Influence of Pile Foundation Construction on Existing Tunnels in a Metro Protection Area: Field Test and Numerical Simulation

Abstract

:1. Introduction

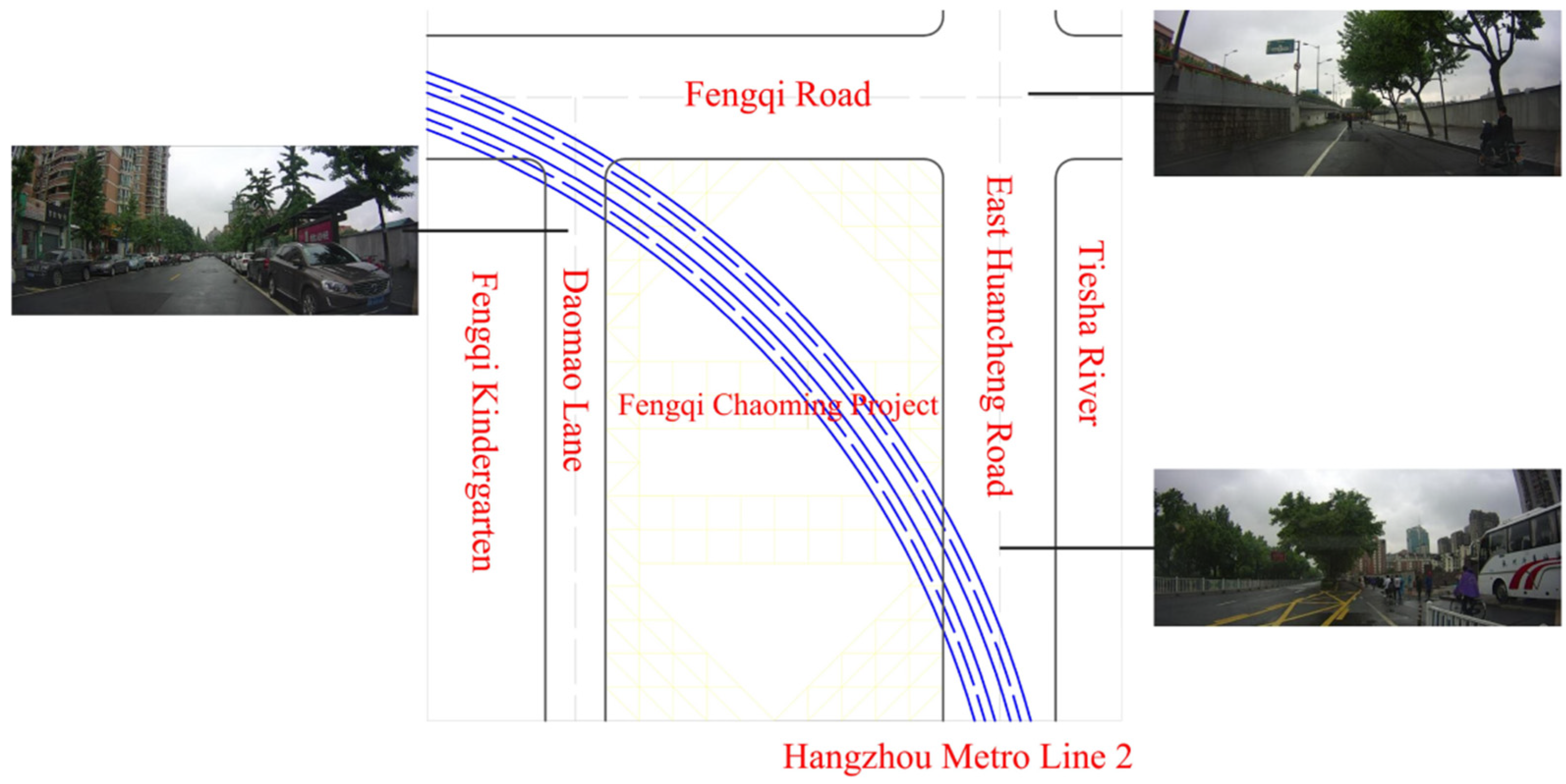

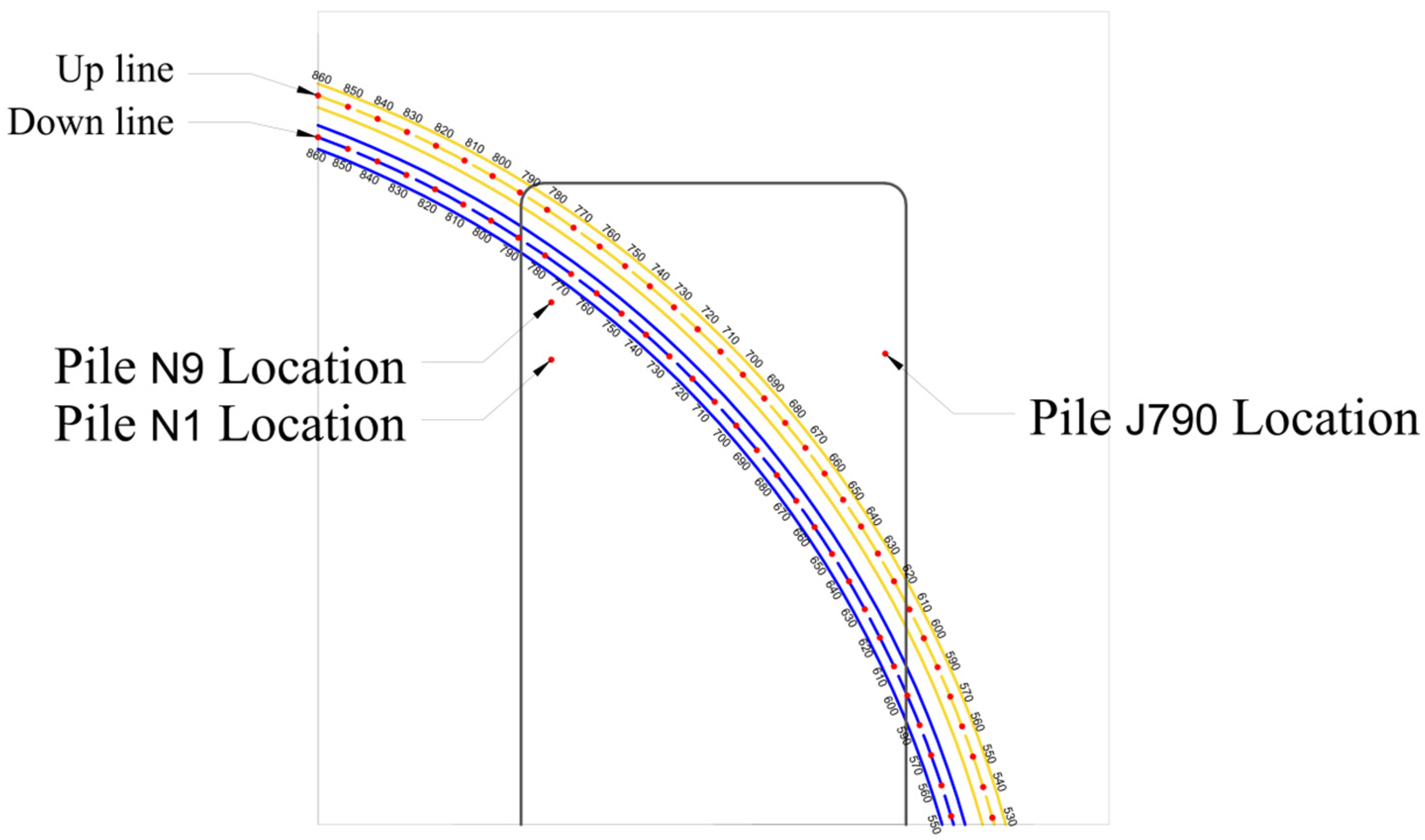

2. Engineering Background

3. In Situ Test

3.1. Test Method

3.2. Geological Parameters of Test Pile Site

3.3. Parameters and Detection of Test Piles

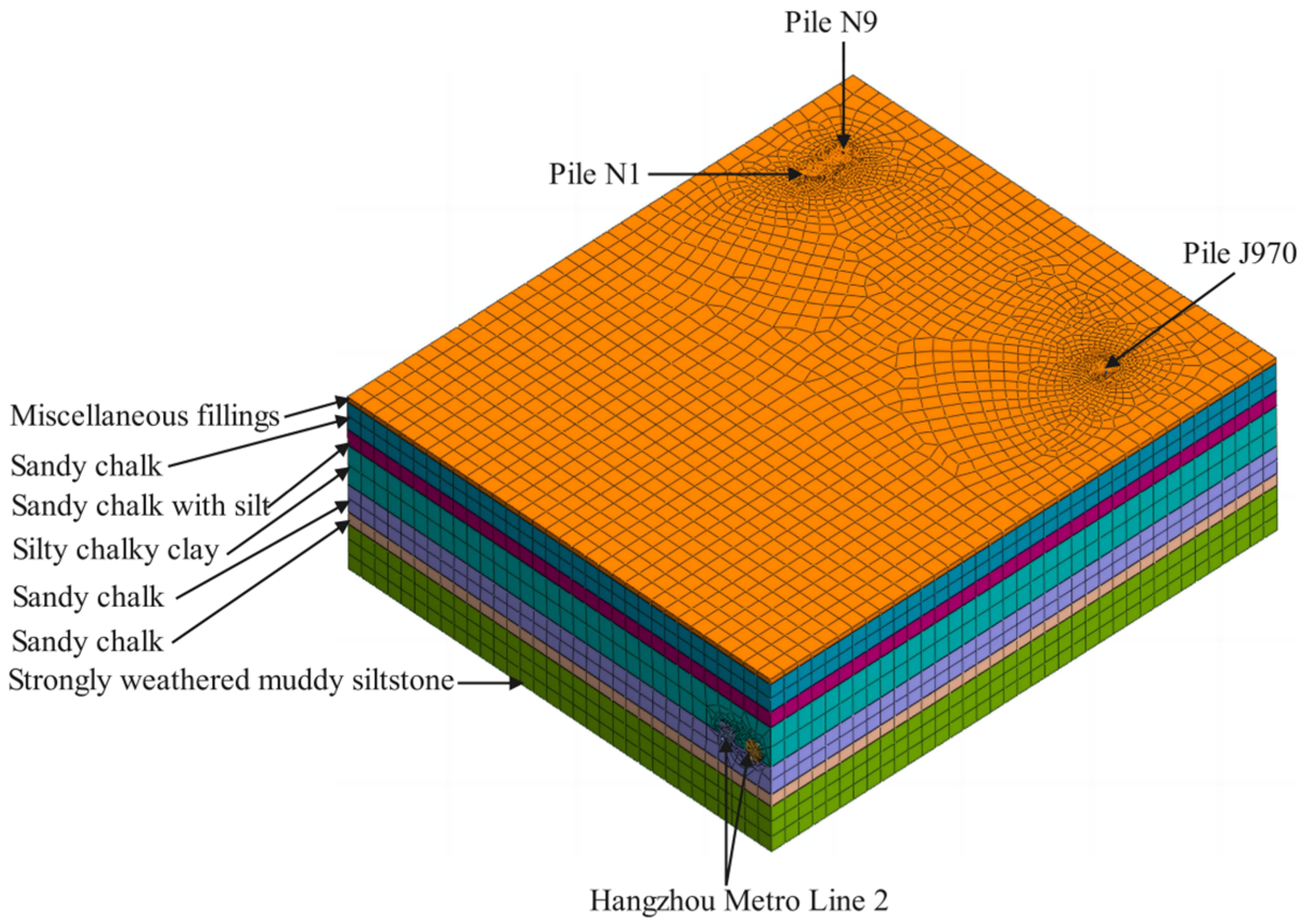

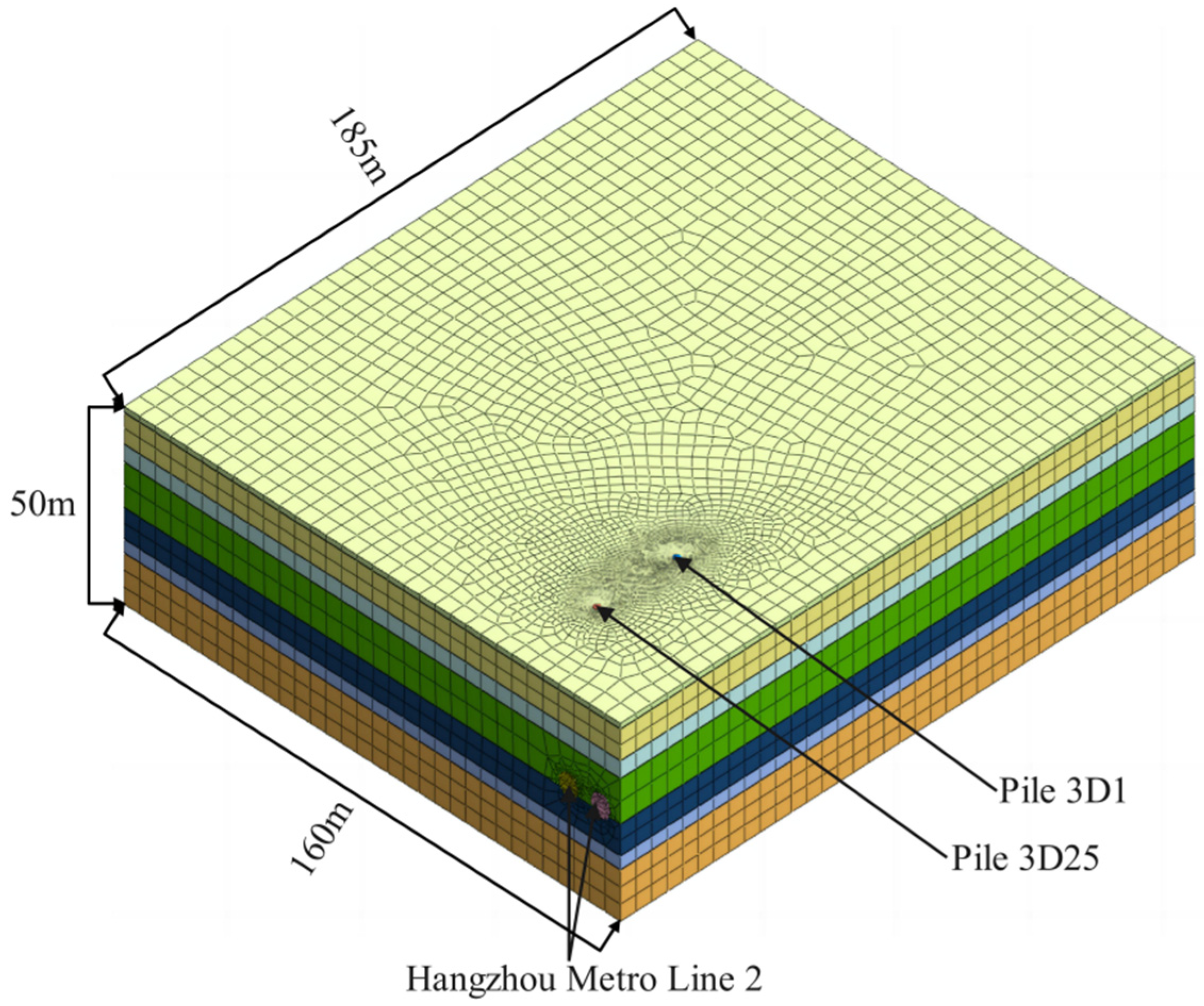

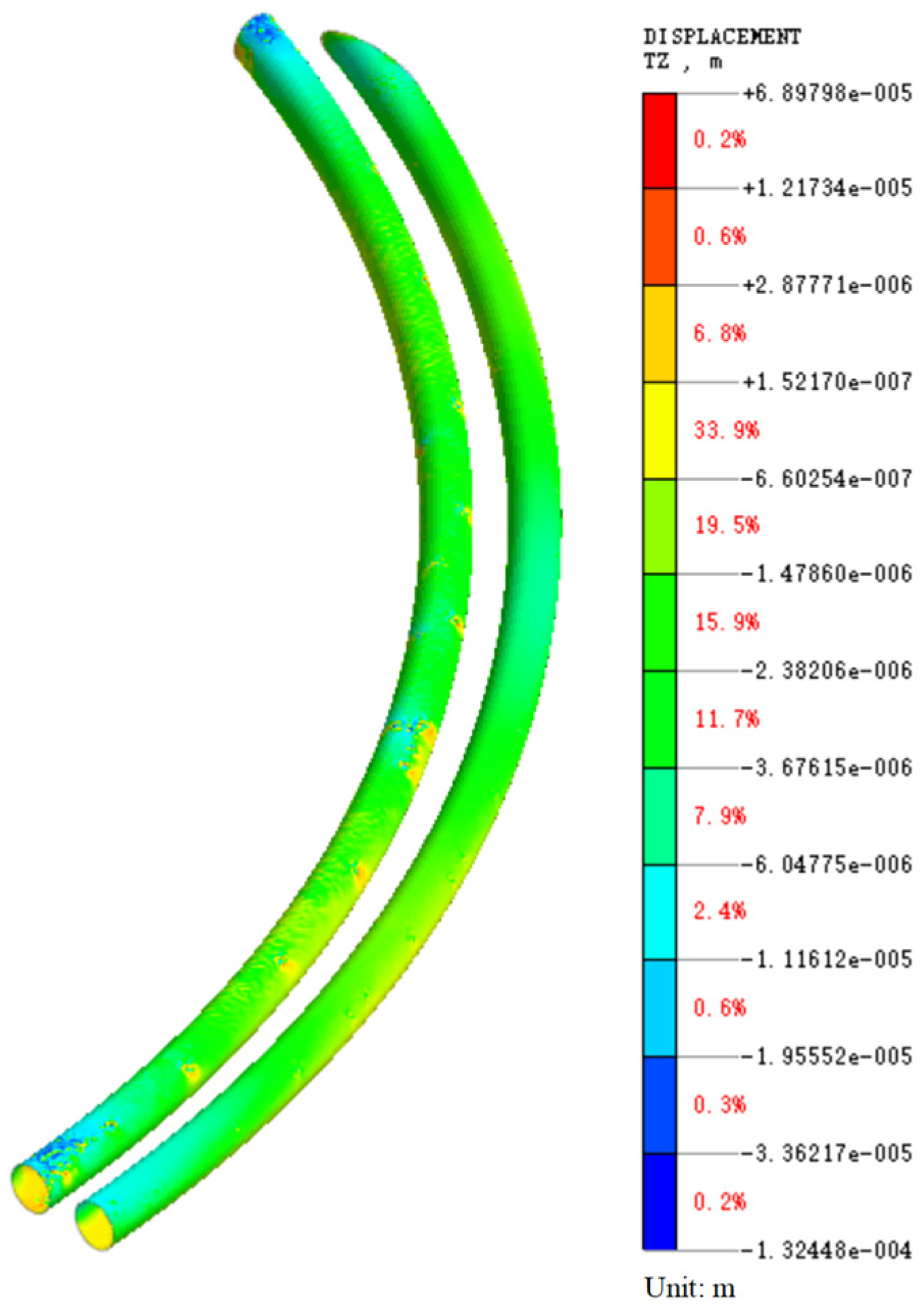

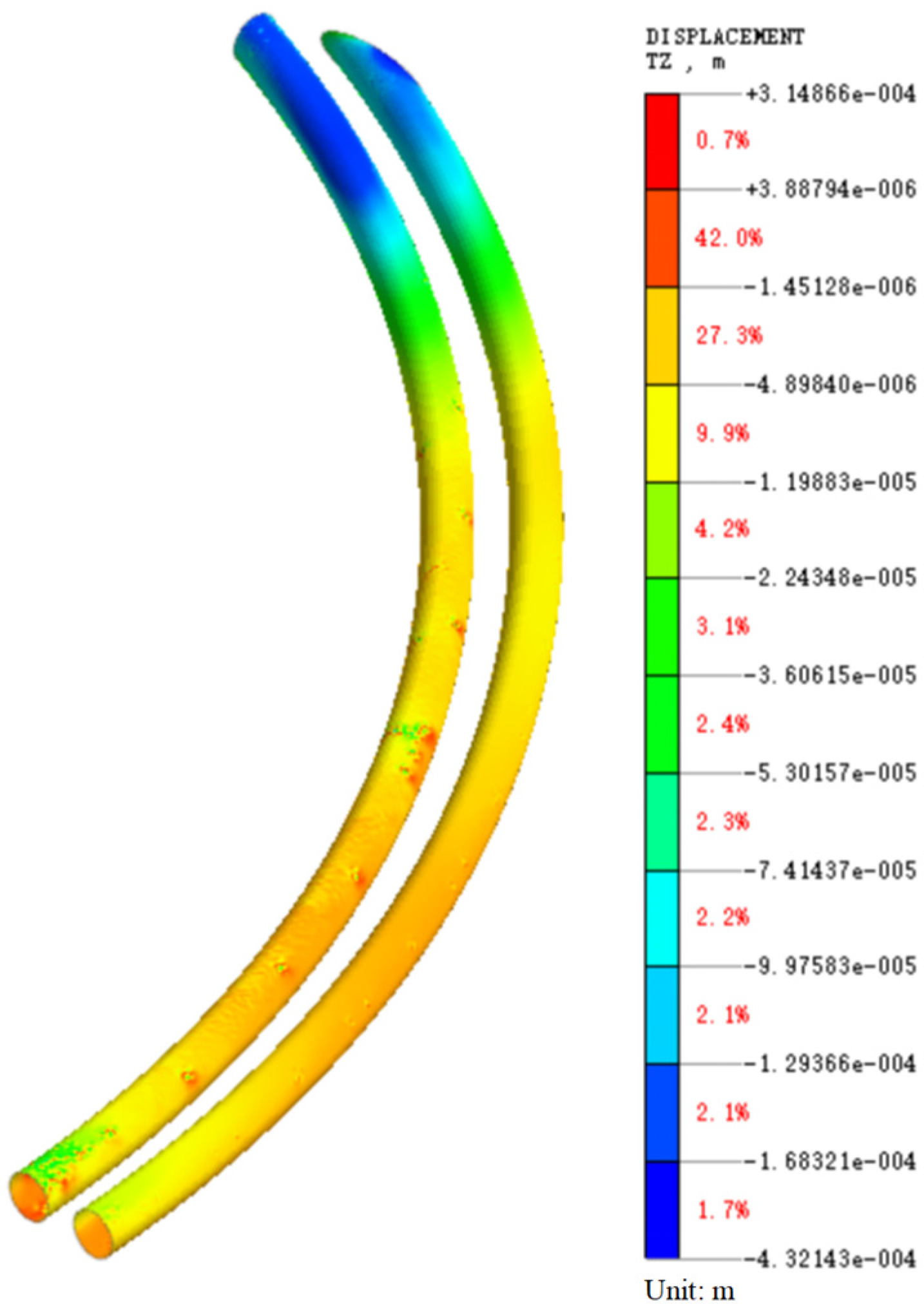

4. Three-Dimensional Finite Element Analysis

4.1. Model Parameter

4.2. Model Establishment

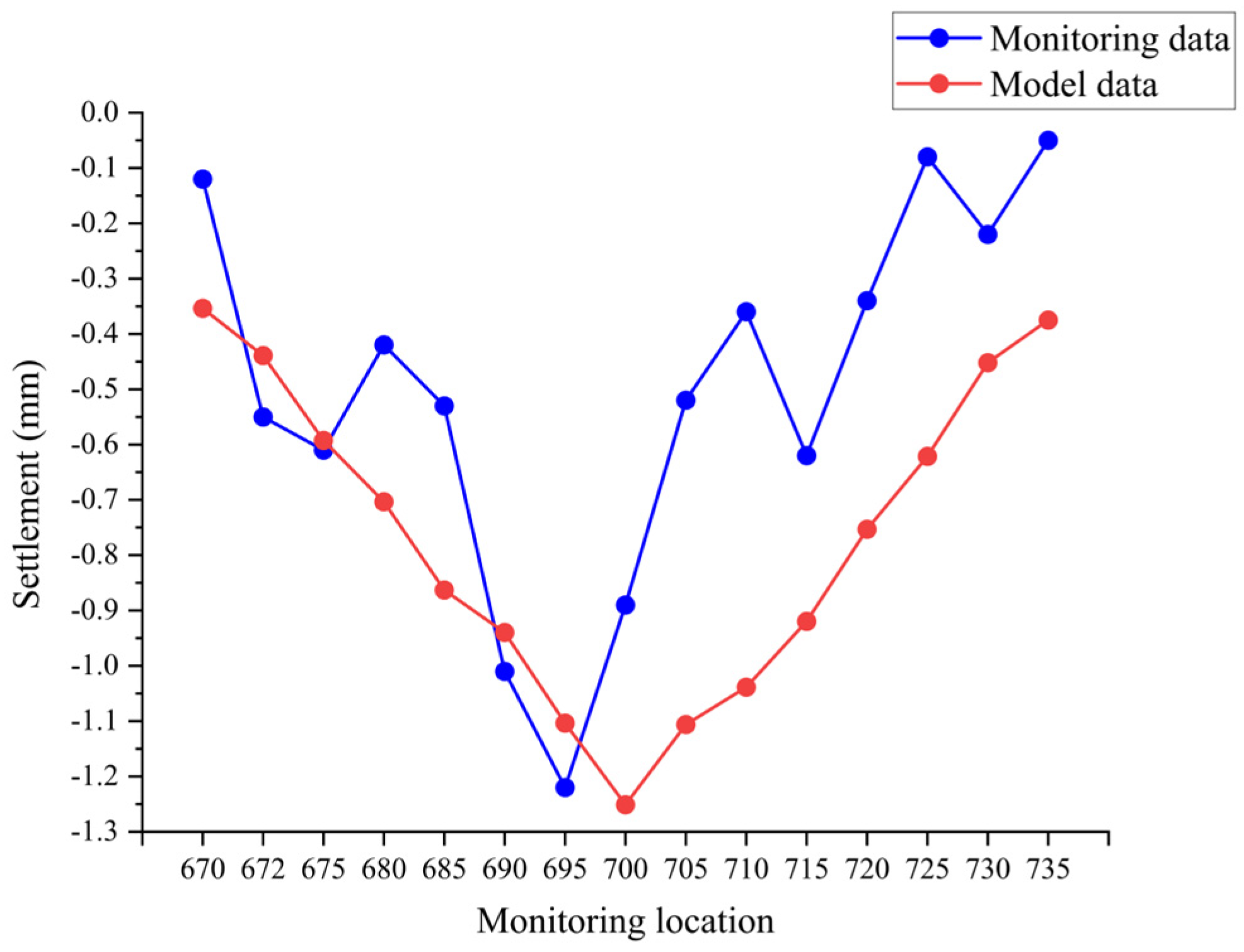

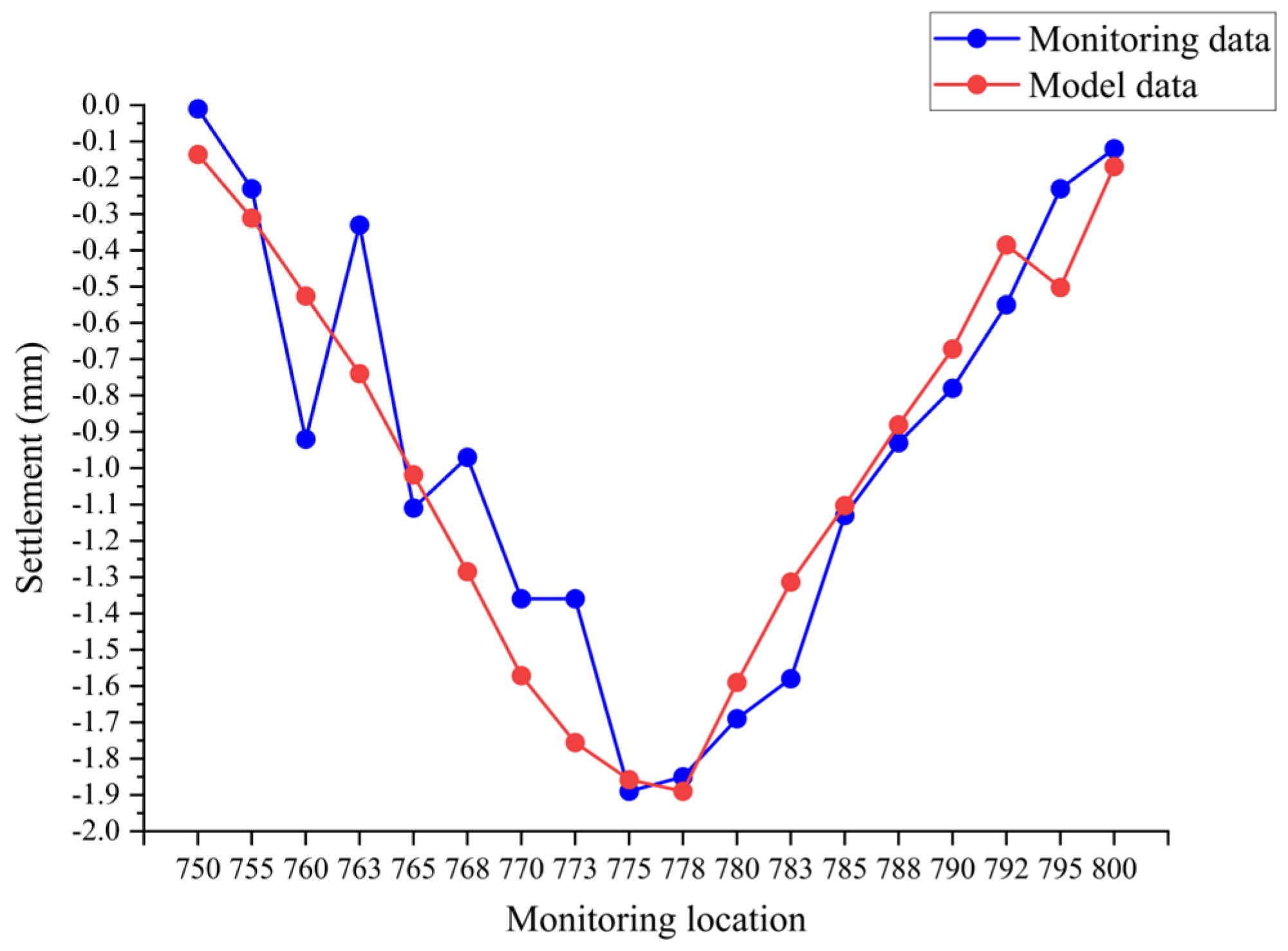

5. Data Analysis and Discussion

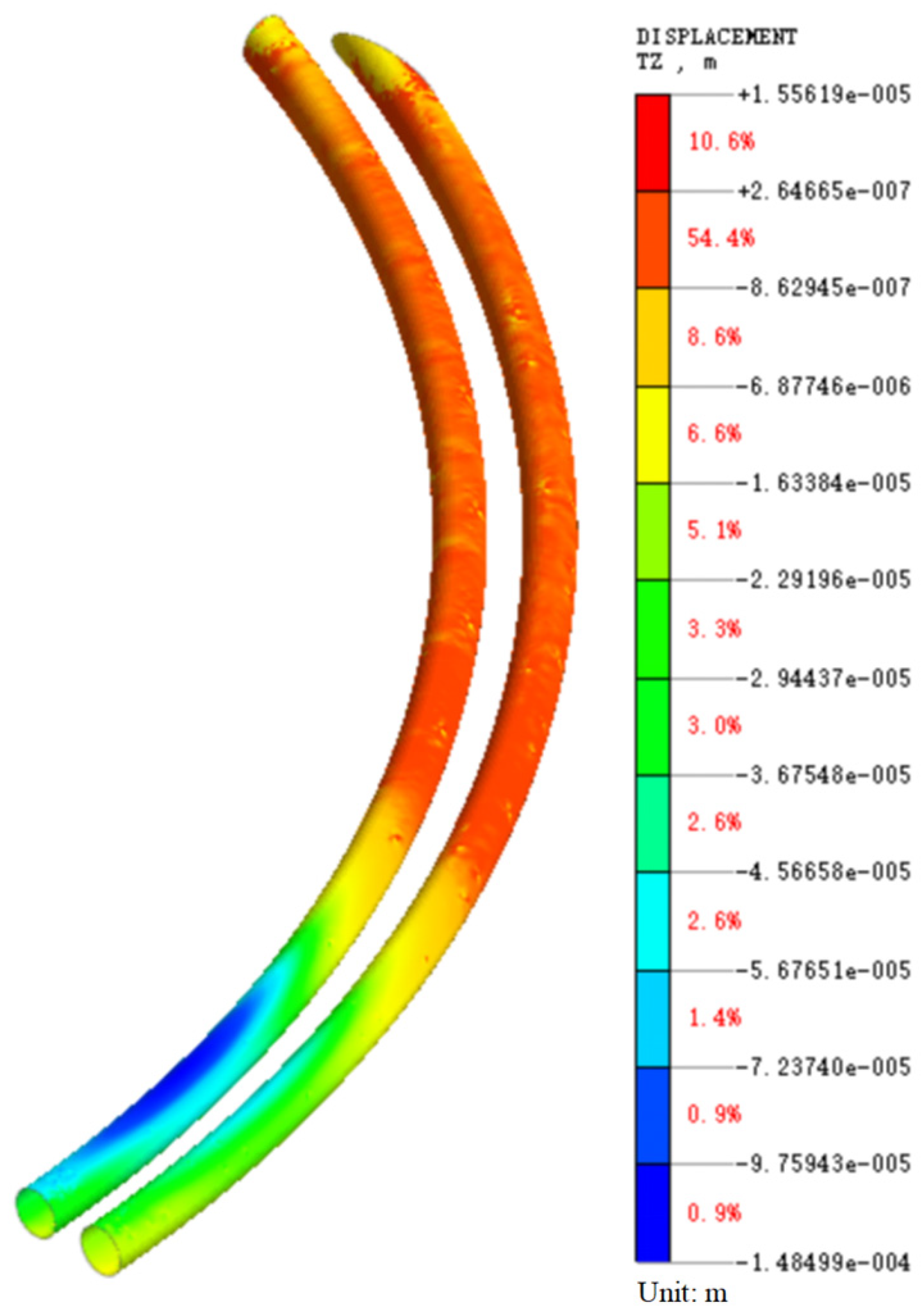

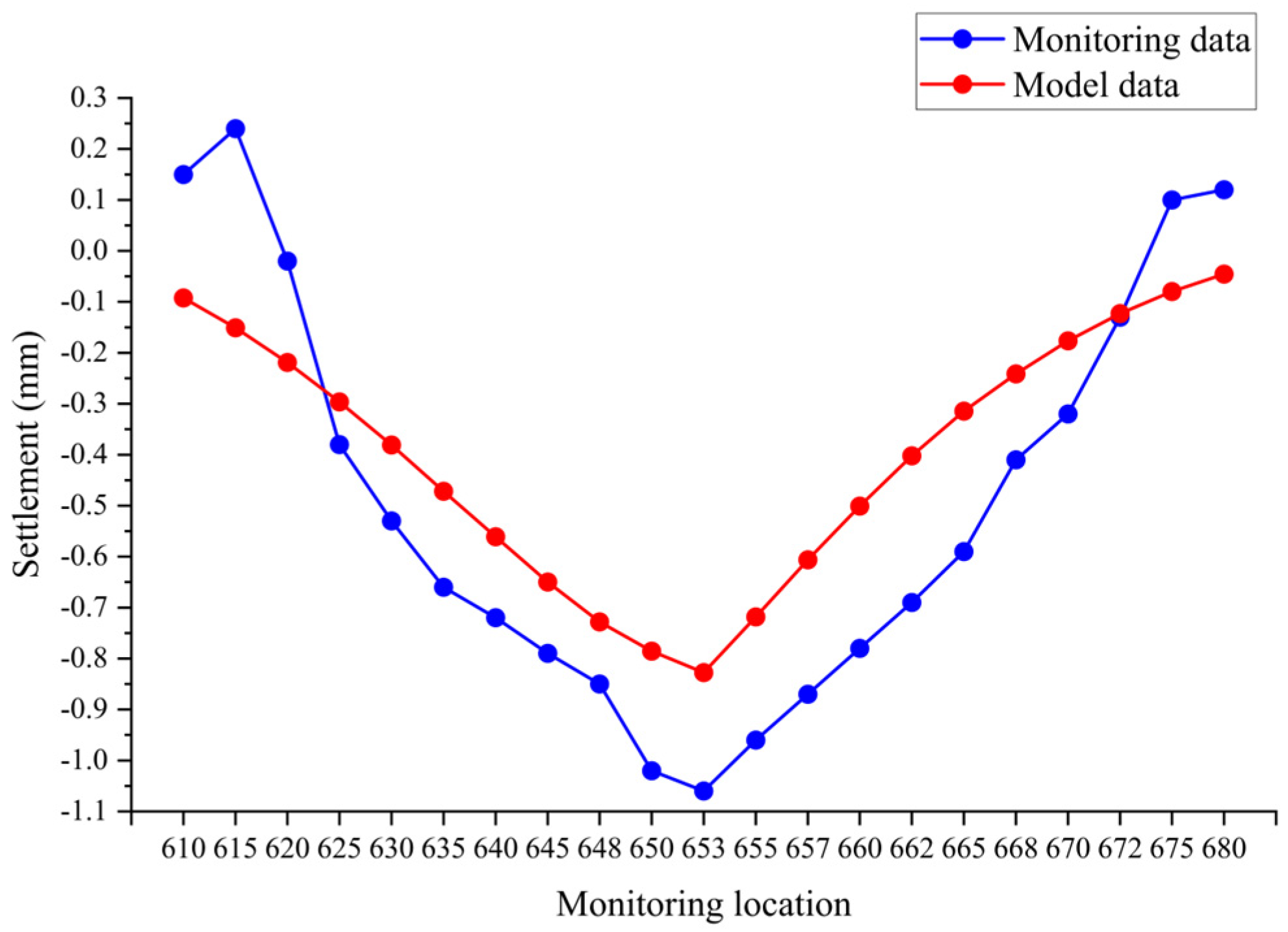

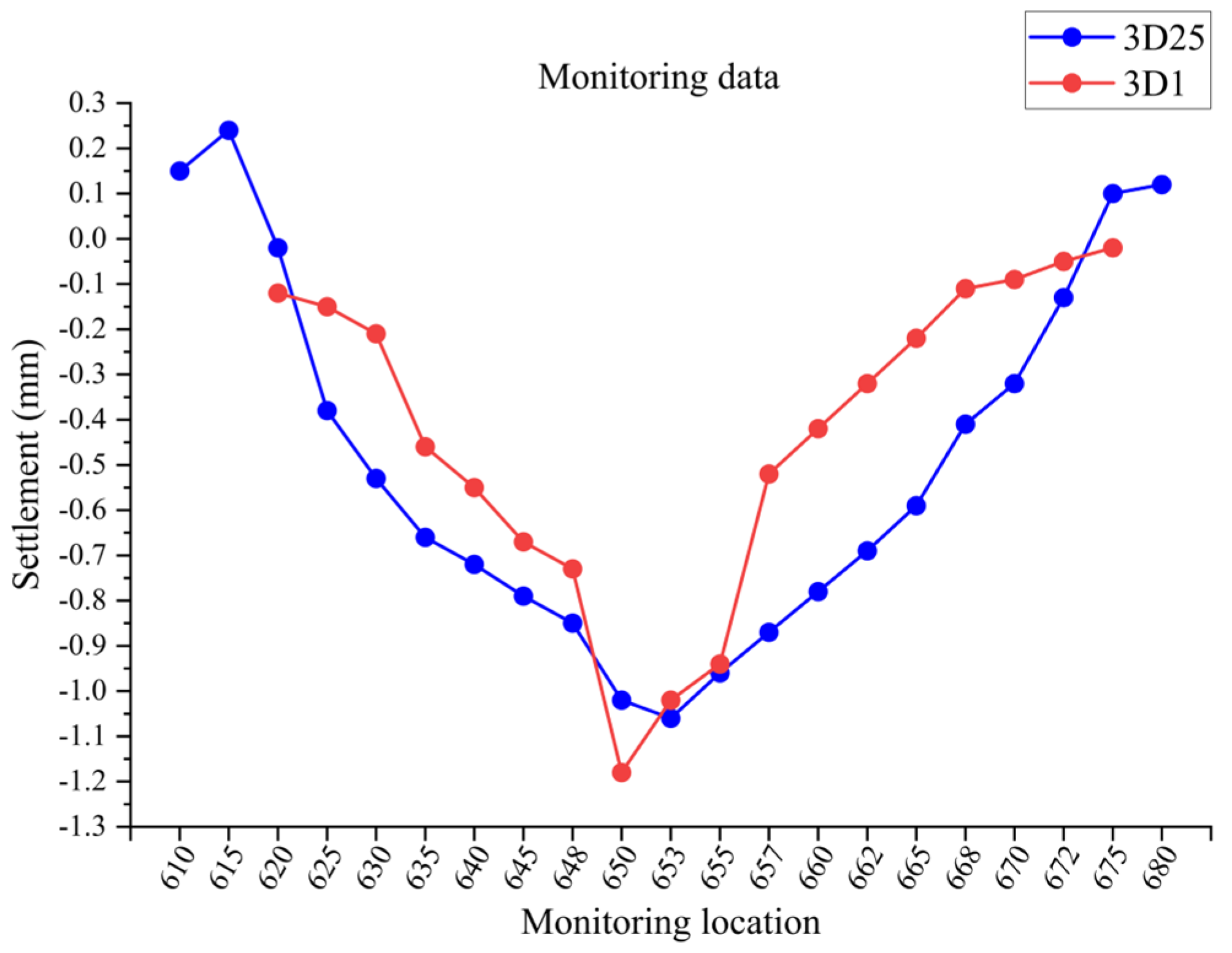

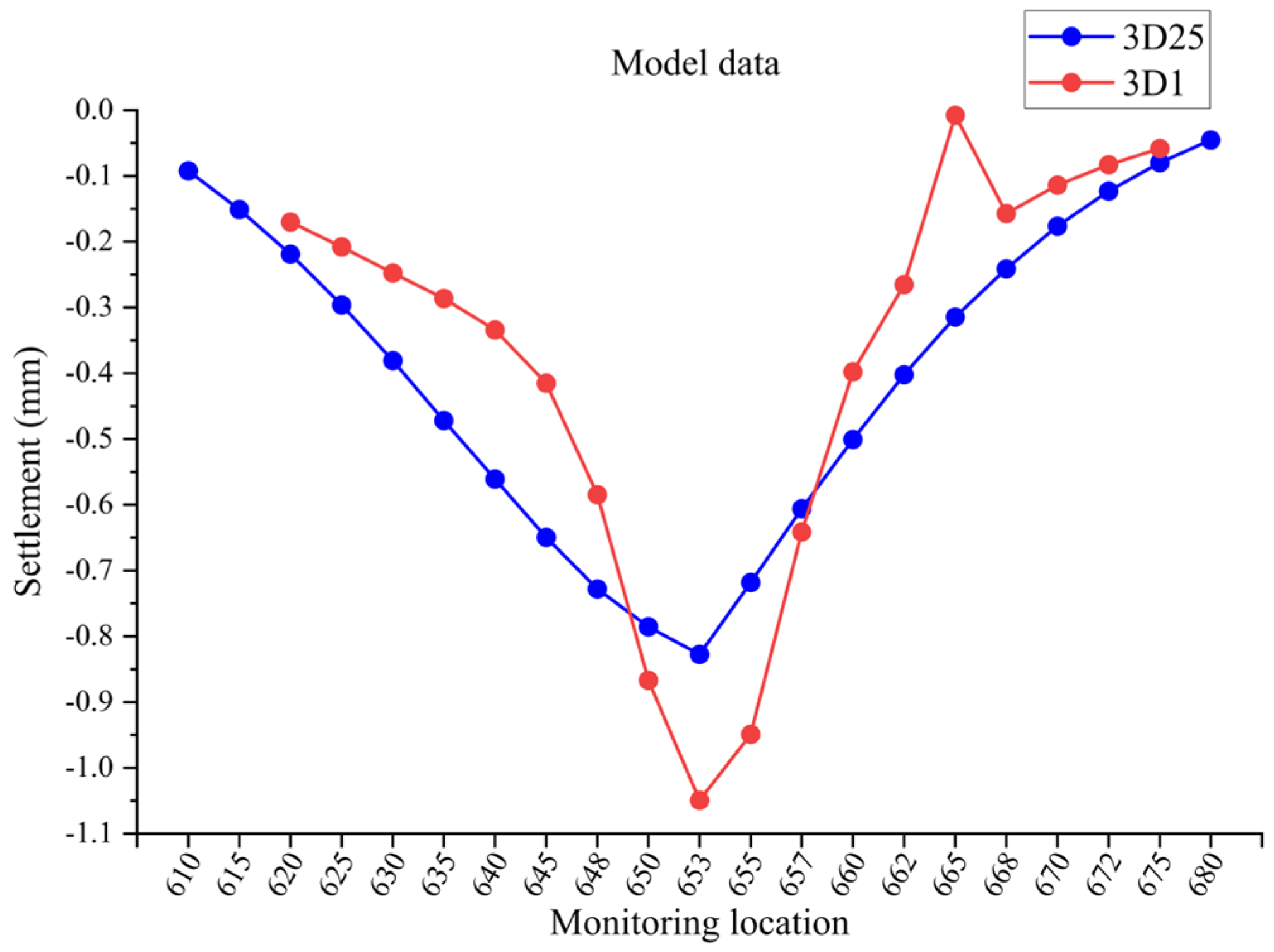

5.1. TCM Pile

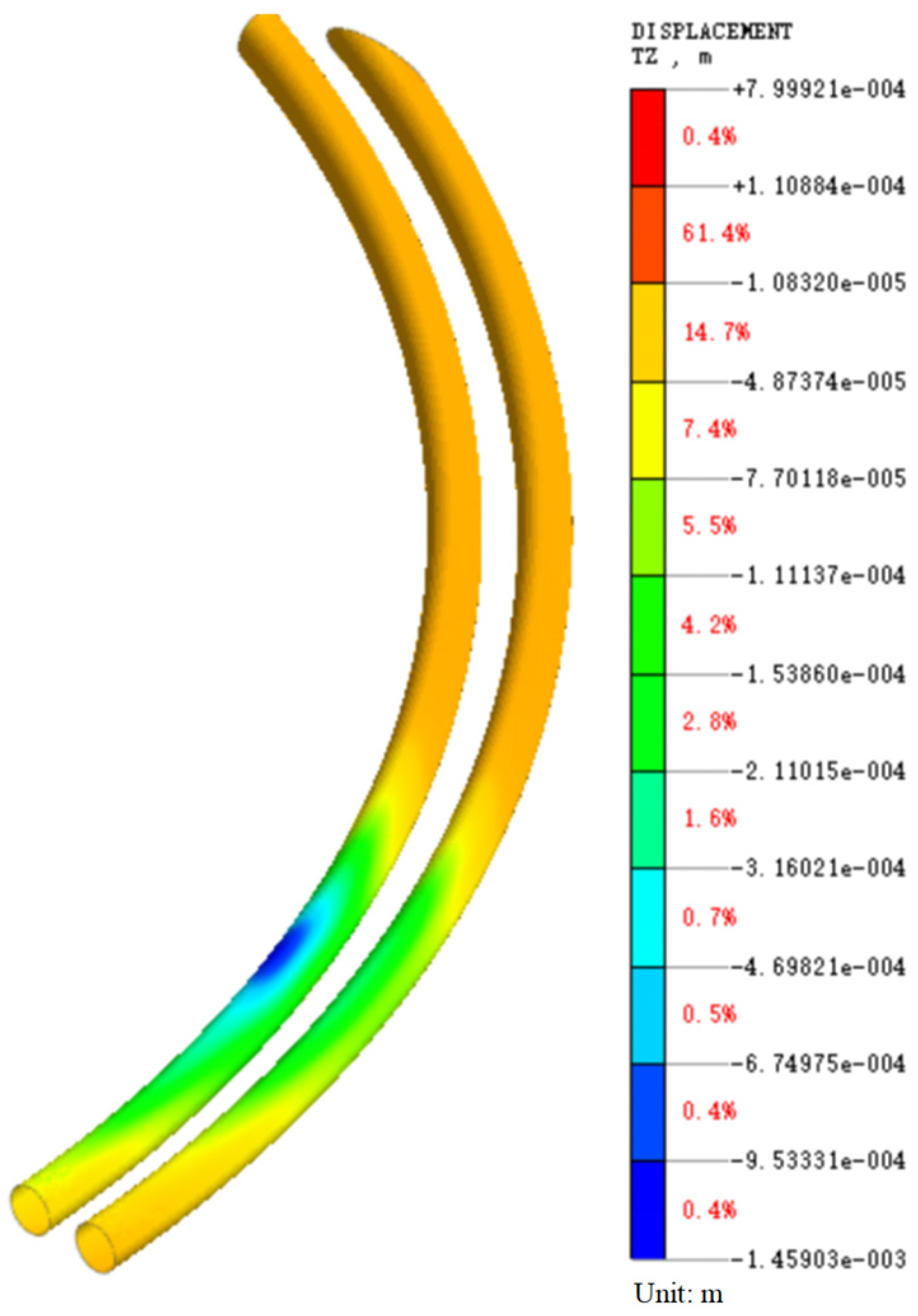

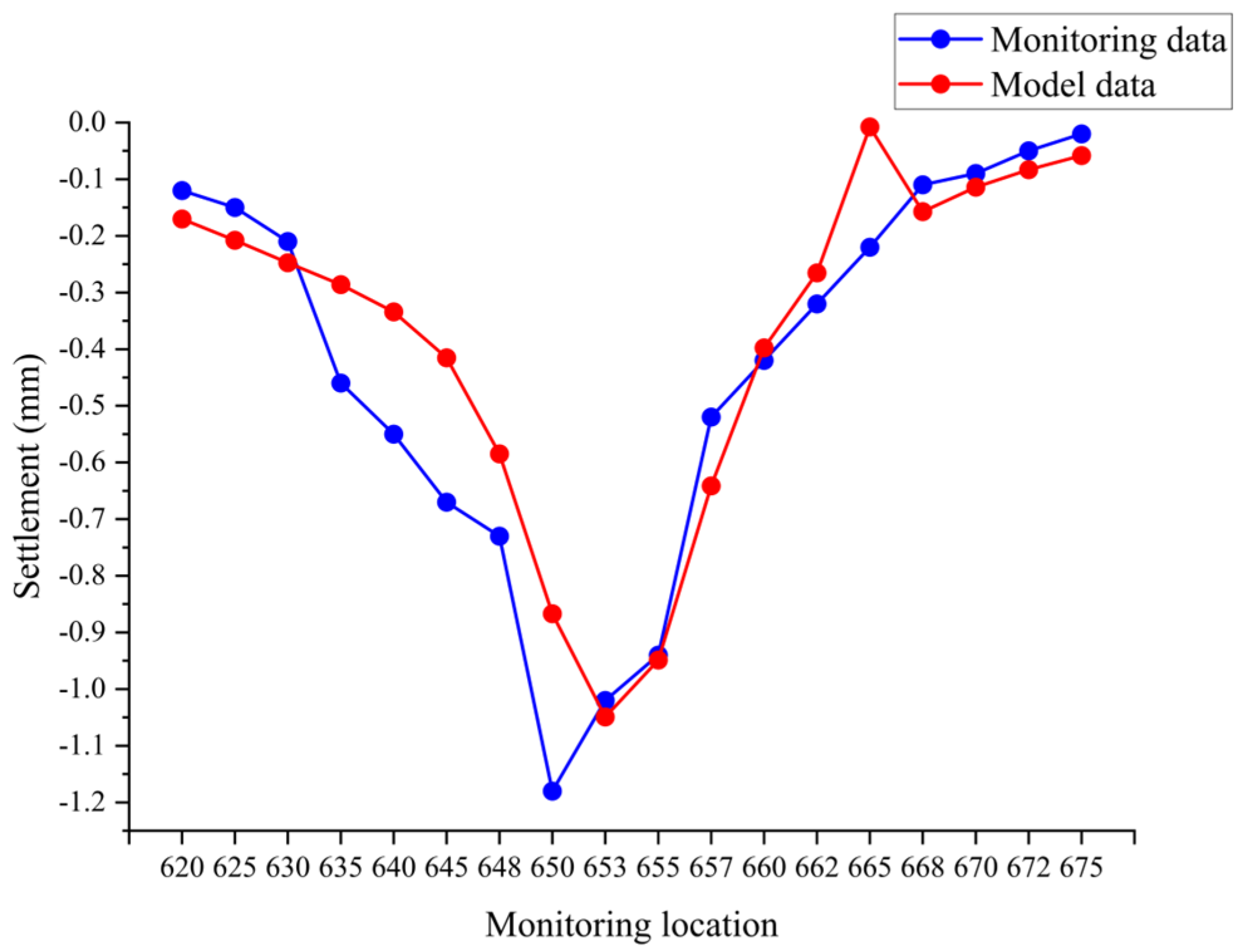

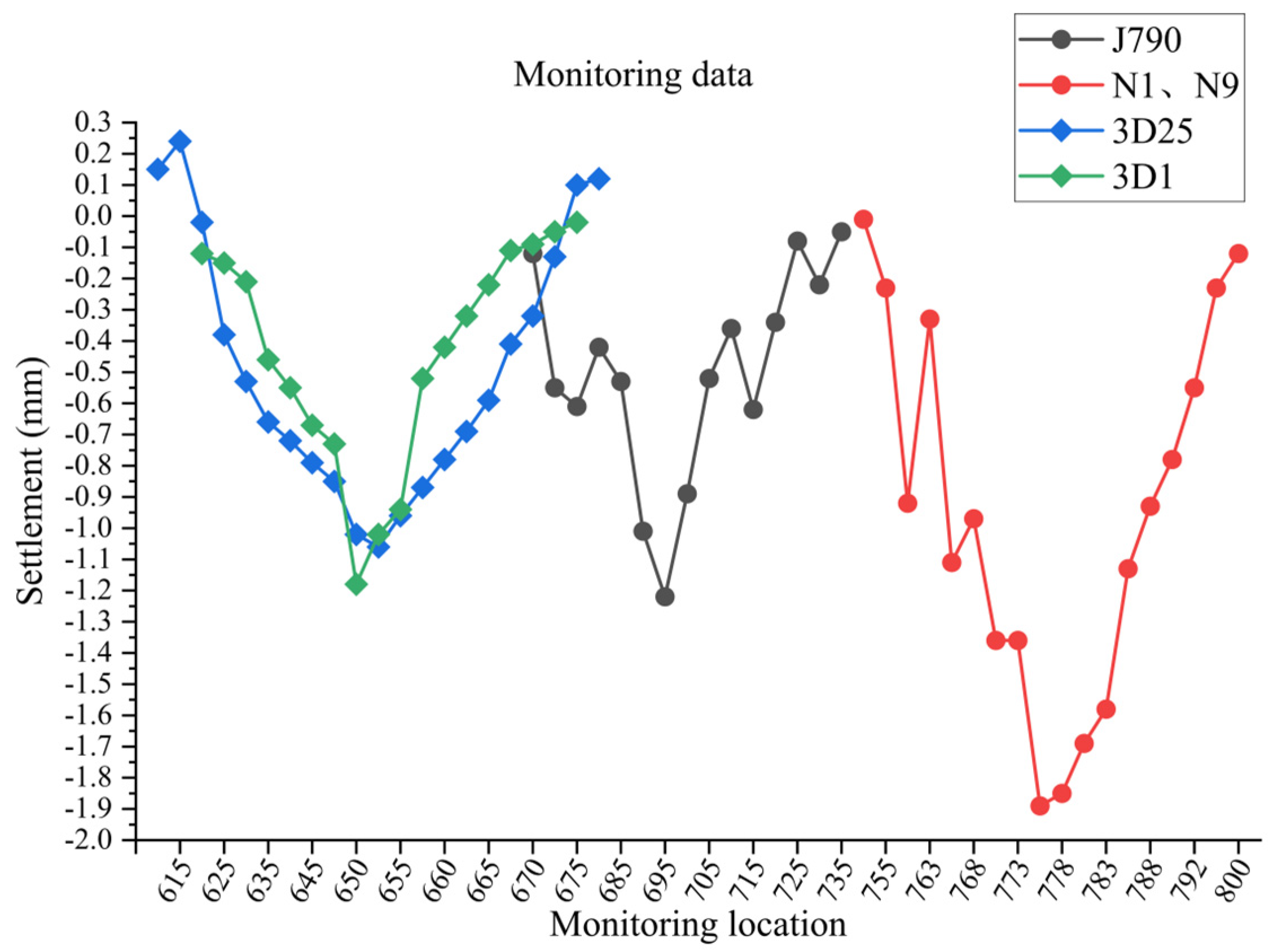

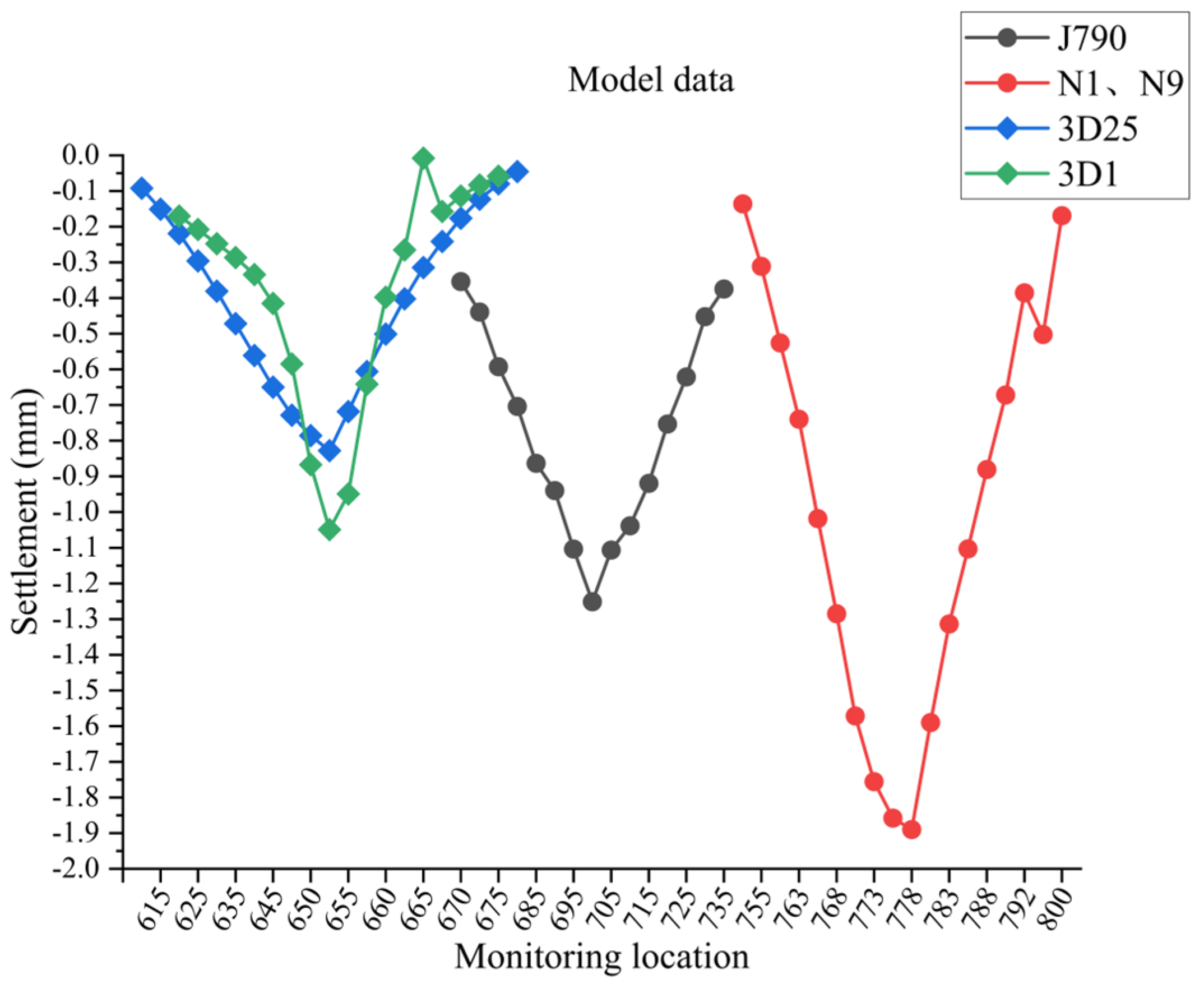

5.2. HMO Pile

5.3. Overall Analysis

6. Conclusions

- 1.

- The project on which this study is based is located in the metro protection area, and the pile foundation construction is carried out between the upbound and downbound metro tunnels, so its construction will have a certain influence on the existing metro tunnels. The monitoring data of the in situ pile tests reveal that the maximum settlements of the two groups of TCM piles and the two groups of HMO piles are all within 15 mm of the structural deformation control index of the metro tunnels. The numerical simulation also shows that the maximum settlement of the test piles is within 15 mm. This indicates that the pile foundation construction of the project has less influence on the existing metro tunnels, and the construction process is safe and controllable for the metro shield tunnel.

- 2.

- The monitoring results of both the TCM piles and HMO piles show that the settlement at different metro tunnel monitoring locations caused by the same test pile decreases with increasing distance, and that the maximum degree of influence at different distances from the metro tunnels caused by the same pile type also decreases with increasing distance. An increase in the distance between the pile foundation and the metro tunnel leads to a decrease in the degree of influence.

- 3.

- The maximum settlement corresponding to TCM piles is larger than that corresponding to HMO piles. Different types of pile foundations lead to different degrees of influence, in which the TCM piles have a greater influence on the metro tunnels than the HMO piles.

- 4.

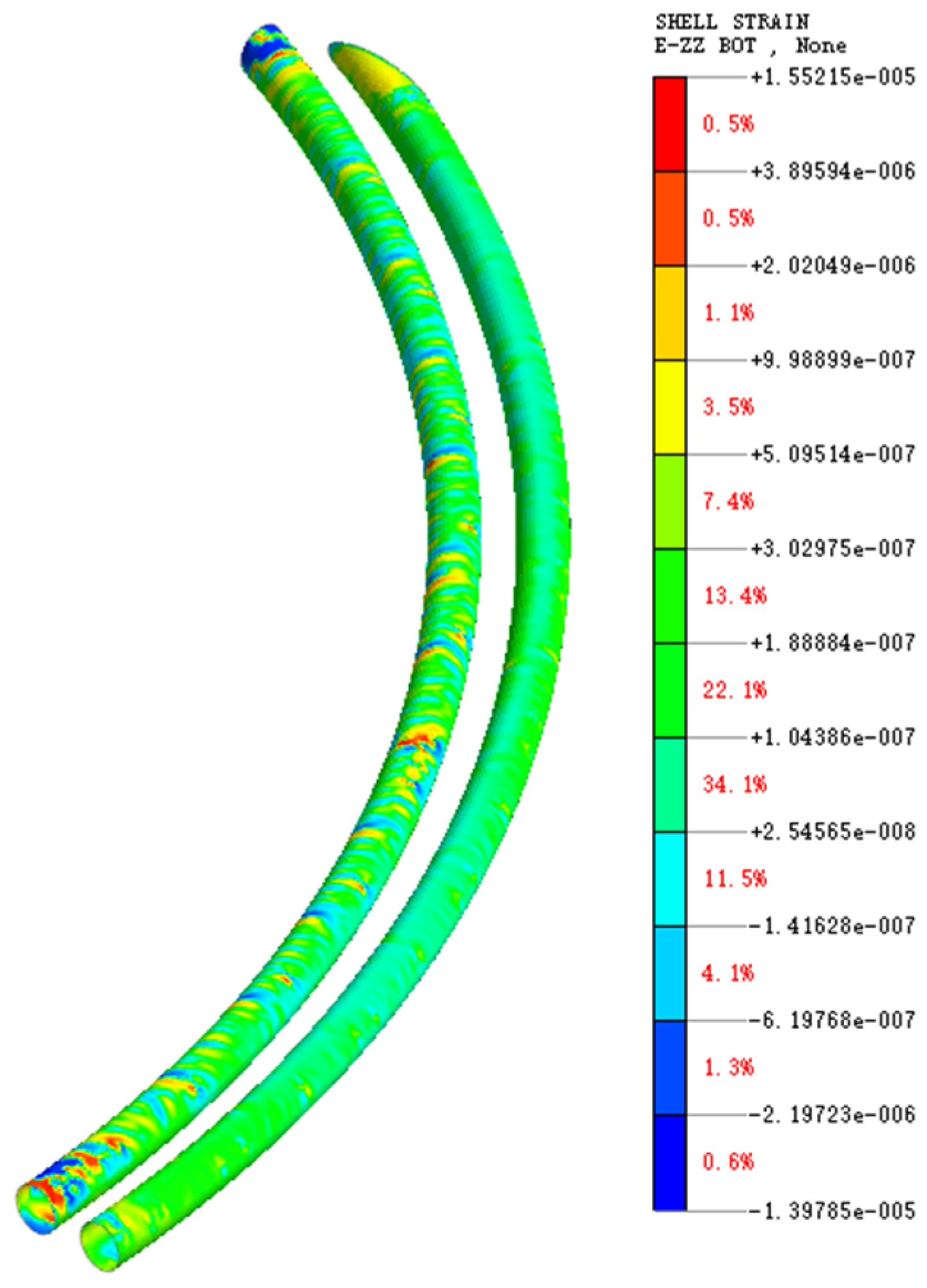

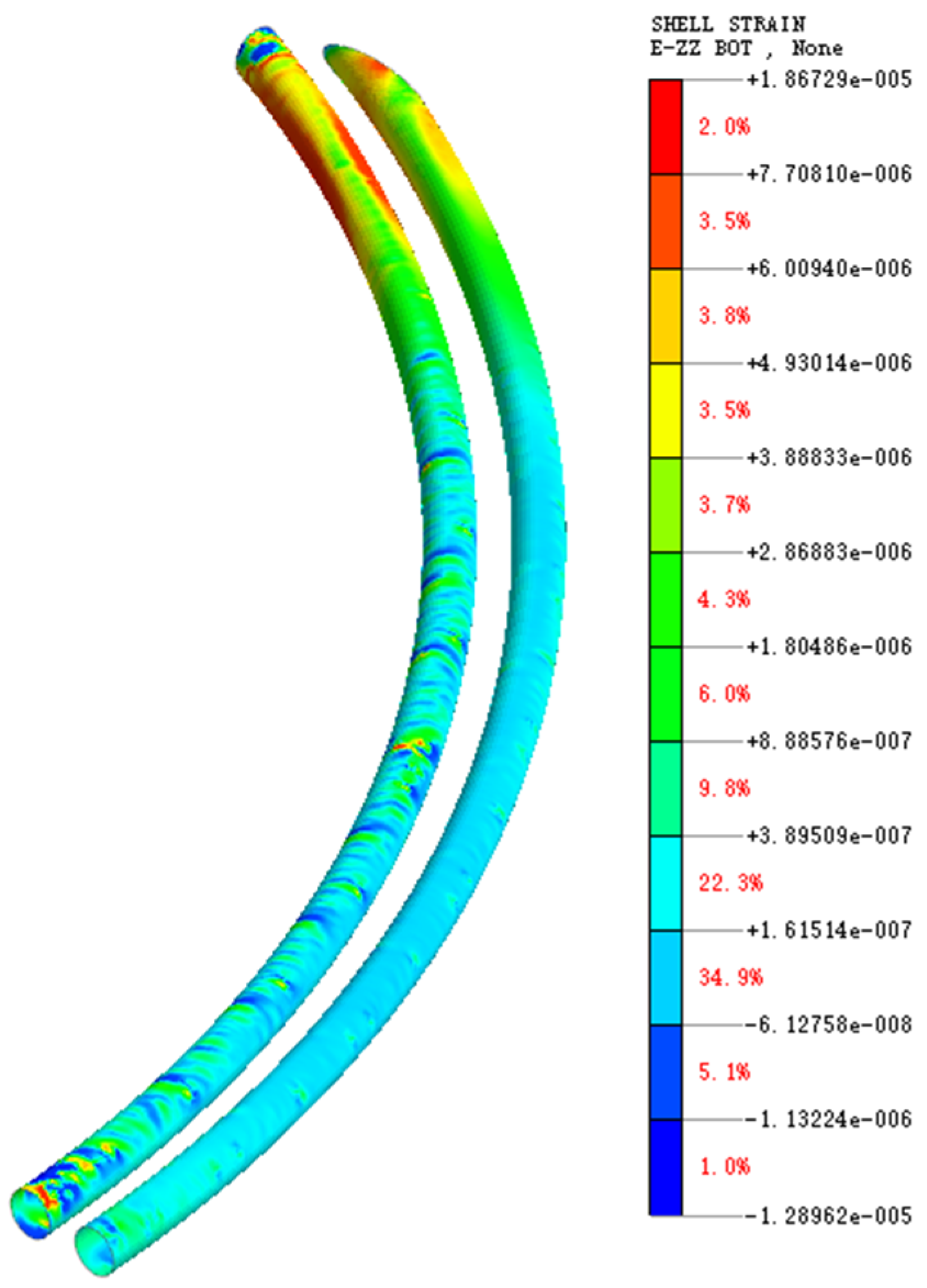

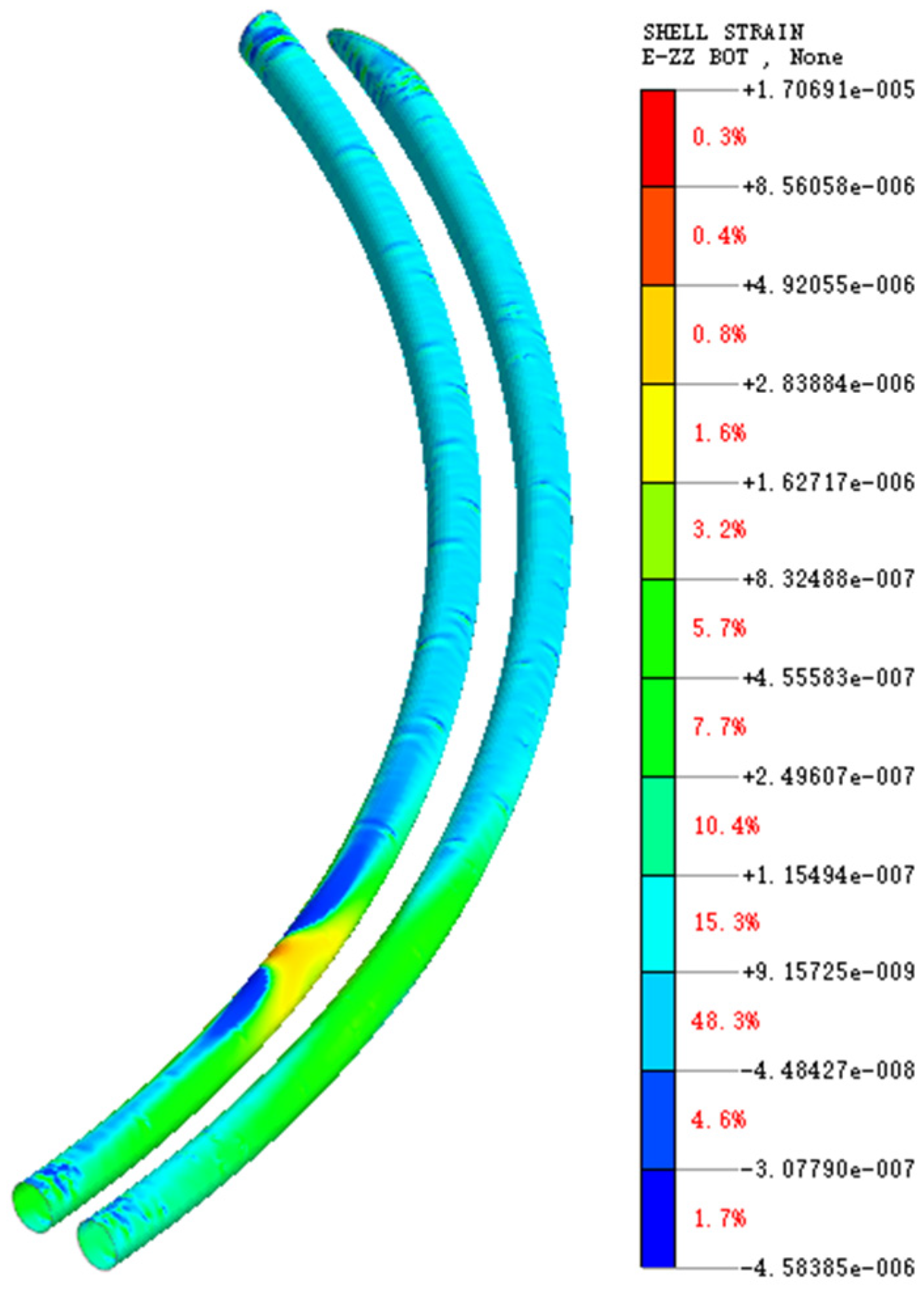

- Based on the in situ test, this paper establishes a three-dimensional finite element model to analyze the influences of each test pile on the existing metro tunnels. The reliability of the numerical simulation is verified by comparing the simulation results with the monitoring data of the in situ test piles. Considering the lack of influencing factors in the in situ pile test, the influence of each test pile on the Z-axis strain of the existing metro tunnel is investigated. It is found that the trend of the Z-axis strain is similar to that of the settlement, where the closer the test pile is to the test pile location, the greater the Z-axis strain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, Y.; Zhou, S.; Jia, J.; Yuan, Q.; Zhou, Z.; Liu, M.; He, H. Construction stability analysis of intersection tunnel in city under CRD method. Front. Earth Sci. 2023, 11, 1264140. [Google Scholar] [CrossRef]

- Ng, C.W.; Lee, K.M.; Tang, D.K. Three-dimensional numerical investigations of new Austrian tunnelling method (NATM) twin tunnel interactions. Can. Geotech. J. 2004, 41, 523–539. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, T.; Diao, Y. Mechanism and countermeasures of preceding tunnel distortion induced by succeeding EPBS tunnelling in close proximity. Comput. Geotech. 2015, 66, 53–65. [Google Scholar] [CrossRef]

- Chen, R.-P.; Li, J.; Kong, L.-G.; Tang, L.-J. Experimental study on face instability of shield tunnel in sand. Tunn. Undergr. Space Technol. 2013, 33, 12–21. [Google Scholar] [CrossRef]

- Yoo, C.; Kim, S.B. Three-dimensional numerical investigation of multifaced tunneling in water-bearing soft ground. Can. Geotech. J. 2008, 45, 1467–1486. [Google Scholar] [CrossRef]

- Liang, R.; Xia, T.; Hong, Y.; Yu, F. Effects of above-crossing tunnelling on the existing shield tunnels. Tunn. Undergr. Space Technol. 2016, 58, 159–176. [Google Scholar] [CrossRef]

- Islam, S.; Iskander, M. Twin tunnelling induced ground settlements: A review. Tunn. Undergr. Space Technol. 2021, 110, 103614. [Google Scholar] [CrossRef]

- Yoo, C. Three dimensional numerical investigation on the effect of bridge construction on existing tunnel. KSCE J. Civ. Eng. 2014, 18, 794–802. [Google Scholar] [CrossRef]

- Tao, W.; Le, W.; Nan, C.L. The Influence of Bridge Construction and Operation on Adjacent Nanjing Yangtze River Tunnels. Adv. Mater. Res. 2013, 838–841, 1018–1023. [Google Scholar]

- Chen, R.; Meng, F.; Li, Z.; Ye, Y.; Ye, J. Investigation of response of metro tunnels due to adjacent large excavation and protective measures in soft soils. Tunn. Undergr. Space Technol. 2016, 58, 224–235. [Google Scholar] [CrossRef]

- Sharma, J.; Hefny, A.; Zhao, J.; Chan, C. Effect of large excavation on deformation of adjacent MRT tunnels. Tunn. Undergr. Space Technol. 2001, 16, 93–98. [Google Scholar] [CrossRef]

- Doležalová, M. Tunnel complex unloaded by a deep excavation. Comput. Geotech. 2001, 28, 469–493. [Google Scholar] [CrossRef]

- Meguid, M.A.; Rowe, R.K.; Lo, K.Y. 3D effects of surface construction over existing subway tunnels. Int. J. Geomech. 2002, 2, 447–469. [Google Scholar] [CrossRef]

- Liang, R.; Xia, T.; Huang, M.; Lin, C. Simplified analytical method for evaluating the effects of adjacent excavation on shield tunnel considering the shearing effect. Comput. Geotech. 2017, 81, 167–187. [Google Scholar] [CrossRef]

- Veeraraghavan, S. Semi-analytical solution for the 3D response of tunnels subjected to seismic waves. Tunn. Undergr. Space Technol. 2024, 152, 105925. [Google Scholar] [CrossRef]

- Xu, C.; Chen, Q.; Luo, W.; Liang, L. Evaluation of permanent settlement in Hangzhou Qingchun road crossing-river tunnel under traffic loading. Int. J. Geomech. 2019, 19, 06018037. [Google Scholar] [CrossRef]

- Lee, Y.J.; Bassett, R.H. A model test and numerical investigation on the shear deformation patterns of deep wall–soil–tunnel interaction. Can. Geotech. J. 2006, 43, 1306–1323. [Google Scholar] [CrossRef]

- Franza, A.; Marshall, A.M.; Haji, T.; Abdelatif, A.O.; Carbonari, S.; Morici, M. A simplified elastic analysis of tunnel-piled structure interaction. Tunn. Undergr. Space Technol. 2017, 61, 104–121. [Google Scholar] [CrossRef]

- Schroeder, F.C. The Influence of Bored Piles on Existing Tunnels. Ph.D. Thesis, Imperial College London, London, UK, 2003. [Google Scholar]

- Arora, K.; Gutierrez, M. Viscous-elastic-plastic response of tunnels in squeezing ground conditions: Analytical modeling and experimental validation. Int. J. Rock Mech. Min. Sci. 2021, 146, 104888. [Google Scholar] [CrossRef]

- Liu, H.; Small, J.; Carter, J.; Williams, D. Effects of tunnelling on existing support systems of perpendicularly crossing tunnels. Comput. Geotech. 2009, 36, 880–894. [Google Scholar] [CrossRef]

- Saleh Asheghabadi, M.; Rahgozar, M.A. Finite element seismic analysis of soil–tunnel interactions in clay soils. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 835–849. [Google Scholar] [CrossRef]

- Liu, H.; Small, J.; Carter, J. Full 3D modelling for effects of tunnelling on existing support systems in the Sydney region. Tunn. Undergr. Space Technol. 2008, 23, 399–420. [Google Scholar] [CrossRef]

- Yoo, C. Interaction between tunneling and groundwater—Numerical investigation using three dimensional stress–pore pressure coupled analysis. J. Geotech. Geoenviron. Eng. 2005, 131, 240–250. [Google Scholar] [CrossRef]

- Shi, J.; Ng, C.W.W.; Chen, Y. Three-dimensional numerical parametric study of the influence of basement excavation on existing tunnel. Comput. Geotech. 2015, 63, 146–158. [Google Scholar] [CrossRef]

- Li, T.; Yang, M.; Chen, X. A Simplified Analytical Method for the Deformation of Pile Foundations Induced by Adjacent Excavation in Soft Clay. Buildings 2023, 13, 1919. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, M.; Jiang, Y.; Bai, Q.; Zhao, Q. Analytical prediction for ground movements and liner internal forces induced by shallow tunnels considering non-uniform convergence pattern and ground-liner interaction mechanism. Soils Found. 2017, 57, 211–226. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, X. Calculation of rotation and shearing dislocation deformation of underlying shield tunnels due to foundation pit excavation. J. Cent. South Univ. 2019, 50, 2273–2284. [Google Scholar]

- Zhou, P.; Liu, H.; Zhou, H.; Xu, C.; Cui, J.; Ding, X. Experimental study on the development of surrounding soil stress during XCC pile installation in sand. Acta Geotech. 2023, 19, 4017–4035. [Google Scholar] [CrossRef]

- Zhou, P.; Liu, H.; Zhou, H.; Cao, G.; Ding, X. A simplified analysis approach for the effect of the installation of adjacent XCC pile on the existing single XCC pile in undrained clay. Acta Geotech. 2022, 17, 5499–5519. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, H.; Liu, H.; Li, X.; Ding, X.; Wang, Z. Analysis of lateral response of existing single pile caused by penetration of adjacent pile in undrained clay. Comput. Geotech. 2020, 126, 103736. [Google Scholar] [CrossRef]

- Zhou, P.; Liu, H.; Zhou, H.; Cao, G.; Ding, X. A lateral soil resistance model for XCC pile in soft clay considering the effect of the geometry of cross section. Acta Geotech. 2022, 17, 4681–4697. [Google Scholar] [CrossRef]

- Alver, O.; Eseller-Bayat, E.E. A new p-y model for soil-pile interaction analyses in cohesionless soils under monotonic loading. Soils Found. 2024, 64, 101441. [Google Scholar] [CrossRef]

- Sakellariadis, L.; Anastasopoulos, I. Analytical 3D failure envelopes for RC pile groups under combined loading: A generalised design approach. Soil Dyn. Earthq. Eng. 2024, 181, 108570. [Google Scholar] [CrossRef]

- Lee, Y.J.; Bassett, R.H. Influence zones for 2D pile–soil-tunnelling interaction based on model test and numerical analysis. Tunn. Undergr. Space Technol. 2007, 22, 325–342. [Google Scholar] [CrossRef]

- Franza, A.; Marshall, A.M. Centrifuge modeling study of the response of piled structures to tunneling. J. Geotech. Geoenviron. Eng. 2018, 144, 04017109. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, C.; Jiang, K.; Wang, Z.; Jiang, Y.; Zhao, Q.; Lu, M. Analytical prediction for tunnel-soil-pile interaction mechanics based on Kerr foundation model. KSCE J. Civ. Eng. 2019, 23, 2756–2771. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M.; Xu, C.; Jiang, Y.; Wang, W. Simplified solution for tunnel-soil-pile interaction in Pasternak’s foundation model. Tunn. Undergr. Space Technol. 2018, 78, 146–158. [Google Scholar] [CrossRef]

- Dias, T.G.S.; Bezuijen, A. Data analysis of pile tunnel interaction. J. Geotech. Geoenviron. Eng. 2015, 141, 04015051. [Google Scholar] [CrossRef]

- Marshall, A.M.; Haji, T. An analytical study of tunnel–pile interaction. Tunn. Undergr. Space Technol. 2015, 45, 43–51. [Google Scholar] [CrossRef]

- Cheng, C.Y.; Dasari, G.R.; Chow, Y.K.; Leung, C.F. Finite element analysis of tunnel–soil–pile interaction using displacement controlled model. Tunn. Undergr. Space Technol. 2007, 22, 450–466. [Google Scholar] [CrossRef]

- Schroeder, F.C.; Potts, D.M.; Addenbrooke, T.I. The influence of pile group loading on existing tunnels. Geotechnique 2004, 54, 351–362. [Google Scholar] [CrossRef]

- Lin, Z.; Jiang, Y.; Xiong, Y.; Xu, C.; Guo, Y.; Wang, C.; Fang, T. Analytical solution for displacement-dependent active earth pressure considering the stiffness of cantilever retaining structure in cohesionless soil. Comput. Geotech. 2024, 170, 106258. [Google Scholar] [CrossRef]

- Lueprasert, P.; Jongpradist, P.; Jongpradist, P.; Schweiger, H.F. Structural responses of a tunnel lining due to an adjacent loaded pile. Int. J. Civ. Eng. 2023, 21, 1027–1043. [Google Scholar] [CrossRef]

- Lueprasert, P.; Jongpradist, P.; Jongpradist, P.; Suwansawat, S. Numerical investigation of tunnel deformation due to adjacent loaded pile and pile-soil-tunnel interaction. Tunn. Undergr. Space Technol. 2017, 70, 166–181. [Google Scholar] [CrossRef]

- Lueprasert, P.; Jongpradist, P.; Charoenpak, K.; Chaipanna, P.; Suwansawat, S. Three dimensional finite element analysis for preliminary establishment of tunnel influence zone subject to pile loading. Maejo Int. J. Sci. Technol. 2015, 9, 209–223. [Google Scholar]

- Mroueh, H.; Shahrour, I. Three-dimensional finite element analysis of the interaction between tunneling and pile foundations. Int. J. Numer. Anal. Methods Geomech. 2002, 26, 217–230. [Google Scholar] [CrossRef]

| Monitoring Projects | Control Value | Note | |

|---|---|---|---|

| Tunnel Structure | Shield tunnel uplift and subsidence | ≤15 mm | Monitoring value ≥ daily monitoring indicators or monitoring value ≥ 1/2 of the total deformation control volume need to be alarmed, and shall not affect its safe and normal use. |

| Shield Tunnel Horizontal Displacement | ≤10 mm | ||

| Shield tunnel tube sheet lateral deformation | ≤5 mm | ||

| Maximum Horizontal Displacement of Enclosure Structure | <20 mm | ||

| Soil Layer Name | Gravity (kN/m3) | Cohesion (kPa) | Angle of Internal Friction (°) | Compressed Modulus ES MPa | Poisson’s Ratio |

|---|---|---|---|---|---|

| Miscellaneous fillings | 18.0 | 12.0 | 12.0 | 4.0 | 0.2 |

| Sandy chalk | 18.1 | 4.0 | 23.5 | 10.0 | 0.2 |

| Sandy chalk with silt | 19.2 | 3.0 | 29.5 | 9.0 | 0.2 |

| Silty chalky clay | 18.0 | 12.0 | 9.5 | 3.0 | 0.2 |

| Sandy chalk | 19.0 | 6.0 | 18.0 | 5.8 | 0.2 |

| Sandy chalk | 18.5 | 18.0 | 11.9 | 4.0 | 0.2 |

| Strongly weathered muddy siltstone | 20.0 | 0.3 |

| Stake | Borehole Diameter (mm) | Concrete Grade | Drilling Dept (m) | Construction Date | Distance to Subway (m) | Influence Ring Number |

|---|---|---|---|---|---|---|

| J790 | 850@600 | C40 | 20.5 | 7–20 | 40.0 | Up line 670–730 |

| N1 | 850@600 | C40 | 15.5 | 7–22 | 20.3 | Down line 750–800 |

| N9 | 850@600 | C40 | 15.5 | 7–22 | 8.4 | Down line 760–800 |

| Stake | Borehole Diameter (mm) | Concrete Grade | Drilling Dept (m) | Construction Date | Distance to Subway (m) | Influence Ring Number |

|---|---|---|---|---|---|---|

| 3D25 | 1000 | C40 | 25.0 | 7–22 | 12.0 | Down line 610–670 |

| 3D1 | 1000 | C40 | 25.0 | 7–25 | 4.9 | Down line 620–670 |

| Soil Layer Name | Soil Thickness (m) | E50 (MPa) | Eoed (MPa) | Eur (MPa) | Gravity (kN/m3) | Cohesion (kPa) | Angle of Internal Friction (°) | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|---|

| Miscellaneous fillings | 1.5 | 4000 | 4000 | 21,000 | 18.0 | 12.0 | 12.0 | 0.2 |

| Sandy chalk | 8.0 | 10,000 | 10,000 | 45,000 | 18.1 | 4.0 | 23.5 | 0.2 |

| Sandy chalk with silt | 4.5 | 9000 | 9000 | 40,000 | 19.2 | 3.0 | 29.5 | 0.2 |

| Silty chalky clay | 11.5 | 3000 | 3000 | 20,000 | 18.0 | 12.0 | 9.5 | 0.2 |

| Sandy chalk | 8.0 | 5800 | 5800 | 40,000 | 19.0 | 6.0 | 18 | 0.2 |

| Sandy chalk | 3.5 | 4000 | 4000 | 35,000 | 18.5 | 18.0 | 11.9 | 0.2 |

| Strongly weathered Muddy siltstone | 13.0 | 20.0 | 0.3 |

| Stake | Borehole Diameter (mm) | Concrete Grade | Drilling Dept (m) | Modulus of Elasticity ES MPa | Gravity (kN/m3) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| J790 | 850@600 | C40 | 20.5 | 3.25 × 104 | 24.39 | 0.2 |

| N1 | 850@600 | C40 | 15.5 | 3.25 × 104 | 24.39 | 0.2 |

| N9 | 850@600 | C40 | 15.5 | 3.25 × 104 | 24.39 | 0.2 |

| 3D25 | 1000 | C40 | 25.0 | 3.25 × 104 | 24.39 | 0.2 |

| 3D1 | 1000 | C40 | 25.0 | 3.25 × 104 | 24.39 | 0.2 |

| Concrete Grade | Modulus of Elasticity ES MPa | Gravity (kN/m3) | Poisson’s Ratio | Tunnel Depth (m) |

|---|---|---|---|---|

| C50 | 3.55 × 104 | 25.0 | 0.2 | 24.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, G.; Ke, W.; Guo, S.; Lin, Z.; Xu, C.; Chi, M.; Xiao, Y. Influence of Pile Foundation Construction on Existing Tunnels in a Metro Protection Area: Field Test and Numerical Simulation. Buildings 2024, 14, 2280. https://doi.org/10.3390/buildings14082280

Lin G, Ke W, Guo S, Lin Z, Xu C, Chi M, Xiao Y. Influence of Pile Foundation Construction on Existing Tunnels in a Metro Protection Area: Field Test and Numerical Simulation. Buildings. 2024; 14(8):2280. https://doi.org/10.3390/buildings14082280

Chicago/Turabian StyleLin, Gang, Wenbin Ke, Shuaishuai Guo, Zhaorui Lin, Changjie Xu, Minliang Chi, and Yue Xiao. 2024. "Influence of Pile Foundation Construction on Existing Tunnels in a Metro Protection Area: Field Test and Numerical Simulation" Buildings 14, no. 8: 2280. https://doi.org/10.3390/buildings14082280