Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study

Abstract

:1. Introduction

1.1. Background

1.2. Problem Statement

1.3. Objective

- Assess the effectiveness of SBS, AB, and WCO in enhancing bitumen’s performance under various loading conditions.

- Identify the trade-offs between different modifiers regarding high-temperature resistance, elasticity, and fatigue life.

- Explore the combined effects of these modifiers to provide insights into their suitability for sustainable and high-performance asphalt mixtures.

2. Literature Review

- Exploration of Animal Bone Powder (AB): Using calcium-rich AB as a bio-based modifier is a relatively new approach. This research identifies the optimal concentration (4%) to balance stiffness and fatigue resistance and provides new insights through advanced rheological evaluations such as Frequency Sweep and LAS tests.

- Investigation of Waste Cooking Oil (WCO): While WCO is known as a rejuvenator for aged bitumen, this study uniquely focuses on its effects on fresh binders. The findings reveal critical trade-offs between enhanced fatigue resistance and reduced structural stiffness, emphasizing the importance of its cautious application in high-performance contexts.

- Comprehensive Testing Across Multiple Metrics: The application of advanced techniques, including the creation of master curves, Cole–Cole plots, and G*/sin δ evaluations under varied frequencies and temperatures, provides a deeper understanding of the modifiers’ viscoelastic behavior and their impact on performance.

- Quantification of Trade-Offs and Synergy: The study quantifies the trade-offs between stiffness, fatigue resistance, and elasticity for each modifier. Additionally, it uniquely explores the potential synergy between SBS and AB, offering practical recommendations for optimal performance.

- Challenging Existing Generalizations: By showing the limitations of WCO due to its plasticizing effects, this research challenges existing generalizations about its benefits, presenting a more nuanced understanding of its impact on performance.

3. Materials and Methodology

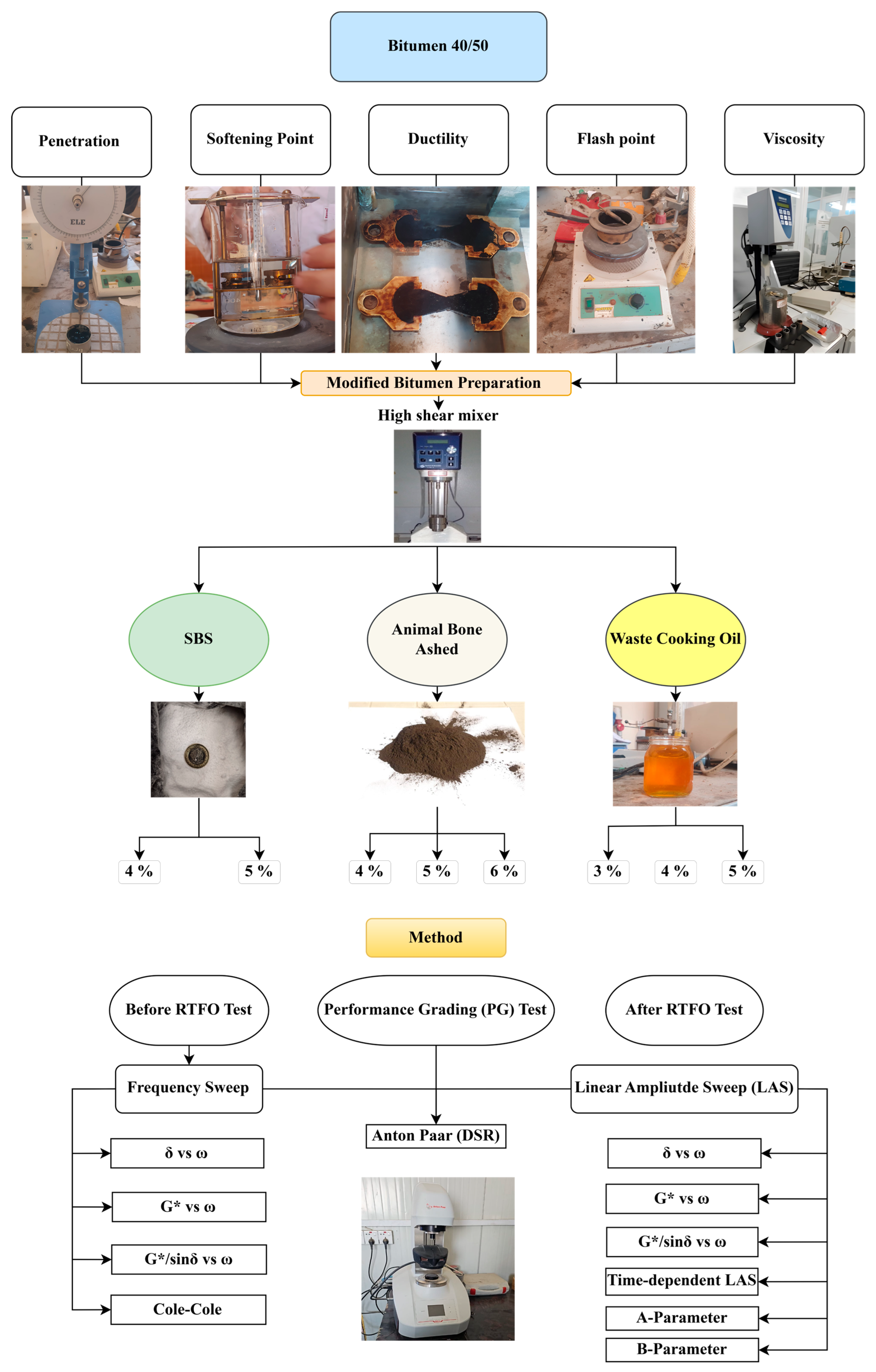

3.1. Methodology Overview

3.2. Materials and Sample Preparation

3.2.1. Bitumen

3.2.2. Styrene-Butadiene–Styrene (SBS)

3.2.3. Waste Cooking Oil (WCO)

3.2.4. Animal Bones (AB)

3.3. Testing Methods

3.3.1. Performance Grading (PG) Test

3.3.2. Frequency Sweep Test

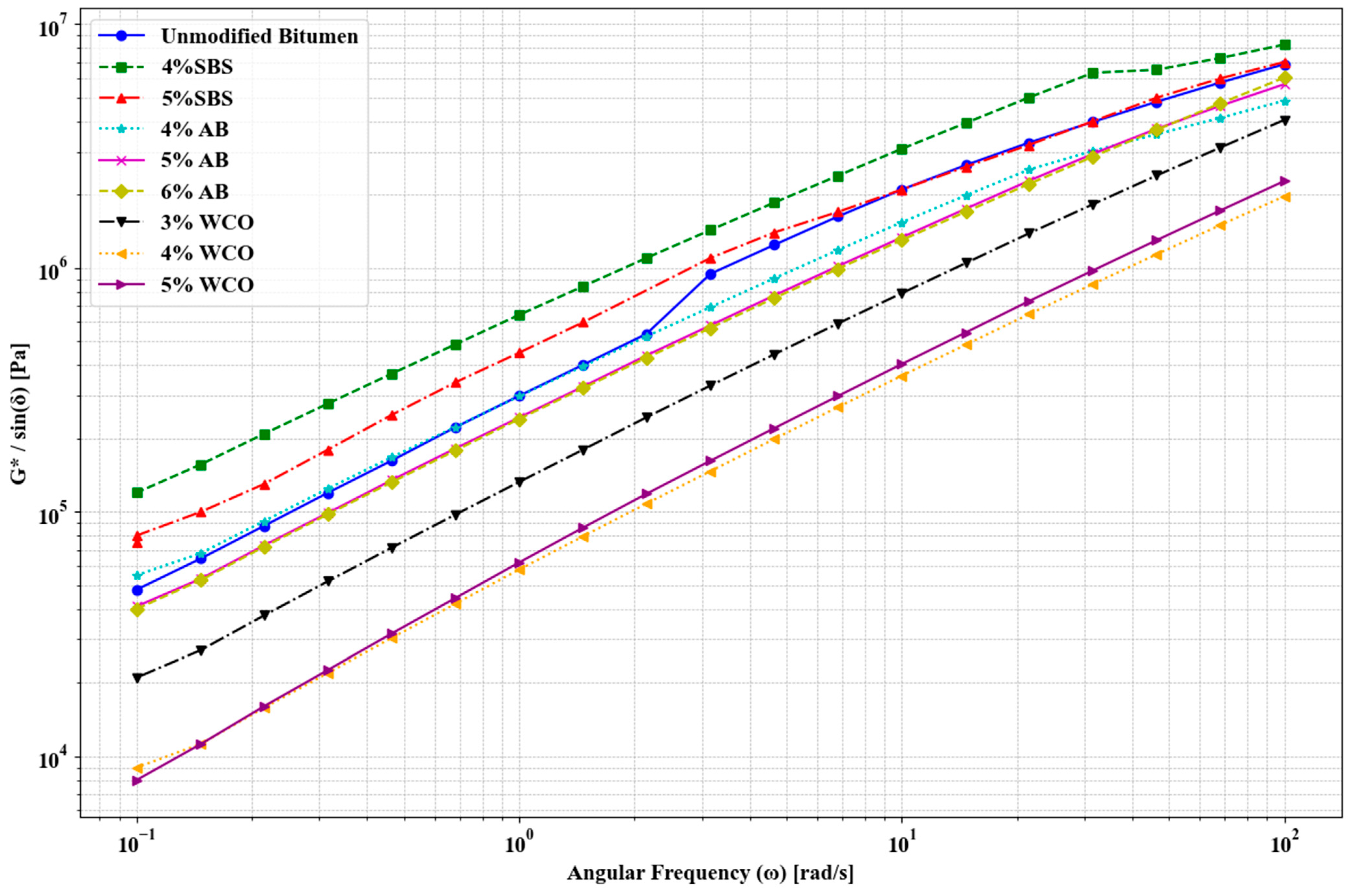

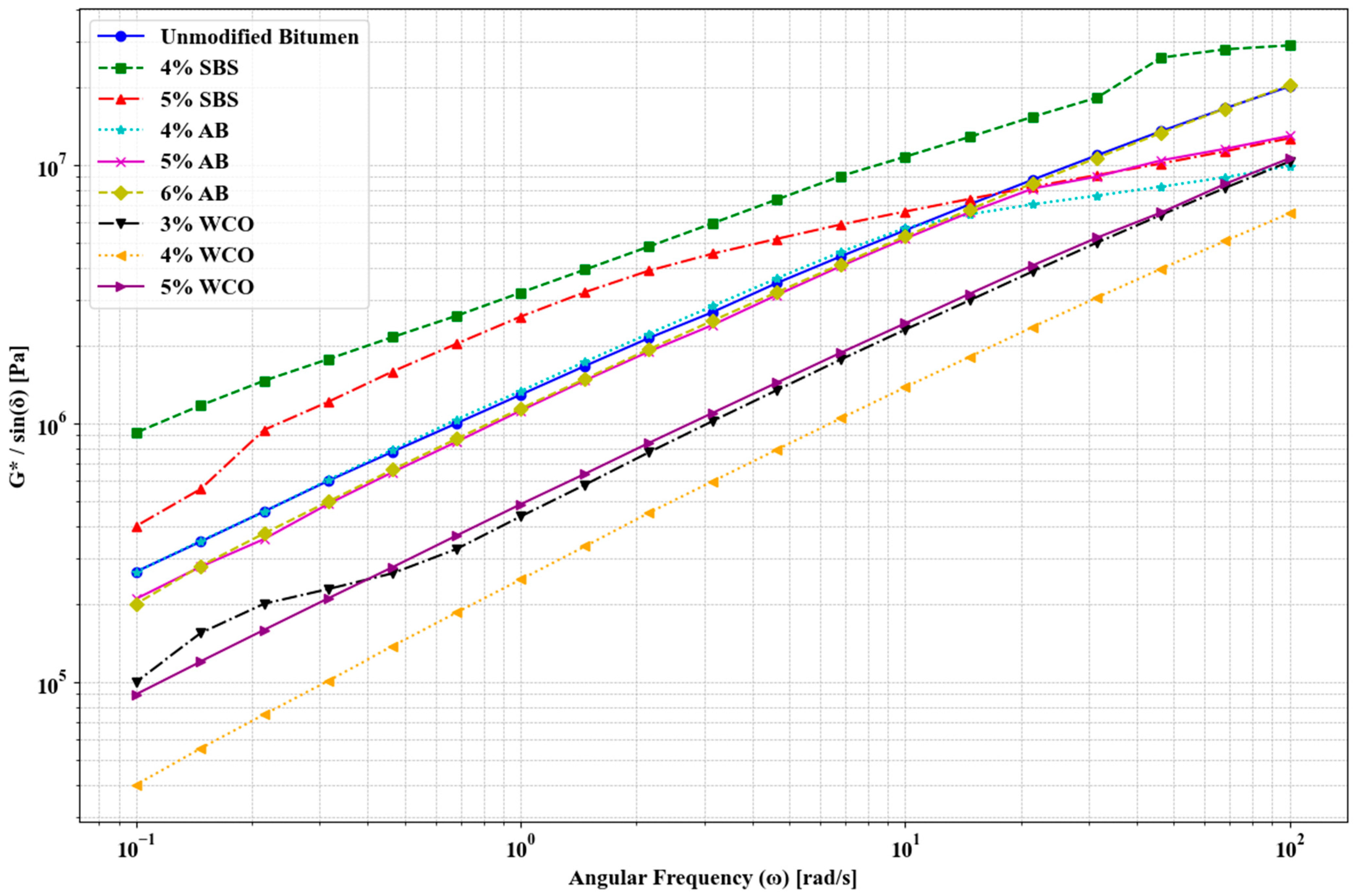

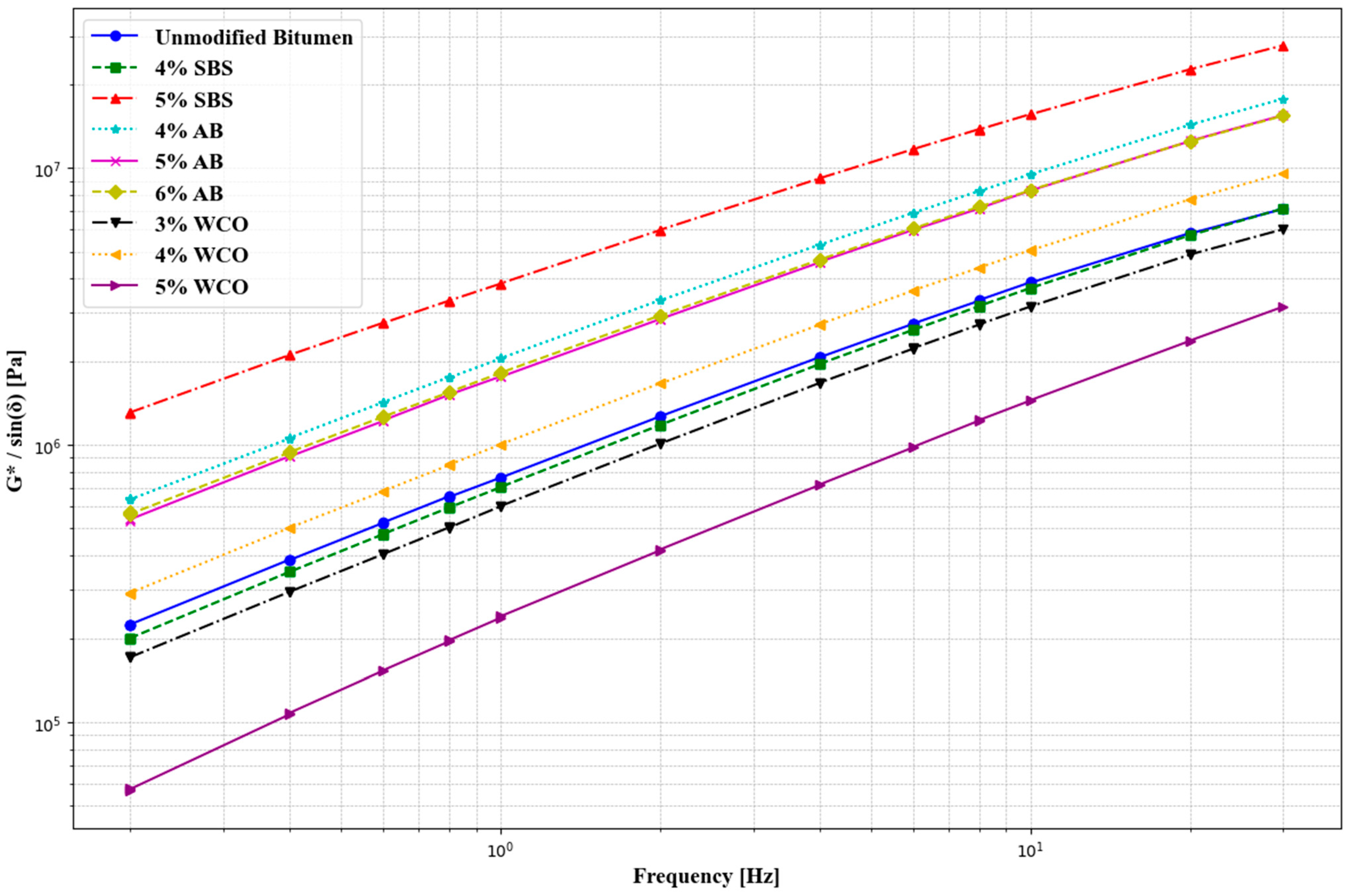

- G*/sin δ: The parameter G*/sin δ was calculated at each frequency and temperature to assess the binder’s ability to resist permanent deformation under high temperatures and repeated loading.

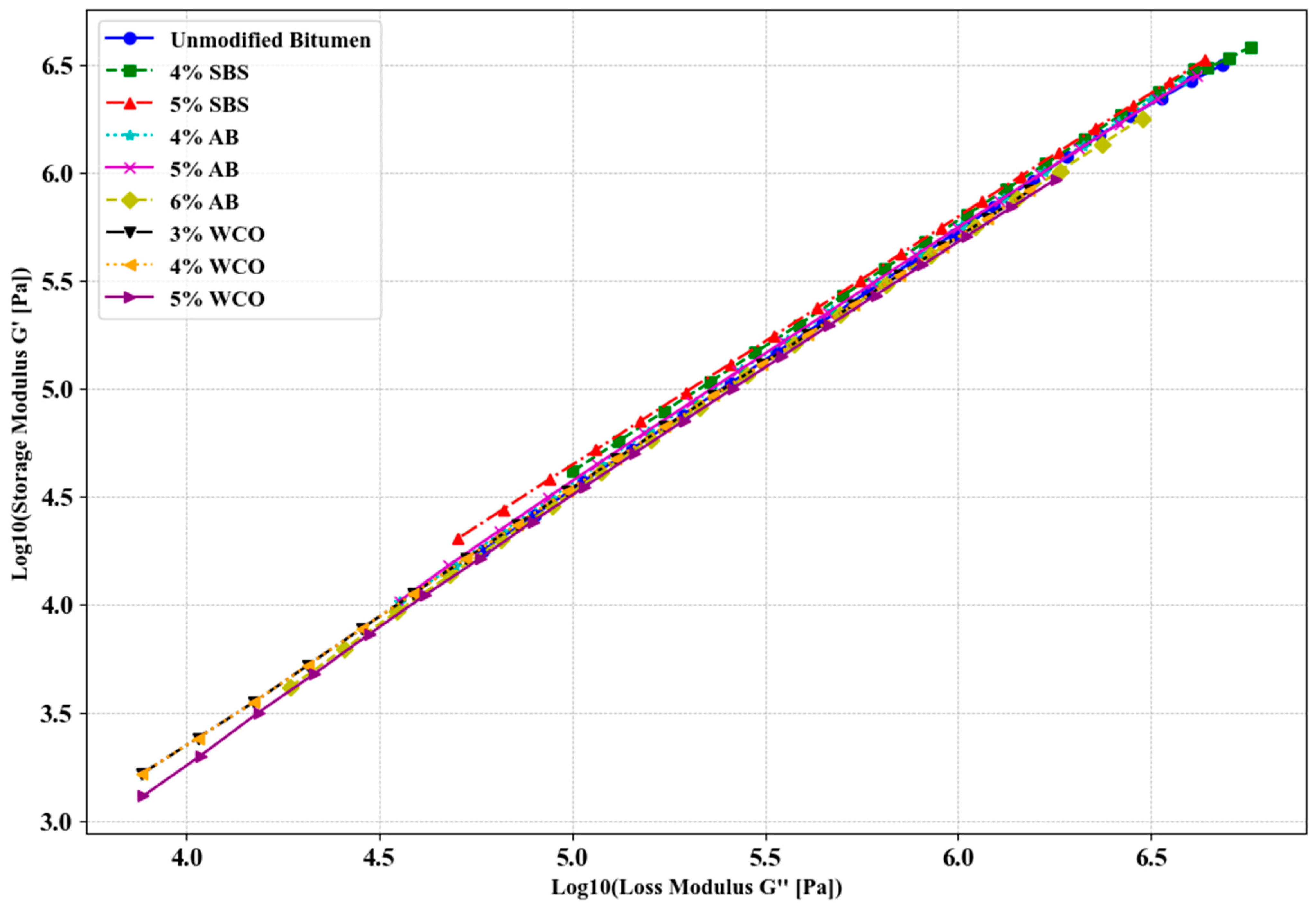

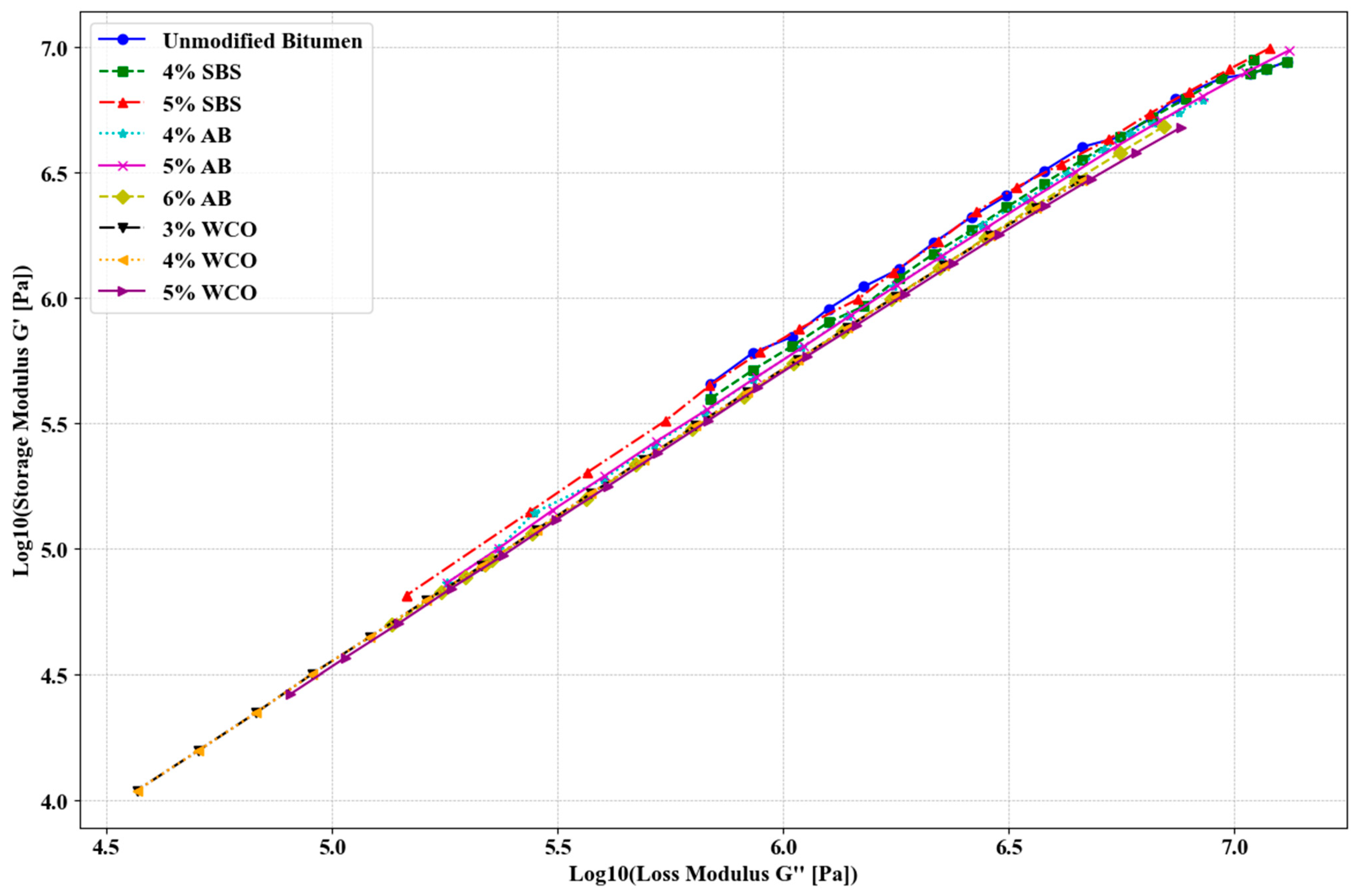

- Cole–Cole Plot: A Cole–Cole plot was generated by plotting the G′ against the G″. This provided a graphical representation of the transition between elastic (energy storage) and viscous (energy dissipation) behavior, characterizing the viscoelastic nature of the bitumen.

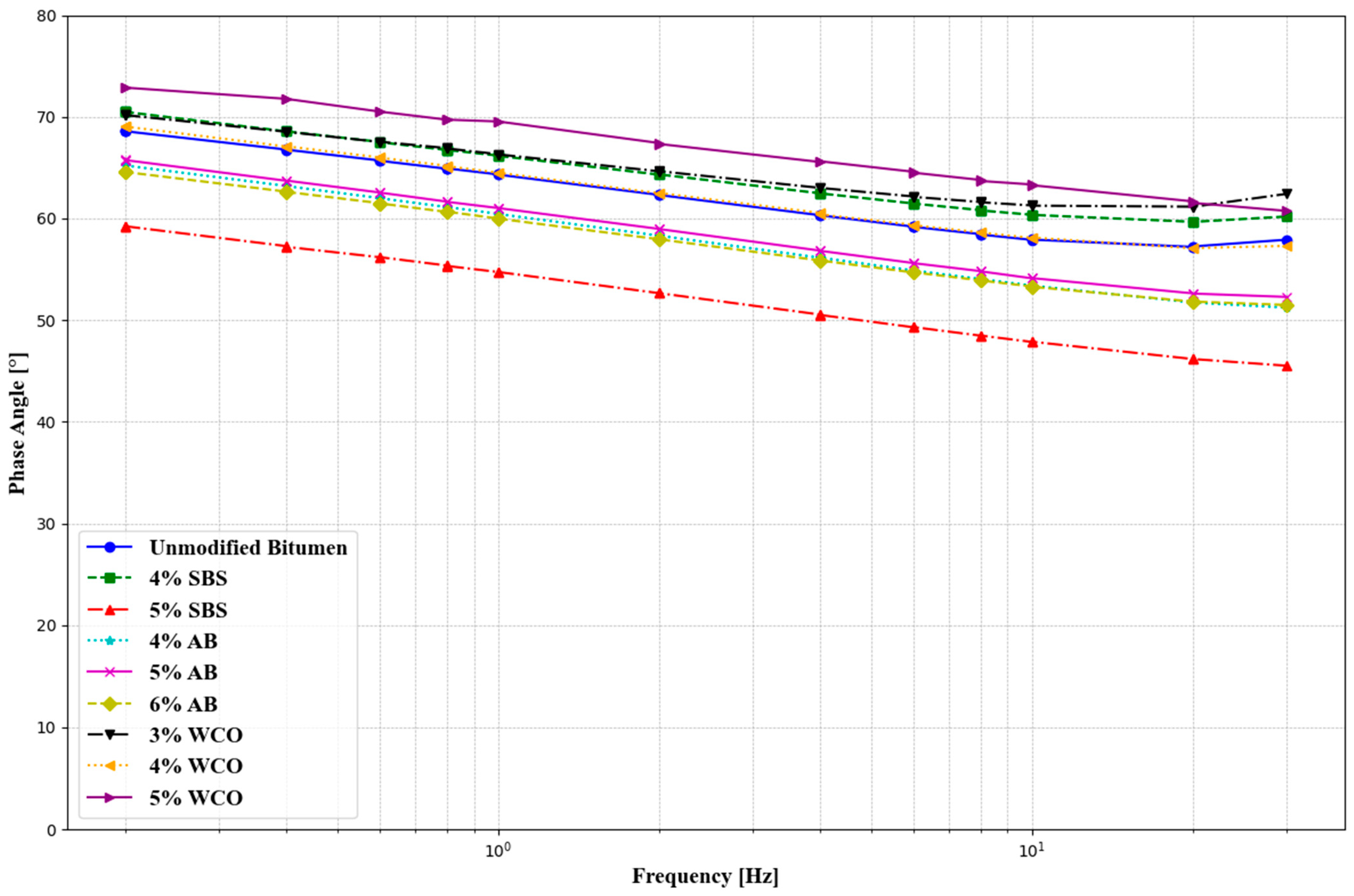

- Frequency-Dependent Behavior: The data were analyzed to construct master curves that illustrate the frequency-dependent behavior of the G* and δ. These curves predicted the material’s performance over a broader range of service conditions.

3.3.3. Linear Amplitude Sweep (LAS) Test

4. Results

4.1. Performance Grade (PG) Results

4.2. Frequency Sweep Results

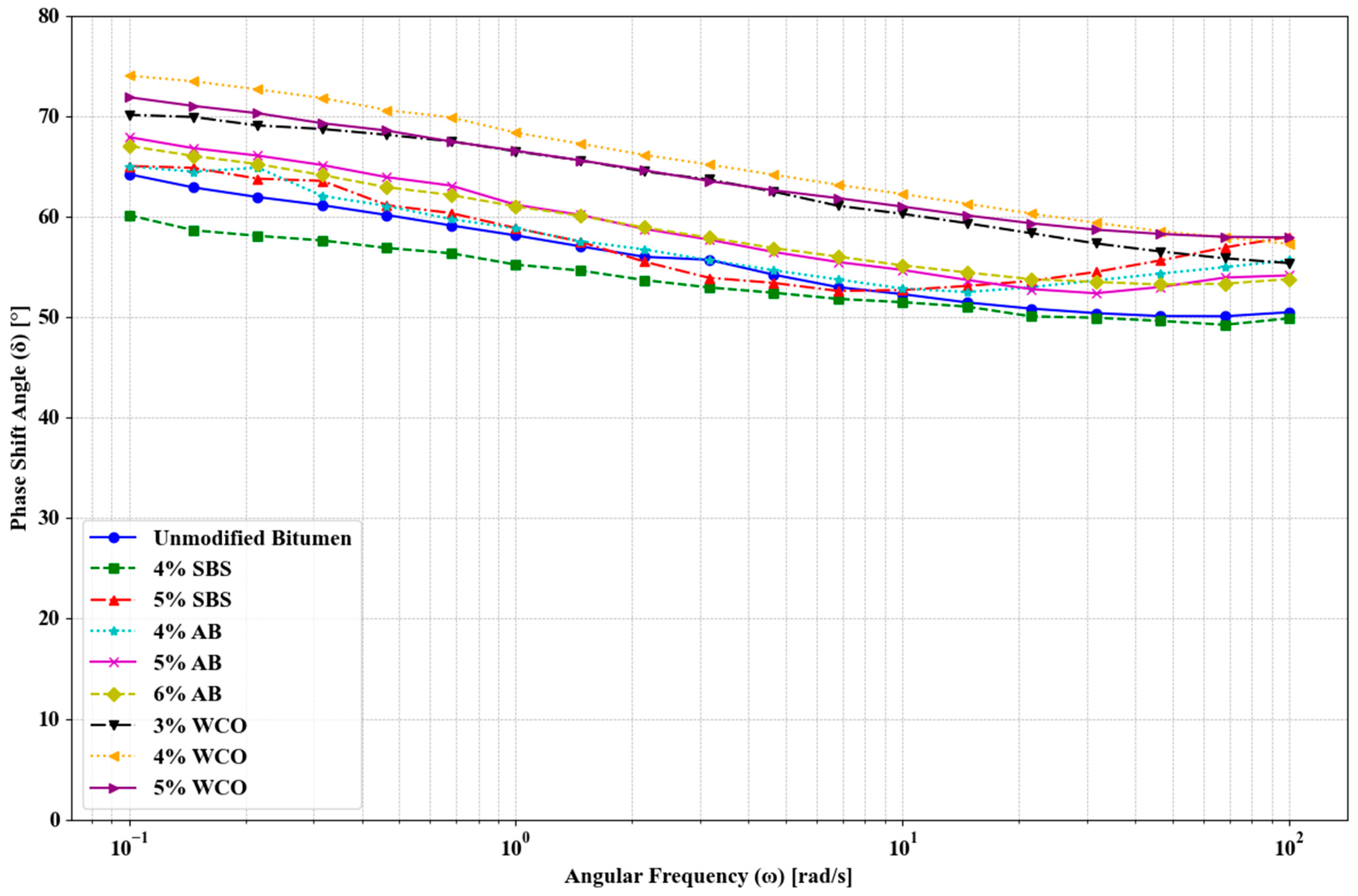

4.2.1. Phase Angle vs. Angular Frequency

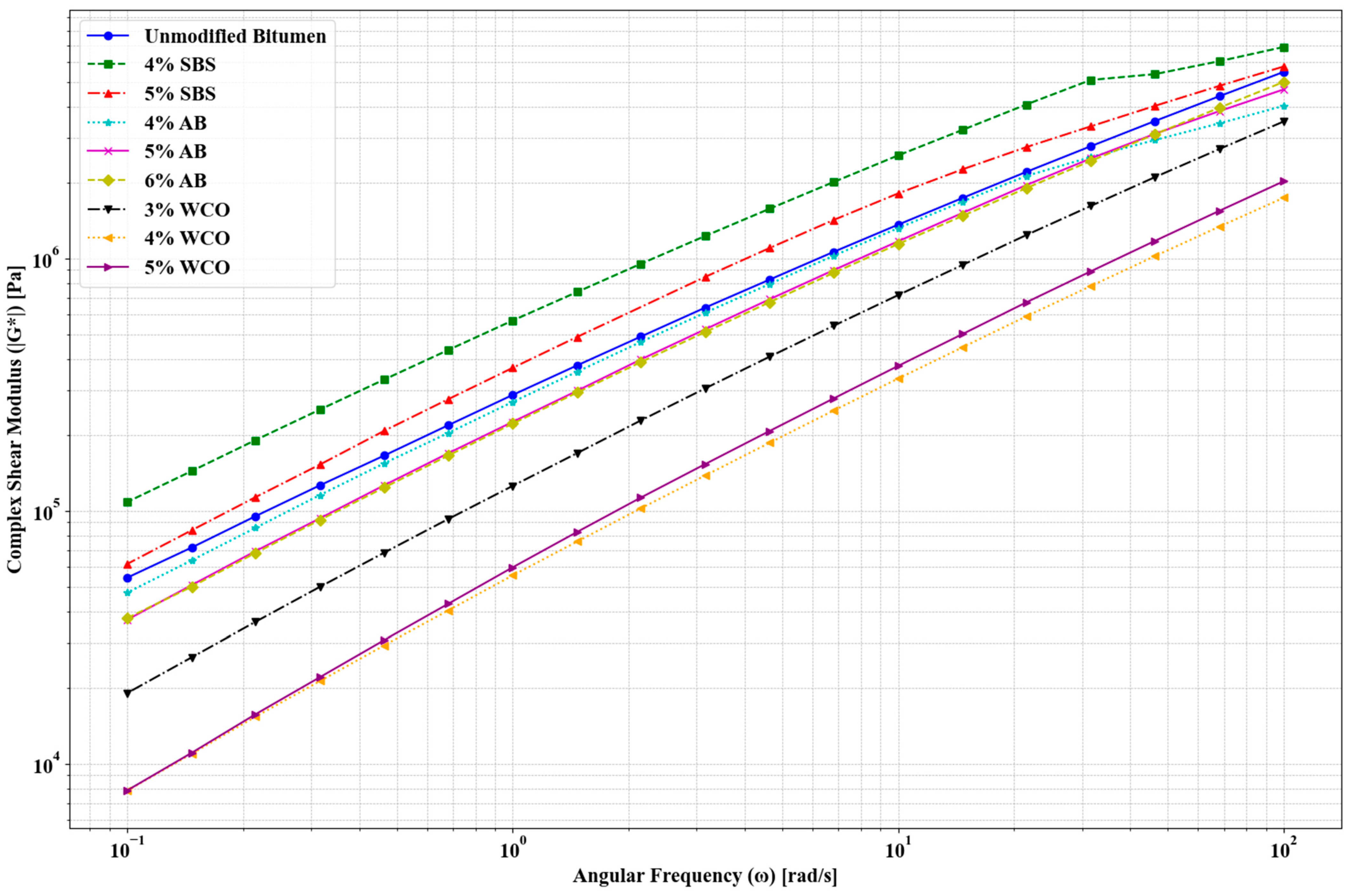

4.2.2. Complex Shear Modulus vs. Angular Frequency

4.2.3. G*/sin δ vs. Angular Frequency

4.2.4. Cole–Cole Plot

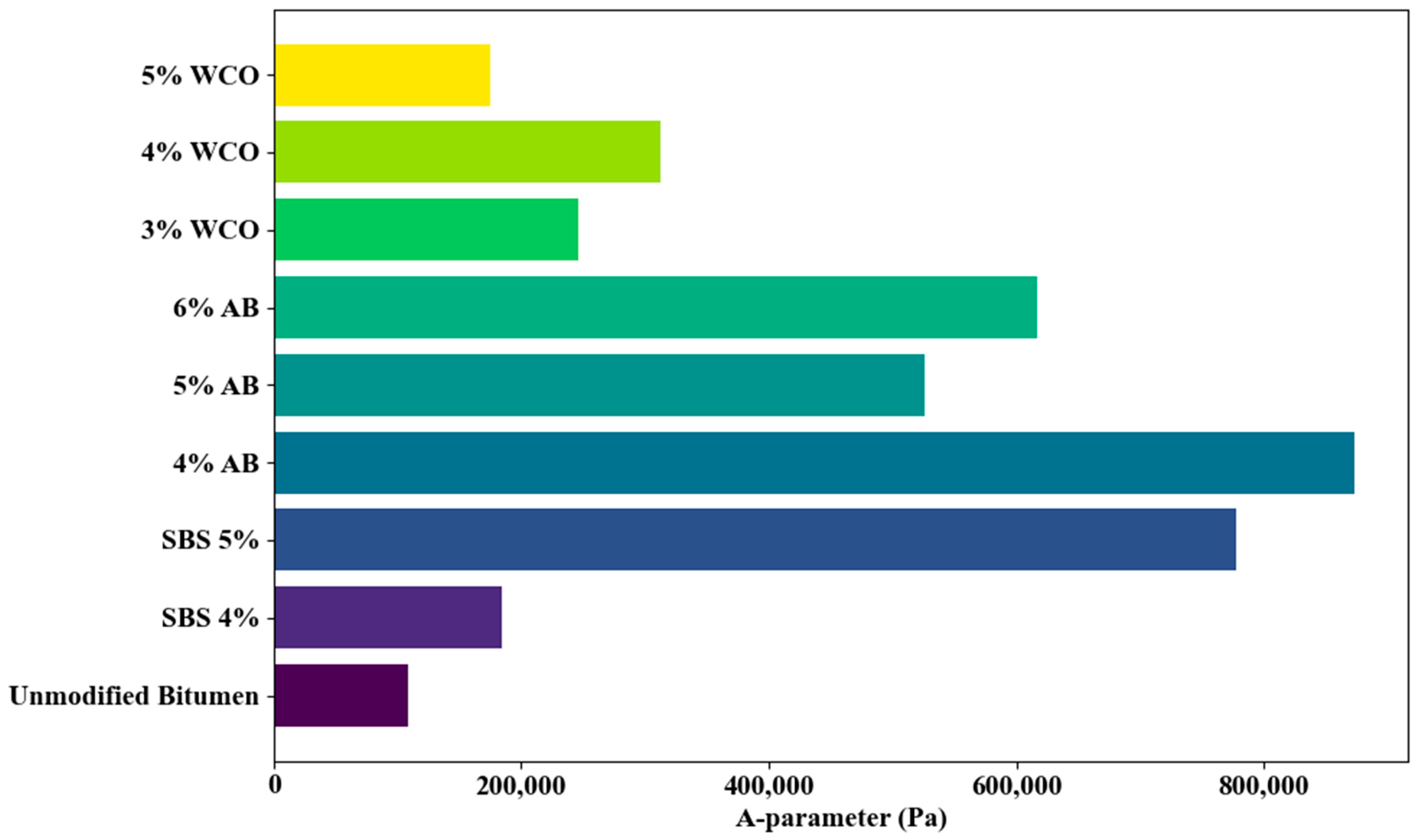

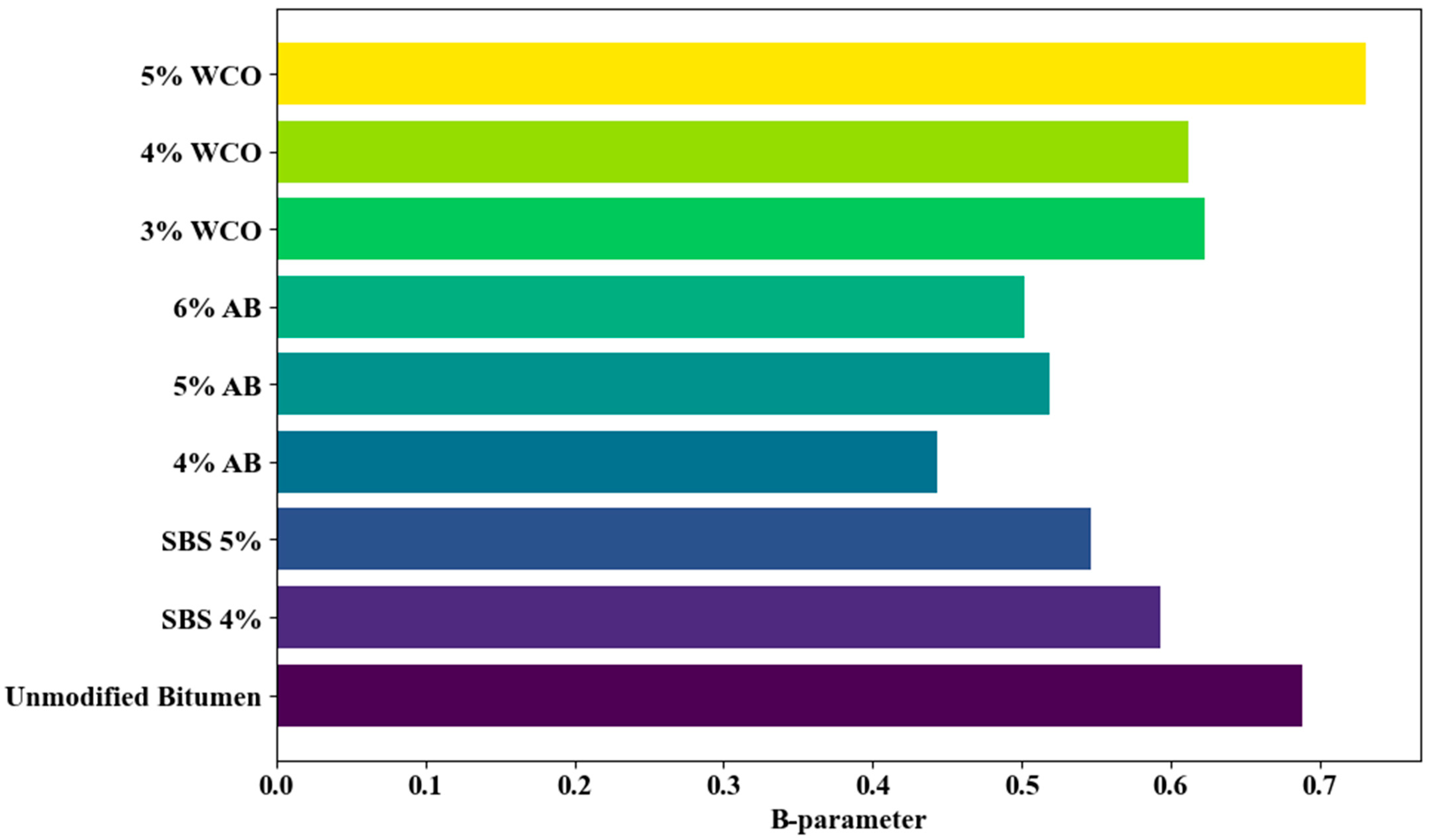

4.3. Linear Amplitude Sweep (LAS) Results

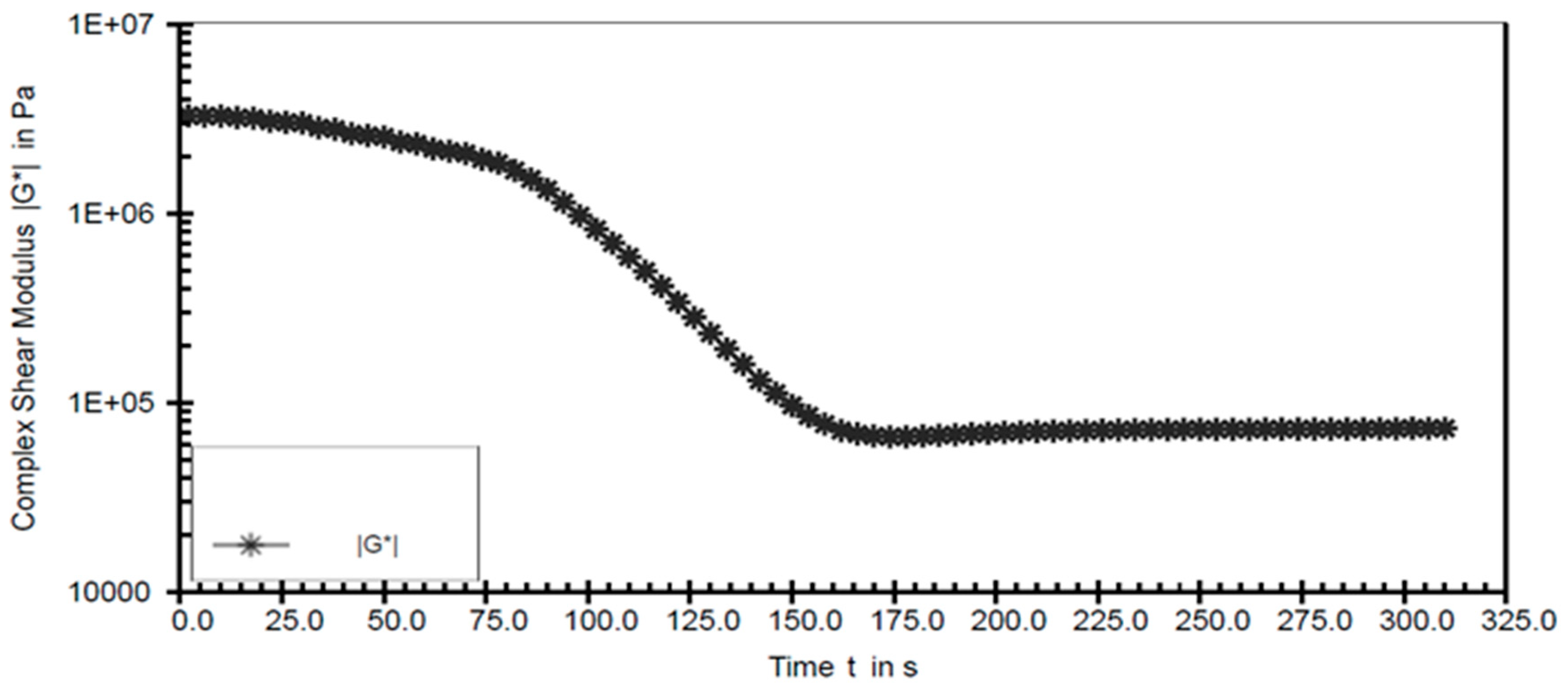

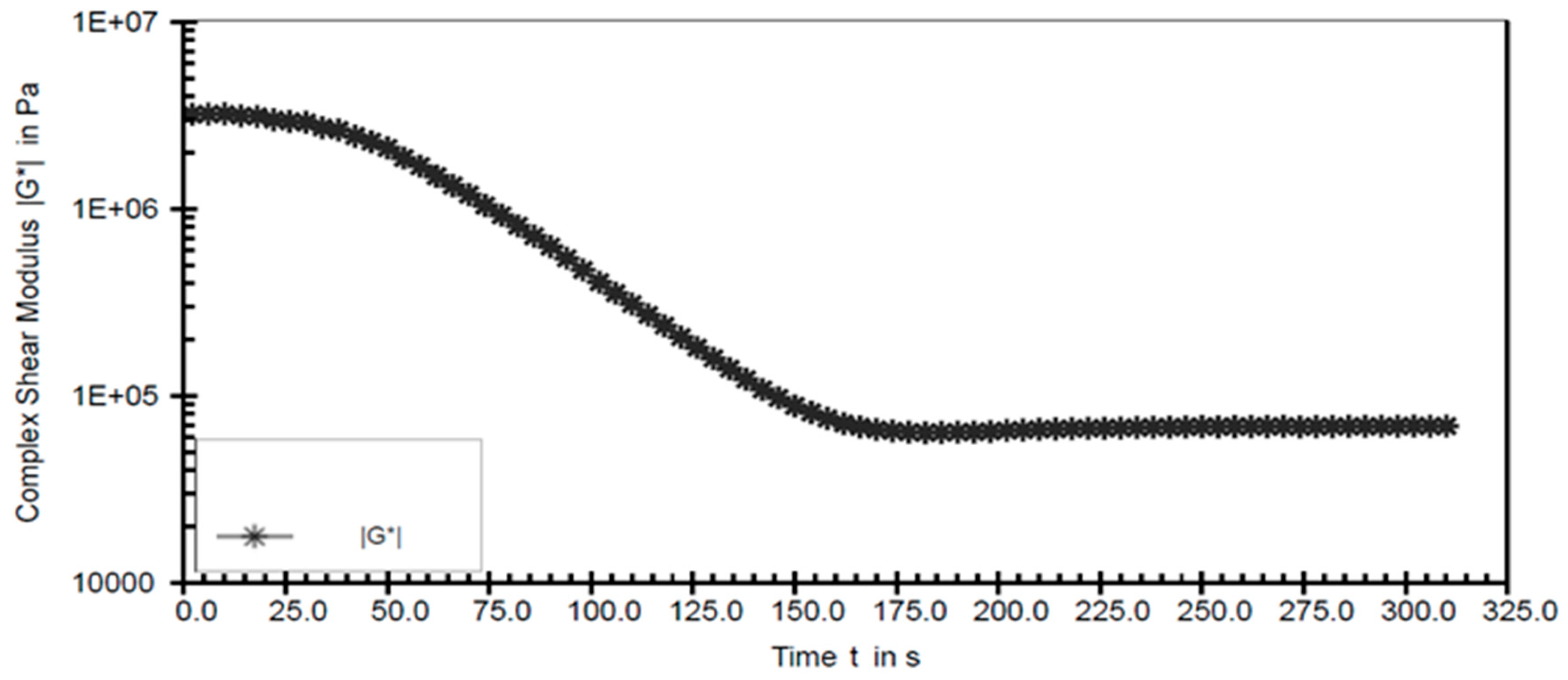

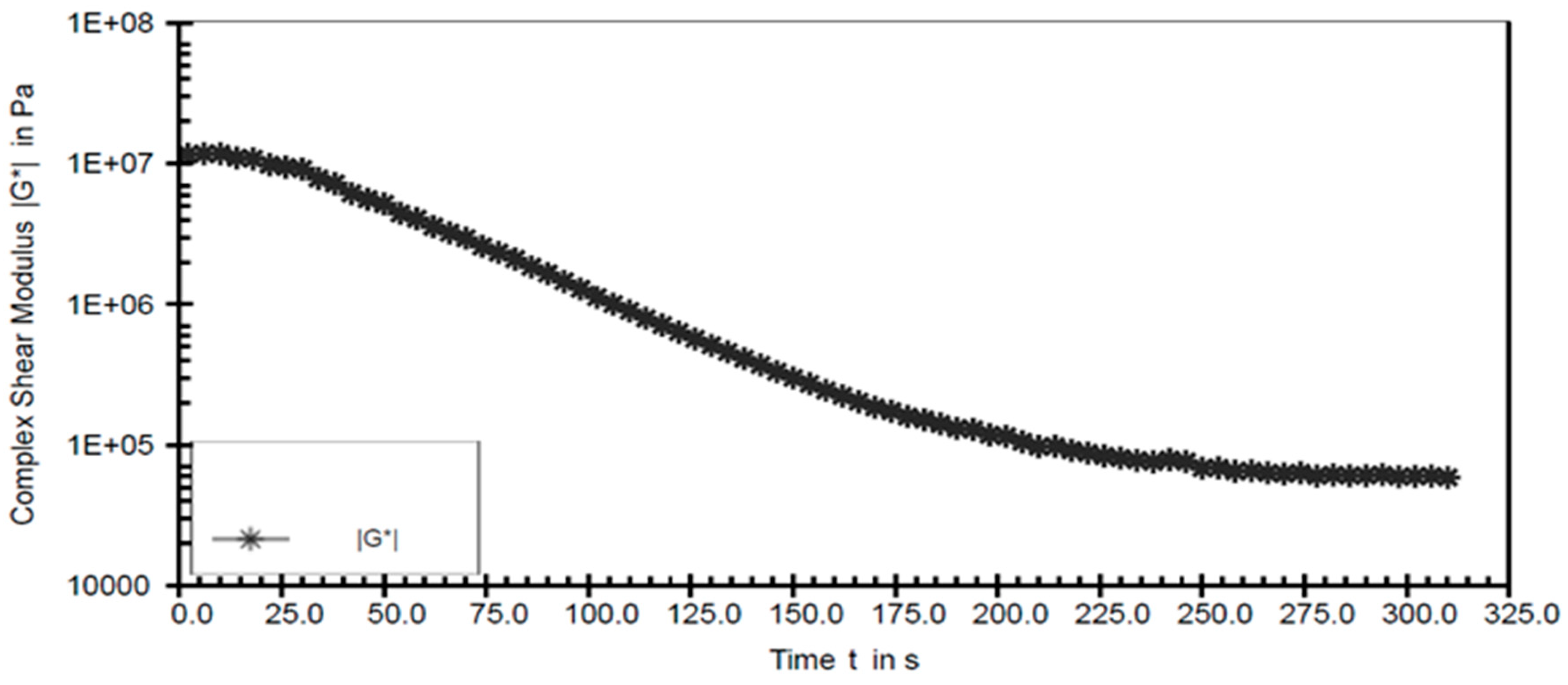

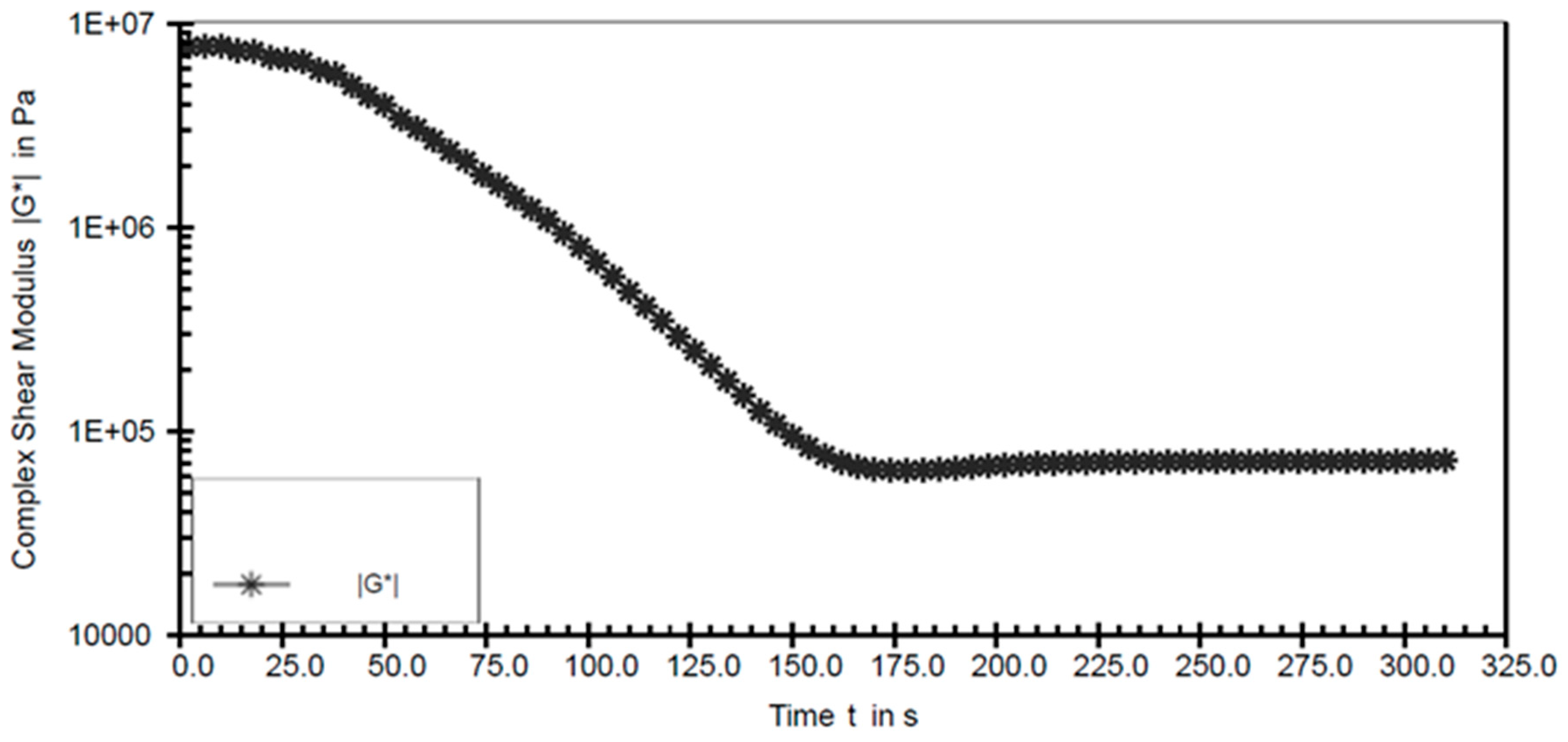

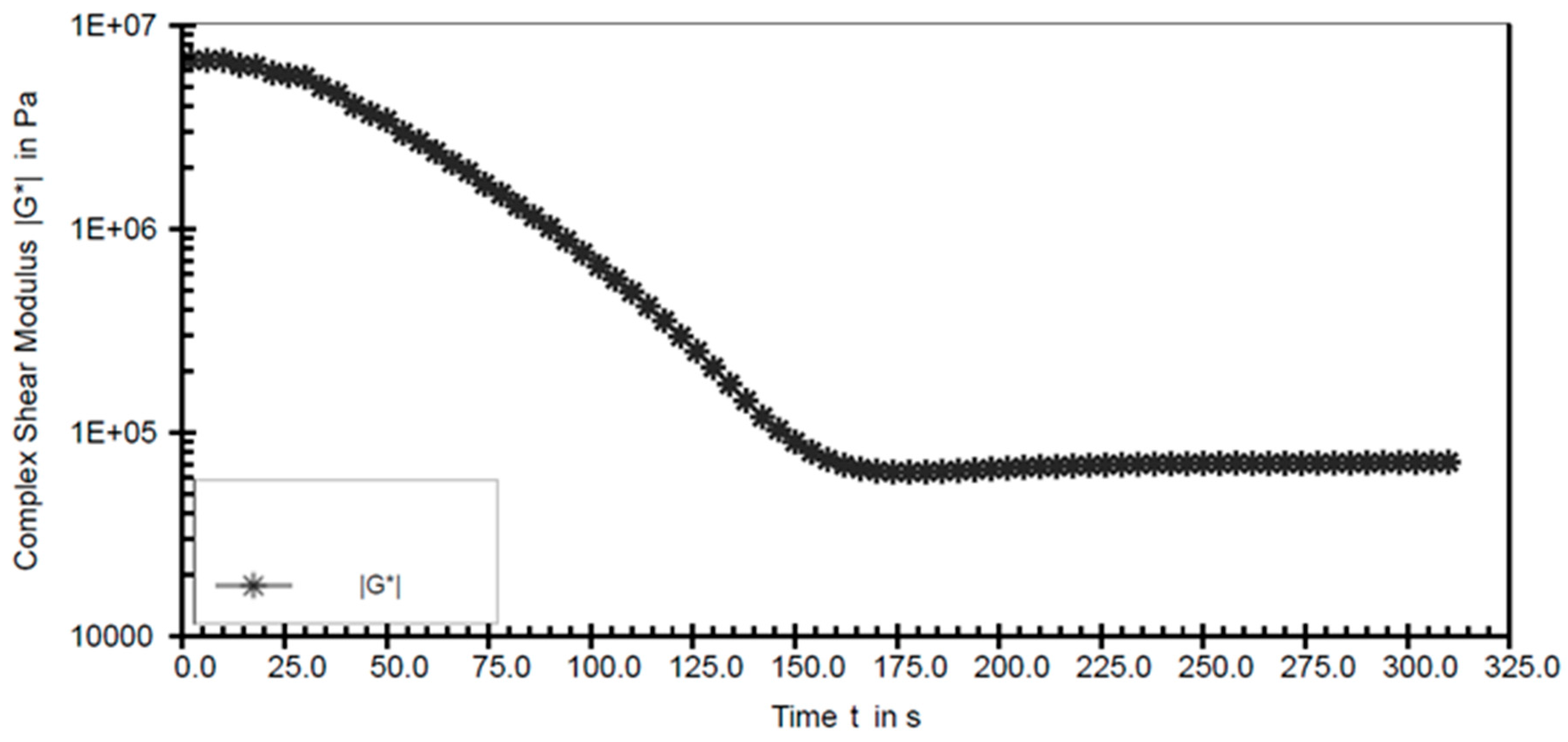

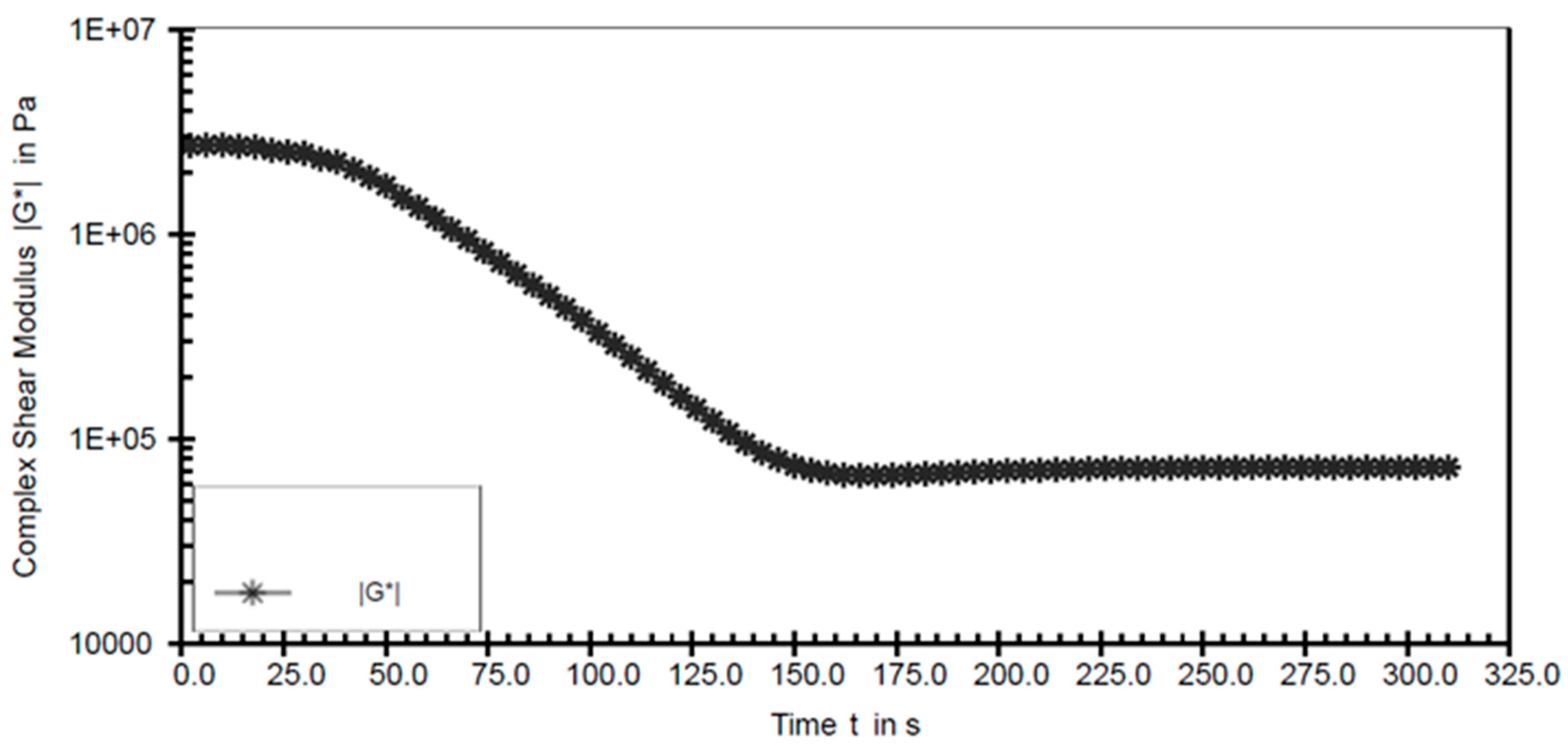

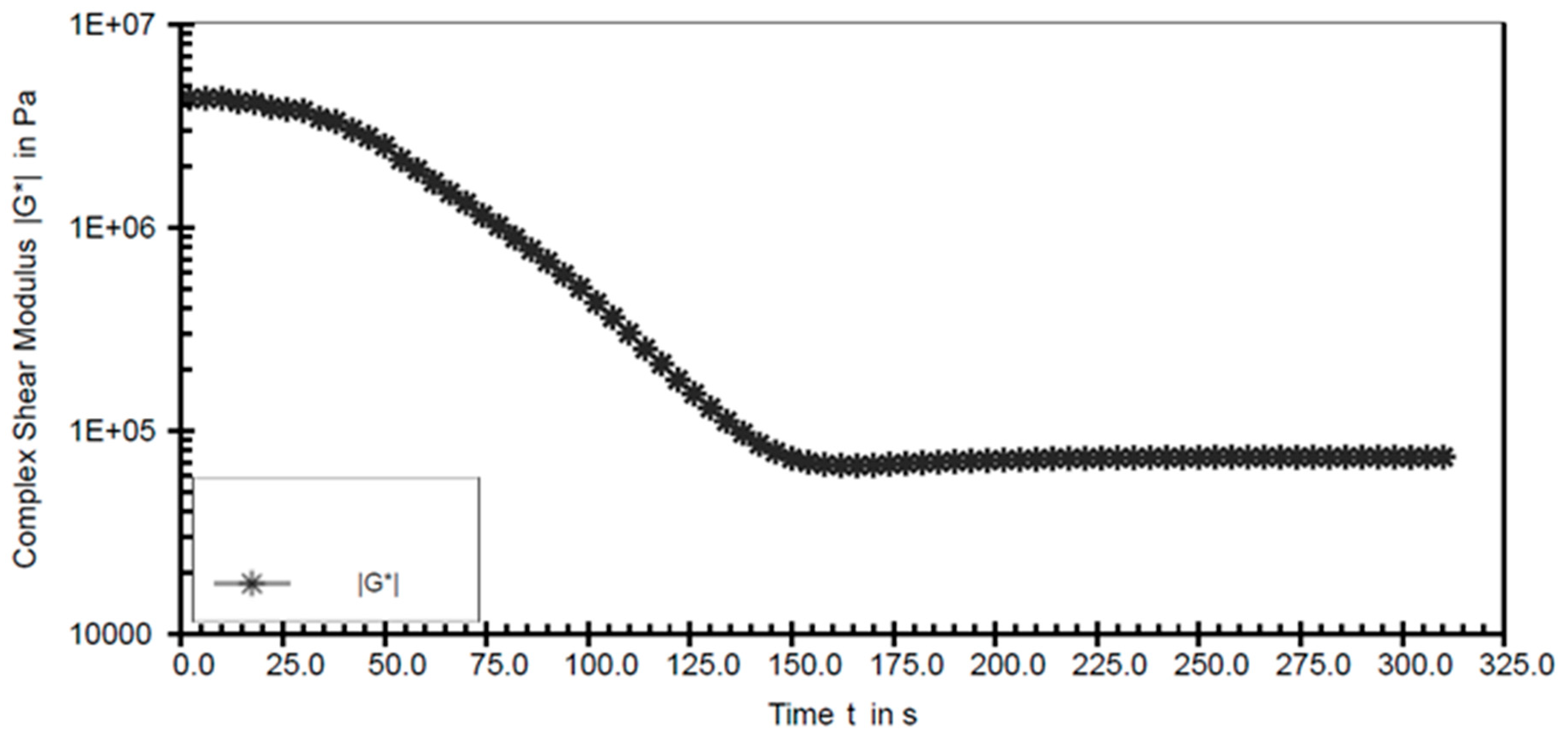

4.3.1. Frequency Sweep Output of Linear Amplitude Sweep (LAS) Test Results

4.3.2. Time-Dependent LAS Result

4.3.3. LAS Result for Bitumen Fatigue

5. Discussion

6. Conclusions

7. Limitations and Future Research Directions

- Conducting field trials to validate the laboratory findings under real-world conditions.

- Investigating long-term aging to assess the durability of modified bitumen over extended periods.

- Exploring the combined use of modifiers (e.g., SBS with AB or WCO) to identify potential synergistic effects that could further enhance bitumen performance.

- Evaluating the environmental impact of using bio-based additives like AB and WCO, including their carbon footprint and sustainability benefits.

- Optimizing the blending process to improve the compatibility of modifiers with different types of base bitumen.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | Animal Bone |

| DSR | Dynamic Shear Rheometer |

| G* | Complex Shear Modulus |

| LAS | Linear Amplitude Sweep |

| PG | Performance Grade |

| SBS | Styrene-Butadiene–Styrene |

| WCO | Waste Cooking Oil |

Nomenclature

| Symbol | Description | Unit |

| G* | Complex shear modulus | Pa |

| δ | Phase angle | Degrees |

| G′/G” | Storage/Loss modulus | Pa |

| G*/sinδ | Rutting-resistance parameter | kPa |

| τ | Shear stress | Pa |

| γ | Shear strain | - |

| T | Temperature | °C |

| ω | Angular frequency | rad/s |

| - | Penetration | mm |

| - | Ductility | cm |

| - | Softening Point | °C |

| - | Flash Point | °C |

| - | Rotational viscosity | Pa.s |

| - | Retained penetration | % |

References

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Almusawi, A.; Jaleel, M.M.; Shoman, S.; Lupanov, A.P. Enhancing waste asphalt durability through cold recycling and additive integration. Funct. Compos. Mater. 2024, 5, 10. [Google Scholar] [CrossRef]

- İbiş, A.B.; Şengöz, B.; Almusawi, A.; Özdemir, D.K.; Topal, A. Mechanical Characteristics of Environmentally Friendly Permeable Pavement: Enhanced Porous Asphalt. Jordan J. Civ. Eng. 2024, 18, 212–223. [Google Scholar]

- Almusawi, A.; Sengoz, B.; Ozdemir, D.K.; Topal, A. Economic and environmental impacts of utilizing lower production temperatures for different bitumen samples in a batch plant. Case Stud. Constr. Mater. 2022, 16, e00987. [Google Scholar] [CrossRef]

- Abualia, A.; Akentuna, M.; Mohammad, L.N.; Cooper, S.B., III; Cooper, S.B., Jr. Improving Asphalt Binder Durability Using Sustainable Materials: A Rheological and Chemical Analysis of Polymer-, Rubber-, and Epoxy-Modified Asphalt Binders. Sustainability 2024, 16, 5379. [Google Scholar] [CrossRef]

- Zheng, Q.; He, P.; Zhang, D.; Weng, Y.; Lu, J.; Wang, T. A Holistic View of Asphalt Binder Aging under Ultraviolet Conditions: Chemical, Structural, and Rheological Characterization. Buildings 2024, 14, 3276. [Google Scholar] [CrossRef]

- Merheb, A.; Palese, J.; Hartsough, C.M.; Zarembski, A.; Bernucci, L. The Influence of Seasonal Effects on Railway Vertical Track Modulus. Infrastructures 2024, 9, 120. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Mülhaupt, R. Green polymer chemistry and bio-based plastics: Dreams and reality. Macromol. Chem. Phys. 2013, 214, 159–174. [Google Scholar] [CrossRef]

- Vargas, A.I.W. Production and Characterisation of Waste Lignin and Biodiesel-Derived Residues as Potential Bitumen Modifiers. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2022. [Google Scholar]

- Lin, C.S.K.; Pfaltzgraff, L.A.; Herrero-Davila, L.; Mubofu, E.B.; Abderrahim, S.; Clark, J.H.; Koutinas, A.A.; Kopsahelis, N.; Stamatelatou, K.; Dickson, F.; et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 2013, 6, 426–464. [Google Scholar] [CrossRef]

- Wang, W.; Guo, D.; Liu, C.; Falchetto, A.C.; Li, X.; Wang, T. Exploring the Self-Healing Capability and Fatigue Performance of Modified Bitumen Incorporating Waste Cooking Oil and Polyphosphoric Acid. Buildings 2023, 13, 1188. [Google Scholar] [CrossRef]

- Rodrigues, C.; Capitão, S.; Picado-Santos, L.; Almeida, A. Full recycling of asphalt concrete with waste cooking oil as rejuvenator and LDPE from urban waste as binder modifier. Sustainability 2020, 12, 8222. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, H.; Zhang, H.; Kuang, D.; Wu, J.; Zhang, X. A study on physical and rheological properties of rubberized bitumen modified by different methods. Materials 2019, 12, 3538. [Google Scholar] [CrossRef]

- Connolley, T.; Mchugh, P.; Bruzzi, M. A review of deformation and fatigue of metals at small size scales. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 1119–1152. [Google Scholar] [CrossRef]

- Khan, I.; Khattak, A.W.; Bahrami, A.; Khattak, S.; Ejaz, A. Engineering Characteristics of SBS/Nano-Silica-Modified Hot Mix Asphalt Mixtures and Modeling Techniques for Rutting. Buildings 2023, 13, 2352. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Mehmood, R.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Daud, N.N.N.; Ansari, A.H. Waste engine oil as a sustainable approach for asphalt rejuvenation and modification: A review. Heliyon 2024, 10, e40737. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A.; Stefańska, A.; Koda, E.; Jakimiuk, A.; Vaverková, M.D.; Winkler, J.; Duarte, C.C.; Corticos, N.D. A state of review on instigating resources and technological sustainable approaches in green construction. Sustainability 2023, 15, 6751. [Google Scholar] [CrossRef]

- Ramadan, S.; Kassem, H.; ElKordi, A.; Joumblat, R. Incorporating Artificial Intelligence Applications in Flexible Pavements: A Comprehensive Overview. Int. J. Pavement Res. Technol. 2024, 1–26. [Google Scholar] [CrossRef]

- Whitelegg, J. Critical Mass: Transport, Environment and Society in the Twenty-First Century; Pluto Press: London, UK, 1997. [Google Scholar]

- Oke, O.O. A Study on the Development of Guidelines for the Production of Bitumen Emulsion Stabilised RAPs for Roads in the Tropics. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2011. [Google Scholar]

- Wu, W.; Cavalli, M.C.; Jiang, W.; Kringos, N. Differing perspectives on the use of high-content SBS polymer-modified bitumen. Constr. Build. Mater. 2024, 411, 134433. [Google Scholar] [CrossRef]

- Awogbemi, O.; Ojo, A.A.; Adeleye, S.A. Advancements in the application of metal oxide nanocatalysts for sustainable biodiesel production. Discov. Appl. Sci. 2024, 6, 250. [Google Scholar] [CrossRef]

- Anupam, K.; Akinmade, D.; Kasbergen, C.; Erkens, S.; Adebiyi, F. A state-of-the-art review of Natural bitumen in pavement: Underlining challenges and the way forward. J. Clean. Prod. 2023, 382, 134957. [Google Scholar] [CrossRef]

- Chen, C.; Lu, J.; Ma, T.; Zhang, Y.; Gu, L.; Chen, X. Applications of vegetable oils and their derivatives as Bio-Additives for use in asphalt binders: A review. Constr. Build. Mater. 2023, 383, 131312. [Google Scholar] [CrossRef]

- Kök, B.V.; Yilmaz, M.; Geçkil, A. Evaluation of low-temperature and elastic properties of crumb rubber–and SBS-modified bitumen and mixtures. J. Mater. Civ. Eng. 2013, 25, 257–265. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar] [CrossRef]

- Maharaj, R.; Ramjattan-Harry, V.; Mohamed, N. Rutting and fatigue cracking resistance of waste cooking oil modified trinidad asphaltic materials. Sci. World J. 2015, 2015, 385013. [Google Scholar] [CrossRef]

- Rahman, M.T.; Hainin, M.R.; Bakar, W.A.W.A. Use of waste cooking oil, tire rubber powder and palm oil fuel ash in partial replacement of bitumen. Constr. Build. Mater. 2017, 150, 95–104. [Google Scholar] [CrossRef]

- Bardella, N.; Facchin, M.; Fabris, E.; Baldan, M.; Beghetto, V. Waste Cooking Oil as Eco-Friendly Rejuvenator for Reclaimed Asphalt Pavement. Materials 2024, 17, 1477. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Chandrappa, A.K. Critical review on waste cooking oil rejuvenation in asphalt mixture with high recycled asphalt. Environ. Sci. Pollut. Res. 2023, 30, 77981–78003. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.; Wu, Z.; Xie, Q.; Fang, J.; Hu, Y.; Lu, M.; Xia, F.; Nie, Y.; Ji, J. Structural modification of waste cooking oil methyl esters as cleaner plasticizer to substitute toxic dioctyl phthalate. J. Clean. Prod. 2018, 186, 1021–1030. [Google Scholar] [CrossRef]

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.; Moeini, A.; Berahman, B. The effect of nanoclay on rheological properties and storage stability of SBS-modified bitumen. Pet. Sci. Technol. 2011, 29, 850–859. [Google Scholar] [CrossRef]

- Remišová, E. Improvement in properties of bitumen using selected additives. Road Rail Infrastruct. V 2018, 5, 17–19. [Google Scholar]

- Kotenko, N.P.; Shcherba, Y.S.; Evforitskiy, A.S. Effect of polymer and functional additives on the properties of bitumen and asphalt-concrete. Plast. Massy 2020, 1, 47–49. [Google Scholar] [CrossRef]

- Podolsky, J.; Hohmann, A.; Chen, C.; Sotoodeh-Nia, Z.; Manke, N.; Saw, B.; Hernandez, N.; Ledtje, P.; Forrester, M.; Williams, R.C.; et al. Effect of Soybean Oil Derived Additives on Improved Performance of Polymer-Modified Asphalt Binder and Mix Containing 50% Fine-Graded RAP. In Proceedings of the RILEM International Symposium on Bituminous Materials: ISBM Lyon, Lyon, France, 14–16 December 2020; Springer: Cham, Switzerland, 2022; pp. 615–621. [Google Scholar]

- Mu, Y.; Ma, F.; Dai, J.; Li, C.; Fu, Z.; Yang, T.; Jia, M. Investigation on high temperature rheological behaviors and fatigue performance of trans-polyoctenamer-activated crumb rubber modified asphalt binder. Coatings 2020, 10, 771. [Google Scholar] [CrossRef]

- Desidery, L.; Lanotte, M. Effect of waste polyethylene and wax-based additives on bitumen performance. Polymers 2021, 13, 3733. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xu, G.; Gong, M.; Yang, J.; Li, S.; Cai, D. Full range temperature susceptibility of aged bitumen rejuvenated by polymer modified bio-derived rejuvenator. Mater. Struct. 2021, 54, 97. [Google Scholar] [CrossRef]

- Ghabchi, R.; Zaman, M.; Singh, D.; Barman, M.; Boeck, D.L. Effectiveness of using polymer-modified asphalt binders in enhancing fatigue life of asphalt mixes containing RAS and RAP. In Challenges and Innovations in Geomechanics. IACMAG 2021. Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2021; Volume 125, pp. 213–219. [Google Scholar]

- Abe, A.A.; Rossi, C.O.; Caputo, P. Biomaterials and Their Potentialities as Additives in Bitumen Technology: A Review. Molecules 2022, 27, 8826. [Google Scholar] [CrossRef] [PubMed]

- Akpolat, M. Investigation of rutting, fatigue and cracking resistance parameters of CR modified warm asphalt binders compare with SBS modified binders. Rev. Constr. 2022, 21, 309–328. [Google Scholar]

- Joohari, I.B.; Maniam, S.; Giustozzi, F. Effect of Long-Term Aging on Polymer Degradation and Fatigue Resistance of Hybrid Polymer-Modified Bitumen. J. Mater. Civ. Eng. 2022, 34, 04022286. [Google Scholar] [CrossRef]

- Tabaković, A.; Lemmens, J.; Tamis, J.; van Vliet, D.; Nahar, S.; Suitela, W.; van Loosdrecht, M.; Leegwater, G. Bio-polymer modified bitumen. Constr. Build. Mater. 2023, 406, 133321. [Google Scholar] [CrossRef]

- Wang, H.; Du, Z.; Liu, G.; Luo, X.; Yang, C. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers 2023, 15, 2911. [Google Scholar] [CrossRef]

- Queiroz, R.F.R.; Rodrigues, J.K.G.; Patricio, J.D.; da Silva, P.H.; Carvalho, J.R.; Neto, O.d.M.M.; Rodrigues, L.G.; de Lima, R.K.B. Linear viscoelastic properties and fatigue S-VECD based evaluation of polymer-modified asphalt mixtures. J. Build. Eng. 2023, 75, 106916. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, G.; Yan, S.; Feng, J.; Li, D. Performance and Mechanism of High-Viscosity and High-Elasticity Bitumen (HVE-MB) Modified with Five Additives. Sustainability 2023, 15, 14089. [Google Scholar] [CrossRef]

- Tian, G.; Chen, C.; Zhang, T.; Gao, Y.; Wang, S.; Jia, Y.; Chen, Z.; Li, Y.; Zhou, Z.; Wei, Z. Effect of high-elasticity anti-rutting additive on viscoelastic behavior of asphalt binder and its modification mechanism. Case Stud. Constr. Mater. 2023, 19, e02504. [Google Scholar] [CrossRef]

- Al-gurah, E.R.; Al-ghurabi, S.J.; Al-Humeidawi, B.H. Laboratory evaluation of properties of modified asphalt binder with different types of additives. IOP Conf. Ser. Earth Environ. Sci. 2023, 1232, 012043. [Google Scholar] [CrossRef]

- Olalekan, S.T.; Olatunde, A.A.; Kolapo, S.K.; Omolola, J.M.; Olukemi, O.A.; Mufutau, A.A.; Olaosebikan, O.O.; Saka, A.A. Durability of bitumen binder reinforced with polymer additives: Towards upgrading Nigerian local bitumen. Heliyon 2024, 10, e30825. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Shen, Z.; Yu, Z.; Jiang, L.; Long, Q.; He, C. Performance study of SBS/CRMA with different composite crumb rubber particle size ratios. Case Stud. Constr. Mater. 2024, 20, e03232. [Google Scholar] [CrossRef]

- Huang, W.; Li, Y.; Meng, Y.; He, C.; Ye, X.; Chen, X.; Hu, C. Comprehensive study on the performance of SBS and crumb rubber composite modified asphalt based on the rubber pretreatment technology. Case Stud. Constr. Mater. 2024, 20, e03141. [Google Scholar] [CrossRef]

- Kumar, G.; Tomar, R.; Kidwai, F.A. PInfluence of Crumb Rubber on Temperature Susceptibility and Activations Energy of Crumb Rubber Modified Bitumen. In Proceedings of the 2024 International Conference on Communication, Computer Sciences and Engineering (IC3SE), Gautam Buddha Nagar, India, 9–11 May 2024; pp. 1–4. [Google Scholar]

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2006. [CrossRef]

- ASTM D113-17; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D92-18; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Almusawi, A.; Sengoz, B.; Topal, A. Evaluation of mechanical properties of different asphalt concrete types in relation with mixing and compaction temperatures. Constr. Build. Mater. 2021, 268, 121140. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr. Build. Mater. 2008, 22, 1897–1905. [Google Scholar] [CrossRef]

- Adanikin, A.; Funsho, F.; Adewale, O. Volumetric properties of Cow Bone Ash (CBA) filler-based asphaltic concrete using aggregates from different sources. J. Appl. Res. Ind. Eng. Vol. 2020, 7, 13–24. [Google Scholar]

- Kadhim, Y.N.; Hussain, W.A.M.; Abdulrasool, A.T. The effect of animal bone ash on the mechanical properties of asphalt concrete. Civ. Eng. J 2021, 7, 1741–1752. [Google Scholar] [CrossRef]

- ASTM D6373-21a; Standard Specification for Performance-Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM D7175-23; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- AASHTO TP 101-12; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018.

- Zhang, L.; Li, P.; Hu, G.; Zhang, S.; Hong, B.; Wang, H.; Wang, D.; Oeser, M. Study on the aging resistance of polyurethane precursor modified bitumen and its mechanism. Sustainability 2021, 13, 9520. [Google Scholar] [CrossRef]

- Remisova, E.; Briliak, D.; Holy, M. Evaluation of Thermo-Viscous Properties of Bitumen Concerning the Chemical Composition. Materials 2023, 16, 1379. [Google Scholar] [CrossRef] [PubMed]

- Dabiri, A.; Silva, H.M.; Oliveira, J.R. Enhancing Pavement Durability: Comparative Rheological Evaluation of Conventional and Rejuvenated Reclaimed Binders under Aging Conditions. Materials 2024, 17, 3305. [Google Scholar] [CrossRef] [PubMed]

- Al-Mohammed, M.; Al-Hadidy, A. Durability and rutting resistance of SBS-modified asphalt mixtures containing blowdown as a sustainable filler. Al-Rafidain Eng. J. 2023, 28, 48–57. [Google Scholar] [CrossRef]

- Dehnad, M.H.; Damyar, B.; Farahani, H.Z. Rheological evaluation of modified bitumen by EVA and crumb rubber using RSM optimization. Adv. Mater. Sci. Eng. 2021, 2021, 9825541. [Google Scholar] [CrossRef]

- Sangregorio, A.; Guigo, N.; Vincent, L.; de Jong, E.; Sbirrazzuoli, N. Furanic humins from biorefinery as biobased binder for bitumen. Polymers 2022, 14, 1019. [Google Scholar] [CrossRef]

- Javadi, N.H.S.; Heydari, S.; Hajimohammadi, A. Evaluating Effectiveness of Multi-Component Waste Plastic Bags on Bitumen Properties: Physical, Rheological, and Aging. Polymers 2024, 16, 1669. [Google Scholar] [CrossRef] [PubMed]

- Elahi, Z.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste cooking oil as a sustainable bio modifier for asphalt modification: A review. Sustainability 2021, 13, 11506. [Google Scholar] [CrossRef]

- Rasman, M.; Hassan, N.A.; Hainin, M.R.; Jaya, R.P.; Haryati, Y.; Shukry, N.A.M.; Abdullah, M.E.; Kamaruddin, N.H.M. Engineering properties of bitumen modified with bio-oil. MATEC Web Conf. 2018, 250, 02003. [Google Scholar] [CrossRef]

| Reference | Year | Study Objective | Methodology/Tools Used | Key Findings |

|---|---|---|---|---|

| [35] | 2018 | Improvement in properties of bitumen using selected additives | Experimental measurements; adhesion testing between bitumen and aggregate | Additives improved adhesion, softening point, and viscosity. Sasobit and Licomont BS significantly increased softening point. |

| [36] | 2019 | Effect of polymer and functional additives on the properties of bitumen and asphalt-concrete | Use of copolymers and carbon nanotubes; rheological and performance tests | Copolymers and nanotubes improved heat resistance, elasticity, shear stability, and strength in asphalt concrete. |

| [37] | 2020 | Effect of soybean oil-derived additives on polymer-modified asphalt with RAP | Rheology experiments; Multiple Stress Creep Recovery (MSCR) testing | Soybean oil-derived additives improved fatigue and low-temperature performance. SESO maintained elastic recovery. |

| [38] | 2020 | Investigation of high-temperature rheological behaviors and fatigue performance | TFOT and PAV aging tests; RV, DSR, and LAS tests | TOR-activated CRMA improved high-temperature properties but negatively impacted fatigue performance compared to SBSMA. |

| [39] | 2021 | Effect of waste polyethylene and wax-based additives on bitumen performance | Analysis of viscoelastic properties; blending polyethylene and Fischer–Tropsch waxes | Long-chain waxes enhanced resistance to permanent deformations, while short-chain waxes negatively affected rutting resistance. |

| [40] | 2021 | Temperature susceptibility of aged bitumen rejuvenated by polymer-modified bio-derived rejuvenator | BBR, DSR, RV, and SARA analysis tests | PMBR showed superior long-term performance and preferable temperature susceptibility compared to conventional rejuvenators. |

| [41] | 2021 | Effectiveness of polymer-modified asphalt binders with RAS and RAP | Four-point bending-beam method for fatigue testing | Polymer-modified binders improved fatigue life of asphalt mixes containing RAS and RAP; RAS alone negatively impacted performance. |

| [42] | 2022 | Biomaterials as additives in bitumen technology for sustainability | Literature review of bio-based materials | Biomaterials offer eco-friendly approaches and improved bitumen properties for asphalt applications. |

| [43] | 2022 | Comparison of rutting, fatigue, and cracking resistance in CR and SBS modified binders | MSCR and LAS tests | CR + Sasobit improved rutting but reduced fatigue life at high strain values. |

| [44] | 2022 | Long-term aging effects on hybrid polymer-modified bitumen | PAV aging simulation; rheological and thermal analysis | SBS degraded, improving elastic response; RLLDPE showed minimal degradation under long-term aging. |

| [45] | 2023 | Bio-polymer modified bitumen | Gel Permeation Chromatography, FTIR, DSC, and DSR tests | PHBV improved bitumen’s physical and mechanical properties, demonstrating sustainability as a bio-polymer modifier. |

| [46] | 2023 | Aging impact on fatigue and thermal cracking performance of bio-blend bitumen | PAV system, LAS tests, BBR tests | Compound-modified bitumen exhibited better fatigue resistance and anti-aging performance. |

| [47] | 2023 | Fatigue evaluation of polymer-modified asphalt mixtures using S-VECD model | S-VECD and LAS tests | Polymer-modified mixtures demonstrated superior fatigue and mechanical performance with reduced viscous behavior. |

| [48] | 2023 | High-viscosity and high-elasticity bitumen modified with five additives | Rheological property evaluation; compounding modifiers | Additives significantly enhanced viscoelasticity; reclaimed rubber improved bitumen sustainably. |

| [49] | 2023 | High-elasticity anti-rutting additive effect on asphalt binder performance | RV, FTIR, AFM, FM tests | Additives improved viscosity, elasticity, and reduced temperature susceptibility; compatibility influenced performance. |

| [50] | 2023 | Properties of polymer-modified bitumen with various additives | Penetration, ductility, softening point, RV, and TFOT tests | Different PMBs improved asphalt properties; high SBS content increased viscosity, affecting workability. |

| [51] | 2023 | Durability of polymer additives in upgrading Nigerian bitumen | Systematic literature review; evaluation of waste-packaging polymers | Polymer additives offered sustainable alternatives, enhancing local bitumen performance. |

| [52] | 2024 | Performance study of SBS/CRMA with different composite crumb-rubber particle size ratios | Brookfield viscosity measurements; storage stability, rheology, LAS, FTIR, FM analysis | Finer CR particles improved asphalt performance; composite CR ratios enhanced SBS/CRMA significantly. |

| [53] | 2024 | Performance of SBS and crumb-rubber composite-modified asphalt using pretreatment | FEO pretreatment; DSR, FTIR, SEM, FM, penetration, softening-point tests | CR pretreatment enhanced compatibility and storage stability; there was mild impairment in high-temperature resistance. |

| [54] | 2024 | Influence of crumb rubber on temperature susceptibility and activation energy of CRM bitumen | Viscosity temperature susceptibility; activation energy; penetration index evaluations | Increased CRM content enhanced viscosity and reduced activation energy, improving temperature susceptibility. |

| Specification | Unit | Typical Value | Test Method |

|---|---|---|---|

| Penetration | mm | 49 | 40–50 (ASTM D5 [55]) |

| Ductility | cm | >150 | ≥100 (ASTM D113 [56]) |

| Softening Point | °C | 50 | - |

| Flash Point | °C | 245 | 232 min (ASTM D92 [57]) |

| Specific Gravity | - | 1.02 | - |

| Rotational viscosity | Pa.s. | 0.488 | - |

| Rolling Thin-Film Oven Test | |||

| Retained penetration | % | 80 | ≥55 (ASTM D5 [55]) |

| Penetration Index (PI) | - | −1.25 | - |

| Sample | Temperature (°C) | G* (Pa) | Phase Angle (δ °) | G*/sin(δ) (kPa) | Strain Amplitude (%) |

|---|---|---|---|---|---|

| Unmodified Bitumen | 52.0 | 25,000.0 | 79.4 | 25.438 | 12.17 |

| 4% SBS | 76.0 | 2135.9 | 81.6 | 2.1593 | 12.37 |

| 5% SBS | 76.0 | 3584.9 | 75.4 | 3.7041 | 12.48 |

| 4% AB | 64.0 | 3779.9 | 85.0 | 3.7945 | 12.28 |

| 5% AB | 76.0 | 1001.9 | 85.7 | 1.0048 | 12.20 |

| 6% AB | 76.0 | 1001.6 | 86.4 | 1.0036 | 12.04 |

| 3% WCO | 52.0 | 9470.3 | 82.5 | 9.5524 | 12.14 |

| 4% WCO | 52.0 | 7498.8 | 83.0 | 7.5552 | 12.33 |

| 5% WCO | 52.0 | 5171.7 | 83.8 | 5.2017 | 12.13 |

| Sample | Temperature (°C) | G* (Pa) | Phase Angle (δ °) | G*/sin(δ) (kPa) | Strain Amplitude (%) |

|---|---|---|---|---|---|

| Unmodified Bitumen | 52.0 | 21,213.0 | 78.9 | 21.615 | 12.01 |

| 4%SBS | 76.0 | 3428.3 | 76.0 | 3.533 | 12.12 |

| 5%SBS | 76.0 | 4982.0 | 63.9 | 5.306 | 12.31 |

| 4% AB | 64.0 | 3640.4 | 84.9 | 3.655 | 11.83 |

| 5% AB | 76.0 | 1278.1 | 86.4 | 1.280 | 12.23 |

| 6% AB | 76.0 | 1234.5 | 86.5 | 1.236 | 12.06 |

| 3% WCO | 52.0 | 13,098.0 | 80.0 | 13.300 | 12.24 |

| 4% WCO | 52.0 | 8937.1 | 81.2 | 9.043 | 12.46 |

| 5% WCO | 52.0 | 11,509.0 | 80.3 | 11.674 | 12.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almusawi, A.; Nasraldeen, S.T.; Albdairi, M.; Norri, H.H. Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study. Buildings 2025, 15, 306. https://doi.org/10.3390/buildings15030306

Almusawi A, Nasraldeen ST, Albdairi M, Norri HH. Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study. Buildings. 2025; 15(3):306. https://doi.org/10.3390/buildings15030306

Chicago/Turabian StyleAlmusawi, Ali, Shvan Tahir Nasraldeen, Mustafa Albdairi, and Hussein H Norri. 2025. "Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study" Buildings 15, no. 3: 306. https://doi.org/10.3390/buildings15030306

APA StyleAlmusawi, A., Nasraldeen, S. T., Albdairi, M., & Norri, H. H. (2025). Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study. Buildings, 15(3), 306. https://doi.org/10.3390/buildings15030306