Effects of Niobium Addition on the Mechanical Properties and Corrosion Resistance of Microalloyed Steels: A Review

Abstract

1. Introduction

2. Effects of Nb on Microalloyed Steels

2.1. Effects at the Microstructural Level

2.2. Grain Refinement Impact on the Steel Mechanical Properties

2.3. Effects on Cyclic Mechanical Behavior

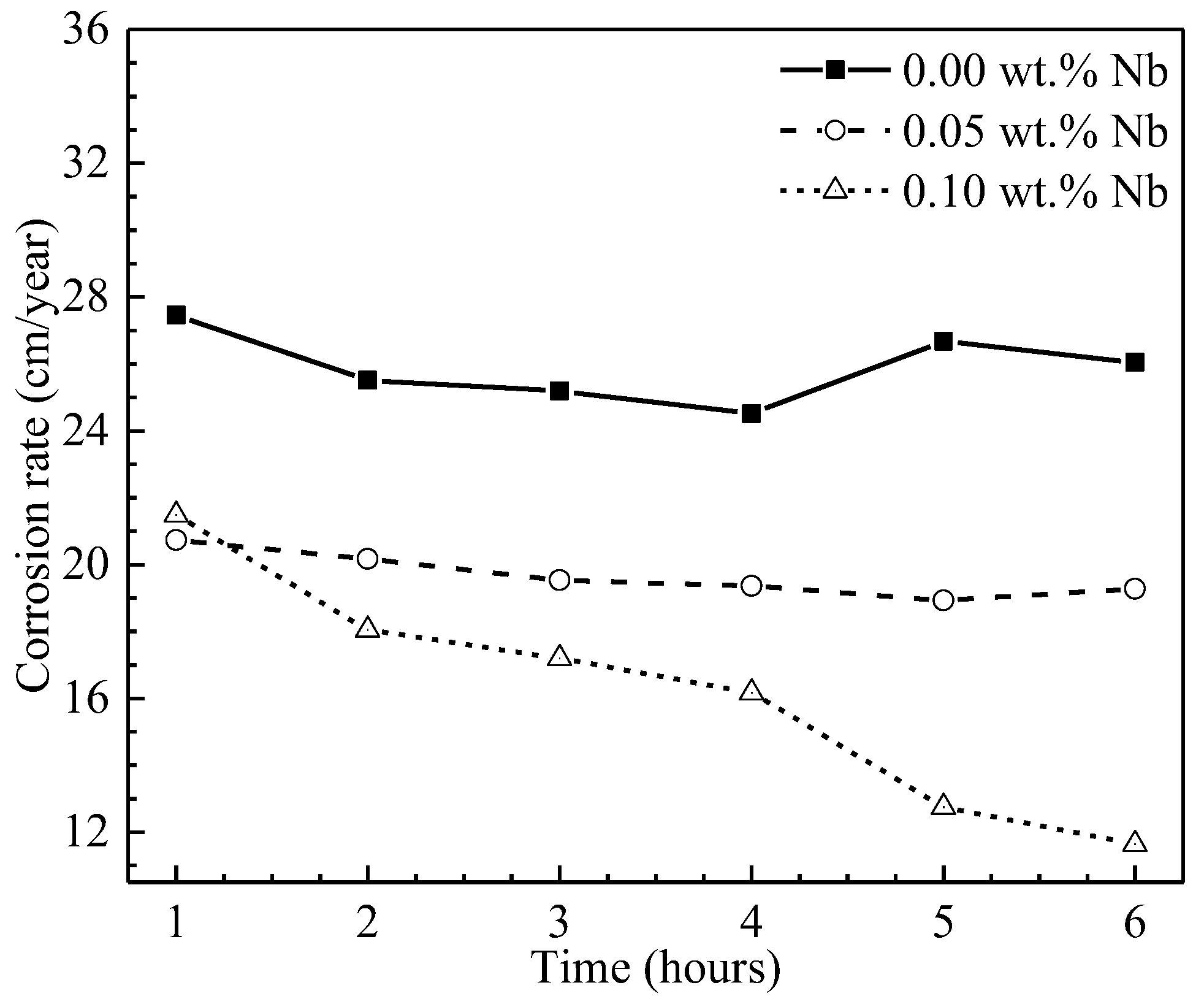

2.4. Effects on Corrosion Resistance

3. Mechanical Behavior of Corroded Steel Beams

4. Effects of Corrosion on Weld Integrity

5. Current Challenges and Future Research Needs

- Although several studies have explored the impact of Nb addition on the mechanical properties and corrosion resistance of microalloyed steels, the improvement in properties and a subsequent deleterious effect as the percentage of Nb increases suggests the existence of an optimal percentage for each type of alloy. Future studies can be conducted to identify optimal additions for structural additions that could be subjected to high loads and corrosive environments.

- Although the positive influence of Nb addition on the mechanical properties of steels is widely known, studies elucidating the effects of Nb addition on steels exposed to salt spray are quite limited. Experimental investigations must be conducted to identify the optimal Nb addition percentages that would generate better mechanical and durability performance. The results of these studies can be applied to the production of Nb-microalloyed steels for structures exposed to the marine atmosphere.

- As discussed throughout the paper, several factors, such as the corrosion level, corrosion rate, and steel composition, influence the mechanical behavior of corroded steel structures. There is no standard for evaluating the properties affected by the corrosive process, and each study considers different scenarios and variables. Therefore, it is a challenge to compare different studies and evaluate the contribution of each factor in the residual properties of corroded elements, aiming to establish the best material solution for each design configuration.

- As discussed throughout the paper, corrosion in the welded joints is important for structural behavior, as it can be the weakest region for corrosion. In this regard, no studies addressing alveolar beams under corrosion were found during the information-gathering process. In these beams, the cutting and welding process is typically applied to increase the structural performance. Conducting studies to assess its corrosion resistance and exploring potential methods to enhance its performance, such as utilizing Nb, are of paramount importance.

- Some relevant aspects have not been investigated yet. The phenomenological changes in microstructure are achieved by adding Nb to the material nonlinear hardening behavior. Also, cyclic test results to understand hysteresis, which are fundamental to applying or developing constitutive models, can buster the investigations on a meso and macroscale and promote the material application.

- No investigation was found on Nb-microalloys submitted to stress states in aggressive environments, which is essential for other steel types, like stainless steel [100]. Such an investigation represents the actual condition of the structural elements and is necessary for expanding the use of such alloys.

- The literature mapping revealed that there are no studies that evaluate the influence of temperature corrosive environments on the mechanical property degradation of Nb-microalloyed steels. Future studies could be developed on this topic through the use of temperature-controlled salt spray chambers.

6. Conclusions

- While some standards prescribe a limit addition value of 0.07 wt.% Nb, the experimental studies reviewed provide evidence that higher addition values can significantly enhance corrosion resistance. This suggests that although the value established by standards may optimize improvements in mechanical parameters, such as the yield strength, ultimate strength, and toughness of the steel, it may not necessarily yield the best durability performance when the steel is exposed to corrosive atmospheres.

- The addition of niobium to steel consistently enhances its corrosion resistance across various types of corrosive atmospheres. This improvement is attributed to the formation of a compact layer of niobium oxides that shields the steel from dissolution. However, it is crucial to monitor the quantity of niobium added, as excessive amounts (>1.0 wt.%) can result in the formation of Fe2Nb, which actually increases the steel’s susceptibility to corrosion.

- Generally, higher levels of corrosion result in significant reductions in the mechanical behavior of steel beams. This degradation is challenging to predict consistently due to the wide range of variables present in different studies. Moreover, corrosion influences the slenderness ratio of the flange and the web, which are critical factors in the structural design of steel members. This interconnectedness highlights how corrosion impacts not only the material strength but also the fundamental design parameters of steel structures.

- Incorporating Nb as a microalloy significantly enhances the properties of the HAZ, improving toughness, strength, and corrosion resistance. Additionally, Nb contributes to reducing the grain size in the HAZ and promotes the formation of acicular ferrite. This leads to improved fracture toughness and resistance to plastic deformation, demonstrating how Nb plays a multifaceted role in enhancing the overall performance of the material.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Research | Span (m) | Steel Beam | Corrosion Method | Experimental Test | Mass Loss | Failure Mode | Peak Load Reduction(%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel Nom. | fy | h | hw | tw | tf | bf | Nb Content | |||||||

| (MPa) | (mm) | (mm) | (mm) | (mm) | (mm) | (%) | ||||||||

| Peng et al. [70] | 1.8 | Q460D | 460 | 200 | 184 | 8 | 8 | 150 | 0.19 | Immersion in a 5 wt.% NaCl solution. Corrosion current: 1880 mA | 4-point bending test | 0 | local buckling of upper flange | 0 |

| 5 | local buckling of upper flange | 6.09 | ||||||||||||

| 10 | local buckling of upper flange | 13.41 | ||||||||||||

| 15 | buckling of upper flange and web near mid-span | 32.90 | ||||||||||||

| Zhang et al. [72] | 1.5 | Q345 | 345 | 200 | 182 | 6 | 9 | 150 | ≤0.07 † | Outdoor artificial accelerated corrosion test up to 12 months | 4-point bending test | 0 | local buckling of upper flange | 0 |

| 5.63 | local buckling of upper flange | 17.4 | ||||||||||||

| 6.89 | buckling of upper flange and web near mid-span | 21.71 | ||||||||||||

| 13.1 | buckling of upper flange and web near mid-span | 27.54 | ||||||||||||

| 16.88 | buckling of upper flange and web near mid-span | 30.5 | ||||||||||||

| Xiao et al. [74] | 1.8 | Q460D | 460 | 200 | 184 | 8 | 8 | 150 | 0.19 | Immersion in a 5 wt.% NaCl solution. Corrosion current: 0.005 mA/cm2 | 4-point bending test | 0 | buckling of upper flange | 0 |

| 4.87 | buckling of upper flange | 2.83 | ||||||||||||

| 9.61 | buckling of upper flange | 12.97 | ||||||||||||

| 11.67 | web buckling failure | 30.89 | ||||||||||||

| 14.87 | web buckling failure | 64.15 | ||||||||||||

References

- Xie, H.; Du, L.; Hu, J.; Misra, R. Microstructure and mechanical properties of a novel 1000 MPa grade TMCP low carbon microalloyed steel with combination of high strength and excellent toughness. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2014, 612, 123–130. [Google Scholar] [CrossRef]

- Patterson, T.; Lippold, J. Effect of niobium on the microstructure and properties of submerged arc welds in HSLA steel. Weld. World 2020, 64, 1089–1105. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Yang, L.; Liu, Z.; Li, X.; Li, Y. Corrosion and SCC initiation behavior of low-alloy high-strength steels microalloyed with Nb and Sb in a simulated polluted marine atmosphere. J. Mater. Res. Technol. 2020, 9, 12976–12995. [Google Scholar] [CrossRef]

- Zhao, Q.; Fan, E.; Wang, S.; Zhao, J.; Huang, Y.; Li, X. Understanding the Effect of Nanosized NbC Precipitates on the Stress Corrosion Cracking of High-Strength Low-Alloy Steel in a Simulated Deep-Sea Environment. J. Mater. Eng. Perform. 2021, 30, 2159–2173. [Google Scholar] [CrossRef]

- Jia, J.; Cheng, X.; Yang, X.; Li, X.; Li, W. A study for corrosion behavior of a new-type weathering steel used in harsh marine environment. Constr. Build. Mater. 2020, 259, 119760. [Google Scholar] [CrossRef]

- Yu, H.; Wu, K.; Dong, B.; Yu, L.; Liu, J.; Liu, Z.; Xiao, D.; Jing, X.; Liu, H. Effect of Niobium Content on the Microstructure and Mechanical Properties of Simulated Coarse-Grained Heat-Affected Zone (CGHAZ) of High-Strength Low-Alloy (HSLA) Steels. Materials 2022, 15, 3318. [Google Scholar] [CrossRef]

- Villalobos, J.; Del-Pozo, A.; Campillo, B.; Mayen, J.; Serna, S. Microalloyed Steels through History until 2018: Review of Chemical Composition, Processing and Hydrogen Service. Metals 2018, 8, 351. [Google Scholar] [CrossRef]

- Baker, T. Microalloyed steels. Ironmak. Steelmak. 2016, 43, 264–307. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wang, Y.M.; Zhai, Y.D.; Li, P.; Su, G.Q. Study on the role of niobium in corrosion mechanism of low-alloy pipeline steel in H2S-saturated solution. Int. J. Hydrogen Energy 2023, 48, 22192–22208. [Google Scholar] [CrossRef]

- Zhang, C.; Hui, W.; Zhao, X.; Zhang, Y.; Zhao, X. The potential significance of microalloying with Nb in enhancing the resistance to hydrogen-induced delayed fracture of 1300-MPa-grade high-strength bolt steel. Eng. Fail. Anal. 2022, 135, 106–144. [Google Scholar] [CrossRef]

- Tian, S.; Liu, Z.; Fu, R.; Wang, X. Effect of niobium alloying on the austenite grain growth and mechanical properties of ultrahigh-strength stainless steel. Mater. Res. Express 2022, 9, 026511. [Google Scholar] [CrossRef]

- Liu, X.; Wang, H.; Liu, Y.; Wang, C.; Song, Q.; Cui, H.; Zhang, C.; Huang, K. The effect of Nb content on microstructure and properties of laser cladding 316L SS coating. Surf. Coat. Technol. 2021, 425, 127684. [Google Scholar] [CrossRef]

- Qiao, Q.; Lu, L.; Fan, E.; Zhao, J.; Liu, Y.; Peng, G.; Huang, Y.; Li, X. Effects of Nb on stress corrosion cracking of high-strength low-alloy steel in simulated seawater. Int. J. Hydrogen Energy 2019, 44, 27962–27973. [Google Scholar] [CrossRef]

- Hutchinson, C.; Zurob, H.; Sinclair, C.; Brechet, Y. The comparative effectiveness of Nb solute and NbC precipitates at impeding grain-boundary motion in Nb steels. Scr. Mater. 2008, 59, 635–637. [Google Scholar] [CrossRef]

- Sun, L.; Liu, X.; Xu, X.; Lei, S.; Li, H.; Zhai, Q. Review on niobium application in microalloyed steel. J. Iron Steel Res. Int. 2022, 29, 1513–1525. [Google Scholar] [CrossRef]

- Jack, T.; Szpunar, J. Effect of Nb-induced microstructure on pipeline steel corrosion and stress corrosion cracking performance in acidic environment. Corros. Sci. 2023, 218, 111196. [Google Scholar] [CrossRef]

- Nam, N.; Kim, J. Effect of niobium on the corrosion behaviour of low alloy steel in sulfuric acid solution. Corros. Sci. 2010, 52, 3377–3384. [Google Scholar] [CrossRef]

- Ardila, M.; Labiapari, W.; de Mello, J. The Influence of Crystallographic Texture and Niobium Stabilisation on the Corrosion Resistance of Ferritic Stainless Steel. Mater. Res.-Ibero-Am. J. Mater. 2017, 20, 576–583. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Li, J.; Wu, X.; Huang, Y.; Li, X. Effects of Niobium on the Mechanical Properties and Corrosion Behavior of Simulated Weld HAZ of HSLA Steel. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2018, 49, 187–197. [Google Scholar] [CrossRef]

- Fernandez, J.; Illescas, S.; Guilemany, J. Effect of microalloying elements on the austenitic grain growth in a low carbon HSLA steel. Mater. Lett. 2007, 61, 2389–2392. [Google Scholar] [CrossRef]

- Mandal, P.; Kant, R. Effect of microalloying elements on mechanical properties in the high strength low alloy steel. Mater. Sci. Forum 2015, 830–831, 231–233. [Google Scholar] [CrossRef]

- Orban, M.; Palfalvi, A. A Comparative Study of the Possibilities of B. Nb, Ti and V Using as Microalloying Elements in PM Steels Strengthening. Microstruct. Investig. Anal. 2000, 4, 248–251. [Google Scholar] [CrossRef]

- Bu, F.; Wang, X.; Yang, S.; Shang, C.; Misra, R. Contribution of interphase precipitation on yield strength in thermomechanically simulated Ti-Nb and Ti-Nb-Mo microalloyed steels. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2015, 620, 22–29. [Google Scholar] [CrossRef]

- Gu, Y.; Qiao, G.; Wu, D.; Liao, B.; Xiao, F. Precipitation kinetics of Nb carbonitride in austenite and acicular ferrite and its effect on hardness of high-Nb steel. Mater. Chem. Phys. 2016, 183, 506–515. [Google Scholar] [CrossRef]

- Massey, C.; Hoelzer, D.; Seibert, R.; Edmondson, P.; Kini, A.; Gault, B.; Terrani, K.; Zinkle, S. Microstructural evaluation of a Fe-12Cr nanostructured ferritic alloy designed for impurity sequestration. J. Nucl. Mater. 2019, 522, 111–122. [Google Scholar] [CrossRef]

- Rancel, L.; Gomez, M.; Medina, S. Influence of Microalloying Elements (Nb, V, Ti) on Yield Strength in Bainitic Steels. Steel Res. Int. 2008, 79, 947–953. [Google Scholar] [CrossRef]

- Callister, W.; Rethwisch, D. Materials Science and Engineering: An Introduction, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Calhoun, R.; Dunand, C. Dislocations in Metal Matrix Composites: Metal Matrix Composites. In Comprehensive Composite Materials: Metal Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2000; pp. 27–59. [Google Scholar] [CrossRef]

- Ke, R.; Hu, C.; Zhong, M.; Wan, X.; Wu, K. Grain refinement strengthening mechanism of an austenitic stainless steel: Critically analyze the impacts of grain interior and grain boundary. J. Mater. Res. Technol. 2022, 17, 2999–3012. [Google Scholar] [CrossRef]

- Antonov, S.; Detrois, M.; Tin, S. Design of Novel Precipitate-Strengthened Al-Co-Cr-Fe-Nb-Ni High-Entropy Superalloys. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2018, 49, 305–320. [Google Scholar] [CrossRef]

- Abdullah, B.; Alias, S.K.; Jaffar, A.; Rashid, A.A.; Ramli, A. Mechanical properties and microstructure analysis of 0.5% Niobium alloyed ductile iron under austempered process in salt bath treatment. In Proceedings of the International Conference on Mechanical and Electrical Technology, Singapore, 10–12 September 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 610–614. [Google Scholar] [CrossRef]

- Bai, G.; Lu, S.; Li, D.; Li, Y. Influences of niobium and solution treatment temperature on pitting corrosion behaviour of stabilised austenitic stainless steels. Corros. Sci. 2016, 108, 111–124. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, C.; Zhang, S.; Wang, Q.; Liu, Y.; Abdullah, A. Effect of Nb addition on microstructure and corrosion resistance of novel stainless steels fabricated by direct laser metal deposition. Mater. Res. Express 2018, 5, 036524. [Google Scholar] [CrossRef]

- Yu, H.; Wu, K.; Dong, B.; Liu, J.; Liu, Z.; Xiao, D.; Jin, X.; Liu, H.; Tai, M. Effect of Heat-Input on Microstructure and Toughness of CGHAZ in a High-Nb-Content Microalloyed HSLA Steel. Materials 2022, 15, 3588. [Google Scholar] [CrossRef] [PubMed]

- Raj, B.; Jappes, J.; Khan, M.; Dillibabu, V.; Brintha, N. Studies on heat treatment and electrochemical behaviour of 3D printed DMLS processed nickel-based superalloy. Appl. Phys. A-Mater. Sci. Process. 2019, 125, 722. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, W.; Cheng, L.; Liu, J.; Wu, K.; Liu, M. Effects of niobium and rare earth elements on microstructure and initial marine corrosion behavior of low-alloy steels. Appl. Surf. Sci. 2019, 475, 83–93. [Google Scholar] [CrossRef]

- Fu, J.; Wang, J.; Li, F.; Cui, K.; Du, X.; Wu, Y. Effect of Nb addition on the microstructure and corrosion resistance of ferritic stainless steel. Appl. Phys. A-Mater. Sci. Process. 2020, 126, 194. [Google Scholar] [CrossRef]

- Hajsman, J.; Kucerova, L.; Burdova, K. The Influence of Varying Aluminium and Manganese Content on the Corrosion Resistance and Mechanical Properties of High Strength Steels. Metals 2021, 11, 1446. [Google Scholar] [CrossRef]

- Moradi, S.; Zangeneh, S.; Vardak, S.; Bahrami, R. New Co-Cr-Mo-Nb-Cu alloy for implant applications: Properties characterization. J. Alloys Compd. 2022, 925, 166387. [Google Scholar] [CrossRef]

- Wu, W.; Liu, Z.; Wang, Q.; Li, X. Improving the resistance of high-strength steel to SCC in a SO2-polluted marine atmosphere through Nb and Sb microalloying. Corros. Sci. 2020, 170, 108693. [Google Scholar] [CrossRef]

- Zong, Y.; Liu, C. Microstructure, mechanical properties, and Corrosion Behavior of Ultra-Low Carbon Bainite Steel with Different Niobium Content. Materials 2021, 14, 311. [Google Scholar] [CrossRef]

- Xu, X.; Wu, W.; Li, N.; Zhang, L.; Wang, Y.; Liu, Z.; Li, X. Effect of 0.1 wt% Nb on the microstructure and corrosion fatigue performance of high strength steels. Corros. Sci. 2023, 219, 111242. [Google Scholar] [CrossRef]

- Zhao, P.; Liu, Z.; Du, F.; Misra, R.; Zhang, C.; Zhou, X.; Yan, E. Ultra-high cycle fatigue property of a multiphase steel microalloyed with niobium. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2018, 718, 1–8. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; Gao, G.; Hui, W.; Misra, R.; Bai, B.; Weng, Y. The potential significance of microalloying with niobium in governing very high cycle fatigue behavior of bainite/martensite multiphase steels. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2016, 650, 438–444. [Google Scholar] [CrossRef]

- Lima, C.; Belém, M.; Camargo, F. Analysis of Mechanical and Tribocorrosion Properties of Thermally Sprayed Nb2O5 Coatings. In Proceedings of the International Thermal Spray Conference (ITSC2018), Orlando, FL, USA, 7–10 May 2018; pp. 781–786. [Google Scholar]

- Liu, S.; Gao, C.; Yan, P. Effect of Niobium Micro-Alloying Addition on Electrochemical Corrosion Behavior of Mild Steel in a Highly Alkaline Environment. Int. J. Electrochem. Sci. 2020, 15, 5333–5341. [Google Scholar] [CrossRef]

- Li, J.; Wu, J.; Wang, Z.; Zhang, S.; Wu, X.; Huang, Y.; Li, X. The effect of nanosized NbC precipitates on electrochemical corrosion behavior of high strength low -alloy steel in 3.5%NaCl solution. Int. J. Hydrogen Energy 2017, 42, 22175–22184. [Google Scholar] [CrossRef]

- Tzortzinis, G.; Knickle, B.; Bardow, A.; Brena, S.; Gerasimidis, S. Strength evaluation of deteriorated girder ends. I: Experimental study on naturally corroded I-beams. Thin-Walled Struct. 2021, 159, 107220. [Google Scholar] [CrossRef]

- Inkscape Project. Inkscape Version 1.3 [Internet]. 2020. Available online: https://inkscape.org (accessed on 15 January 2024).

- Tzortzinis, G.; Ai, C.; Brena, S.; Gerasimidis, S. Using 3D laser scanning for estimating the capacity of corroded steel bridge girders: Experiments, computations and analytical solutions. Eng. Struct. 2022, 265, 114407. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, S.; Li, A. Flexural performance evaluation of corroded steel beams based on 3D corrosion morphology. Struct. Infrastruct. Eng. 2020, 16, 1562–1577. [Google Scholar] [CrossRef]

- Kuang, Y.; Feng, J.; Yu, Z.; Liu, X. Experimental study and analysis of the structural behavior of steel-concrete composite beam after shear connector corrosion. Appl. Mech. Mater. 2014, 578–579, 1522–1530. [Google Scholar] [CrossRef]

- Sheng, J.; Xia, J.; Ma, R. Experimental study on the coupling effect of sulfate corrosion and loading on the mechanical behavior of steel and H-section beam. Constr. Build. Mater. 2018, 189, 711–718. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, H.; Yu, Q. Monotonic and fatigue behavior of steel-concrete composite beams subjected to corrosion. Structures 2021, 34, 1973–1984. [Google Scholar] [CrossRef]

- Luo, L.; Fu, H.; Zhang, Y.; Xie, X. Experimental Study on the Overall Stability of Corroded H-Shaped Steel Beams. Buildings 2022, 12, 1923. [Google Scholar] [CrossRef]

- Nie, B.; Xu, S.; Zhang, Z.; Gu, R. Experimental investigation on corroded cold-formed steel beam-columns under compression and major axis bending. J. Constr. Steel Res. 2020, 169, 106026. [Google Scholar] [CrossRef]

- Wang, B.; Huang, W.; Zheng, S. Study on Restoring Force Performance of Corrosion Damage Steel Frame Beams under Acid Atmosphere. Appl. Sci. 2019, 9, 103. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Zhang, Z.; Liu, X.; Xu, S. Cyclic behavior and hysteresis model of beam-column joint under salt spray corrosion environment. J. Constr. Steel Res. 2021, 183, 106737. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, T.; Ma, R.; Xu, S. Experimental study on seismic performance of H-section beam-column welded connections corroded in general atmosphere. J. Build. Struct. 2022, 43, 184. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, S.; Zhao, X. Experimental and numerical investigations into seismic behavior of corroded steel frame beams and columns in offshore atmospheric environment. J. Constr. Steel Res. 2023, 201, 107757. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, S.; Zhao, X. Experimental and numerical study on seismic performance of corroded steel frames in chloride environment. J. Constr. Steel Res. 2020, 171, 106164. [Google Scholar] [CrossRef]

- Xiao, L.; Peng, J.; Zhang, J.; Cai, C. Experimental investigation and numerical analysis on stiffness degradation of high-performance steel beams with local shear-span corrosion. Earth Space 2021, 2021, 533–541. [Google Scholar] [CrossRef]

- Bao, A.; Guillaume, C.; Satter, C.; Moraes, A.; Williams, P.; Kelly, T.; Guo, Y. Testing and evaluation of web bearing capacity of corroded steel bridge girders. Eng. Struct. 2021, 238, 112276. [Google Scholar] [CrossRef]

- Zakowski, K.; Narozny, M.; Szocinski, M.; Darowicki, K. Influence of water salinity on corrosion risk-the case of the southern Baltic Sea coast. Environ. Monit. Assess. 2014, 186, 4871–4879. [Google Scholar] [CrossRef]

- Zhu, J.; Li, D.; Chang, W.; Wang, Z.; Hu, L.; Zhang, Y.; Wang, M.; Yang, Z.; Song, J.; Chen, S.; et al. In situ marine exposure study on corrosion behaviors of five alloys in coastal waters of western Pacific Ocean. J. Mater. Res. Technol. 2020, 9, 8104–8116. [Google Scholar] [CrossRef]

- Morcillo, M.; Chico, B.; Diaz, I.; Cano, H.; de la Fuente, D. Atmospheric corrosion data of weathering steels. A review. Corros. Sci. 2013, 77, 6–24. [Google Scholar] [CrossRef]

- ISO 9223:2012; Corrosion of Metals and Alloys, Corrosivity of Atmospheres, Classification, Determination and Estimation. ISO: Geneva, Switzerland, 2022; p. 15.

- Ranji, A.R.; Zakeri, S. Mechanical properties and corrosion resistance of normal strength and high strength steels in chloride solution. In Proceedings of the Corrosion 2011, Houston, TX, USA, 13–17 March 2011. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, A.; Jin, W. Behavior of Steel–Concrete Composite Beams with Corroded Shear Studs Under Negative Bending Moment. In Proceedings of the 4th International Conference on the Durability of Concrete Structures, West Lafayette, IN, USA, 24–26 July 2014; pp. 127–136. [Google Scholar] [CrossRef]

- Peng, J.; Xiao, L.; Zhang, J.; Cai, C.; Wang, L. Flexural behavior of corroded HPS beams. Eng. Struct. 2019, 195, 274–287. [Google Scholar] [CrossRef]

- Drazic, D.; Vasciz, V. The correlation between accelerated laboratory corrosion tests and atmospheric corrosion station tests on steels. Corros. Sci. 1989, 29, 1197–1204. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, S.; Wang, H.; Nie, B.; Su, C. Flexural buckling behavior of corroded hot-rolled H-section steel beams. Eng. Struct. 2021, 229, 111614. [Google Scholar] [CrossRef]

- Sheng, J.; Xia, J.; Chang, H. Bending Behavior of Corroded H-Shaped Steel Beam in Underground Environment. Appl. Sci. 2021, 11, 938. [Google Scholar] [CrossRef]

- Xiao, L.; Peng, J.; Cai, C.; Chen, H. Experimental and numerical investigations on the mechanical behavior of coastal high performance steel beams with local corrosion within the shear-span. Appl. Ocean Res. 2023, 136, 103581. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, J.; Fan, Y.; Huang, Y.; Liu, Z.; Du, C.; Li, X. Comparative study on corrosion fatigue behaviour of high strength low alloy steel and simulated HAZ microstructures in a simulated marine atmosphere. Int. J. Fatigue 2020, 137, 105666. [Google Scholar] [CrossRef]

- Guo, Y.; Shao, Y.; Gao, X.; Li, T.; Zhong, Y.; Luo, X. Corrosion fatigue crack growth of serviced API 5L X56 submarine pipeline. Ocean Eng. 2022, 256, 111502. [Google Scholar]

- Zhou, X.; Zhang, X.; Xu, R.; Li, B.; Ren, X.; Zhu, J.; Jin, Y. Galvanic Corrosion and Fatigue Behavior of a SM480C Welded Joint Steel in a Sea-Crossing Suspension Bridge. Int. J. Corros. 2022, 2022, 2665663. [Google Scholar] [CrossRef]

- Ashby, M.; Easterling, K. The transformation hardening of steel surfaces by laser beams—I. Hypo-eutectoid steels. Acta Metall. 1984, 32, 1935–1948. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2006. [Google Scholar]

- Radaj, D.; Sonsino, C.; Fricke, W. Fatigue Assessment of Welded Joints by Local Approaches, 2nd ed.; Woodhead Publishing: Sawston, UK, 2006. [Google Scholar] [CrossRef]

- Barbaro, F.; Kuzmikova, L.; Zhu, Z.; Li, H. Weld Haz Properties in Modern High Strength Niobium Pipeline Steels. In Energy Materials 2014: Conference Proceedings; Springer International Publishing: Cham, Switzerland, 2016; pp. 657–664. [Google Scholar] [CrossRef]

- David, S.; Debroy, T. Current issues and problems in welding science. Science 1992, 257, 497–502. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Liu, Z.; Hu, S.; Du, C.; Li, X. Effect of Hydrogen Charging on the Stress Corrosion Behavior of 2205 Duplex Stainless Steel Under 3.5 wt.% NaCl Thin Electrolyte Layer. J. Mater. Eng. Perform. 2017, 26, 2837–2846. [Google Scholar] [CrossRef]

- Zhou, Y.; Jia, T.; Zhang, X.; Liu, Z.; Misra, R. Microstructure and toughness of the CGHAZ of an offshore platform steel. J. Mater. Process. Technol. 2015, 219, 314–320. [Google Scholar] [CrossRef]

- Yan, W.; Luo, X.; Xu, G.; Wang, H.; Wang, Z.; Chen, X. Significant improvement in CGHAZ toughness of HSLA steel via welding with trailing mechanical treatment. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2022, 837, 142725. [Google Scholar] [CrossRef]

- Liang, G.; Yang, S.; Wu, H.; Liu, X. Microstructure and mechanical performances of CGHAZ for oil tank steel during high heat input welding. Rare Met. 2013, 32, 129–133. [Google Scholar] [CrossRef]

- Cao, X.; Zhou, X.; Wang, H.; Luo, Z.; Duan, J. Microstructures and mechanical properties of laser offset welded 5052 aluminum to press-hardened steel. J. Mater. Res. Technol. 2020, 9, 5378–5390. [Google Scholar] [CrossRef]

- Sun, M.; Wang, Z.; Wang, X.; Misra, R. The significance of variant pairing in governing toughness of coarse-grained heat affected zone (CGHAZ) in Nb-bearing high strength structural steels. Mater. Lett. 2020, 260, 126974. [Google Scholar] [CrossRef]

- Li, Y.; Baker, T. Effect of morphology of martensite-austenite phase on fracture of weld heat affected zone in vanadium and niobium microalloyed steels. Mater. Sci. Technol. 2010, 26, 1029–1040. [Google Scholar] [CrossRef]

- Jha, R.; Bhuyan, P.; Mandal, S.; Pal, S. Insights into the role of Nb segregation on grain boundary structural transition and mechanical response in a Ni-Nb system. Mater. Chem. Phys. 2023, 299, 127531. [Google Scholar] [CrossRef]

- Mha, P.; Tongne, A.; Pantalé, O. A generalized non-linear flow law based on modified Zerilli-Armstrong model and its implementation into Abaqus/Explicit FEM Code. World J. Eng. Technol. 2022, 10, 334–362. [Google Scholar] [CrossRef]

- ASTM E23-12a; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2013; p. 24.

- BS EN 10045-1:1990; Charpy Impact Test on Metallic Materials. Test Method (V- and U-Notches). BSI: Brussels, Belgium, 2007; p. 14.

- Jegdić, B.; Bobić, B.; Bošnjakov, M.; Alić, B. Testing of intergranular and pitting corrosion in sensitized welded joints of austenitic stainless steel. Metall. Mater. Eng. 2017, 23, 109–117. [Google Scholar] [CrossRef] [PubMed]

- ASTM G5-14; Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements. ASTM: West Conshohocken, PA, USA, 2021; p. 9.

- ASTM G59-23; Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements. ASTM: West Conshohocken, PA, USA, 2023; p. 4.

- ASTM G102-23; Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements. ASTM: West Conshohocken, PA, USA, 2023; p. 8.

- Zhu, Y.; Ma, J.; Wang, G.; Song, K.; Stock, H. Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment. Nanotechnol. Rev. 2020, 9, 596–609. [Google Scholar] [CrossRef]

- Kaiser, M.; Qadir, M. Electrochemical corrosion performance of commercially used aluminium engine block and piston in 0.1 m NaCl. J. Mech. Eng. 2015, 45, 48–52. [Google Scholar] [CrossRef][Green Version]

- Wu, X.; Li, L.; Li, H.; Li, B.; Ling, Z. Effect of strain level on corrosion of stainless steel bar. Constr. Build. Mater. 2018, 163, 189–199. [Google Scholar] [CrossRef]

- GB/T 1591-2008; High Strength Low Alloy Structural Steels. State Administration of Technical Supervision and Inspection: Beijing, China, 2008. (In Chinese)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benedito, A.V.; Benedetty Torres, C.A.; Silva, R.M.d.C.; Krahl, P.A.; Cardoso, D.C.T.; Silva, F.d.A.; Martins, C.H. Effects of Niobium Addition on the Mechanical Properties and Corrosion Resistance of Microalloyed Steels: A Review. Buildings 2024, 14, 1462. https://doi.org/10.3390/buildings14051462

Benedito AV, Benedetty Torres CA, Silva RMdC, Krahl PA, Cardoso DCT, Silva FdA, Martins CH. Effects of Niobium Addition on the Mechanical Properties and Corrosion Resistance of Microalloyed Steels: A Review. Buildings. 2024; 14(5):1462. https://doi.org/10.3390/buildings14051462

Chicago/Turabian StyleBenedito, André Vitor, Carlos Alberto Benedetty Torres, Rebecca Mansur de Castro Silva, Pablo Augusto Krahl, Daniel Carlos Taissum Cardoso, Flávio de Andrade Silva, and Carlos Humberto Martins. 2024. "Effects of Niobium Addition on the Mechanical Properties and Corrosion Resistance of Microalloyed Steels: A Review" Buildings 14, no. 5: 1462. https://doi.org/10.3390/buildings14051462

APA StyleBenedito, A. V., Benedetty Torres, C. A., Silva, R. M. d. C., Krahl, P. A., Cardoso, D. C. T., Silva, F. d. A., & Martins, C. H. (2024). Effects of Niobium Addition on the Mechanical Properties and Corrosion Resistance of Microalloyed Steels: A Review. Buildings, 14(5), 1462. https://doi.org/10.3390/buildings14051462