Analysis of the Influence of Incorporating Different Thermal-Insulating Materials into the Sub-Ballast Layers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Measuring Equipment and Method of Evaluating Measured Data

- The mean daily air temperature θs in °C, where θ7, θ14 and θ21 denote the air temperatures measured at 7:00, 14:00 and 21:00 o’clock GMT at a height of 2.0 m above the ground surface;

- The average annual air temperature θm in °C;

- Air frost index IF in °C, day (sum of mean daily air temperatures θs of the frost period);

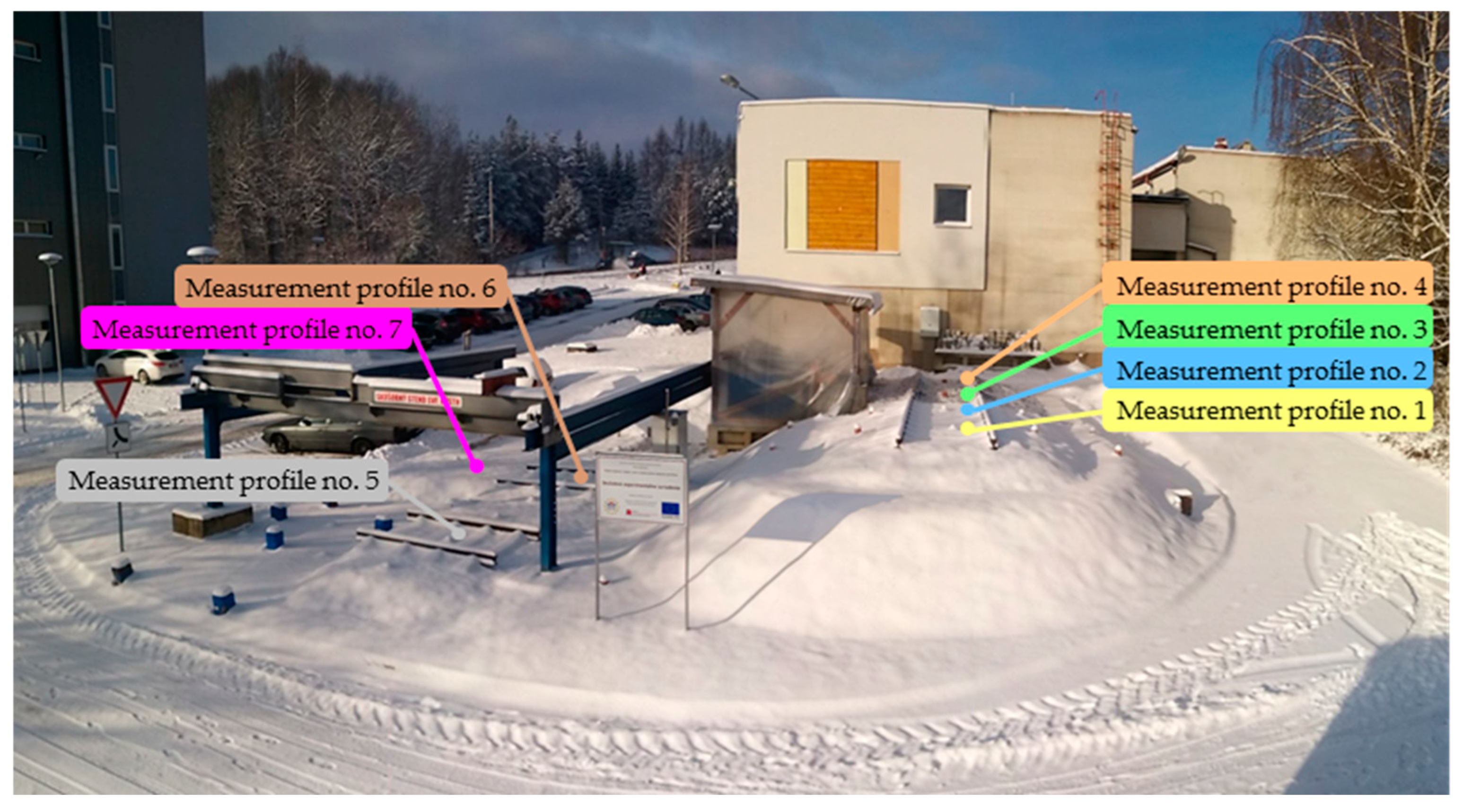

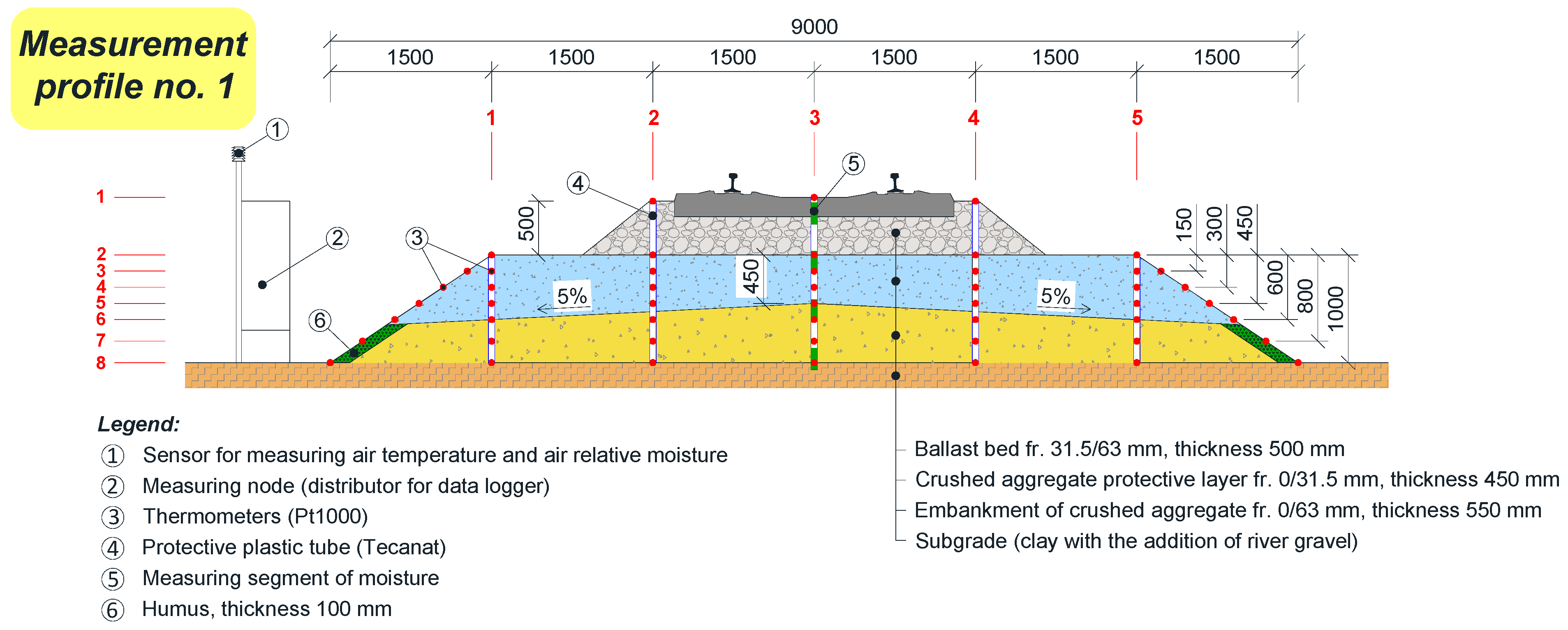

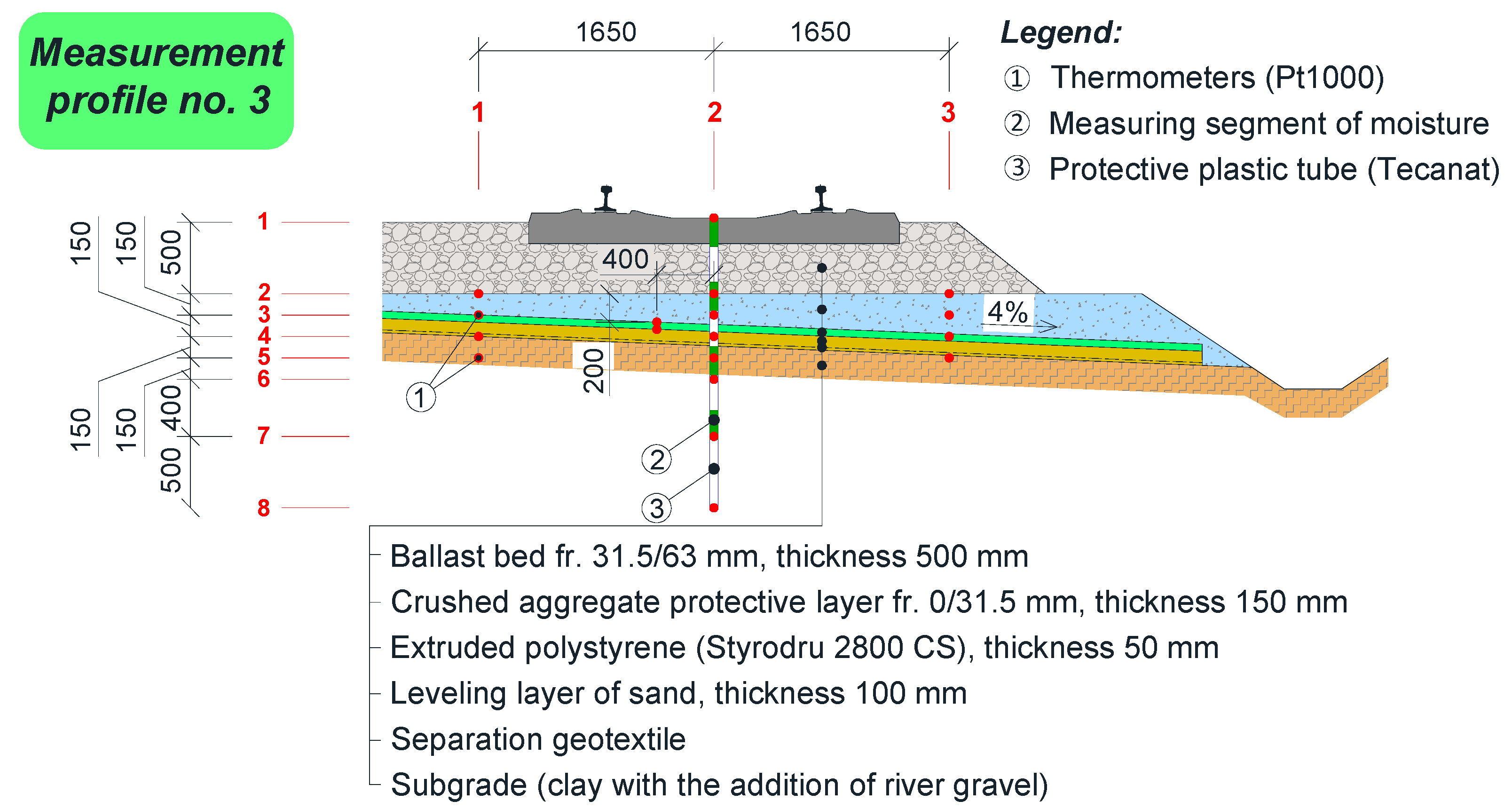

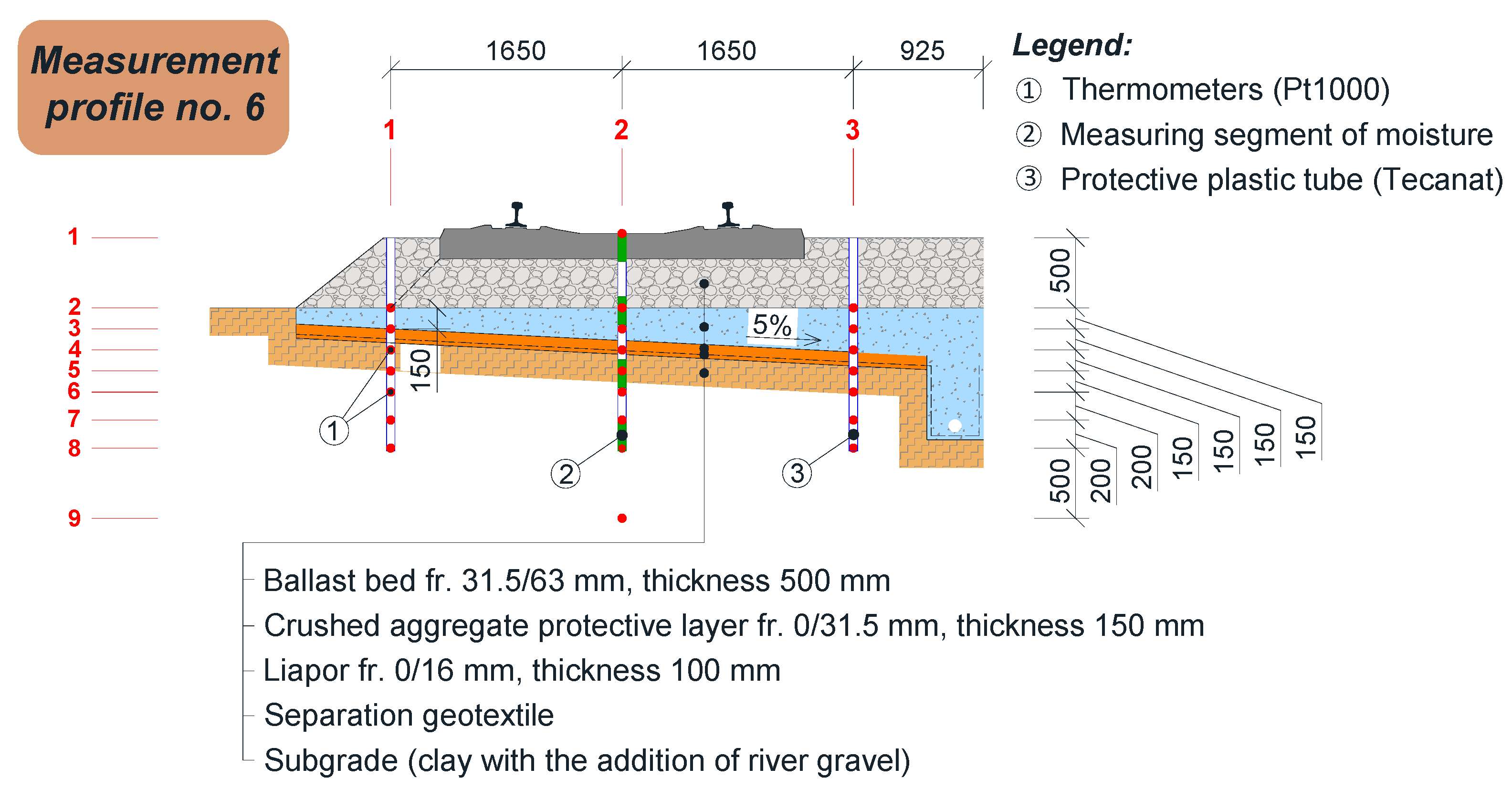

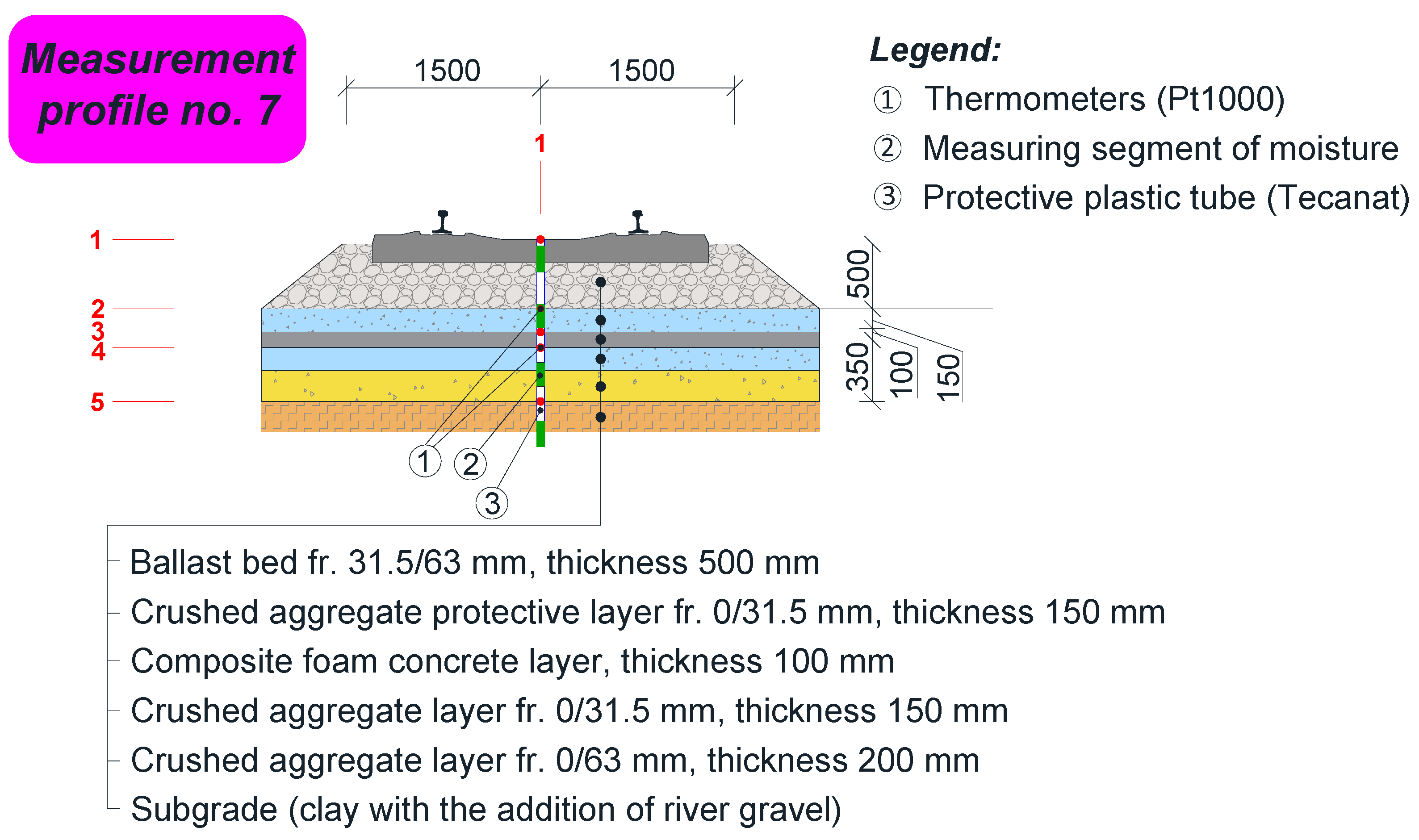

2.2. Characteristics of Individual Measurement Profiles of the Test Stand

3. Results and Discussion

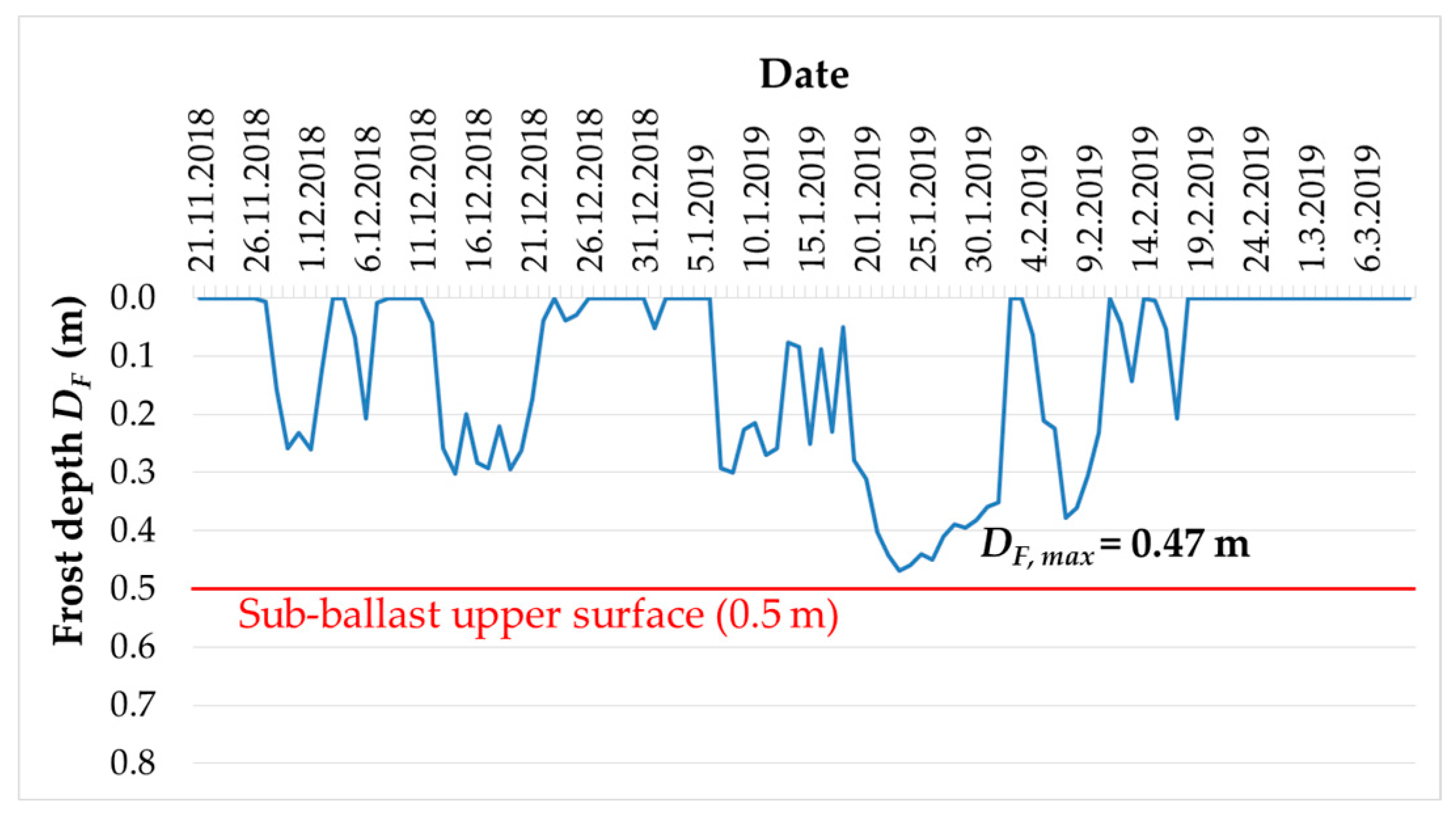

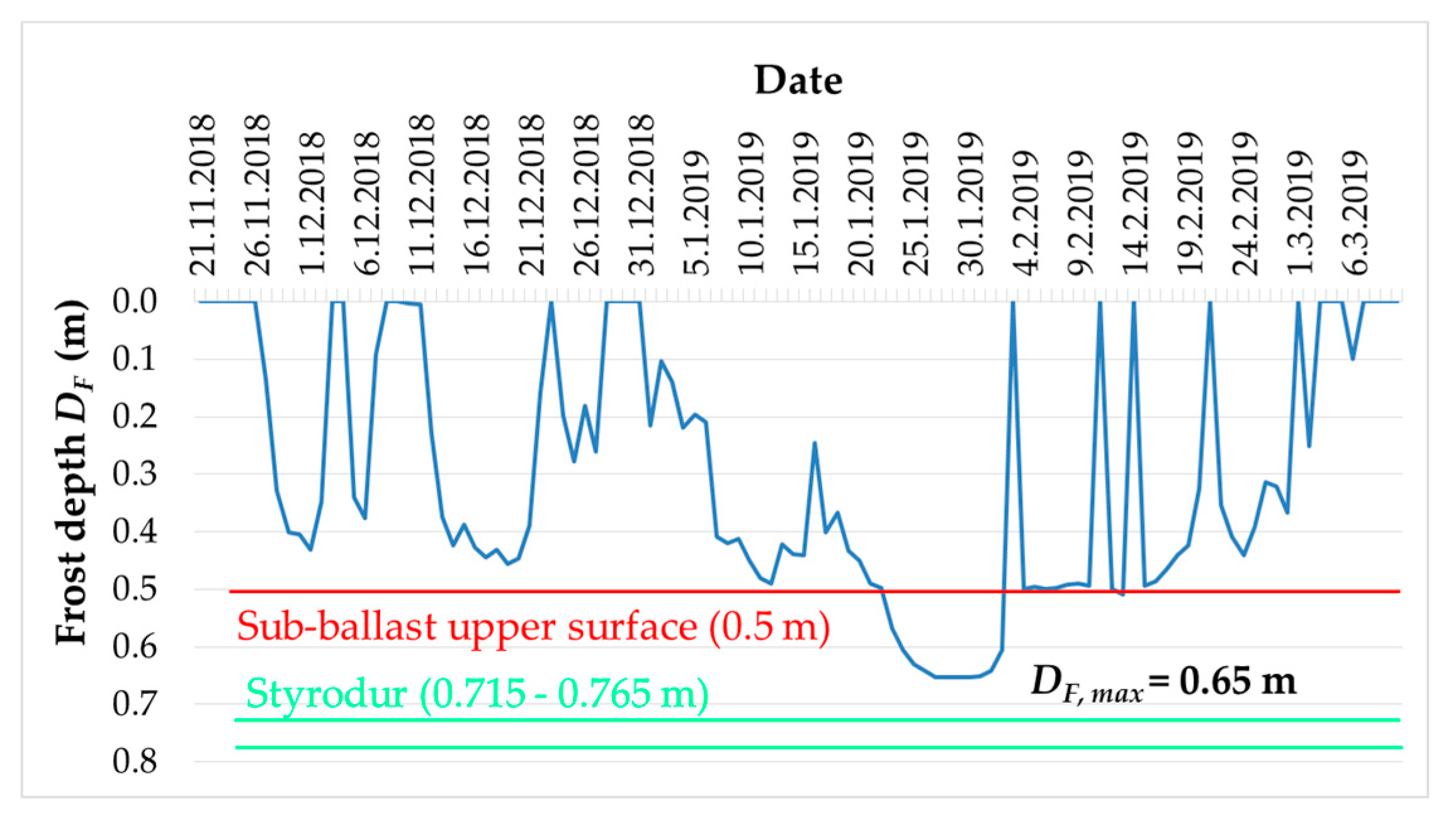

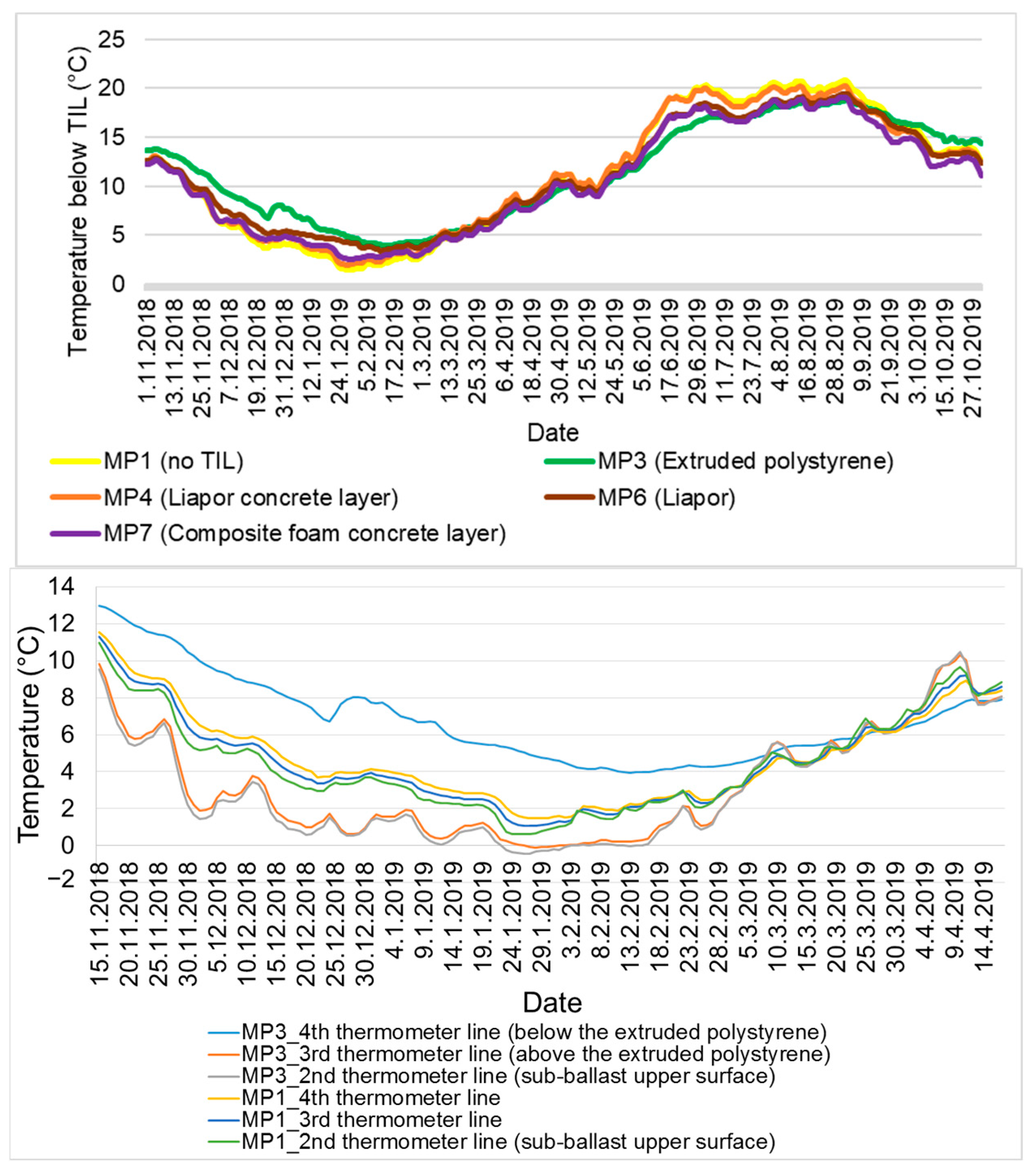

3.1. Experimental Measurements

- Mean daily air temperature θs;

- Average annual air temperature θm;

- Air frost index IF;

- Air freezing index at the surface of the ballast bed IFS;

- The frost depth of the track structure (measurement profile) DF.

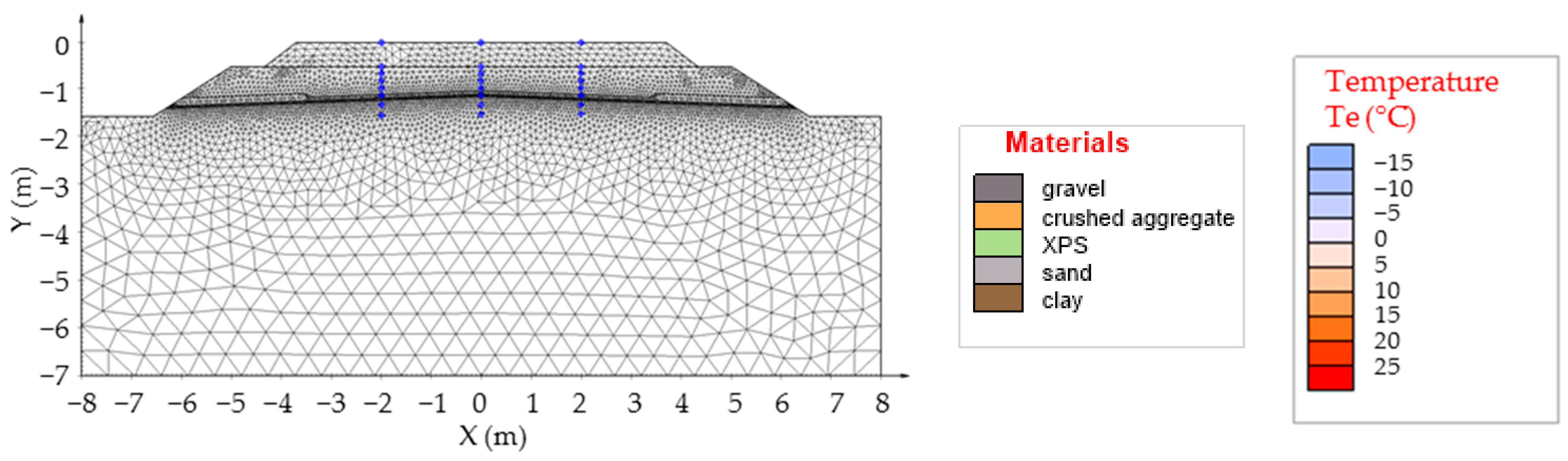

3.2. Numerical Modelling—Structure with Extruded Polystyrene (XPS) Layer in the Sub-Ballast Layers

4. Conclusions

- The frost depth of the railway track structure does not primarily depend on the air frost index IF, but also the average annual air temperature θm, that affects the amount of heat accumulated in the track bed before the freezing period, the course of the winter period (the number and intensity of frost and thaw periods), and the presence of snow cover (especially “dry” snow has a significant thermal-insulating effect);

- The application of thermal insulation material in the sub-ballast layers provides a significant thermal resistance to frost penetration into the subgrade but results in greater freezing of the overlying layers of the railway track structure (layers located above the thermal insulation material);

- The frost index on the surface of the ballast bed IFS is lower than the air frost index IF due to the thermal-insulating effect of snow cover. In the case of the standard design of the sub-ballast layers (without embedded thermal insulation material), the surface frost index IFS is significantly lower compared to the modified sub-ballast layers (with applied thermal insulation material), which causes greater cooling of the overlying layers);

- The highest thermal resistance in the railway track structure is provided by the XPS layer (when comparing the above-mentioned thermal insulation materials);

- In the case of highly adverse climatic loads on the railway track structure (air frost indices ranging from IF = 800–2000 °C, day and average annual air temperatures from θm = +4 to −1 °C), significant freezing of the subgrade surface occurs even within the active zone of traffic load, extending from the berm and the embankment slope;

- Complete protection of the subgrade surface against freezing across the entire width of the active traffic load zone can be achieved by designing various thicknesses of XPS, as determined through numerical modelling (see Table 4);

- Based on the relationship provided in Equation (5) (see Section 2.1) and the thermal technical parameters listed in Table 3 (see Section 3.2), the total thermal resistance (R) for the designed material composition in the numerical model listed in Table 4 (see Section 3.2) can be calculated as R = 3.0 m2·K·W−1 (for IF = 2000 °C, day) or R = 1.58 m2·K·W−1 (for IF = 800 °C, day).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DRETM | Department of Railway Engineering and Track Management |

| EPS | expanded polystyrene |

| GLASOPOR | trademark for aggregate made from waste glass |

| LECA/LIAPOR | trademark for artificial aggregate made from extruded clay |

| MP | measuring profile |

| SHI | Slovak Hydrometeorological Institute |

| TDR | time domain reflectometry |

| TECANAT | trademark for the protective tube of the moisture probe |

| TIL | thermal insulation layer |

| UNIZA | University of Žilina |

| XPS | extruded polystyrene |

References

- Hodás, S.; Pultznerová, A.; Vrchovský, E. Experimental Monitoring of Transition Zones in Railway Tunnels. Civ. Environ. Eng. 2023, 19, 464–473. [Google Scholar] [CrossRef]

- Yang, X.; Sun, J.; Pang, R.; Meng, W.; Tao, Z. Experimental Study on the Variation of Unfrozen Water Content and Pore Water in Unsaturated Soil during Thawing Process. IOP Conf. Ser. Earth Environ. Sci. 2021, 861, 052111. [Google Scholar] [CrossRef]

- Kou, J.; Teng, J.; Zhang, S. Experimental Study on the Unfrozen Water Content and Pore Size Distribution of Frozen Soil. J. Xi´Univ. Sci. Technol. 2018, 2018, 246–252. [Google Scholar] [CrossRef]

- Lu, J.; Pei, W.; Zhang, X.; Bi, J.; Zhao, T. Evaluation of Calculation Models for the Unfrozen Water Content of Freezing Soils. J. Hydrol. 2019, 575, 976–985. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P.; Holešová, M. Non-Traffic Stresses of Railway Substructures; EDIS-Publisher: Žilina, Slovakia, 2023; ISBN 978-80-554-2001-1. (In Slovak) [Google Scholar]

- Long, X.; Cen, G.; Cai, L.; Chen, Y. Experimental Research on Frost Heave Characteristics of Gravel Soil and Multifactor Regression Prediction. Adv. Mater. Sci. Eng. 2018, 2018, 5682619. [Google Scholar] [CrossRef]

- Wang, P.; Zhou, G. Frost-Heaving Pressure in Geotechnical Engineering Materials during Freezing Process. Int. J. Min. Sci. Technol. 2018, 28, 287–296. [Google Scholar] [CrossRef]

- Zhou, G.; Zhou, Y.; Hu, K.; Wang, Y.; Shang, X. Separate-Ice Frost Heave Model for One-Dimensional Soil Freezing Process. Acta Geotech. 2018, 13, 207–217. [Google Scholar] [CrossRef]

- Fredlund, D.G. State of Practice for Use of the Soil-Water Characteristics Curve (SWCC) in Geotechnical Engineering. Can. Geotech. J. 2019, 56, 1059–1069. [Google Scholar] [CrossRef]

- He, H.; Zhao, Y.; Dyck, M.F.; Si, B.; Jin, H.; Lv, J.; Wang, J. A Modified Normalized Model for Predicting Effective Soil Thermal Conductivity. Acta Geotech. 2017, 12, 1281–1300. [Google Scholar] [CrossRef]

- Kömle, N.I.; Hütter, E.S.; Feng, W.J. Thermal Conductivity Measurements of Coarse-Grained Gravel Materials Using a Hollow Cylindrical Sensor. Acta Geotech. 2010, 5, 211–223. [Google Scholar] [CrossRef]

- Siabil, S.M.A.G.; Tafreshi, S.N.M.; Dawson, A.R.; Omran, M.P. Behavior of Expanded Polystyrene (EPS) Blocks under Cyclic Pavement Foundation Loading. In Geosynthetics International; Emerland Publishing: England, UK, 2019; Volume 26, pp. 1–25. [Google Scholar] [CrossRef]

- Bian, J.; Cao, W.; Yang, L.; Xiong, C. Experimental Research on the Mechanical Properties of Tailing Microcrystalline Foam Glass. Materials 2018, 11, 2048. [Google Scholar] [CrossRef] [PubMed]

- Hisham, N.A.N.; Zaid, M.H.M.; Aziz, S.H.A.; Muhammad, F.D. Comparison of Foam Glass-Ceramics with Different Composition Derived from Ark Clamshell (ACS) and Soda Lime Silica (SLS) Glass Bottles Sintered at Various Temperatures. Materials 2021, 14, 570. [Google Scholar] [CrossRef] [PubMed]

- Qin, Z.; Li, G.; Tian, Y.; Ma, Y.; Shen, P. Numerical Simulation of Thermal Conductivity of Foam Glass Based on the Steady-State Method. Materials 2019, 12, 54. [Google Scholar] [CrossRef] [PubMed]

- Paunescu, L.; Axinte, S.M.; Dragoescu, M.F.; Cosmulescu, F. Adequate Correlation between the Physical and Mechanical Properties of Glass Foam. J. Multiapp 2021, 2, 14–26. [Google Scholar] [CrossRef]

- Yu, W.; Liang, X.; Ni, F.M.; Oyeyi, A.G.; Tighe, S. Characteristics of Lightweight Cellular Concrete and Effects on Mechanical Properties. Materials 2020, 13, 2678. [Google Scholar] [CrossRef]

- Falliano, D.; Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental Investigation on the Compressive Strength of Foamed Concrete: Effect of Curing Conditions, Cement Type, Foaming Agent and Dry Density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Sun, C.; Zhu, Y.; Guo, J.; Zhang, Y.; Sun, G. Effects of Foaming Agent Type on the Workability, Drying Shrinkage, Frost Resistance and Pore Distribution of Foamed Concrete. Constr. Build. Mater. 2018, 186, 833–839. [Google Scholar] [CrossRef]

- Kadela, M.; Kukiełka, A.; Małek, M. Characteristics of Lightweight Concrete Based on a Synthetic Polymer Foaming Agent. Materials 2020, 13, 4979. [Google Scholar] [CrossRef]

- Kozłowski, M.; Kadela, M. Mechanical Characterization of Lightweight Foamed Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 6801258. [Google Scholar] [CrossRef]

- Krzywoń, R.; Dawczyński, S. Strength Parameters of Foamed Geopolymer Reinforced with GFRP Mesh. Materials 2021, 14, 689. [Google Scholar] [CrossRef]

- Niu, F.; Jiang, H.; Su, W.; Jiang, W.; He, J. Performance Degradation of Polymer Material under Freeze-Thaw Cycles: A Case Study of Extruded Polystyrene Board. Polym. Test. 2021, 96, 107067. [Google Scholar] [CrossRef]

- Tafreshi, S.N.M.; Siabil, S.M.A.G.; Dawson, A.R. Expanded Polystyrene Geofoam. In New Materials in Civil Engineering; Butterworth-Heinemann: England, UK, 2020; Volume 2020, pp. 117–153. [Google Scholar] [CrossRef]

- Nurmikolu, A.; Kolisoja, P. Extruded polystyrene (XPS) foam frost insulation boards in railway structures. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–15 September 2005. [Google Scholar] [CrossRef]

- Addison, P.; Lautala, P.; Oommen, T.; Vallos, Z. Embankment Stabilization Techniques for Railroads on Permafrost. In Proceedings of the 2016 Joint Rail Conference, Columbia, SC, USA, 12–15 April 2016. [Google Scholar] [CrossRef]

- Partyka, J.; Wysoczański, A. Utilization Aspects of Extruded Polystyrene and Expanded Clay Aggregate in Road Frost Protection Structures. Innov. Infrastruct. Solut. 2024, 9, 41. [Google Scholar] [CrossRef]

- Loranger, E.; Kuznetsova, E.; Hoff, I.; Aksnes, J.; Skoglund, K.A. Evaluation of Norwegian Gradation Based Regulation for Frost Susceptibility of Crushed Rock Aggregates in Roads and Railways. In Bearing Capacity of Roads, Railways and Airfields; CRC Press: Boca Raton, FL, USA, 2017; pp. 2077–2085. [Google Scholar] [CrossRef]

- Oyeyi, A.G.; Badewa, E.A.; Ni, F.M.; Tighe, S. Field Study on Thermal Behavior of Lightweight Cellular Concrete as Pavement Subgrade Protection in Cold Regions. Cold Reg. Sci. Technol. 2023, 214, 103966. [Google Scholar] [CrossRef]

- Zhuo, Z.; Ali, A.; Zhu, C.; Mehta, Y.; Lein, W.; DeCarlo, C.; Elshaer, M.; Kennedy, D. Evaluating the Potential of Using Foamed Concrete as the Insulation Layer for Pavements in Cold Regions. Constr. Build. Mater. 2022, 341, 127903. [Google Scholar] [CrossRef]

- Huang, J.; Su, Q.; Zhao, W.; Li, T.; Zhang, X. Experimental Study on Use of Lightweight Foam Concrete as Subgrade Bed Filler of Ballastless Track. Constr. Build. Mater. 2017, 149, 911–920. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P.; Holešová, M.; Navikas, D. Numerical Modelling of Thermal Regime of Railway Track—Structure with Thermal Insulation (Styrodur). J. Civ. Eng. Manag. 2021, 27, 525–538. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P.; Drusa, M.; Kadela, M.; Holešová, M. Experimental and Numerical Verification of the Railway Track Substructure with Innovative Thermal Insulation Materials. Materials 2022, 15, 160. [Google Scholar] [CrossRef]

- Decký, M.; Hodásová, K.; Papánová, Z.; Remišová, E. Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe. Sustainability 2022, 14, 9034. [Google Scholar] [CrossRef]

- TNŽ 73 6312; Proposed Construction Design of the Subgrade Layers. Directorate General of the Railways of the Slovak Republic: Bratislava, Slovak Republic, 2005. (In Slovak)

- Pieš, J.; Môcová, L. Application of TDR Test Probe for Determination of Moisture Changes of Railway Substructure Materials. In Proceedings of the 13th International Scientific Conference on Sustainable, Modern and Safe Transport, Novy Smokovec, Slovak Republic, 29–31 May 2019. [Google Scholar] [CrossRef]

- Ižvolt, L.; Dobeš, P.; Pieš, J. Verification of Boundary Conditions of Numerical Modeling of the Track Substructure Thermal Regime—Influence of the Snow Cover. Arch. Transp. 2018, 48, 51–60. [Google Scholar] [CrossRef]

- Thode, R. 2D/3D Geothermal Modeling Software, Tutorial Manual; SVHEAT: Saskatoon, SK, Canada, 2012; Available online: https://manualzilla.com/doc/5907794/svheat-tutorial-manual (accessed on 15 October 2021).

- Fredlund, M.; Haihua, L. 2D/3D Visualization Software, User’s Manual; ACUMESH: Saskatoon, SK, Canada, 2011. [Google Scholar]

- Decký, M.; Papánová, Z.; Juhas, M.; Kudelčíková, M. Evaluation of the Effect of Average Annual Temperatures in Slovakia between 1971 and 2020 on Stresses in Rigid Pavements. Land 2022, 11, 764. [Google Scholar] [CrossRef]

- Song, C.; Dai, C.; Gao, Y.; Wang, C.; Yu, M.; Tu, W.; Jia, M.; Li, R. Spatial-Temporal Characteristics of Freezing/Thawing Index and Permafrost Distribution in Heilongjiang Province, China. Sustainability 2022, 14, 16899. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, T.; Clow, G.D. Permafrost Thermal Responses to Asymmetrical Climate Changes: An Integrated Perspective. Geophys. Res. Lett. 2023, 50, e2022GL100327. [Google Scholar] [CrossRef]

| Winter Period | θs, min (°C) | θm (°C) | IF (°C, day) | IFS (°C, day) | DF (m) |

|---|---|---|---|---|---|

| 2013/2014 | −11.7 | 9.6 | 38 | 22 | 0.41 |

| 2014/2015 | −10.8 | 10.2 | 77 | 32 | 0.41 |

| 2015/2016 | −10.2 | 9.9 | 99 | 72 | 0.46 |

| 2016/2017 | −19.0 | 9.2 | 284 | 248 | 0.65 |

| 2017/2018 1 | −11.2 | 9.0 | 107 | 66 | 0.56 |

| 2018/2019 | −11.3 | 10.3 | 124 | 58 | 0.47 |

| 2019/2020 | −7.7 | 10.1 | 50 | 28 | 0.37 |

| 2020/2021 | −12.4 | 9.6 | 110 | 27 | 0.37 |

| 2021/2022 | −8.2 | 8.8 | 60 | 37 | 0.41 |

| 2022/2023 | −9.9 | 9.7 | 59 | 31 | 0.45 |

| 2023/2024 | −8.3 | 10.2 | 49 | 44 | 0.41 |

| Winter Period | Achieved Frost Depth—DF (m) | ||||

|---|---|---|---|---|---|

| MP1 | MP3 | MP4 | MP6 | MP7 | |

| 2018/2019 | 0.47 | 0.65 | 0.49 | 0.38 1 | 0.49 |

| Structural Layer/Material Characteristics | Ballast Bed-New | Protective Layer | Thermal Insulation Layer | Levelling Layer | Subgrade |

|---|---|---|---|---|---|

| Layer material | gravel fr. 31.5/63 mm | crushed aggregate fr. 0/31.5 mm | extruded polystyrene | sand fr. 0/1 mm | clay |

| Temperature θ (°C) | 2 | 3 | 5 | 5 | 10 |

| Moisture w (%) | 1 | 5.5 | 12 | 12 | 26 |

| Bulk density ρ (kg·m−3) | 1900 | 1930 | 35 | 1750 | 1650 |

| Specific heat capacity c (J·kg−1·K−1) | 980 | 1090 | 2060 | 960 | 1095 |

| Thermal conductivity coefficient λ (W·m−1·K−1) | 0.7 | 1.73 | 0.04 | 2.00 | 1.55 |

| Air Frost Index IF (°C, day) | Average Annual Air Temperature θm (°C) | Duration of Frost Period (Days) | Protective Layer Thickness tpl (mm) | XPS Thickness in the Track Centreline (mm) | XPS Thickness at the Embankment Slope (mm) |

| 800 | 4 | 110 | 200 | 30 | 50 |

| 1000 | 2 | 180 | 450 | 50 | 60 |

| 1200 | 1 | 190 | 500 | 50 | 80 |

| 1400 | 1 | 200 | 500 | 60 | 100 |

| 1600 | −0.5 | 220 | 500 | 80 | 120 |

| 1800 | −1 | 240 | 500 | 80 | 140 |

| 2000 | −1 | 255 | 500 | 80 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ižvolt, L.; Dobeš, P.; Mečár, M.; Navikas, D. Analysis of the Influence of Incorporating Different Thermal-Insulating Materials into the Sub-Ballast Layers. Buildings 2025, 15, 239. https://doi.org/10.3390/buildings15020239

Ižvolt L, Dobeš P, Mečár M, Navikas D. Analysis of the Influence of Incorporating Different Thermal-Insulating Materials into the Sub-Ballast Layers. Buildings. 2025; 15(2):239. https://doi.org/10.3390/buildings15020239

Chicago/Turabian StyleIžvolt, Libor, Peter Dobeš, Martin Mečár, and Deividas Navikas. 2025. "Analysis of the Influence of Incorporating Different Thermal-Insulating Materials into the Sub-Ballast Layers" Buildings 15, no. 2: 239. https://doi.org/10.3390/buildings15020239

APA StyleIžvolt, L., Dobeš, P., Mečár, M., & Navikas, D. (2025). Analysis of the Influence of Incorporating Different Thermal-Insulating Materials into the Sub-Ballast Layers. Buildings, 15(2), 239. https://doi.org/10.3390/buildings15020239