Exposed to High Temperatures. J. Civ. Constr. Environ. Eng. 2018, 3, 47. [Google Scholar] [CrossRef]

- Saint-Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete Quality Designation based on Ultrasonic Pulse Velocity. Constr. Build. Mater. 2016, 125, 1022–1027. [Google Scholar] [CrossRef]

- World Steel Association. World Steel in Figures 2022; World Steel Association: Brussels, Belgium, 2022; Available online: https://worldsteel.org/data/world-steel-in-figures-2022/ (accessed on 29 October 2023).

- Soares, C.T.d.M.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2021, 176, 105905. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2017, 3, 1. [Google Scholar] [CrossRef]

- CLC Corporation. Available online: https://www.clc.com.tw/en/ (accessed on 29 October 2023).

| w/b | GGBFS | Fly Ash | SSRS Substitution Amount (%) | SSRS | Cement | Sand | Water |

|---|---|---|---|---|---|---|---|

| 0.44 | 87.20 | 43.60 | 0 | 0 | 437 | 1534.9 | 249.7 |

| 5 | 30.70 | 405.8 | |||||

| 10 | 61.40 | 374.6 | |||||

| 0.55 | 76.50 | 38.27 | 0 | 0 | 383.5 | 1534.9 | 274 |

| 5 | 27 | 356.1 | |||||

| 10 | 53.90 | 328.7 | |||||

| 0.63 | 87.20 | 34.09 | 0 | 0 | 341.72 | 1534.9 | 292.91 |

| 5 | 24.02 | 317.32 | |||||

| 10 | 48.04 | 292.91 |

| w/c | PE Substitution Amount (%) | PE | Cement | Sand | Water |

|---|---|---|---|---|---|

| 0.4 | 0 | 0 | 936.40 | 2302.32 | 374.56 |

| 1 | 13.85 | ||||

| 2 | 27.69 | ||||

| 3 | 41.54 | ||||

| 4 | 55.38 | ||||

| 0.5 | 0 | 0 | 821.85 | 2302.32 | 410.92 |

| 1 | 13.85 | ||||

| 2 | 27.69 | ||||

| 3 | 41.54 | ||||

| 4 | 55.38 | ||||

| 0.6 | 0 | 0 | 732.27 | 2302.32 | 439.36 |

| 1 | 13.85 | ||||

| 2 | 27.69 | ||||

| 3 | 41.54 | ||||

| 4 | 55.38 |

| Manufacturer/Provider | Address | Province/County | Remarks |

|---|---|---|---|

| Tang Rong Iron Works Co., Ltd. | No. 4, Coastal 2nd Road, Xiaogang District, Kaohsiung City | Kaohsiung | SSRS provider |

| Yelian Iron and Steel Co., Ltd. | No. 600, Xinglong Street, Gangshan District, Kaohsiung City | Kaohsiung | SSRS provider |

| Walsin Lihwa Co., Ltd. | No. 3-10, Neighborhood 12, Xizhouliao 12, Xishuili, Yanshui District, Tainan City | Tainan | SSRS provider |

| Ronggang Material Technology Co., Ltd. | No. 35, Xinzhong Road, Xinying District, Tainan City | Tainan | SSRS provider |

| Shin Feng Concrete Co., Ltd. | No. 779, Dachang Road, Wandan Township, Pingtung County | Pingtung | Concrete pavement manufacturer |

| Tianjiu Industrial Co., Ltd. | No. 12-39, Shangjiaji, Houbi District, Tainan City | Tainan | Concrete pavement manufacturer |

| Tai Fu Cement Products Co., Ltd. | Changhua 1 and 2 plants: No. 52-1, Xinggong Road, Shengang Township, Changhua County (Quanxing Industrial Zone) | Changhua | Concrete pavement manufacturer |

| Yama Development Co., Ltd. | No. 5, Industrial North 1st Road, Nantou City, Nantou County | Nantou | Concrete pavement manufacturer |

| Shangmei Industrial Co., Ltd. | 80-15, Adjacent to Dadongkeng 80, Dongpingli, Guanxi Town, Hsinchu County | Hsinchu | Concrete pavement manufacturer |

| Zhenglong Co., Ltd. | 300 Section 2, Changqing Road, Zhubei, Hsinchu County | Hsinchu | Single-use plastic provider |

| Aplus Molds & Plastics Co., Ltd. | 63 Lane 350 Chong Jeng Road, Yongkang District, Tainan City | Tainan | Plastic pavement manufacturer |

| Material | Emission Factor (kg CO2-e/kg) | Reference |

|---|---|---|

| Cement | 0.745 | [46] |

| Explosives | 0.440 | [47] |

| Diesel | 2.680 | [47] |

| Coarse aggregates | 0.041 | [47] |

| Fine aggregates | 0.014 | [47] |

| Electricity | 0.458 | [48] |

| Water | 0.540 | [49] |

| Concrete | 0.012 | [47] |

| SSRS Provider | Concrete Pavement Manufacturer | Distance (km) | Duration of Trip | Transportation Cost per Day (TWD) |

|---|---|---|---|---|

| Tang Rong Iron Works Co., Ltd. (Kaohsiung) | Shin Feng Concrete Co., Ltd. (Pingtung) | 19.3 | 30 min | 3000 |

| Tang Rong Iron Works Co., Ltd. (Kaohsiung) | Tianjiu Industrial Co., Ltd. (Tainan) | 114 | 1 h 30 min | 6000 |

| Yelian Iron and Steel Co., Ltd. (Kaohsiung) | Shin Feng Concrete Co., Ltd. (Pingtung) | 50.4 | 1 h | 4500 |

| Yelian Iron and Steel Co., Ltd. (Kaohsiung) | Tianjiu Industrial Co., Ltd. (Tainan) | 81.3 | 1 h | 4500 |

| Walsin Lihwa Co., Ltd. (Tainan) | Tianjiu Industrial Co., Ltd. (Tainan) | 14.8 | 20 min | 3000 |

| Walsin Lihwa Co., Ltd. (Tainan) | Tai Fu Cement Products Co., Ltd. (Changhua) | 110 | 1 h 20 min | 6000 |

| Walsin Lihwa Co., Ltd. (Tainan) | Yama Development Co., Ltd. (Nantou) | 106 | 1 h 15 min | 6000 |

| Walsin Lihwa Co., Ltd. (Tainan) | Shangmei Industrial Co., Ltd. (Hsinchu) | 226 | 2 h 30 min | 12,000 |

| Ronggang Material Technology Co., Ltd. (Tainan) | Tianjiu Industrial Co., Ltd. (Tainan) | 24.3 | 20 min | 3000 |

| Ronggang Material Technology Co., Ltd. (Tainan) | Tai Fu Cement Products Co., Ltd. (Changhua) | 108 | 1 h 20 min | 6000 |

| Ronggang Material Technology Co., Ltd. (Tainan) | Yama Development Co., Ltd. (Nantou) | 104 | 1 h 10 min | 6000 |

| Ronggang Material Technology Co., Ltd. (Tainan) | Shangmei Industrial Co., Ltd. (Hsinchu) | 224 | 2 h 20 min | 12,000 |

| Single-Use Plastic Provider | Plastic Pavement Manufacturer | Distance (km) | Duration of Trip | Total Transportation Cost per Day (TWD) |

|---|---|---|---|---|

| Zhenglong Co., Ltd. | Aplus Molds & Plastics Co., Ltd. | 235 | 2 h 40 min | 12,000 |

| w/b | SSRS Substitution Amount (%) | Cement | Aggregates | Others | Total |

|---|---|---|---|---|---|

| 0.44 | 0 | 325.57 | 23.32 | 485.38 | 834.27 |

| 5 | 302.32 | 24.58 | 567.66 | 894.56 | |

| 10 | 279.08 | 25.84 | 649.93 | 954.85 | |

| 0.55 | 0 | 285.71 | 23.10 | 455.54 | 764.35 |

| 5 | 265.29 | 24.20 | 527.90 | 817.40 | |

| 10 | 244.88 | 25.31 | 600.00 | 870.18 | |

| 0.63 | 0 | 254.58 | 23.19 | 483.23 | 761.00 |

| 5 | 236.40 | 24.17 | 547.60 | 808.18 | |

| 10 | 218.22 | 25.16 | 611.98 | 855.35 |

| w/c | PE Substitution Amount (%) | Cement | Aggregates | Others | Total |

|---|---|---|---|---|---|

| 0.4 | 0 | 697.62 | 32.23 | 0.54 | 762.62 |

| 1 | 697.62 | 32.80 | 0.58 | 763.80 | |

| 2 | 697.62 | 33.37 | 0.61 | 764.97 | |

| 3 | 697.62 | 33.94 | 0.65 | 766.14 | |

| 4 | 697.62 | 34.50 | 0.69 | 767.31 | |

| 0.5 | 0 | 612.28 | 32.23 | 0.54 | 677.28 |

| 1 | 612.28 | 32.80 | 0.58 | 678.46 | |

| 2 | 612.28 | 33.37 | 0.61 | 679.63 | |

| 3 | 612.28 | 33.94 | 0.65 | 680.80 | |

| 4 | 612.28 | 34.50 | 0.69 | 681.97 | |

| 0.6 | 0 | 545.54 | 32.23 | 0.54 | 610.55 |

| 1 | 545.54 | 32.80 | 0.58 | 611.72 | |

| 2 | 545.54 | 33.37 | 0.61 | 612.89 | |

| 3 | 545.54 | 33.94 | 0.65 | 614.06 | |

| 4 | 545.54 | 34.50 | 0.69 | 615.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, S.-L.; Wang, H.-Y.; Lin, K.-T.; Hung, C.-C. A Novel Eco-Friendly Thermal-Insulating High-Performance Geopolymer Concrete Containing Calcium Oxide-Activated Materials from Waste Tires and Waste Polyethylene Terephthalate. Buildings 2024, 14, 1437. https://doi.org/10.3390/buildings14051437

Tsai S-L, Wang H-Y, Lin K-T, Hung C-C. A Novel Eco-Friendly Thermal-Insulating High-Performance Geopolymer Concrete Containing Calcium Oxide-Activated Materials from Waste Tires and Waste Polyethylene Terephthalate. Buildings. 2024; 14(5):1437. https://doi.org/10.3390/buildings14051437

Chicago/Turabian StyleTsai, Shen-Lun, Her-Yung Wang, Keng-Ta Lin, and Chang-Chi Hung. 2024. "A Novel Eco-Friendly Thermal-Insulating High-Performance Geopolymer Concrete Containing Calcium Oxide-Activated Materials from Waste Tires and Waste Polyethylene Terephthalate" Buildings 14, no. 5: 1437. https://doi.org/10.3390/buildings14051437

APA StyleTsai, S.-L., Wang, H.-Y., Lin, K.-T., & Hung, C.-C. (2024). A Novel Eco-Friendly Thermal-Insulating High-Performance Geopolymer Concrete Containing Calcium Oxide-Activated Materials from Waste Tires and Waste Polyethylene Terephthalate. Buildings, 14(5), 1437. https://doi.org/10.3390/buildings14051437