Abstract

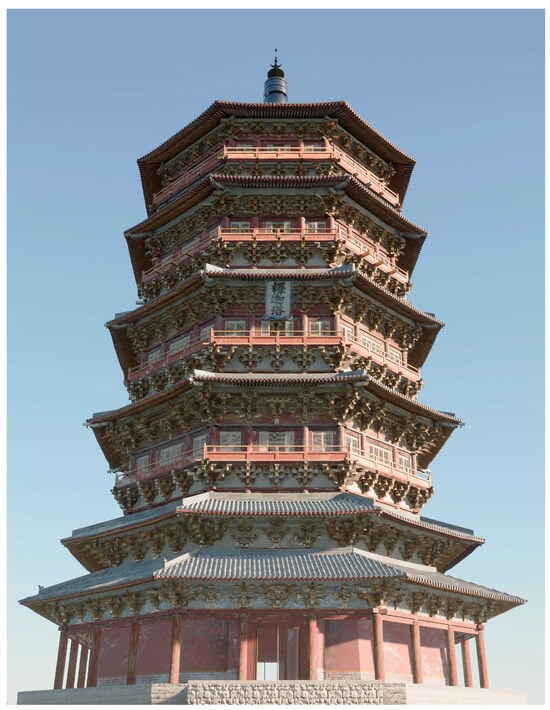

The Sakyamuni Pagoda of Fogong Temple, also known as the Yingxian Wooden Pagoda or the Wooden Pagoda of Ying County, is China’s oldest and tallest wooden pagoda. This pagoda was constructed in 1056 and has faced many challenges, including earthquakes, wars, and mistreatment. However, it is currently in danger of potential collapse due to severe structural challenges. Preserving this historic monument requires interdisciplinary collaboration across architectural history, materials science, and engineering. This paper proposes the development of a parametric model to build the pagoda that can be used for future preservation efforts. While not precisely reflecting the pagoda’s current condition, with the changes in inputs, the geometries of the structural members can be updated in real time, which offers adaptability crucial for preservation efforts. With the understanding of the original construction techniques, including its leaning column systems, the model not only helps preservation but also reveals the creativity of the architects or the craftsmen at the time. The 3D model, which includes more than 32,000 pieces along with the parametric files that can generate the column grid and dougongs, has been published along with this paper, and those files are available in the Data Availability Statement. In summary, the full digital model presented alongside this paper, unavailable elsewhere to the general public, serves as a practical preservation tool that can also be used for raising awareness for this cultural heritage site.

1. Introduction

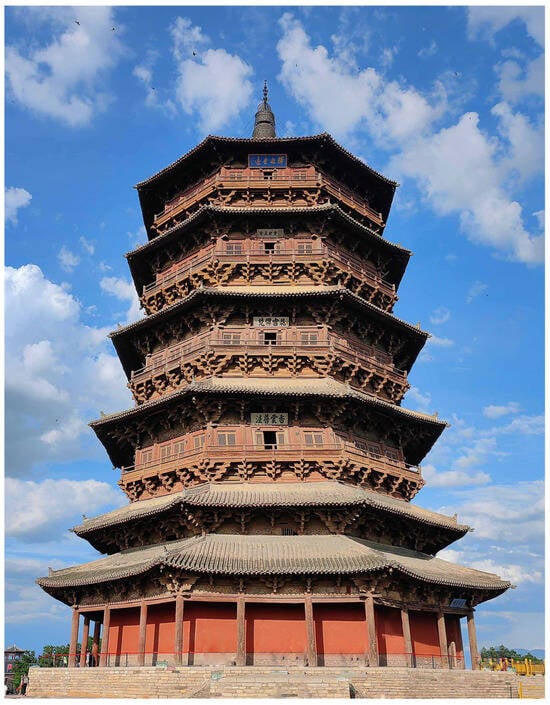

The Sakyamuni Pagoda of Fogong Temple, also known as the Yingxian Wooden Pagoda or the Wooden Pagoda of Ying County, is the oldest wooden pagoda that is still standing in China [1]. The pagoda, which is located in Ying County (Yingxian), Shanxi Province, was funded by the royal family in the Liao Dynasty, and the construction was finished in 1056 [1]. This pagoda is considered as the best record of the various types of dougongs, a special type of structural member found in ancient wooden architecture in China. According to Chen, there are 54 types of dougongs that can be found within the pagoda [1].

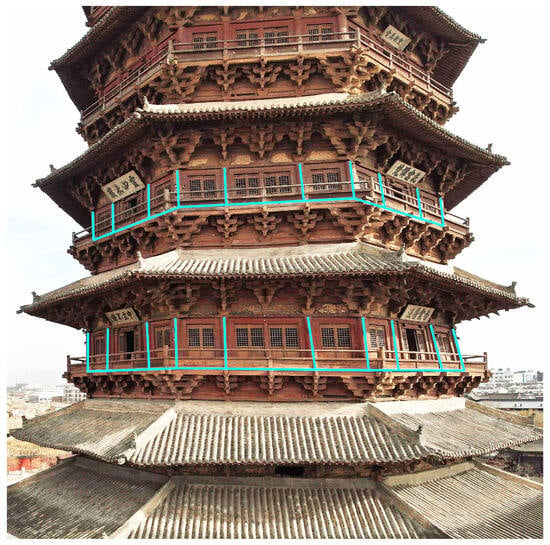

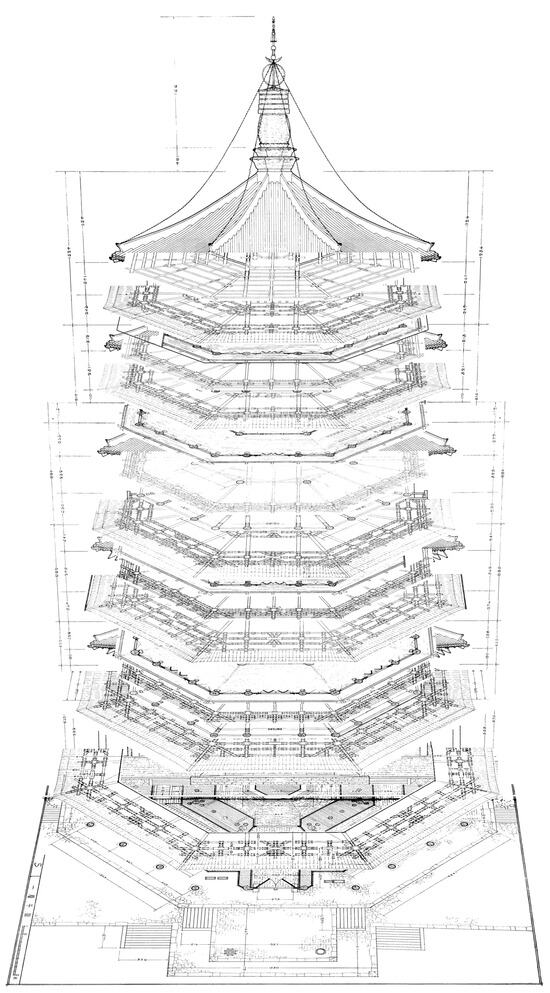

After more than 900 years, the stability of this pagoda is at risk, major actions are needed in order to preserve and keep the structural integrity of this cultural heritage site. Many challenges in the preservation process are based on the fact that the structure of the pagoda is very complicated. Traditional media, such as drawings and photos, do not have the capability to record and show the complexity of this pagoda, as presented in Figure 1. A digital model with enough details is needed for educational and preservation purposes.

Figure 1.

Yingxian Wooden Pagoda. Reproduced with permission from Le Liu, 2024 [2].

In research presented by Chen et al., one of the 54 types of dougongs within the Yingxian Wooden Pagoda was made in both physical and digital form [3]. Then, the physical models were tested under vertical load, and different types of structural failure of the components of the dougongs were identified, providing a great reference for understanding the structural behaviors of the components of the dougongs within the pagoda [3]. However, this project only explored limited types of dougongs within the pagoda and can only be used for structural analysis in limited sections of the structure. Similarly, in a study presented by Sha et al. the team fabricated two full-scale models that each included a dougong layer consisting of three dougongs and a beam–column frame on top [4]. One model had doors within the beam–column frame, while the other was equipped with diagonal braces [4]. The models were then tested under great load, and the structural behaviors of the two models were compared [4]. Likewise, this study also explored a limited portion of the structure. In order to better understand the structure of the pagoda, a structural simulation and analysis for the whole structure is needed. Such analysis cannot be performed without building a detailed digital or physical model. Since building a physical model is very expensive and labor-intensive, a digital model is a more feasible option.

Many researchers have explored the idea of building a digital model of the whole pagoda. For example, a finite element model was constructed using SAP2000, mainstream structural analysis software, by Deng and his team [5]. According to Deng et al., the finite element model they built sets a useful foundation to evaluate the structural behavior of the pagoda under seismic loads [5]. However, the finite element model was a simplified version of the pagoda, where all the important structural members were turned into simple elements; it does not reflect sufficient geometric features of the structural members. As a result, it cannot be used for detailed analysis, visualization of the pagoda, and restoration processes.

In the research published by Guo et al., a 3D model of the pagoda was generated using unmanned aerial vehicle (UAV) images and terrestrial LiDAR point clouds [6]. According to the authors, the overall registration accuracy of this model reaches 0.6 cm, which can be useful for monitoring the deformation of the pagoda and as an important reference for a scheme design for future restoration [6]. However, due to the nature of UAV and LiDAR point cloud technology, the 3D model that was generated in this project cannot be divided into individual structural members, which limits its applicability as a reference for restoration processes, where the structural members would need to be disassembled.

Lai et al. presented the first floor of the pagoda model as built in Autodesk Revit, a building information modeling software that is used by architects and engineers [7]. With the help of Revit, many types of drawings for the 3D model can be seamlessly generated. However, the model was presumably generated manually, which cannot be updated easily during the future restoration process when new data are available.

To streamline the modeling process and update the model in real time, parametric design tools can be used. Parametric design is a process that focuses on manipulating the design outcome, such as geometries, shapes, and forms, via changing the inputs of the algorithms and rules. It allows users to iterate the output by simply updating the data input, which can be efficient and productive. Parametric design tools can be very useful in generating geometries that are highly repetitive and interrelated.

A parametric method using Dynamo, a visual programming plugin for Autodesk Revit, for generating dougongs with parametric inputs was developed by Jiang et al. [8]. At the same time, this research used the Yingxian Wooden Pagoda as an example to showcase the capability of this method [8]. However, the end results presented by this research lacked important features of the dougong members, such as carvings on the gongs. In addition, this study mainly focused on developing the algorithm used to generate the dougongs, while other structural members, such as columns and beams, were manually modeled in the 3D environment [8]. Since these members are also highly interrelated and repetitive, parametric tools can also be applied. Meanwhile, without applying parametric tools for the columns and beams, in a real-world restoration process this model cannot accommodate real-time updates for the whole pagoda. Therefore, the logic of developing such tools will be heavily explored in this research.

This research aims to introduce the forms and structure of the pagoda, while also introducing a parametric framework for the digitization process of the pagoda. Using this framework, researchers will be able to change the model with updated measurements in real time, which will be useful in real-world preservation processes. Another goal is to generate a detailed 3D model using a parametric modeling method. This model can help future researchers understand the pagoda’s structure and also sets the foundation for future simulation and preservation projects. The attached digital model of the pagoda can also be used to generate games and videos, which can be used to promote general awareness of this pagoda, and such awareness can also be beneficial to the preservation of this cultural heritage site.

2. Background

2.1. Structure of the Pagoda

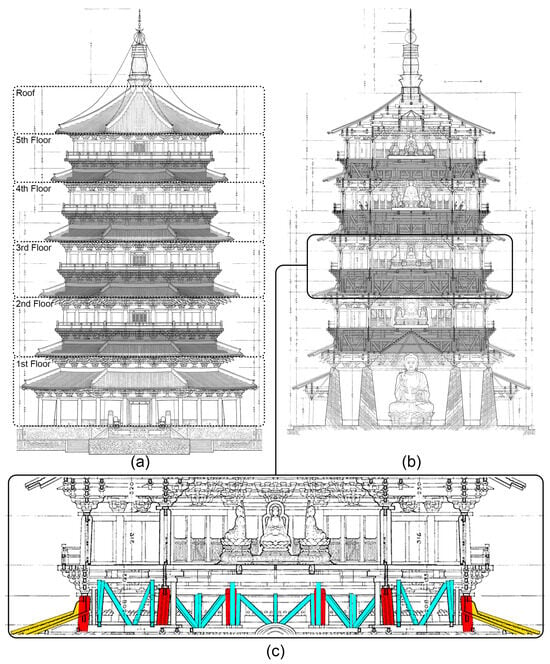

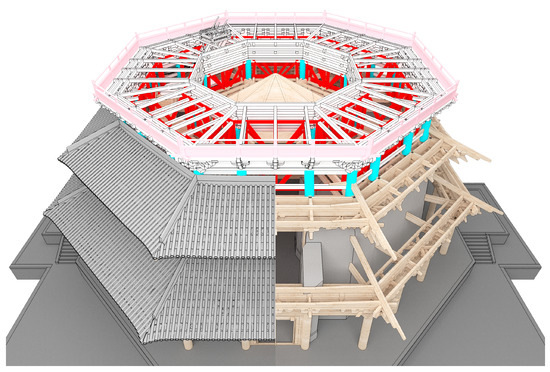

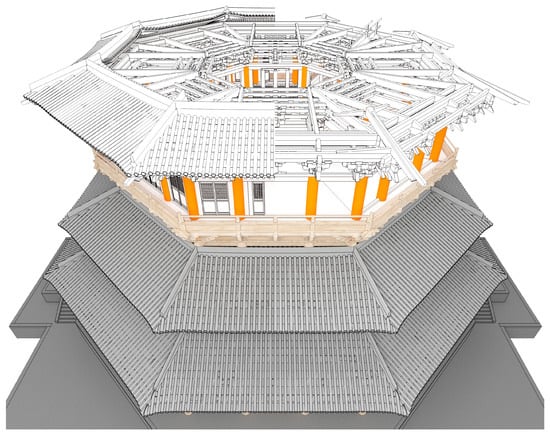

As shown in Figure 2a, the pagoda has five floors. Except for the first floor, which only has an occupiable level and a buttress level, each of the other floors consists of one structural level and one occupiable level. The structural levels are highlighted in gray in Figure 2a,b; as shown, the occupiable levels sit atop their respective structural levels. For clarity, in discussion within this study “floor” refers to one of the five floors of the pagoda, while “level” encompasses either the structural level, the occupiable level, or the buttress level.

Figure 2.

Occupiable and structural levels: (a) elevation of the pagoda; (b) section of the pagoda; (c) zoom in of the section [1].

As depicted in Figure 2c, the structural levels comprise columns, highlighted in red, diagonal bracing members for lateral stability, highlighted in cyan, and dougongs. This design allows the occupiable floor to have a relatively higher ceiling, with spaces within dedicated to statues and ritual ceremonies.

One of the notable designs within the pagoda is that the dense bracing and lateral structural members in the structural level are hidden by the roof’s eaves on each floor, highlighted in yellow in Figure 2c. This means that as visitors look at the outside of the pagoda, they receive the impression that the structures of the tower are light and elegant.

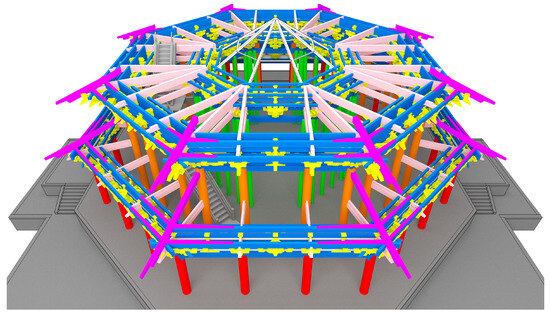

As Figure 3 demonstrates, the overall floor plan of the pagoda is a regular octagon, which means that there is no actual difference between the front facade and side facade in terms of placement of columns. Therefore, in this study, all of the facades are referred to as side facades, and the dimensions along all sides are considered identical. The structure sits on top of the base, which is colored dark gray, that is paved with stone. On the first floor, there are three layers of columns: the interior layer (green), the exterior layer (orange), and the extra layer of columns (red). The extra layer of columns is much shorter than the other two, and this layer is only present on the first floor; this level of structure provides lateral support for the first floor, so it is referred to as the buttress level in this research. The columns in different layers are connected by beams, which are the pink-coded structure members in Figure 3. The columns within the same layer are connected through tie beams, which are marked in blue in Figure 3. The connectors between the beams, tie beams, and columns are called dougongs (yellow), a type of structural element composed of interlocking wooden brackets that function as the joints between structural members. An important function of dougongs is to transfer the loads of the eaves, overhangs of the roofs, and above structures to the columns that it sits on. There are hip rafters (purple) sitting on top of the corner columns of the buttress level (red) and the first floor (orange), which are used to support the edge of the eaves. The stairs are colored in light gray, and provide circulation to the upper levels. The white members sitting on top are the structural members for the caisson.

Figure 3.

First floor structural diagram.

The interior layer of columns and exterior layer of columns on the first floor are covered with earth walls, which are marked in green and blue on the right side of Figure 4; the left side of Figure 4 demonstrates the presence of eaves.

Figure 4.

First floor earth walls.

The second floor sits on top of the first floor. As previously introduced, the second floor contains two levels: the structural level and the occupiable level. As Figure 5 indicates, the structural level has short columns (cyan) and, similar to the first floor, the structural level has two layers of columns, which both sit on top of the dougongs of the first floor. The details of such connections will be explored in the following paragraph. The connections between the columns, beams, and tie beams are the same as the details presented in Figure 3; the difference is there are vertical, horizontal, and diagonal bracing members in the structural level, which have been marked in red, and can only be found in the structural levels. The railings of the balcony sit on top of the upper edge of the structural level; they have been highlighted in pink.

Figure 5.

Second floor structural level.

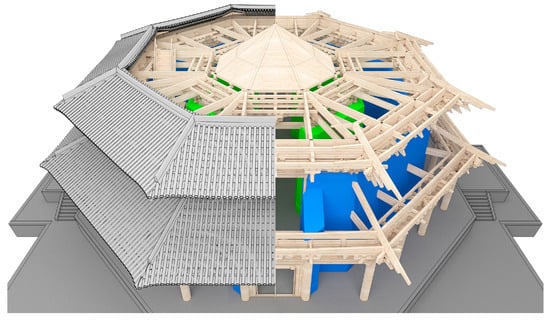

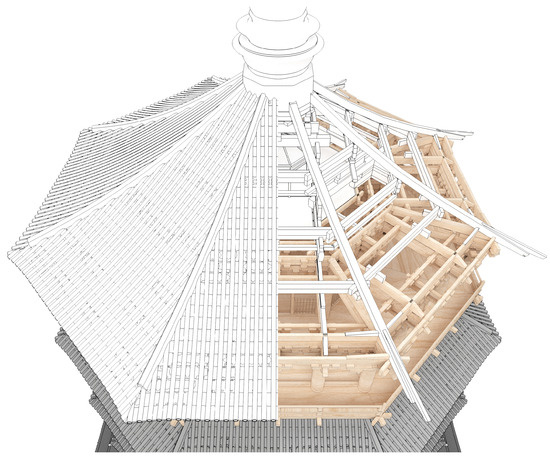

On top of the second floor structural level is the second floor occupiable level, as shown in Figure 6; like the first floor, the occupiable level has two layers of columns (orange), beams, and tie beams, which are all connected by dougongs. The upper floors use the same logic: the structural level sits on top of the lower level, and the occupiable level sits on top of the structural level. This logic continues until the fifth floor; on top of the fifth floor’s occupiable level is the roof, which has different sets of structures, as Figure 7 presents.

Figure 6.

Second floor occupiable level.

Figure 7.

Roof structure.

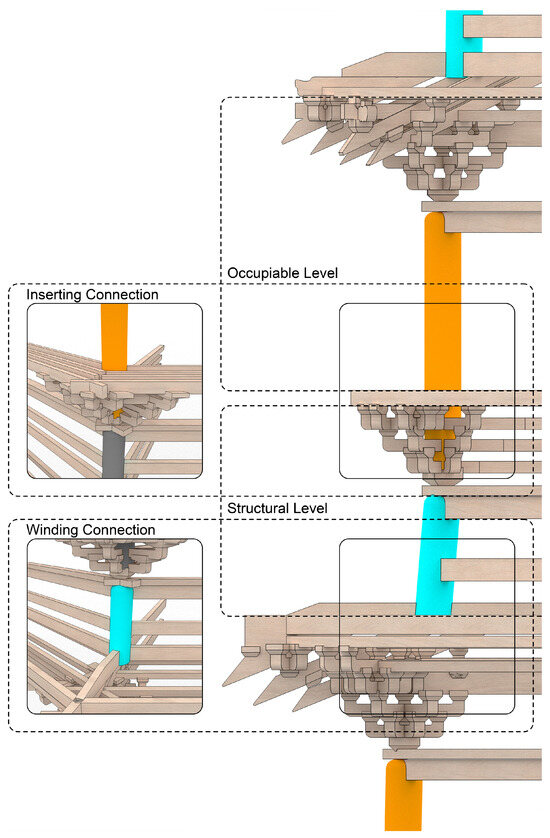

The connections between different levels can be categorized into two different types: inserting connections and winding connections. As shown in Figure 8, the inserting connections are applied between the occupiable level and the structural level. For this type of connection, the column is inserted into the bottom part of the dougong that it sits on. The other column connection is called the winding connection, which is used between different floors. As shown in Figure 8, when the winding connection is applied, the column does not insert into the dougong underneath; instead, it sits on the beam that connects between the exterior and interior layer of the dougongs. In addition, it sits closer to the center of the floor plan rather than on the center line of the dougong underneath; this offset is the largest contributor to the overall tapering form of the structure.

Figure 8.

Connections between different floors for exterior layer of columns.

The connections between different levels for the interior layer of columns are similar to the winding connection; they also do not insert into the dougong underneath, but the difference is that most of those columns sit on or near the center line of the dougong underneath.

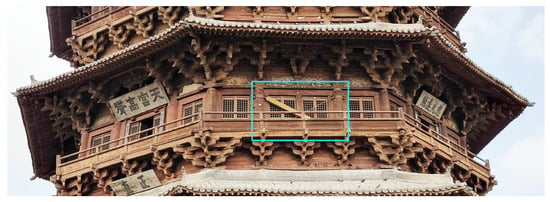

2.2. Current Condition

Over the past nine centuries, the transitions between different dynasties often involved wars, mass migrations, and even mass destruction, but none of the regimes attempted to demolish this pagoda. Many restoration attempts were made throughout history. There were at least five major restoration projects that were initiated by different dynasties [9]. Their strategies included adding extra columns, bracing members, and shear walls [9]. During these attempts, many measures were taken to help figure out how to reinforce the structure of the pagoda and slow down the aging and deterioration process of the materials [9]. However, in 1935, for the sake of Feng Shui, some of the local officials decided to demolish all of the shear walls and some other structural members that had been placed in 1722, which caused irreversible damage to the structure and inadvertently sped up the distortion process [9]. More specifically, as Figure 9 indicates, the most significant challenges for those seeking to preserve the pagoda are the leaning structures on its second and third floors. Most of the columns are on the brink of structural failure, and any extra lateral loads from wind and earthquakes may trigger the collapse of the whole structure. At the same time, the displacement and deformation process is a vicious cycle: more unevenly distributed load in the structure can potentially cause more displacement and deformation of specific structural members, and the increased displacement and deformation will then cause more unevenly distributed load among these and other structural members.

Figure 9.

Yingxian Wooden Pagoda’s second floor and third floor.

All the challenges and the risks of collapse that the pagoda is facing right now demand the actions of preservation; however, the debate of which method of preservation to take is a contentious topic among experts from the related fields.

2.3. Preservation Methods

2.3.1. Total Disassembly and Reassembly

Since the main structure of the pagoda is made out of wood, and most of the structural connections in the pagoda are mortise and tenon joints, the structure could theoretically be dismantled and restored. Similar to the procedure of furniture restoration, this method allows the preservation team to disassemble the structural members in the pagoda, repair or replace the damaged members, and then, reassemble them back to the ideal state [10]. This method has been widely used in many wooden structures in China and Japan. Undoubtedly, this restoration technique would extend the lifespan of the pagoda and simultaneously give modern technicians the opportunity to gain a better understanding of ancient building methods from the ancient structure, which is valuable for future preservation in similar circumstances.

Nevertheless, many other researchers argue that such preservation process will contaminate the authenticity of the pagoda from a multitude of perspectives. For example, a lot of the valuable historical information inherent to the pagoda, such as murals and earth, will be eliminated during this process.

In comparison to facing the ruins after the collapse of the pagoda, the information lost in the disassembly process might be trivial. At the same time, the amount of knowledge that the engineers and craftsmen can gain during the preservation process may be tremendous, which can be helpful for future preservation projects for this pagoda and other cultural heritage sites.

2.3.2. Steel Frame Retrofitting

Another idea that has been discussed was proposed by Ruizhu Wang, a scholar at the Chinese Academy of Engineering [10]. Wang proposed building a steel frame structure that would go through the first three floors and share the load from above, which could potentially extend the lifespan of the pagoda. This proposal received harsh criticism from the other experts since the steel structure would inevitably damage the existing floors, foundation, and many other structural members. In addition, this process challenges the self-standing capability of the pagoda, which can be seen as undermining the key values of its heritage [10].

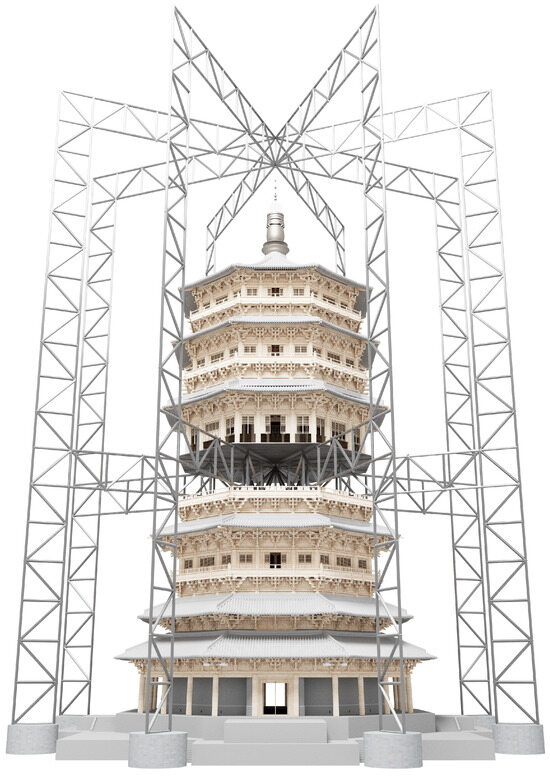

2.3.3. Lifting Method

Another proposal that can be considered as a partial disassembly and reassembly method is called the lifting method. This proposal was made by Xiurun Ge and the research group from Taiyuan University of Technology [10]. Since the conditions of the top three floors are relatively good, some experts claim that they can elevate those top floors as one joined piece, and then, put them back after the repair and restoration of the first two floors has taken place, as presented in Figure 10 [10]. The benefits of this proposal are obvious, it has the capability to preserve most of the information of the tower in the upper floors, while solving the issues on the second floor. However, this proposal received criticism for being expensive, risky, and ultimately unfeasible. Shiren Wang, a researcher of heritage preservation, stated that this method is unprecedented, and it is irresponsible to put a national heritage site like this at risk [11]. Additionally, according to Wang, researchers have since identified many issues among the top three floors, which means they will be in need of restoration in the coming years as well [11]. Lastly, the steel frame system in Figure 10 imposes a tremendous amount of load on the surrounding area, which may cause damage to the tower base [11].

Figure 10.

Lifting method.

Meanwhile, another expert in heritage preservation, Bingjian Ma, pointed out that the distortion process has taken place over centuries, and the deformation among those members is plastic deformation, which means that when the first two floors have been adjusted to the ideal condition, the above structures will not match with the corresponding structural joints of those underneath [12]. Therefore, according to Ma, this proposal is a dead end from the beginning.

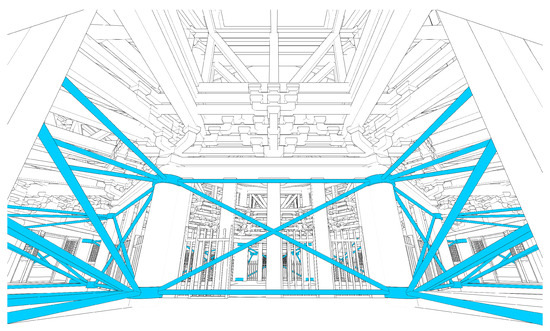

2.3.4. Reinforcement of Existing Structure

Another method is to reinforce the existing structure, which can be seen in Figure 11. This method can slow down the process of future distortion and damage, and has been partially applied on the site already, as Figure 12 presents. A series of bracing members were applied to the second floor to improve its performance under existing loads. There are many obvious drawbacks to this method. Firstly, it is a temporary bandage that can slow down structural failure but not fully stop it. Secondly, it would occupy a lot of space on the second floor, which blocks circulation. Lastly, this method applies many visible members to the pagoda, which compromises its visual integrity. Therefore, other methods and interventions are still needed to solve the existing problems.

Figure 11.

Structural bracing on the second floor.

Figure 12.

Existing bracing members on the second floor.

2.3.5. The Paradox of Decision Making

Among all the contentious debates of which method is the most ideal for the preservation and repair process, one consensus among most of the researchers and engineers is that the condition of the pagoda is critical, and without effective and useful measures, the pagoda may collapse due to a minor earthquake or heavy lateral force from the wind. This research has no ambition to find the most ideal measures for the preservation of the pagoda, but rather to provide a framework for future preservation processes.

3. Methodology

3.1. Research Objective and Workflow

The primary objective of this study was to build a detailed and near comprehensive parametric model based on data from previous surveys on the pagoda; the model proposed by this paper generates a template that reflects the ideal condition of this pagoda instead of the existing condition and can serve as a starting point for future restoration and preservation efforts.

There are two main reasons to apply parametric modeling techniques. The first reason is the drawings from Chen’s book depict the ideal measurements of the wooden pagoda, while the actual structure may differ significantly. Therefore, a parametric model allows future workers to adjust the 3D model based on onsite measurements during restoration. The second reason is there are many repetitive structures throughout the pagoda since the floor plans of this structure are all octagonal and both axially symmetrical along the line connecting the center of each floor to the midpoint of each side and centrosymmetric. Additionally, it is evident that engineers embraced the idea of modularization in the manufacturing process for many members, particularly among the dougongs. Within the dougongs, many structural components share the same width and height but have different lengths. Because of the strength of parametric design in generating variations of forms by altering certain inputs, it is an ideal tool for this type of modeling process.

The modeling process involved constructing a detailed model, and the entire workflow consisted of six essential parts: reference data collection, modeling environment setup, column grid modeling, dougong modeling, modeling of other structural members, and modeling of non-structural members.

3.2. Modeling Process

3.2.1. Reference Data Collection

Beginning in 1934, several groups of architects and architectural historians went to Yingxian to conduct architectural surveys of the pagoda. The leading architects of the first group were Sicheng Liang and Dunzhen Liu [13]. In Liang’s book, The Record of Chinese Architecture, many detailed drawings from the 1930s were presented; unfortunately, due to many limitations, the survey was not detailed and accurate enough. Additionally, during the following wars, many of the original drawings were damaged or lost [13].

Fortunately, in the 1960s, Dunzhen Liu’s assistant, Mingda Chen, completed a detailed and comprehensive survey that included many drawings and measurements of the pagoda’s structure, and then, published the first edition of his book, Yingxian Timber Pagoda, in 1966 [1]. Chen produced detailed documentation, recording all the ideal dimensions within the pagoda, from the diameters and leaning angles of the columns to the overall height of the structure. To record the data and reveal the relationships between all the dimensions, he made a series of tables to document the data for future reference and interpretation, including Table 1 and Table 2. Chen also produced a set of highly detailed drawings of floor plans, elevations, sections, and even the details of the dougongs.

Table 1.

Floor diameters and distances between the extra and exterior layers of columns [1].

Table 2.

Detailed dimensions of dougong members [1].

As Table 2 indicates, the dimensions of the dougong members within the pagoda are highly repetitive, and all the repeated data have been color-coded, which indicates the concept of modularization within the fabrication process. For instance, as the third column of the chart shows, throughout the structure, the depth of the Gong, Ti Mu, and Shua Tou is always 17 cm. Meanwhile, as the fourth column presents, the heights of those members are either 25.5 (= 17 × 1.5) cm or 12 or 13 cm, which is about half of 25.5 cm. These interrelated patterns over the dimensions indicate the highly efficient and sophisticated assembly line-like manufacturing process.

It is reasonable to assume that a group of workers was assigned to supply wood with standard dimensions, while others were in charge of cutting that wood down into those specific members on site or at the prefabrication location, and then, those members were installed in place.

All these standardized dimensions and modularization concepts have the potential to streamline the design process, improve the efficiency of the construction, and make this project a perfect paradigm to apply the method of coding and scripting. By adjusting a few scripts within the program, different members of the dougong can be generated automatically, which increases the speed of modeling, streamlines the updated process when new measurements are given, and reflects the modularization process in a quantitative manner. Grasshopper in Rhino 8 was chosen as the software to use for this project. Grasshopper is a visual programming language that is designed for architects, artists, and engineers; it allows users to generate geometries by using logic and scripts. It runs within Rhinoceros (Rhino), a 3D computer-aided design software.

Chen’s book was used as the main reference for the modeling process offered by this paper. However, considering the observational errors and construction errors that may have occurred, several assumptions, corrections, and resulting conclusions of the logic behind those dimensions were made, and the model reflects those conclusions correspondingly.

3.2.2. Modeling Environment Setup

As Figure 13 indicates, the drawings from Chen’s book were scaled to the right size and imported into the 3D environment. They were utilized as references for the subsequent modeling process. The unit for this model is centimeters, consistent with the unit used by Chen in his book. The placement of section and floor plans established the overall scale for the modeling process, ensuring the accuracy of column grid placement.

Figure 13.

Reference drawings in the 3D environment [1].

3.2.3. Column Grid Modeling

To accommodate the restoration process that may take place in the future and to provide the future researchers a model that has great flexibility, a set of Grasshopper scripts was written to create the column grids, and is available in the Data Availability Statement.

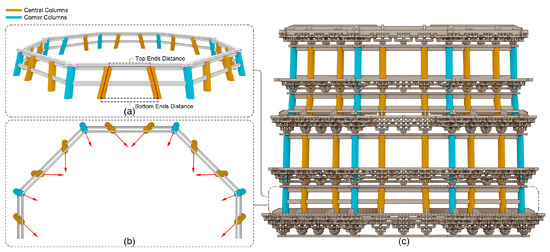

Except for the first floor’s interior and exterior layers of columns, which are covered by earth walls, all the extra and exterior layer of columns have four columns on each side, which are referred to as the corner columns and the central columns. All the distances between those columns can be found in Table 1. For all the interior layers of columns, there is one column on each corner, and the related data can also be found in Chen’s book.

The process of creating one layer of columns can be summarized in four steps. Step (1) is to draw a regular octagon scaled based on the reference drawing where the center of this octagon is the origin, and the vertices and points on each edge serve as the lower endpoints for the center line of a column. Step (2) is to draw the second regular octagon with the center point (0, 0, h), where the h value is based on the height of the columns, and to scale it based on the reference drawing; the vertices and points on each edge serve as the upper endpoints for the center line of a column. Step (3) is to make connections between the column endpoints on the first octagon and the second octagon, representing the center lines of the columns. Lastly, step (4) is to make the columns based on the center lines created in the previous step.

Since the first floor has three layers of columns, this process had to be repeated three times for the first floor. For the other floors, each floor has two levels, and each level has two layer of columns; therefore, this process needed to be applied to each level twice.

For the exterior layer of columns, an important point is that since it only involves inserting connections within the same floor, it means that the columns of the occupiable level sit on top of the columns of the structural level within the same floor. Therefore, the reference octagon for the bottom of the occupiable level should have the same size as the octagon for the top of the structural level, and the only difference is their heights, so they were linked in the script. As a result, any changes in the structural levels will affect the occupiable levels. Similar relationships also exist between the different floors where winding connections are applied, so the changes on the bottom floors eventually affect the top floors. The top of each column was then used as the base point for the dougong to sit on, and those reference points were incorporated into the following modeling process.

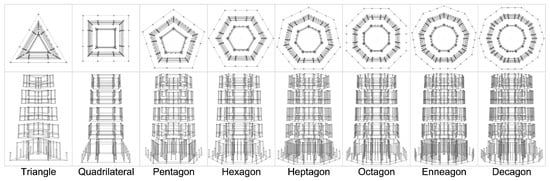

Because of the flexibility of the algorithm and the interrelationships of the parameters, simply changing the input of the number of sides of the polygon enables this set of scripts to generate column grids with different sides while maintaining a similar form and logic. This is shown in Figure 14, and indicates the strength of this method in exploring the typology of the forms of pagoda design.

Figure 14.

Variations of the form.

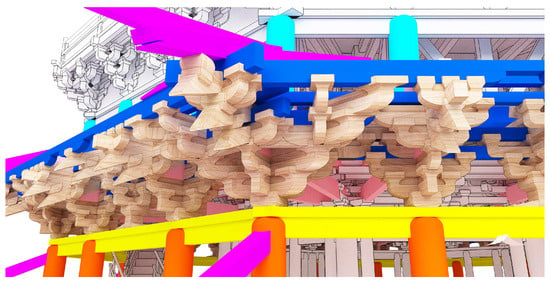

3.2.4. Dougong Modeling

As Figure 15 presents, the dougongs act as connectors for all types of structural members. The architrave, which is marked in yellow, and the tie beams, which are highlighted in blue, all connect to the dougong. At the same time, the pink pieces represent the beams that connect the exterior layer of dougongs to the interior layer of dougongs that sit on the interior layer of columns. The architrave, tie beams, and beams mentioned above are the horizontal connections that the corner dougong is responsible for. The columns, which are marked in orange and cyan, demonstrate the dougong’s function as a connector in the vertical direction; the detail of these types of connections can be seen in Figure 8. The horizontal member in purple represents the hip rafter that sits on top of the dougong, which reveals another main function for the dougong: transfer the load of the overhang of the eaves or the roof to the columns that it sits on. This process of load transfer allows the pagoda to have deep eaves, which provide expressive and iconic spacial experience while protecting the wooden structure underneath them from water damage.

Figure 15.

Dougong as connector.

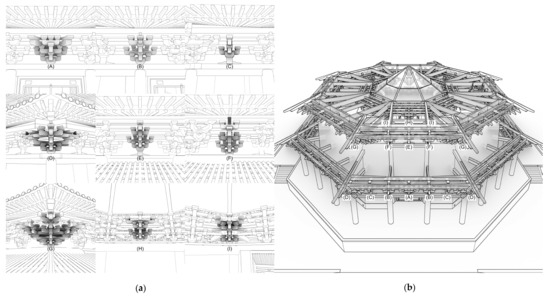

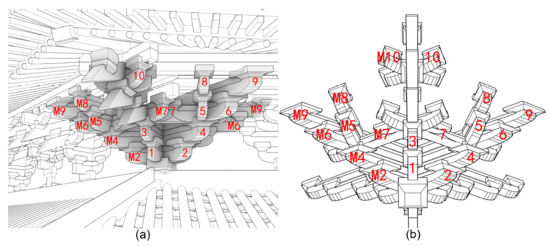

The lower the dougong sits, the greater the forces it takes. Other than the overhangs and eaves on the exterior layer of the columns, which only exist on the first floor, the lower the floor is, the deeper the overhangs and eaves are. Therefore, dougongs on lower floors are generally larger than those on upper floors. Dougongs in corners, compared to the others on the same level, have more complicated forms due to the number of different structural members they connect to. Additionally, in some cases, even for the dougongs that sit at the centrosymmetric positions, architects and builders incorporated various types of forms for aesthetic or practical reasons. Consequently, many types of dougongs were developed throughout the pagoda. All generated as part of this research project, the first floor includes nine of them. Their forms and relative locations on the pagoda can be seen in Figure 16.

Figure 16.

Nine types of dougong on the first floor: (a) each type of dougong; (b) their relative locations.

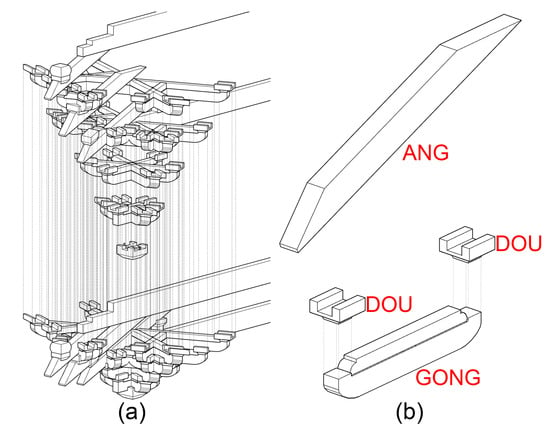

Dougongs in this pagoda include all different types of members; nevertheless, as Figure 17 demonstrates, most of the components of the dougongs can be categorized into three types, which are dou, gong, and ang. Dous are the square blocks that serve as the base for the gongs or the angs, gongs are the horizontal timber that provide the support for the upper layer, and angs are inclined braces that help distribute the weight of the overhangs and balance the structure.

Figure 17.

Components of dougongs: (a) exploded diagram of dougong; (b) dou, gong, and ang.

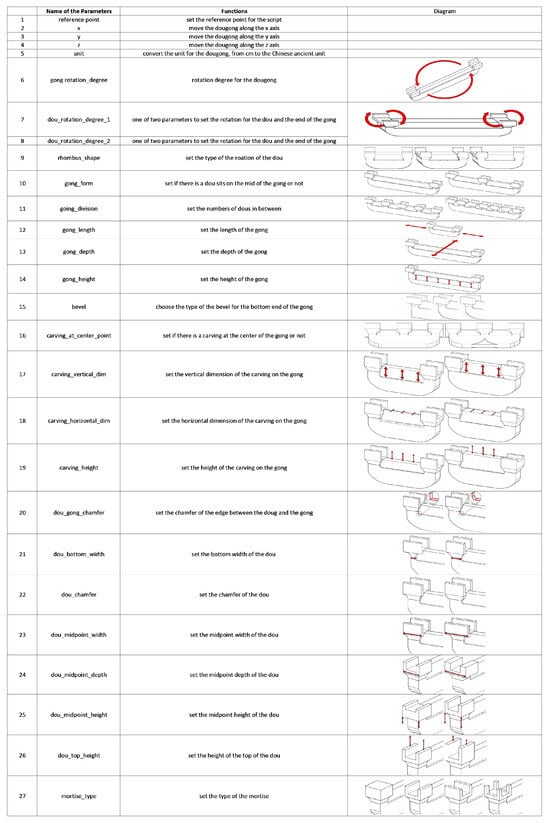

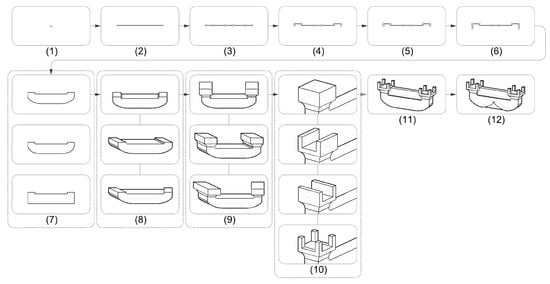

As mentioned, the dous and gongs are highly repetitive; at least on the same level, all of the gongs have the same height and depth, so a script was generated for the gongs and dous. As Figure 18 presents, this script includes 27 parameters; by adjusting those parameters, this script has the capability to generate most types of gongs and their corresponding dous throughout the whole pagoda. It is imperative to note that a dougong refers to a combination of gongs and dous, and sometimes includes ang(s). One gong with two or multiple dous sitting on top of it cannot be considered as a dougong, and will be referred to as a set of dous and a gong in this research.

Figure 18.

Variations of dous and gongs.

The logic behind this set of scripts is presented in Figure 19, and it can be split into 12 steps: (1) Set up the reference point in the 3D environment by using parameter 1. (2) Set up a horizontal line based on the location of the point, and then, set the parameters to control the x, y, and z values, i.e., the length, unit, and the rotation angle of the line, which are linked to parameters 2, 3, 4, 5, 6, and 12. (3) Divide the curve into segments, where certain portions of the segments are the center lines for the dous to sit on, and the length of those segments is controlled by parameter 21; parameters 10 and 11 are also linked to those segments, where one controls if there will be a dou on the center of the gong, while the other one controls the number of dous on the gong other than the ones that sit on the end and the center. (4) Raise the designated segments to a certain height, then make connections in between, and this height links to parameter 17. (5) Fillet certain corners on the curve based on parameters 10 and 11, and the radius of the fillet is linked to parameter 20. (6) Copy and move the endpoints of the line generated by step (2) along the z direction, and the magnitude of this movement is controlled by parameter 14. (7) Choose one of the three bevel types in parameter 15, then make connections and cuts between the existing lines, and the profile of the gong will be generated. (8) Parameter 9 controls if the two ends of the gong are extruded to the same direction or not, as shown in the flow diagram. There are three options. The first option is where both ends of the gong are extruded along the direction perpendicular to the surface generated from the profile of the gong. The second option is where both ends are extruded at an angle, and the angle is based on parameter 7 and 8. The last option is to have one end extrude in the direction perpendicular to the surface, while the other end is at an angle, which is also set by parameters 7 and 8 together. The magnitude of the extrusion is controlled by parameter 13. (9) Generate the dous based on the top surfaces on the gong; the dous are a cube sitting above those surfaces, and there are bevels in between. There is a series of parameters used to control all the dimensions of the dous, and these inputs are parameters 22, 23, 24, 25, and 26. (10) Set the type of the mortise for the dous using parameter 27; there are four options: “no mortise”, ”mortise along gong’s direction”, “mortise perpendicular to gong’s direction”, and “mortise in both directions”. (11) Set the carving piece on the gong, and parameters 18 and 19 are used to set its depth and height. (12) Choose to have an extra carving on the gong or not; controlled by parameter 16.

Figure 19.

Dougong generation: script logic flow diagram.

Parameter 1, which sets the reference points where the script of the dougongs starts from, are the points generated in the column grid, so all the elements are connected and integrated into the same framework. Putting them into the same file can link them together, which means that changes in the input for the column grid can affect the positions of the dougongs that sit on the top of the columns.

The script to generate the dous and gongs can be considered as a near-general solution for these members in the pagoda; for example, the diagrams for parameter 11 in Figure 18 present a type of gong that has more than three dous sitting on top of it. This type of gong can only be found in two types of dougong in the whole pagoda, which both have one gong and five dous, and is illustrated in Figure 20. Traditionally, these types of dous and gongs need their own modeling processes, but for this script, variations of a few inputs can generate this set of one gong and multiple dous.

Figure 20.

Gongs with 5 dous: (a) second floor exterior center dougongs; (b) third floor interior center dougong in 4 out 8 facades. directions.

Another example is the corner dougong on the first floor. As Figure 21 presents, there are 18 gongs in this dougong, and 16 of them have symmetrical pairs, and the pair of gongs are marked as “x” and “Mx”. Other than the basic inputs such as x, y, and z values, the other parameters play a big role in forming this set of dougongs. The gongs marked 2, 4, 6, and 9 in Figure 21 can be generated when parameter 9 is set to option 3. For gong 1, parameter 15 needs to be set to “none”. Meanwhile, gong 7 is the only one in this set that needs a carving on the center, which means parameter 16 needs to be set to true.

Figure 21.

First floor corner dougong: (a) front perspective view; (b) bottom perspective view.

The detailed data for generating all the dous and gongs can be found in Table 3. Except for the angs and a few dous sitting on top of the angs, all members can be generated by the script. This process can not only streamline the modeling process and simplify the updating process, but can also be used to train future deep learning-based models to generate dougongs.

Table 3.

Parameters for dous and gongs of the first floor corner dougong.

3.2.5. Modeling of Other Structural Members

Among the other types of structural members, such as the base, earth walls, beams, tie beams, and hip rafters, some are suitable examples for applying parametric modeling techniques. For example, tie beams can be easily generated with Grasshopper, but due to their mundane logic and process, they will not be described in this research. Other members, such as the base and earth walls, are not ideal examples for using parametric tools due to their lack of repetitiveness and geometric complexity, and were modeled manually in Rhinoceros.

3.2.6. Modeling of Non-Structural Members

For the non-structural members in this pagoda, such as the doors, windows, and stairs, many members did not involve a parametric design process due to their lack of repetition where parametric tools are not the optimal solution for the modeling process in terms of efficiency. Meanwhile, the modeling process for these members is not the focus of this study, so it will not be heavily discussed here. However, these members are all included in the 3D model attached in the Data Availability Statement.

Some other important elements are the roof tiles and railings for the balcony. Although parametric tools were heavily involved in their construction, the process did not include complex logic. Therefore, these will also not be discussed here. Nonetheless, these members are also included in the attached 3D file.

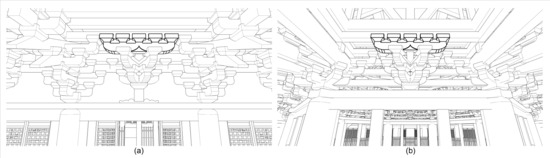

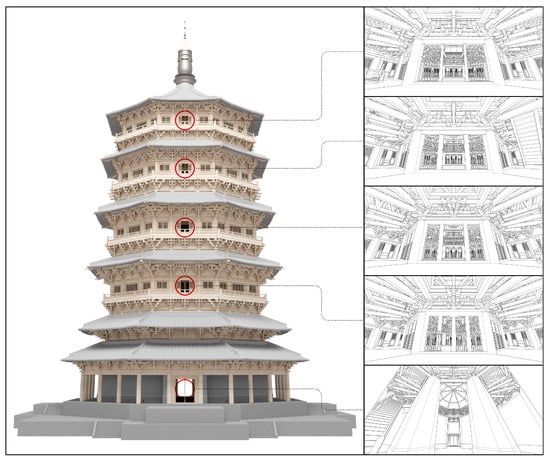

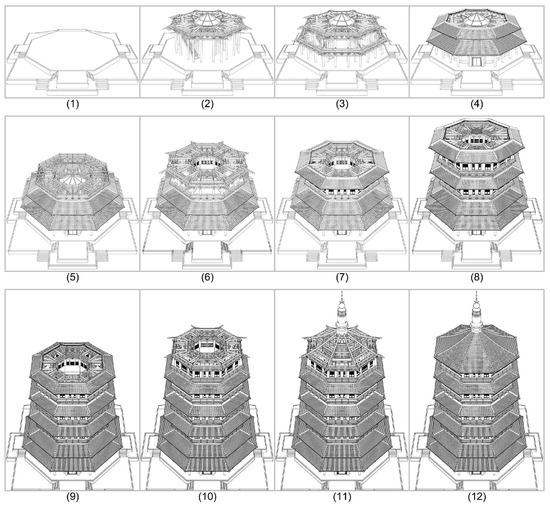

4. Results

The left part of Figure 22 shows the exterior appearance of the digital model, while the right part includes the views on different floors within the pagoda. An Unreal Engine-based game is under development for this project, which aims to provide users a real immersive experience to explore the pagoda, and the demo of the game can be found in the Data Availability Statement. Figure 23 is a screenshot of the game that illustrates the model’s level of detail and the complexity of the pagoda’s structure. With the detailed model that has been produced during this research, a series of diagrams, such as Figure 24, and videos have been created to simulate the manufacturing, installation, and construction process, which promotes the understanding of the thought process and methods behind the design and construction process.

Figure 22.

Digital model of the Yingxian Wooden Pagoda.

Figure 23.

The rendering of the Yingxian Wooden Pagoda.

Figure 24.

Construction process simulation.

At the same time, the construction simulation process also offers a great opportunity for researchers and engineers to study the pagoda in detail, which can help them to be prepared for the future preservation mission.

5. Discussion

5.1. Tapering Form

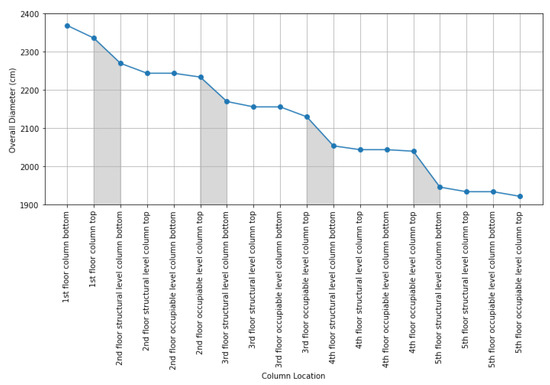

The second column of data in Table 1 refers to the diameters of the regular octagons at the different levels. Figure 25 was generated based on the first two columns of data without including the buttress level, yet it still suggests that the form of the pagoda is tapered. Tapered forms can not only increase the lateral stiffness of the structure, but also decrease the wind loads applied to the buildings [14]. Both of these advantages can naturally improve structural efficiency and increase the lifespan of the structure. As shown in Figure 25, in this pagoda, the reduction in the overall footprint of each floor is not a linear change. The gray-colored portions represent relatively greater reductions, which result from applying winding connections. The rest of the dimensional changes are achieved by leaning the columns, which are more subtle than the ones using winding connections.

Figure 25.

Overall dimensions within different levels.

5.2. Leaning Columns

As seen in many examples of ancient Chinese architecture, the traditional method of achieving a tapering form dictates that the exterior layer of columns within a given structure should lean toward the inside of the building. The amount at which each column leans is based on the height of the columns. More specifically, according to the Song Dynasty treatise by Jie Li, Yingzao Fashi [15], which was written in the late 11th or early 12th century CE, the columns along the front facade of the building should lean toward the inside, perpendicular to the line defined by the facade, with the ratio of the lean distance to the height being 1/100. Similarly, the ratio that applies to the side columns is 8/1000. The columns in the corners should lean toward both directions in correspondence with the required ratio along each direction. This method of having the columns lean towards the center of the building to achieve a tapering form for a simple four-sided structure can be seen in Figure 26.

Figure 26.

Illustrated instructions for leaning columns from the Song Dynasty architectural treatise Yingzao Fashi [15].

Nevertheless, Yingzao Fashi [15] can only be used as a reference to understand this pagoda, since it was published circa 1100 CE and the pagoda was finished in 1056 CE. Therefore, although there are many overlaps between the instructions from the book and the construction methods that can be identified in the pagoda, several noteworthy differences still remain. For instance, according to the survey from Chen, other than the corner columns, many of the exterior layer columns along the side also lean in two directions, which differs from the instructions in Li’s book. The two-directional leaning prototype is a challenge for the construction process, since measuring two directions for the column placement process is much more complicated than measuring one direction.

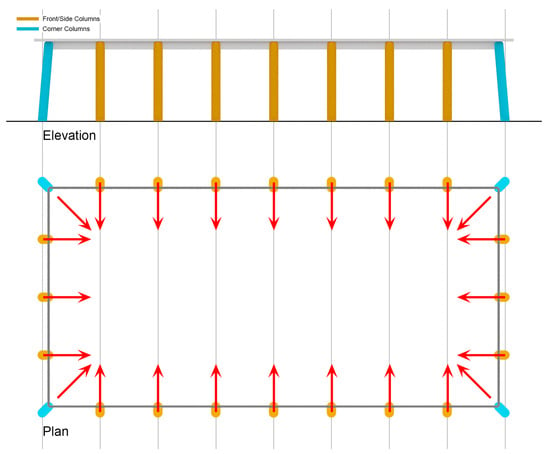

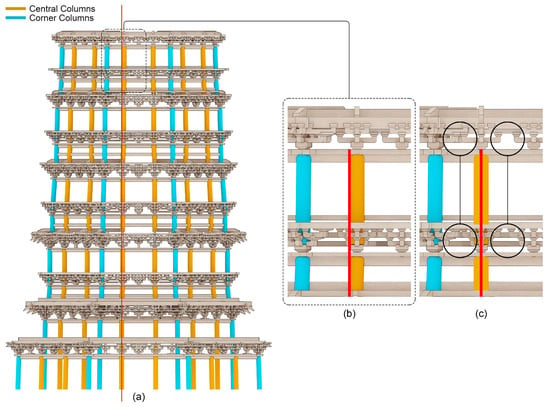

As previously mentioned, other than the interior and exterior layers of columns on the first floor, each facade has four columns: two corner columns, which are shared with the neighboring facades; and two side columns, which are referred to as the central columns. As depicted in Figure 27, the corner columns of the exterior layer simply lean toward the center of the floor plan, but the central columns point both toward each other and inward, and this type of leaning method is referred to as two-directional leaning in this research. According to column four of Table 4 above, the distances between the top and the bottom end of each pair of central columns vary among different floors, and the difference between the distances is defined as the leaning amount, which is calculated by subtracting the bottom end’s distance from the top end’s distance, shown in Figure 27a; the leaning amounts are presented in the fourth column of Table 4. It is worth nothing that the distance between central columns for the first floor column top and the second floor structural level column bottom should be equal, since there are inserting connections applied between the columns, as shown in Figure 8. However, the measurements show a 20 cm difference. For the same type of connection between the other floors, the distances for the pairs of columns are either equal or approximately equal, with the differences varying from 0 to 6 cm. The second floor occupiable level column top and third floor structural level column bottom are 417 cm and 417 cm. The third floor occupiable level column top and fourth floor structural level column bottom are 381 cm and 380 cm. The fourth floor occupiable level column top and fifth floor structural level column bottom are 376 cm and 370 cm. The reason behind this illogical phenomenon may be related to the fact that the second floor has great damage and torsion. Therefore, it is reasonable to assume that the distance between central columns at the first floor column top and second floor structural level column bottom should be equal, and the leaning amount, which is –20 cm, should be distributed to the difference between the second floor structural level column bottom and second floor structural level column top. The updated data are shown in parentheses in Table 4.

Figure 27.

Two-directional leaning method: (a) perspective view of the structural level, (b) plan view of the structural level, and (c) elevation of the exterior layer of structure.

Table 4.

Original data of structural dimensions from Chen’s survey [1].

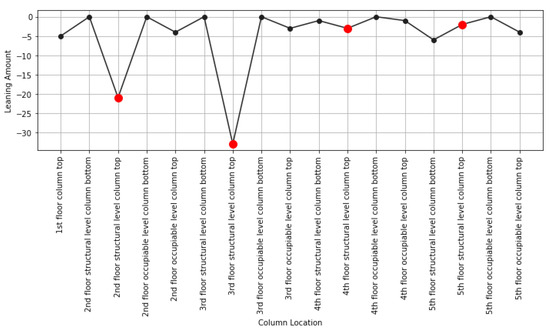

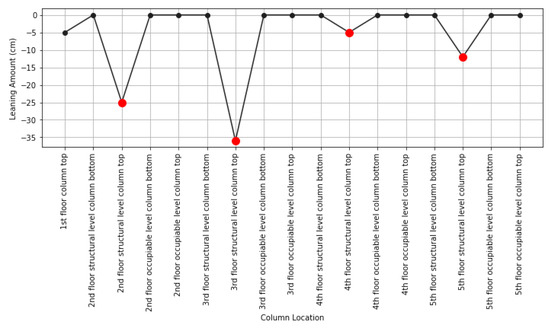

Figure 28 represents how the leaning amounts along the facade direction have been assigned quantitatively. This figure shows the changes in leaning amount between different floors, and the leaning amounts among the structural levels are marked by red dots. The two outliers both occurred on the structural levels, which reveals that the engineers at the time intentionally let most of the two-directional leaning of the central columns occur inside the structural floors.

Figure 28.

Original data of leaning amounts within different levels.

As Figure 29 illustrates, one reason for implementing the two-directional leaning column system mainly on structural levels is to accommodate space for the dougong structure of the upper floors. This system permits a one-directional leaning column arrangement for occupiable levels. Simultaneously, since the structural levels are obscured by the pagoda’s eaves of each floor to outside observers, only the occupiable levels’ columns can be seen from the outside, and those columns that lean in one direction provide more visual consistency. From a structural perspective, as depicted in Figure 29c, for the central columns, the absence of leaning towards each other would result in varying gaps between structural members, as circled, leading to unevenly distributed loads along the tie beams, a scenario modern structural engineers strive to avoid. In summary, the two-directional leaning column system preserves space for upper-level structural members, ensures visual coherence in the overall structure, and facilitates even load distribution.

Figure 29.

Reasons behind the two-directional leaning column system: (a) elevation of the exterior layer of structure, (b) alignment of the columns when two-directional leaning column system is applied, and (c) alignment of the columns when one-directional leaning column system is applied.

Although the intention was clear, the data from Chen’s book still indicate that the columns from the occupiable levels lean towards each other as well. Such data can be seen in Table 4, where the red-colored data pairs represent the distance between the central column’s top and bottom in the occupiable levels, and the blue-colored data indicate the leaning amount of each pair. These differences can be considered construction tolerances or caused by the deformation process, since this structure was finished more than 900 years ago, and those leaning amounts are all less than 5 cm.

Based on all of those inferences and analysis, an ideal and optimized set of dimensions has been generated and presented in Table 5. All the data that have been modified are also color-coded, with the main purpose of limiting the application of the two-directional leaning system to the structural levels only. This decreases the construction labor costs due to it being a simpler shape to measure.

Table 5.

Optimized data of structural dimensions.

Drawing from this optimized set of data, Figure 30 indicates the leaning amount, aside from the first floor, which has been covered by the earth wall, with the leaning amount equal to zero among all the occupiable levels. Non-zero leaning amounts only appear among the structural levels, which are marked by red dots. This means all of the two-directional-leaning central columns are located in structural levels.

Figure 30.

Optimized data of leaning amounts within different levels.

5.3. Contributions to the Existing Literature

Since the publication of Chen’s book, many physical models of the pagoda have been built; however, existing physical models are hard to disassemble for both educational and research purposes and cannot be used with structure simulation software. In recent decades, many researchers have explored digital tools to build 3D models of this pagoda; most of these models lack sufficient details, while the relatively comprehensive ones are not available to the general public. The 3D model attached to this paper is the first one that is available to the public and contains a sufficient amount of information.

5.4. Limitations

As previously presented, rather than honestly reflecting the current condition of the pagoda, this model demonstrates the ideal condition of the pagoda. This means that many of the measurements may differ greatly from the actual dimensions, and such differences need to be checked based on onsite measurements.

Although the model developed in this research is detailed enough for the purposes of video making and game development, the lack of exploration of mortise and tenon joints remains. For example, in all the dougongs, many wooden members meet at specific points, and the details of those specific joints need to be scanned with X-rays, which is non-invasive, or disassembled to be revealed. Due to the limitations of this research, such data cannot be obtained. The application of parametric tools can also be helpful in the process of creating the mortise and tenon joints for the dougongs, but more information is needed about the related details before making a new algorithm. For future restoration processes, this information needs to be added to the digital model to create a more detailed version.

Meanwhile, the attached 3D model was based on interpretations of reference images and drawings; many mistakes and inaccuracies may exist, so improvements are needed in future exploration. The conclusions about the measurements of the column grid previously mentioned were discovered during the modeling process and were not used to modify the model. Additionally, the development and improvement of the algorithm took years, and most of the dougongs were built using early versions of the generation algorithm, which is not capable of generating the correct versions of the bevel for the bottom end of the gong, as presented in Figure 14, parameter 15. Such known discrepancies or mistakes do not affect the usage of this model for general education, video making, or even structural analysis purposes since a lot of detailed information has been embedded into this model. However, for restoration or historical heritage information preservation purposes, future endeavors are needed to improve the quality of the model.

6. Conclusions

The primary goal of this research was simple: to build a digital model of the Yingxian Wooden Pagoda. Nevertheless, a series of challenges were encountered during the process, which led to a series of questions as a result. Before building the model, the columns’ grid had to be determined, but before determining the columns’ grid layout, the patterns of the leaning columns had to be identified, and before identifying the pattern of the column grid, the data from the original survey had to be processed and analyzed. This process of working backwards helped to answer many questions regarding this pagoda, and ultimately the answers revealed insights into the original design process and construction methods. For instance, as discussed in the previous section, the two-directional leaning column system, despite the challenges it presents and the precision it demands, has been effectively utilized in the structure, which shows the expertise of the designers and the engineers at the time. Additionally, the concept of modularization that can be found in the dimensions of the structural members also demonstrates the advanced development of production and assembly processes that people mastered at the time of the original construction. Therefore, the application of the parametric tools made logical sense, and throughout this project has been proven to be effective and efficient, building a bridge between the old and new, and indicating the powerful tools that the modern generation has that can be valuable to the preservation of historical heritage sites.

Author Contributions

Conceptualization, D.W.; methodology, D.W. and S.Y.L.; software, D.W. and R.L.; validation, D.W., S.Y.L. and R.L.; formal analysis, D.W.; investigation, D.W.; resources, D.W.; data curation, D.W.; writing—original draft preparation, D.W.; writing—review and editing, D.W., S.Y.L., J.H. and A.W.; visualization, D.W., R.L. and A.W.; supervision, D.W. and J.H.; project administration, D.W.; funding acquisition, D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by North Carolina State University’s summer research fellowship.

Data Availability Statement

All the Grasshopper and Rhinoceros files were created by the corresponding author. Key files are available at: https://drive.google.com/drive/folders/1OYKjZZPXLcOWRyCKTPBmz3EVBWbQQnDU?usp=sharing. For those unable to access this link, please email the corresponding author for the file(s). Commercial use of these files is strictly prohibited. All other uses, including academic purposes, require proper citation.

Acknowledgments

This paper was edited based on the thesis written by the corresponding author for a course during his time at the Yale School of Architecture. The corresponding author expresses his gratitude to the instructors of the course, Sunil Bald and Aniket Shahane. The corresponding author also expresses his gratitude to Chao Zhang, Heng Zhou, and Guang Zhu for their invaluable resources and expertise in Chinese architecture. He also thanks Nick Geller and Jackson Kiel for their assistance in proofreading this manuscript. Many thanks to the late Mingda Chen; his extraordinary work laid the foundation for this paper during extremely challenging times.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, M. The Yingxian Timber Pagoda, 2nd ed.; Cultural Relics Press: Beijing, China, 1980. [Google Scholar]

- Liu, L. Yingxian Wooden Pagoda. Photograph, 8 June 2024. [Google Scholar]

- Chen, Z.; Zhu, E.; Lam, F.; Pan, J. Structural performance of Dou-Gong brackets of Yingxian Wood Pagoda under vertical load–An experimental study. Eng. Struct. 2014, 80, 274–288. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0141029614005501 (accessed on 1 May 2024). [CrossRef]

- Sha, B.; Xie, L.; Yong, X.; Li, A. An experimental study of the combined hysteretic behavior of dougong and upper frame in Yingxian Wood Pagoda. Constr. Build. Mater. 2021, 305, 124723. Available online: https://www.sciencedirect.com/science/article/pii/S0950061821024788 (accessed on 1 May 2024). [CrossRef]

- Deng, Y.; Li, Y.; Li, A. Seismic safety assessments of historical timber buildings using updated finite element models: Case study of Yingxian wooden pagoda, China. J. Build. Eng. 2023, 63, 105454. Available online: https://www.sciencedirect.com/science/article/pii/S2352710222014607 (accessed on 1 May 2024). [CrossRef]

- Guo, M.; Sun, M.; Pan, D.; Wang, G.; Zhou, Y.; Yan, B.; Fu, Z. High-precision deformation analysis of Yingxian wooden pagoda based on UAV image and terrestrial LiDAR point cloud. Herit. Sci. 2023, 11, 1. [Google Scholar] [CrossRef]

- Lai, D.S.; Leung, A.K.; Chan, D.; Ching, S.H. Cultural heritage preservation using new media methods: Yingxian Wooden Pagoda, China. Virtual Archaeol. Rev. 2019, 10, 103–115. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, A.; Xie, L.; Hou, M.; Qi, Y.; Liu, H. Development and Application of an Intelligent Modeling Method for Ancient Wooden Architecture. ISPRS Int. J. Geo-Inf. 2020, 9, 167. Available online: https://www.mdpi.com/2220-9964/9/3/167 (accessed on 1 May 2024). [CrossRef]

- Yuan, J.; Peng, S.; Shi, Y.; Wang, J. Research on restoration scheme of Ying-Xian Timber Pagoda. In Structural Analysis of Historical Constructions: Anamnesis, Diagnosis, Therapy, Controls; Taylor & Francis Group: London, UK, 2016. [Google Scholar]

- Hou, W.; Wang, L.; Yong, X. Yingxian Wood Tower China Protection Research; Cultural Relics Press: Beijing, China, 2016. [Google Scholar]

- Wang, S. Opinions on the Elevation and Restoration Plan for the Conservation Project of the Yingxian Wooden Pagoda in Shanxi. Tradit. Chin. Archit. Gard. Technol. 2006, 2, 10. [Google Scholar]

- Ma, B. How Should the Yingxian Wooden Pagoda in Shanxi be Repaired? Tradit. Chin. Archit. Gard. Technol. 2006, 2, 3. [Google Scholar]

- Liang, S. Chinese Ancient Buildings Survey Report; Joint Publishing: Beijing, China, 2000. [Google Scholar]

- Moon, K. Comparative Evaluation of Structural Systems for Tapered Tall Buildings. Buildings 2018, 8, 108. [Google Scholar] [CrossRef]

- Li, J. Architecture Methods & Rules, 1st ed.; Chinese Bookstore Press: Beijing, China, 1991. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).