Experimental Study on Axial Compressive Performance of Recycled Steel Fiber Reinforced Concrete Short Columns with Steel Pipes

Abstract

:1. Introduction

2. General Situation of Experiment

2.1. Material Properties

2.1.1. Steel Pipe

2.1.2. Recycled Steel Fibers

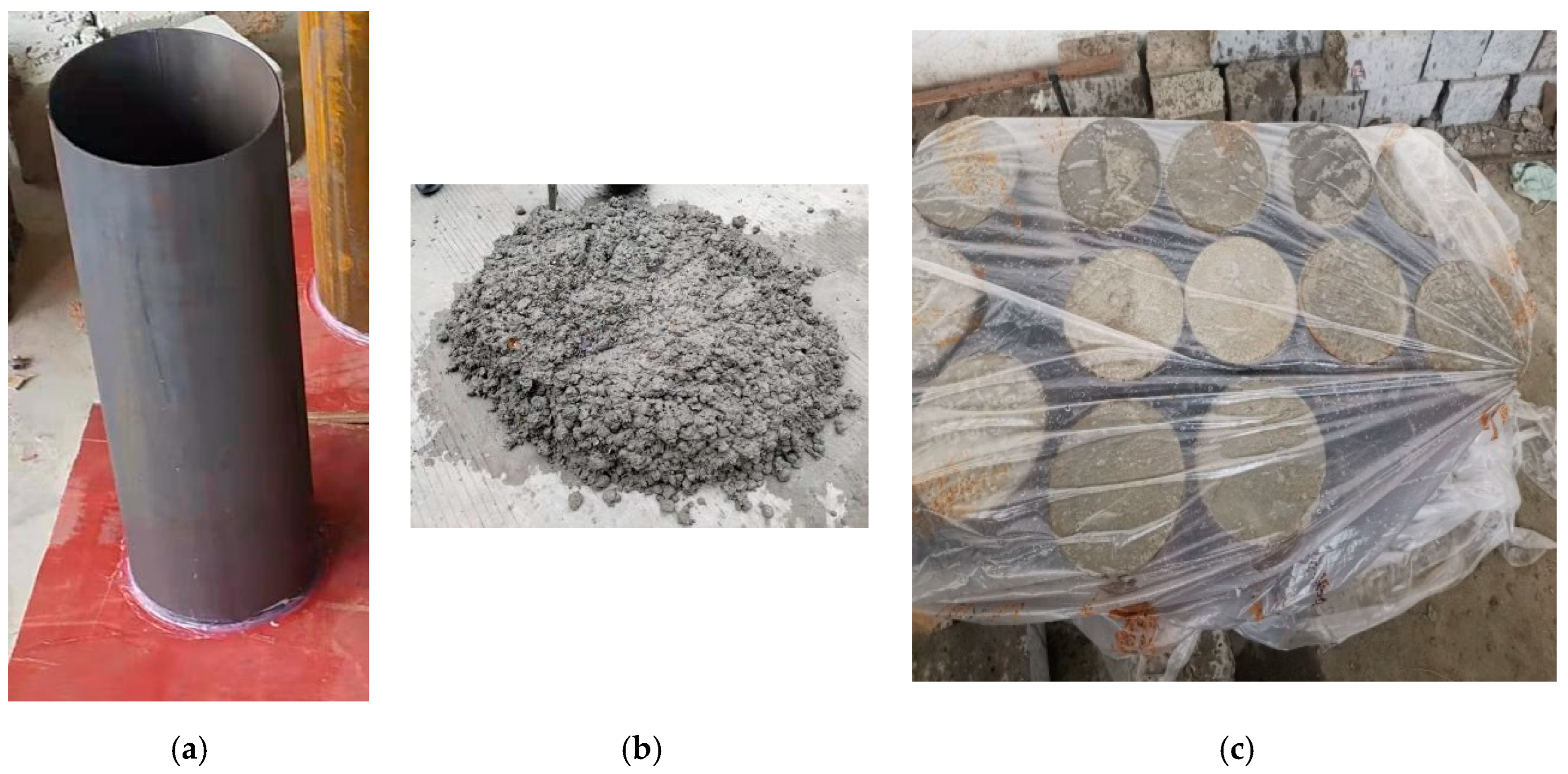

2.1.3. Concrete

2.2. Test Piece Design and Production

2.3. Test Method

2.3.1. Loading Equipment and Measurement Point Layout

2.3.2. Loading Method

3. Result Analysis and Discussion

3.1. Deformation Process and Failure Mode

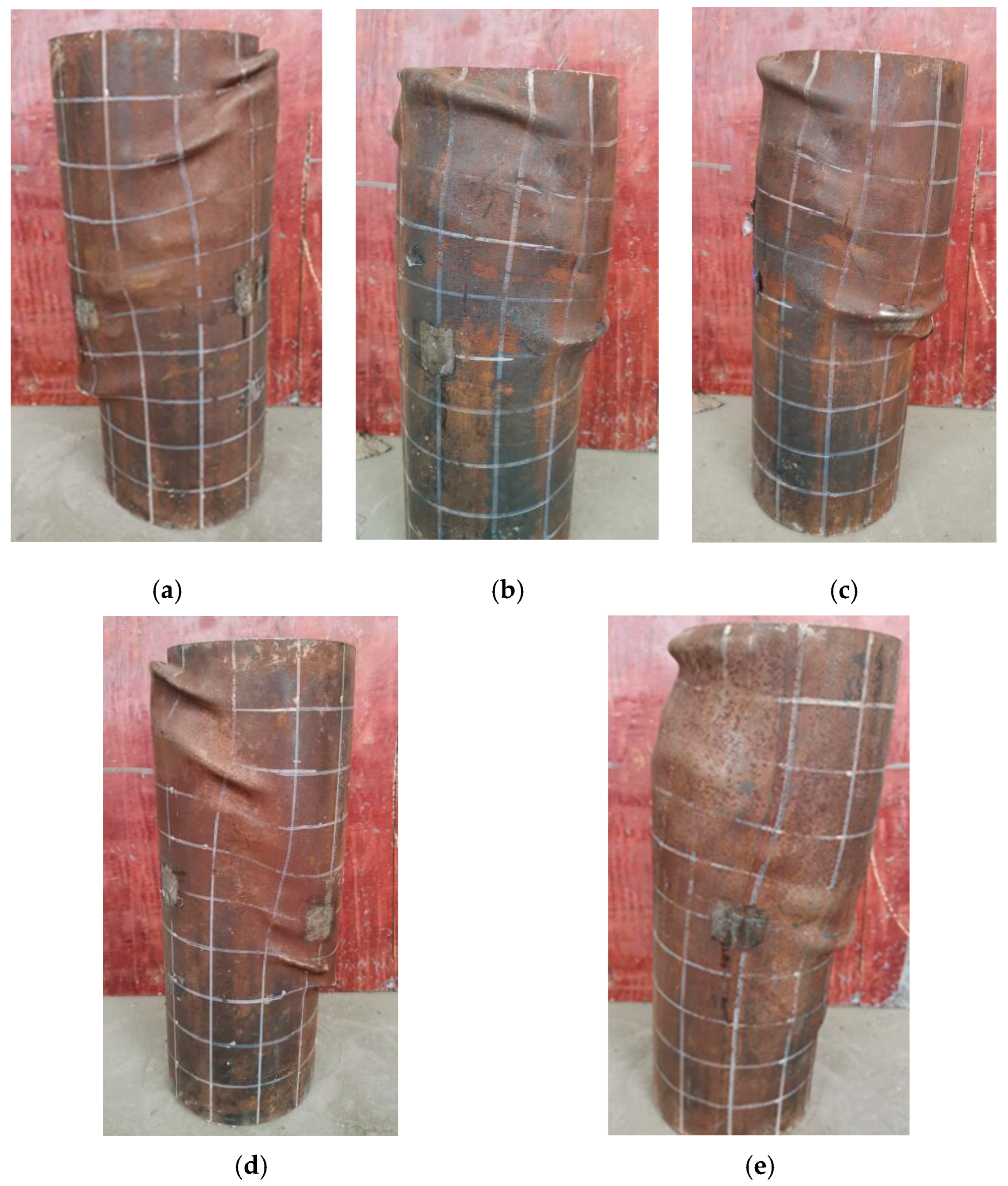

3.1.1. C30-2 Series Specimens

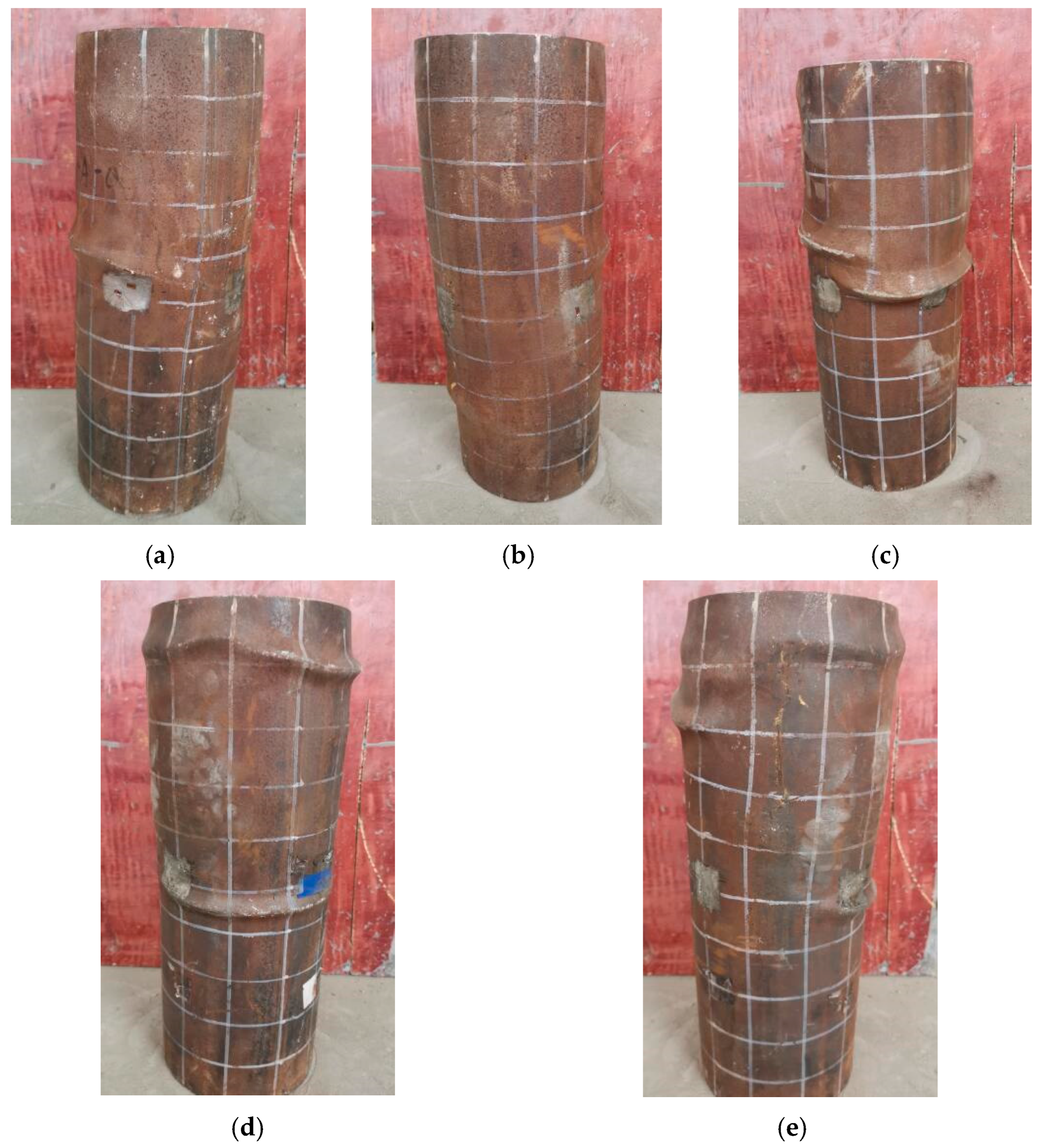

3.1.2. C30-3 Series Specimens

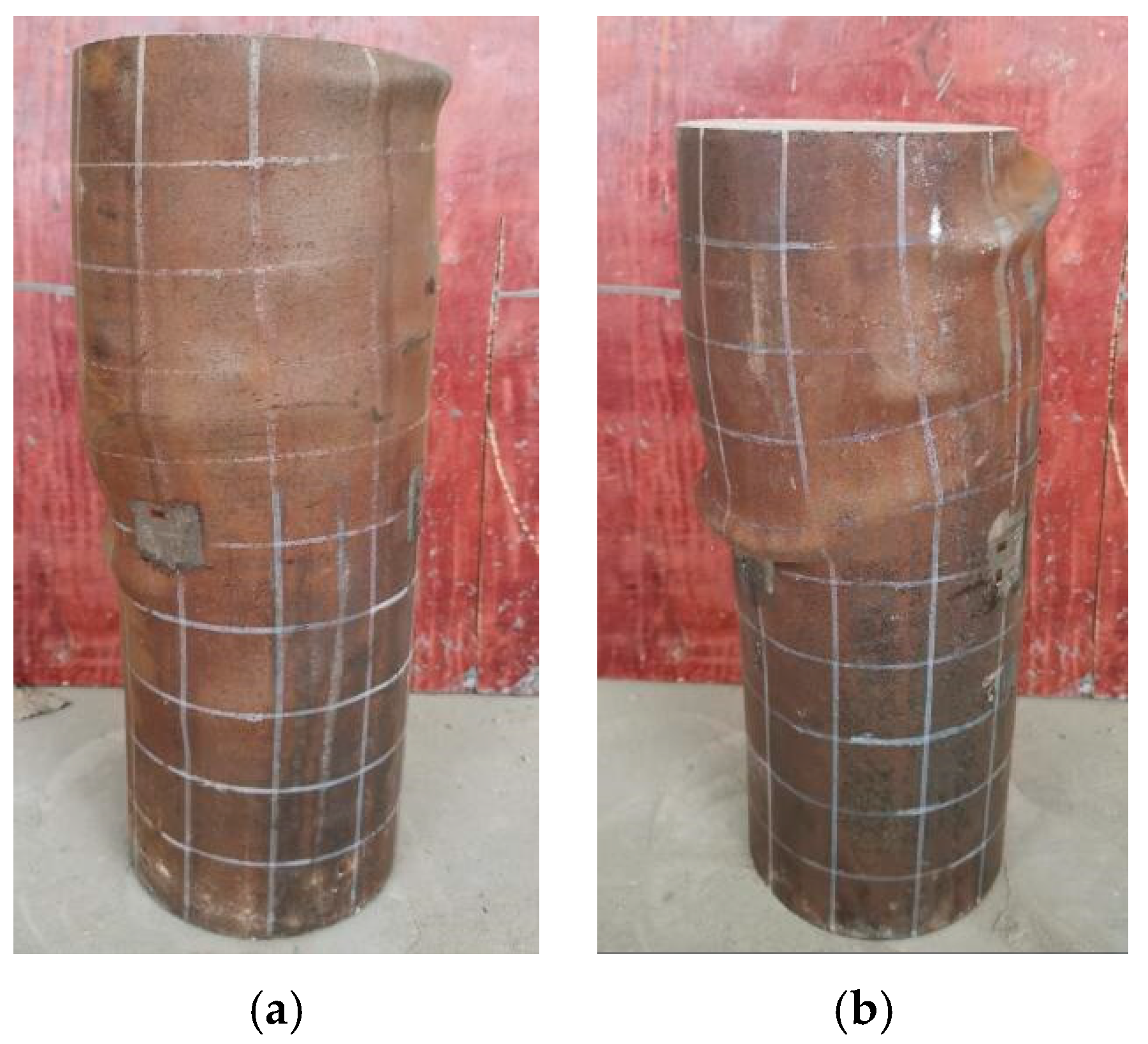

3.1.3. C50-2 Series Specimens

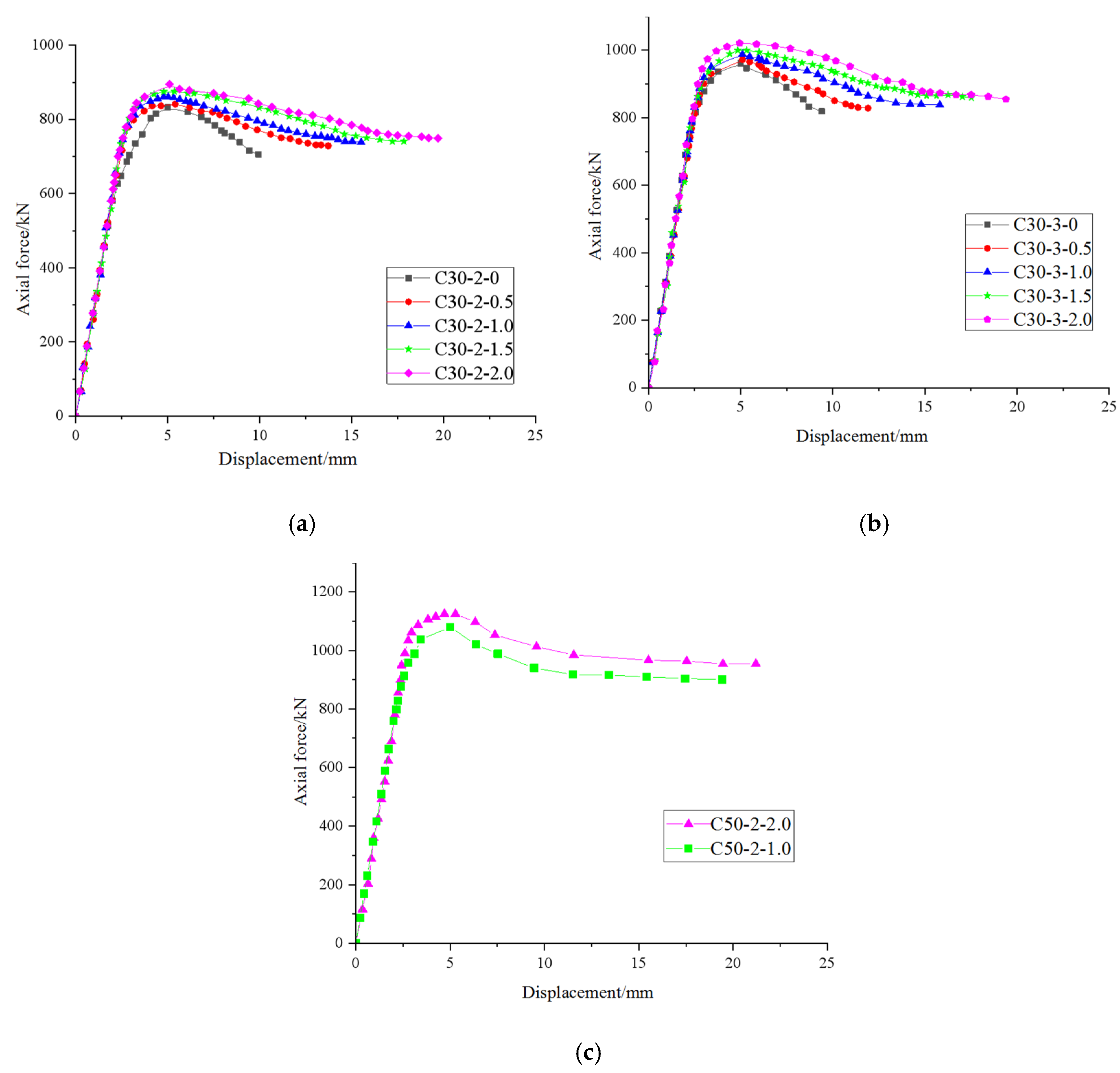

3.2. Load Deformation Curve

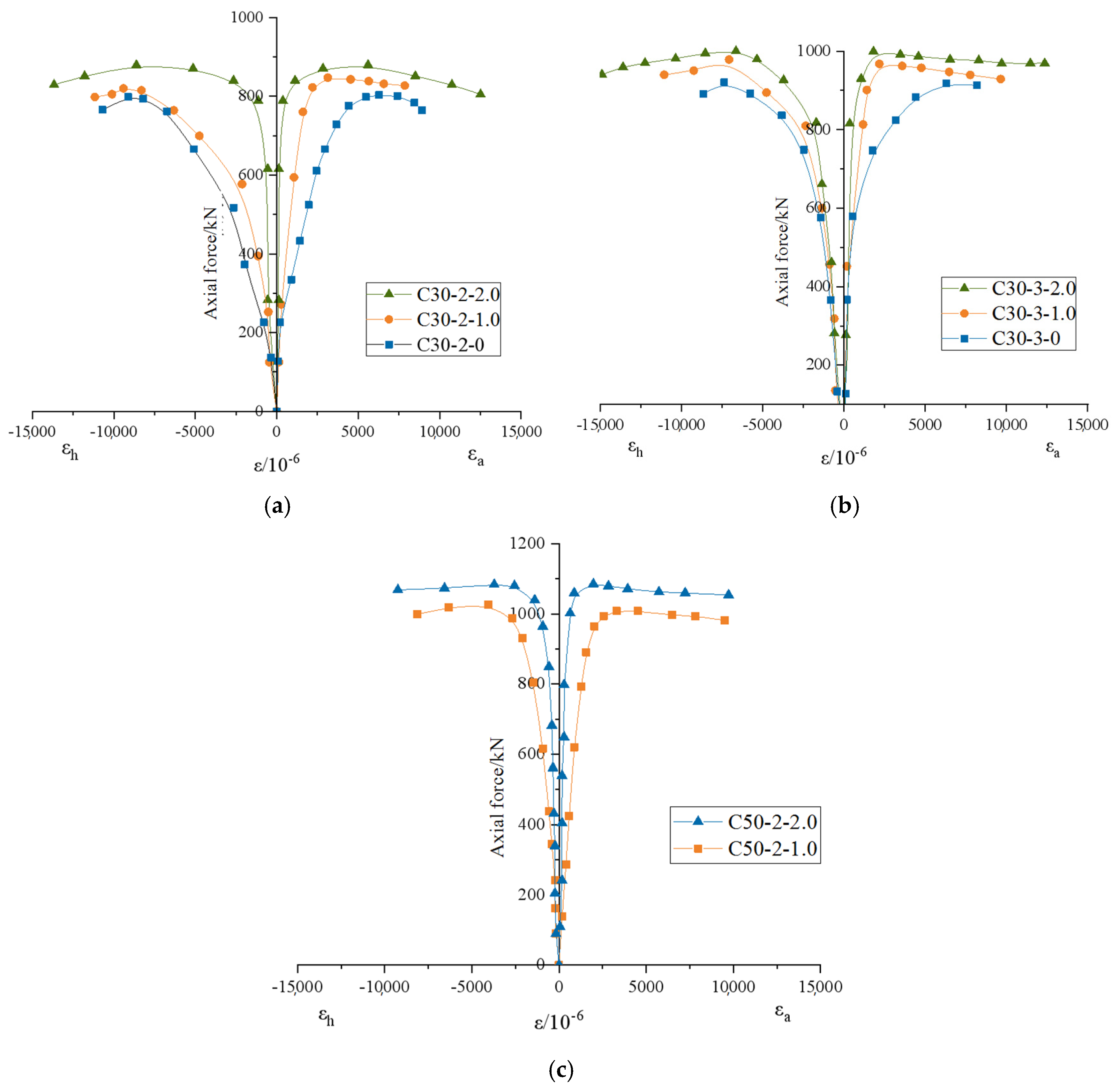

3.3. Load Strain Relationship

3.4. Lateral Deformation Coefficient

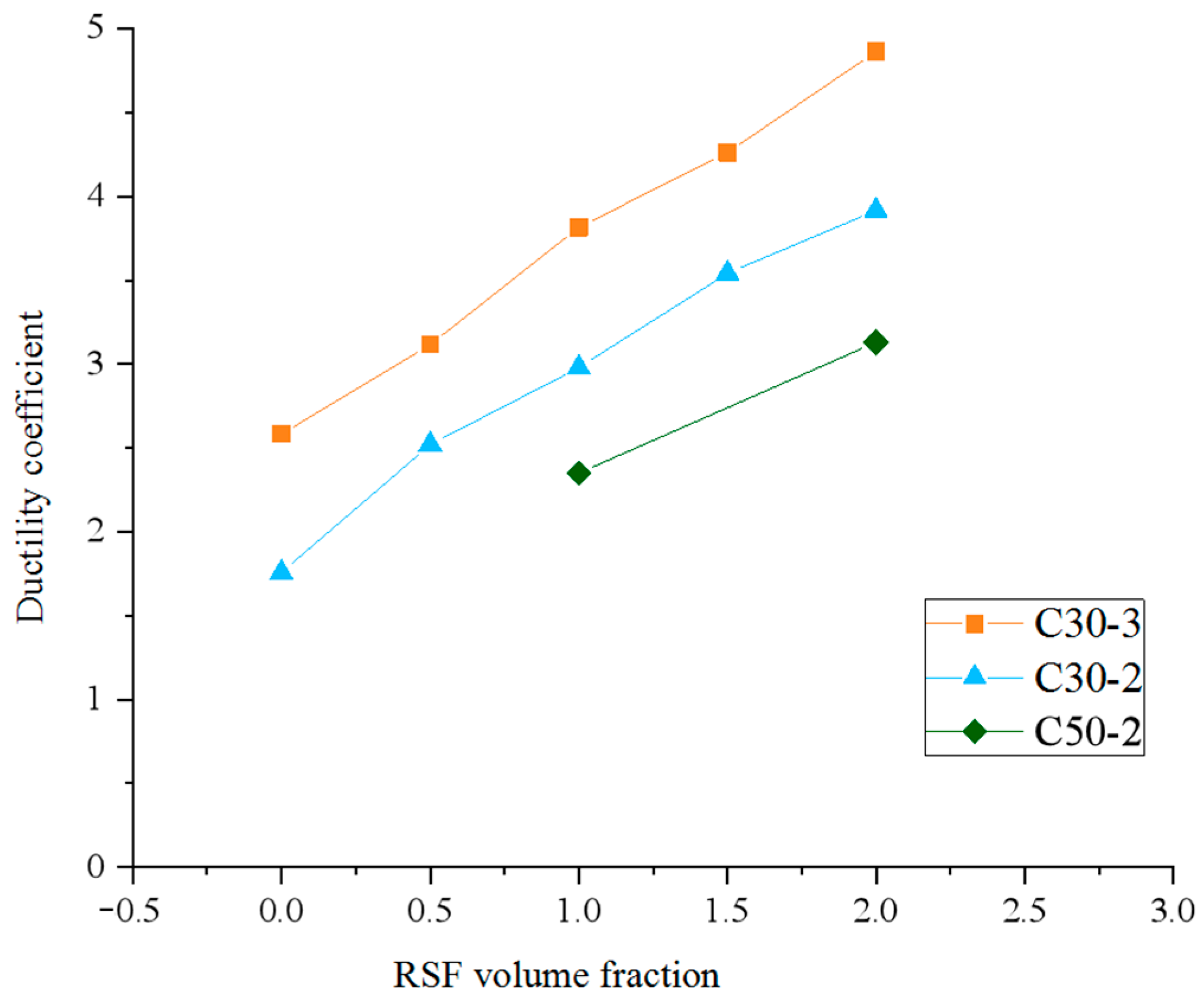

3.5. Ductility Performance

3.6. Combined Elastic Modulus

3.7. Axial Compressive Bearing Capacity

3.7.1. Factors Affecting Axial Compressive Bearing Capacity

3.7.2. Calculation Method for Axial Compressive Bearing Capacity

4. Conclusions

- (1)

- The influence of steel content on the failure mode of STRSFRCSC is significant. When the steel content is 2.84%, the specimens are subjected to shear failure. When the steel content is 4.24%, the specimens are subjected to waist drum failure, which tends to transition to shear failure. The influence of concrete strength grade and RSF content on the failure mode of specimens is not significant.

- (2)

- The higher the steel content and concrete strength grade, the higher is the ultimate bearing capacity and composite elastic modulus of the specimens. The optimal RSF is 2%, and the maximum increase in the bearing capacity of STRSFRCSCs is 13.4%. As the RSF content increases, the peak strain during the loading process of the specimens decreases and the combined elastic modulus increases.

- (3)

- The addition of RSF significantly improves ductility. As the volume fraction of RSF increases, the ductility coefficient of the specimens gradually increases. As the steel content increases, its bearing capacity and displacement ductility coefficient both increase. As the strength grade of concrete increases, the bearing capacity of the column increases, but the displacement ductility coefficient shows a decreasing trend.

- (4)

- On the basis of existing research results and combined with experimental data, the influence of RSF volume fraction on the bearing capacity of specimens was considered, and the calculation formula for the axial compressive bearing capacity of STRSFRCSCs was obtained through regression analysis. By comparing and analyzing the experimental data, it is shown that the calculated results of this formula are in good agreement with the experimental results, with a low degree of dispersion and a concise calculation method, which can effectively predict the ultimate bearing capacity of STRSFRCSCs under axial compression.

- (5)

- This study only conducted axial compression tests on STRSFRCSCs, and a comparison of bearing capacity with similar components made of native steel fibers has not been conducted yet. Compression bending tests, bending tests, and shear tests of STRSFRCSCs have not yet been carried out, and these are all future research directions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.Z.; Zhang, S.M.; Lu, W.; Li, J. Axial compressive behavior of steel-tube-confined concrete-filled-steel-tubes. Thin-Walled Struct. 2022, 181, 110138. [Google Scholar] [CrossRef]

- Zhu, T.; Liang, H.J.; Lu, Y.Y.; Li, W.J.; Zhang, H. Axial behaviour of slender concrete-filled steel tube square columns strengthened with square concrete-filled steel tube jackets. Adv. Struct. Eng. 2020, 23, 1074–1086. [Google Scholar] [CrossRef]

- Khalifa, M.; Shaat, A.; Ibrahim, S. Optimum concrete filling ratio for partially filled noncompact steel tubes. Thin-Walled Struct. 2019, 134, 159–173. [Google Scholar] [CrossRef]

- Zhang, T.H.; Wang, Y.H.; Zhai, X.M.; Zhi, X.D.; Zhou, H.Y.; Yu, X. Impact response of stainless steel tube locally-strengthened by concrete-filled steel tube. Int. J. Impact Eng. 2024, 186, 104895. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Investigating concrete durability: The impact of natural pozzolan as a partial substitute for microsilica in concrete mixtures. Constr. Build. Mater. 2024, 419, 135491. [Google Scholar] [CrossRef]

- Alatshan, F.; Osman, S.A.; Hamid, R.; Mashiri, F. Stiffened concrete-filled steel tubes: A systematic review. Thin-Walled Struct. 2018, 148, 106590. [Google Scholar] [CrossRef]

- Abed, F.H.; Abdelmageed, Y.I.; Ilgun, A.K. Flexural response of concrete-filled seamless steel tubes. J. Constr. Steel Res. 2021, 149, 53–63. [Google Scholar] [CrossRef]

- Zheng, J.L.; Wang, J.J. Concrete-filled steel tube arch bridges in China. Engineering 2018, 4, 143–155. [Google Scholar] [CrossRef]

- Ahmad, S.; Kumar, A.; Kumar, K. Axial performance of GGBFS concrete filled steel tubes. Structures 2020, 23, 539–550. [Google Scholar] [CrossRef]

- Ahmad, H.S.; Abendeh, R.M.; Hunaiti, Y.M. Evaluation of concrete-steel interfaces in steel tubes filled with chipped rubber-concrete. Proc. Inst. Civ. Eng.-Struct. Build. 2023, 176, 91–113. [Google Scholar] [CrossRef]

- Xu, X.; Cheng, R.; Yang, P.; Liu, R.Q. Cyclic Loading Test for Concrete-Filled U-Shaped Steel Beam to Concrete-Filled Steel Tube Column Connections. Int. J. Steel Struct. 2020, 20, 1859–1870. [Google Scholar] [CrossRef]

- Shen, P.L.; Lu, J.X.; Zheng, H.B.; Lu, L.N.; Wang, F.Z.; He, Y.J.; Hu, S.G. Expansive ultra-high performance concrete for concrete-filled steel tube applications. Cem. Concr. Compos. 2020, 114, 103813. [Google Scholar] [CrossRef]

- Ding, C.T.; Pan, X.B.; Bai, Y.; Shi, G. Prefabricated connection for steel beam and concrete-filled steel tube column. J. Constr. Steel Res. 2019, 162, 105751. [Google Scholar] [CrossRef]

- Elghazouli, A.Y.; Mujdeci, A.; Bompa, D.V.; Guo, Y.T. Experimental cyclic response of rubberised concrete-filled steel tubes. J. Constr. Steel Res. 2022, 199, 107622. [Google Scholar] [CrossRef]

- Krishan, A.L.; Astafeva, M.A.; Chernyshova, E.P. Strength Calculation of Short Concrete-filled Steel Tube Columns. Int. J. Concr. Struct. Mater. 2019, 12, 84. [Google Scholar] [CrossRef]

- Li, W.T.; Zha, X.X.; Wang, H.Y. A unified formulation for axial compression of steel tube-confined concrete and concrete-filled steel tube stub columns. Structures 2023, 58, 105319. [Google Scholar] [CrossRef]

- Kanishchev, R.; Kvocak, V. Local buckling of rectangular steel tubes filled with concrete. Steel Compos. Struct. 2019, 31, 201–216. [Google Scholar]

- Ekmekyapar, T.; Al-Eliwi, B.J.M. Concrete filled double circular steel tube (CFDCST) stub columns. Eng. Struct. 2017, 135, 68–80. [Google Scholar] [CrossRef]

- Mobaraki, B.; Ma, H.Y.; Galant, J.A.L.; Turmo, J. Structural Health Monitoring of 2D Plane Structures. Appl. Sci. 2021, 11, 2000. [Google Scholar] [CrossRef]

- Li, X.Z.; Zhang, S.M.; Tao, Y.; Zhang, B. Numerical Study on the Axial Compressive Behavior of Steel-Tube-Confined Concrete-Filled Steel Tubes. Materials 2024, 17, 155. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wang, W.; Xie, Z.Y. Nonlinear cyclic behavior of steel tube in concrete-filled steel tube members including local buckling. Thin-Walled Struct. 2023, 191, 111055. [Google Scholar] [CrossRef]

- Wei, Y.; Zhu, C.; Miao, K.T.; Zheng, K.Q.; Tang, Y. Compressive performance of concrete-filled steel tube columns with in-built seawater and sea sand concrete-filled FRP tubes. Constr. Build. Mater. 2022, 317, 125933. [Google Scholar] [CrossRef]

- Ye, Y.; Li, W.; Liu, X.J.; Guo, Z.X. Behaviour of concrete-filled steel tubes with concrete imperfection under axial tension. Mag. Concr. Res. 2021, 73, 743–756. [Google Scholar] [CrossRef]

- Skalomenos, K.A.; Hayashi, K.; Nishi, R.; Inamasu, H.; Nakashima, M. Experimental Behavior of Concrete-Filled Steel Tube Columns Using Ultrahigh-Strength Steel. J. Struct. Eng. 2016, 14, 04016057. [Google Scholar] [CrossRef]

- Liu, Z.N.; Lu, Y.Y.; Li, S.; Liao, J.C. Shear response of steel fiber reinforced recycled concrete-filled steel tube columns. Adv. Struct. Eng. 2021, 24, 2684–2704. [Google Scholar] [CrossRef]

- Dai, P.; Yang, L.; Wang, J.; Fan, J.W.; Lin, M.F. Experimental study on the steel-concrete bond behaviour of circular concrete-filled stainless steel tubes. Thin-Walled Struct. 2021, 169, 108506. [Google Scholar] [CrossRef]

- Wang, Z.B.; Zhang, J.B.; Li, W.; Wu, H.J. Seismic performance of stiffened concrete-filled double skin steel tubes. J. Constr. Steel Res. 2020, 169, 106020. [Google Scholar] [CrossRef]

- Lin, S.C.; Liu, F.B.; Bai, Q. Bond Behavior of Concrete-Filled Steel Tube with Molybdenum Tailing. Int. J. Steel Struct. 2024, 24, 354–365. [Google Scholar] [CrossRef]

- Roeder, C.W.; Stephens, M.T.; Lehman, D.E. Concrete Filled Steel Tubes for Bridge Pier and Foundation Construction. Int. J. Steel Struct. 2018, 18, 39–49. [Google Scholar] [CrossRef]

- Alhussainy, F.; Sheikh, M.N.; Hadi, M.N.S. Behaviour of small-diameter self-compacting concrete-filled steel tubes. Mag. Concr. Res. 2018, 70, 811–821. [Google Scholar] [CrossRef]

- Zhang, Y.T.; Shan, B.; Xiao, Y. Axial impact behaviors of stub concrete-filled square steel tubes. Adv. Struct. Eng. 2019, 22, 2490–2503. [Google Scholar] [CrossRef]

- Dong, M.H.; Elchalakani, M.; Karrech, A.; Fawzia, S.; Ali, M.S.M.; Yang, B.; Xu, S.Q. Circular steel tubes filled with rubberised concrete under combined loading. J. Constr. Steel Res. 2019, 162, 105613. [Google Scholar] [CrossRef]

- Liu, Z.Z.; Ma, X.X.; Li, N.; Chen, J.; Lu, Y.Y. Research advances in fiber-reinforced concrete-filled steel tube columns. Struct. Des. Tall Spec. Build. 2024, e2155. [Google Scholar] [CrossRef]

- Samingthong, W.; Hoy, M.; Ro, B.; Horpibulsuk, S.; Yosthasaen, T.; Suddeepong, A.; Yaowarat, T.; Arulrajah, A. Natural Rubber Latex-Modified Concrete with PET and Crumb Rubber Aggregate Replacements for Sustainable Rigid Pavements. Sustainability 2023, 15, 14147. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical properties of slurry infiltrated fiber concrete produced with waste steel fibers. Constr. Build. Mater. 2018, 186, 1082–1091. [Google Scholar] [CrossRef]

- George, C.; Selvan, S.S.; Kumar, V.S.; Murali, G.; Giri, J.; Makki, E.; Sathish, T. Enhancing the fire-resistant performance of concrete-filled steel tube columns with steel fiber-reinforced concrete. Case Stud. Constr. Mater. 2024, 20, e02741. [Google Scholar] [CrossRef]

- Domski, J.; Zakrzewski, M. Deflection of Steel Fiber Reinforced Concrete Beams Based on Waste Sand. Materials. 2020, 13, 392. [Google Scholar] [CrossRef] [PubMed]

- Zeybek, O.; Özkilic, Y.O.; Çelik, A.I.; Deifalla, A.F.; Ahmad, M.; Sabri, M.M.S. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Ojeda, J.P.; Mercante, I.T.; de Borbón, F.M.; Zerbino, R.; Torrijos, M.C.; Giaccio, G. Pull-out performance of plastic and steel fibers recycled from waste. J. Reinf. Plast. Compos. 2024. [Google Scholar] [CrossRef]

- Gok, S.G.; Sengul, O. The effect of recycled waste glass as a coarse aggregate on the properties of portland cement concrete and geopolymer concrete. Constr. Build. Mater. 2023, 408, 133697. [Google Scholar] [CrossRef]

- Yan, J.Q.; Gao, Y.T.; Tang, M.G.; Ding, N.S.; Xu, Q.; Peng, M.; Zhao, H. Experimental Study on the Mechanical Properties of Recycled Spiral Steel Fiber-Reinforced Rubber Concrete. Buildings 2024, 14, 897. [Google Scholar] [CrossRef]

- Yan, J.Q.; Gao, Y.T.; Fan, T.; Xu, Q.; Yuan, W.G.; Zhao, X. Experimental Study on Flexural Performance of Recycled Steel Fiber Concrete Beams. Buildings 2023, 13, 3046. [Google Scholar] [CrossRef]

- Akça, K.R.; Ipek, M.; Çelenk, S.; Karabulak, A. Experimental investigation on mechanical properties of HSSCC containing waste steel fibers obtained from end-of-life tires. Rev. Constr. 2023, 22, 87–101. [Google Scholar]

- Lehmann, M.; Glodkowska, W. Shear Capacity and Behaviour of Bending Reinforced Concrete Beams Made of Steel Fibre-Reinforced Waste Sand Concrete. Materials 2021, 14, 2996. [Google Scholar] [CrossRef] [PubMed]

- Dezhampanah, S.; Nikbin, I.M.; Charkhtab, S.; Fakhimi, F.; Bazkiaei, S.M.; Mohebbi, R. Environmental performance and durability of concrete incorporating waste tire rubber and steel fiber subjected to acid attack. J. Clean. Prod. 2020, 268, 122216. [Google Scholar] [CrossRef]

- Deng, Z.M. Utilisation of steel fibres to reinforce waste glass concrete: Alkali-silica reaction, engineering properties, and 3D mesoscale modelling. Case Stud. Constr. Mater. 2022, 17, e01686. [Google Scholar] [CrossRef]

- Smrkic, M.F.; Damjanovic, D.; Baricevic, A.; Uros, M. Experimental and numerical analysis of concrete slabs reinforced with rebar and recycled steel fibers from waste car tyres. Struct. Concr. 2023, 24, 1807–1820. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Alsharari, F.; Yosri, A.M.; Isleem, H.F. Evaluating the impact of nano-silica on characteristics of self-compacting geopolymer concrete with waste tire steel fiber. Arch. Civ. Mech. Eng. 2022, 23, 48. [Google Scholar] [CrossRef]

- Fakoor, M.; Nematzadeh, M. Evaluation of post-fire pull-out behavior of steel rebars in high-strength concrete containing waste PET and steel fibers: Experimental and theoretical study. Constr. Build. Mater. 2021, 299, 123917. [Google Scholar] [CrossRef]

- Abbas, S. Preventive measures of Alkali-Silica Reaction in concrete buildings: Use of hybrid waste coal ash and steel wire cut fibers. Buildings 2023, 13, 710. [Google Scholar] [CrossRef]

- Chen, M.; Sun, J.Q.; Zhang, T.; Shen, Y.; Zhang, M.Z. Enhancing the dynamic splitting tensile performance of ultra-high performance concrete using waste tyre steel fibres. J. Build. Eng. 2023, 80, 108102. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Fallah-Valukolaee, S. Compressive performance of steel fiber-reinforced rubberized concrete core detached from heated CFST. Constr. Build. Mater. 2020, 239, 117832. [Google Scholar] [CrossRef]

- Liang, W.; Dong, J.F.; Wang, Q.Y. Axial compressive behavior of concrete-filled steel tube columns with stiffeners. Steel Compos. Struct. 2018, 29, 151–159. [Google Scholar]

- Guler, S.; Lale, E.; Aydogan, M. Non-linear analysis of steel fibre reinforced concrete-filled steel tube columns. Proc. Inst. Civ. Eng.-Struct. Build. 2013, 166, 298–306. [Google Scholar] [CrossRef]

- Jegadesh, J.S.S.; Jayalekshmi, S. Using fibres and fly ash in concrete-filled steel tube columns. Proc. Inst. Civ. Eng.-Struct. Build. 2016, 169, 741–755. [Google Scholar] [CrossRef]

- Miao, K.T.; Wei, Y.; Dong, F.H.; Zheng, K.Q.; Wang, J.Q. Experimental study on concrete-filled steel tube columns with inner distributed seawater and sea sand concrete-filled fiber-reinforced polymer tubes under axial compression. Compos. Struct. 2023, 320, 117181. [Google Scholar] [CrossRef]

- Xiong, Y.M.; Yang, M.; Yang, M.; Shi, H.; Zhao, J.K.; Yuan, Y.; Guo, X.Y. Axial compression behavior of concrete-filled prefabricated aligned steel fiber UHPC tubes. J. Build. Eng. 2024, 89, 109353. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Li, N.; Li, S.; Liang, H.J. Behavior of steel fiber reinforced concrete-filled steel tube columns under axial compression. Constr. Build. Mater. 2015, 95, 74–85. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, P.T.; Lu, Y.Y.; Liu, Z.Z. Hysteresis performance of steel fiber-reinforced high-strength concrete-filled steel tube columns. J. Constr. Steel Res. 2024, 219, 108755. [Google Scholar] [CrossRef]

- GB/T51446-2021; Technical Standard for Concrete-Filled Steel Tubular Hybrid Structures. China Architecture & Building Press: Beijing, China, 2021. (In Chinese)

- GB50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. China Architecture & Building Press: Beijing, China, 2021. (In Chinese)

- Anas, S.M.; Alam, M.; Umair, M. Experimental and numerical investigations on performance of reinforced concrete slabs under explosive-induced air-blast loading: A state-of-the-art review. Structures 2021, 31, 428–461. [Google Scholar] [CrossRef]

- Liu, Z.Z.; Lu, Y.Y.; Li, S.; Zong, S.; Yi, S. Flexural behavior of steel fiber reinforced self-stressing recycled aggregate concrete-filled steel tube. J. Clean. Prod. 2020, 274, 122724. [Google Scholar] [CrossRef]

- Li, J.T.; Chen, Z.P.; Xu, J.J.; Jing, C.G.; Xue, J.Y. Cyclic behavior of concrete-filled steel tubular column-reinforced concrete beam frames incorporating 100% recycled concrete aggregates. Adv. Struct. Eng. 2018, 21, 1802–1814. [Google Scholar] [CrossRef]

- Chen, J.; Kuder, K.G.; Lehman, D.E.; Roeder, C.W.; Lowes, L.N. Creep modeling of concretes with high volumes of supplementary cementitious materials and its application to concrete-filled tubes. Mater. Struct. 2017, 50, 89. [Google Scholar] [CrossRef]

- Xu, C.Y.; Han, L.H.; Hou, C. Behaviour of recycled aggregate concrete-filled stainless steel tubular columns subjected to lateral monotonic and cyclic loading. Eng. Struct. 2023, 293, 116663. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Han, L.H.; Hou, C.; Lyu, W.Q. Performance of recycled aggregate concrete-filled high-strength steel tubes under axial compression, tension and torsion. Thin-Walled Struct. 2023, 184, 110478. [Google Scholar] [CrossRef]

| D × t/mm | Yield Strength /MPa | Ultimate Strength /MPa | Elastic Modulus/(×105 MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| 140 × 2 | 253 | 356 | 1.99 | 0.297 |

| 140 × 3 | 260 | 362 | 2.01 | 0.299 |

| Strength Grade | Water-Cement Ratio | Cement /kg/m3 | Dilatant /kg/m3 | Aggregate /kg/m3 | Water /kg/m3 | Sand /kg/m3 | Superplasticizer /kg/m3 | |

|---|---|---|---|---|---|---|---|---|

| Coarse | Fine | |||||||

| C30 | 0.53 | 339.6 | 34 | 682.6 | 558.5 | 180 | 639.3 | 6.8 |

| C50 | 0.38 | 474.3 | 47 | 672.2 | 549.9 | 180 | 524.8 | 9.5 |

| Test Block Number | Concrete Strength Grade | /MPa | /MPa |

|---|---|---|---|

| Test block group 1 | C30 | 32.6 | 31.9 |

| 31.1 | |||

| 31.9 | |||

| Test block group 2 | C50 | 50.3 | 50.1 |

| 50.7 | |||

| 49.4 |

| Test Piece Number | Diameter D/mm | Wall Thickness t/mm | Length L/mm | Steel Content /% | RSF Volume Fraction/% |

|---|---|---|---|---|---|

| C30-2-0 | 140 | 2 | 400 | 2.84 | 0 |

| C30-2-0.5 | 140 | 2 | 400 | 2.84 | 0.5 |

| C30-2-1.0 | 140 | 2 | 400 | 2.84 | 1.0 |

| C30-2-1.5 | 140 | 2 | 400 | 2.84 | 1.5 |

| C30-2-2.0 | 140 | 2 | 400 | 2.84 | 2.0 |

| C30-3-0 | 140 | 3 | 400 | 4.24 | 0 |

| C30-3-0.5 | 140 | 3 | 400 | 4.24 | 0.5 |

| C30-3-1.0 | 140 | 3 | 400 | 4.24 | 1.0 |

| C30-3-1.5 | 140 | 3 | 400 | 4.24 | 1.5 |

| C30-3-2.0 | 140 | 3 | 400 | 4.24 | 2.0 |

| C50-2-1.0 | 140 | 2 | 400 | 2.84 | 1.0 |

| C50-2-2.0 | 140 | 2 | 400 | 2.84 | 2.0 |

| Test Piece Number | Combination Elastic Modulus Esc/MPa | Test Piece Number | Combination Elastic Modulus Esc/MPa |

|---|---|---|---|

| C30-2-0 | 39,514 | C30-3-0 | 44,044 |

| C30-2-0.5 | 39,632 | C30-3-0.5 | 44,085 |

| C30-2-1.0 | 39,690 | C30-3-1.0 | 44,123 |

| C30-2-1.5 | 39,721 | C30-3-1.5 | 44,165 |

| C30-2-2.0 | 39,754 | C30-3-2.0 | 44,200 |

| C50-2-1.0 | 41,080 | C50-2-2.0 | 41,157 |

| Test Piece Number | Diameter (mm) | Length (mm) | Length to Diameter Ratio | RSF Content Characteristic Value () |

|---|---|---|---|---|

| C30-2-0.5 | 0.75 | 30 | 40 | 0.20 |

| C30-2-1.0 | 0.75 | 30 | 40 | 0.40 |

| C30-2-1.5 | 0.75 | 30 | 40 | 0.60 |

| C30-2-2.0 | 0.75 | 30 | 40 | 0.80 |

| C30-3-0.5 | 0.75 | 30 | 40 | 0.20 |

| C30-3-1.0 | 0.75 | 30 | 40 | 0.40 |

| C30-3-1.5 | 0.75 | 30 | 40 | 0.60 |

| C30-3-2.0 | 0.75 | 30 | 40 | 0.80 |

| C50-2-1.0 | 0.75 | 30 | 40 | 0.40 |

| C50-2-2.0 | 0.75 | 30 | 40 | 0.80 |

| Test Piece Number | Calculated Value N1 | Experimental Value Ntest | N1/Ntest |

|---|---|---|---|

| C30-2-0 | 802.5 | 798 | 1.0056 |

| C30-2-0.5 | 819.9 | 825 | 0.9938 |

| C30-2-1.0 | 837.3 | 833 | 1.0052 |

| C30-2-1.5 | 854.8 | 873 | 0.9792 |

| C30-2-2.0 | 872.2 | 905 | 0.9638 |

| C30-3-0 | 968.6 | 971 | 0.9975 |

| C30-3-0.5 | 985.5 | 980 | 1.0056 |

| C30-3-1.0 | 1002.5 | 988 | 1.0147 |

| C30-3-1.5 | 1019.4 | 1009 | 1.0103 |

| C30-3-2.0 | 1036.3 | 1045 | 0.9918 |

| C50-2-1.0 | 1151.2 | 1079 | 1.0669 |

| C50-2-2.0 | 1209.3 | 1132 | 1.0683 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Lv, H.; Gao, Y.; Tang, M.; Ding, N.; Zhao, X.; Zhao, H.; Hu, X. Experimental Study on Axial Compressive Performance of Recycled Steel Fiber Reinforced Concrete Short Columns with Steel Pipes. Buildings 2024, 14, 2498. https://doi.org/10.3390/buildings14082498

Wang B, Lv H, Gao Y, Tang M, Ding N, Zhao X, Zhao H, Hu X. Experimental Study on Axial Compressive Performance of Recycled Steel Fiber Reinforced Concrete Short Columns with Steel Pipes. Buildings. 2024; 14(8):2498. https://doi.org/10.3390/buildings14082498

Chicago/Turabian StyleWang, Bin, Hui Lv, Yongtao Gao, Minggao Tang, Nansheng Ding, Xiao Zhao, Hua Zhao, and Xiao Hu. 2024. "Experimental Study on Axial Compressive Performance of Recycled Steel Fiber Reinforced Concrete Short Columns with Steel Pipes" Buildings 14, no. 8: 2498. https://doi.org/10.3390/buildings14082498