Research on Monitoring Technology for Frame Piers of Continuous Box-Girder Bridges Constructed by the Cantilever Method

Abstract

:1. Introduction

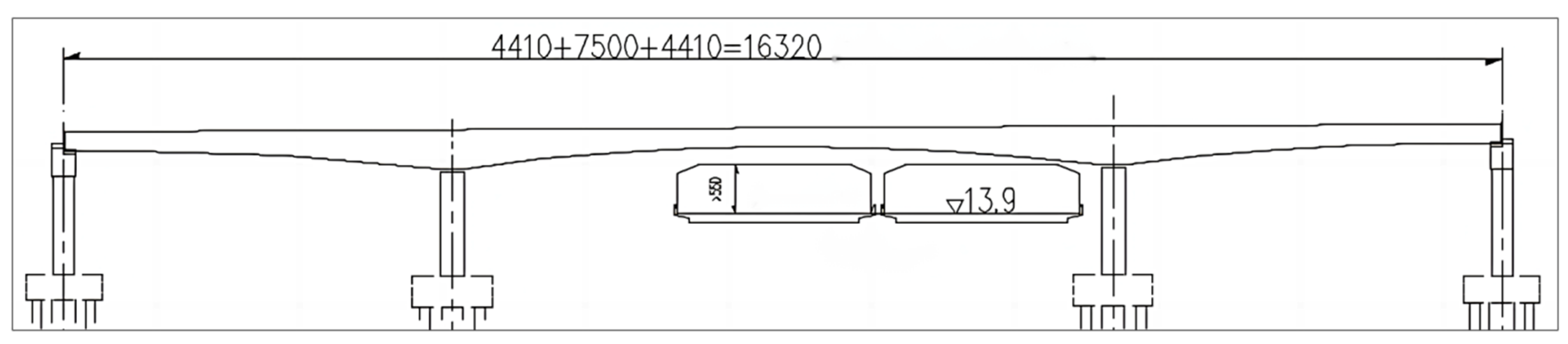

2. Overview of the Project

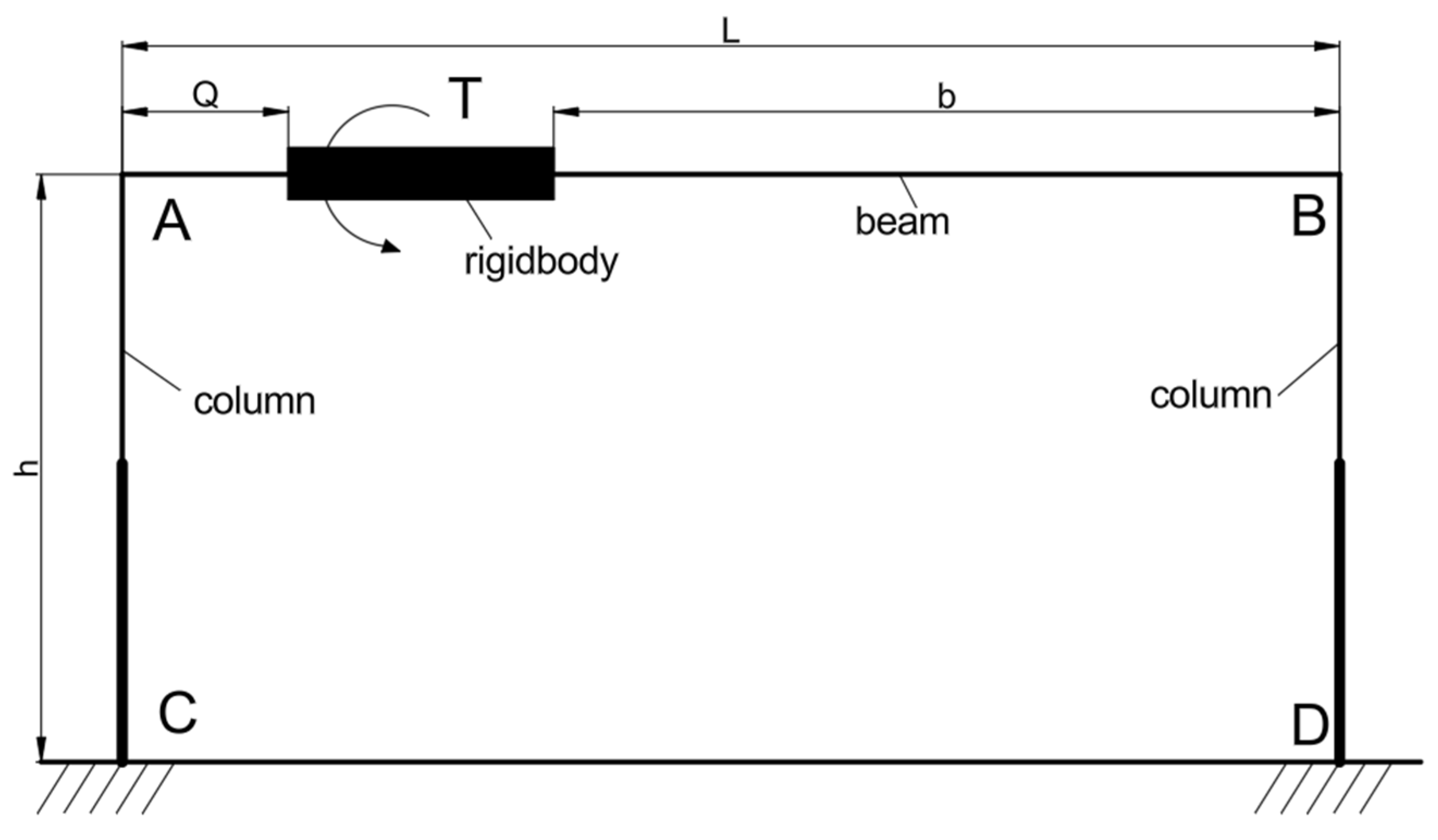

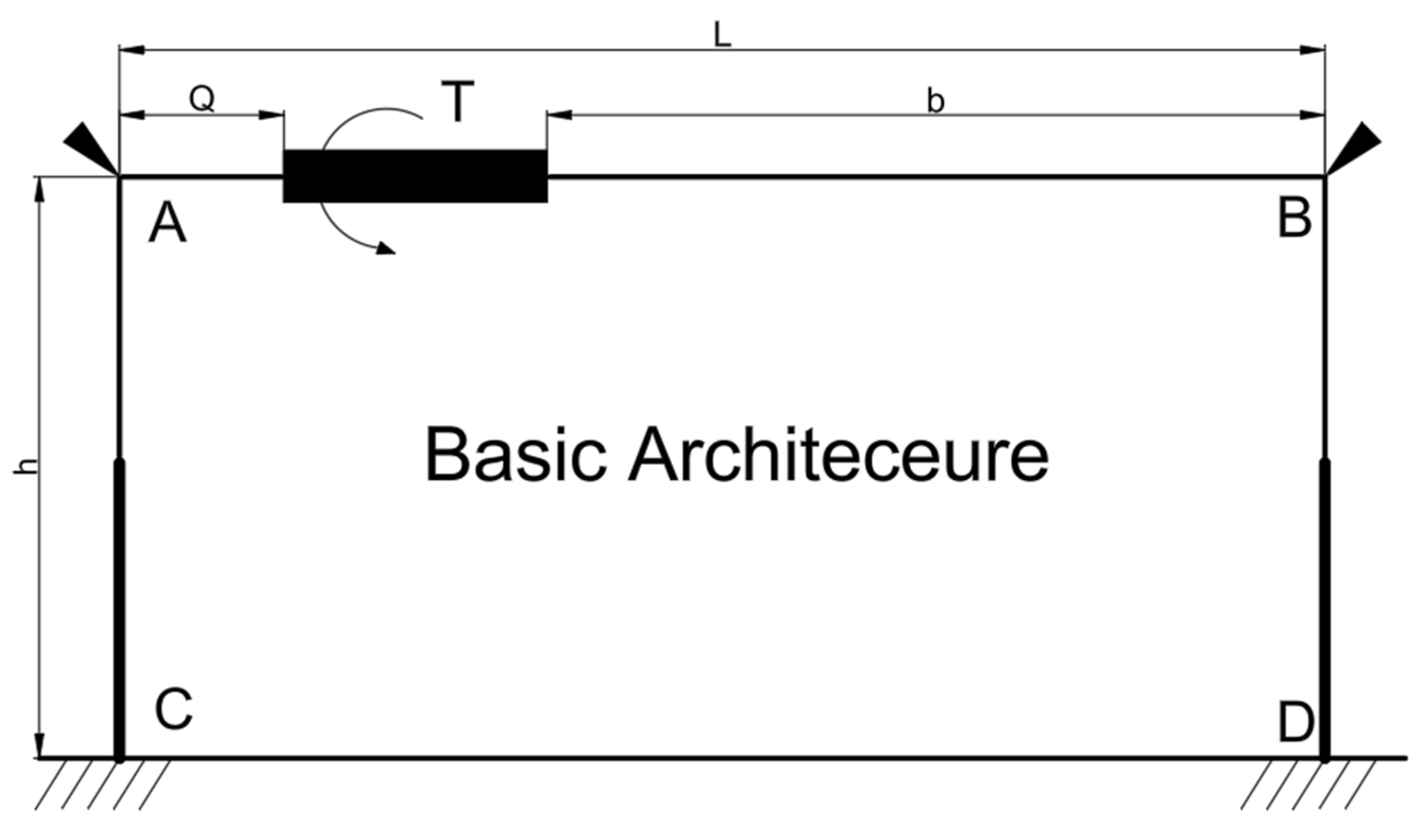

3. Analysis of Pier and Beam Torsion during Cantilever Construction

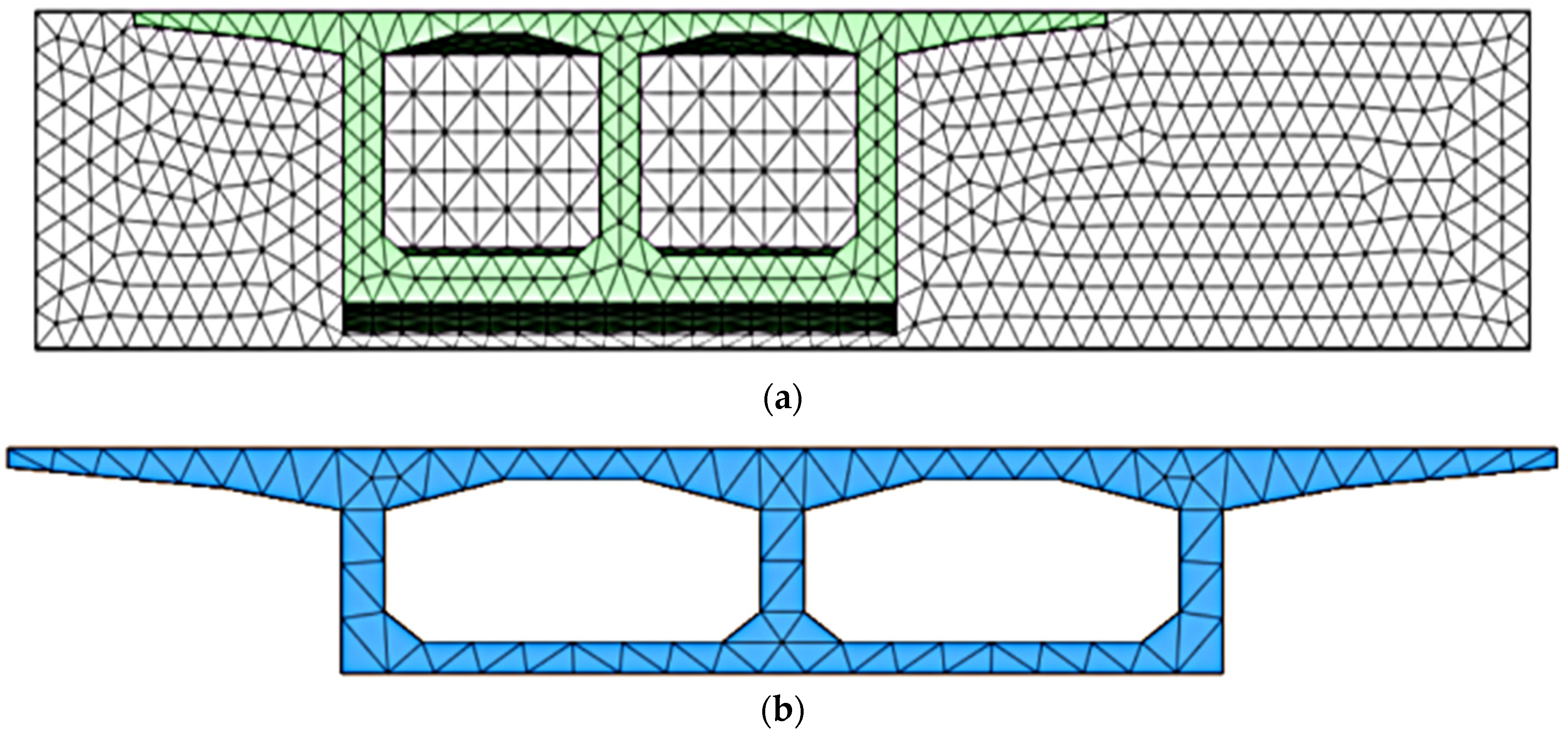

3.1. Refinement of Finite Element Model Establishment [10]

3.2. Analysis of Torsion of Pier Crossbeam during Construction of Symmetrical Cantilever of Box Girder

- (1)

- A deviation in the self-weight of the box girder sections on both sides of the cantilever, with a deviation range of ±4%;

- (2)

- Placement of tools and materials on the beam, with an evenly distributed load of 8 kN/m acting on one side of the cantilever;

- (3)

- Deviation in the weight of the hanging basket and formwork, with a deviation coefficient of 1.2 on one end and 0.8 on the other;

- (4)

- Unsynchronized removal of hanging baskets, with one end completely dismantled and the other end dismantled by 50%;

- (5)

- Unsynchronized construction of the last cast box girder section, with concrete poured 100% on one side and 50% on the other side;

- (6)

- Vertical wind load: considering the asymmetric static wind load acting on both sides of the cantilever of the T-girder, with an asymmetry coefficient of 0.5. Calculate the equivalent static wind load on the main girder according to the “Code for Wind Resistance Design of Highway Bridges”.

4. Research on Torsion Monitoring Technology of Pier Crossbeam during Cantilever Construction

4.1. Theoretical Formula for Torsion Monitoring Calculation of Pier Crossbeam

4.2. Finite Element Method for Monitoring and Calculation of Pier Crossbeam Torsion

4.3. Comparative Study of Construction Monitoring Methods

- (1)

- The precision of high-accuracy electronic inclinometers used in engineering inspections domestically can reach 0.001 degrees. Therefore, by using the previously obtained Ca girder inclination flexibility coefficient and substituting the measurement precision of the inclinometer into calculation Formula (11), the measurement precision of an unbalanced bending moment using such precision electronic inclinometers can be calculated as 315 kN·m.

- (2)

- Domestic displacement sensors (such as dial gauges) can achieve a measurement accuracy of 0.001 mm. Similarly, according to the calculation Formula (15) provided in this paper, the pier top horizontal displacement flexibility Ka = 3.39 can be obtained. Thus, using this sensor (dial gauge) for measuring unbalanced bending moments yields a precision of 2.95 kN·m. Additionally, the horizontal displacement flexibility coefficient in the middle of the pier is represented as Kac . Therefore, the measurement precision of an unbalanced bending moment using this sensor (dial gauge) is 12.77 kN·m.

5. Conclusions

- By establishing a refined finite element model of the entire bridge using Midas/FEA, an analysis of potential unbalanced load combinations during symmetrical cantilever construction was conducted. The results indicate that the torsional resistance of frame pier crossbeams does not meet design specifications during construction.

- By separating the frame pier from the box girder and employing structural mechanics methods to analyze the deformation of frame piers under torsional loads, this paper derived theoretical calculation formulas for the relationship between unbalanced bending moments and pier crossbeam inclination, as well as the relationship between unbalanced bending moments and horizontal displacement of variable section piers. These formulas provide convenient theoretical calculations for monitoring the torsion of frame pier crossbeams during construction.

- Building upon the theoretical formulas for calculating frame pier crossbeam monitoring, two methods for monitoring the torsion of frame pier crossbeams during construction were proposed: a method combining water tank counterweight control with monitoring of pier crossbeam end inclination, and a method combining water tank counterweight control with monitoring of pier horizontal displacement.

- In practical engineering construction monitoring, using a refined finite element bridge model to establish numerical fitting formulas for the relationship between unbalanced bending moments and pier crossbeam inclination yields results consistent with the theoretical formulas derived in this paper. This validates the correctness of the theoretical calculation formulas obtained in this study. Moreover, these theoretical formulas for frame pier crossbeam monitoring are convenient to use, require minimal computational effort, and hold significant value for widespread application.

- Through practical engineering application and comparative analysis, it was found that the method combining water tank counterweight control with monitoring of pier horizontal displacement achieves higher accuracy in unbalanced bending moment monitoring. However, difficulties may arise in implementing fixed bracket installation for sensor placement. On the other hand, the method combining water tank counterweight control with monitoring of pier crossbeam end inclination is operationally convenient and provides sufficient accuracy for unbalanced bending moment monitoring to meet engineering requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Li, Y.; Wang, X.; Chang, Z. Study on the mechanical properties of the prestressed concrete cover beam for the frame pier. Concrete 2023, 33, 146–148. (In Chinese) [Google Scholar]

- Song, Z.; Li, Z. Discussion on the space analysis and design and calculation method of large cantilever and wide box beam. Highw. Eng. 2022, 47, 9–12. (In Chinese) [Google Scholar]

- Li, F. Study on the design of long-span steel beam frame pier of high-speed railway high pier. China Railw. 2020, 10, 94–102. (In Chinese) [Google Scholar]

- Wang, J. Analysis of influence factors of railway steel beam frame pier design. Shanxi Archit. 2020, 36, 132–134. (In Chinese) [Google Scholar]

- Zhang, M. Application of large-span frame pier in the span bridge. Highway 2009, 99–101. (In Chinese) [Google Scholar]

- Du, Z.; Zhao, W.; Chen, J.; Liu, G. Local force analysis of the box beam. Highw. Eng. 2022, 45, 30–35. (In Chinese) [Google Scholar]

- Xu, Y.; Sun, T. Research on automatic monitoring technology of single-box three-room suspended cast girder bridge construction. Highway 2023, 142–148. (In Chinese) [Google Scholar]

- Jin, Y.; Zhu, Q.; Xu, W.; Wang, J.; Han, F. Construction control technology for multi-span corrugated steel web continuous beam bridge. Highway 2023, 163–165. (In Chinese) [Google Scholar]

- Liu, Y. Research on Construction Monitoring Technology of Yanshi Railway. Master’s Thesis, Beijing University of Technology, Beijing, China, 2023. (In Chinese). [Google Scholar]

- Beijing Midas Technology Co., Ltd. MIDAS/FEA User Manual Book 2-Analysis and Computing Tational Principles; Beijing Midas Technology Co., Ltd.: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Yang, F.; Li, J. Structural Mechanics; Higher Education Press: Beijing, China, 1998. (In Chinese) [Google Scholar]

- Hong, Y. Experimental Study of Reinforced Concrete Beams Strengthened with CFRP. In Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021, Nanchang, China, 4–5 December 2021; Feng, G., Ed.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 213. [Google Scholar] [CrossRef]

- Fan, K. Comparative Analysis of the Displacement Dynamic Load Allowance and Bending Moment Dynamic Load Allowance of Highway Continuous Girder Bridge. In Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021, Nanchang, China, 4–5 December 2021; Feng, G., Ed.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 213. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, Y.; Liu, H.; Li, X. Symplectic Elastic Solution of Multi-layer Thick-Walled Cylinder Under Different Interlayer Constraints. In Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021, Nanchang, China, 4–5 December 2021; Feng, G., Ed.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 213. [Google Scholar] [CrossRef]

- Xiao, Y.; Fu, K.; Li, Z.; Zeng, Z.; Bai, J.; Huang, Z.; Huang, X.; Yuan, Y. Research on Construction Process of Steel Beam Incremental Launching Based on Finite Element Method. In Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021, Nanchang, China, 4–5 December 2021; Feng, G., Ed.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 213. [Google Scholar] [CrossRef]

- Jiang, Y.; Long, P. Parameter Sensitivity Analysis of Long Span PC Continuous Beam Bridge with Corrugated Steel Webs. In Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021, Nanchang, China, 4–5 December 2021; Feng, G., Ed.; Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 213. [Google Scholar] [CrossRef]

- The finite element software Midas/FEA.

- Belwal, A.; Thapliyal, S.; Jhinkwan, V.S. Construction Stage Analysis of Continuous Box Girder Bridge Constructed via Full Staging and Balance Cantilever Method. In Recent Advances in Structural Engineering and Construction Management; Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2023; Volume 277, pp. 89–99. Available online: https://www.engineeringvillage.com/app/doc/?docid=cpx_M4cb62b1842f969ae4M65f21017816355 (accessed on 10 June 2024). [CrossRef]

- Farré-Checa, J.; Komarizadehasl, S.; Ma, H.; Lozano-Galant, J.A.; Turmo, J. Direct simulation of the tensioning process of cable-stayed bridge cantilever construction. Autom. Constr. 2022, 137, 104197. Available online: https://www.engineeringvillage.com/app/doc/?docid=cpx_2e3e64ee187d8e1af9bM71a010178165143&pageSize=25&index=1&searchId=4bd5dcf1fed44e568a22ac3fd7bc40bd&resultsCount=24&usageZone=resultslist&usageOrigin=searchresults&searchType=Quick (accessed on 10 June 2024). [CrossRef]

- Rashed, M.; Mehanny, S.S.F. Simulating creep induced moment redistribution in prestressed concrete bridges constructed by the balanced cantilever method: Ad hoc traditional formulae versus real time-dependent analysis. J. Eng. Appl. Sci. 2023, 70, 28. Available online: https://www.engineeringvillage.com/app/doc/?docid=cpx_2e3e64ee187d8e1af9bM71a010178165143&pageSize=25&index=2&searchId=5f271ece67bc4190a5cb20df770c204d&resultsCount=26933&usageZone=resultslist&usageOrigin=searchresults&searchType=Quick (accessed on 10 June 2024). [CrossRef]

- Dias Filho, J.L.E.; de Almeida Maia, P.C. A Non-conventional Durability Test for Simulating Creep of Geosynthetics Under Accelerated Degradation. Int. J. Geosynth. Ground Eng. 2021, 7. Available online: https://www.engineeringvillage.com/app/doc/?docid=cpx_Ma74c417bdf9d9ca5M6ebf1017816328&pageSize=25&index=3&searchId=4bd5dcf1fed44e568a22ac3fd7bc40bd&resultsCount=24&usageZone=resultslist&usageOrigin=searchresults&searchType=Quick (accessed on 10 June 2024). [CrossRef]

- Musarat, M.A.; Khan, A.M.; Alaloul, W.S.; Blas, N.; Ayub, S. Automated monitoring innovations for efficient and safe construction practices. Results Eng. 2024, 22, 102057. Available online: https://www.engineeringvillage.com/app/doc/?docid=cpx_6179457f18ee12b5cb4M635a1017816523&pageSize=25&index=4&searchId=800c9673907c4cc695c858c4f987be74&resultsCount=116857&usageZone=resultslist&usageOrigin=searchresults&searchType=Quick (accessed on 10 June 2024). [CrossRef]

- Gong, B.; Feng, L.; Liu, J.; Liu, S.; Wang, Z.; Liu, Y. Finite-Element Analysis of Temperature Field and Effect on Steel-Concrete Composite Pylon of Cable-Stayed Bridge without Backstays. Buildings 2024, 14, 1731. [Google Scholar] [CrossRef]

- Liu, F.; Gu, L.; Fu, H.; Li, X.; Zhao, X.; Ma, N.; Guo, Z. Research on the Method of Prestressing Tendon Layout for Large-Span Prestressed Components Continuous Rigid Frame Bridge Based on “Zero Bending Moment Dead Load Theory”. Buildings 2024, 14, 1588. [Google Scholar] [CrossRef]

- Zhou, H.; Qi, X.; Liu, Z.; Xue, W.; Sun, J.; Liu, J.; Gui, S.; Yang, X. Asymmetric Cantilever Construction Control of a U-Shaped Box Concrete Continuous Bridge in Complex Environment. Buildings 2023, 13, 591. [Google Scholar] [CrossRef]

- Xu, F.; Cheng, Y.; Wang, K.; Zhou, M. Transverse Analysis of Box Girders with Corrugated Steel Webs. Buildings 2024, 14, 574. [Google Scholar] [CrossRef]

- He, X.; Wang, Z.; Li, C.; Gao, C.; Liu, Y.; Li, C.; Liu, B. Experimental Test and Finite Element Analysis on a Concrete Box Girder of a Cable-Stayed Bridge with W-Shaped Prestressed Concrete Diagonal Braces. Buildings 2024, 14, 506. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Yu, M.; Hu, X.; He, W.; Qin, K.; Zhu, Y.; Wei, X. Structural Design and Mechanical Behavior Investigation of Steel–Concrete Composite Decks of Narrow-Width Steel Box Composite Bridge. Buildings 2024, 14, 912. [Google Scholar] [CrossRef]

- Peng, W.; Lu, W.; Liu, S.; Liu, Y.; Xu, L.; Li, F. Experimental and Numerical Study on the Seismic Performances of Reinforcement-Embedded RC Column-to-Precast Cap Beams with Socket Connections. Buildings 2023, 13, 2367. [Google Scholar] [CrossRef]

| Details of the Model | |

|---|---|

| Model composition | Solid elements |

| Meshing method | Using automatically generated tetrahedral solid meshes with smooth variation in size. |

| Grids size | 0.5 m |

| Types of loads | Unbalanced loads |

| Specific methods of applying loads | The specific method of applying loads involves applying a surface pressure of 0.49 kPa on one side to support materials for cantilever stacking tools. Deviations in the basket and template are addressed by applying a concentrated force of 840 kN on one side of the cantilever end and 560 kN on the other side. For the final cantilever block, asynchronous construction is achieved by only modeling half of the segment on one side for calculation purposes. Asymmetric vertical wind loads are addressed by applying a surface pressure of 0.23 kPa on one side. |

| Number | Days | Description of Construction Content |

|---|---|---|

| 1 | 45 | Main pier and foundation |

| 2 | 30 | Pour 0# segments |

| 3 | 1 | Pull T1 and F1 |

| 4 | 20 | Hang the basket assembly, pre-press |

| 5 | 8 | Pouring section 1# |

| 6 | 1 | Pull T2 and F2 |

| 7 | 1 | Hang the basket forward |

| 8~30 | 79 | Past and tension the 2#–9# section |

| 31 | 8 | Side across the pouring |

| 32 | 10 | The edge across the close |

| 33 | 2 | Tension side across the steel beam |

| 34 | 0 | Remove the side span bracket and make temporary consolidation |

| 35 | 10 | In the cross close |

| 36 | 2 | Tension in the span steel beam |

| 37 | 8 | Remove the whole bridge hanging basket |

| 38 | 10 | The second phase of paving |

| 39 | 3650 | Operating for ten years |

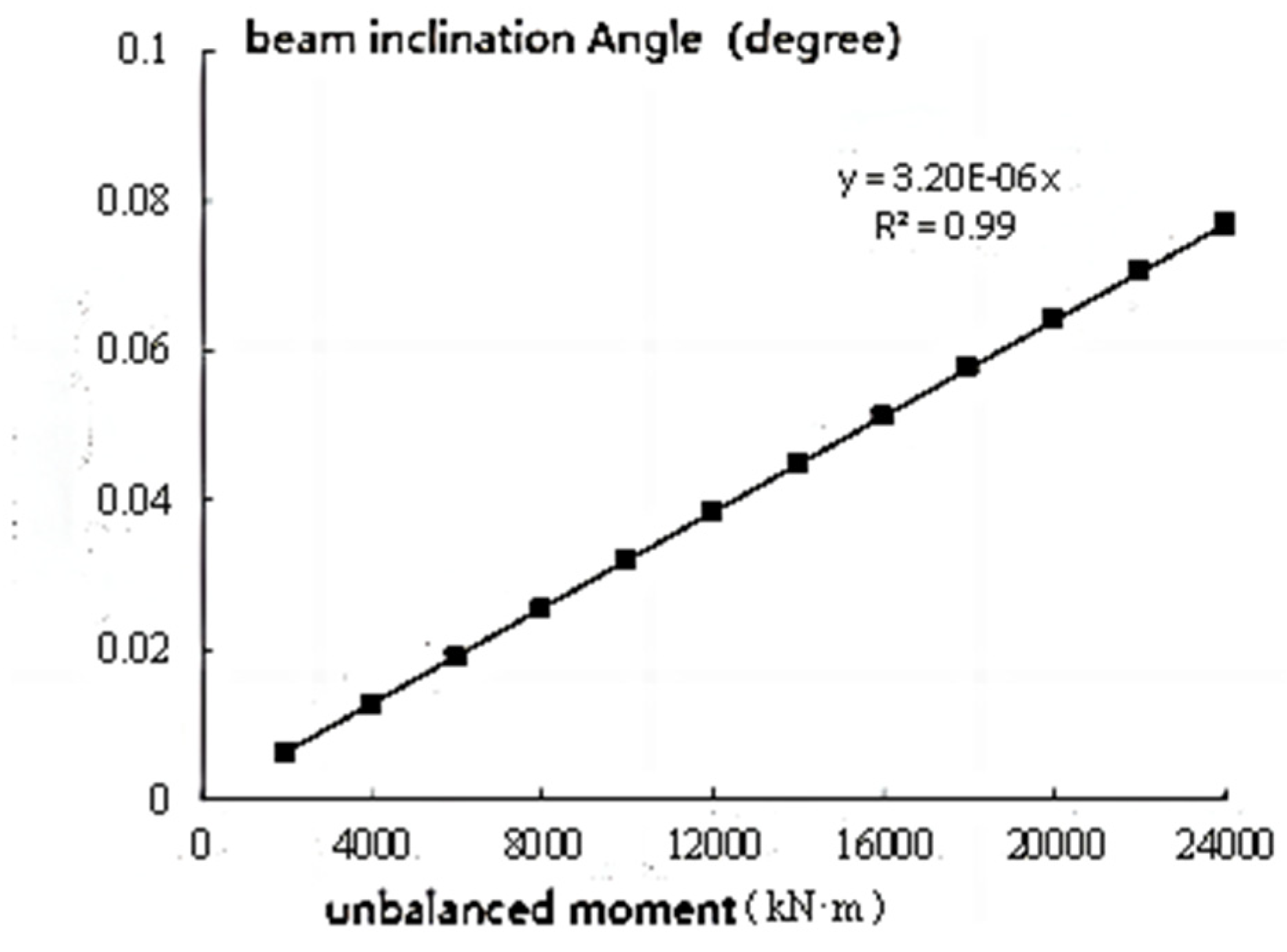

| Unbalanced Moment (kN·m) | Cross am Inclination (degree) | Unbalanced Moment (kN·m) | Cross am Inclination (degree) |

|---|---|---|---|

| 2000 | 0.0064 | 14,000 | 0.0448 |

| 4000 | 0.0128 | 16,000 | 0.0513 |

| 6000 | 0.0192 | 18,000 | 0.0577 |

| 8000 | 0.0256 | 20,000 | 0.0641 |

| 10,000 | 0.0320 | 22,000 | 0.0705 |

| 12,000 | 0.0384 | 24,000 | 0.0769 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Gu, L.; Fu, H.; Li, X.; Zhao, X.; Ma, N.; Liu, S. Research on Monitoring Technology for Frame Piers of Continuous Box-Girder Bridges Constructed by the Cantilever Method. Buildings 2024, 14, 2409. https://doi.org/10.3390/buildings14082409

Liu F, Gu L, Fu H, Li X, Zhao X, Ma N, Liu S. Research on Monitoring Technology for Frame Piers of Continuous Box-Girder Bridges Constructed by the Cantilever Method. Buildings. 2024; 14(8):2409. https://doi.org/10.3390/buildings14082409

Chicago/Turabian StyleLiu, Fanggang, Lixiong Gu, Haishan Fu, Xinping Li, Xiaolong Zhao, Niujing Ma, and Shixun Liu. 2024. "Research on Monitoring Technology for Frame Piers of Continuous Box-Girder Bridges Constructed by the Cantilever Method" Buildings 14, no. 8: 2409. https://doi.org/10.3390/buildings14082409