Silica Aerogel-Incorporated Cement and Lime Plasters for Building Insulation: An Experimental Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composition Designs and Samples

- (i)

- Allowing the moulds for lime plaster and cement to wet cure for seven days inside a polyethylene bag.

- (ii)

- Removing moulds from the bag and unmoulding.

- (iii)

- Curing in the chamber with controlled temperature and humidity conditions, 20 ± 2 °C and 65 ± 5% relative humidity, until 28 days, in accordance with EN 1015-11 [24].

2.3. Experimental Methods

3. Results

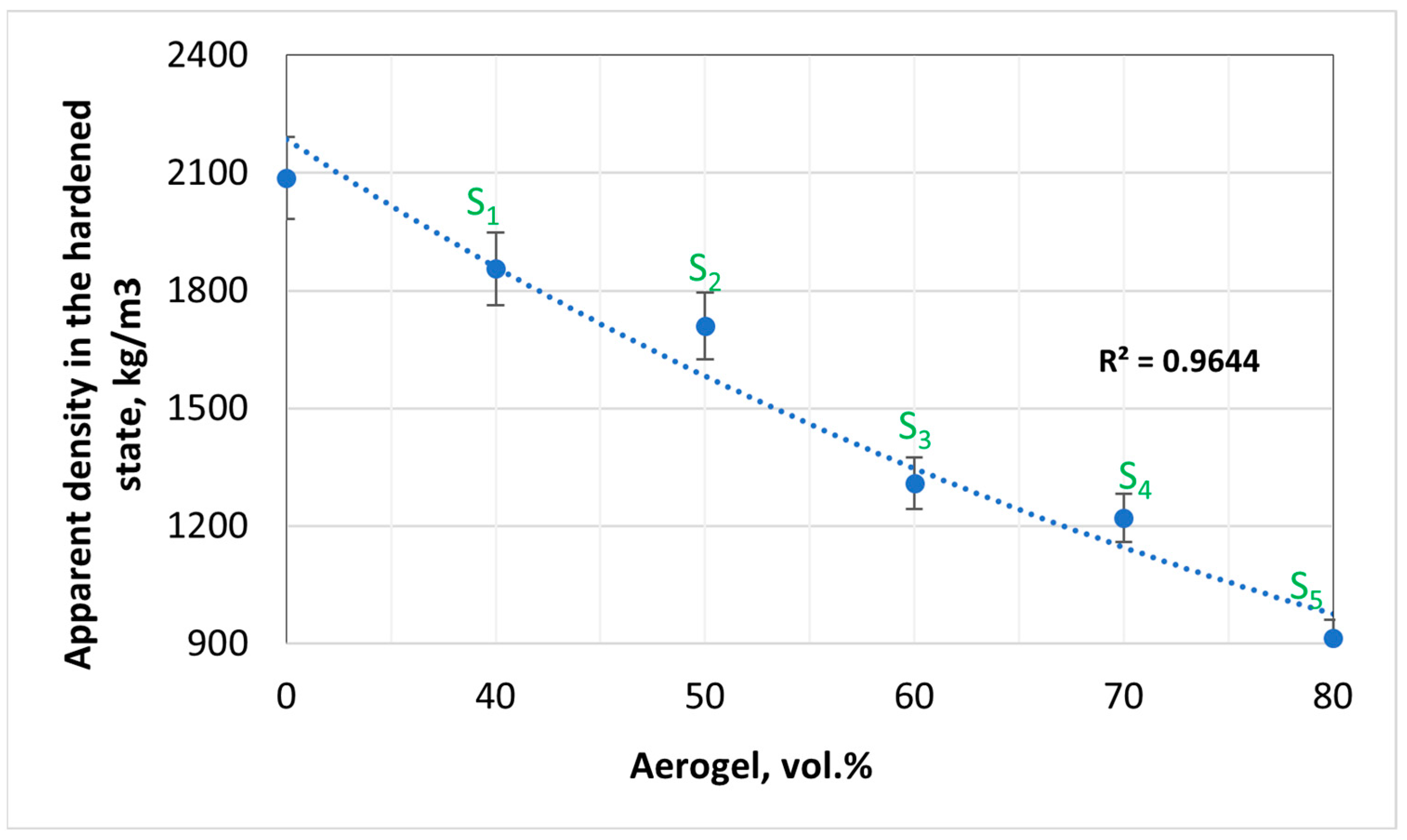

3.1. Apparent Mass Density

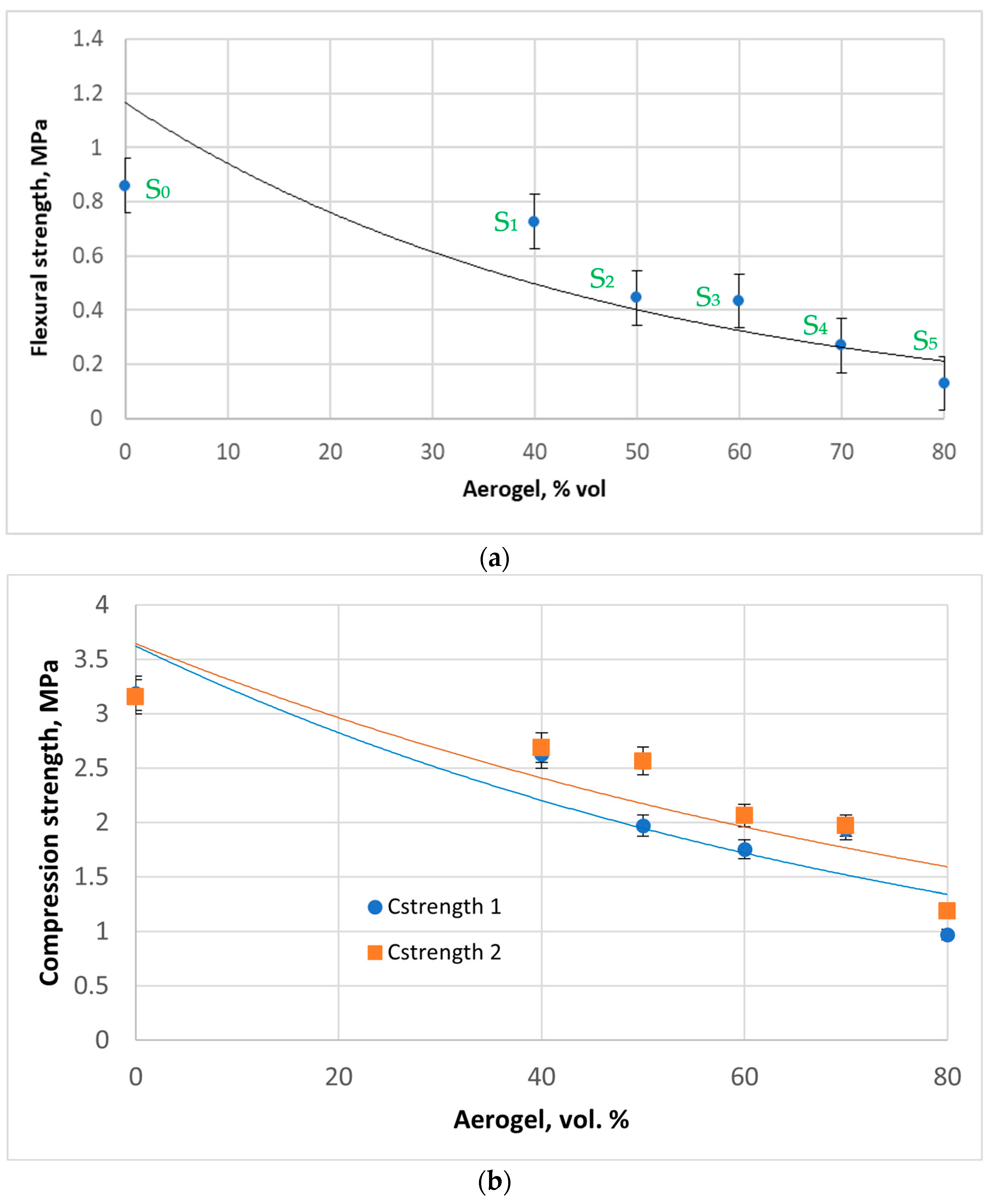

3.2. Mechanical Strengths

3.3. Thermal Conductivity

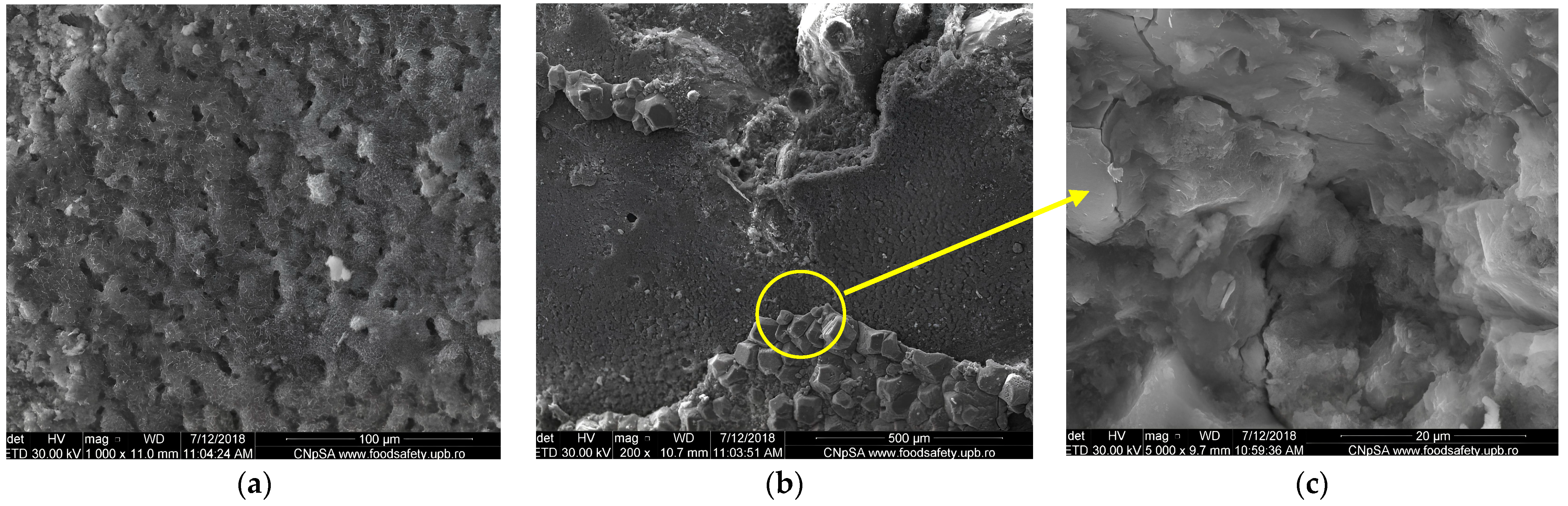

3.4. Morphological Structure

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Buonomano, A.; De Luca, G.; Montanaro, U.; Palombo, A. Innovative technologies for NZEBs: An energy and economic analysis tool and a case study of a non-residential building for the Mediterranean climate. Energy Build. 2016, 121, 318–343. [Google Scholar] [CrossRef]

- Westgate, P.; Paine, K.; Ball, R.J. Physical and mechanical properties of plasters incorporating aerogel granules and polypropylene monofilament fibres. Constr. Build. Mater. 2018, 158, 472–480. [Google Scholar] [CrossRef]

- Nearly-Zero Energy and Zero-Emission Buildings. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-and-zero-emission-buildings_en (accessed on 6 June 2024).

- Lamy-Mendes, A.; Rodrigues Pontinha, A.D.; Alves, P.; Santos, P.; Durães, L. Progress in silica aerogel-containing materials for buildings’ thermal insulation. Constr. Build. Mater. 2021, 286, 122815. [Google Scholar] [CrossRef]

- Balaji, D.; Sivalingam, S.; Bhuvaneswari, V.; Amarnath, V.; Adithya, J.; Balavignesh, V.; Ganesh, R. Aerogels as alternatives for thermal insulation in buildings–A comparative teeny review. Mater. Today Proc. 2022, 62, 5371–5377. [Google Scholar] [CrossRef]

- Glória Gomes, M.; Flores-Colen, I.; da Silva, F.; Pedroso, M. Thermal conductivity measurement of thermal insulating mortars with EPS and silica aerogel by steady-state and transient methods. Constr. Build Mater. 2018, 172, 696–705. [Google Scholar] [CrossRef]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Silva, L.; Ilharco, L. Physical, mechanical, and microstructural characterization of an innovative thermal insulation render incorporating silica aerogel. Energy Build. 2020, 211, 109793. [Google Scholar] [CrossRef]

- Stahl, S.; Brunner, S.; Zimmermann, M.; Wakilli Ghazi, K. Thermo-hygric properties of a newly developed aerogel-based insulation rendering for both interior and exterior applications. Energy Build. 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Agosti, F. Development of innovative aerogel-based plasters: Preliminary thermal and acoustic performance evaluation. Sustainability 2014, 6, 5839–5852. [Google Scholar] [CrossRef]

- Fixit Aerogel Insulating Plaster. Available online: https://www.fixit-aerogel.com/en/application (accessed on 22 May 2020).

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sust. Energ. Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Stahl, T.; Wakili, K.G.; Hartmeier, S.; Franov, E.; Niederberger, W.; Zimmermann, M. Temperature and moisture evolution beneath an aerogel-based rendering applied to historic building. J. Build. Eng. 2017, 22, 140–146. [Google Scholar] [CrossRef]

- Hanus, M.J.; Harris, A.T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Dowson, M.; Pegg, I.; Harrison, D.; Dehouche, Z. Predicted and in situ performance of a solar air collector incorporating a translucent granular aerogel cover. Energy Build. 2012, 49, 173–187. [Google Scholar] [CrossRef]

- Akimov, Y.K. Fields of application of aerogels (review). Instrum. Exp. Tech. 2003, 46, 287–299. [Google Scholar] [CrossRef]

- Wernery, J.; Ben-Ishai, A.; Binder, B.; Brunner, S. Aerobrick—An aerogel-filled insulating brick. Energy Procedia 2017, 134, 490–498. [Google Scholar] [CrossRef]

- Cabot Aerogel Particles. Available online: https://www.cabotcorp.com/solutions/products-plus/aerogel/particles (accessed on 22 May 2020).

- Bergmann Becker, P.F.; Effting, C.; Schackow, A. Lightweight thermal insulating coating mortars with aerogel, EPS, and vermiculite for energy conservation in buildings. Cem. Concr. Compos. 2022, 125, 104283. [Google Scholar] [CrossRef]

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Silva, L.; Sequeira, P.; de Brito, J. Characterisation of a multilayer external wall thermal insulation system. Application in a Mediterranean climate. J. Build. Eng. 2020, 30, 101265. [Google Scholar] [CrossRef]

- Berardi, U. Aerogel-enhanced system for building energy retrofits: Insights from a case study. Energy Build. 2018, 159, 370–381. [Google Scholar] [CrossRef]

- SR EN 413-1:2011; Masonry Cement—Part 1: Composition, Specifications, and Conformity Criteria. Romanian/European Standard: Bucharest, Romania, 2011. Available online: https://magazin.asro.ro/ro/standard/190437 (accessed on 6 June 2024).

- SR EN 459-1:2015; Construction Lime—Part 1: Definitions, Specifications, and Conformity Criteria. Romanian/European Standard: Bucharest, Romania, 2015. Available online: https://magazin.asro.ro/ro/standard/235361 (accessed on 6 June 2024).

- SR EN 12620+A1:2008; Aggregates for Concretes. Romanian/European Standard: Bucharest, Romania, 2008. Available online: https://magazin.asro.ro/ro/standard/219880 (accessed on 6 June 2024).

- EN 196-1:2006; Test Methods of Cements—Part 1: Determination of Mechanical Strengths. Romanian/European Standard: Bucharest, Romania, 2006. Available online: https://magazin.asro.ro/ro/standard/246612 (accessed on 6 June 2024).

- EN 1015-3:2001/A1:2004; Methods of Testing Masonry Mortars—Part 3: Determination of Consistency of Fresh Mortar (with Spreading Mass). Romanian/European Standard: Bucharest, Romania, 2004. Available online: https://magazin.asro.ro/ro/standard/94922 (accessed on 6 June 2024).

- EN 1015-11:2020; Methods of Testing Masonry Mortars—Part 11: Determination of Flexural Strength of Hardened Mortar. Romanian/European Standard: Bucharest, Romania, 2020. Available online: https://magazin.asro.ro/ro/standard/273625 (accessed on 6 June 2024).

- SR EN 1015-10:2002/A1:2007; Methods of Testing Masonry Mortars—Part 10: Determination of Apparent Density of Hardened Mortar. Romanian/European Standard: Bucharest, Romania, 2007. Available online: https://magazin.asro.ro/ro/standard/117980 (accessed on 6 June 2024).

- EN 1745:2020; Masonry and Elements for Masonry. Methods for Determining Thermal Characteristics. Romanian/European Standard: Bucharest, Romania, 2020. Available online: https://magazin.asro.ro/ro/standard/274909 (accessed on 6 June 2024).

- Soares, A.; de Fátima Júlio, M.; Flores-Colen, I.; Ilharco, L.M.; de Brito, J. EN 998-1 performance requirements for thermal aerogel-based renders. Constr. Build. Mater. 2018, 179, 453–460. [Google Scholar] [CrossRef]

- Ng, S.; Sandberg, L.I.C.; Jelle, B.P. Insulating and strength properties of an aerogel-incorporated mortar based an UHPC formulations. Key Eng. Mater. 2014, 629–630, 43–48. [Google Scholar] [CrossRef]

- Liu, Z.; Ding, Y.; Wang, F.; Deng, Z. Thermal insulation material based on SiO2 aerogel. Constr. Build. Mater. 2016, 122, 548–555. [Google Scholar] [CrossRef]

- Hanif, A.; Diao, S.; Lu, Z.; Fan, T.; Li, Z. Green lightweight cementitious composite incorporating aerogels and fly ash cenospheres–Mechanical and thermal insulating properties. Constr. Build. Mater. 2016, 116, 422–430. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Sandberg, L.I.C.; Gao, T.; Wallevik, O.H. Experimental investigation of aerogel-incorporated ultra-high incorporated concrete. Constr. Build. Mater. 2015, 77, 307–3016. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Zhen, Y.; Wallevik, O.H. Effect of storage and curing conditions at elevate temperatures on aerogel-incorporated mortar samples based on UHPC recipe. Constr. Build. Mater. 2016, 106, 640–649. [Google Scholar] [CrossRef]

- Berardi, U. The benefits of using aerogel-enhanced systems in building retrofits. Energy Proc. 2017, 134, 626–635. [Google Scholar] [CrossRef]

- Ababneh, A.; Matalkah, F.; Aqel, R. Synthesis of kaolin –based alkali-activated cement: Carbon footprint, cost and energy assessment. J. Mater. Res. Technol. 2020, 9, 8367–8378. [Google Scholar] [CrossRef]

- Abbas, N.; Khalid, H.R.; Ban, G.; Kim, H.T.; Lee, H.K. Silica aerogel derived from rice husk: An aggregate replacer for lightweight and thermally insulating cement-based composites. Constr. Build. Mater. 2019, 195, 312–322. [Google Scholar] [CrossRef]

- Zhu, P.; Brunner, S.; Zhao, S.; Griffa, M.; Leemann, A.; Toropovs, N.; Malekos, A.; Koebel, M.M.; Lura, P. Study of physical properties and microstructure of aerogel-cement mortars for improving the fire safety of high-performance concrete linings in tunnels. Cem. Concr. Compos. 2019, 104, 103414. [Google Scholar] [CrossRef]

| Material | Property | Value | According to EU Norm |

|---|---|---|---|

| Cement Z100 | Portland clinker High-purity limestone LL Min. compressive strength/7 days Standard compressive strength/28 days Air content in fresh plaster Water retention SiO2 Al2O3 Fe2O3 CaO MgO K2O Na2O Cl− SO3 Apparent density | Min. 40% Max. 60% Min. 7 MPa Min. 12.5 MPa Min. 8% 80% 20.32% 4.12% 3.87% 63.02% 2.43 0.6% 0.3% 0.08% 2.91% 1650 kg/m3 | SR EN 413-1:2011 [21] |

| Hydrated lime Supercalco M | CaO MgO CO2 H2O CaCO3 Ca(OH)2 Insoluble residue Apparent density | 91.1% 1.7% 0.9% 1.2% 2.0% 4.8% 5.1% 580 kg/m3 | SR EN 459-1:2015 [22] |

| P100 Cabot aerogel particles | Particle size range Pore diameter Porosity Particle density Bulk density | 0.1–4.0 mm ~20 nm >90% 120–180 kg/m3 80–100 kg/m3 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meliță, L.; Calotă, R.; Amăreanu, M. Silica Aerogel-Incorporated Cement and Lime Plasters for Building Insulation: An Experimental Study. Buildings 2024, 14, 2300. https://doi.org/10.3390/buildings14082300

Meliță L, Calotă R, Amăreanu M. Silica Aerogel-Incorporated Cement and Lime Plasters for Building Insulation: An Experimental Study. Buildings. 2024; 14(8):2300. https://doi.org/10.3390/buildings14082300

Chicago/Turabian StyleMeliță, Larisa, Răzvan Calotă, and Marin Amăreanu. 2024. "Silica Aerogel-Incorporated Cement and Lime Plasters for Building Insulation: An Experimental Study" Buildings 14, no. 8: 2300. https://doi.org/10.3390/buildings14082300

APA StyleMeliță, L., Calotă, R., & Amăreanu, M. (2024). Silica Aerogel-Incorporated Cement and Lime Plasters for Building Insulation: An Experimental Study. Buildings, 14(8), 2300. https://doi.org/10.3390/buildings14082300