Critical Insights into White and Yellow Light Marks on Various Asphalt Pavements: A Comparative Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Database and Asphalt Type

- ▪

- 33 km of “Tama” type (SMA): This section is made up of coarse aggregate (type A basalt coarse aggregate), fine aggregate (type A fine limestone/dolomite aggregate, pre-screened to ensure that it contains no less than 60% sand-sized aggregate), melamine, bitumen (PG70-10 or PG76-10), and stabilizing fibers.

- ▪

- 10.0 km of DCG mixtures, using exclusively basalt aggregate: This section will be referred to as “Basalt”.

- ▪

- 22.1 km of DCG mixtures with a blend of basalt and dolomite aggregates: In this section, the coarse aggregate (retained on a 4.75 mm sieve) consists of a mix of at least 60% basalt aggregate by weight and, at most, 40% dolomite aggregate. Of this segment, 14.0 km have a known maintenance history. This section will be referred to as “Zebra”.

2.2. Statistical Analysis

3. Results

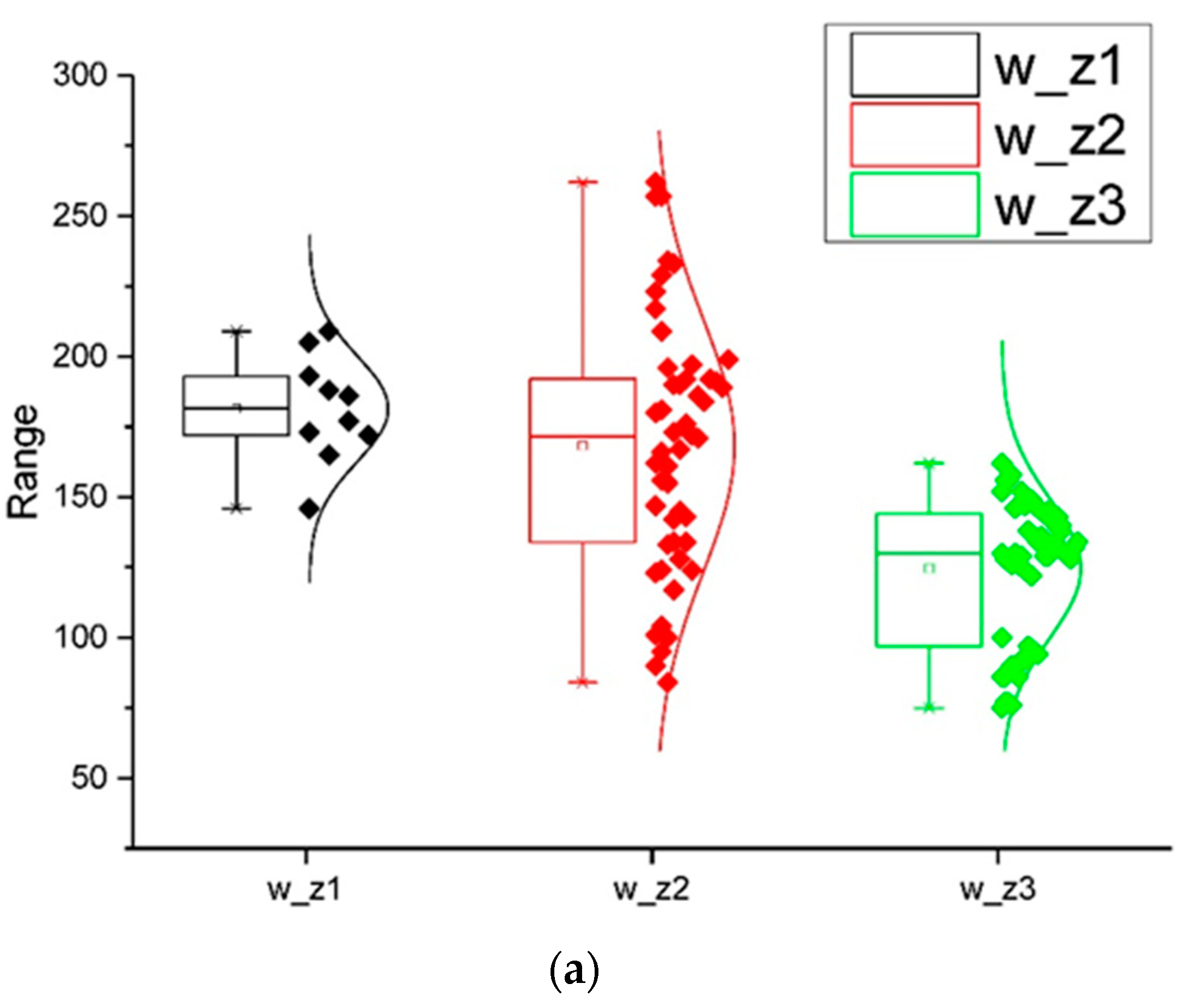

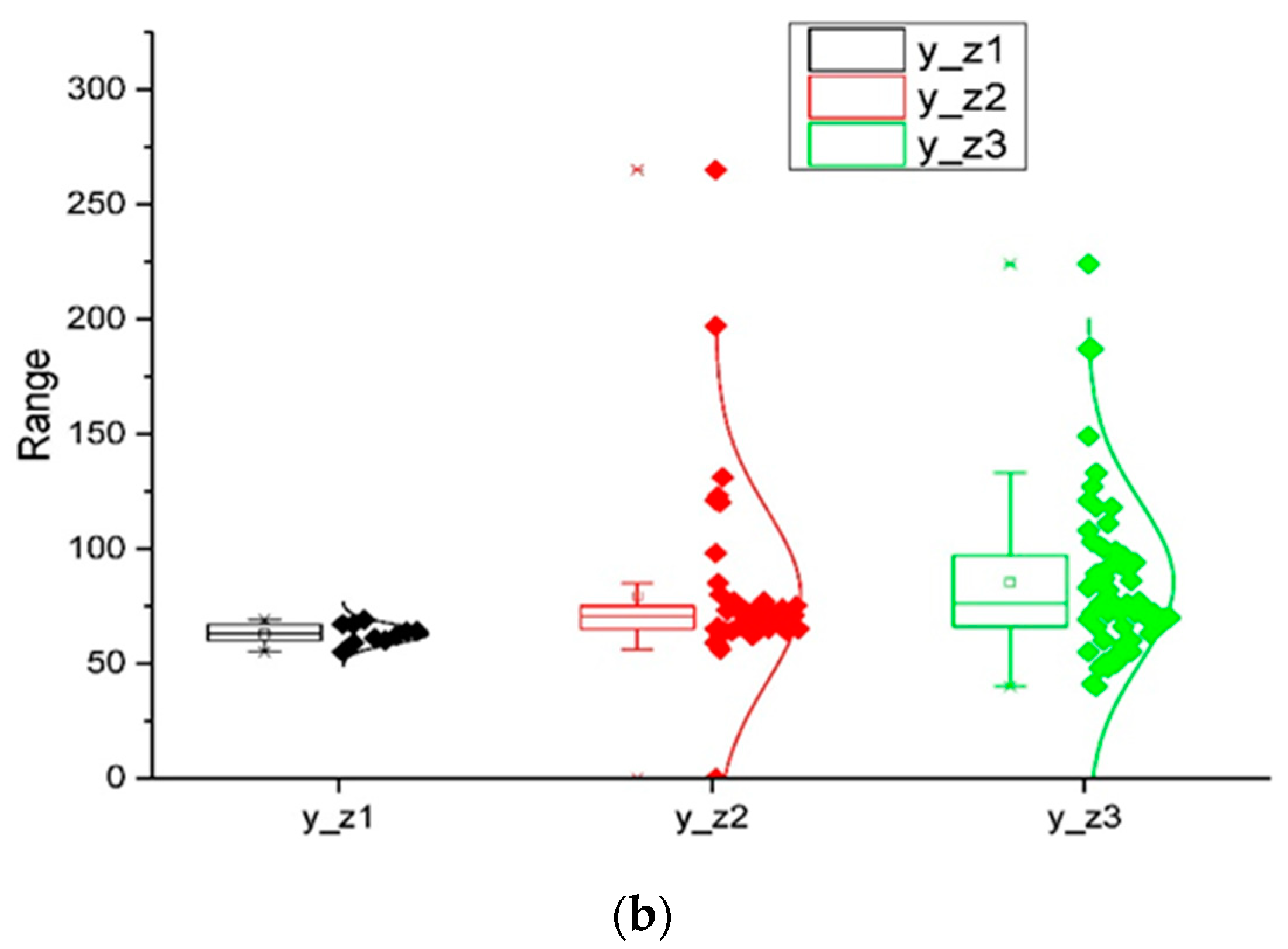

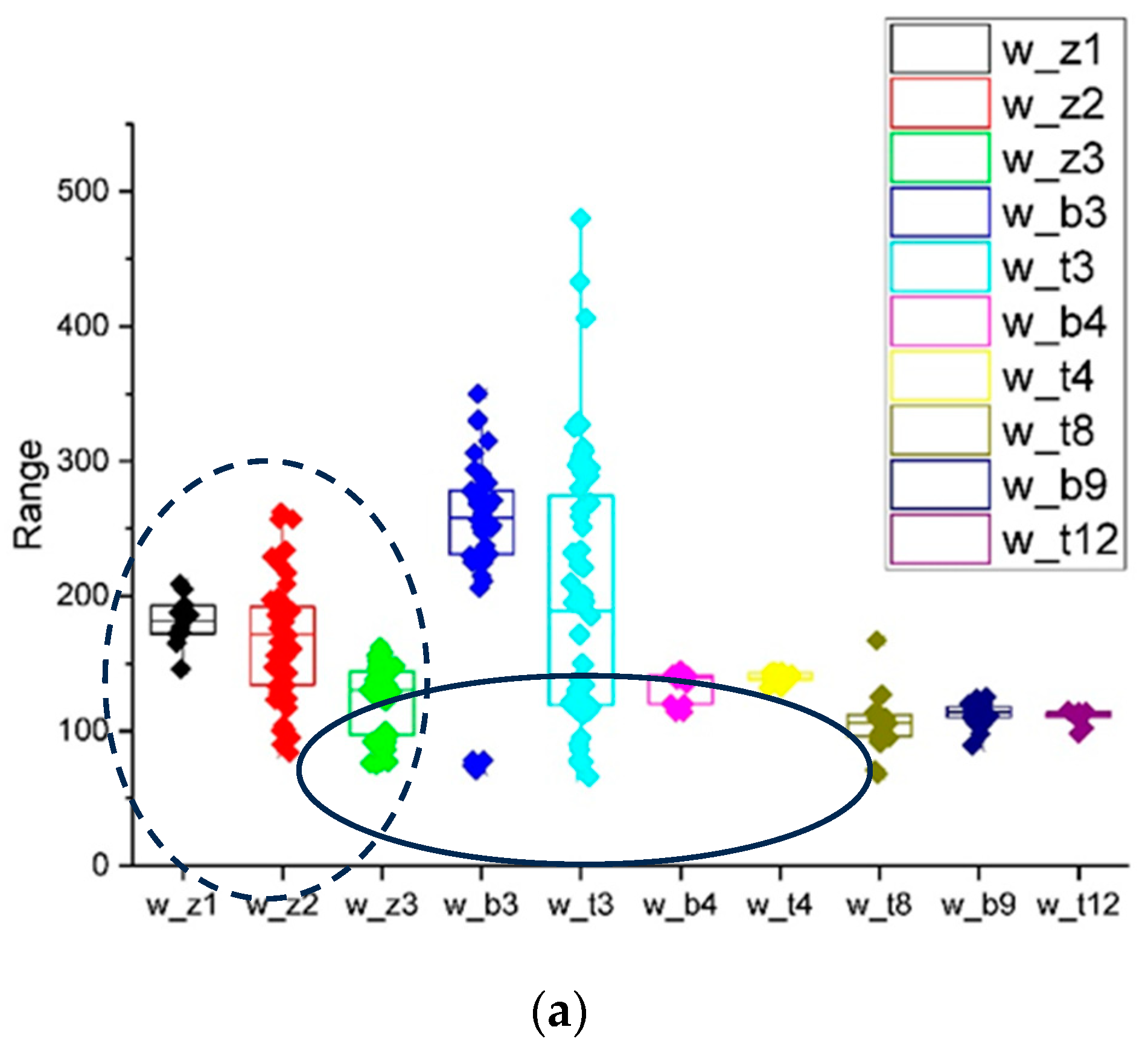

3.1. The “Zebra” Type of Asphalt Mixture

3.2. The “Basalt” Type of Asphalt Mixture

3.3. The “Tama” Type of Asphalt Mixture

3.4. Retroreflectivity Comparison of Three Types of Asphalt Pavement

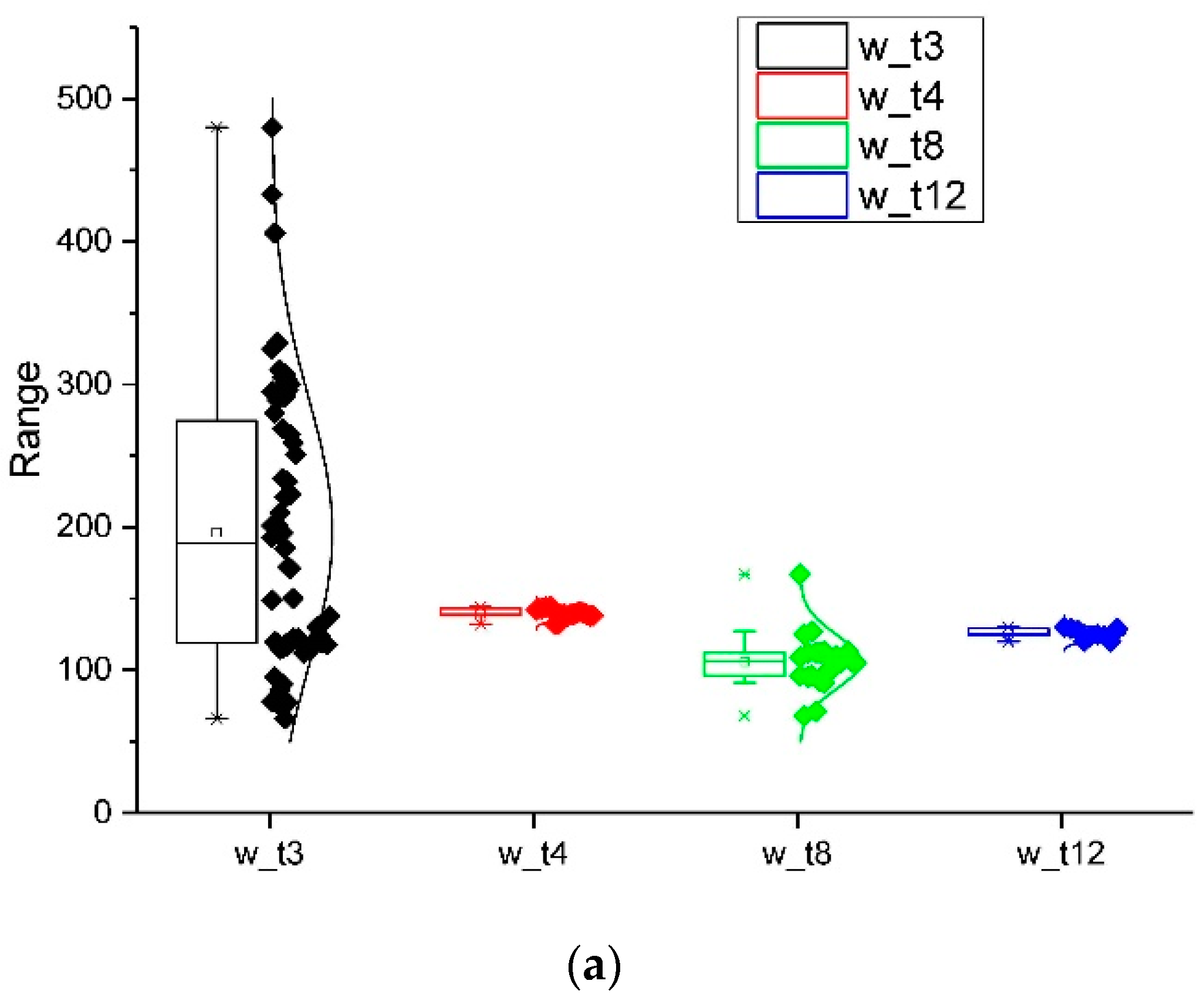

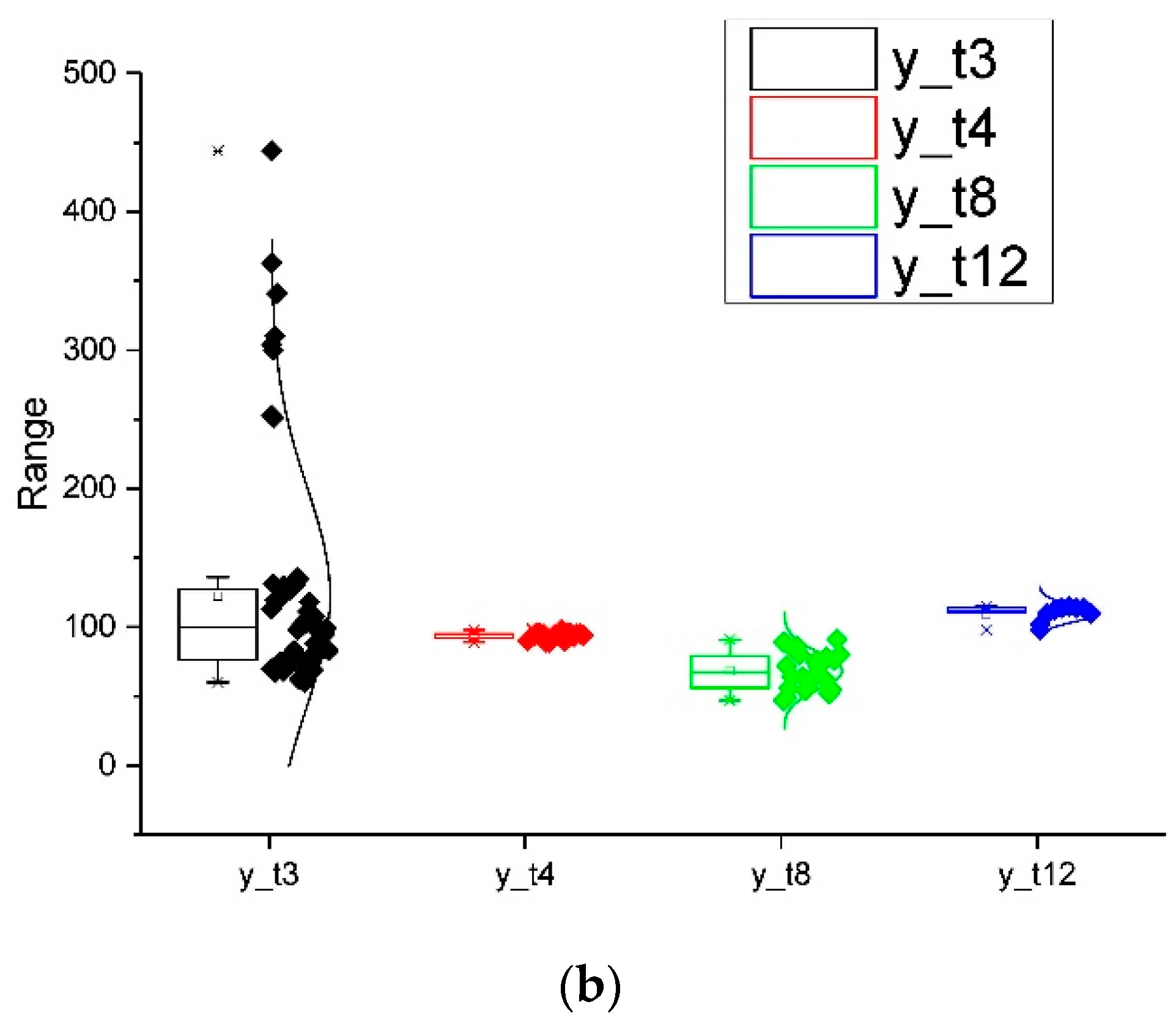

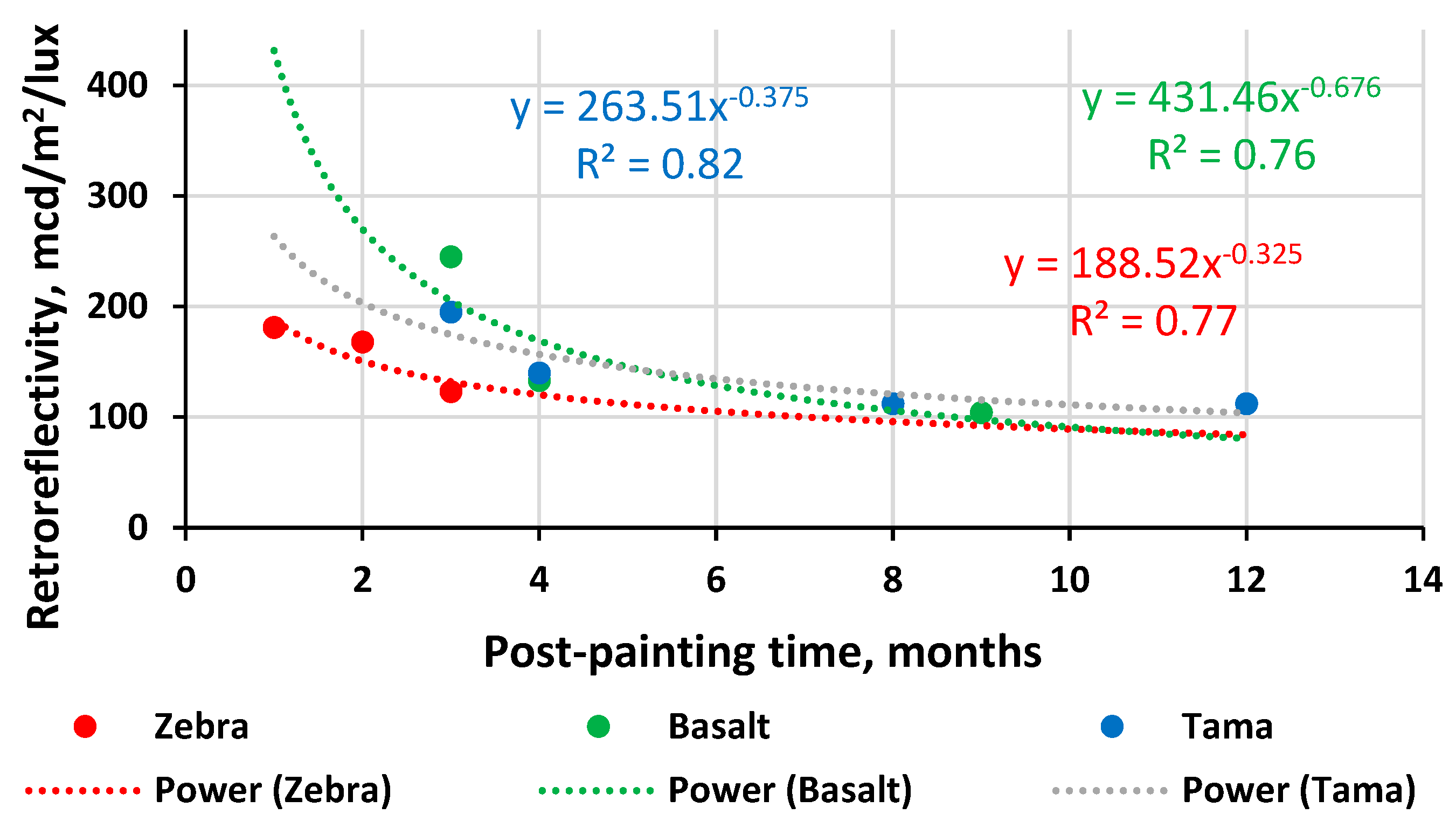

3.5. Relationship between the Post-Painting Time and the Retroreflectivity Values for Three Types of Asphalt Pavement

3.6. Effect of Annual Average Daily Traffic (AADT)

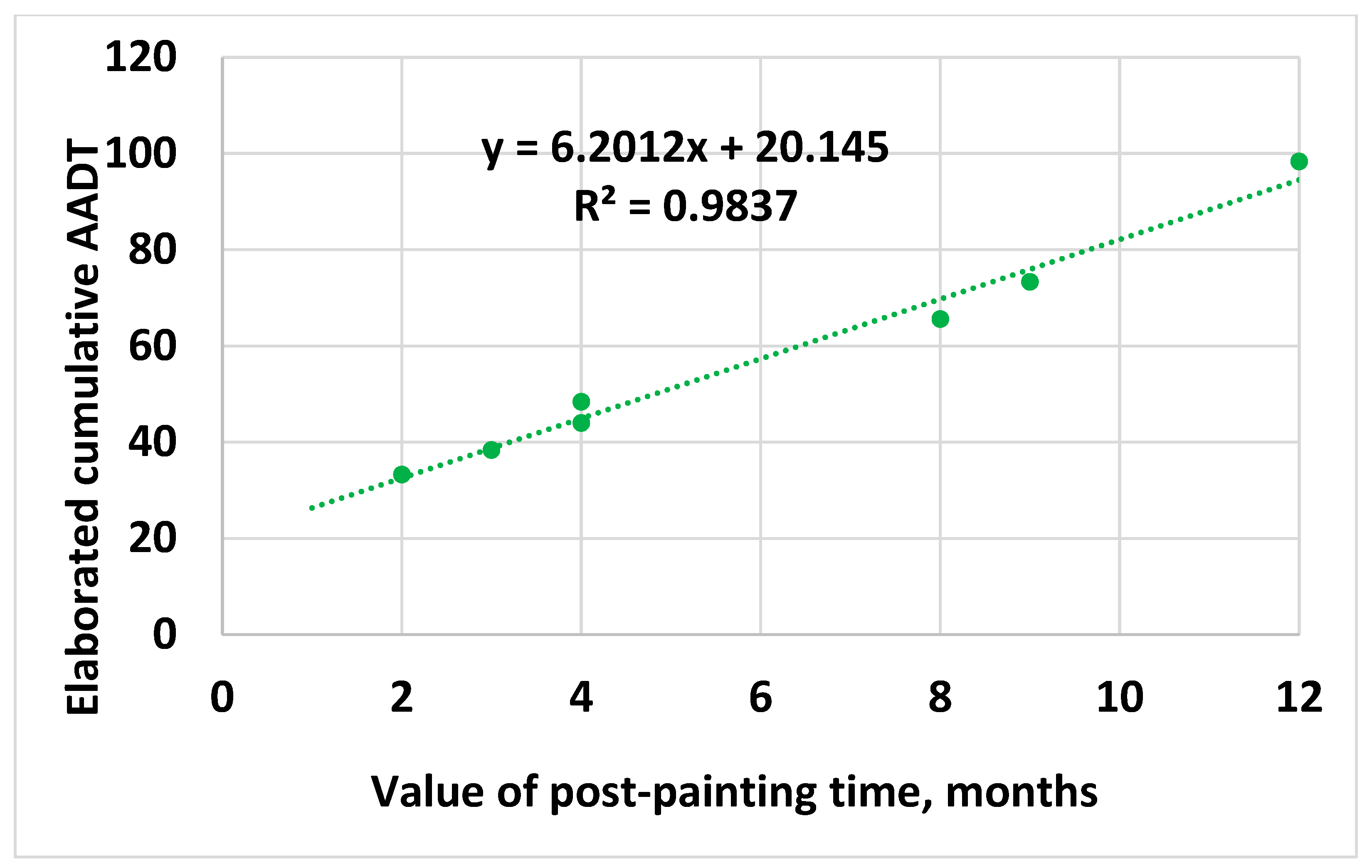

3.6.1. Analysis of Annual Average Daily Traffic vs. Post-Painting Time

3.6.2. Analysis of Mean Values of Retroreflectivity vs. Post-Painting Time

3.6.3. Relationship between Mean Values of Retroreflectivity and Values of Average Cumulative AADT

4. Discussion

5. Conclusions

- This study investigates how the content of three asphalt mixtures affects the retroreflectivity of the road marks painted on the road surface.

- The results show that the retroreflectivity values of white road markings vary depending on the asphalt mixtures under study.

- Of the three mixtures tested—the “Basalt” and “Zebra” dense, coarse-graded mixtures, and the “Tama” stone mastic mixture—the “Basalt” mixture was the most effective in enhancing road marking visibility, with higher initial retroreflectivity values.

- A relationship between the annual average daily traffic (AADT) and retroreflectivity mean values was identified, following a fractional power pattern, as demonstrated by the high regression coefficient of the cross-correlation line between the calculated and measured retroreflectivity values.

- Data analysis uncovered a significant variation in the retroreflectivity values for the white and yellow road markings across the different asphalt mixtures.

- The asphalt mixture did not appear to affect the yellow road markings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vereen, S.; Hummer, J.; Rasdorf, W. Alternative approaches for state agencies to address the proposed minimum retro-reflectivity standards. Public Work. Manag. Policy 2004, 8, 235–248. [Google Scholar] [CrossRef]

- Migletz, J.; Fish, J.K.; Graham, J.L. Roadway Delineation Practices Handbook; Report No. FHWA-SA-93-001; Federal Highway Administration, Department of Transportation: Washington, DC, USA, 1994. [Google Scholar]

- Migletz, J.; Graham, J.L.; Bauer, K.M.; Harwood, D.W. Service Life of Durable Pavement Markings. Transp. Res. Rec. 2001, 1749, 3–21. [Google Scholar] [CrossRef]

- Dravitzki, V.K.; Classen, C.T.; Lough, B.D.; Kneebone, D.C. The use of road studs: Effects on driving performance. Road Transp. Res. 2003, 12, 3–14. [Google Scholar]

- Zwahlen, H.T.; Schnell, T. Remaining Night-Time Visibility of Roadway Delineation Systems. In Proceedings of the Transportation Research Board 78th Annual Meeting, Washington, DC, USA, 10–14 January 1999. [Google Scholar]

- Villa, C.; Brémond, R.; Eymond, F.; Saint-Jacques, E. Characterization of luminescent road markings. Light. Res. Technol. 2023, 55, 459–473. [Google Scholar] [CrossRef]

- Bullough, J.D.; Liu, X. Assessing the visibility of raised pavement markers and alternative forms of delineation. Transport 2020, 35, 98–107. [Google Scholar] [CrossRef]

- Ye, F.; Pike, A. Studying the Nighttime Visibility Performance of Retroreflective Pavement Markers. Transp. Res. Rec. 2019, 2673, 334–344. [Google Scholar] [CrossRef]

- Zhu, B.; Song, C.; Guo, Z.; Zhang, Y.; Zhou, Z. Effectiveness of Active Luminous Lane Markings on Highway at Night: A Driving Simulation Study. Sustainability 2021, 13, 1043. [Google Scholar] [CrossRef]

- Cho, Y.; Kabassi, K.; Pyeon, J.-H.; Choi, K.; Wang, C.; Norton, T. Effectiveness study of methods for removing temporary pavement markings in roadway construction zones. J. Constr. Eng. Manag. 2013, 139, 257–266. [Google Scholar] [CrossRef]

- Wang, K.; Lu, Z.; Zou, Y.; Zhu, Y.; Yu, J. Preparation and Performance Characterization of an Active Luminous Coating for Asphalt Pavement Marking. Coatings 2023, 13, 1108. [Google Scholar] [CrossRef]

- Chen, J.; Li, R.; Zhang, Y.; Wu, Y.; He, H. Study on the Reflective Principle and Long-Term Skid Resistance of a Sustainable Hydrophobic Hot-Melt Marking Paint. Sustainability 2023, 15, 9950. [Google Scholar] [CrossRef]

- Burghardt, T.E.; Babic, D.; Pashkevich, A. Sustainability of thin layer road markings based on their service life. Transp. Res. Part D 2022, 109, 103339. [Google Scholar]

- Burghardt, T.E.; Pashkevich, A. Green Public Procurement criteria for road marking materials from insiders’ perspective. J. Clean. Prod. 2021, 298, 126521. [Google Scholar] [CrossRef]

- Hong, C.-W. Properties of Temperature Reduction of Cooling Asphalt Pavements Using High-Reflectivity Paints. KSCE J. Civ. Environ. Eng. Res. 2013, 33, 317–327. [Google Scholar] [CrossRef]

- Smadi, O.; Hawkins, N.; Nlenanya, I.; Aldemir-Bektas, B. Pavement marking retro-reflectivity and the safety effects of pavement marking maintenance. Transp. Res. Rec. 2016, 2585, 61–73. [Google Scholar]

- Zwahlen, H.T.; Russ, A. Photometric measurements of retroreflective raised pavement markers in Ohio. Transp. Res. Rec. 2002, 1794, 93–100. [Google Scholar]

- Gates, T.J.; Hawkins, H.G.; Rose, E.R. Effective Placement of Raised Pavement Markers to Assist Older Drivers; Texas Transportation Institute, Texas A&M University System: College Station, TX, USA, 2003. [Google Scholar]

- Sadeghpour, F.; Mohaymany, A.S.; Mehin, H.K. Intelligent transportation system: A planning support functionality for road studs. J. Transp. Eng. 2009, 135, 629–638. [Google Scholar]

- Shaheen, S.; Lipman, T.E. Reducing greenhouse gas emissions and fuel consumption: Sustainable approaches for surface transportation. IATSS Res. 2007, 31, 6–20. [Google Scholar] [CrossRef]

- Bahar, G.; Mollett, C.; Persaud, B.; Lyon, C.; Smiley, A.; Smahel, T.; McGee, H. Safety Evaluation of Permanent Raised Pavement Markers; NCHRP Report 518; National Research Council: Washington, DC, USA, 2004. [Google Scholar]

- Sun, X.; Das, S. Driver perception of raised pavement markers in snowstorms. J. Transp. Eng. 2012, 138, 705–711. [Google Scholar]

- Abboud, N.; Bowman, B.L. Establishing Crash-Based Retroreflectivity Threshold. In Proceedings of the 81st Annual Meeting of the Transportation Research Board, Washington, DC, USA, 13–17 January 2002. [Google Scholar]

- Graham, J.R.; Harrold, J.K.; King, L.E. Pavement Marking Retroreflectivity Requirements for Older Drivers. Transp. Res. Rec. 1996, 1529, 65–70. [Google Scholar] [CrossRef]

- Loetterle, F.E.; Beck, R.A.; Carlson, J. Public Perception of Pavement Marking Brightness. In Proceedings of the Transportation Research Board 78th Annual meeting, Washington, DC, USA, 10–14 January 1999. [Google Scholar]

- Migletz, J.; Graham, J.L.; Bauer, K.; Harwood, D.W.; City, K. Field Surveys of Pavement-Marking Retroreflectivity. Transp. Res. Rec. 1999, 1657, 71–78. [Google Scholar] [CrossRef]

- Lee, J.T.; Maleck, T.L.; Taylor, W.C. Analysis of the Correlation between Pavement Marking Visibility and Nighttime Accidents. In Proceedings of the 77th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 11–15 January 1998. [Google Scholar]

- Craig, W.N.; Sitzabee, W.E.; Hummer, J.E.; Rasdorf, W. Impact of line location on Pavement marking retroreflectivity degradation. J. Public Work. Manag. Policy 2007, 12, 431–450. [Google Scholar] [CrossRef]

- Obeng, D.A.; Owusu, V.; Tuffour, Y.A. Degradation of retro-reflectivity of thermoplastic pavement markings on trunk roads in Ghana. Transp. Eng. 2021, 5, 100082. [Google Scholar] [CrossRef]

- Thanasupsin, K.; Sukniam, S. Degradation of the Retroreflectivity and Diffuse Illumination of Thermoplastic Pavement Markings: A Case Study in Thailand. In IOP Conference Series: Materials Science and Engineering, Proceedings of the Annual Conference on Computer Science and Engineering Technology (AC2SET), Medan, Indonesia, 23 September 2020; IOP Publishing: Bristol, UK, 2021; Volume 1088, p. 012056. [Google Scholar]

- Chou, C.-P.; Leong, K.-W.; Chen, A.-C.; Lee, Y.-X. Road marking retroreflectivity study via a visual algorithm. Int. J. Pavement Res. Technol. 2020, 13, 614–620. [Google Scholar] [CrossRef]

- De Salles, L.S.; da Silva Pereira, D.; Teixeira, D.L.K.; Pereira, L.P.S. Avaliação retrorrefletiva de pintura de demarcação horizontal: Peculiaridades e considerações sobre a norma e os requisitos mínimos nacionais. Transportes 2015, 23, 5–17. [Google Scholar] [CrossRef][Green Version]

- He, H.; Zhou, Y.; Zhang, J.; Cao, J.; Leng, Z.; Su, W. Measuring Method and Standard System for Retroreflective Traffic Marking’s Photometric Characteristic. In Optical Measurement Systems for Industrial Inspection XI, Proceedings of the SPIE Optical Metrology 2019, Munich, Germany, 24–28 June 2019; Proc. SPIE: Bellingham, WA, USA, 2019; p. 11056. [Google Scholar] [CrossRef]

- Mazzoni, L.N.; Machado, D.D.N.; Vasconcelos, K.L.; Bernucci, L.L.B.; Linhares, G.R.; Branco, V.T.F.C. Characterization of glass beads by image methods for pavement marking retroreflectivity. Transportes 2022, 30, 12. [Google Scholar] [CrossRef]

- Owusu, V.; Tuffour, Y.A.; Obeng, D.A.; Salifu, M. Degradation of Retro-Reflectivity of Thermoplastic Pavement Markings: A Review. Open J. Civ. Eng. 2018, 8, 301–311. [Google Scholar] [CrossRef]

- Onyango, M.A.; Malyuta, D.; Owino, J.; Chimba, D. Verification of Pavement Marking Degradation Models using Eastern Tennessee Pavement Marking Retroreflectivity Data. In Proceedings of the 2nd Pan African International Conference on Science, Computing and Telecommunications, Arusha, Tanzania, 14–18 July 2014. [Google Scholar]

- Zhang, G.; Hummer, J.E.; Rasdorf, W.; Mastin, N. The Impact of Pavement Type and Roughness on Paint Marking Retroreflectivity. Public Work. Manag. Policy 2013, 18, 41–55. [Google Scholar] [CrossRef]

- National Asphalt Pavement Association. Designing and Constructing SMA Mixtures-State-of-the-Practice. Quality Improvement Series 122; National Asphalt Pavement Association: Lanham, MD, USA, 2002; pp. 20706–24407. Available online: https://www.asphaltpavement.org/ (accessed on 12 August 2024).

- National Asphalt Pavement Association. HMA Pavement Mix Type Selection Guide. Information Series 128; National Asphalt Pavement Association and Federal Highways Administration: Lanham, MD, USA, 2001; pp. 20706–24413. [Google Scholar]

- Netivei Israel. Chapter 51: Paving Works, Subchapter 04: Asphalt Layers. In The General Specification for Paving and Bridging Works; The National Transportation Infrastructure Company Ltd.: Or-Yehuda, Israel, 2016. [Google Scholar]

- Hyndman, R.J.; Fan, Y. Sample Quantiles in Statistical Packages. Am. Stat. 1996, 50, 361–365. [Google Scholar] [CrossRef]

- Lane, D. Percentiles. In Introduction to Statistic; Rice University: Houston, TX, USA, 2003; Retrieved 15 September 2007. [Google Scholar]

- Schoonjans, F.; de Bacquer, D.; Schmid, P. Estimation of population percentiles. Epidemiology 2011, 22, 750–751. [Google Scholar] [CrossRef]

- Langford, E. Quartiles in Elementary Statistics. J. Stat. Educ. 2006, 14, 1–20. [Google Scholar] [CrossRef]

- Federal Highway Administration. Traffic Data Computation Method Pocket Guide; Publication No. FHWA-PL-18-027; The Federal Highway Administration (FHWA), Department of Transportation: Washington, DC, USA, 2018. [Google Scholar]

- Schroeder, B.J. Transportation Planning. In Highway Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Donnell, E.; Karwa, V.; Sathyanarayanan, S. Analysis of Effects of Pavement Marking Retroreflectivity on Traffic Crash Frequency on Highways in North Carolina: Application of Artificial Neural Networks and Generalized Estimating Equations. Transp. Res. Rec. 2009, 2103, 50–60. [Google Scholar] [CrossRef]

| Mixture Type | Percentage Passing, mm | |||||

|---|---|---|---|---|---|---|

| 19 | 12.5 | 9.5 | 4.75 | 2 | 0.075 | |

| Tama | 100 | 90–95 | 25–30 | 20–25 | 15–25 | 8–11 |

| Basalt | 100 | 82–94 | 56–72 | 36–50 | 5–9 | |

| Zebra | 100 | 90–95 | 70–75 | 32–37 | 23–27 | 5–8 |

| Mixture Type | Properties | |||

|---|---|---|---|---|

| Porosity, % | Minimum VMA, % | Remaining Strength, % | Filler/ Bitumen Ratio | |

| Tama | 15–25 | 17 | 80 | 1.5–1.8 |

| Basalt | 6–7.5 | 14–14.5 | 80 | 1.1–1.5 |

| Zebra | 6–7.5 | 14–14.5 | 80 | 1.1–1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elias, W.; Abu Ahmad, M.; Frid, V. Critical Insights into White and Yellow Light Marks on Various Asphalt Pavements: A Comparative Analysis. Buildings 2024, 14, 2525. https://doi.org/10.3390/buildings14082525

Elias W, Abu Ahmad M, Frid V. Critical Insights into White and Yellow Light Marks on Various Asphalt Pavements: A Comparative Analysis. Buildings. 2024; 14(8):2525. https://doi.org/10.3390/buildings14082525

Chicago/Turabian StyleElias, Wafa, Moamar Abu Ahmad, and Vladimir Frid. 2024. "Critical Insights into White and Yellow Light Marks on Various Asphalt Pavements: A Comparative Analysis" Buildings 14, no. 8: 2525. https://doi.org/10.3390/buildings14082525

APA StyleElias, W., Abu Ahmad, M., & Frid, V. (2024). Critical Insights into White and Yellow Light Marks on Various Asphalt Pavements: A Comparative Analysis. Buildings, 14(8), 2525. https://doi.org/10.3390/buildings14082525