A Comparative Study to Assess the Energy Efficiency of Temporary Structures to Guarantee Emergency Basic Healthcare in Italy

Abstract

1. Introduction

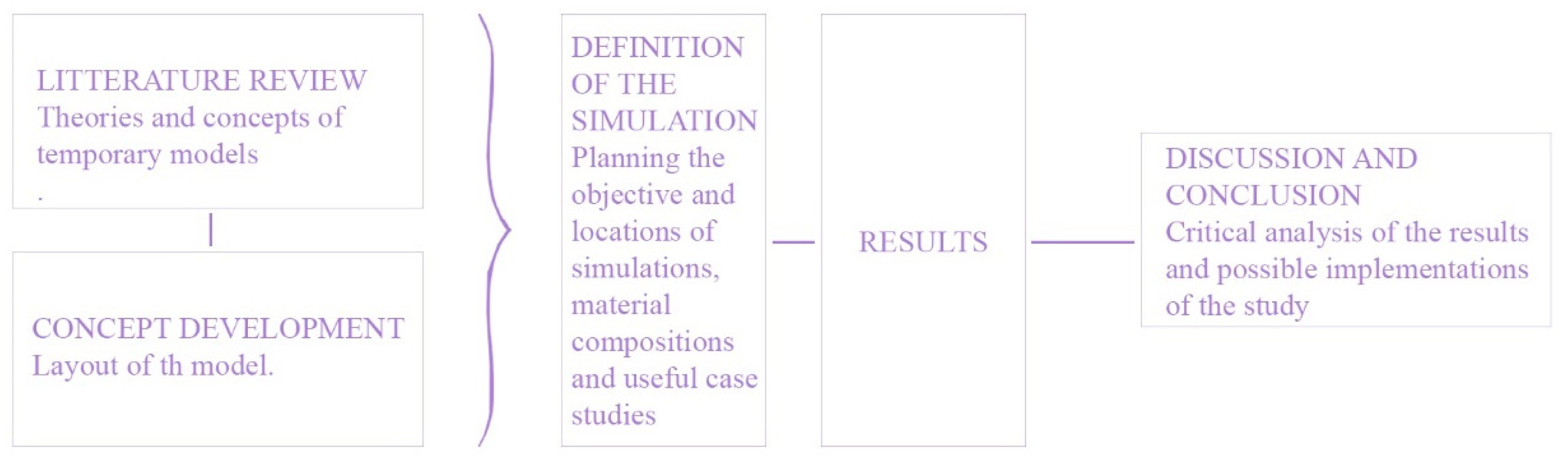

2. Materials and Methods

- Model definition. This initial phase describes the conceptual framework and preliminary design for non-conventional healthcare spaces, highlighting the benefits of a secure space as a foundational element for care services and community engagement.

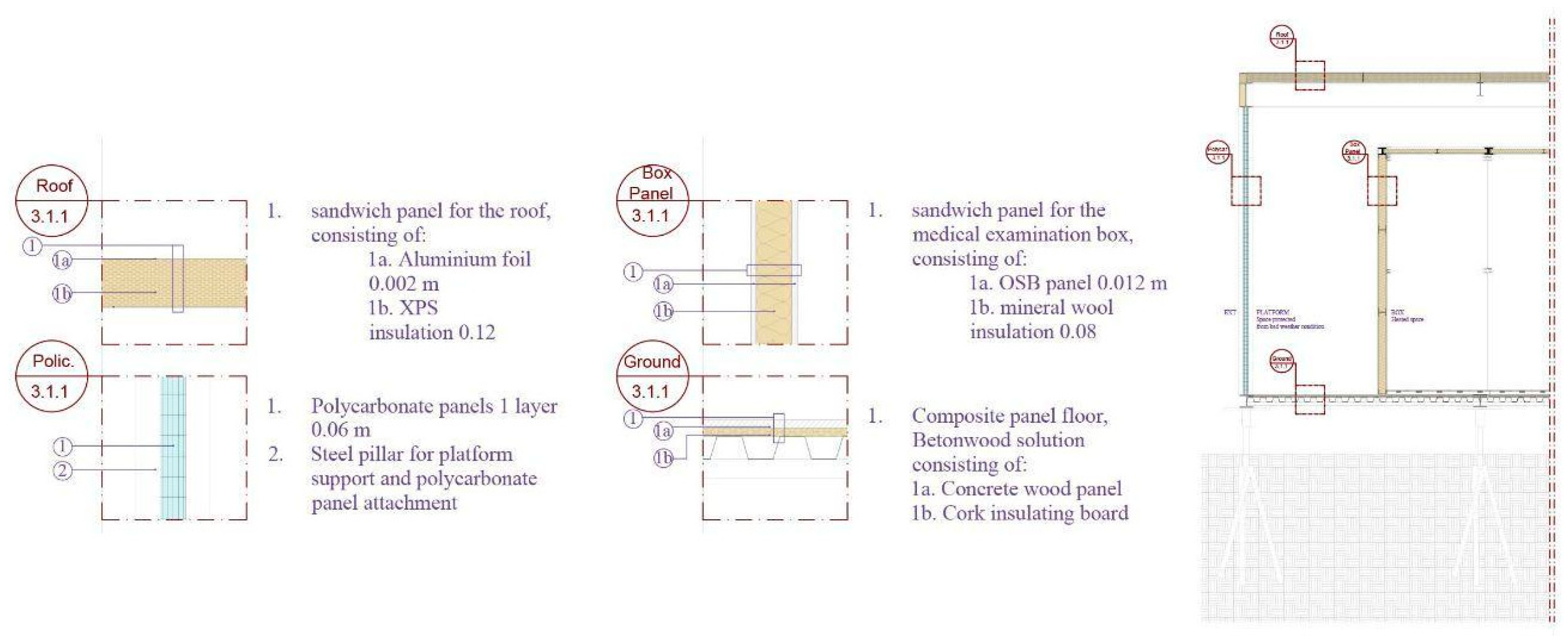

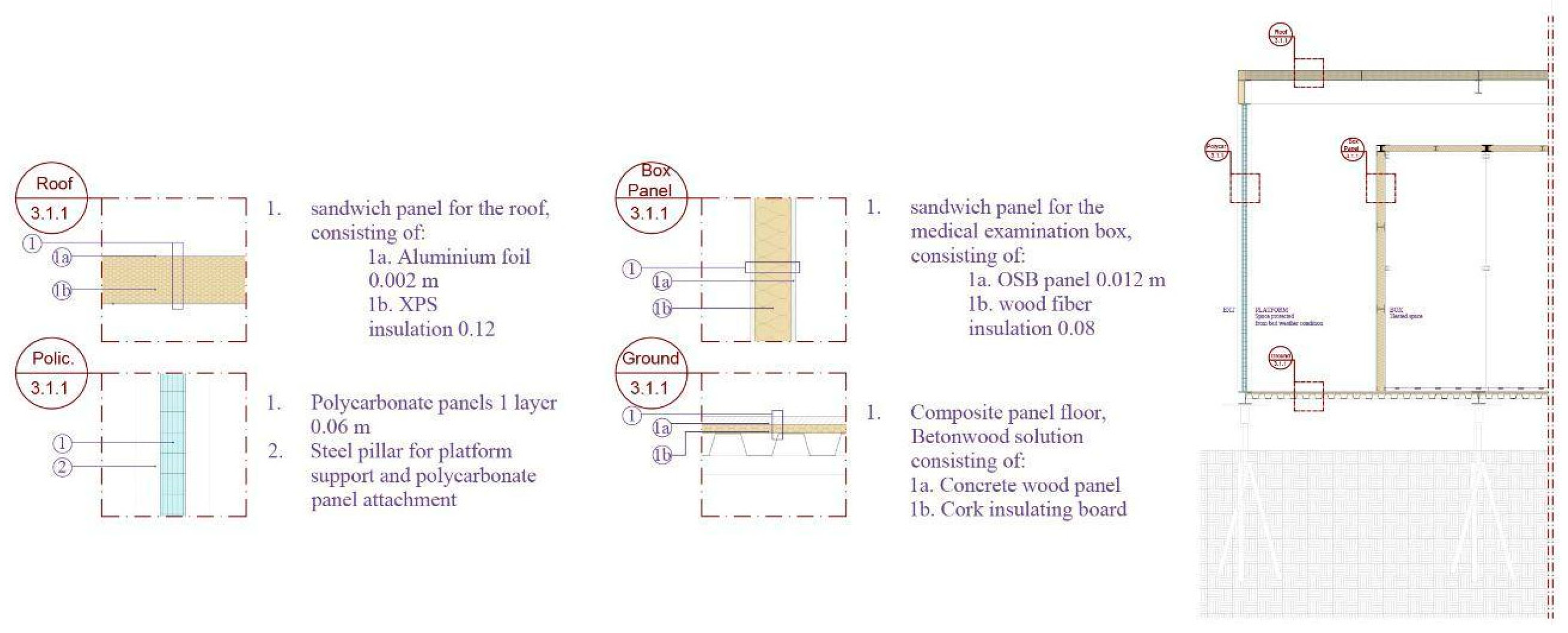

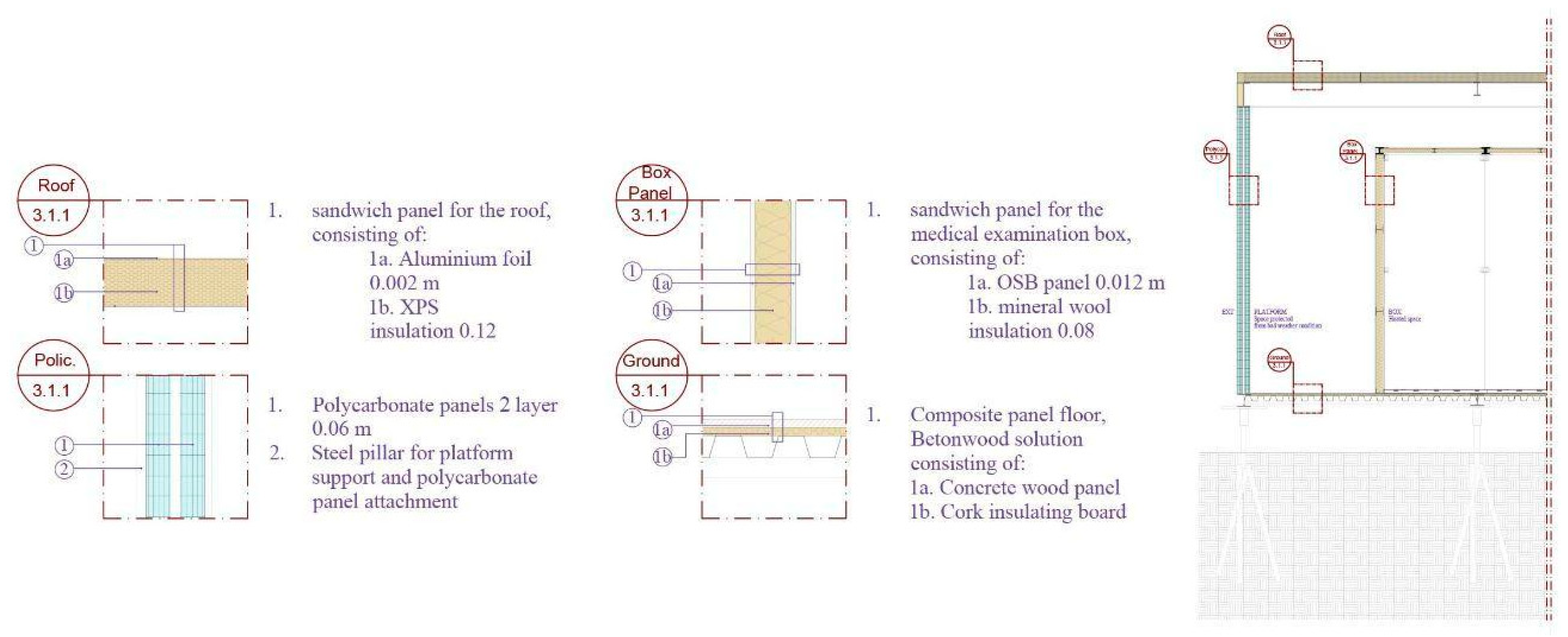

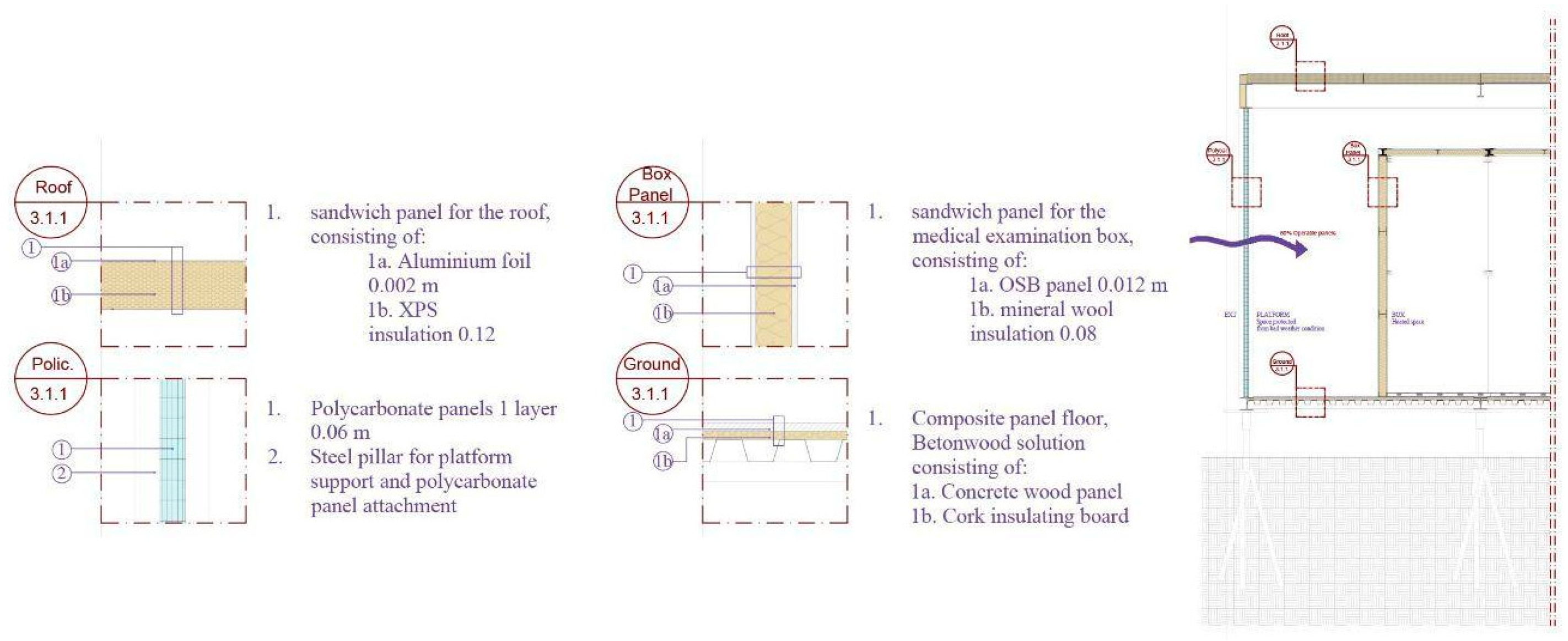

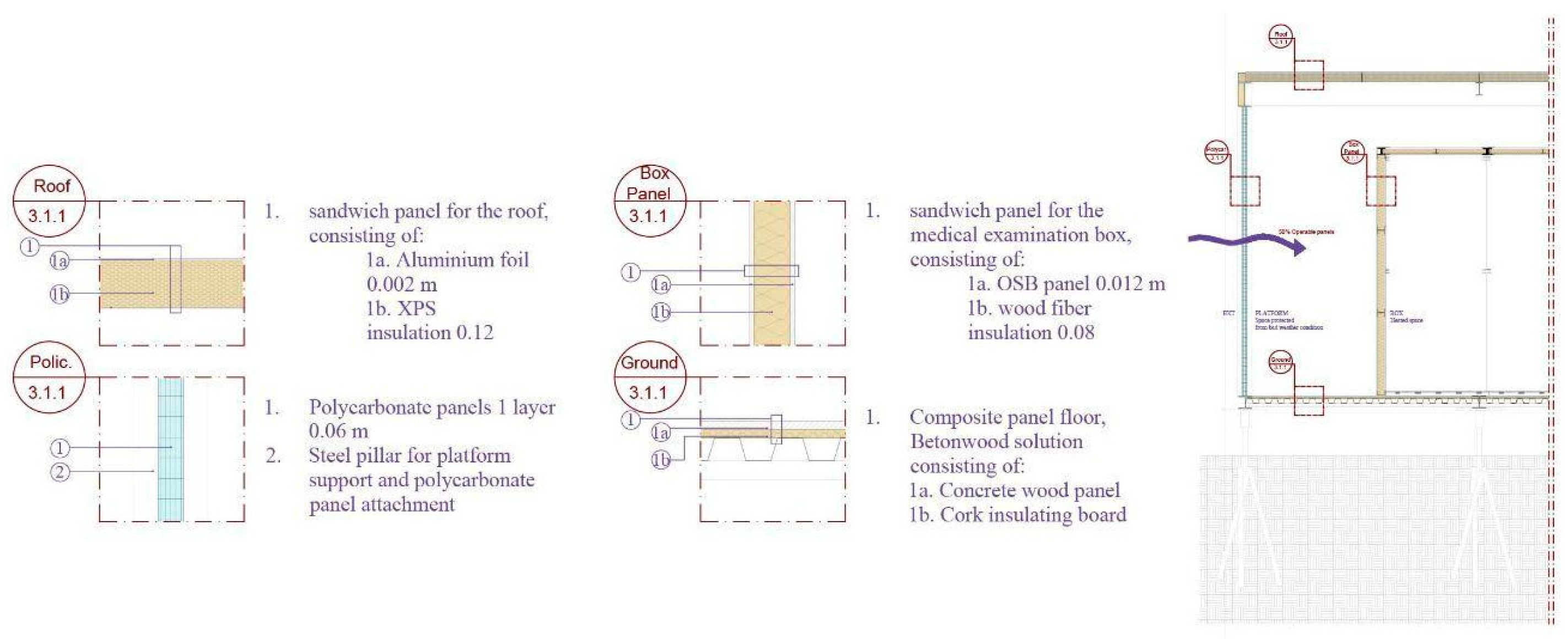

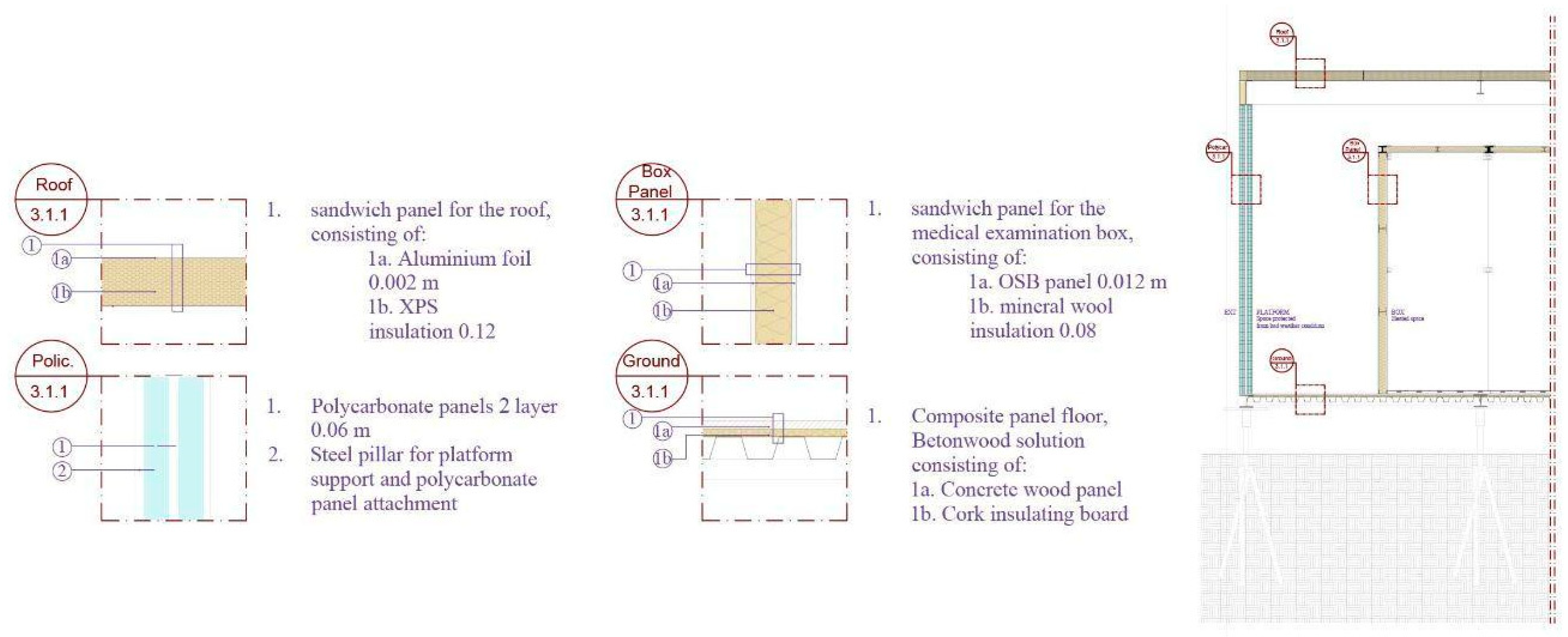

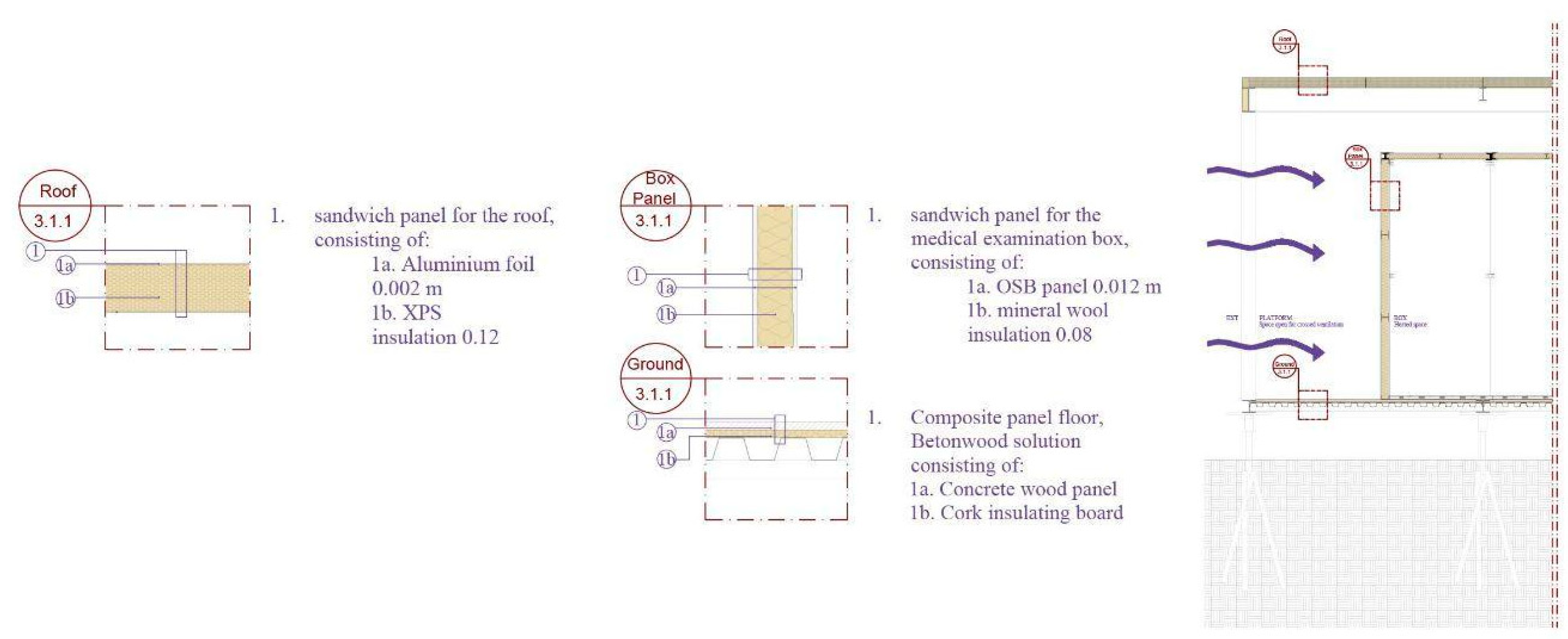

- Technology definition. This phase outlines the technological requirements and configurations of different box and platform setups.

- Energy simulations. In the final phase, the thermal performances of the model are analyzed by comparing various panel structures in two distinct climatic regions of Italy: Bolzano (representative of the cold area) and Palermo (representative of the hot Mediterranean area). The simulations were conducted using SketchUp 2023 and EnergyPlus V23-2-0 software, delineating two thermal zones—the box and the platform—and analyzing the passive contributions derived from their interaction.

3. Model Definition

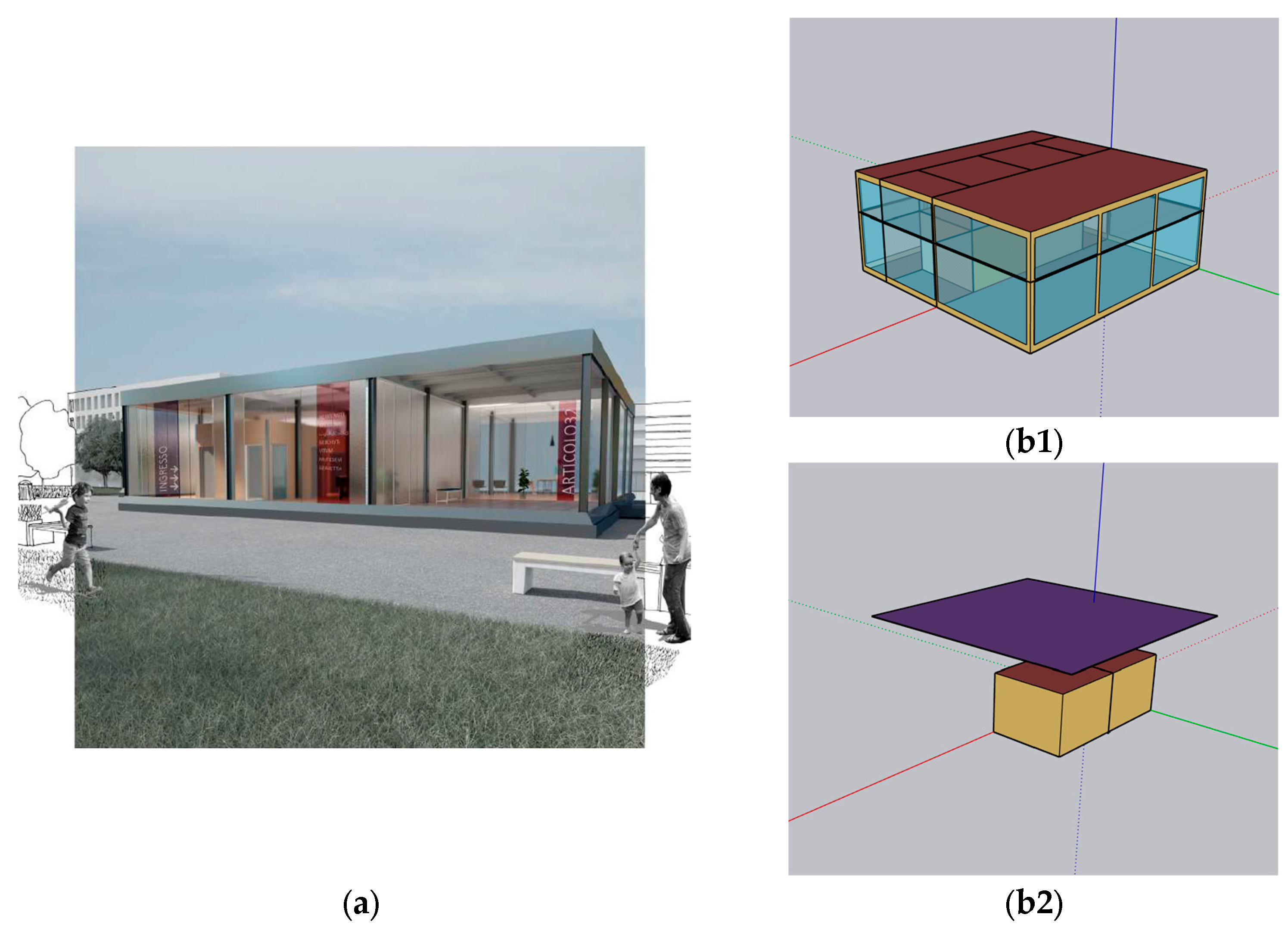

3.1. Conceptual Framework: The Architecture

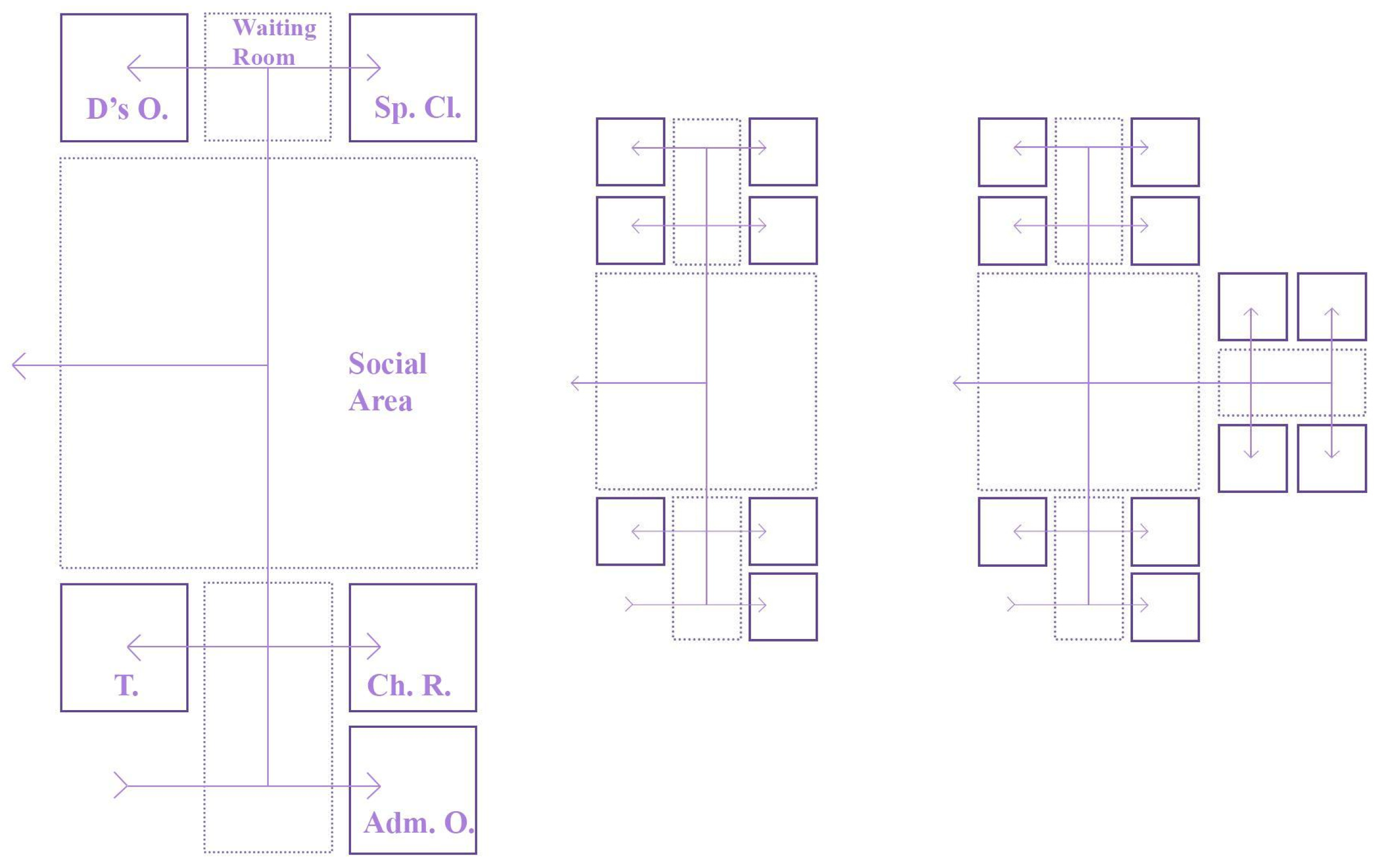

- The common space: this area is flexible and adaptable to the lot’s dimensions, fluxes, and shape. It functions as an internal-external space, as no HVAC is needed (no thermal zone).

- The box space: These are the proper modules designed to provide medical care. The box organization includes different medical offices, such as general practitioner offices, gynecologist offices, and psychological and psychiatric offices. An abacus for the main offices is provided (Figure 2b). During the design process, the position of boxes considered Hall’s definition of interpersonal distance [31], with designs varying according to the needed levels of privacy. The boxes are equipped with heating and wiring.

3.2. Technological Framework: Definition of the Prototype and Requirements

4. Energy Analysis

4.1. Climate Definition

4.2. Definition of the Model

4.3. Materials Characterization and Input Data

5. Results

5.1. Simulation Results—Bolzano Area

5.1.1. Bolzano—Simulation 1

5.1.2. Bolzano—Simulation 2

5.1.3. Bolzano—Simulation 3

5.2. Simulation Results—Palermo Area

5.2.1. Palermo—Simulation 1

5.2.2. Palermo—Simulation 2

5.2.3. Palermo—Simulation 3

5.2.4. Palermo—Simulation 4

5.3. Simulation Results—No Platform as Thermal Zone

6. Discussion and Conclusions

- The system, which does not include a cooling system and only provides heating in the box area, generally maintains acceptable temperature ranges across simulations. In Bolzano, the box temperatures are approximately 68 °F (20 °C), while the platform temperatures are around 60.8 °F (16 °C). In Palermo, the Mediterranean climate leads to more variable results: the box temperature is typically 73.4 °F (23 °C), though it reaches 68 °F (20 °C) in the first simulation. The platform temperature averages 73.4 °F (23 °C), but rises to 75.2 °F (24 °C) in simulation 4 due to the double layer of polycarbonate panels.

- Simulations assessed various insulating materials within the sandwich panels, including mineral wool and wood fiber, with different thermal properties and densities. Although wood fiber performs better in hot climates, the annual temperature variations are relatively minor in both climatic zones.

- The platform, designated as a buffer zone without a heating system, can reduce equipment needs. In the northern site (Bolzano), results in Table 4 show that the platform area spends approximately 3550 h at temperatures around 56 °F (13 °C), which is considered a good outcome. However, the use of double polycarbonate panels results in a slight improvement, with 3518 h at 56 °F (Table 6).

- On the other hand, in Palermo, where summer temperatures are very high, the risk of overheating is evident. Table 7 shows that the platform (common area) exceeds 88 °F (32 °C) for 2539 h.

- Simulation 2 in Palermo indicates that simple measures, such as opening windows or increasing the mass of the polycarbonate panels, can improve results. Operable windows reduce overheating above 88 °F (31 °C) from 2539 h to 1240 h in the platform (Table 8). Additionally, in the final simulation (Table 11), where the platform is open and functions as a shading device for the boxes, the impact on these is notable, with a significant reduction in heating hours above 83 °F.

- In Bolzano (cold climate), using a closed platform is advantageous as it protects internal structures and improves thermal exchanges. Table 4 shows that the platform, being closed for the simulation, results in 1874 h at 56–61 °F (13–16 °C) compared to 2336 h when external panels are removed (Table 11)

- On the other hand, in Palermo (hot climate), the simulations indicate that omitting the panels enhances air circulation, reducing extreme overheating to 83–88 °F (28–31 °C) from 1295 h (739 if operable) (see Table 7) to 64 h and overheating above 88 °F (31 °C) from 596 h (336 if operable) to 0 h, as seen in Table 11.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hosseini, S.M.A.; Farahzadi, L.; Pons, O. Assessing the sustainability index of different post-disaster temporary housing unit configuration types. J. Build. Eng. 2021, 42, 102806. [Google Scholar] [CrossRef]

- Wallemacq, P.; House, R.; Economic Losses, Poverty & Disaster, 1998–2017. CRED & UNISDR. Available online: https://www.preventionweb.net/files/61119_credeconomiclosses.pdf (accessed on 26 April 2024).

- EEA Technical Report. Mapping the Impacts of Natural Hazards and Technological Accidents in Europe; Technical report No 13; EEA: Copenhagen, Denmark, 2010; ISSN 1725-2237. [Google Scholar]

- Al-Atrash, F.Z.; Hamdan, M.; Mualla, R. Energy efficient shelter for displaced person: Towards sustainable camps. Bauphysik 2023, 45, 3. [Google Scholar] [CrossRef]

- Bologna, R.; Terpolilli, C. Emergenza del Progetto. Progetto dell’Emergenza. Architetture Con-Temporaneità; Jodidio, P., Ed.; Federico Motta Editore: Milano, Italy, 2005; Temporary Architecture Now!, TASCHEN GMBH, Bonn 2011. [Google Scholar]

- Falasca, C.C. Architetture ad Assetto Variabile. Modelli Evolutivi per L’habitat Provvisorio; Tecnologia e Progetto 3; Alinea Editrice: Firenze, Italy, 2000. [Google Scholar]

- Paparella, R.; Caini, M. Sustainable Design of Temporary Buildings in Emergency Situations. Sustainability 2022, 14, 8010. [Google Scholar] [CrossRef]

- Montalbano, G.; Santi, G. Sustainability of Temporary Housing in Post-Disaster Scenarios: A Requirement-Based Design Strategy. Buildings 2023, 13, 2952. [Google Scholar] [CrossRef]

- Cascone, S.M.; Caporlingua, M.; Russo, G.; Tomasello, N. La “prefabbricazione per l’emergenza”: Excursus storico dalla nascita alle moderne applicazioni. In Proceedings of the 3 Convegno Internazionale “Storia dell’Ingegneria”, Napoli, Italy, 23–24 April 2018. [Google Scholar]

- UNHCR. Available online: https://emergency.unhcr.org/emergency-assistance/shelter-camp-and-settlement/shelter-and-housing/emergency-shelter-solutions-and-standards (accessed on 26 April 2024).

- Potangaroa, R. Climate responsive design tools for emergency shelter. In Hand-Book for Emergencies; UNHCR: Ginevra, Switzerland, 2006. [Google Scholar]

- Manfield, P. Modeling of a Cold Climate Emergency Shelter: Prototype and comparison with the United Nations Winter Tent; Martin Centre: Cambridge, UK, 2000. [Google Scholar]

- Cornaro, C.; Sapori, D.; Bucci, F.; Pierro, M.; Corrado, G. Thermal performance analysis of an emergency shelter using dynamic building simulation. Energy Build. 2015, 88, 122–134. [Google Scholar] [CrossRef]

- Lv, T.; Liu, B.; Liu, R.; Zhu, L.; Huo, Y.; Ji, M. Construction and Electrothermal Performance Evaluation of a Solar-Powered Emergency Shelter. Energies 2024, 17, 118. [Google Scholar] [CrossRef]

- Ribera, F.; Regno, R.D.; Cucco, P. New Frontiers of Temporary Buildings. Passive housing Modules. AGATHÓN Int. J. Archit. Art Des. 2018, 4, 159–168. [Google Scholar]

- Félix, D.; Monteiro, D.; Branco, J.M.; Bologna, R.; Feio, A. The role of temporary accommodation buildings for post-disaster housing reconstruction. J. Hous. Built Environ. 2015, 30, 683–699. [Google Scholar] [CrossRef]

- Mayo, A.J.; Nohria, N. Their Time: The Greatest Business Leaders of the Twentieth Century; Harvard Business Review Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Levinson, M. The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger; Princeton University Press: Princeton, NJ, USA, 2006. [Google Scholar]

- Eberhardt, L.C.M.; Birkved, M.; Birgisdottir, H. Building design and construction strategies for a circular economy. Archit. Eng. Des. Manag. 2022, 18, 93–113. [Google Scholar] [CrossRef]

- Park, B.; Cho, J.; Jeong, Y. Thermal Performance Assessment of Flexible Modular Housing Units for Energy Independence Following Disasters. Sustainability 2019, 11, 5561. [Google Scholar] [CrossRef]

- Moon, J. A Study on the Planning Method Temporary Dwellings for Sufferers from a Disaster; Decree of the Yonsei University: Seoul, Republic of Korea, 2007. [Google Scholar]

- Košir, M.; Iglič, N.; Kunič, R. Optimisation of heating, cooling and lighting energy performance of modular buildings in respect to location’s climatic specifics. Renew. Energy 2018, 129, 527–539. [Google Scholar] [CrossRef]

- Al Dakheel, J.; Tabet Aoul, K. Building applications, opportunities and challenges of active shading systems: A state-of-the-art review. Energies 2017, 10, 1672. [Google Scholar] [CrossRef]

- Marin, P.; Saari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Zubair, M.; Bilal Awan, A.; Al-Ahmadi, A.; Abo-Khalil, A. NPC based design optimization for a net zero office building in hot climates with PV panels as shading device. Energies 2018, 11, 1391. [Google Scholar] [CrossRef]

- Pan, W.; Zhang, Z. Evaluating Modular Healthcare Facilities for COVID-19 Emergency Response—A Case of Hong Kong. Buildings 2022, 12, 1430. [Google Scholar] [CrossRef]

- Smolova, M.; Smolova, D. Emergency architecture. Modular construction of healthcare facilities as a response to pandemic outbreak. E3S Web Conf. 2021, 274, 01013. [Google Scholar] [CrossRef]

- Brunoro, S.; Mensi, L. A Modular Structure for Immediate and Transitory Interventions to Guarantee Access to Basic Healthcare in Italy. Sci 2023, 5, 17. [Google Scholar] [CrossRef]

- World Health Organization. Available online: https://www.who.int/news-room/questions-and-answers/item/determinants-of-health (accessed on 26 April 2024).

- Hay, A.; Gomez-Palacio, A.; Martyn, N. Planning resilient communities. In Resilience and Risk, NATO Science for Peace and Security Series C: Environmental Security; Linkov, I., Palma-Oliveira, J., Eds.; Springer: Dordrecht, The Netherlands, 2017; pp. 313–326. [Google Scholar] [CrossRef]

- Hall, E.T. La Dimensione Nascosta che cosa è la Prossemica? Bompiani: Firenze, Italy, 1969. [Google Scholar]

| Emergency Shelters | Temporary Shelter | Temporary Housing: Containers | Temporary Housing: Panels | ||

|---|---|---|---|---|---|

| Sustainability | Energy efficiency | 1 | 2 | 1 | to be assessed |

| Renewable implementation | 2 | 3 | 1 | 2 | |

| Indoor quality | 1 | 2 | 1 | to be assessed | |

| Flexibility | Adaptability to external conditions | 1 | 1 | 1 | 3 |

| Implementation and composition of the system | 1 | 2 | 2 | 3 | |

| Construction | Speed of Construction | 3 | 2 | 3 | 2 |

| Economic solutions | 3 | 2 | 3 | 1 |

| Bolzano | Palermo | |

|---|---|---|

| Weather file from energyplus.net/weather | Bolzano—ITA IGDG WMO# = 160,200 | PALERMO—ITA IWEC WMO# = 164,050 |

| Latitude | 46.47 | 38.18 |

| Longitude | 11.33 | 13.10 |

| Elevation | 791 ft | 112 ft |

| s | λ | ρ | Cs | |

|---|---|---|---|---|

| OSB | 0.012 | 0.10 | 530 | 1000 |

| Mineral Wool | 0.08 | 0.034 | 80 | 1000 |

| Wood Fiber | 0.08 | 0.037 | 110 | 2100 |

| XPS | 0.12 | 0.036 | 32 | 1700 |

| Wood–concrete | 0.40 | 0.26 | 1350 | 1880 |

| Polycarbonate | 0.06 | 0.21 | 200 | 1170 |

| Aluminum | 0.002 | 172 | 2800 | 962 |

| S275 | 0.21 | 45 | 7850 | 502 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 1874 | 845 | 874 | 447 | 1818 | 707 | 610 | 868 | 493 | 216 | 8 |

| TZ- PLATFORM | 3556 | 601 | 499 | 631 | 305 | 298 | 278 | 288 | 515 | 470 | 385 | 934 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 1804 | 861 | 862 | 442 | 1798 | 711 | 639 | 872 | 521 | 244 | 6 |

| TZ- PLATFORM | 3554 | 594 | 500 | 618 | 321 | 303 | 278 | 286 | 526 | 479 | 379 | 992 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 1955 | 915 | 959 | 578 | 2079 | 737 | 544 | 607 | 359 | 27 | 0 |

| TZ- PLATFORM | 3518 | 654 | 542 | 624 | 338 | 367 | 316 | 326 | 582 | 483 | 419 | 591 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 0 | 275 | 1223 | 661 | 1364 | 534 | 512 | 1059 | 1241 | 1295 | 596 |

| TZ- PLATFORM | 157 | 1054 | 765 | 693 | 308 | 336 | 359 | 311 | 685 | 786 | 767 | 2539 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 0 | 282 | 1247 | 828 | 1768 | 1017 | 753 | 1021 | 769 | 739 | 336 |

| TZ- PLATFORM | 157 | 1059 | 794 | 860 | 637 | 700 | 582 | 516 | 1243 | 683 | 289 | 1240 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 0 | 141 | 1222 | 896 | 1775 | 1055 | 783 | 975 | 758 | 770 | 385 |

| TZ- PLATFORM | 147 | 1043 | 790 | 881 | 641 | 695 | 600 | 530 | 1240 | 672 | 292 | 1229 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TZ- BOX | 0 | 0 | 431 | 1526 | 735 | 1439 | 548 | 554 | 1211 | 1475 | 822 | 19 |

| TZ- PLATFORM | 127 | 1134 | 844 | 755 | 350 | 386 | 377 | 351 | 733 | 827 | 802 | 2074 |

| <56 | 56–61 | 61–66 | 66–68 | 68–70 | 70–72 | 72–74 | 74–76 | 76–78 | 78–83 | 83–88 | ≥88 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BOLZANO | 0 | 2336 | 933 | 1359 | 570 | 2478 | 431 | 284 | 263 | 106 | 0 | 0 |

| PALERMO | 0 | 331 | 1157 | 1336 | 706 | 1797 | 666 | 679 | 1284 | 740 | 64 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunoro, S.; Mensi, L. A Comparative Study to Assess the Energy Efficiency of Temporary Structures to Guarantee Emergency Basic Healthcare in Italy. Buildings 2024, 14, 2295. https://doi.org/10.3390/buildings14082295

Brunoro S, Mensi L. A Comparative Study to Assess the Energy Efficiency of Temporary Structures to Guarantee Emergency Basic Healthcare in Italy. Buildings. 2024; 14(8):2295. https://doi.org/10.3390/buildings14082295

Chicago/Turabian StyleBrunoro, Silvia, and Lisa Mensi. 2024. "A Comparative Study to Assess the Energy Efficiency of Temporary Structures to Guarantee Emergency Basic Healthcare in Italy" Buildings 14, no. 8: 2295. https://doi.org/10.3390/buildings14082295

APA StyleBrunoro, S., & Mensi, L. (2024). A Comparative Study to Assess the Energy Efficiency of Temporary Structures to Guarantee Emergency Basic Healthcare in Italy. Buildings, 14(8), 2295. https://doi.org/10.3390/buildings14082295