Exploring Critical Factors Influencing the Resilience of the Prefabricated Construction Supply Chain

Abstract

:1. Introduction

2. Literature Review

2.1. Prefabricated Construction Supply Chain

2.2. Resilience of the Prefabricated Construction Supply Chain

3. Method

3.1. Concept Identification

3.1.1. Factor Screening

3.1.2. Taxonomy

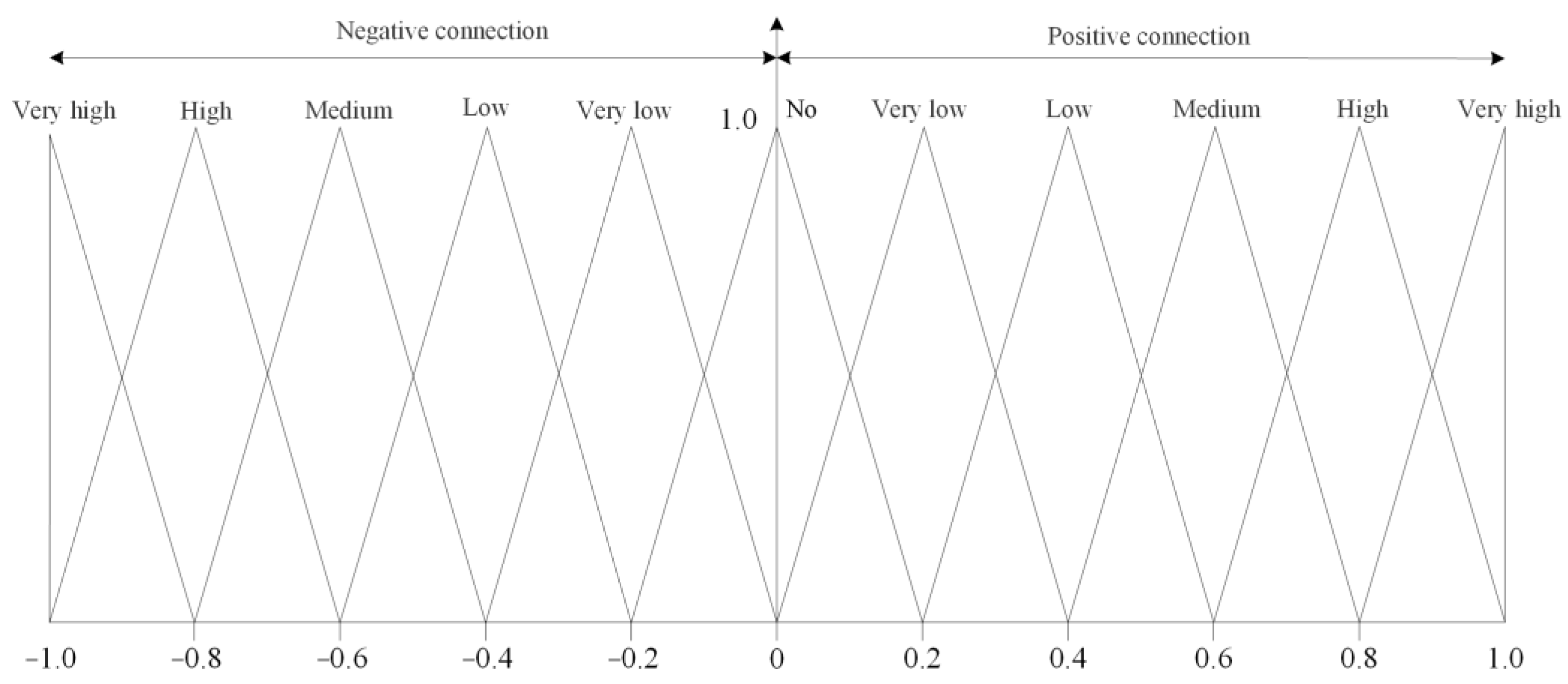

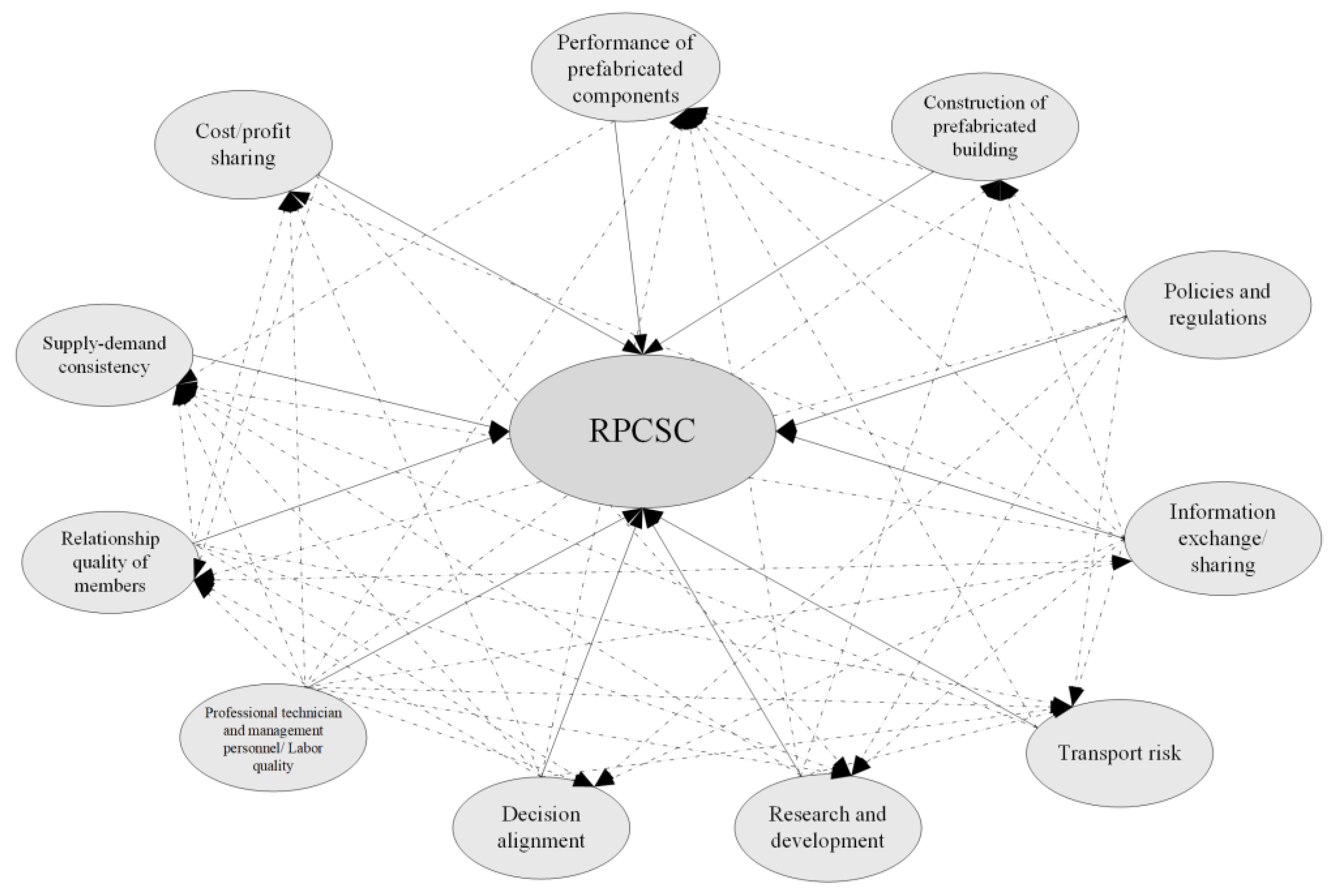

3.2. Fuzzy Cognitive Maps (FCMs)

- (a)

- It is necessary to determine an initialized state vector An (0);

- (b)

- It is necessary to obtain the interaction matrix with the help of expert knowledge and experience;

- (c)

- Multiple iterative calculations of the initial state vector are carried out through Equations (2) and (3). When the final result satisfies An (t) = An (t + 1), the iteration is stopped. At this time, FCM reaches A stable state, and the whole iteration process ends.

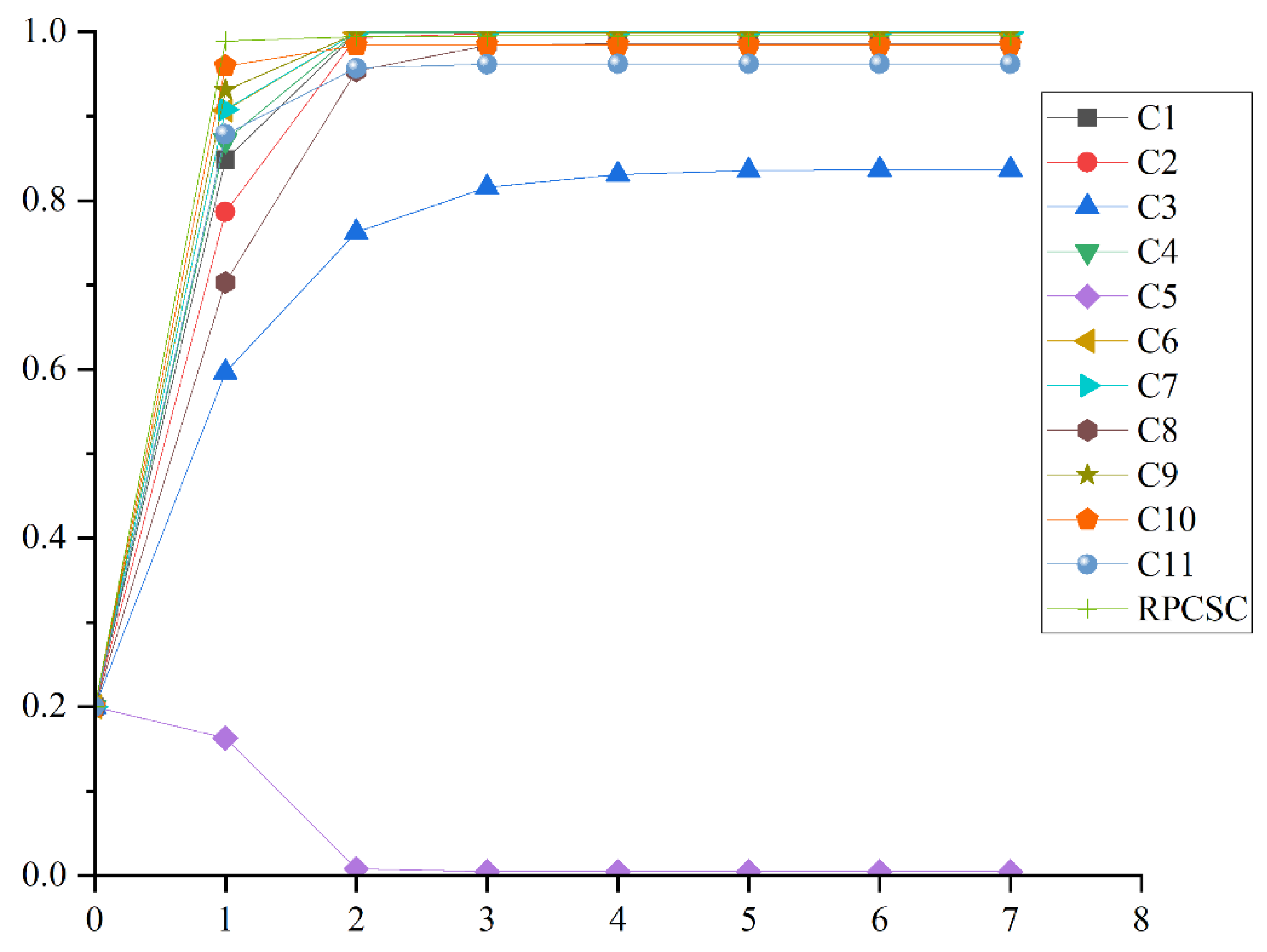

4. Results

4.1. Case Information

4.2. Case Analysis

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qian, L.-P.; Xu, L.-Y.; Huang, B.-T.; Li, Y.; Lan, J.; Gong, F.; Guan, H. Functionalization of waste-derived artificial aggregates: A state-of-the-art review. Resour. Conserv. Recycl. 2025, 212, 107999. [Google Scholar] [CrossRef]

- Lee, C.; Won, J.W.; Jang, W.; Jung, W.; Han, S.H.; Kwak, Y.H. Social conflict management framework for project viability: Case studies from Korean megaprojects. Int. J. Proj. Manag. 2017, 35, 1683–1696. [Google Scholar] [CrossRef]

- Dong, Y.; Lan, J.; Zang, M.; Lu, H.; Zhang, D.; Huang, B.-T. Eco-friendly preparation of self-bonding materials from natural aeolian sand and secondary aluminum dross for sustainable desert construction. J. Clean. Prod. 2024, 144, 144214. [Google Scholar] [CrossRef]

- Ma, S.; Li, Z.; Li, L.; Yuan, M. Coupling coordination degree spatiotemporal characteristics and driving factors between new urbanization and construction industry: Evidence from China. Eng. Constr. Archit. Manag. 2023, 30, 5280–5301. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, B.; Shen, Y.; Wang, X. The energy efficiency of China’s regional construction industry based on the three-stage DEA model and the DEA-DA model. KSCE J. Civ. Eng. 2016, 20, 34–47. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Y.; Shi, L.; Hou, L.; Zhang, G. Current state of using prefabricated construction in Australia. Buildings 2022, 12, 1355. [Google Scholar] [CrossRef]

- Mostafa, S.; Chileshe, N.; Zuo, J. A synergistic supply chain enhancing offsite manufacturing uptake in Australian house building. In Proceedings of the 30th Annual ARCOM Conference, Portsmouth, UK, 1–3 September 2014; Raiden, A.B., Aboagye-Nimo, E., Eds.; Association of Researchers in Construction Management: London, UK, 2014; pp. 1143–1152. [Google Scholar]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and economic performance of prefabricated construction: A review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Hofman, E.; Voordijk, H.; Halman, J. Matching supply networks to a modular product architecture in the house-building industry. Build. Res. Inf. 2009, 37, 31–42. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, J.; Cheng, C. Research on Urban Resilience from the Perspective of Land Intensive Use: Indicator Measurement, Impact and Policy Implications. Buildings 2024, 14, 2564. [Google Scholar] [CrossRef]

- Cheng, S.; Zhou, X.; Zhang, Y.; Duan, M.; Gao, J. Study on resilience factors and enhancement strategies in prefabricated building supply chains. Buildings 2024, 14, 195. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.; González, V.A.; Roy, K.; Khan, K.I.A. A systematic review on supply chain management in prefabricated house-building research. Buildings 2022, 12, 40. [Google Scholar] [CrossRef]

- Ahmed, A.E.; Ucbasaran, D.; Cacciotti, G.; Williams, T.A. Integrating psychological resilience, stress, and coping in entrepreneurship: A critical review and research agenda. Entrep. Theory Pract. 2022, 46, 497–538. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.; Kumaraswamy, M.; Owusu, E.K. A fuzzy synthetic evaluation of vulnerabilities affecting supply chain resilience of industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2022, 29, 2358–2381. [Google Scholar] [CrossRef]

- Shen, K.; Li, X.; Cao, X.; Zhang, Z. Prefabricated construction process optimization based on rework risk. J. Constr. Eng. Manag. 2022, 148, 04022031. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply chain management for prefabricated building projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, L. Resilience-cost tradeoff supply chain planning for the prefabricated construction project. J. Civ. Eng. Manag. 2021, 27, 45–59. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Obot, O.; John, A.; Udo, I.; Attai, K.; Johnson, E.; Udoh, S.; Nwokoro, C.; Akwaowo, C.; Dan, E.; Umoh, U.; et al. Modelling differential diagnosis of febrile diseases with fuzzy cognitive map. Trop. Med. Infect. Dis. 2023, 8, 352. [Google Scholar] [CrossRef]

- Du, Q.; Pang, Q.; Bao, T.; Guo, X.; Deng, Y. Critical factors influencing carbon emissions of prefabricated building supply chains in China. J. Clean. Prod. 2021, 280, 124398. [Google Scholar] [CrossRef]

- Du, Q.; Hao, T.; Huang, Y.; Yan, Y. Prefabrication decisions of the construction supply chain under government subsidies. Environ. Sci. Pollut. Res. 2022, 29, 59127–59144. [Google Scholar] [CrossRef]

- Han, Y.; Yan, X.; Piroozfar, P. An overall review of research on prefabricated construction supply chain management. Eng. Constr. Archit. Manag. 2023, 30, 5160–5195. [Google Scholar] [CrossRef]

- Hussein, M.; Eltoukhy, A.E.; Karam, A.; Shaban, I.A.; Zayed, T. Modelling in off-site construction supply chain management: A review and future directions for sustainable modular integrated construction. J. Clean. Prod. 2021, 310, 127503. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Li, L.; Gao, Y. Constraints on the promotion of prefabricated construction in China. Sustainability 2018, 10, 2516. [Google Scholar] [CrossRef]

- Masood, R.; Lim, J.B.; González, V.A. Performance of the supply chains for New Zealand prefabricated house-building. Sustain. Cities Soc. 2021, 64, 102537. [Google Scholar] [CrossRef]

- Chang, Y.; Li, X.; Masanet, E.; Zhang, L.; Huang, Z.; Ries, R. Unlocking the green opportunity for prefabricated buildings and construction in China. Resour. Conserv. Recycl. 2018, 139, 259–261. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Stroebele, B.S.; Kiessling, A.J.; Zhang, J. Impact analysis of complexity drivers in the supply chain of prefabricated houses. J. Manag. Strategy 2017, 8, 1–9. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Stakeholder management in prefabricated prefinished volumetric construction projects: Benchmarking the key result areas. Built Environ. Proj. Asset Manag. 2020, 10, 407–421. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.; Zhang, Y. Exploring the risk propagation mechanisms of supply chain for prefabricated building projects. J. Build. Eng. 2023, 74, 106771. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.; Mahmud, A.T. Critical risk factors in the application of modular integrated construction: A systematic review. Int. J. Constr. Manag. 2019, 22, 133–147. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-averse supply chain for modular construction projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Ng, S.T.; Lu, W.; Shen, G.Q.; Huang, G.Q. Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Jafari, M.; Khoshand, A.; Sadeghi, N.; Mirzanagh, P.A. A comparative LCA of external wall assemblies in context of Iranian market: Considering embodied and operational energy through BIM application. Environ. Sci. Pollut. Res. 2024, 31, 7364–7379. [Google Scholar] [CrossRef] [PubMed]

- Rangasamy, V.; Yang, J.-B. The convergence of BIM, AI and IoT: Reshaping the future of prefabricated construction. J. Build. Eng. 2024, 84, 108606. [Google Scholar] [CrossRef]

- Van Meerbeek, K.; Jucker, T.; Svenning, J.C. Unifying the concepts of stability and resilience in ecology. J. Ecol. 2021, 109, 3114–3132. [Google Scholar] [CrossRef]

- Shishodia, A.; Sharma, R.; Rajesh, R.; Munim, Z.H. Supply chain resilience: A review, conceptual framework and future research. Int. J. Logist. Manag. 2023, 34, 879–908. [Google Scholar] [CrossRef]

- Wieland, A.; Durach, C.F. Two perspectives on supply chain resilience. J. Bus. Logist. 2021, 42, 315–322. [Google Scholar] [CrossRef]

- Conz, E.; Magnani, G. A dynamic perspective on the resilience of firms: A systematic literature review and a framework for future research. Eur. Manag. J. 2020, 38, 400–412. [Google Scholar] [CrossRef]

- Liu, J.J.; Reed, M.; Girard, T.A. Advancing resilience: An integrative, multi-system model of resilience. Personal. Individ. Differ. 2017, 111, 111–118. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Ji, B. Influencing factors of resilience of PBSC based on empirical analysis. Buildings 2021, 11, 467. [Google Scholar] [CrossRef]

- Spiegler, V.L.; Naim, M.M.; Wikner, J. A control engineering approach to the assessment of supply chain resilience. Int. J. Prod. Res. 2012, 50, 6162–6187. [Google Scholar] [CrossRef]

- Abimbola, M.; Khan, F. Resilience modeling of engineering systems using dynamic object-oriented Bayesian network approach. Comput. Ind. Eng. 2019, 130, 108–118. [Google Scholar] [CrossRef]

- Arshad, H.; Zayed, T. Critical influencing factors of supply chain management for modular integrated construction. Autom. Constr. 2022, 144, 104612. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The evolution of resilience in supply chain management: A retrospective on ensuring supply chain resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Ekanayake, E.M.A.C.; Shen, G.Q.P.; Kumaraswamy, M.M. A fuzzy synthetic evaluation of capabilities for improving supply chain resilience of industrialised construction: A Hong Kong case study. Prod. Plan. Control 2023, 34, 623–640. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Li, Z.; Huang, G. Production lead-time hedging and coordination in prefabricated construction supply chain management. Int. J. Prod. Res. 2017, 55, 3984–4002. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, G. A novel hybrid methodology to study the risk management of prefabricated building supply chains: An outlook for sustainability. Sustainability 2022, 15, 361. [Google Scholar] [CrossRef]

- Wang, Y. Research on risk management of prefabricated construction supply chain based on immune principle. IOP Conf. Ser. Earth Environ. Sci. 2019, 371, 052058. [Google Scholar]

- Olawumi, T.O.; Chan, D.W.; Ojo, S.; Yam, M.C. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Yong, Y.W.; Keng, K.A.; Leng, T.L. A Delphi forecast for the Singapore tourism industry: Future scenario and marketing implications. Int. Mark. Rev. 1989, 6, 3. [Google Scholar]

- Kosko, B. Fuzzy cognitive maps. Int. J. Man-Mach. Stud. 1986, 24, 65–75. [Google Scholar] [CrossRef]

- Baker, C.M.; Holden, M.H.; Plein, M.; McCarthy, M.A.; Possingham, H.P. Informing network management using fuzzy cognitive maps. Biol. Conserv. 2018, 224, 122–128. [Google Scholar] [CrossRef]

- Demiralp, G.; Guven, G.; Ergen, E. Analyzing the benefits of RFID technology for cost sharing in construction supply chains: A case study on prefabricated precast components. Autom. Constr. 2012, 24, 120–129. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, T.; Hu, H.; Gong, J.; Ren, X.; Xiao, Q. Blockchain-based framework for improving supply chain traceability and information sharing in precast construction. Autom. Constr. 2020, 111, 103063. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, J.; Ye, M.; Huang, Q.; Si, X. An evaluation of supply chain performance of China’s prefabricated building from the perspective of sustainability. Sustainability 2022, 14, 1299. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Q.K.; Straub, A.; Visscher, H. Exploring transaction costs in the prefabricated housing supply chain in China. J. Clean. Prod. 2019, 226, 550–563. [Google Scholar] [CrossRef]

- Sabahi, S.; Parast, M.M. Firm innovation and supply chain resilience: A dynamic capability perspective. Int. J. Logist. Res. Appl. 2020, 23, 254–269. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Q.K.; Straub, A.; Visscher, H. Stakeholder perceptions of transaction costs in prefabricated housing projects in China. J. Constr. Eng. Manag. 2021, 147, 04020145. [Google Scholar] [CrossRef]

- Xie, L.; Wu, S.; Chen, Y.; Chang, R.; Chen, X. A case-based reasoning approach for solving schedule delay problems in prefabricated construction projects. Autom. Constr. 2023, 154, 105028. [Google Scholar] [CrossRef]

- Wen, Y. Research on the intelligent construction of prefabricated building and personnel training based on BIM5D. J. Intell. Fuzzy Syst. 2021, 40, 8033–8041. [Google Scholar] [CrossRef]

- Chen, Q.; Hall, D.M.; Adey, B.T.; Haas, C.T. Identifying enablers for coordination across construction supply chain processes: A systematic literature review. Eng. Constr. Archit. Manag. 2020, 28, 1083–1113. [Google Scholar] [CrossRef]

- Du, J.; Sugumaran, V. Ontology-based information integration and decision making in prefabricated construction component supply chain. In Proceedings of the Twenty-third Americas Conference on Information System, Boston, MA, USA, 10–12 August 2017; pp. 1–10. [Google Scholar]

- Du, J.; Sugumaran, V.; Gao, B. RFID and multi-agent based architecture for information sharing in prefabricated component supply chain. IEEE Access 2017, 5, 4132–4139. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.; Kumaraswamy, M.M. Critical capabilities of improving supply chain resilience in industrialized construction in Hong Kong. Eng. Constr. Archit. Manag. 2020, 28, 3236–3260. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.Q.; Kumaraswamy, M.M. Identifying supply chain capabilities of construction firms in industrialized construction. Prod. Plan. Control 2021, 32, 303–321. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.Q.; Kumaraswamy, M.M.; Owusu, E.K. Identifying supply chain vulnerabilities in industrialized construction: An overview. Int. J. Constr. Manag. 2020, 22, 1464–1477. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Establishing outsourcing and supply chain plans for prefabricated construction projects under uncertain productivity. In Lecture Notes in Computer Science; Proceedings of International Conference on Computational Logistics; Springer: Cham, Switzerland, 2017; pp. 529–543. [Google Scholar] [CrossRef]

- Liu, K.; Su, Y.; Zhang, S. Evaluating supplier management maturity in prefabricated construction project-survey analysis in China. Sustainability 2018, 10, 3046. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, S. Assessment of sustainable development capacity of prefabricated residential building supply chain. In Proceedings of the International Conference on Construction and Real Estate Management, Charleston, SC, USA, 9–10 August 2018. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, J.; Shen, L. A conceptual development framework for prefabricated construction supply chain management: An integrated overview. Sustainability 2020, 12, 1878. [Google Scholar] [CrossRef]

- Luo, L.; Shen, G.Q.; Xu, G.; Liu, Y.; Wang, Y. Stakeholder-associated supply chain risks and their interactions in a prefabricated building project in Hong Kong. J. Manag. Eng. 2019, 35, 05018015. [Google Scholar] [CrossRef]

- Mao, C.; Shen, L.; Luo, L.; Li, Z. Identification of risk factors influencing the implementation of industrialized building system in China. In Proceedings of the 19th International Symposium on Advancement of Construction Management and Real Estate; Shen, L., Ye, K., Mao, C., Eds.; Springer: Berlin, Germany, 2015; pp. 219–230. [Google Scholar] [CrossRef]

- Wang, D.; Luo, J.; Wang, Y. Multifactor uncertainty analysis of prefabricated building supply chain: Qualitative comparative analysis. Eng. Constr. Archit. Manag. 2022, 31, 1994–2010. [Google Scholar] [CrossRef]

- Wang, X.; Sun, S. Research on collaborative mode of prefabricated construction supply chain based on supply-hub. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 242, p. 062005. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Ren, H.; Ji, F.R. Cooperative innovation evolutionary game analysis of industrialized building supply chain. Appl. Mech. Mater. 2018, 878, 213–218. [Google Scholar] [CrossRef]

- Yang, H.; Ren, W. Research on risk management of green supply chain of prefabricated buildings based on QCA. In E3S Web of Conferences; EDP Sciences: Paris, France, 2021; p. 03041. [Google Scholar]

- Zhang, H.; Yu, L. Dynamic transportation planning for prefabricated component supply chain. Eng. Constr. Archit. Manag. 2020, 27, 2553–2576. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhong, R.Y.; Huang, G.Q. Buffer space hedging and coordination in prefabricated construction supply chain management. Inter. J. Prod. Econ. 2018, 200, 192–206. [Google Scholar] [CrossRef]

| Code | Concept | Description | Main Factors Involved |

|---|---|---|---|

| C1 | The performance of prefabricated components and equipment | All issues related to component design and production. | The performance of prefabricated components, the unproven durability of prefabricated goods, geometric and dimensional intolerance, and the performance of transport and lifting equipment. |

| C2 | Construction of prefabricated building | Factors related to the construction of prefabricated buildings. | Construction technology used for prefabricated components, machine breakdown, safety issues, and the installation errors of precast elements. |

| C3 | Policies and regulations | The completeness and changes of laws and regulations related to the prefabricated building supply chain. | Local government policy preferences, implementation of new laws/regulation, changes in the political economy, and the unreasonable site layout of prefabricated components. |

| C4 | Information exchange/sharing | The type, quantity, form and medium of information exchange between supply chain members. | Communication breakdown/issues, information loss, inadequate IT systems, and information misuse. |

| C5 | Transport risk | All risks that may occur during prefabricated components and raw material transportation. | Transport disruptions, including port stoppages, site logistics, damage to prefabricated elements during transportation. |

| C6 | Research and development (R&D) | The process and elements of supply chain members developing new technologies and new products. | Technology failure, the cost of technology investment share, cooperative innovation, the absence of standard modular components, a monopoly of techniques by a few firms, and a lack of R&D input. |

| C7 | Decision alignment | The degree of consistency of management decisions of supply chain members. | Conflict resolution, buffer space hedging, strategy alignment, solution consistency, and inappropriate business strategies. |

| C8 | Professional management personnel/labor quality | The quantity and quality of managerial personnel, labor of the members of the prefabricated construction supply chain. | A lack of highly skilled workers, insufficient construction capacity, a lack of management best practices, inaccurate cost estimation, and operation efficiency. |

| C9 | Relationship quality of members’ relationships | The level of friendship and trust among members of the prefabricated building supply chain. | Relationship coordination, poor cooperation across multiple interfaces, trust between members, and stakeholders’ lack of awareness. |

| C10 | Supply–demand consistency | The degree of matching between products and demand in the prefabricated building supply chain. | Variations and/or rework, quality loss, supply–demand mismatch/shortages, supply–demand mismatches, or shortages. |

| C11 | Cost/profit sharing | Reasonable and fair degree of cost and benefit distribution among members of assembly building supply chain. | Cost of technology investment share, and transaction costs. |

| Code | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | RPCSC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.395 | 0.000 | 0.298 |

| C2 | 0.363 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.172 |

| C3 | 0.274 | 0.200 | 0.000 | 0.000 | −0.134 | 0.176 | 0.377 | 0.000 | 0.302 | 0.000 | 0.000 | 0.758 |

| C4 | 0.186 | 0.144 | 0.000 | 0.000 | −0.456 | 0.771 | 0.835 | 0.000 | 0.815 | 0.775 | 0.447 | 0.660 |

| C5 | −0.288 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | −0.186 | 0.000 | −0.493 |

| C6 | 0.819 | 0.642 | 0.000 | 0.000 | −0.214 | 0.000 | 0.000 | 0.000 | 0.000 | 0.530 | 0.000 | 0.353 |

| C7 | 0.311 | 0.000 | 0.000 | 0.000 | −0.358 | 0.000 | 0.000 | 0.000 | 0.633 | 0.856 | 0.535 | 0.716 |

| C8 | 0.823 | 0.842 | 0.000 | 0.521 | −0.344 | 0.771 | 0.200 | 0.000 | 0.381 | 0.260 | 0.358 | 0.493 |

| C9 | 0.000 | 0.000 | 0.000 | 0.847 | −0.521 | 0.433 | 0.846 | 0.000 | 0.000 | 0.651 | 0.637 | 0.805 |

| C10 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.693 |

| C11 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.335 | 0.000 | 0.000 | 0.479 | 0.000 | 0.000 | 0.488 |

| RPCSC | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Iterative Rounds | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | RPCSC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 | 0.2000 |

| 1 | 0.8482 | 0.7865 | 0.5964 | 0.8711 | 0.163 | 0.9067 | 0.9079 | 0.7029 | 0.9307 | 0.9595 | 0.8787 | 0.989 |

| 2 | 0.9987 | 0.9931 | 0.7622 | 0.9997 | 0.0079 | 0.9991 | 0.9992 | 0.9537 | 0.9976 | 0.9839 | 0.957 | 0.9945 |

| 3 | 0.9997 | 0.9981 | 0.8159 | 0.9999 | 0.0048 | 0.9997 | 0.9996 | 0.9838 | 0.9983 | 0.9844 | 0.9614 | 0.9948 |

| 4 | 0.9997 | 0.9983 | 0.8311 | 0.9999 | 0.0046 | 0.9998 | 0.9996 | 0.9857 | 0.9983 | 0.9844 | 0.9617 | 0.9949 |

| 5 | 0.9997 | 0.9983 | 0.8352 | 0.9999 | 0.0046 | 0.9998 | 0.9996 | 0.9858 | 0.9983 | 0.9844 | 0.9617 | 0.9949 |

| 6 | 0.9997 | 0.9983 | 0.8363 | 0.9999 | 0.0046 | 0.9998 | 0.9996 | 0.9859 | 0.9983 | 0.9844 | 0.9617 | 0.9949 |

| 7 | 0.9997 | 0.9983 | 0.8366 | 0.9999 | 0.0046 | 0.9998 | 0.9996 | 0.9859 | 0.9983 | 0.9844 | 0.9617 | 0.9949 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Ma, L.; Fu, H. Exploring Critical Factors Influencing the Resilience of the Prefabricated Construction Supply Chain. Buildings 2025, 15, 289. https://doi.org/10.3390/buildings15020289

Liu T, Ma L, Fu H. Exploring Critical Factors Influencing the Resilience of the Prefabricated Construction Supply Chain. Buildings. 2025; 15(2):289. https://doi.org/10.3390/buildings15020289

Chicago/Turabian StyleLiu, Tianyang, Li Ma, and Hongwei Fu. 2025. "Exploring Critical Factors Influencing the Resilience of the Prefabricated Construction Supply Chain" Buildings 15, no. 2: 289. https://doi.org/10.3390/buildings15020289

APA StyleLiu, T., Ma, L., & Fu, H. (2025). Exploring Critical Factors Influencing the Resilience of the Prefabricated Construction Supply Chain. Buildings, 15(2), 289. https://doi.org/10.3390/buildings15020289