Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials

Abstract

:1. Introduction

1.1. Background

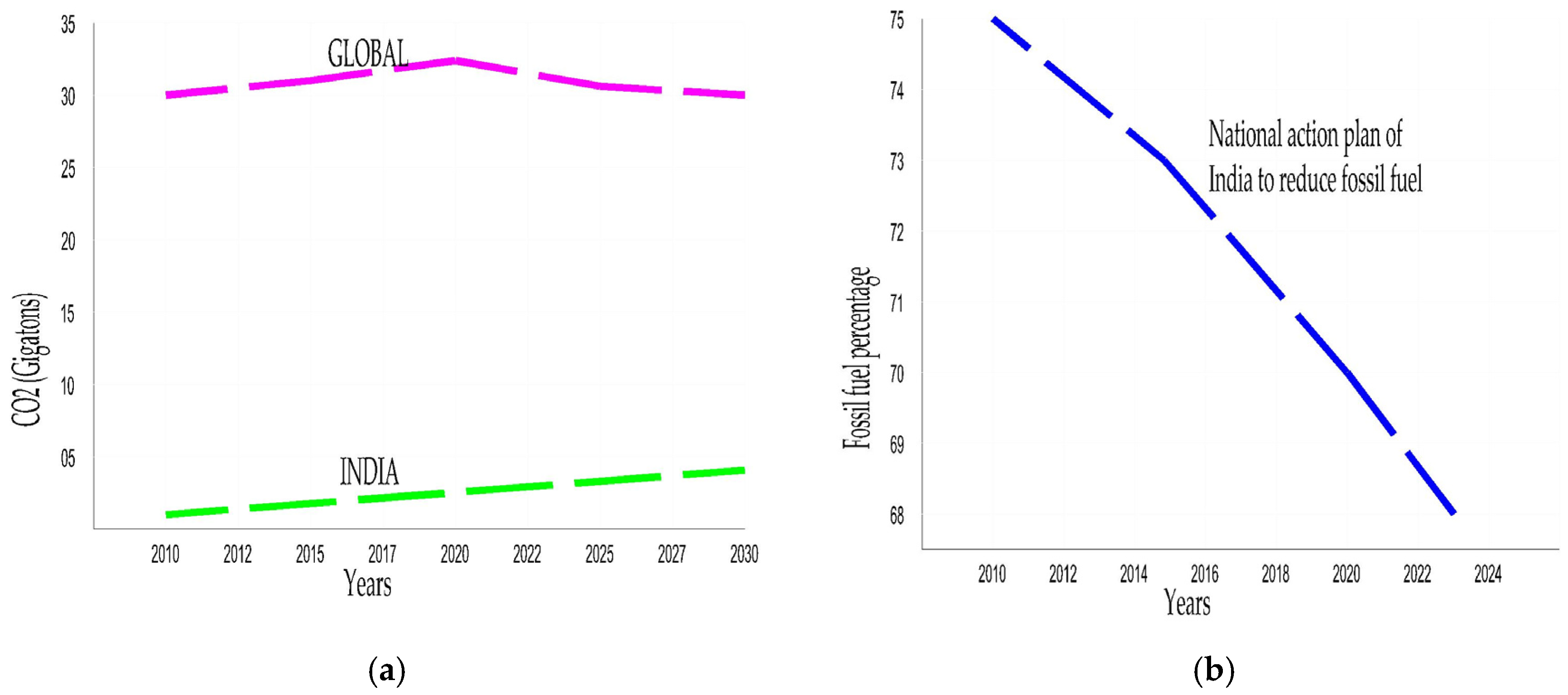

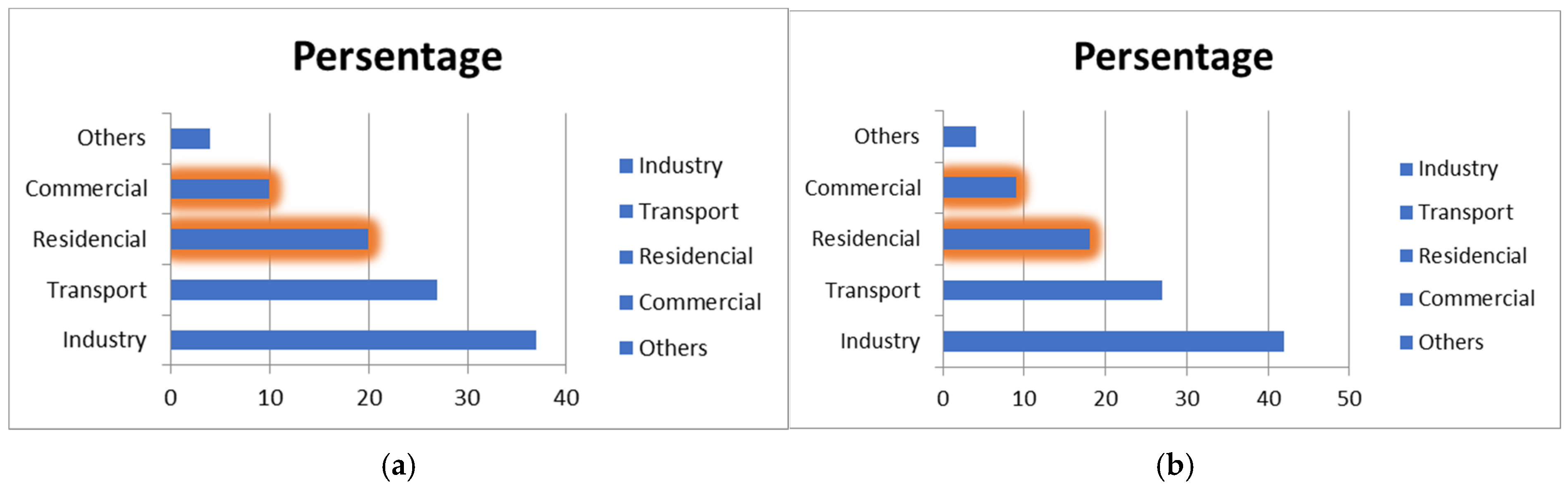

1.2. Environmental Issues Connected to Energy Generation

1.3. Energy Scenario

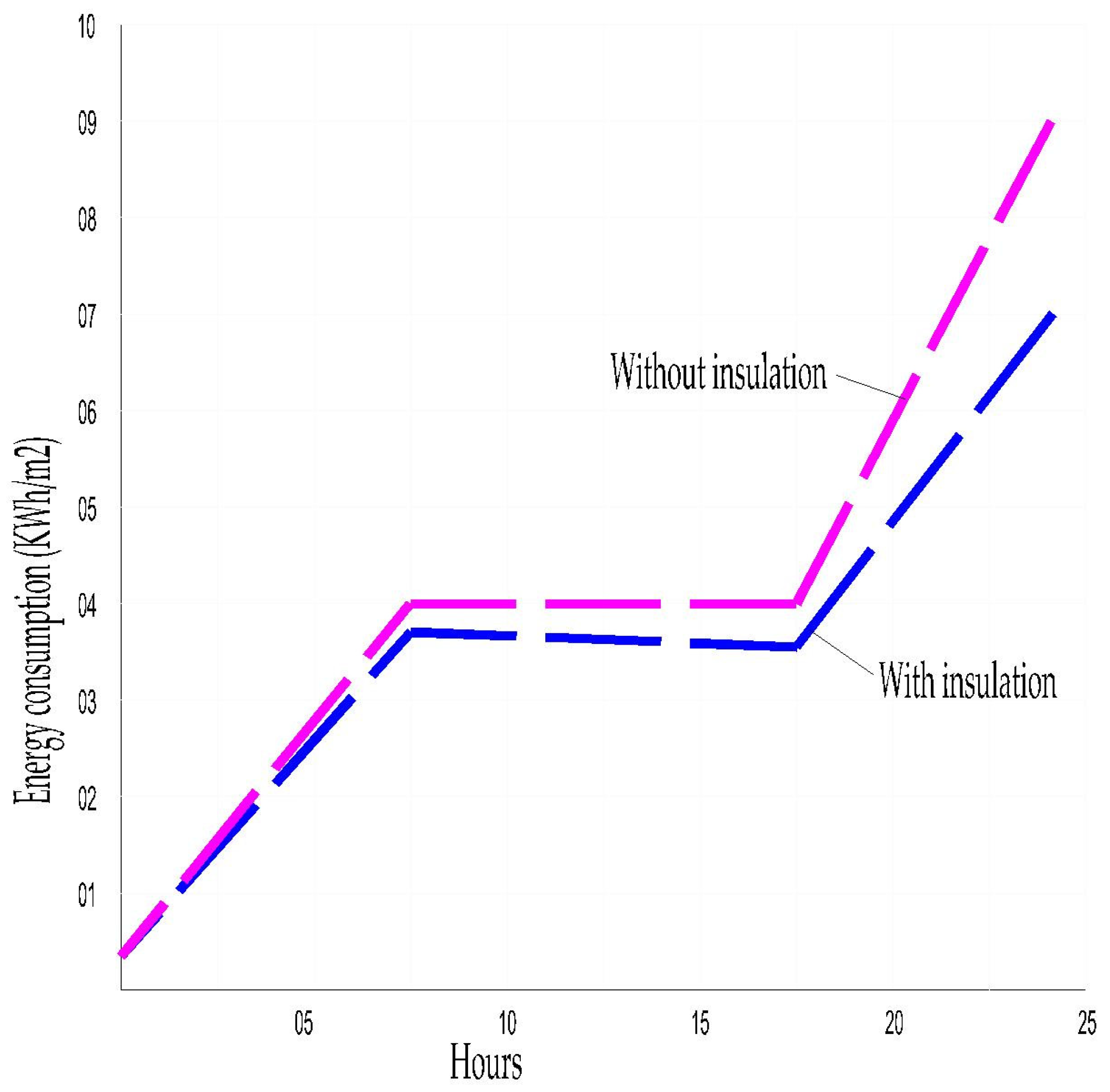

1.4. Role of Thermal Insulation

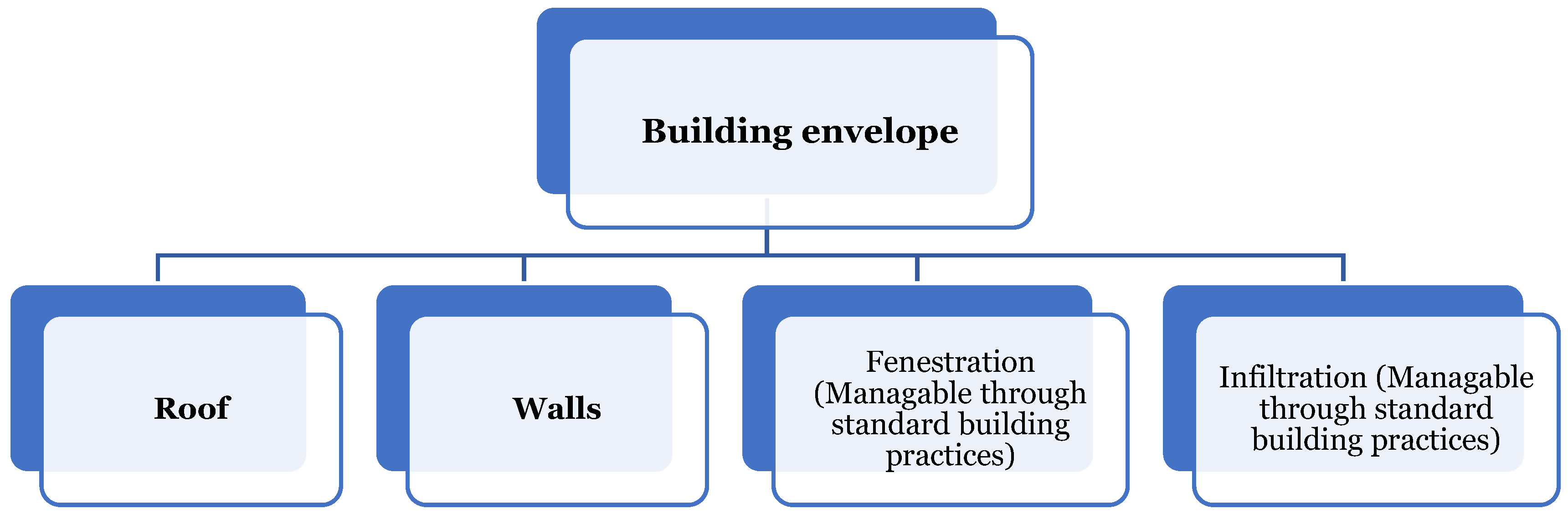

1.5. Building Envelope

1.6. Thermal Comfort

1.7. Selective Overview

- A.

- Building envelope thermal comfort.

- B.

- Sustainable materials.

1.8. Sustainable Materials

1.9. Unique Contributions

- Assess the heat conductivity and insulation value of bamboo biochar, fly ash, and lime to determine their insulation effectiveness.

- Analyze the sustainability performance of these materials through life cycle analysis and carbon footprint assessment.

- Identify research gaps and offer recommendations for future research in the development of sustainable insulation systems.

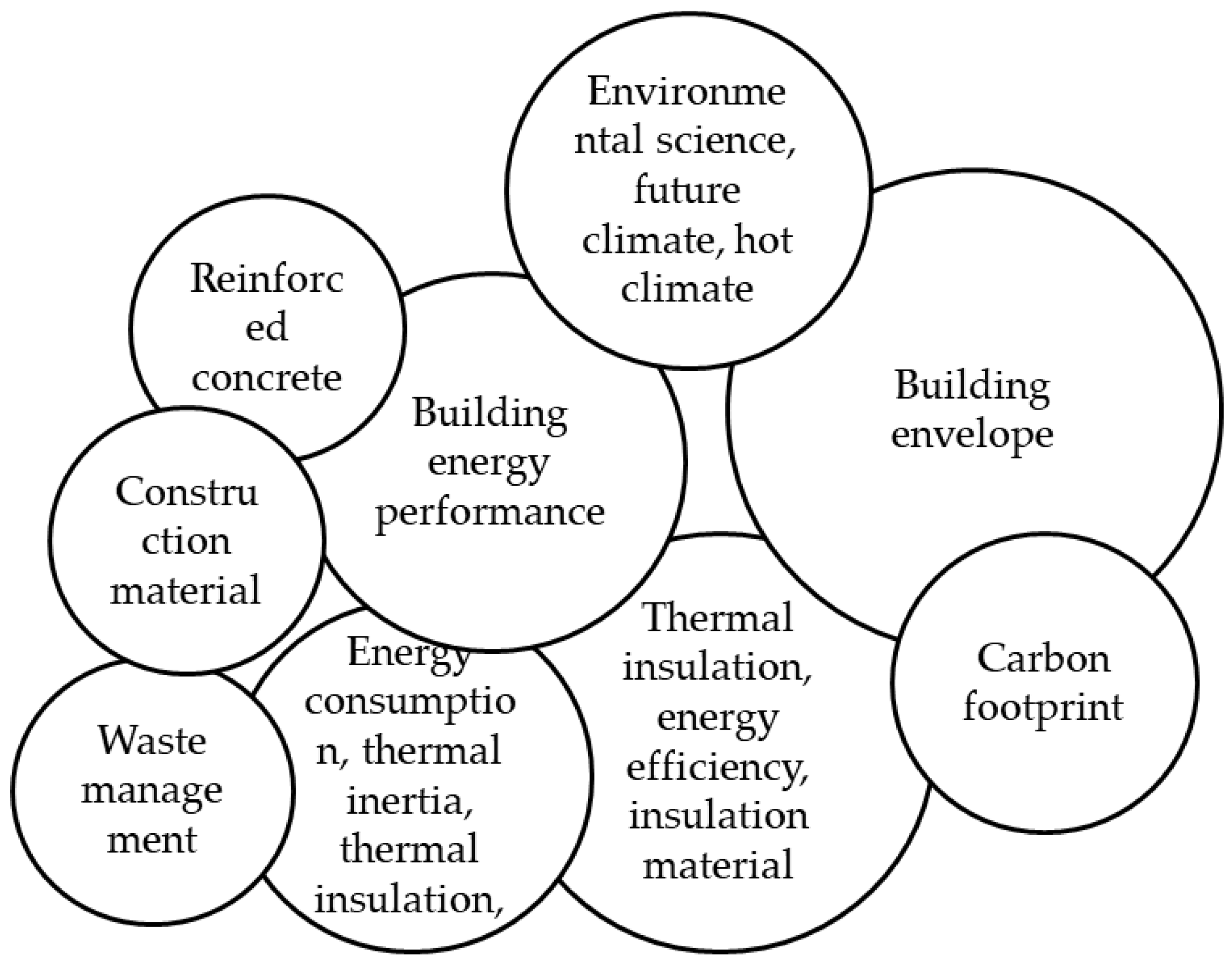

2. Literature Review

2.1. Thermal Performance

2.1.1. Research Review for Bamboo Biochar, Ash, and Lime

2.1.2. Fly Ash

2.1.3. Lime

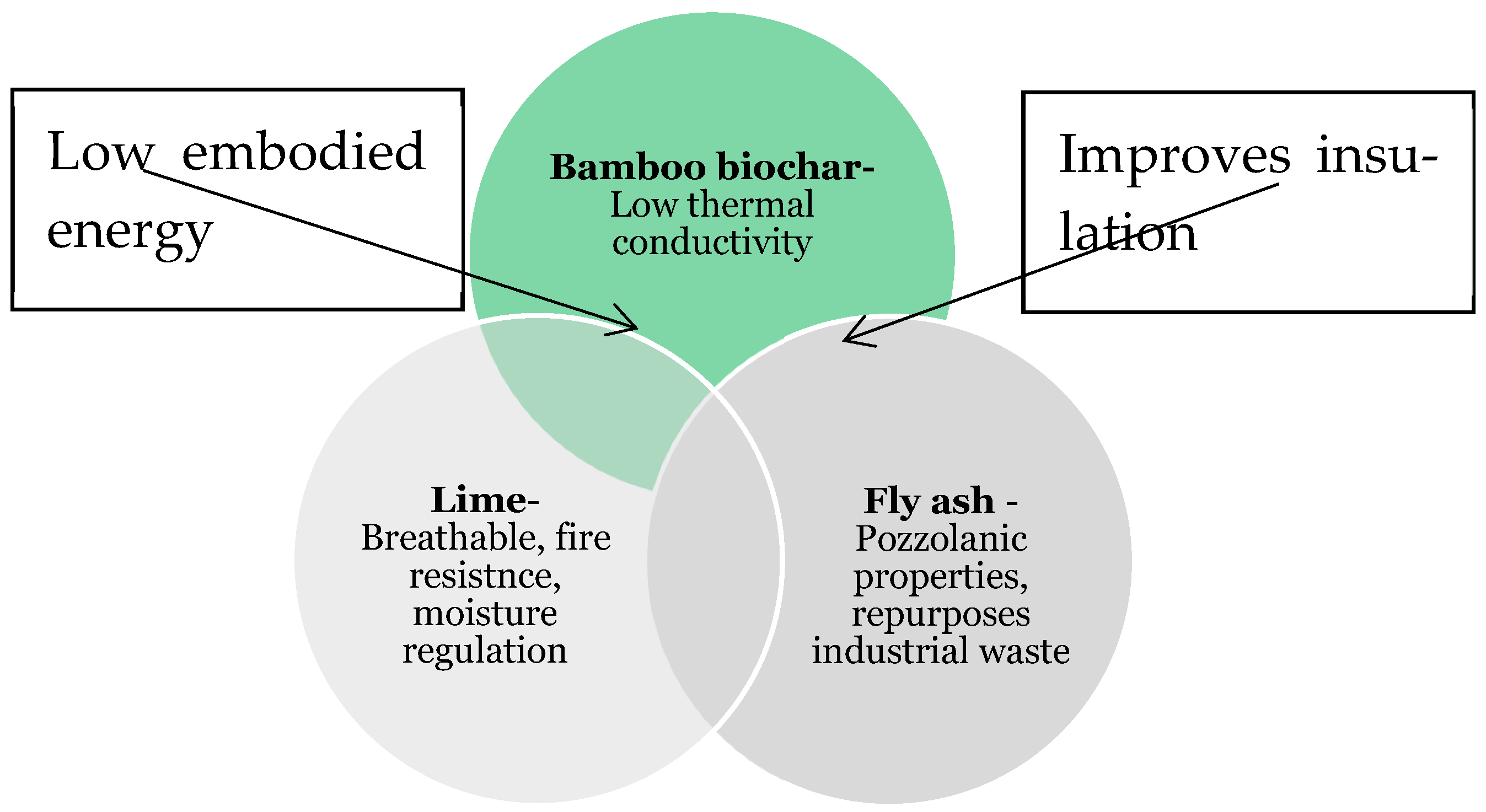

- Bamboo Biochar: Bamboo biochar exhibits low thermal conductivity due to its unique structure and carbon content. Studies report a U-value range of 0.6–0.51 W/m2K, making it effective for insulation. Additionally, its capacity for CO2 absorption supports its use in building materials where thermal resistance and carbon reduction are priorities.

- Fly Ash: Fly ash demonstrates moderate thermal insulation properties, with U-values ranging between 0.66 and 0.05 W/m2K, depending on composition and treatment. Its inclusion in concrete and mortar improves insulation while also enhancing structural durability, though optimization of mix ratios is necessary to maximize insulation without compromising mechanical strength.

- Lime: Lime-based materials provide notable thermal insulation (U-value 0.63–0.35 W/m2K) and humidity regulation. Their natural insulating properties can stabilize indoor temperatures by reducing heat flux through walls. Lime’s moisture-regulating capabilities further contribute to building comfort, particularly in humid climates.

- The literature review indicated that all three sustainable materials have significant potential for use as building insulation. The Table 11 demonstrates that the U-value ranges of these materials are very close to the standard value. However, fly ash and lime exhibit lower values that exceed the standard compliance limit of 0.40, as per ECBC guidelines. This suggests room for improvement to meet higher standards such as ECBC and ECBC Super standards. Therefore, an optimal combination of these three materials could achieve superior ECBC compliance.

| Material | ECBC Standards | U-Value Range (W/m2K) | Important Properties |

|---|---|---|---|

| Bamboo biochar | 0.40 | 0.60–0.51 | Insulation, CO2 sequestration |

| Fly ash | 0.66–0.05 | Insulation, improves mechanical properties | |

| Lime | 0.63–0.35 | Insulation, humidity control, fire resistance |

- Chronological order—The chronological arrangement of literature data offers clear insights for selecting the most effective material typology with the highest proven performance. It also facilitates informed decision-making by identifying the optimal form of the material while presenting alternative options with comparable values.

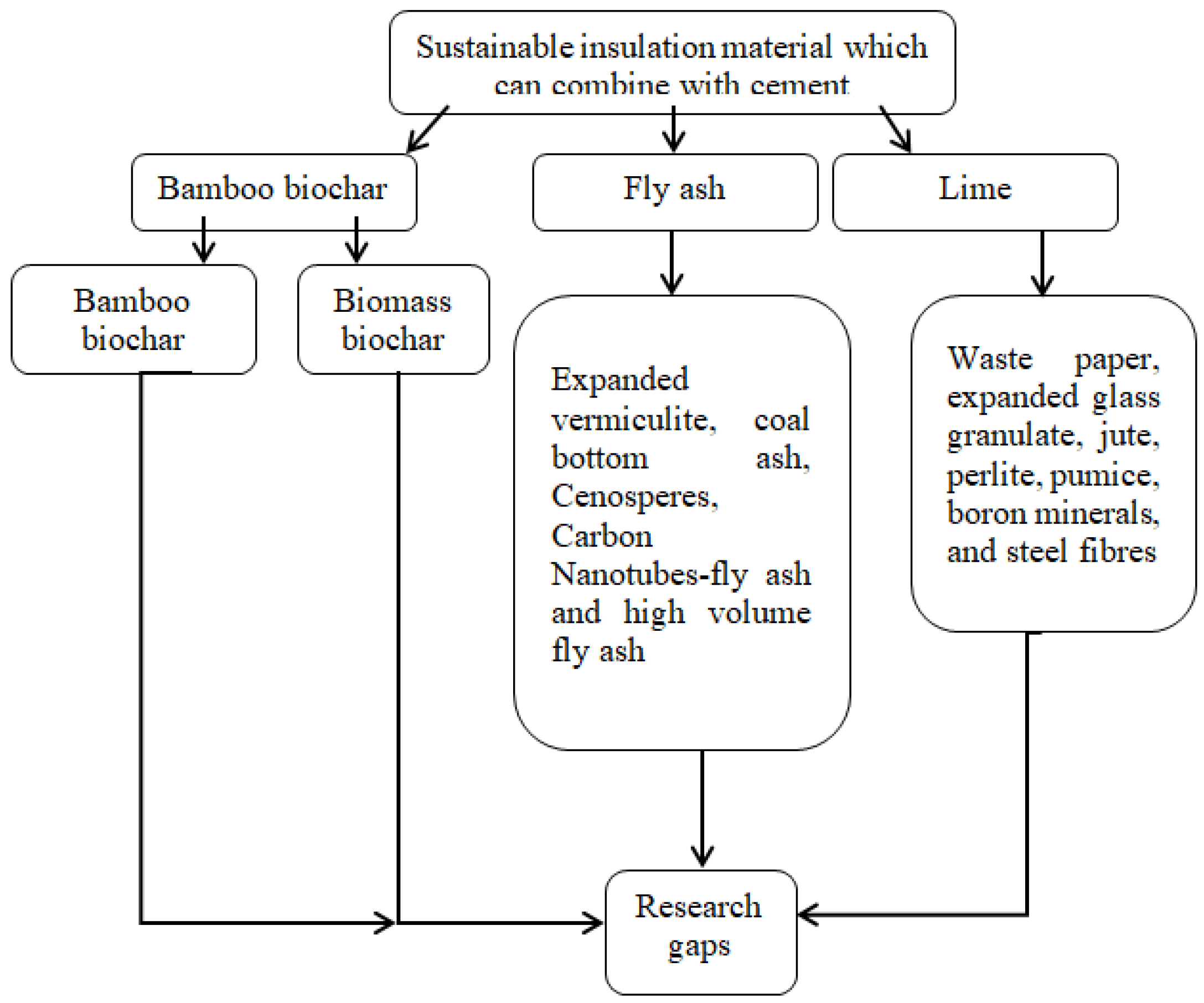

- Bamboo biochar—A chronological analysis of the literature results demonstrated that biochar alone offers superior insulation properties. However, bamboo biochar has not yet been explored for its potential as a building insulation material. Other options in the sequence, such as combinations of biochar with foam, geopolymer materials, biochar bricks, and cement admixtures, have shown limited effectiveness. This analysis provides a clear, informed basis for decision-making, confirming that biochar alone can be incorporated into the proposed mix. Nonetheless, there is significant potential for further research into the insulation properties of bamboo biochar.

- Fly ash—A chronological analysis of the literature data revealed that wood ash exhibits the lowest insulation value, while 100% sand replacement yields the best performance among all options. However, wood ash was not considered due to its exclusion from the research scope. C-type fly ash, cenospheres, and high-volume (50%) fly ash are identified as viable alternatives for incorporation into the proposed mix. The remaining options in chronological order serve as references, indicating the minimum achievable results with the inclusion of fly ash.

- Lime—The chronological analysis suggests that lime, when combined with other sustainable materials, presents significant opportunities for achieving improved results. Starting with the lowest insulation value, the combination of lime and aerosol material is an initial option. However, due to the high cost of aerosol, this combination may not be practical. Aggregates like olive stone, perlite, and pumice offer a more feasible next step when paired with lime. Waste paper emerges as the most promising option, providing the highest potential for performance while also reducing costs through the reuse of waste materials.

- Comparative Analysis—Among the three materials, biochar alone offers better thermal conductivity (0.8–0.02 W/mK), positioning it as a strong candidate for insulation. Fly ash and lime also contribute significantly to thermal regulation, with fly ash enhancing concrete’s durability and lime providing moisture control as well as fire resistance.

2.2. Environmental Impact

- Goal and Scope Definition: ISO 14040 highlights the importance of clearly defining the goals and boundaries of a life cycle assessment, focusing on aspects such as raw material extraction, production, use, and disposal stages for embodied energy and carbon footprint assessment [128].

- Life Cycle Inventory (LCI): This phase involves quantifying inputs (raw materials, energy) and outputs (emissions, waste) across each stage, providing the data foundation for embodied energy and carbon footprint analysis.

- Life Cycle Impact Assessment (LCIA): The impact assessment translates LCI data into meaningful metrics such as global warming potential (carbon footprint) and cumulative energy demand (embodied energy).

- Interpretation: This final phase involves interpreting results to identify critical environmental impacts and improvement opportunities.

- Bamboo Biochar: Biochar sequesters carbon, offsetting emissions generated during production. Fast-growing bamboo, which reaches maturity in 3–5 years, presents a renewable resource option. Additionally, biochar production involves pyrolysis, a process that reduces waste by converting organic matter to a carbon-rich material.

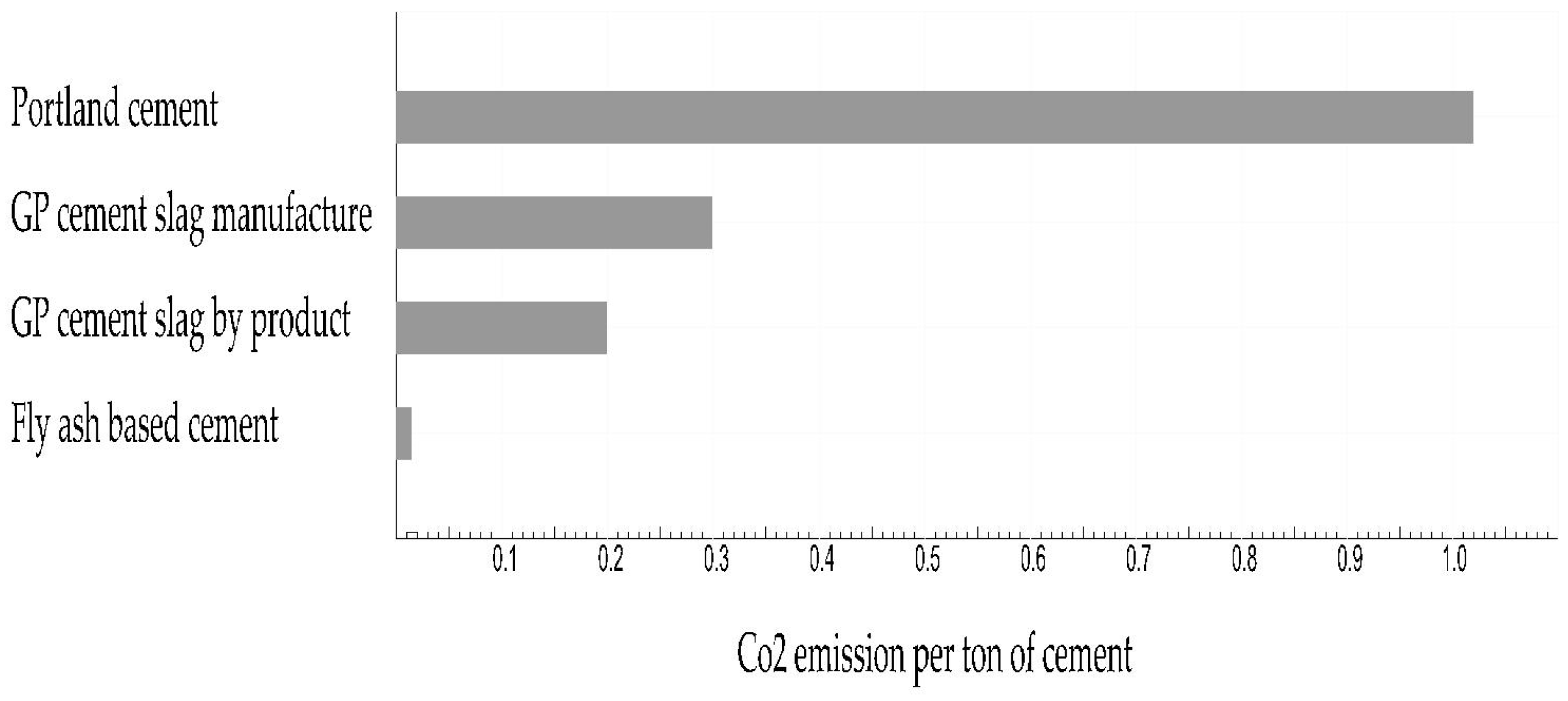

- Fly Ash: As a byproduct of coal combustion, fly ash reduces landfill waste and repurposes industrial residue. By using fly ash in construction, overall CO2 emissions are minimized, as it replaces energy-intensive cement components. Studies suggest fly ash incorporation can decrease concrete’s carbon footprint by up to 65%.

- Lime: Lime has a moderate carbon footprint, primarily due to CO2 emissions during calcination. However, lime’s recyclability and ability to be produced locally in many regions help lower its embodied energy. When used in plasters and mortars, lime also supports indoor air quality by permitting natural ventilation and moisture control.

- Comparative Analysis: Bamboo biochar has the lowest carbon footprint due to carbon sequestration, followed by fly ash as an effective reuse of industrial waste. Lime, while emitting CO2 during production, remains eco-friendly due to its longevity and recyclability.

- A previous research paper quantifies embodied energy by examining the total energy required for material production, from raw material extraction to final application. For example, the embodied energy of bamboo biochar, fly ash, and lime is calculated by including energy used in processing (e.g., pyrolysis for bamboo biochar) and transportation.

- The emphasis on renewable materials like bamboo biochar aligns with reducing embodied energy, as bamboo grows rapidly with minimal energy input, reducing its life cycle energy footprint.

- Carbon sequestration potential of bamboo biochar, which can offset emissions by storing carbon during its life cycle.

- Emissions from raw material extraction, processing, and end-of-life disposal (e.g., CO2 released during lime production is noted but offset by its ability to reabsorb CO2 over time).

- Specific metrics, such as CO2 savings per ton of biochar-added concrete, are referenced, showcasing quantitative alignment with LCA carbon footprint methodologies.

- The research incorporates life cycle thinking as prescribed by ISO 14040 by evaluating the materials’ environmental impact at every stage—from production to disposal.

- The study’s comparative approach to bamboo biochar, fly ash, and lime reflects the LCIA principle of identifying critical impact categories (e.g., global warming potential and energy demand).

2.3. Cost

- Bamboo Biochar: Although slightly more costly due to specialized production (pyrolysis), biochar’s longevity and insulation efficiency can lead to long-term savings. Studies indicate that biochar’s application in insulation reduces energy costs by approximately 20–30% over a building’s life cycle [68].

- Fly Ash: As an industrial byproduct, fly ash is low-cost and widely available. Its integration into building materials reduces reliance on cement, providing both initial savings and reduced life cycle costs. Fly ash’s economic benefits are particularly evident in regions where coal power plants are prevalent, as transportation costs are minimized. The distribution of coal power plants across India, as highlighted in the material availability section of the results and discussion, indicates that fly ash is readily available throughout India, with the exception of the extreme northern and eastern regions [129].

- Lime: Lime is moderately priced and available globally. Its low-maintenance requirements and durability make it cost-effective over time. Lime-based materials reduce energy demand for heating and cooling, offsetting initial expenses through lower utility costs.

- Comparative Analysis: Fly ash is the most cost-effective due to its status as an industrial byproduct. Bamboo biochar, while more expensive initially, offers long-term energy savings. Lime’s cost is balanced by its availability and durability, making it economically viable for insulation applications Table 14.

| Material | Initial Cost (INR/kg or INR/sq.m) | Durability | Maintenance Frequency | Long-Term Maintenance Cost | Environmental Impact |

|---|---|---|---|---|---|

| Bamboo biochar | 220–250 per kg | High | Minimal | Low | Eco-friendly, carbon sequestration |

| Fly ash | 2–5 per kg | High | Minimal | Negligible | Sustainable, repurposes waste |

| Lime | 5–10 per kg | High | Moderate | Low | Sustainable, low carbon footprint |

| Fiberglass | 150–300 per sq.m | Moderate | Frequent inspections | Moderate to high | Moderate environmental impact |

| Polystyrene (EPS) | 1500–2600 per sq.m | High | Periodic checks | Moderate | High carbon footprint |

| Polystyrene (XPS) | 450–700 per sq.m | Moderate | Periodic checks | Moderate | High carbon footprint |

2.3.1. Economic Analysis

- Initial Costs:

- Durability and Maintenance:

- Environmental Impact:

2.3.2. Savings Calculation

- Bamboo Biochar: Offers the highest insulation efficiency, reducing both energy costs and emissions significantly over the building’s lifespan.

- Fly Ash: Provides moderate insulation performance and is the most economical option upfront, suitable for large-scale applications.

- Lime: Balances cost and performance, providing medium insulation efficiency and durability.

2.3.3. Life Cycle Cost Assessment (LCCA)

3. Methodology

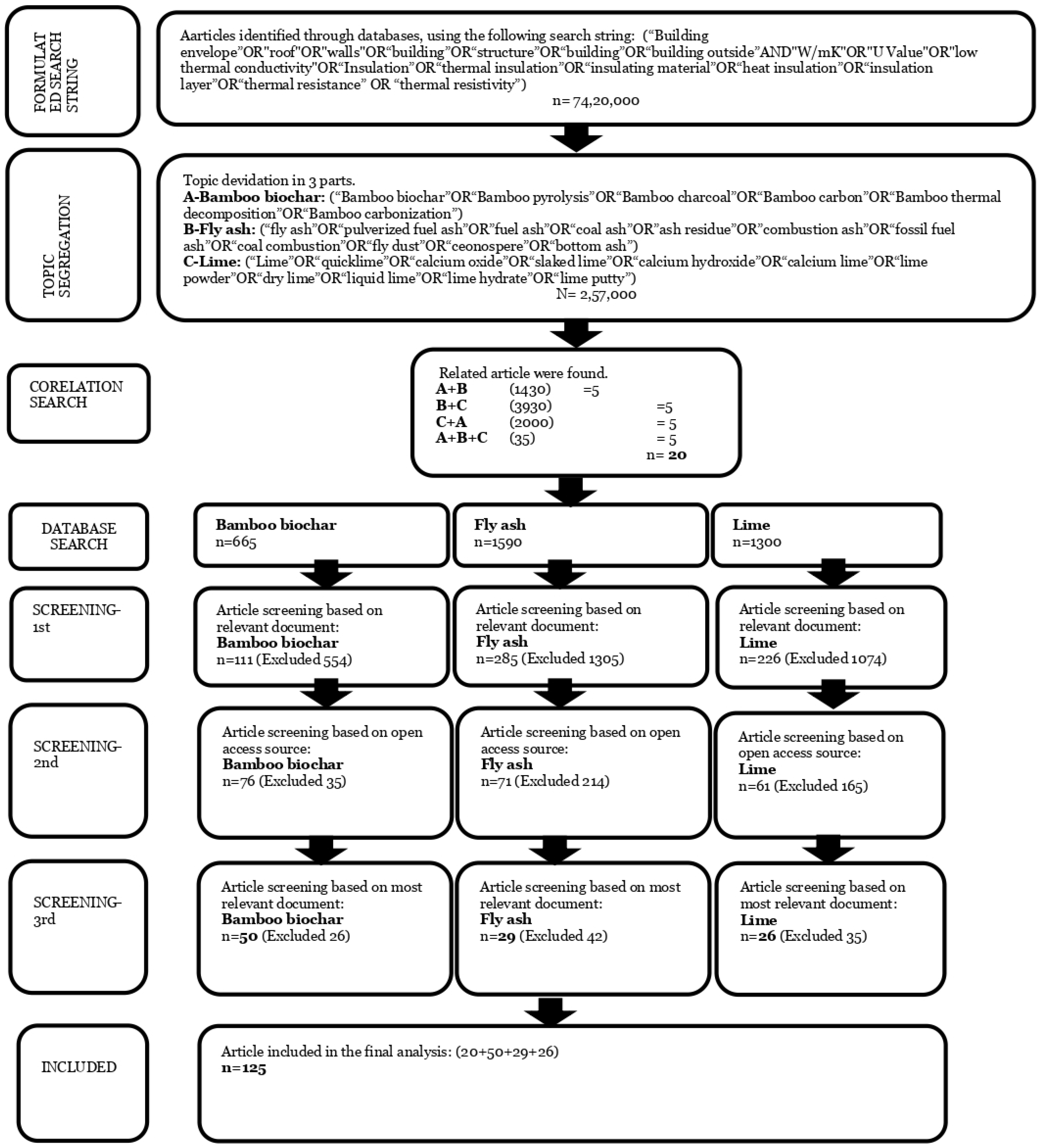

3.1. Literature Review and Data Collection

- Thermal conductivity or resistance of materials.

- Integration of sustainable materials.

- Life cycle analysis (LCA), carbon sequestration, and circular economy contributions. This review focused on bamboo biochar, fly ash, and lime, analyzing their thermal properties, environmental impact, and material performance. No real-time experiments were conducted; data were sourced entirely from the published literature.

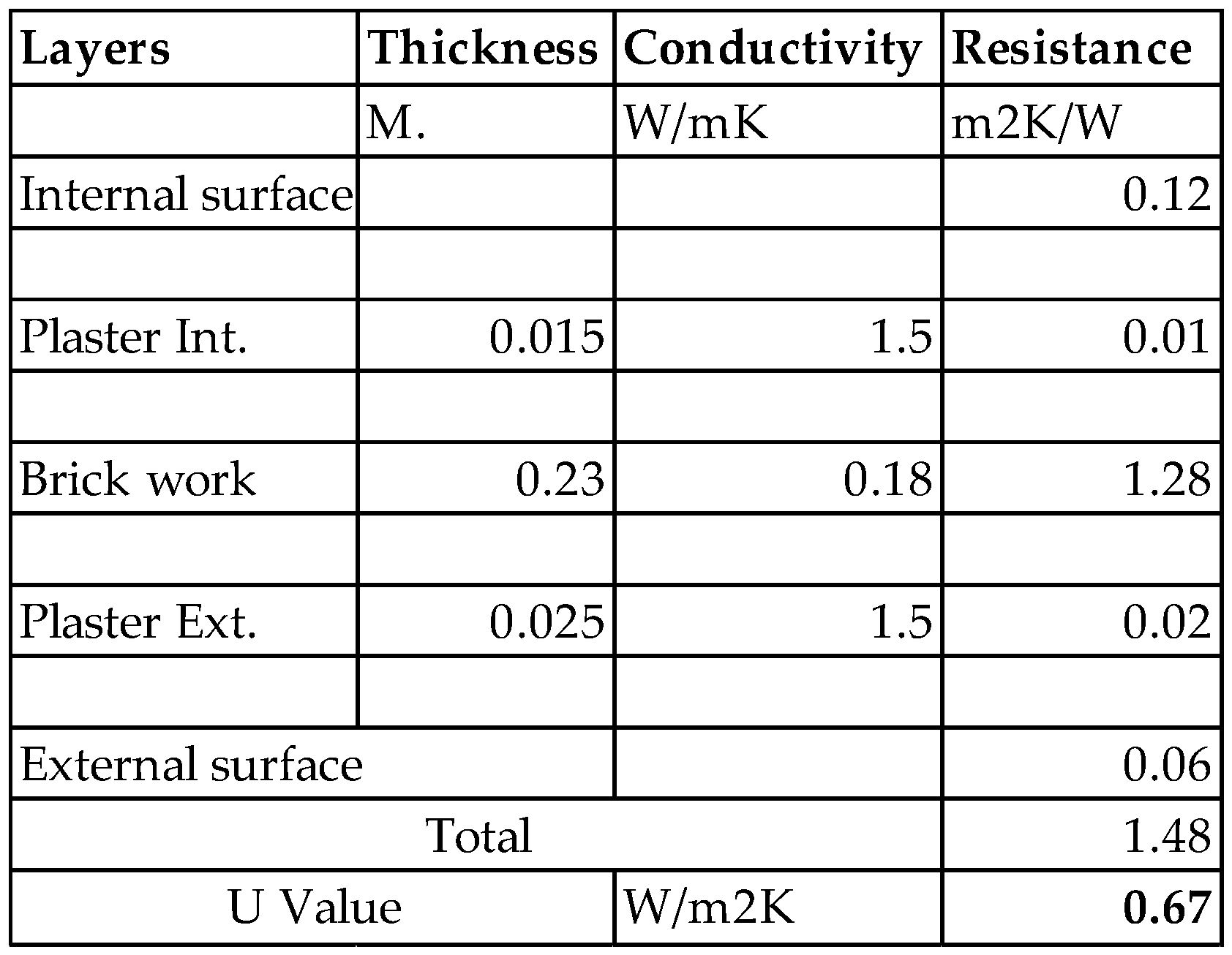

3.2. U-Value Calculation

- Reason for U-value use: U-values quantify thermal transmittance, directly correlating with energy efficiency in building envelopes.

- The calculated U-values were benchmarked against building insulation standards and validated using cross-referenced studies.

- Results were organized chronologically to highlight advancements in material properties over time.

3.3. Life Cycle Analysis (LCA)

- Embodied Energy: Total energy used in production and transportation, emphasizing the benefits of waste-based materials like fly ash.

- Carbon Footprint: Bamboo biochar’s carbon sequestration, fly ash’s emissions reduction as a byproduct, and lime’s moderate CO2 contribution during calcination were assessed.

- End-of-Life: Recyclability and reuse potential of materials were analyzed, focusing on minimizing their environmental impact.

3.4. Chronological Analysis and Gap Identification

- Identify trends and technological advancements in thermal performance.

- Highlight gaps in existing research, including the following:

- ○

- Limited experimental validation.

- ○

- The need for further exploration of composite materials combining bamboo biochar, fly ash, and lime for optimal performance.

3.5. Future Directions

- Real-time experimental validation of the heat efficiency of these materials is recommended.

- Composite formulations of bamboo biochar, fly ash, and lime should be explored for achieving target U-values of 0.4 for walls and 0.33 for roofs.

- LCA findings indicate opportunities to reduce carbon emissions and enhance sustainability through optimized resource use.

4. Results and Discussion

4.1. Correlation

4.1.1. Biochar and Fly Ash (A + B)

4.1.2. Fly Ash and Lime (B + C)

4.1.3. Lime and Biochar (C + A)

4.1.4. Biochar, Fly Ash, and Lime (A + B + C)

4.2. Economic Viability and Cost Implications

4.2.1. Initial Cost Analysis

4.2.2. Long-Term Cost Savings

4.2.3. Life Cycle Cost Assessment (LCCA) and Cost-Effectiveness

4.2.4. Scalability and Market Availability

4.2.5. Policy and Incentives

4.2.6. Cost–Benefit Analysis

4.3. Sustainability

4.4. Material Availability

4.5. Policy and Industrial Implications

4.6. Novelty and Unique Contributions

4.7. Real World Application

5. Conclusions

6. Recommendations

Author Contributions

Funding

Conflicts of Interest

Appendix A. Extension of Figure 10

References

- Miller, S.A.; John, V.M. The environmental impact of cement production: Addressing carbon emissions and energy consumption. J. Clean. Prod. 2022, 312, 127864. [Google Scholar] [CrossRef]

- EEA, European Environment Agency. 2004. Available online: https://www.eea.europa.eu/help/glossary/eea-glossary/environmental-impact-of-energy#:~:text=The%20environmental%20problems%20directly%20related,pollution%2C%20and%20solid%20waste%20disposal (accessed on 26 November 2024).

- IEA, International Energy Agency. Global Energy Review: CO2 Emissions in 2021. 2022. Available online: https://www.iea.org/reports/global-energy-review-co2-emissions-in-2021-2 (accessed on 26 November 2024).

- Ministry of Environment, Forest and Climate Change. India’s Third Biennial Update Report to the UNFCCC. 2023. Available online: https://moef.gov.in (accessed on 26 November 2024).

- CPCB, Central Pollution Control Board. Air Quality Status Report. 2023. Available online: https://cpcb.nic.in (accessed on 26 November 2024).

- WHO, World Health Organization. Housing and Health Guidelines. 2021. Available online: https://www.who.int/publications/i/item/9789241550376 (accessed on 26 November 2024).

- IEA, Intergovernmental Panel on Climate Change. Special Report: Global Warming of 1.5 °C. 2023. Available online: https://www.ipcc.ch/sr15/ (accessed on 26 November 2024).

- IEA, International Energy Agency. World Energy Outlook. 2023. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 26 November 2024).

- MoP, Ministry of Power. National Electricity Plan. 2023. Available online: https://powermin.gov.in (accessed on 26 November 2024).

- World Bank. The Cost of Air Pollution: Strengthening the Economic Case for Action. Available online: https://openknowledge.worldbank.org/handle/10986/25013 (accessed on 26 November 2024).

- Ministry of Finance. Economic Survey of India 2023. 2023. Available online: https://finmin.nic.in (accessed on 26 November 2024).

- Bamcore Wall Systim; Technical Evaluation Report; TER 1507-03; 2024. Available online: https://www.drjcertification.org/ter/1507-03 (accessed on 26 November 2024).

- BEE, Bureau of Energy Efficiency, Ministry of Power, Government of India. Energy Efficiency in Buildings; BEE India: New Delhi, India, 2020.

- DoS, Department of Science, Technology and Environment, Puducherry Climate Change Cell. Energy Benchmarking Guidelines for Climate Proofing Buildings in U.T. of Puducherry; Department of Science, Technology and Environment, Government of Puducherry: Puducherry, India, 2022. [Google Scholar]

- Gupta, V.; Deb, C. Energy retrofit analysis for an educational building in Mumbai. Sustain. Futures 2022, 4, 100096. [Google Scholar] [CrossRef]

- BEE. Energy Efficiency and Conservation in India. 2023. Available online: https://beeindia.gov.in (accessed on 26 November 2024).

- CEA, Central Electricity Authority, Government of India. CO2 Baseline Database for the Indian Power Sector; CEA India: New Delhi, India, 2020.

- ACEEE, American Council for an Energy-Efficient Economy. The Role of Building Energy Codes in the Clean Energy Transition. 2021. Available online: https://www.aceee.org/research-report/u2101 (accessed on 26 November 2024).

- U.S. Department of Energy. Insulation. 2021. Available online: https://www.energy.gov/energysaver/weatherize/insulation (accessed on 26 November 2024).

- Liu, H.; Maghoul, P.; Holländer, H.M. Sensitivity Analysis and Optimum Design of a Hydronic Snow Melting System of Bridge Decks during Snowfall. Phys. Chem. Earth 2019, 113, 31–42. Available online: https://www.researchgate.net/publication/330397966 (accessed on 26 November 2024). [CrossRef]

- Alwetaishi, M. Impact of building orientation on energy consumption in residential buildings in hot climates using building simulation software. J. King Saud Univ. Eng. Sci. 2017, 29, 358–365. [Google Scholar] [CrossRef]

- Alvarez, S.; Molina, J.L.; Sanchez, F. The role of the building envelope in the heat gain of residential buildings in hot climates. Energy Build. 2013, 56, 205–215. [Google Scholar] [CrossRef]

- Asadi, E.; da Silva, M.G.; Antunes, C.H.; Dias, L. Multi-objective optimization for building retrofit strategies: A model and an application. Energy Build. 2012, 44, 81–87. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Asimakopoulos, D.N. The role of urban microclimate in energy consumption and conservation in buildings. J. Build. Environ. 2009, 44, 763–772. [Google Scholar] [CrossRef]

- Yang, T.; Yang, Y. Evaluating the potential of biochar-lime composites in sustainable construction: A review. Constr. Build. Mater. 2023, 325, 126778. [Google Scholar]

- Kibert, C.J. Sustainable Construction: Green Building Design and Delivery; John Wiley & Sons: New York, NY, USA, 2016. [Google Scholar]

- ISO 21930; Sustainability in Building Construction—Environmental Declaration of Building Products. International Organization for Standardization: Geneva, Switzerland, 2007.

- US Green Building Council (USGBC). LEED Rating System; USGBC: Washington, DC, USA, n.d.; Available online: https://www.usgbc.org/leed (accessed on 26 November 2024).

- BRE Global Ltd. BREEAM; BRE Global Ltd.: Watford, UK, n.d.; Available online: https://bregroup.com/expertise/ (accessed on 26 November 2024).

- Rahul, J. A Study on Sustainable Construction Materials: Exploring Alternatives to Traditional Materials. 2023. Available online: https://www.researchgate.net/publication/367339271_A_Study_on_Sustainable_Construction_Materials_Exploring_Alternatives_to_Traditional_Materials (accessed on 26 November 2024).

- Das, M.; Bhattacharya, S.; Singh, P.; Filgueiras, T.S.; Pal, A. Bamboo taxonomy and diversity in the Era of molecular markers. Adv. Bot. Res. 2008, 47, 225–268. [Google Scholar]

- Bystriakova, N.; Kapos, V.; Lysenko, I.; Stapleton, C. Distribution and conservation status of forest bamboo biodiversity in the Asia-Pacific region. Biodivers. Conserv 2003, 12, 1833–1841. [Google Scholar] [CrossRef]

- Yeasmin, L.; Ali, M.N.; Gantait, S.; Chakraborty, S. Bamboo: An overview on its genetic diversity and characterization. 3 Biotech 2015, 5, 1–11. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Binfield, L.; Britton, T.L.; Dai, C.; Innes, J. Evidence on the social, economic, and environmental impact of interventions that facilitate bamboo industry development for sustainable livelihoods: A systematic map protocol. Environ. Evid. 2002, 11, 33. [Google Scholar] [CrossRef]

- Bonivento, J.; Vieira, G.; Togo, I. Thermal Performance of Bamboo as a Multilayer Insulation Wall. 2017. Available online: https://www.researchgate.net/publication/321150881_Thermal_Performance_of_Bamboo_as_a_Multilayer_Insulation_Wall (accessed on 26 November 2024).

- Wu, J.; Wang, X.; Fei, B.; Xu, X.; Lian, C.; Chen, H. The mechanical properties and thermal conductivity of bamboo with freeze–thaw treatment. J. Wood Sci. 2021, 67, 66. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, A.; Neogi, S. Reuse of fly ash and bottom ash in mortars with improved thermal conductivity performance for buildings. Heliyon 2018, 4, e00934. [Google Scholar] [CrossRef]

- Zemanova, L.; Pokorny, J.; Pavlikova, M.; Pavlik, Z. Hygric properties of Cement-Lime Plasters with Incorporated Lightweight Mineral Admixture. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 022046. [Google Scholar] [CrossRef]

- Chaturvedi, K.; Singhwane, A.; Dhangar, M.; Mili, M.; Gorhae, N.; Naik, A. Bamboo for producing charcoal and biochar for versatile applications. Biomass Convers. Biorefinery 2023, 14, 15159–15185. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, S.; Chen, H. Bamboo for producing charcoal and biochar for versatile applications. J. Sustain. Mater. 2023, 14, 451–463. [Google Scholar]

- Revathi, S.; Alice Elizabeth Tania, D.; Ancy Shadin, S.; Keerthana, J. Effect of zeolite and bamboo biochar as CO2 absorbant in concrete. Carbon Res. 2024, 3, 43. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.C.; Weiss, J. Bamboo-based biochar: A still too little-studied black gold. Renew. Mater. Res. 2021, 8, 121–136. [Google Scholar]

- Toppo, A.L.; Jujjavarapu, S.E. Gold Nanoparticle-Fortified Bamboo Biochar Nanocomposite; National Institute of Technology Raipur: Chhattisgarh, India, 2021. [Google Scholar] [CrossRef]

- Chen, H.; Yu, Y.; Zhong, T.H. Utilizing bamboo biochar in cement mortar. Adv. Compos. Hybrid Mater. 2022, 4, 647–661. [Google Scholar]

- Osman, A.I.; Farghali, M.; Ihara, I.; Elgarahy, A.M.; Ayyad, A.; Mehta, N.; Ng, K.H.; Abd El-Monaem, E.M.; Eltaweil, A.S.; Hosny, M.; et al. Materials, fuels, upgrading, economy, and life cycle assessment of the pyrolysis of algal and lignocellulosic biomass: A review. Environ. Chem. Lett. 2023, 21, 1419–1476. [Google Scholar] [CrossRef]

- Aziz, M.A.; Zubair, M.; Saleem, M.; Alharthi, Y.M.; Ashraf, N.; Alotaibi, K.S.; Aga, O.; Al Eid, A.A.A. Mechanical, non-destructive, and thermal characterization of biochar-based mortar composite. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Yadav, K.; Sharma, R.L. Comparative study of biochar and charcoal and their application in the construction industry. Asian J. Civ. Eng. 2024, 25, 1179–1194. [Google Scholar] [CrossRef]

- Pandey, D.; Chhimwal, M.; Srivastava, R.K. Engineered Biochar as Construction Material. In Engineered; Ramola, S., Mohan, D., Masek, O., Méndez, A., Tsubota, T., Eds.; Springer: Singapore, 2022. [Google Scholar]

- Farges, R.; Gharzouni, A.; Ravier, B.; Rossignol, S. Biochar for improving the properties of construction materials. Constr. Build. Mater. 2023, 141, 111731. [Google Scholar]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Wen, J.; Wang, B.; Dai, Z.; Shi, X.; Jin, Z.; Wang, H.; Jiang, X. New insights into the green cement composites with low carbon footprint: The role of biochar as cement additive/alternative. Resour. Conserv. Recycl. 2023, 197, 107081. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Enders, A.; Lehmann, J. Short- and long-term flammability of biochars. Biomass Bioenergy 2024, 69, 183–191. [Google Scholar] [CrossRef]

- Babu, K.; Das, O.; Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, Á.; Berto, F. Fire Behavior of 3D-Printed Polymeric Composites. J. Mater. Eng. Perform. 2021, 30, 4745–4755. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, B.; Zheng, Y.; Hu, X.; Creamer, A.E.; Annable, M.D.; Li, Y. Biochar for volatile organic compound (VOC) removal: Sorption performance and governing mechanisms. Bioresour. Technol. 2017, 245 Part A, 606–614. [Google Scholar] [CrossRef]

- Kua, H.W.; Ng, M.S.; Ong, K. Innovative uses of biochar as carbon sequestering building materials in wall plaster and pellets. Acad. J. Civ. Eng. 2017, 35, 575–580. [Google Scholar]

- Liwu, L.; Fang, J.; Huang, B.; Wang, A.; Deng, M. Combined effects of biochar and MgO expansive additive on the autogenous shrinkage, internal relative humidity and compressive strength of cement pastes. Constr. Build. Mater. 2019, 229, 116877. [Google Scholar] [CrossRef]

- BEE, Bureau of Energy Efficiency. Energy Conservation Building Code for Residential Buildings (Part I: Building Envelope Design); Ministry of Power, Government of India: New Delhi, India, 2018.

- Maxwell, B.; Joshua, K.; Brina, P.; Aime, L.T. Biochar Bricks for Building Material Closed Project File. University of Rochester. 2020. Available online: https://www.hajim.rochester.edu/senior-design-day/biochar-bricks-for-building-materials/ (accessed on 26 November 2024).

- Wu, S.; Chen, D.; Zhao, G.; Cheng, Y.; Sun, B.; Yan, X.; Han, W.; Chen, G.; Zhang, X. Controllable synthesis of a robust sucrose-derived bio-carbon foam with 3D hierarchical porous structure for thermal insulation, flame retardancy and oil absorption. Chem. Eng. J. 2022, 434, 134514. [Google Scholar] [CrossRef]

- Lee, H.; Yang, S.; Wi, S.; Kim, S. Thermal transfer behavior of biochar-natural inorganic clay composite for building envelope insulation. Constr. Build. Mater. 2019, 223, 668–678. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C.W. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431 Pt 1, 133946. [Google Scholar] [CrossRef]

- Rodier, L.; Bilba, K.; Onésippe, C.; Arsène, M.-A. Utilization of bio-chars from sugarcane bagasse pyrolysis in cement-based composites. Ind. Crops Prod. 2019, 141, 111731. [Google Scholar] [CrossRef]

- Prasad, B.S.; Balaji, A. Study on engineering properties of bamboo fiber/biochar reinforced epoxy composites rod. Biomass Convers. Biorefinery 2024, 15, 1525–1534. [Google Scholar] [CrossRef]

- Kumar, R.N.; Parthipan, G. Optimization of reinforcement characteristics on eco-friendly polymer composite rebar building material developed using domestically discarded vegetable waste biochar and areca chopped fiber. Biomass Convers. Biorefinery 2023, 14, 21497–21505. [Google Scholar] [CrossRef]

- Osman, A.I.; Fawzy, S.; Farghali, M.; El-Azazy, M.; Elgarahy, A.M.; Fahim, R.A.; Maksoud, M.A.; Ajlan, A.A.; Yousry, M.; Saleem, Y.; et al. 2022, Biochar for agronomy, animal farming, anaerobic digestion, composting, water treatment, soil remediation, construction, energy storage, and carbon sequestration: A review. Environ. Chem. Lett. 2022, 20, 2385–2485. [Google Scholar] [CrossRef] [PubMed]

- Chhimwal, M.; Pandey, D.; Srivastava, R.K. Pristine Biochar and Engineered Biochar: Differences and Application Engineered Biochar. In Engineered Biochar: Fundamentals, Preparation, Characterization and Applications; Singapore: Singapore, 2022; ISBN 978-981-19-2487-3. [Google Scholar]

- Osman, A.I.; Farghali, M.; Dong, Y.; Kong, J.; Yousry, M.; Rashwan, A.K.; Chen, Z.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.S. Reducing the carbon footprint of buildings using biochar-based bricks and insulating materials: A review. Environ. Chem. Lett. 2024, 22, 71–104. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.; Wang, L.; Yan, J.; Ma, B.; Zhu, X.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C. Biochar as construction materials for achieving carbon neutrality. Biochar 2022, 4, 59. [Google Scholar] [CrossRef]

- Uram, K.; Kurańska, M.; Andrzejewski, J.; Prociak, A. Rigid Polyurethane Foams Modified with Biochar. Materials 2021, 14, 5616. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef] [PubMed]

- Praneeth, S.; Guo, R.; Wang, T.; Dubey, B.K.; Sarmah, A.K. Accelerated carbonation of biochar reinforced cement-fly ash composites: Enhancing and sequestering CO2 in building materials. Constr. Build. Mater. 2020, 244, 118702. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Combination of Biochar and Silica Fume as Partial Cement Replacement in Mortar: Performance Evaluation Under Normal and Elevated Temperature. Waste Biomass Valorization 2019, 11, 2807–2824. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Brewer, C.E.; Chuang, V.J.; Masiello, C.A.; Gonnermann, H.; Gao, X.; Dugan, B.; Driver, L.E.; Panzacchi, P.; Zygourakis, K.; Davies, C.A. New approaches to measuring biochar density and porosity. Biomass Bioenergy 2014, 66, 176–185. [Google Scholar] [CrossRef]

- Jiang, X.; Li, B.; Guo, J. Study on the properties of different biochar to cement paste. IOP Conf. Ser. Earth Environ. Sci. 2020, 526, 012085. [Google Scholar] [CrossRef]

- Xiong, T.; Ok, Y.S.; Dissanayake, P.D.; Tsang, D.C.W.; Kim, S.; Kua, H.W.; Shah, K.W. Preparation and thermal conductivity enhancement of a paraffin wax-based composite phase change material doped with garlic stem biochar microparticles. Sci. Total Environ. 2022, 827, 154341. [Google Scholar] [CrossRef] [PubMed]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Belletti, B.; Milanese, D.; Malcevschi, A. Combined Effects of Biochar and Recycled Plastic Aggregates on Mechanical Behavior of Concrete. Struct. Concr. 2023, 24, 6721–6737. [Google Scholar] [CrossRef]

- Kua, H.W.; Choo, S.Y.G. Chapter 17—The Use of Biochar-Coated Lime Plaster Pellets for Indoor Carbon Dioxide Sequestration. In Biochar from Biomass and Waste; Ok, Y.S., Tsang, D.C.W., Bolan, N., Novak, J.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 305–317. ISBN 9780128117293. [Google Scholar] [CrossRef]

- Bentz, D.P.; Peltz, M.A. Thermal Properties of High-Volume Fly Ash Mortars and Concretes; Building and Fire Research Laboratory National Institute of Standards and Technology: Gaithersburg, MD, USA, 2009. [Google Scholar]

- Shishkin, A.; Abramovskis, V.; Zalite, I.; Singh, A.K.; Mezinskis, G.; Popov, V.; Ozolins, J. Physical, Thermal, and Chemical Properties of Fly Ash Cenospheres Obtained from Different Sources. Materials 2023, 16, 2035. [Google Scholar] [CrossRef]

- Priyadarshani, S. Thermal transmittance (u-value calculations) of sustainable building materials for walls. IJCRT 2018, 6. Available online: https://www.ijcrt.org/papers/IJPUB1801109.pdf (accessed on 26 November 2024).

- Kaya, M.; Köksal, F. Physical and mechanical properties of C class fly ash based lightweight geopolymer mortar produced with expanded vermiculite aggregate. Rev. Constr. 2022, 21, 21–35. [Google Scholar] [CrossRef]

- Saygılı, A.; Baykal, G. A new method for improving the thermal insulation properties of fly ash. Energy Build. 2011, 43, 3236–3242. [Google Scholar] [CrossRef]

- Kunthe, V.D.; Manavendra, G.; Sondur, V.M. Effect of thermal properties on fly ash based concrete. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 396–400. [Google Scholar]

- Zhang, X.; Han, Y. Thermal Insulation Properties of Fly Ash and Waste. Chem. Eng. 2016, 55, 253–258. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Gamage, K.; De Silva, I.; Attanayaka, V. Thermal performance of rice husk ash mixed mortar in concrete and masonry buildings. Bud. I Archit. 2020, 19, 43–52. [Google Scholar] [CrossRef]

- Bharti, A.; Kumar, G. Comparative Study of Thermal Conductivity of CNT Based Fly Ash Waste Composite and Study Its Mechanical Property-Review. Int. J. Res. Publ. Rev. 2022, 3, 505–508. [Google Scholar]

- Durán-Herrera, A.; Campos-Dimas, J.K.; Valdez-Tamez, P.L.; Bentz, D.P. Effect of a micro-copolymer addition on the thermal conductivity of fly ash, mortars. J. Build. Phys. 2015, 40, 3–16. [Google Scholar] [CrossRef]

- Zorić, D.; Lazar, D.; Rudić, O.; Radeka, M.; Ranogajec, J.; Hiršenberger, H. Thermal conductivity of lightweight aggregate based on coal fly ash. J. Therm. Anal. Calorim. 2012, 110, 489–495. [Google Scholar] [CrossRef]

- Agustini, N.K.A.; Triwiyono, A.; Sulistyo, D.; Suyitno, S. Mechanical Properties and Thermal Conductivity of Fly Ash-Based Geopolymer Foams with Polypropylene Fibers. Appl. Sci. 2021, 11, 4886. [Google Scholar] [CrossRef]

- Muia, L.M.; Gaitho, F. Thermal Conductivity of Wood Ash Diotomite Composite Using the Transient Hot Strip Method. Physics Department, Egerton University, Kenya, 2003. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/35/024/35024578.pdf (accessed on 26 November 2024).

- Yang, I.-H.; Park, J.; Kyoung-Chul, K.; Sung-Won, Y. A Comparative Study on the Thermal Conductivity of Concrete with Coal Bottom Ash under Different Drying Conditions. Adv. Civ. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Jose, C.; Radhakrishnan, G.; Anandan, A.; Althaf, T.A.; Sankar, B. Review of Mechanical, Durability, and Thermal properties of Light weight concrete containing cenosphere. E3S Web Conf. 2024, 529, 01032. [Google Scholar] [CrossRef]

- Lee, J.K.; Shang, J.Q. Evolution of thermal and mechanical properties of mine tailings and fly ash mixtures during curing period. Can. Geotech. J. 2014, 51, 570–582. [Google Scholar] [CrossRef]

- Talebi, H.R.; Kayan, B.A.; Asadi, I.; Hassan, Z.F.B.A. Investigation of Thermal Properties of Normal Weight Concrete for Different Strength Classes. J. Environ. Treat. Tech. 2020, 8, 908–914. [Google Scholar]

- Yurohman, Y.; Prabowo, S.; Novriadi, D.; Ramadhoni, B.; Vicalnetor, D.N.; Pratama, A.; Rizkyta, A.G.; Wijaya, A.M.; Radini, F.A.; Zainuddin, Z.; et al. Effect of fly ash content on the thermal conductivity and moisture content of multilayer packaging. AIP Conf. Proc. 2024, 3003, 020046. [Google Scholar] [CrossRef]

- Wang, W.W.; Lu, C.; Li, Y.; Li, Q. An investigation on thermal conductivity of fly ash concrete after elevated temperature exposure. Constr. Build. Mater. 2017, 148, 148–154. [Google Scholar] [CrossRef]

- Namboonruang, W.; Rawangkul, R.; Yodsudjai, W. Strength Properties of Low Thermal Conductivity Fly Ash Bricks: Compressive and Flexural Strength Aspects. Appl. Mech. Mater. 2012, 117–119, 1352–1357. [Google Scholar] [CrossRef]

- Azzahran, S.F. Compressive Strength and Thermal Conductivity of Fly Ash Geopolymer Concrete Incorporated with Lightweight Aggregate, Expanded Clay Aggregate and Foaming Agent. Revista de Chimie SRL. Available online: https://www.academia.edu/57322414/Compressive_Strength_and_Thermal_Conductivity_of_Fly_Ash_Geopolymer_Concrete_Incorporated_with_Lightweight_Aggregate_Expanded_Clay_Aggregate_and_Foaming_Agent (accessed on 26 November 2024).

- Laksanakit, C. Effect of Rubberwood Fly Ash on Thermal Conductivity of Cement Fiber Board. Res. Mod. Sci. Util. Technol. Innov. J. (RMUTI J.) 2023, 16, 61–65. [Google Scholar]

- Jiang, Y.C.; Xu, J.; Zhao, B.C.; Wang, Y. A Study on the Influence of Fly Ash on the Thermal Parameters of Shrinkage Compensating Concrete. Key Eng. Mater. 2018, 768, 336–340. [Google Scholar] [CrossRef]

- Choo, H.; Won, J.; Burns, S.E. Thermal conductivity of dry fly ashes with various carbon and biomass contents. Waste Manag. 2021, 135, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Bicer, A. Effect of production temperature on thermal and mechanical properties of polystyrene–fly ash composites. Adv. Compos. Lett. 2020, 29, 2633366X2091798. [Google Scholar] [CrossRef]

- Pokorný, J.; Pavlíková, M.; Pavlík, Z. The use of lightweight aggregate in preparation of thermal insulation lime-based renders. Acta Polytech. CTU Proc. 2019, 22, 83–87. [Google Scholar] [CrossRef]

- Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal Characterization of Recycled Materials for Building Insulation. Energies 2021, 14, 3564. [Google Scholar] [CrossRef]

- Theodoridou, M.; Kyriakou, L.; Ioannou, I. PCM-enhanced Lime Plasters for Vernacular and Contemporary Architecture. Energy Procedia 2016, 97, 539–545. [Google Scholar] [CrossRef]

- Bianco, L.; Serra, V.; Fantucci, S.; Dutto, M.; Massolino, M. Thermal insulating plaster as a solution for refurbishing historic building envelopes: First experimental results. Energy Build. 2014, 95, 86–91. [Google Scholar] [CrossRef]

- Mandili, B.; Taqi, M.; El Bouari, A.; Errouaiti, M. Experimental study of a new ecological building material for a thermal insulation based on waste paper and lime. Constr. Build. Mater. 2019, 228, 117097. [Google Scholar] [CrossRef]

- Liblik, J.; Küppers, J.; Just, A.; Maaten, B.; Pajusaar, S. Material properties of clay and lime plaster for structural fire design. Fire Mater. 2019, 45, 355–365. [Google Scholar] [CrossRef]

- Belayachi, N.; Bouasker, M.; Hoxha, D.; Al-Mukhtar, M. Thermo-Mechanical Behaviour of an Innovant Straw Lime Composite for Thermal Insulation Applications. Appl. Mech. Mater. 2013, 390, 542–546. [Google Scholar] [CrossRef]

- Divandari, J.; Najari, F. The structure of the building life cycle assessment (LCA) for selecting sustainable materials in residential complexes in Tehran. Turk. Online J. Des. Art Commun. (TOJDAC) 2016, 6, 2155–2167. [Google Scholar] [CrossRef]

- Stefanidou, M. Cement-based renders with insulating properties. Constr. Build. Mater. 2014, 65, 427–431. [Google Scholar] [CrossRef]

- Ustabas, I.; Cuce, E. Thermal insulation and mechanical properties of a specially improved insulation plaster under freezing–thawing and high-temperature conditions. Int. J. Low-Carbon Technol. 2023, 18, 682–688. [Google Scholar] [CrossRef]

- Karim, A.N.; Johansson, P.; Kalagasidis, A.S. Super insulation plasters in renovation of buildings in Sweden: Energy efficiency and possibilities with new building materials. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 042050. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Zaleska, M.; Pavlikova, M.; Pivak, A.; Pavlik, Z. Thermal insulation repair lime plaster with perlite—Functional parameters and salt crystallization resistance. In Proceedings of the Conference: 22nd SGEM International Multidisciplinary Scientific GeoConference 2022, Albena, Bulgaria, 4–10 July 2022. [Google Scholar] [CrossRef]

- Pavlík, Z.; Trník, A.; Pavlíková, M.; Keppert, M.; Černý, R. Lime-Pozzolan Plasters with Enhanced Thermal Capacity. Int. J. Civ. Environ. Eng. 2013, 7, 818–822. [Google Scholar]

- Pavlíková, M.; Pernicová, R.; Pavlík, Z. Thermophysical Properties of Hydrophobised Lime Plaster–Experimental Analysis of Moisture Effect. AIP Conf. Proc. 2016, 1752, 040022. [Google Scholar] [CrossRef]

- Bochen, J.; Labus, M. Study on physical and chemical properties of external lime–sand plasters of some historical buildings. Constr. Build. Mater. 2013, 45, 11–19. [Google Scholar] [CrossRef]

- Liblik, J.; Just, A.; Maaten, B. Fire Safety of Historic Timber Buildings with Traditional Plasters in Europe. World Conference on Timber Engineering 2018. Available online: https://www.tandfonline.com/doi/abs/10.1080/17480272.2020.1714726 (accessed on 26 November 2024).

- Pavlík, Z.; Fořt, J.; Pavlíková, M.; Pokorný, J.; Trník, A.; Černý, R. Modified lime-cement plasters with enhanced thermal and hygric storage capacity for moderation of interior climate. Energy Build. 2016, 126, 113–127. [Google Scholar] [CrossRef]

- Koňáková, D.; Čáchová, M.; Vejmelková, E.; Keppert, M.; Jerman, M.; Bayer, P.; Rovnaníková, P.; Černý, R. Lime-based plasters with combined expanded clay-silica aggregate: Microstructure, texture and engineering properties. Cem. Concr. Compos. 2017, 83, 374–383. [Google Scholar] [CrossRef]

- Govaerts, Y.; Hayen, R.; de Bouw, M.; Verdonck, A.; Meulebroeck, W.; Mertens, S.; Grégoire, Y. Performance of a lime-based insulating render for heritage buildings. Constr. Build. Mater. 2018, 159, 376–389. [Google Scholar] [CrossRef]

- Damle, R.M.; Khatri, N.; Rawal, R. Experimental investigation on hygrothermal behaviour of cement and lime plaster. Build. Environ. 2022, 217, 109098. [Google Scholar] [CrossRef]

- Vejmelková, E.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Černý, R. Mechanical, fracture-mechanical, hydric, thermal, and durability properties of lime–metakaolin plasters for renovation of historical buildings. Constr. Build. Mater. 2012, 31, 22–28. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Ministry of Coal. Annual Reports and Statistics. Government of India. 2023. Available online: https://coal.gov.in/ (accessed on 26 November 2024).

- Pacific Northwest National Laboratory (PNNL). High-Performance Insulation Materials and Their Benefits in Reducing Energy Consumption (PNNL-20405); Pacific Northwest National Laboratory: Richland, WA, USA, 2010. [Google Scholar]

- Chen, R.F.; Congress, S.S.C.; Cai, G.J.; Duan, W.; Liu, S.Y. Sustainable utilization of biomass waste-rice husk ash as a new solidified material of soil in geotechnical engineering: A review. Constr. Build. Mater. 2021, 292, 123219. [Google Scholar] [CrossRef]

- Kordi, M.; Farrokhi, N.; Pech-Canul, M.I.; Ahmadikhah, A. (Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Sci. 2024, 31, 14–32. [Google Scholar] [CrossRef]

- Farid, S.A.; Zaheer, M.M. Production of new generation and sustainable concrete using rice husk ash (RHA): A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Mujtaba, G.; Rizvi, M.; Sharma, A.; Bhatt, M. Carbon sequestration potential of biochar-fly ash composites in construction materials. Mater. Res. Proc. 2023, 29, 192–200. [Google Scholar]

- Wibowo, A.; Uddin, M.S.; Hasan, A.; Shahidul, I. RHA and pozzolan cement for soil stabilization: A review of application in geotechnical engineering. Constr. Build. Mater. 2023, 321, 124215. [Google Scholar]

- Abetie, A. Enhancing the properties of swelling soils with lime, fly ash, and natural fibers for construction applications. Constr. Build. Mater. 2023, 302, 124287. [Google Scholar]

- Okeke, F.O.; Ahmed, A.; Imam, A. A review of corncob-based building materials as a sustainable solution for the construction industry. Hybrid Adv. 2024, 6, 100269. [Google Scholar] [CrossRef]

- Shao, K.; Yunxing, D.; Zhou, F. Feasibility of using treated corncob aggregates in cement mortars. Constr. Build. Mater. 2023, 301, 124215. [Google Scholar]

- Thomas, B.S.; Yang, J.; Mo, K.H. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. Cem. Concr. Compos. 2024, 125, 104621. [Google Scholar] [CrossRef]

- Njeumen Nkayem, D.E.; Mbey, J.A.; Kenne Diffo, B.B. Preliminary study on the use of corncob as pore forming agent in lightweight clay bricks: Physical and mechanical features. Constr. Build. Mater. 2023, 320, 124215. [Google Scholar]

- Shoudho, K.N.; Khan, T.H.; Ara, U.R.; Khan, M.R.; Shawon, Z.B.Z.; Hoque, M.E. Bamboo biochar in global carbon cycle: Towards sustainable development goals. Curr. Res. Green Sustain. Chem. 2024, 8, 100409. [Google Scholar] [CrossRef]

- Rahman, M.; Khan, T.H.; Ara, U.R. Sustainability of biomass-based insulation materials in buildings: Current trends and future research directions. J. Sustain. Build. Mater. 2024, 15, 123–135. [Google Scholar]

- Jha, P.; Singh, R.; Gupta, V.K. Advances in the application of biochar in agriculture and construction: A comprehensive review. Environ. Sci. Pollut. Res. 2022, 29, 4512–4527. [Google Scholar]

- Yuan, J.; Liu, X.; Zhao, Z. Impact of biochar and lime on soil properties and crop yield: Implications for sustainable agriculture and construction. Agric. Ecosyst. Environ. 2023, 350, 108595. [Google Scholar]

- Winters, D.; Boakye, K.; Simske, S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability 2022, 14, 4633. [Google Scholar] [CrossRef]

- Valenzuela, M.; Ciudad, G.; Cárdenas, J.P.; Medina, C.; Salas, A.; Onate, A.; Tuninetti, V. Towards the development of performance-efficient compressed earth blocks. Renew. Sustain. Energy Rev. 2024, 194, 114323. [Google Scholar] [CrossRef]

- Malkanthi, M.; Jayasuriya, J.; Premalal, M. Enhancing the properties of swelling soils with lime, fly ash, and biochar. Constr. Build. Mater. 2024, 321, 124215. [Google Scholar]

- Błaszczyński, T.; Król, M. Usage of Green Concrete Technology in Civil Engineering. Procedia Eng. 2015, 122, 296–301. [Google Scholar] [CrossRef]

- Asante, K.O.H.; Akoto, D.S.; Derkyi, N.S.A.; Abugre, S. Advancing circular economy for the growth, root development, and elemental characteristics of bamboo (Bambusa vulgaris) on galamsey-degraded soil. Adv. Bamboo Sci. 2024, 6, 100054. Available online: https://www.sciencedirect.com/science/article/pii/S277313912300040X (accessed on 26 November 2024). [CrossRef]

- Rathour, R.; Kumar, H.; Prasad, K.; Anerao, P. Multifunctional applications of bamboo crop beyond environmental management: An Indian prospective. Environ. Technol. Innov. 2022, 26, 102263. [Google Scholar] [CrossRef] [PubMed]

- Holmes, S.; Wingate, M. Building with Lime: A Practical Introduction; ITDG Publishing: London, UK, 2002. [Google Scholar]

- Prajapati, G.; Dua, S. A critical review of bamboo as a building material for sustainable development. J. Sustain. Constr. Eng. Proj. Manag. 2021, 4, 1–8. [Google Scholar]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards sustainable coal industry: Turning coal bottom ash into wealth. Sci. Total Environ. 2021, 788, 147759. [Google Scholar] [CrossRef]

- Guimarães, P.A.; Tamura, S.; Costa, M. The cement industry in accordance with the UN Sustainable Development Goals through the C-S-H seeds technology—A critical review. Terr@Plur 2023, 17, 1–15. [Google Scholar] [CrossRef]

| Category | Criteria | Description |

|---|---|---|

| 1. Environmental impact | Embodied energy | The total energy needed to make the material, including obtaining raw materials, making the product, and transporting it. |

| Carbon footprint | The total amount of climate-altering gases discharged throughout the material’s life. | |

| Resource efficiency | The deployment of replenish able or recycled resources in the material’s production. | |

| Toxicity | The presence of harmful chemicals or pollutants in the material. | |

| 2. Economic viability | Cost | Initial cost, maintenance, and potential savings over the building’s life cycle. |

| Availability | The ease of sourcing the material locally to reduce transportation emissions and costs. | |

| Durability | The material’s longevity and resistance to wear and environmental conditions, reducing the need for frequent replacements. | |

| 3. Social impact | Health and safety | The material’s impact on the wellness and quality of life of inhabitants including air quality within buildings and exposure to harmful substances. |

| Aesthetics and comfort | The material’s contribution to the visual and thermal comfort of the building occupants. | |

| 4. Performance | Thermal insulation | The material’s ability to insulate the building, contributing to energy efficiency. |

| Structural integrity | The durability and weight-bearing ability of the material. | |

| Moisture resistance | The material’s strength to keep out moisture and stop mold from growing. | |

| Fire resistance | How well the material can stop and handle fire. | |

| 5. Compliance | Certification and standards | Adherence to industry standards and certifications, such as ECBC, LEED, BREEAM, or other green building standards. |

| 6. Life cycle assessment | Renewability | The material’s potential for renewal and its impact on future resource availability. |

| Recyclability | The ability to reuse the material after it is no longer needed. | |

| End-of-life disposal | The effect on the environment when disposing of the material. |

| Material | Thermal Properties | Environmental Impact | Other Properties |

|---|---|---|---|

| Bamboo biochar | Low thermal conductivity | Carbon sequestration, renewable | Fast-growing, renewable, low energy |

| Fly ash | Reduces thermal transfer | Repurposes waste, low CO2 | Improves concrete strength |

| Lime | Excellent thermal insulation | Low embodied energy, breathable | Fire-resistant, moisture regulation |

| Keywords | Associated Terms |

|---|---|

| Building | Building envelope, building, structure, building outside, building skin, building façade, building exterior, building casing, structural envelope, building enclosure |

| Insulation | W/mK, U-value, insulation, thermal insulation, insulating material, heat insulation, insulation layer, thermal resistance, thermal resistivity, thermal reduction, thermal improvement, low conductivity, reduce thermal conduction, poor conductivity, poor thermal conductivity, low conductance |

| Bamboo biochar | Bamboo biochar, bamboo pyrolysis, bamboo charcoal, bamboo carbon, bamboo thermal decomposition, bamboo carbonization |

| Fly ash | Fly ash, pulverized fuel ash, fuel ash, coal ash, ash residue, combustion ash, fossil fuel ash, coal combustion, fly dust, cenosphere, bottom ash |

| Lime | Different variety of lime include lime, calcium oxide, quicklime, calcium lime, lime powder, dry lime, liquid lime, lime hydrate, calcium hydroxide, slaked lime and lime putty. |

| Composite Climate | ||

|---|---|---|

| ECBC Standards Parameter | Wall U-Value | Roof U-Value |

| ECBC compliance | 0.4 | 0.33 |

| ECBC+ | 0.33 | 0.20 |

| Super ECBC | 0.22 | 0.20 |

| Source | Process | Thermal Conductivity (W/mK) | U-Value (W/m2K) |

|---|---|---|---|

| Biochar | |||

| [50] | Biochar as cement admixture | 0.192 | 0.6 |

| [58] | Biochar cement brick | 0.18 | 0.6 |

| [49] | Biochar–geopolymer materials | 0.13 | 0.57 |

| [59] | Biochar foam | 0.092 | 0.53 |

| [45] | Biochar | 0.08–0.2 | 0.51 |

| Percentage | |||

| [46] | Masonry concrete (41% reduce) | Reduced | 41% |

| [60] | Biochar and clay mix. | Reduced | 67.21% |

| Source | Statement |

|---|---|

| [59] | Reduces initial setting time, as well as water penetration and sorptivity. |

| [61,62] | A 30% biochar addition improves cement hydration and microstructure development, reduces CO2 emissions, sequesters 59 kg CO2 per ton, and generates an overall profit. |

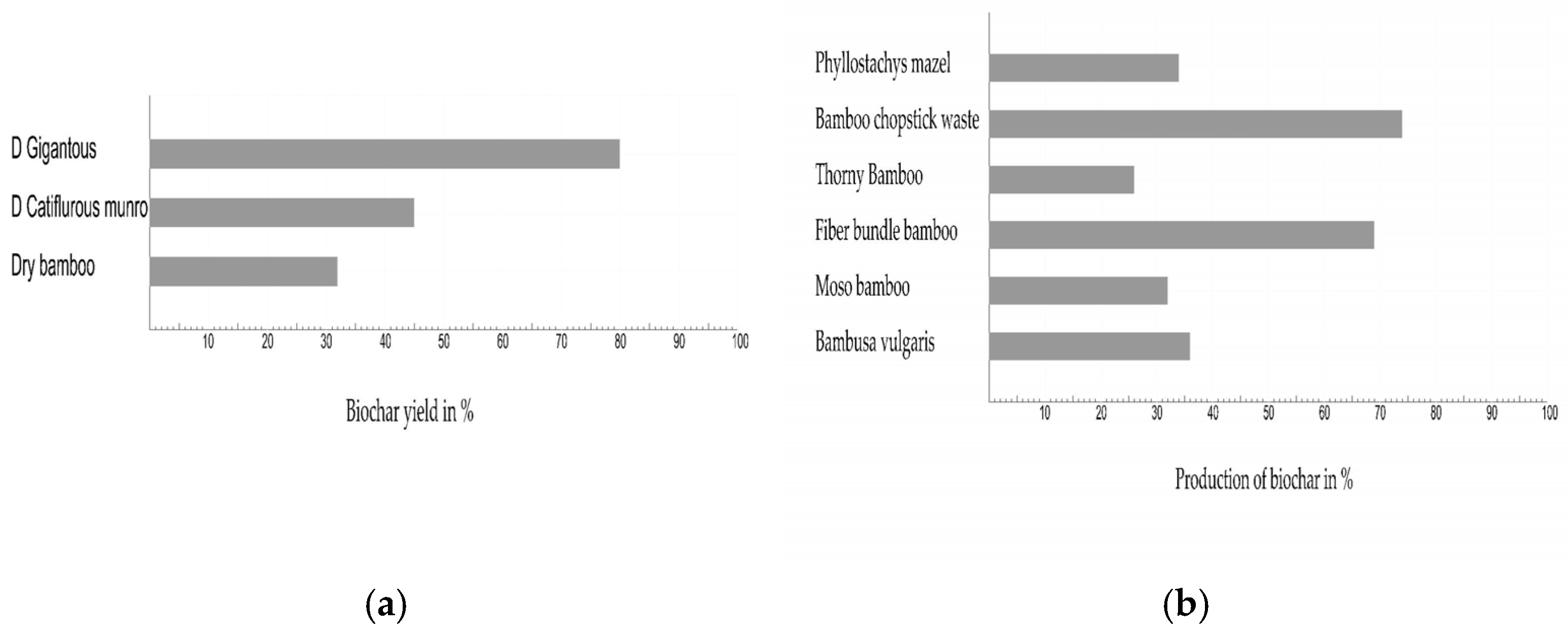

| [39] | Bamboo biochar yields range from 24 to 74%, with a maximum yield of 80% (D. Giganteus bamboo). |

| [63] | Improvements in both mechanical and physical properties. |

| [64] | Biochar and other vegetable fibers shows improvement in tensile strength and water absorbency. |

| [65] | Can also improve insulation, provide electromagnetic protection, and enhance moisture control. |

| [66] | Enhances porosity and surface area modification. |

| [67] | High porosity and low thermal conductivity. |

| [68] | Saves up to 33% of energy and reduces CO2 emissions by 63%. |

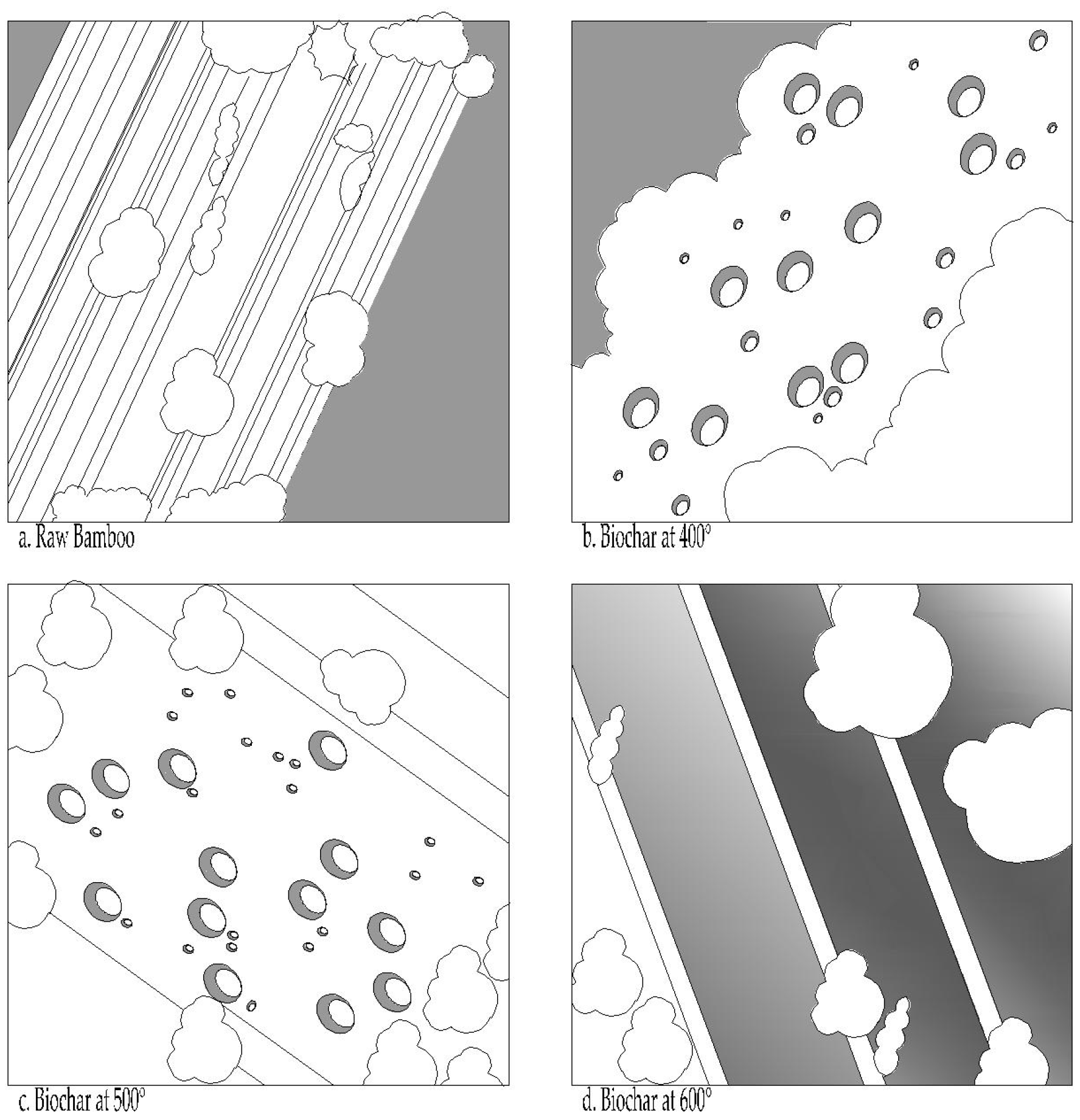

| [69] | Biochar produced at 350 degrees Celsius typically has an average porosity of less than or equal to ten micrometers. |

| [70] | Self-healing in cement—reduces cracks up to 700 μm and regulates humidity. |

| [59] | Bio-carbon enhances thermal insulation, flame retardancy, and mechanical properties. |

| [71] | Biochar-modified polyurethane foam—thermal conductivity of 0.025 W/mK. |

| [60] | A 67.21% decrease in thermal conductivity and 22.58% increase in water vapor resistance. |

| [58] | Biochar cement brick exhibits low thermal conductivity of 0.18 W/mK. |

| [72] | Flexural strength improved 26% (with 20% biochar); low thermal conductivity at optimum 10% biochar |

| [73] | Optimum CO2 uptake was achieved at 4–6% biochar content |

| [74] | Improved compressive strength by 18–20%; reduced water capillary absorption by 50–60% |

| [75] | 40–50% high compressive strength, internal curing with biochar. |

| [76] | Density increases with the pyrolysis temperature. |

| [77] | At 700 °C thermal conductivity lower by 2% cement replacement. |

| [60] | 67.21% reduced thermal conductivity; 22.58% increased water resistance. |

| [78] | 5% biochar improved the thermal conductivity of paraffin wax. |

| [79] | Biochar + lime plaster wall (25 × 25 m) can remove 63.5 kg CO2 annually. |

| [80] | Rice husk biochar: strength—increased by 34%; compressive strength and water tightness—improved by 17 and 23%; capillary absorption—lowered by 23%. |

| [74] | Capillary absorption—lowered by 50%. |

| Source | Process | Thermal Conductivity (W/mK) | U-Value (W/m2K) |

|---|---|---|---|

| Fly Ash | |||

| [90] | Fly ash cement mortar. | 0.816 | 0.66 |

| [91] | Fly ash-based raw composition. | 0.0872 | 0.52 |

| [82] | Cenospheres. | 0.065 | 0.48 |

| [92] | Class C fly ash with polypropylene. | 0.0564 | 0.46 |

| [93] | Wood ash has very low thermal conductivity. | 0.002 | 0.05 |

| Percentage | |||

| [94] | Coal bottom ash in concrete. | Reduce | 15% |

| [89] | High volume (50%/more) fly ash (Class C and F). | Reduce | 45% |

| [37] | Sand replacement 100%. | Reduce | 82% |

| Source | Statement |

|---|---|

| [95] | Cenosphere addition: Decreases thermal conductivity, increases porosity. Improves compressive strength at a later stage; however, to improvise initial setting time, a finer cementitious material can used as an additive. |

| [96] | Mine tailing and ash increase thermal insulation and porosity. |

| [97] | The higher the water/cement ratio, the lower the heat conductivity and compressive resistance. Replacement of fly ash can lower the heat transfer in concrete by up to 80%. |

| [91] | Lightweight aggregates based on fly ash were obtained by heating at 1150 degrees, showing lower thermal conductivity of up to 0.0872 W/mk. |

| [93] | Heat conductivity of wood ash 0.002 W/mK. Wood ash has very low thermal conductivity. |

| [90] | Fly ash alone exhibits a heat conductivity of 0.816 W/mK, a compactness of 2.02 kg/m3, and a particle size of 70 μm. |

| [94] | There is reduction of 15–20% in the thermal conductivity of coal bottom ash (CBA) concrete. |

| [92] | Fly ash-based geopolymer has thermal conductivity of 0.0564 W/mk. |

| [98] | Incorporating fly ash into multilayer packaging reduces the composite’s thermal conductivity. |

| [99] | Fly ash concrete after exposure to a high temp. of 550 °C reduces thermal conductivity by 26%. |

| [100] | 30% by weight of fly ash into bricks reduces their thermal conductivity. |

| [101] | Lightweight aggregate (vermiculate 15–30% by weight) and foam resulted in geopolymer fly ash concrete, showing good mechanical strength and excellent thermal insulating properties. |

| [102] | Incorporating 20% by weight, rubber wood ash in cement fiber board reduces thermal conductivity to 0.62 W/mK without affecting the mechanical properties. |

| [103] | Higher fly ash content results in reduced early hydration rate and reduce adiabatic temperature rise (14th day). It shows high influence on thermal insulation properties due to pore formation. |

| [104] | Result indicates that fly ash thermal conductivity decrease with the increase in content of biomass, pores, carbon content and specific surface. Fly ash conductivity is same or lower than natural soil. |

| [105] | Fly ash and polypropylene mix reduce down thermal conductivity to 0.248 W/mK (225 °C). |

| Source | Process | Thermal Conductivity (W/mK) | U-Value (W/m2K) |

|---|---|---|---|

| Lime | |||

| [114] | Cement–lime with glass spheres as aggregate. | 0.3 | 0.63 |

| [107] | Lime with jute. | 0.162 | 0.59 |

| [115] | Admixtures like perlite and pumice as aggregate, as well as boron minerals and steel fibers with cement and lime. | 0.13 | 0.57 |

| [106] | Perlite lime plaster. | 0.12 | 0.56 |

| [110] | Waste paper and lime. | 0.061 | 0.47 |

| [116] | Lime-based plaster with aerogel (very high cost). | 0.028 | 0.35 |

| Percentage | |||

| [117] | Olive stone in cement–lime mortar. | Reduced | 76% |

| Source | Statement |

|---|---|

| [116] | Cenosphere addition: Decreases thermal conductivity, increases porosity. Improves compressive strength at later stage; however, to improvise initial setting time, a finer cementitious material can be used as an additive. |

| [118] | Lime plaster with 50% by volume sand is replaced with expanded perlite. Provides lightweight plaster with the required mechanical properties, enhanced thermal insulation, high porosity, and resistance to salt crystallization. |

| [119] | Lime–pozzolan plaster with phase-changing material (PCM) addition significantly enhances thermal capacity while maintaining reasonable mechanical strength and improving moisture resistance. |

| [120] | Incorporating hydrophobic and pozzolanic admixtures into lime plasters effectively enhances their durability and thermal capacity. |

| [121] | The external layers of lime–sand plasters were found to have higher density and lower total porosity compared to the backing layers. |

| [122] | Lime plaster provides better fire protection than clay plaster. |

| [123] | Lime–pozzolana (fly ash) plasters can effectively replace traditional lime plasters in historical buildings, offering enhanced strength without compromising essential properties |

| [124] | PCM-modified lime–cement plasters are effective for moderating indoor climates and reducing energy consumption, despite a trade-off in mechanical properties. |

| [125] | Lime-based insulating renders can effectively enhance the comfortable thermal conditions and reduce the electricity usage of heritage buildings, though their moisture retention characteristics in winter need careful consideration to prevent potential damage. |

| [126] | The lime test cell was 3–5 °C cooler, providing comfortable indoor conditions for 40% longer. |

| [127] | Lime–metakaolin plasters offer a cost-effective and durable alternative for historical building renovations, potentially replacing current commercial renovation plasters. |

| Insulation Material | Thermal Conductivity (W/m·K) | Approximate Cost (INR/kg) |

|---|---|---|

| Glass wool | 0.035–0.040 | 100–200 |

| Rock wool | 0.035–0.040 | 120–250 |

| Expanded polystyrene (EPS) | 0.032–0.038 | 100–150 |

| Extruded polystyrene (XPS) | 0.029–0.033 | 150–200 |

| Polyurethane foam (PUF) | 0.022–0.028 | 200–300 |

| Bamboo biochar | 0.200–0.080 | 220–250 |

| Fly ash | 0.816–0.056 | 2–5 |

| Lime | 0.300–0.061 | 5–10 |

| Material | Environmental Impact | ||||||

|---|---|---|---|---|---|---|---|

| CO2 Sequestration | Renewable Resource | Reduces Waste | VOC | Humidity Control | Recycle | Carbon Footprint | |

| Glass wool | No | No | Limited | Low | No | Yes | High |

| Rock wool | No | No | Limited | Low | No | Limited | High |

| Expanded polystyrene (EPS) | No | No | Limited | High | No | Limited | High |

| Extruded polystyrene (XPS) | No | No | Limited | High | No | No | High |

| Polyurethane Foam (PUF) | No | No | Limited | High | No | No | Very high |

| Bamboo biochar | Yes | Yes | Yes | Low | Yes | Limited | Low |

| Fly ash | No | No | Yes | Low | No | Limited | Low |

| Lime | No | Yes | Limited | Low | Yes | Yes | Moderate |

| Parameter | Bamboo Biochar | Fly Ash | Lime | Combined Impact |

|---|---|---|---|---|

| Initial production cost | INR 220–INR 250 per kg | INR 2–INR 5 per kg | INR 5–INR 10 per kg | Moderate due to integration of affordable materials like fly ash and lime. |

| Installation cost | High (due to biochar) | Low | Moderate | Averaged due to balancing biochar with fly ash and lime. |

| Energy savings | 30% | Substantial reductions in heating and cooling loads, saving INR 300 per sq.m annually. | ||

| Maintenance cost | Negligible | Negligible | Moderate | Overall maintenance remains low with periodic lime reapplications. |

| Disposal cost | Low (biodegradable) | Negligible (waste reuse) | Low | Eco-friendly, with fly ash reducing landfill waste. |

| Life cycle savings (50 yrs) | INR 15,000 per sq.m | Total life cycle savings due to consistent energy cost reductions. | ||

| Environmental benefits | Carbon sequestration | Waste utilization | Low carbon footprint | High sustainability impact across all materials. |

| Research Area | (A + B) | (B + C) | (C + A) | (A + B + C) |

|---|---|---|---|---|

| Improve thermal resistance in insulation systems | ✔ | ✔ | ✔ | ✔ |

| Enhance energy efficiency in buildings | ✔ | ✔ | ✔ | |

| Reduce thermal bridging in insulation systems | ✔ | ✔ | ✔ | |

| Lower the carbon footprint of buildings | ✔ | ✔ | ✔ | ✔ |

| Innovative insulation materials’ performance in high-humidity environments | ||||

| Enhance soil stabilization and nutrient retention | ✔ | ✔ | ||

| Improve cementitious properties and thermal insulation | ✔ | |||

| Impact on structural integrity of building envelopes | ✔ | |||

| Performance in retrofitting existing structures | ✔ | |||

| Standardize application in building insulation | ✔ | |||

| Long-term thermal performance in varying climates | ✔ | ✔ | ||

| Carbon sequestration capabilities | ✔ | |||

| Moisture regulation in insulation materials | ✔ | |||

| Impact on indoor air quality | ||||

| Long-term resilience under varying environmental conditions | ✔ | |||

| Optimize mixture ratios for different climatic conditions | ✔ | |||

| Performance in large-scale applications | ✔ | |||

| Identify optimal proportions for maximum thermal performance | ✔ |

| Category | Criteria | Bamboo Biochar | Fly Ash | Lime |

|---|---|---|---|---|

| 1. Environmental impact | Embodied energy | Low to moderate, depending on the production process. | Low, as it is a byproduct of coal combustion. | Moderate to high, depending on the extraction and processing methods. |

| Carbon footprint | Low, as it sequesters carbon during production. | Low to moderate, depending on the transportation and processing. | Moderate, due to CO2 emissions during calcination. | |

| Resource efficiency | High, as it uses renewable bamboo resources. | High, as it repurposes industrial waste. | Moderate, uses natural limestone resources. | |

| Toxicity | Low, generally free from harmful chemicals. | Low to moderate, depending on trace elements in the ash. | Low, but can be caustic in handling. | |

| 2. Economic viability | Cost | Low to moderate, depending on production scale and location. | Low, as it is a waste product with low acquisition costs. | Moderate, depending on production and transportation costs. |

| Availability | High in areas where bamboo is abundant. | High, widely available as a byproduct of coal-fired power plants. | Moderate, widely available but depends on local geology. | |

| Durability | High, contributes to longevity and stability when used in construction materials. | It augments the toughness and lasting power of concrete. | High, known for its long-lasting properties in construction. | |

| 3. Social impact | Health and safety | Safe to use, with no significant health risks associated. | Generally safe; however, handling can release fine particulates. | Safe in use, though caustic during handling. |

| Aesthetics and comfort | Contributes to thermal comfort, but not typically visible in finished construction. | Contributes to thermal mass and strength but not aesthetically significant. | Provides a traditional, smooth finish in construction, contributing to aesthetic appeal. | |

| 4. Performance | Thermal insulation | Good thermal insulation properties, reduces heat transfer. | Moderate, adds to thermal mass but not primarily used for insulation. | Moderate, contributes to thermal regulation when used in lime plaster or render. |

| Structural integrity | Adds strength and stability when combined with other materials. | High, significantly enhances structural integrity in concrete. | High, particularly in lime-based mortars and plasters, providing good binding strength. | |

| Moisture resistance | High, helps in moisture regulation and prevents mold growth. | Moderate to high, depending on the mix and application. | High, especially in lime plaster, which is breathable and resists moisture. | |

| Fire resistance | High, inherently fire-resistant due to its carbon-rich composition. | High, contributes to the fire resistance of concrete. | High, particularly in lime plaster and renders, which are non-combustible. | |

| 5. Compliance | Certification and standards | Can contribute to meeting green building standards like LEED and BREEAM. | Widely recognized and accepted in various construction standards. | Compliant with many traditional and modern construction standards, including LEED and BREEAM. |

| 6. Life cycle assessment | Renewability | High, renewable and sustainable if bamboo is sourced responsibly. | Not renewable, as it is a byproduct of non-renewable coal combustion. | Moderate, depends on the sustainability of limestone extraction. |

| Recyclability | High, can be reused or integrated into other construction materials. | High, often recycled in cement and concrete production. | High, can be recycled into new construction materials or reused in different applications. | |

| End-of-life disposal | Low environmental impact, biodegradable and can be used as soil amendment. | It can be reused or safely thrown away in landfills. | Low environmental impact, can be reused or safely disposed of, and can even enhance soil quality. |

| Type of Work | Cement | Composition | Standards |

|---|---|---|---|

| Internal plaster | 1:4 | 1 unit cement, 4 units sand | IS-1661:1972, cement and cement–lime plaster |

| External plaster | 1:6 | 1 unit cement, 6 units sand | IS-1661:1972, cement and cement–lime plaster |

| IPS flooring | 1:2:4 | 1 unit cement, 2 units sand, 4 units aggregate | Civil Work Specifications 2023 |

| Material | Replacement for | Replacement Percentage | Ratio | Cement Type | Sources |

|---|---|---|---|---|---|

| Bamboo biochar | Cement | 15–20% | 1:4 to 1:6 (internal/external plaster) | Ordinary Portland cement (OPC) | [41,44,45] |

| Sand | 10–12% | OPC/blended cement | [46,80] | ||

| Fly ash | Cement | 25–30% | 1:5 to 1:6 | Blended cement, PPC | [37] |

| Sand | 15% | OPC/blended cement | [82,86] | ||

| Lime | Cement | 20–25% | 1:4 to 1:5 | Hydrated lime + OPC | [106] |

| Sand | 10–15% | Portland pozzolana cement (PPC) | [10,110,119] |

| Category | Criteria | Bamboo Biochar | Fly Ash | Lime |

|---|---|---|---|---|

| Sensory components | Thermal comfort | Low thermal conductivity, enhances indoor temperature stability | Reduces heat transfer in concrete mixes | Maintains stable indoor temperatures |

| Humidity regulation | Minimal contribution | Limited role, depends on integration | High moisture regulation, prevents dampness and allows ventilation | |

| Air quality | Passive VOC absorption | Minimal impact | Improves air quality by reducing mold risks | |

| Physical components | Thermal insulation (U-values) | U-value: 0.6–0.51 W/m2K | U-value: 0.66–0.05 W/m2K | U-value: 0.63–0.35 W/m2K |

| Carbon footprint | High carbon sequestration potential | Reduces CO2 emissions by replacing cement components | Moderate emissions during calcination, partially offset by recyclability | |

| Durability | High structural resilience and cement compatibility | Enhances robustness and longevity of concrete structures | Long-lasting, fire-resistant, suitable for modern and heritage buildings | |

| Recyclability | Limited to soil amendments | Highly reusable as an industrial byproduct | Recyclable into new plasters and construction materials |

| Category | Key Findings | Research Gaps |

|---|---|---|

| Bamboo biochar |

|

|

| Fly ash |

|

|

| Lime |

|

|

| Cost |

|

|

| Compliance |

|

|

| Optimum mix |

|

|

| Thermal performance |

|

|

| Cement Replacement | Sand Replacement | ||

|---|---|---|---|

| Lime | Cement | Bamboo Biochar | Fly Ash |

| 10% | 100% | 10% | 100% |

| 30% | 90% | 30% | 90% |

| 50% | 70% | 50% | 70% |

| 70% | 50% | 70% | 50% |

| 90% | 30% | 90% | 30% |

| 100% | 10% | 100% | 10% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deshmukh, M.; Yadav, M. Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials. Buildings 2025, 15, 230. https://doi.org/10.3390/buildings15020230

Deshmukh M, Yadav M. Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials. Buildings. 2025; 15(2):230. https://doi.org/10.3390/buildings15020230

Chicago/Turabian StyleDeshmukh, Milind, and Madhura Yadav. 2025. "Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials" Buildings 15, no. 2: 230. https://doi.org/10.3390/buildings15020230

APA StyleDeshmukh, M., & Yadav, M. (2025). Optimizing Thermal Efficiency of Building Envelopes with Sustainable Composite Materials. Buildings, 15(2), 230. https://doi.org/10.3390/buildings15020230