Nonplanar Robotic Printing of Earth-Based Material: A Case Study Using Cob-like Mixture

Abstract

1. Introduction

2. Examination of Current Cob Case Studies

3. Methods, Materials, and Working Process

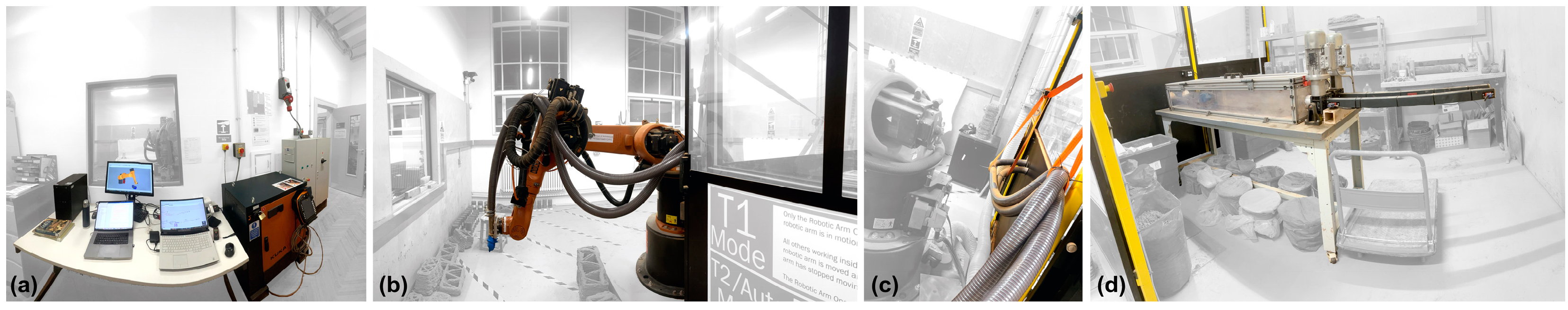

3.1. Lab Setting and Used Equipment

- The location of the printing surface was moved 180° around the centre of the robot location to comply with the updated health and safety regulations within the university. This change in printing location affected the hose length, increasing it from 2 to 3 m to allow for a certain freedom in robot movement. The increased hose length resulted in a greater amount of material being pushed by the extruder, thus, in turn, affecting the required force in relation to material resistance. Due to the variable frequency of the extruder’s control motors, the speed and, therefore, the force of the pushing plate varied in relation to the material’s resistance. Increasing the length of the hose resulted in an increased volume of the pushed material, which led to a substantial increase in material resistance that the dual extruder was unable to cope with, resulting in a complete stop. Therefore, it was important to identify the optimal hose length in relation to the extruder’s pushing force, the rheology of the wet cob, and the build-up of the outputted prototype;

- Two 3 m hoses were directly connected to the two tubes held by the extruder through two funnels, replacing the originally designed two-way aluminium channel. The two hoses converged through a two-way channel attached to the end of the robot arm. This configuration ensured that the material was consistently pushed forward, eliminating any issues with retraction. The pressure and weight of the material in the hoses and tubes, combined with the force of gravity, prevented the material from moving in the reverse direction;

- A rubber seal was added to the push plates of extruder 1 and extruder 2 to prevent the cob material from retracting and ensure its continuous forward movement. The design of the rubber seal underwent several iterations during the experiment to optimise its effectiveness. (Refer to Figure 2);

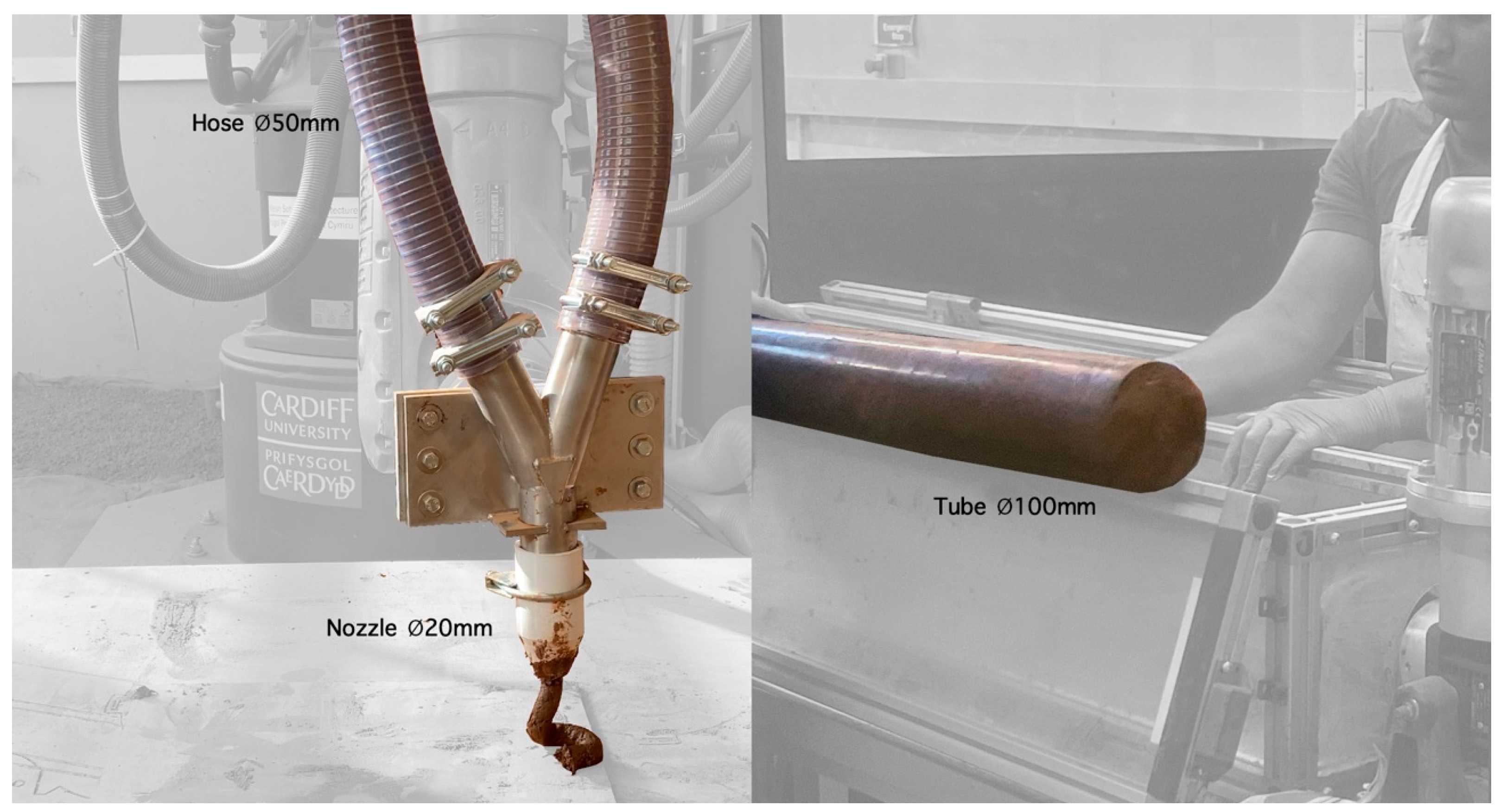

- A 3D-printed 20 mm nozzle was attached to the two-way channel at the end of the robot arm and used for all the printed prototypes. The smaller nozzle size allowed for more precise control over the printed geometry and helped reduce air gaps as the material was compacted at points where the diameter decreased, transitioning from 100 mm tubes to 50 mm hoses to 20 mm nozzles. (Refer to Figure 3);

3.2. Working Methodology

- Preparing the cob’s dry ingredients;

- Preparing the wet cob mixture and storing it;

- Testing the viscosity of the mixture and adjusting it to achieve the desired fluidity;

- Filling the tubes with the cob mixture;

- Loading the tubes into the extruder;

- Preparing the digital file for the desired geometry and dry testing for clashes that were not digitally simulated;

- Printing the desired geometry.

3.3. Cob Material and Robotic Extrusion System

- The pre-extrusion phase began by breaking the subsoil into smaller portions and transporting it from the storage area outside to the robotic lab, where it was spread out to dry. Once dried, it was crushed into smaller pieces using rubber mallets and then filtered through a 10 mm sieve. The subsoil used for the project was obtained in two batches from the same farmland near Cardiff. Several jar tests were conducted to determine the clay content. Despite being sourced from the same farm, the soil had variable clay content: the first subsoil batch had a clay content of 1.5 parts to 5 parts of sand/silt, while the second batch had a clay content of 3 parts to 5 parts of sand/silt. The dry material was arranged in batches consisting of 12 kg of subsoil and 35 g of manually cut straw measuring an average of 1.5 to 2.5 cm in length. Due to water usage restrictions in the lab, the wet mixture was prepared in the adjacent wet-casting room and stored in covered buckets in the lab. Refer to Figure 6 and Figure 7 for the dry and wet cob-like mixture preparation process. Over time and through repeated experiments, an intuition was developed to achieve the correct texture that balances a mixture of fluidity and viscosity, ensuring a smooth material extrusion and facilitating buildability and shape definition during the printing process. Drop tests were performed throughout the process. In the later stages, a standardised measuring cup of 250 mL ensured the use of consistent amounts of soil. The soil sample was shaped into a ball and dropped from a height of 40 cm onto a 50 mm grid. Experimentation revealed that a diameter of 115 to 120 mm indicated a suitable consistency for the cob mixture in the system. The amount of sieved subsoil and straw remained constant, while the quantity of water varied based on the drop test results (refer to Figure 8). Before filling the tubes, the material was checked using the drop test and adjusted accordingly. This process ensured a mixture with consistent rheological properties, allowing for better control of workability and resolving issues related to material overflow, underflow, and fragmented outputs encountered at the start of the research process. It also helped troubleshoot the limitations of the extruder and define a workable mixture recipe. This quantitative measurement approach mitigated the variability in subsoil composition and properties across the two different acquired batches, controlling the rheology of the wet-like cob material at the pre-extrusion stage and thereby ensuring consistent material extrusion and geometry build-up. The material was then manually compacted into 10 cm diameter, 90 cm length tubes to eliminate air gaps. Filled tubes were covered and stored horizontally to minimise settling. If the material remained in the tubes for more than two days, it was removed, readjusted, and then refilled back into the tubes;

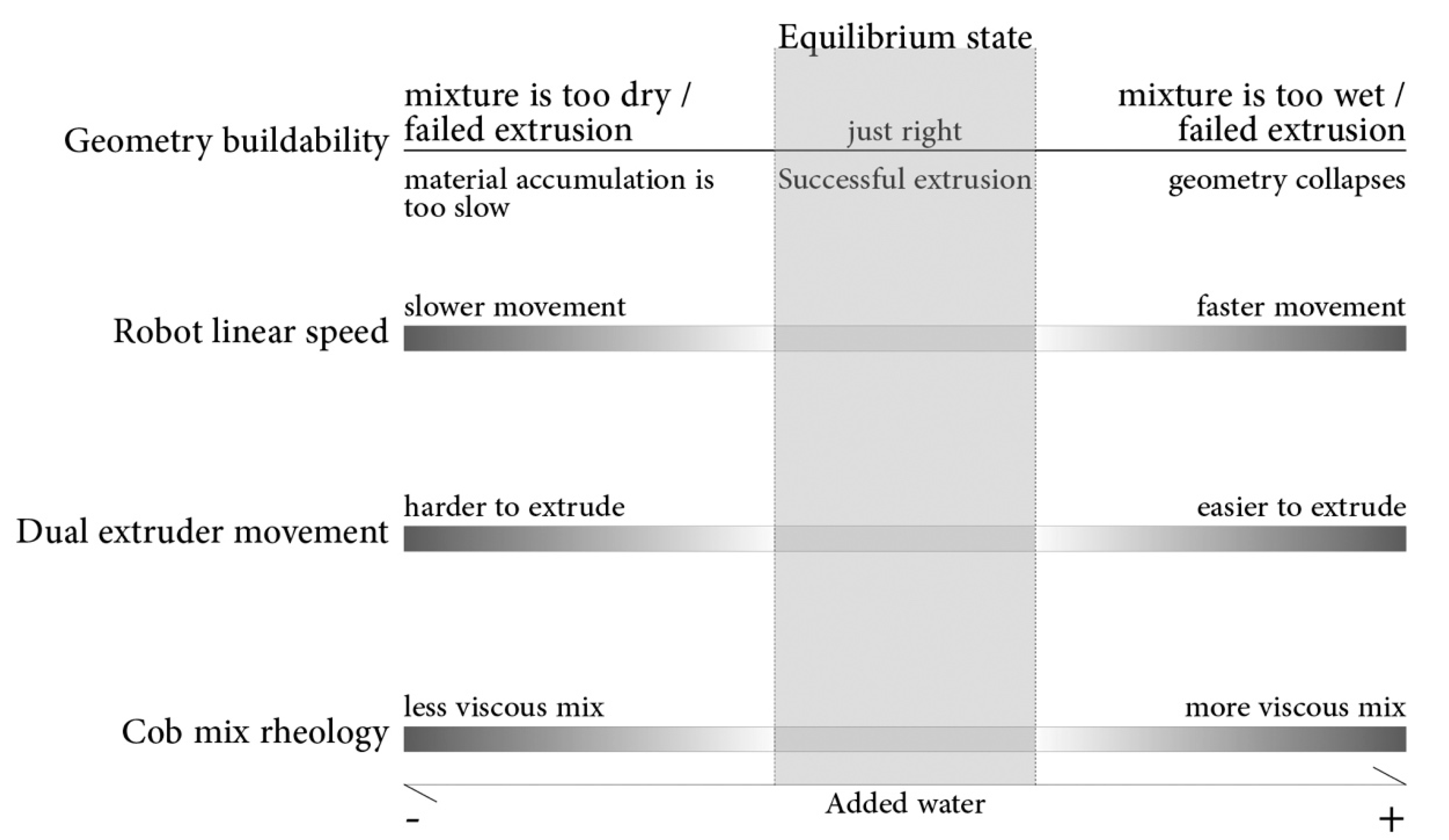

- The extrusion phase involved the extrusion and printing process of the wet material. It focused on material behaviour during system operation. The process began by loading the tubes into the dual extruder, with each hose containing 1.8 times the amount of the soil mixture held in the tube. This posed a challenge as the loaded material was not the same as the extruded one. As such, it was important to seal both ends of the system to minimise moisture evaporation. Material behaviour was evaluated based on two parts: a. Flow and movement speed in the tube and hose in relation to the push force by the plate attached to the moving rod, and b. Consistency, extrusion, and buildability at the nozzle end held by the robotic arm. The sausage or roll test mentioned in the literature [2] was substituted with observing the material behaviour flow from the nozzle positioned at a distance of approximately 20 cm from the printing plate (refer to Figure 9). Overly fluid mixtures, though easily extruded, were found to have poor buildable geometry. On the other hand, using a more solid mix caused the three-phase 0.75 kW to come to a complete stop. Increasing the amount of fibres used altered the resistance and also reduced the flow movement of the mixture. Additionally, the height at which the material was deposited influenced the path and direction of the hose, thus affecting the material-extrusion speed. To calibrate the above, the rheology of the cob mix was controlled to achieve the identified suitable level of fluidity to work with the dual extruder. The inputted extruder speed was 280 mm/s. However, the actual working speed highly varied depending on the consistency of the extruded material. Through observation, data collection, and analysis, the optimum robot speed was identified at 150 mm/s. The researcher then interactively reduced the speed in response to the material behaviour, starting with quarter intervals and refining it further with 5% reduction steps. The latter gave the researcher the needed control over the operation, enabling a digital sculpting process reminiscent of the craftsmanship associated with traditional cob work. It was observed that the optimum behaviour was achieved when the robot operated between 75% and 25% of its inputted speed (210 mm/s–70 mm/s). The variation accounted for differences in the mixture due to human factors or unavoidable drying processes in the tube or hose when the system was not operated for two days. It also accommodated for the slight variation in material behaviour when deposited at different angles and heights;

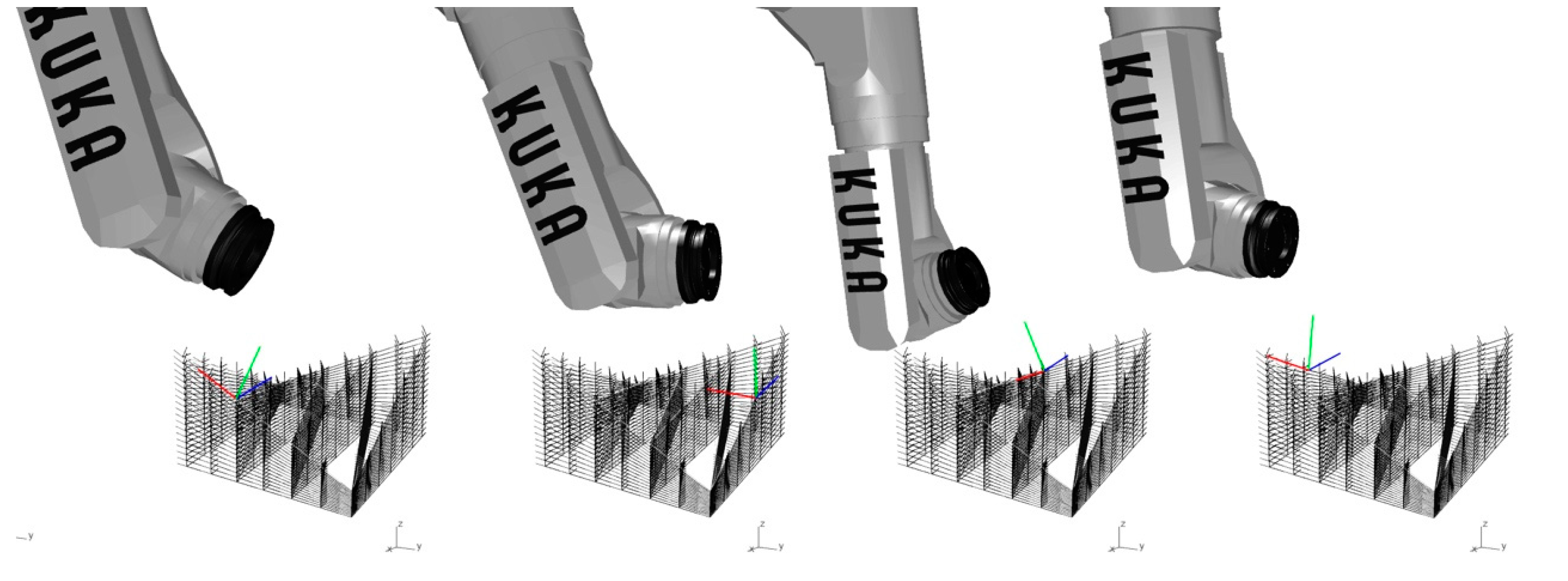

- Post-extrusion refers to the behaviour of the material once it is extruded from the nozzle and deposited on the tool path according to the geometry design. When planning the toolpath, it was ensured that the perpendicular distance between any two points on two consecutive toolpaths ranged between 5 and 15 mm. The variation in layer height, combined with controlled material overlap, allowed for the exploration and, subsequently, the formation of nonplanar geometries. The material was deposited perpendicular to the toolpath and thus compressed in the same perpendicular direction, which contributed to the overall geometric stability and structural integrity (refer to Figure 10). The relatively small size of the nozzle facilitated digitally sculpted geometrical paths. Due to the varied heights of the geometry, a natural level of material overlap occurred between consecutive layers. However, the overlap was avoided within the same toolpath on any single layer to prevent excess material deposition. Additionally, the layers were alternately reversed to ensure a continuous, non-overlapping printing path. While some case studies recommended against reversing the toolpath to allow the cob material to harden and settle before the next layer [40], the experiments conducted in the lab did not show any noticeable disadvantage in material settling when reversing the nozzle direction in the subsequent layers. This observation informed the design of nonplanar geometry for the pieces.

3.4. Prototyping and Outputted Geometry

- Continuous printing using several tubes. Even though, from the operational perspective, continuous, uninterrupted prints could be achieved by sequentially changing the cartridges in the extruder, this approach proved to be unviable as the geometry sagged under its own weight. This was due to the material viscosity and the extruder’s limitations in handling harder mixes, which restrained the reachable height of the printed geometry;

- Interval-continuous printing was adopted as an alternate approach to achieve continuity. The printing process was paused to allow the deposited material to settle and harden, with the settling time ranging from 12 to 24 h. After the settling period, the model was placed in the same position, and the printing process was resumed from the exact point where it was stopped. It was observed that the intermittent printing process facilitated better control and enabled the outputting of more complex nonplanar geometries. However, one drawback of this approach is the extended overall duration of the printing process and having to plan the process over several days;

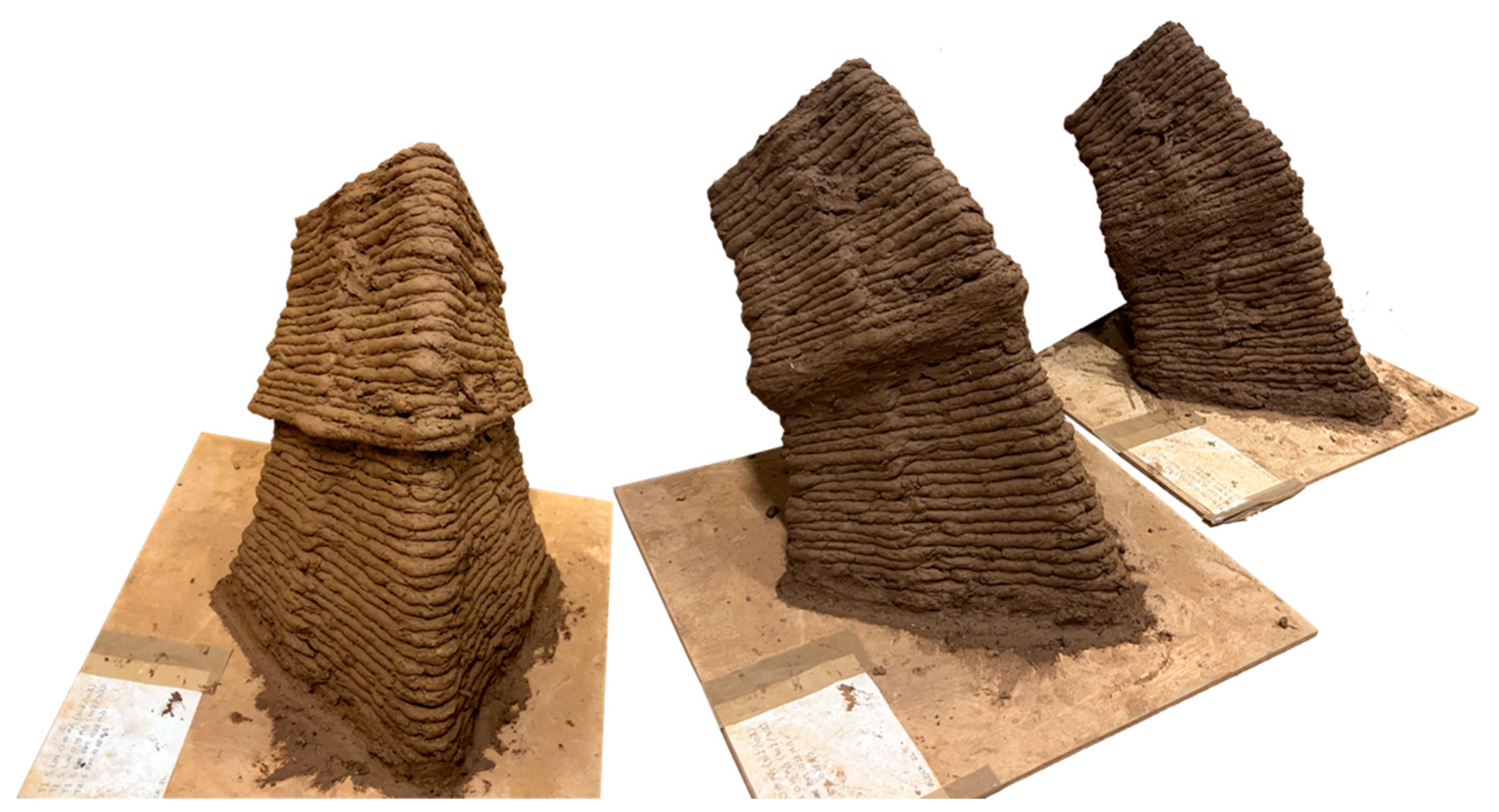

- Modular printing is a sequential process that involves printing pre-planned segments separately and then joining them to form a more complex geometry. It was observed that the drying process, accompanied by geometry shrinkage, is a complex three-dimensional phenomenon that depends on the volumetric positioning of the geometry in relation to the gravitational force and its own weight. The digitally modelled geometries, which had the same dimensions in the wet state, diverged in shape as they transitioned into the dry state. The same shapes and surfaces underwent changes in formation and were altered depending on their positioning during drying. Assembly of the printed segments was carried out when the geometry had passed the wet stage and thus could be moved around. Figure 14 illustrates three examples of two-geometrical assemblies. The prototype on the left consists of two printed pieces assembled after they had completely dried out. The variation in geometry resulted from the material settling during the drying process. The prototypes in the middle and on the right were assembled at different durations after the wet stage but before complete dryness, resulting in smoother geometrical transitions. In the latter case, the drying process continued after assembly, leading to a more homogeneous final outcome. Therefore, it is important to plan the printing times and drying durations of all segments and strategise the assembly order. For the geometric assemblies, a wet cob was used as mortar to hold the pieces together, eliminating the need for any additional substances and ensuring material homogeneity. When designing the geometries and assemblies, the properties of cob as a material were taken into consideration, focusing on geometries that work well in compression. In the assembled arch prototype, the inner compression forces contributed to its overall stability. For more complex geometrical formations, it will be necessary to codify the three-dimensional shrinkage to accurately assess structural forces, thus ensuring a between geometric fidelity and structural integrity.

4. Discussion and Conclusions

- Transforming the subsoil into a wet cob mix is an arduous and repetitive process that could be automated;

- The instability of the dual-extruder and its variable running speed, based on the material resistance, are important aspects to resolve. The research would benefit from having a controlled, stable pushing force that can be applied to the material, allowing for consistent movement at the same speed, regardless of its wet mix rheology;

- There is a need to optimise the robot’s movement by increasing its range while maintaining the fluidity and stability of the material flow.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogue, C. House of Earth: A Complete Handbook for Earthen Construction; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2016; ISBN 9781530642816. [Google Scholar]

- Weismann, A.; Bryce, K. Building with Cob: A Step-by-Step Guide; Green Book: Cambridge, UK, 2006; ISBN 9781903998724. [Google Scholar]

- Steen, B.; Athena, S. Built by Hand: Vernacular Buildings around the World, 1st ed.; Baird, M., Ed.; Gibbs Smith: Kaysville, UT, USA, 2004; ISBN 9781586852375. [Google Scholar]

- Evans, I.; Smith, M.G.; Smiley, L. The Hand-Sculpted House. In A Practical and Philosophical Guide to Building a Cob Cottage; Chelsea Green Publishing: White River Junction, VT, USA, 2002. [Google Scholar]

- Aubert, J.-E.; Faria, P.; Maillard, P.; Ouedraogo, K.A.J.; Ouellet-Plamondon, C.; Prud’homme, E. Characterization of Earth Used in Earth Construction Materials. In Testing and Characterisation of Earth-Based Building Materials and Elements; RILEM State-of-the-Art Reports; Fabbri, A., Morel, J.C., Aubert, J.E., Bui, Q.B., Gallipoli, D., Reddy, B.V.V., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 17–25. [Google Scholar]

- Fabbri, A.; Morel, J.-C.; Aubert, J.-E.; Bui, Q.-B.; Gallipoli, D.; Reddy, B.V.V. (Eds.) Testing and Characterisation of Earth-Based Building Materials and Elements; RILEM State-of-the-Art Reports; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; Volume 35, ISBN 978-3-030-83296-4. [Google Scholar]

- Azil, A.; Le Guern, M.; Touati, K.; Gomina, M.; Sebaibi, N.; Boutouil, M.; Streiff, F.; Goodhew, S.; Louahlia, H. Construction Field Monitoring of a COB Prototype Building. In Proceedings of the 4th International Conference on Bio-Based Building Materials, Barcelona, Spain, 16–18 June 2021; pp. 458–465. [Google Scholar]

- Niroumand, H.; Zain, M.F.M.; Jamil, M. A Guideline for Assessing of Critical Parameters on Earth Architecture and Earth Buildings as a Sustainable Architecture in Various Countries. Renew. Sustain. Energy Rev. 2013, 28, 130–165. [Google Scholar] [CrossRef]

- Morris, W. Devon Historic Buildings Trust; DHBT: Devon, UK, 1992; Available online: https://www.joostdevree.nl/bouwkunde2/jpgl/leem_11_lemen_gebouwen_in_devon_1_geschiedenis_enz_www_devonearthbuilding_com.pdf (accessed on 10 June 2024).

- Watson, L.; McCabe, K. The Cob Building Technique: Past, Present and Future. Inf. Constr. 2011, 63, 59–70. [Google Scholar] [CrossRef]

- Jaquin, P.; Augarde, C. Earth Building: History, Science and Conservation; IHS BRE Press: Watford, UK, 2012. [Google Scholar]

- Quagliarini, E.; Stazi, A.; Pasqualini, E.; Fratalocchi, E. Cob Construction in Italy: Some Lessons from the Past. Sustainability 2010, 2, 3291–3308. [Google Scholar] [CrossRef]

- Bardel, P.; Rioult, J.-J. Les Premieres Formes de Construction En Bauge Dans Le Bassin de Rennes. The First Forms of Cob Construction in the Rennes Area. In L’architecture en Bauge en Europe (Cob Building in Europe); Parc Naturel Regional des Marais du Cotentin et du Bessin: Isigny-sur-Mer, France, 2006; pp. 151–172. [Google Scholar]

- Bavay, G. Trente Annees d’investigations Sur La Bauges En Wallonie (Belgique). La Bauge Dans Le Contexte Des Architectures de Terre. Historiographie et Tendances. (Thirty Years of Investigating Con in the Walloon Area of Belgium. Cob within the Context of Earth-Based Architecture. Historiography and Trends). In L’architecture En Bauge En Europe (Cob building in Europe); Parc Naturel Regional des Marais du Cotentin et du Bessin: Isigny-sur-Mer, France, 2006; pp. 93–116. [Google Scholar]

- Ziegert, C. Analysis of Material, Construction and Damage in Historical Cob Buildings in Central Germany. In Proceedings of the Terra 2000: 8th International Conference on the Study and Conservation of Earthen Architecture, Devon, UK, 6–11 May 2000; James & James: London, UK, 2000. [Google Scholar]

- Aurenche, O.; Klein, A.; de Chazelles, C.-A.; Hubert, G. Essai de Classification Des Modalités de Mise En Œuvre de La Terre Crue En Parois Verticales et de Leur Nomenclature. In Les Cultures Constructives de la Brique Crue; Editions Espérou; ENSAM: Paris, France, 2008; pp. 13–34. [Google Scholar]

- Joshi, O.P. Earthen Architecture in Indian Tribes. In Proceedings of the Terra 2008: The 10th International Conference on the Study and Conservation of Earthen Architectural Heritage, Bamako, Mali, 1–5 February 2008; Getty Publications: Los Angeles, CA, USA, 2008; pp. 109–113. [Google Scholar]

- Norton, J. Building with Earth: A Handbook; ITDG Publishing: Rugby, UK, 1986; ISBN 9780946688333. [Google Scholar]

- Stacked Earth (Cob). Available online: https://www.earth-auroville.com/stacked_earth_en.php (accessed on 8 December 2022).

- Ford, M.; El Kadi, H.; Watson, L. The Relevance of Gis in the Evaluation of Vernacular Architecture. J. Archit. Conserv. 1999, 5, 64–75. [Google Scholar] [CrossRef]

- Harries, R.; Saxton, B.; Coventry, K. The geological and geotechnical properties of earth material from central devon in relation to its suitability for building in “COB”. Proc. Ussher Soc. 1995, 8, 441–444. [Google Scholar]

- Reddy, B.V.V.; Morel, J.-C.; Faria, P.; Fontana, P.; Oliveira, D.V.; Serclerat, I.; Walker, P.; Maillard, P. Codes and Standards on Earth Construction. In Testing and Characterisation of Earth-Based Building Materials and Elements; Springer: Berlin/Heidelberg, Germany, 2021; pp. 243–259. ISBN 9783030832971. [Google Scholar]

- Goodhew, S.; Boutouil, M.; Streiff, F.; Le Guern, M.; Carfrae, J.; Fox, M. Improving the Thermal Performance of Earthen Walls to Satisfy Current Building Regulations. Energy Build 2021, 240, 110873. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Integrating Earthen Building Materials and Methods into Mainstream Construction Using Environmental Performance Assessment and Building Policy. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012139. [Google Scholar] [CrossRef]

- Keefe, L. Earth Building: Methods and Materials, Repair and Conservation; Taylor & Francis Ltd.: Abingdon, UK, 2005; ISBN 9780415323222. [Google Scholar]

- Alqenaee, A.; Memari, A. Experimental Study of 3D Printable Cob Mixtures. Constr. Build Mater. 2022, 324, 126574. [Google Scholar] [CrossRef]

- Gomaa, M.; Carfrae, J.; Goodhew, S.; Jabi, W.; Veliz Reyes, A. Thermal Performance Exploration of 3D Printed Cob. Archit. Sci. Rev. 2019, 62, 230–237. [Google Scholar] [CrossRef]

- Veliz Reyes, A.; Jabi, W.; Gomaa, M.; Chatzivasileiadi, A.; Ahmad, L.; Wardhana, N.M. Negotiated Matter: A Robotic Exploration of Craft-Driven Innovation. Archit. Sci. Rev. 2019, 62, 398–408. [Google Scholar] [CrossRef]

- Moretti, F. 3D Printed Houses for a Renewed Balance between Environment and Technology. Available online: https://www.3dwasp.com/en/3d-printed-houses-for-a-renewed-balance-between-environment-and-technology/ (accessed on 8 December 2022).

- International Energy Agency. Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. In UN Environment Program 2019 Global Status Report for Buildings and Construction; International Energy Agency: Paris, France, 2019; ISBN 9789280737684. [Google Scholar]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental Assessment of Large-Scale 3D Printing in Construction: A Comparative Study between Cob and Concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Mitropoulou, I.; Bernhard, M.; Dillenburger, B. Nonplanar 3D Printing of Bifurcating Forms. 3D Print. Addit. Manuf. 2022, 9, 189–201. [Google Scholar] [CrossRef] [PubMed]

- Piker, D.; Maddock, R. Continuous Robotic Spatial 3D Printing of Topologically Irregular Space Frames. In Proceedings of the Design Modeling Symposium, Berlin, Germany, 23–25 September 2009; Springer: Berlin/Heidelberg, Germany, 2009; pp. 502–516. [Google Scholar] [CrossRef]

- Im, H.C.; Alothman, S.; Castillo, J.L.G. Responsive Spatial Print. Clay 3D Printing of Spatial Lattices Using Real-Time Model Recalibration. In Proceedings of the 38th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Mexico City, Mexico, 18–20 October 2018; pp. 286–293. [Google Scholar]

- Yu, L.; Luo, D. Mesh Optimisation for Spatial Wireframe Robotic 3D Printing. Int. J. Rapid Manuf. 2018, 7, 169. [Google Scholar] [CrossRef]

- Laarman, J.; Jokic, S.; Novikov, P.; Fraguada, L.E.; Markopoulou, A.; Gramazio, F.; Kohler, M.; Langenberg, S. Anti-Gravity Additive Manufacturing. In Fabricate 2014: Negotiating Design & Making; Gramazio, F., Kohler, M., Langenberg, S., Eds.; UCL Press: London, UK, 2017; pp. 192–197. [Google Scholar]

- Sparrow, N. What Is Robotic 3D-Printing Extrusion, and What Is It For? Plastics Today, February 2017. [Google Scholar]

- Jahanmahin, R.; Masoud, S.; Rickli, J.; Djuric, A. Human-Robot Interactions in Manufacturing: A Survey of Human Behavior Modeling. Robot. Comput. Manuf. 2022, 78, 102404. [Google Scholar] [CrossRef]

- Bernard, M.; Architect. R + D Awards. 9 August 2021. Available online: https://www.architectmagazine.com/awards/r-d-awards/award-robotic-constructionthe-glass-vault_o (accessed on 10 June 2024).

- Kofer, D.; Bergner, C.; Deuerlein, C.; Schmidt-Vollus, R.; Heß, P. Human-Robot-Collaboration: Innovative Processes, from Research to Series Standard. Procedia CIRP 2020, 97, 98–103. [Google Scholar] [CrossRef]

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human-Robot Collaboration in Manufacturing Applications: A Review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef]

- Hentout, A.; Aouache, M.; Maoudj, A.; Akli, I. Human–Robot Interaction in Industrial Collaborative Robotics: A Literature Review of the Decade 2008–2017. Adv. Robot. 2019, 33, 764–799. [Google Scholar] [CrossRef]

- ETH Zurich World Economic Forum. 26 May 2018. Available online: https://www.weforum.org/agenda/2018/03/robotic-collaboration-in-timber-construction (accessed on 10 June 2024).

- Palazzo, A.; Macek, D. Contour Crafting Technology: The Toothpaste for Constructions. Bus. IT 2021, 11, 51–59. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Kazemian, A. Contour Crafting: A Revolutionary Platform Technology. Prod. Appl. 2020, 48–53. [Google Scholar]

- Gomaa, M.; Jabi, W.; Veliz Reyes, A.; Soebarto, V. 3D Printing System for Earth-Based Construction: Case Study of Cob. Autom. Constr. 2021, 124, 103577. [Google Scholar] [CrossRef]

- Gin, Y.; Haddad, K.; Jabi, W.; Shah, D.U.; Ramage, M.H. Robotic 3D Printing with Earth: A Case Study for Optimisation of 3D Printing Building Blocks. In Proceedings of the IASS 2022 Symposium Affiliated with APCS 2022 Conference Innovation—Sustainability—Legacy, Beijing, China, 19–22 September 2022; pp. 3206–3217. [Google Scholar]

- Khoshnevis, B. Automated Construction by Contour Crafting—Related Robotics and Information Technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive Construction: State-of-the-Art, Challenges and Opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Kim, D.M. Illumin Article. Writing 340. 2013. Available online: http://illumin.usc.edu/assets/submissions/755/Contour%20Crafting%20revision.pdf (accessed on 10 June 2024).

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-Scale Fabrication by Contour Crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive Manufacturing as an Enabling Technology for Digital Construction: A Perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Winsun Yingchuang Building Technique. Available online: http://www.winsun3d.com/En/About/ (accessed on 8 December 2022).

- COBOD. The Bod. Available online: https://cobod.com/projects-partners/the-bod-building/#:~:text=Europe’s%20first%203D%20printed%20building%20is%20located%20in%20Copenhagen%2C%20Denmark,conventional%20construction%20methods%20of%20today (accessed on 8 December 2022).

- CyBe 3D Studio 2030. Available online: https://cybe.eu/cases/3d-studio-2030/ (accessed on 8 December 2022).

- Thomsen, M. Mail Online. 6 February 2020. Available online: https://www.dailymail.co.uk/sciencetech/article-7975233/Worlds-biggest-3D-printed-building-opens-Dubai-6-900-square-foot-government-office.html (accessed on 10 June 2024).

- Giannakopoulos, S. Pylos Project-Robotic 3D Printing of Clay. The Institute for Advanced Architecture of Catalonia (IAAC). 2015. Available online: https://iaac.net/project/pylos/ (accessed on 8 December 2022).

- Cabay, E.; Dubor, A. TerraPerforma Project. 3D Printed Performative Wall. Available online: https://iaac.net/project/terraperforma/ (accessed on 8 December 2022).

- Dubor, A.; Cabay, E.; Marengo, M.; Chadha, K.; Moreno, S. Digital Adobe. Available online: https://iaac.net/project/digital-adobe/ (accessed on 8 December 2022).

- Chiusoli, A. The First 3D Printed House with Earth|Gaia. Available online: https://www.3dwasp.com/en/3d-printed-house-gaia/ (accessed on 8 December 2022).

- WASP and Mario Cucinella Architects MCA. TECLA. 2021. Available online: https://www.3dwasp.com/en/3d-printed-house-tecla/ (accessed on 8 December 2022).

- Moretti, F. WASP 3D Prints a Unique Concept Store in Collaboration with Dior. Available online: https://www.3dwasp.com/en/3d-printed-pop-up-store-wasp-dior/ (accessed on 8 December 2022).

- Lazzari, G. Crowdfunding for the House of Dust. Available online: https://www.3dwasp.com/en/crowdfunding-for-the-house-of-dust/ (accessed on 8 December 2022).

- Severi, A. Itaca: The Self-Sufficient and Eco-Sustainable 3D Printed House. Available online: https://www.3dwasp.com/en/itaca-the-self-sufficient-and-eco-sustainable-3d-printed-house/ (accessed on 8 December 2022).

- Chiusoli, A. 3D Printed Earth Wall with Embedded Staircase. Available online: https://www.3dwasp.com/en/3d-printed-wall/ (accessed on 10 June 2024).

- Polvi, F.; Bryson, Z. 152 Travessera de Gràcia. Available online: https://www.iaacblog.com/programs/152-travessera-de-gracia/ (accessed on 8 December 2022).

- Emerging Objects. Mud Frontiers: Part II. 2019. Available online: http://emergingobjects.com/project/mud-frontiers-part-ii/ (accessed on 8 December 2022).

- Emerging Objects Casa Covida. Available online: https://www.rael-sanfratello.com/made/casa-covida (accessed on 8 December 2022).

- Perrot, A.; Rangeard, D.; Courteille, E. 3D Printing of Earth-Based Materials: Processing Aspects. Constr. Build. Mater. 2018, 172, 670–676. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Lecompte, T. Field-Oriented Tests to Evaluate the Workability of Cob and Adobe. Mater. Struct. 2018, 51, 54. [Google Scholar] [CrossRef]

- Bee, B. The Cob Builders Handbook. You Can Hand-Sculpt Your Own Home; Chelsea Green: White River Junction, VT, USA; Victoria, BC, Canada, 1997. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, L.; Jabi, W.; Sosa, M. Nonplanar Robotic Printing of Earth-Based Material: A Case Study Using Cob-like Mixture. Buildings 2024, 14, 2589. https://doi.org/10.3390/buildings14082589

Ahmad L, Jabi W, Sosa M. Nonplanar Robotic Printing of Earth-Based Material: A Case Study Using Cob-like Mixture. Buildings. 2024; 14(8):2589. https://doi.org/10.3390/buildings14082589

Chicago/Turabian StyleAhmad, Lina, Wassim Jabi, and Marco Sosa. 2024. "Nonplanar Robotic Printing of Earth-Based Material: A Case Study Using Cob-like Mixture" Buildings 14, no. 8: 2589. https://doi.org/10.3390/buildings14082589

APA StyleAhmad, L., Jabi, W., & Sosa, M. (2024). Nonplanar Robotic Printing of Earth-Based Material: A Case Study Using Cob-like Mixture. Buildings, 14(8), 2589. https://doi.org/10.3390/buildings14082589