Effects of Remolding Water Content and Compaction Degree on the Dynamic Behavior of Compacted Clay Soils

Abstract

:1. Introduction

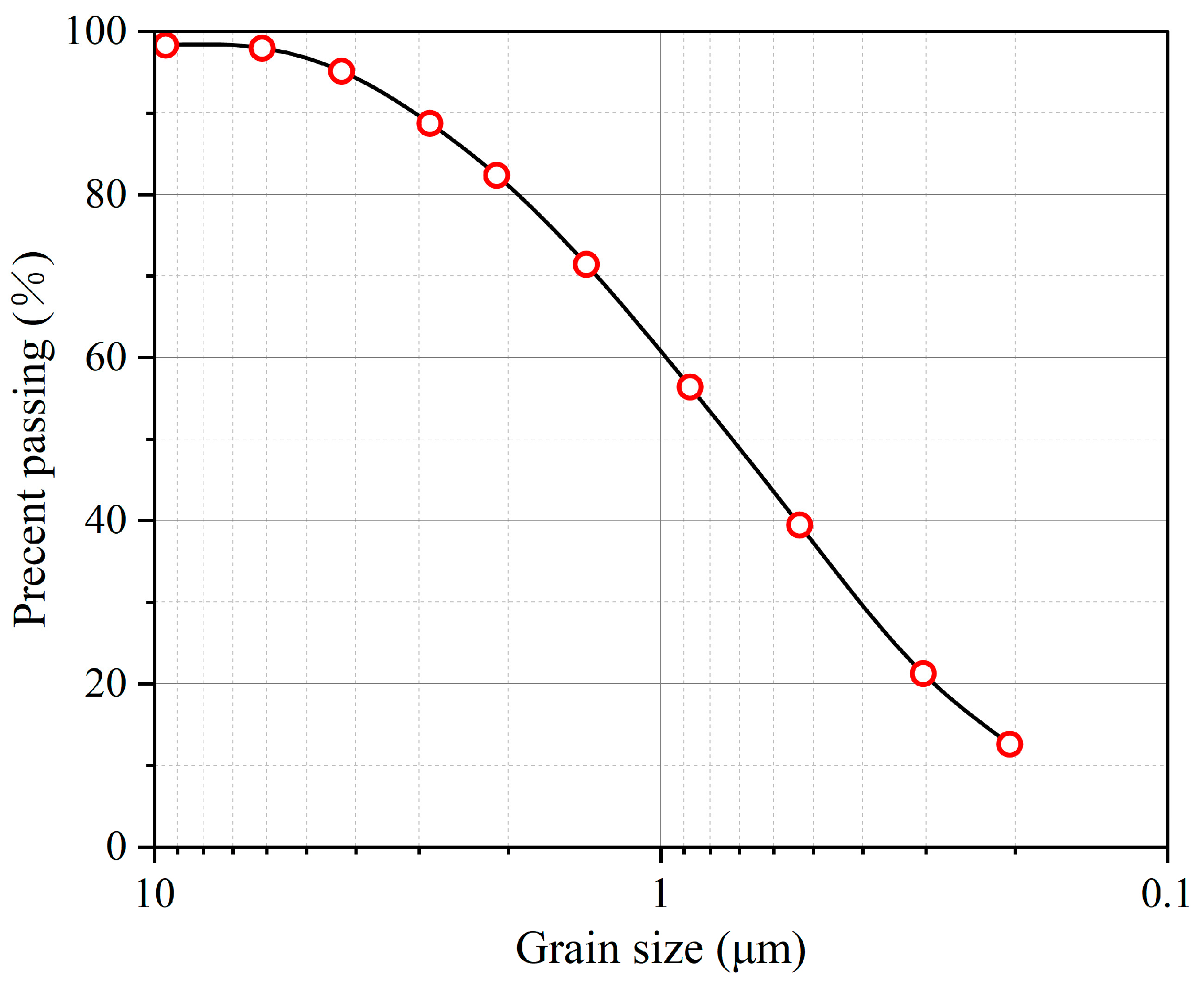

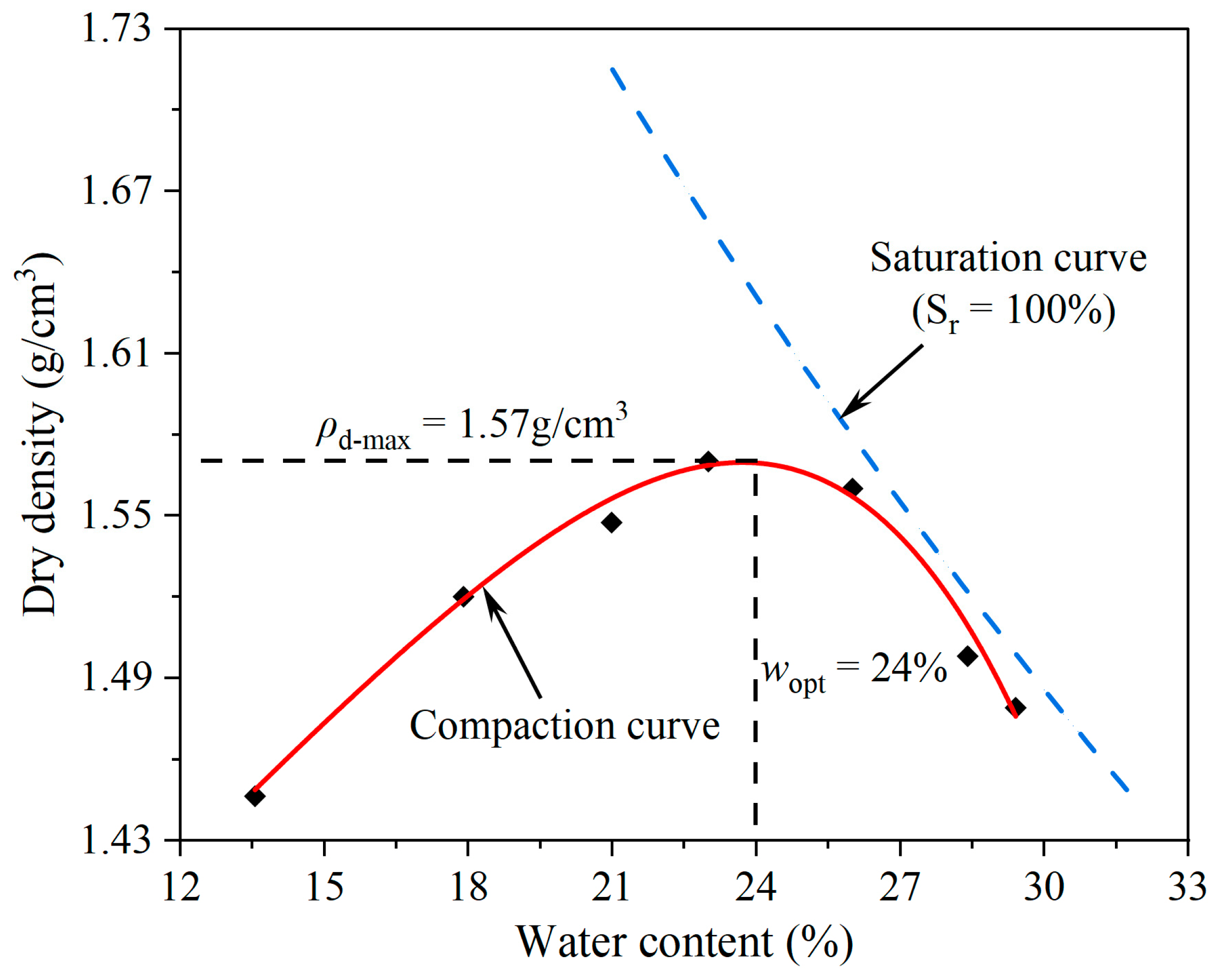

2. Testing Materials

3. Experimental Methods

3.1. Preparation of Specimens

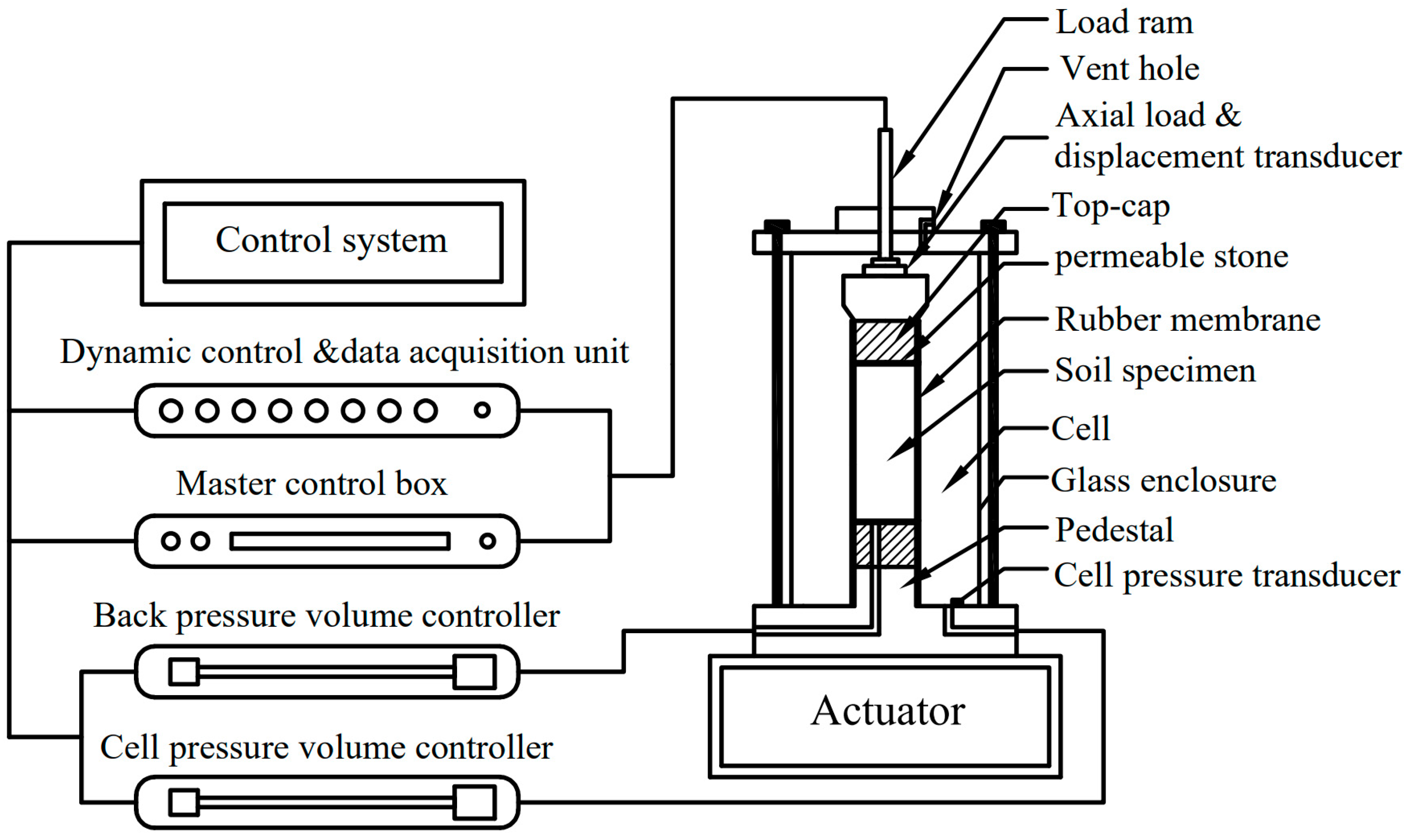

3.2. Testing Apparatus

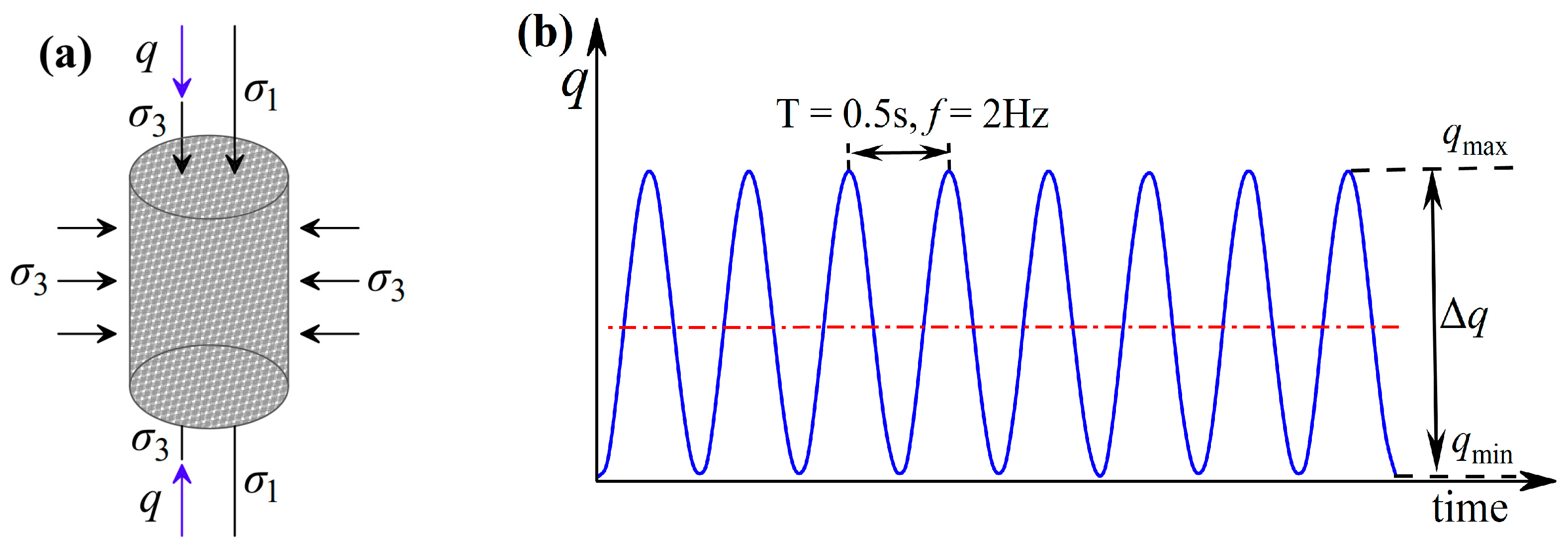

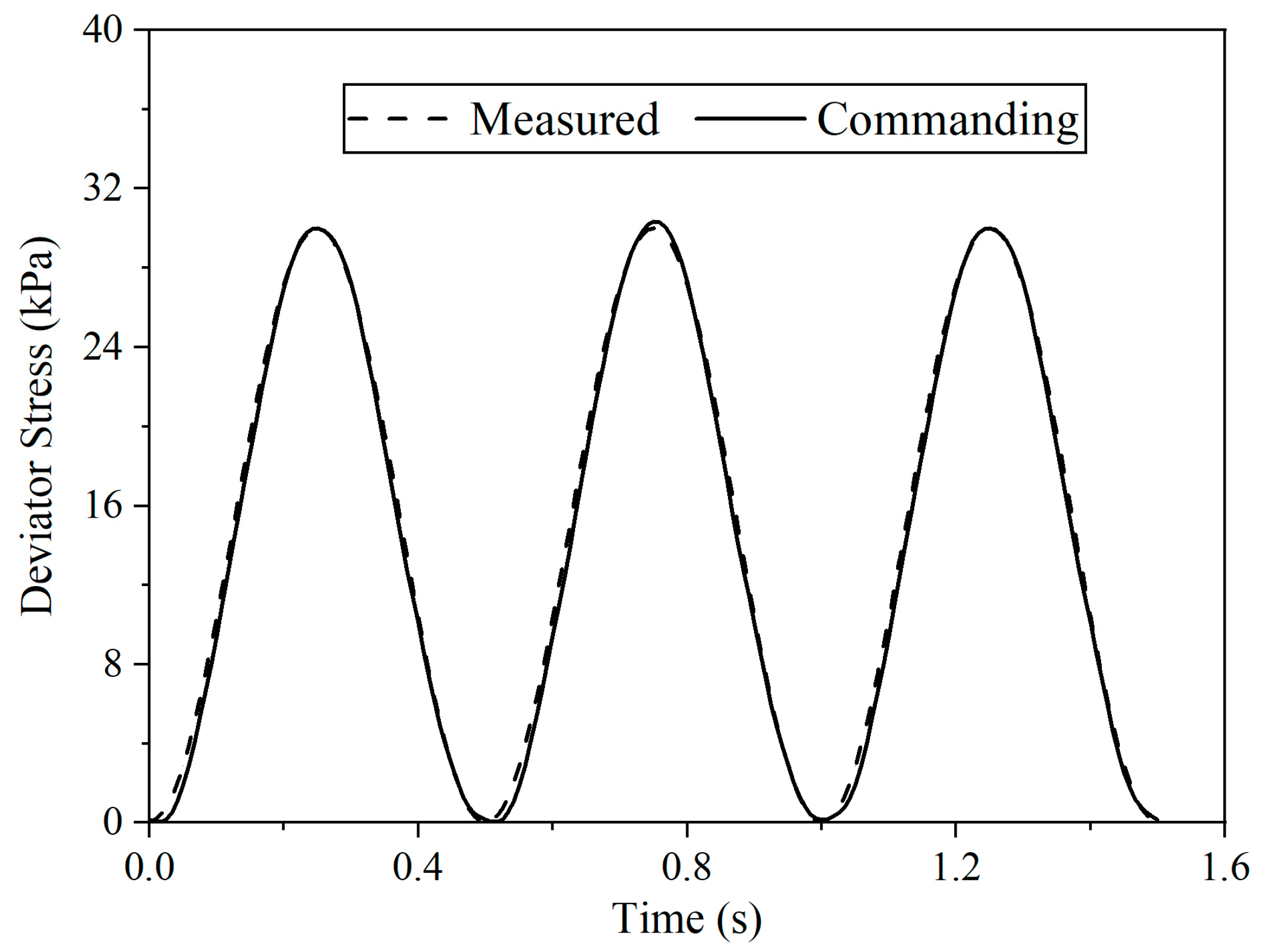

3.3. Cyclic Triaxial Tests

3.4. Microstructure Tests

4. Results and Discussion

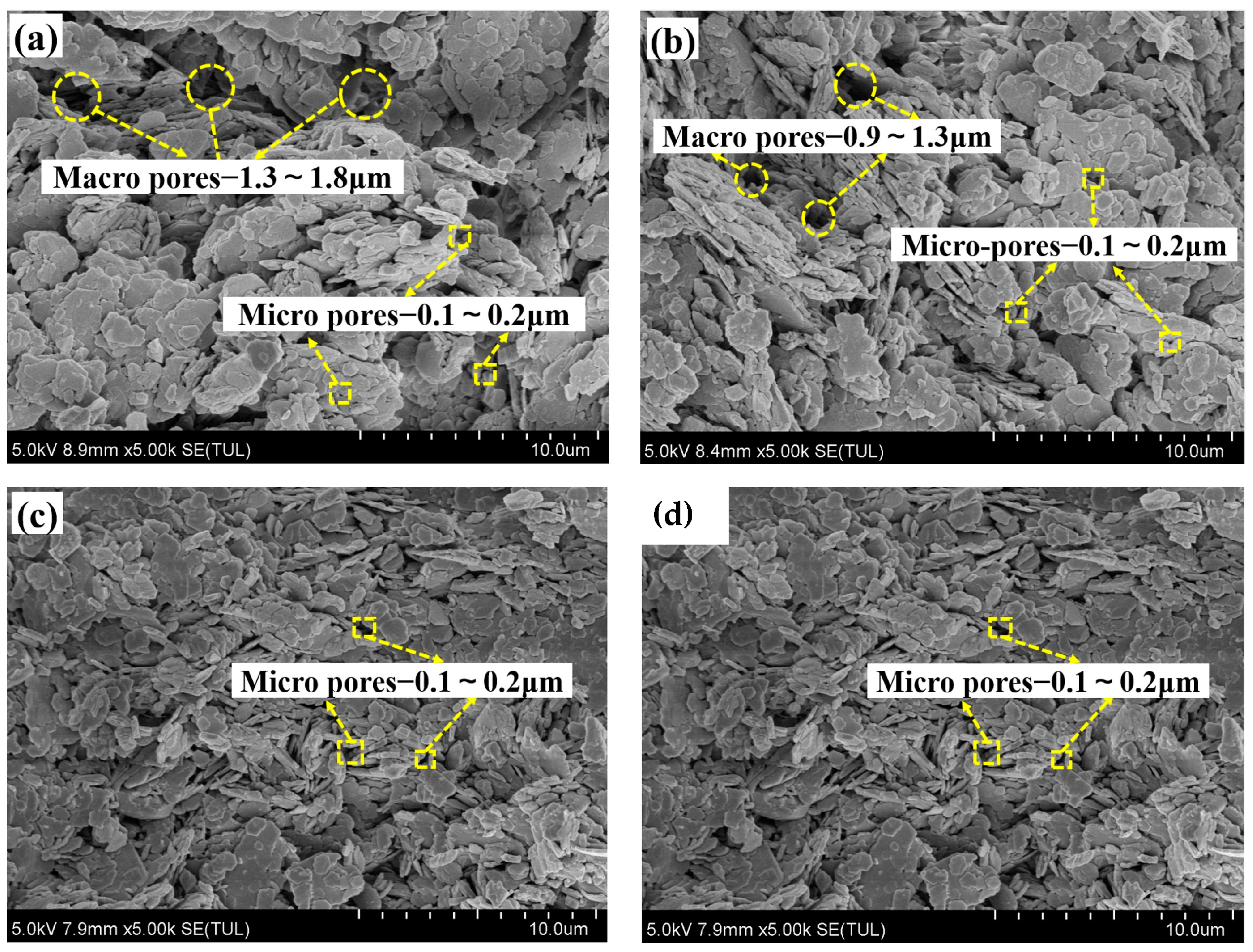

4.1. Microstructure Testing Results

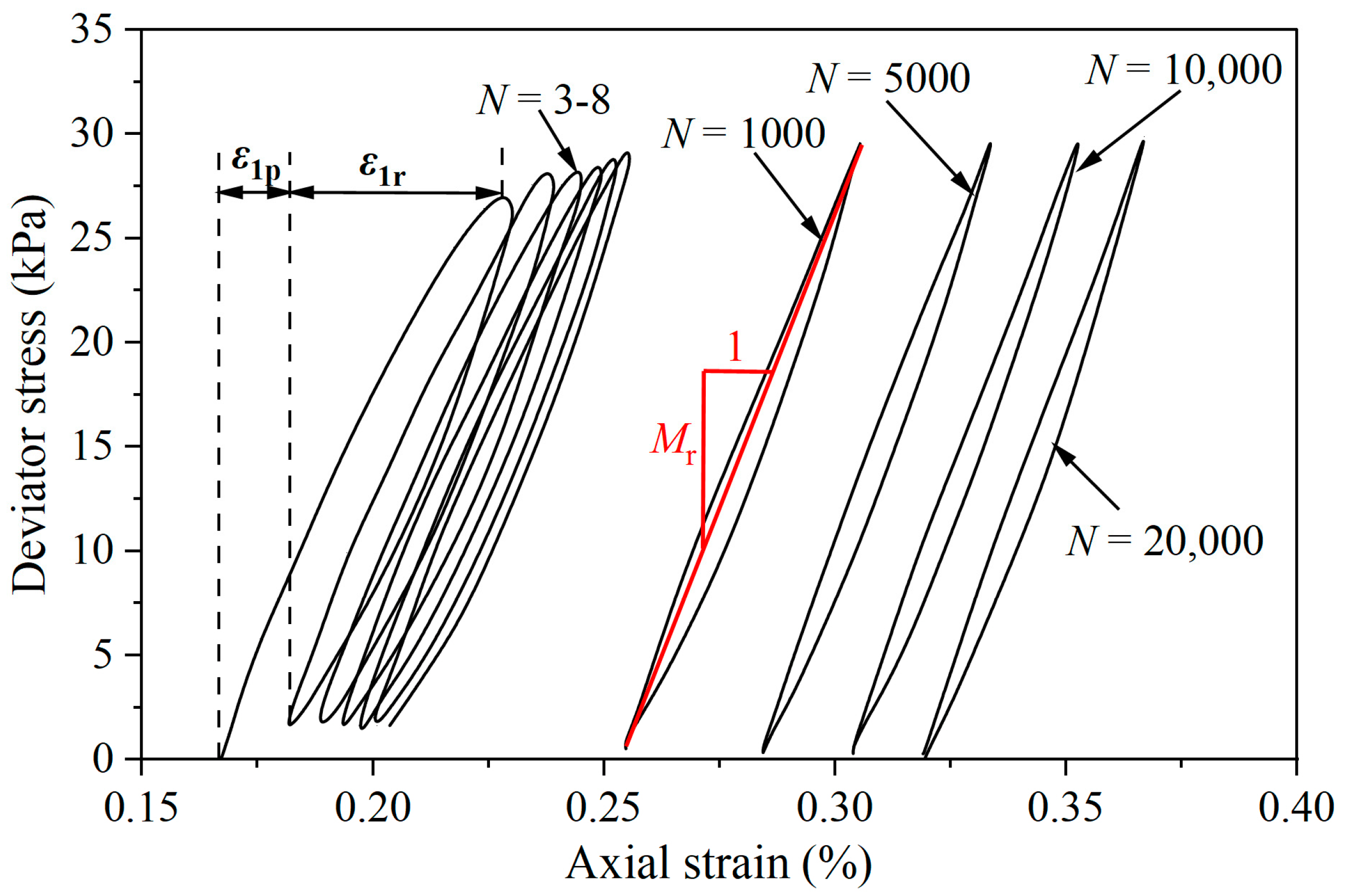

4.2. Typical Relationship between Deviator Stress and Axial Strain

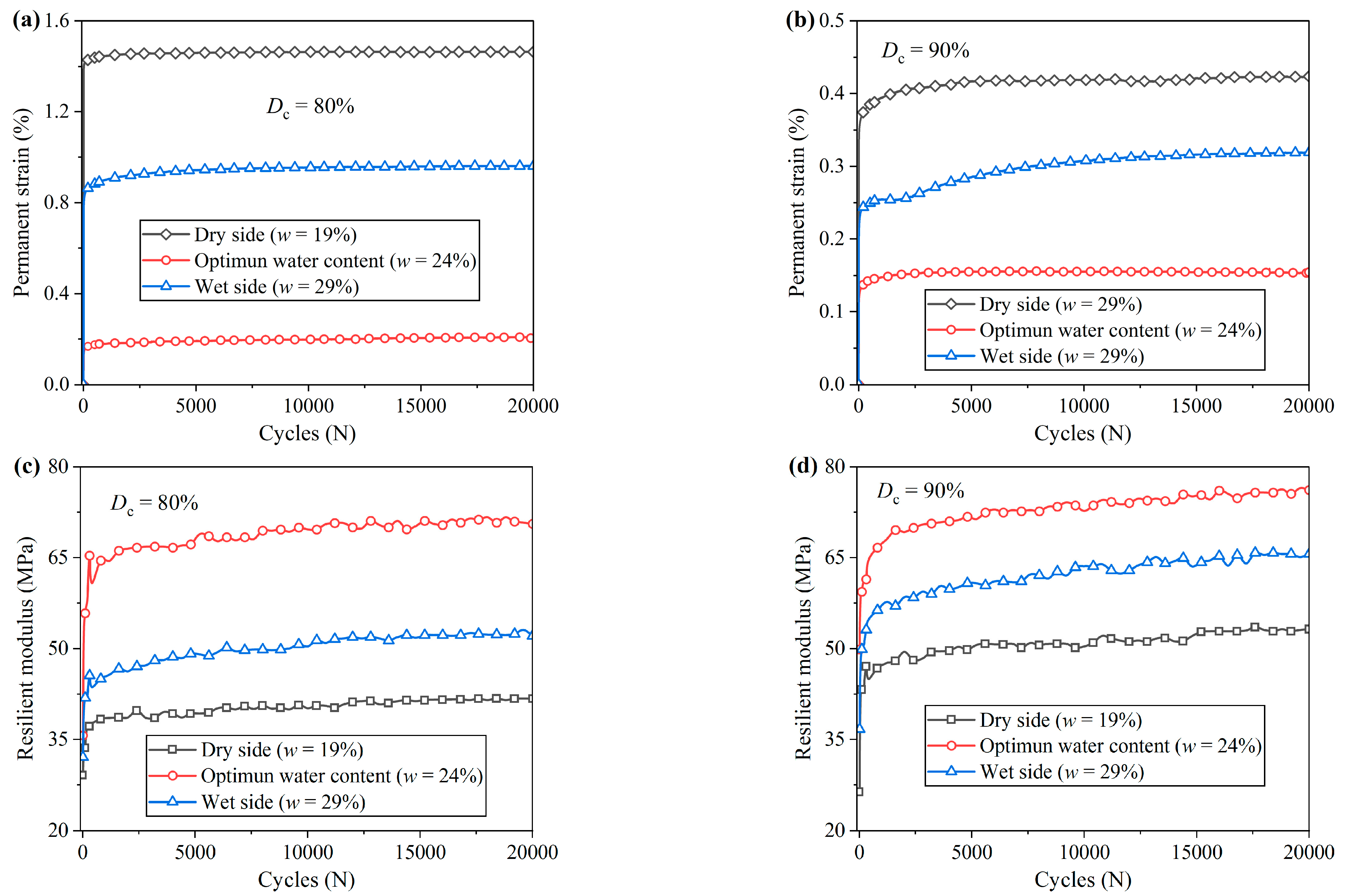

4.3. Change in Dynamic Behavior with Remolding Water Content

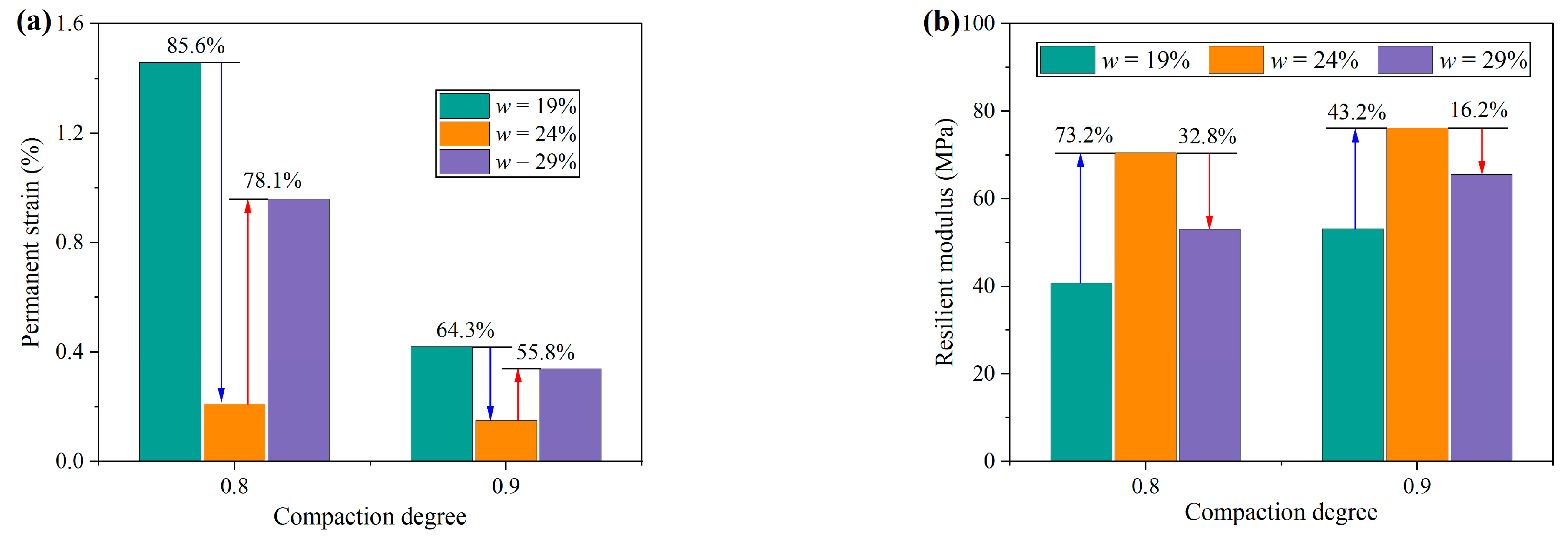

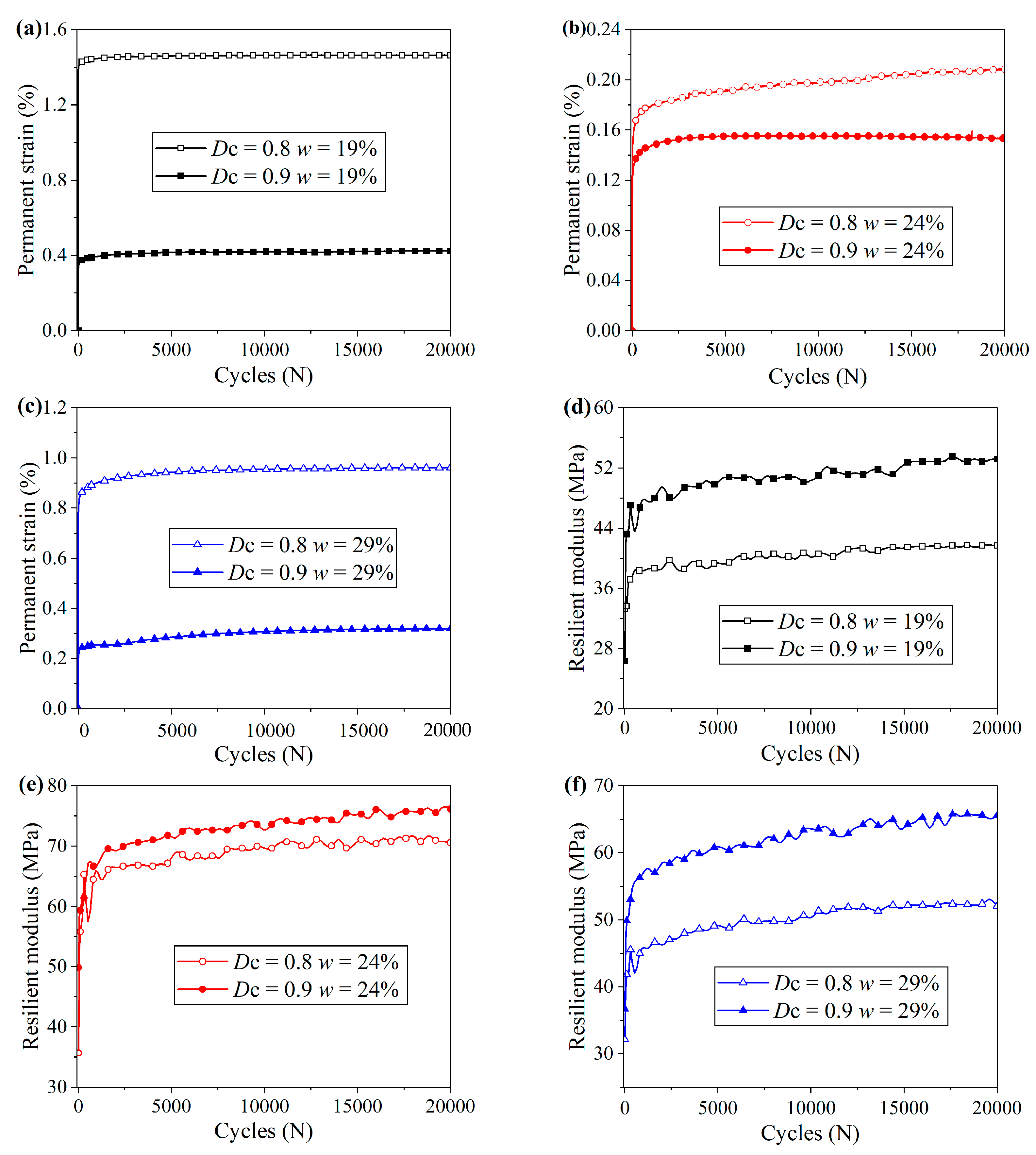

4.4. Change in Dynamic Behavior with Compaction Degree

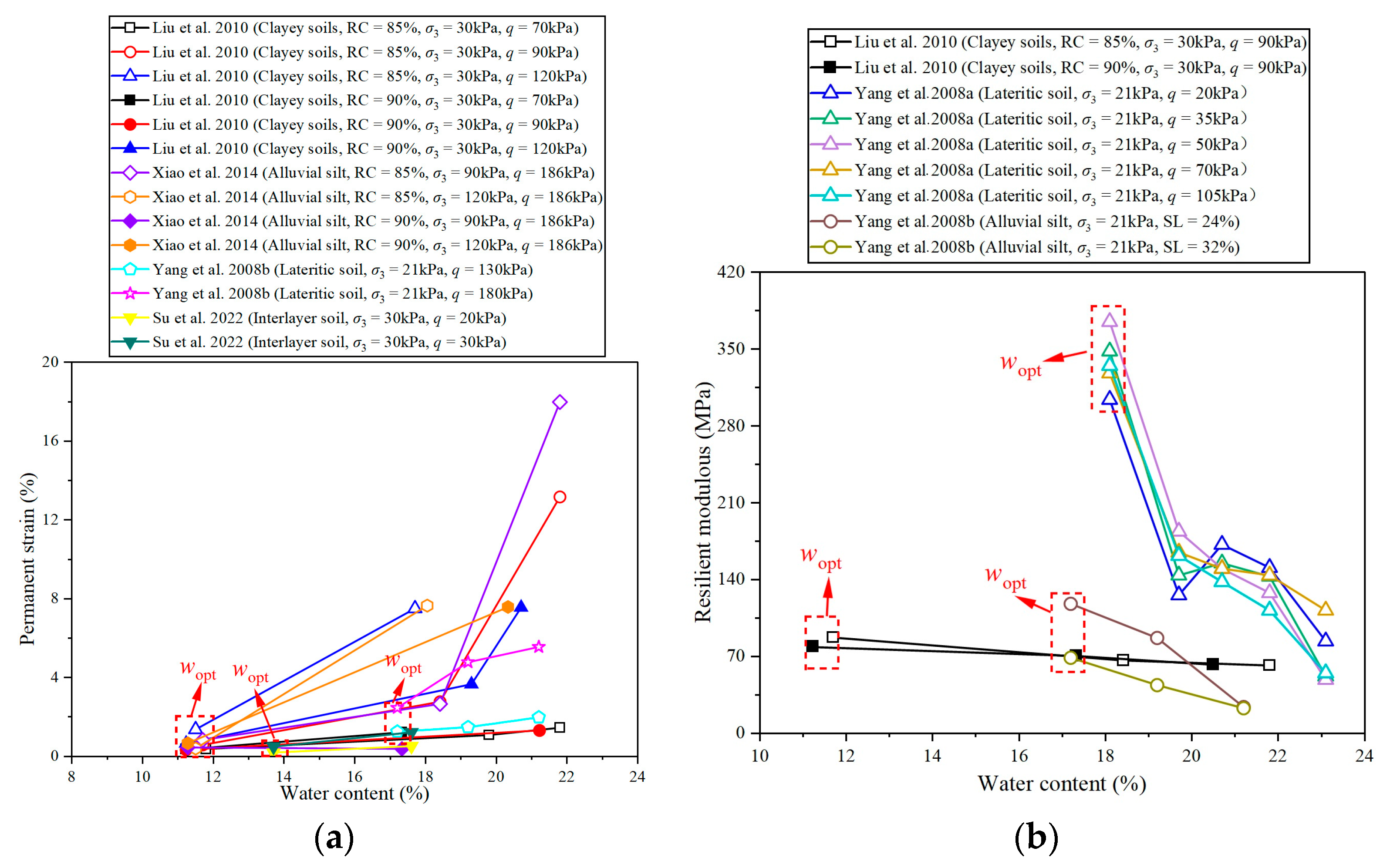

4.5. Comparison with Previous Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| d | pore diameter. |

| Dc | compaction degree. |

| dcha | characteristic pore diameter. |

| f | loading frequency. |

| Gs | specific gravity. |

| Ip | plasticity index. |

| Mr | resilient modulus. |

| mclay | mass of dry clay. |

| mwater | mass of water. |

| N | loading cycle number. |

| q | deviator stress. |

| qmax | maximum deviator stress. |

| qmin | minimum deviator stress. |

| Sr | saturation degree. |

| w | water content. |

| wL | liquid limit. |

| wopt | optimum water content. |

| wP | plastic limit. |

| T | loading cycle. |

| Δq | amplitude of cyclic deviator stress. |

| σ1 | axial stress. |

| σ3 | confining pressure. |

| ρd | dry density. |

| ρd-max | maximum dry density. |

| ε1 | axial strain. |

| ε1p | permanent axial strain. |

| ε1r | resilient axial strain. |

References

- Gu, C.; Gu, Z.Q.; Cai, Y.Q.; Wang, J.; Dong, Q.Y. Effects of cyclic intermediate principal stress on the deformation of saturated clay. J. Geotech. Geoenviron. Eng. 2018, 144, 04018052. [Google Scholar] [CrossRef]

- Ding, Y.; Jia, Y.; Wang, X.; Zhang, J.S.; Luo, H.; Zhang, Y.; Chen, X.B. The influence of geotextile on the characteristics of railway subgrade mud pumping under cyclic loading. Transp. Geotech. 2022, 37, 100831. [Google Scholar] [CrossRef]

- Chen, W.B.; Feng, W.Q.; Yin, J.H.; Borana, L.; Chen, R.P. Characterization of permanent axial strain of granular materials subjected to cyclic loading based on shakedown theory. Construct. Build. Mater. 2019, 198, 751–761. [Google Scholar] [CrossRef]

- Yuan, B.X.; Liang, J.K.; Zhang, B.F.; Chen, W.J.; Huang, X.L.; Huang, Q.Y.; Li, Y.; Yuan, P. Optimized reinforcement of granite residual soil using a cement and alkaline solution: A coupling effect. J. Rock Mech. Geotech. 2024, 2, 1–9. [Google Scholar] [CrossRef]

- Yuan, B.X.; Chen, W.J.; Li, Z.H.; Zhao, J.; Luo, Q.Z.; Chen, W.W.; Chen, T.Y. Sustainability of the polymer SH reinforced recycled granite residual soil: Properties, physicochemical mechanism, and applications. J. Soil. Sediment. 2023, 23, 246–262. [Google Scholar] [CrossRef]

- Inam, A.; Ishikawa, T.; Miura, S. Effect of principal stress axis rotation on cyclic plastic deformation characteristics of unsaturated base course material. Soils Found. 2012, 52, 65–80. [Google Scholar] [CrossRef]

- Werkmeister, S.; Dawson, A.R.; Wellner, F. Permanent deformation behavior of granular materials and the shakedown concept. Transp. Res. Rec. 2001, 1757, 75–81. [Google Scholar] [CrossRef]

- JTG D30-2015; Specifications for Design of Highway Subgrade. Ministry of Communications, People’s Republic of China: Beijing, China, 2015.

- Chen, R.P.; Wang, H.L.; Hong, P.Y.; Cui, Y.J.; Qi, S.; Cheng, W. Effects of degree of compaction and fines content of the subgrade bottom layer on moisture migration in the substructure of high-speed railways. Proc. Inst. Mech. Eng. Part F. J. Rail Rapid Transit 2018, 232, 1197–1210. [Google Scholar] [CrossRef]

- TB10621; Code for Design of High Speed Railway. Ministry of Railways: Beijing, China, 2009.

- Gens, A.; Alonso, E.E.; Suriol, J. Effect of structure on the volumetric behaviour of a compacted soil. In Proceedings of the First International Conference, UNSAT’95, Paris, France, 6–8 September 1995; pp. 83–88. Available online: http://worldcat.org/isbn/9054105836 (accessed on 1 October 1995).

- Lloret, A.; Villar, M.V.; Sanchez, M.; Gens, A. Mechanical behaviour of heavily compacted bentonite under high suction changes. Géotechnique 2003, 53, 27–40. [Google Scholar] [CrossRef]

- Romero, E.; Gens, A.; Lloret, A. Suction effects on a compacted clay under non-isothermal conditions. Géotechnique 2003, 53, 65–81. [Google Scholar] [CrossRef]

- Delage, P.; Audiguier, M.; Cui, Y.J.; Howat, M.D. Microstructure of a compacted silt. Can. Geotech. J. 1996, 33, 150–158. [Google Scholar] [CrossRef]

- Chen, R.P.; Qi, S.; Wang, H.L.; Cui, Y.J. Microstructure and Hydraulic Properties of Coarse-Grained Subgrade Soil Used in High-Speed Railway at Various Compaction Degrees. J. Mater. Civ. Eng. 2019, 31, 04019301. [Google Scholar] [CrossRef]

- Craciun, O.; Lo, S.C.R. Matric suction measurement in stress path cyclic triaxial testing of unbound granular base materials. Geotech. Test. J. 2009, 33, 33–44. [Google Scholar] [CrossRef]

- Gu, C.; Zhan, Y.; Wang, J.; Cai, Y.Q.; Cao, Z.G.; Zhang, Q. Resilient and permanent deformation of unsaturated unbound granular materials under cyclic loading by the large-scale triaxial tests. Acta Geotech. 2020, 15, 3343–3356. [Google Scholar] [CrossRef]

- Duong, T.V.; Cui, Y.J.; Tang, A.M.; Dupla, J.C.; Canou, J.; Calon, N.; Robinet, A. Effects of water and fines contents on the resilient modulus of the interlayer soil of railway substructure. Acta Geotech. 2016, 11, 51–59. [Google Scholar] [CrossRef]

- Chen, W.B.; Feng, W.Q.; Yin, J.H. Effects of water content on resilient modulus of a granular material with high fines content. Construct. Build. Mater. 2020, 236, 117542. [Google Scholar] [CrossRef]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the art. I: Resilient response of unbound aggregates. J. Transpor. Eng. 2000, 126, 66–75. [Google Scholar] [CrossRef]

- Tang, C.S.; Pei, X.J.; Wang, D.Y.; Shi, B.; Li, J. Tensile Strength of Compacted Clayey Soil. J. Geotech. Geoenviron. Eng. 2015, 141, 04014122. [Google Scholar] [CrossRef]

- Liu, J.K.; Xiao, J.H. Experimental study on the stability of railroad silt subgrade with increasing train speed. J. Geotech. Geoenviron. Eng. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Yang, S.R.; Lin, H.D.; Kung, J.H.S.; Huang, W.H. Suction-Controlled Laboratory Test on Resilient Modulus of Unsaturated Compacted Subgrade Soils. J. Geotech. Geoenviron. Eng. 2008, 134, 1375–1384. [Google Scholar] [CrossRef]

- Xiao, J.H.; Juang, C.H.; Xu, C.J.; Li, X.W.; Wang, L. Strength and deformation characteristics of compacted silt from the lower reaches of the Yellow River of China under monotonic and repeated loading. Eng. Geol. 2014, 178, 49–57. [Google Scholar] [CrossRef]

- Feng, D.Z.; Liang, B.; Sun, W.J.; He, X.X.; Yi, F.; Wan, Y. Mechanical properties of solidified dredged soils considering the effects of compaction degree and residual moisture content. Dev. Built. Environ. 2023, 16, 100235. [Google Scholar] [CrossRef]

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM: West Conshohocken, PA, USA, 2012.

- ASTM D3999-11; Standard Test Methods for the Determination of the Modulus and Damping Properties of Soils Using the Cyclic Triaxial Apparatus. ASTM: West Conshohocken, PA, USA, 2012.

- Wang, H.L.; Cui, Y.J.; Lamas-Lopez, F.; Dupla, J.C.; Canou, J.; Calon, N.; Saussine, G.; Aimedieu, P.; Chen, R.P. Effects of inclusion contents on the resilient modulus and damping ratio of unsaturated track-bed materials. Can. Geotech. J. 2017, 54, 1672–1681. [Google Scholar] [CrossRef]

- Liu, J.K. Subgrade Engineering; The Architecture and Building Industry Publishing House of China: Beijing, China, 2006. [Google Scholar]

- Mohammad, L.N.; Titi, H.H.; Herath, A. Effect of Moisture Content and Dry Unit Weight on the Resilient Modulus of Subgrade Soils Predicted by Cone Penetration Test; Louisiana Transportation Research Center Rep. No. FHWA/LA-00/355; Federal Highway Ad-ministration, Texas A&M Univ.: College Station, TX, USA, 2002. [Google Scholar]

- Lamas-Lopez, F.; Cui, Y.J.; Costa D’Aguiar, S.; Calon, N.; Robinet, A.; Tang, A.M.; Dupla, J.C.; Canou, J. In-situ investigation of the behaviour of a French conventional railway platform. In Proceedings of the Transportation Research Board TRB 2015, Washington, DC, USA, 11–15 January 2015. [Google Scholar]

- Lamas-Lopez, F. Field and Laboratory Investigation on the Dyanmic Behavior of Conventional Railway Track-Bed Materials in the Context of Traffic Upgrade. Ph.D. Thesis, Paris Est, École Doctorale Sciences, Ingénierie et Environnement, Champs-sur-Marne, France, 2016. [Google Scholar]

- Cao, Z.G.; Chen, J.Y.; Cai, Y.Q.; Gu, C.; Wang, J. Effects of moisture content on the cyclic behavior of crushed tuff aggregates by large-scale tri-axial test. Soil Dyn. Earthq. Eng. 2017, 95, 1–8. [Google Scholar] [CrossRef]

- Xiong, H.; Cai, Y.Q.; Yang, Z.X.; Chai, J.C. Effect of drained static shear on cyclic deformation behavior of K0-consolidated sand. Soils Found. 2017, 57, 720–732. [Google Scholar] [CrossRef]

- Cai, Y.Q.; Gu, C.; Wang, J.; Juang, C.H.; Xu, C.J.; Hu, X.Q. One-way cyclic triaxial behavior of saturated clay: Comparison between constant and variable confining pressure. J. Geotech. Geoenviron. 2013, 139, 797–809. [Google Scholar] [CrossRef]

- Li, Y.F.; Nie, R.S.; Yue, Z.R.; Leng, W.M.; Guo, Y.P. Dynamic behaviors of fine-grained subgrade soil under single-stage and multi-stage intermittent cyclic loading: Permanent deformation and its prediction model. Soil Dyn. Earthq. Eng. 2021, 142, 106548. [Google Scholar] [CrossRef]

- Delage, P.; Marcial, D.; Cui, Y.J.; Ruiz, X. Ageing effects in a compacted bentonite: A microstructure approach. Géotechnique 2006, 56, 291–304. [Google Scholar] [CrossRef]

- Zhang, T.W.; Cui, Y.J.; Francisco, L.L.; Calon, N.; D’Aguiaret, N.S.C. Compacted soil behaviour through changes of density, suction, and stiffness of soils with remoulding water content. Can. Geotech. J. 2017, 55, 182–190. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.M. Characterization of dual-structure pore-size distribution of soil. Can. Geotech. J. 2009, 46, 129–141. [Google Scholar] [CrossRef]

- Schubert, H. Capillarity in Porous Solid Material Systems; Springer: Berlin, Germany, 1982. [Google Scholar]

- Romero, E.; Gens, A.; Lloret, A. Water permeability, water retention and microstructure of unsaturated compacted Boom clay. Eng. Geol. 1999, 54, 117–127. [Google Scholar] [CrossRef]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E.; Clifton, A.W. Model for the Prediction of Shear Strength with Respect to Soil Suction. Can. Geotech. J. 1996, 33, 379–392. [Google Scholar] [CrossRef]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E. The Relationship between the Soil-Water Characteristic Curve and the Unsaturated Shear Strength of a Compacted Glacial Till. Geotech. Test. J. 1996, 19, 259–268. [Google Scholar] [CrossRef]

- Mancuso, C.; Vassallo, R.; Onofrio, A. Small strain behavior of a silty sand in controlled-suction resonant column—Torsional shear tests. Can. Geotech. J. 2002, 31, 22–31. [Google Scholar] [CrossRef]

- Yang, S.R.; Huang, W.H.; Liao, C.C. Correlation between Resilient Modulus and Plastic Deformation for Cohesive Subgrade Soil under Repeated Loading. Trans. Res. Rec. 2008, 2053, 72–79. [Google Scholar] [CrossRef]

- Su, Y.; Cui, Y.-J.; Dupla, J.-C.; Canou, J. Effect of water content on permanent deformation of fine/coarse soil mixtures with varying coarse grain contents and subjected to multi-stage cyclic loading. Acta Geobalcanica 2022, 17, 3259–3268. [Google Scholar] [CrossRef]

| Index Property | Value |

|---|---|

| Specific gravity, Gs | 2.65 |

| Liquid limit, wL | 63 |

| Plastic limit, wP | 37 |

| Plasticity index, Ip | 26 |

| USUC a classification | MH |

| Optimum water content, wopt | 24% |

| Maximum dry density, ρd-max | 1.57 Mg/m3 |

| Sample | w (%) | Dc | ρd (g/cm3) | Sr (%) | mclay (g) | mwater (g) | σ3 (kPa) | Δq (kPa) |

|---|---|---|---|---|---|---|---|---|

| A1 | 19 | 0.8 | 1.26 | 45.37 | 120.58 | 22.91 | 30 | 30 |

| A2 | 24 | 0.8 | 1.26 | 57.30 | 120.58 | 28.94 | 30 | 30 |

| A3 | 29 | 0.8 | 1.26 | 69.24 | 120.58 | 34.97 | 30 | 30 |

| B1 | 19 | 0.9 | 1.41 | 57.51 | 135.65 | 25.77 | 30 | 30 |

| B2 | 24 | 0.9 | 1.41 | 72.65 | 135.65 | 32.56 | 30 | 30 |

| B3 | 29 | 0.9 | 1.41 | 87.78 | 135.65 | 39.34 | 30 | 30 |

| Liu et al. (2010) [22] | Yang et al. (2008a) [23] | Yang et al. (2008b) [46] | Xiao et al. (2014) [24] | Su et al. (2022) [47] | |

|---|---|---|---|---|---|

| Site | Beijing–Kowloon Railway, China | Northern Taiwan, China | Northern Taiwan, China | Liaocheng area, China | TGV Railway, Senissiat, France |

| Soil type | Clayey soil | Lateritic soil | Lateritic soil | Alluvial silt | Lean clay |

| Gs | 2.66 | 2.67 | 2.71 | 2.66 | 2.68 |

| Liquid limit | 24 | 46 | 54 | 30.4 | 32 |

| Plasticity index | 13 | 19 | 20 | 9 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, S.; Ma, W.; Zhang, X.; Wang, J.; Hu, X.; Wei, Z.; Liu, J. Effects of Remolding Water Content and Compaction Degree on the Dynamic Behavior of Compacted Clay Soils. Buildings 2024, 14, 2258. https://doi.org/10.3390/buildings14082258

Qi S, Ma W, Zhang X, Wang J, Hu X, Wei Z, Liu J. Effects of Remolding Water Content and Compaction Degree on the Dynamic Behavior of Compacted Clay Soils. Buildings. 2024; 14(8):2258. https://doi.org/10.3390/buildings14082258

Chicago/Turabian StyleQi, Shuai, Wei Ma, Xintian Zhang, Jing Wang, Xingbo Hu, Zengzhi Wei, and Jinhui Liu. 2024. "Effects of Remolding Water Content and Compaction Degree on the Dynamic Behavior of Compacted Clay Soils" Buildings 14, no. 8: 2258. https://doi.org/10.3390/buildings14082258

APA StyleQi, S., Ma, W., Zhang, X., Wang, J., Hu, X., Wei, Z., & Liu, J. (2024). Effects of Remolding Water Content and Compaction Degree on the Dynamic Behavior of Compacted Clay Soils. Buildings, 14(8), 2258. https://doi.org/10.3390/buildings14082258