Integration of Emerging Technologies with Construction Practices in Australia

Abstract

:1. Introduction

2. Materials and Methods

2.1. General State of the Construction Industry

Barriers Hindering Emerging Technology Integration with Construction Practices

2.2. Integration of Technologies Across the Four Key Construction Factors

2.2.1. Integration of Emerging Technologies to Improve the Safety of Construction Practices

2.2.2. Integration of Emerging Technologies to Improve the Cost of Construction Practices

2.2.3. Integration of Emerging Technologies to Reduce the Delay of Construction Practices

2.2.4. Integration of Emerging Technologies to Improve the Quality of Construction Practices

2.3. Skills in Using Emerging Technologies

2.3.1. State of Graduate Skills in Using Emerging Technologies

2.3.2. State of Employee Training to Facilitate the Integration of Emerging Technologies

3. Research Methodology

3.1. Literature Review on Different Interview Styles

3.2. Conducting the Interview to Obtain Primary Qualitative Data

3.2.1. Design of Semi-Structured Interviews with Industry Experts

3.2.2. Addressing Limitations of the Semi-Structured Interview with Industry Experts

3.3. Literature Review on Different Survey Styles

3.4. Conducting the Survey to Obtain Primary Quantitative Data

3.4.1. Design of Online Survey for Industry Professionals

3.4.2. Ethical Considerations When Designing the Survey

3.4.3. Addressing Limitations of the Online Survey

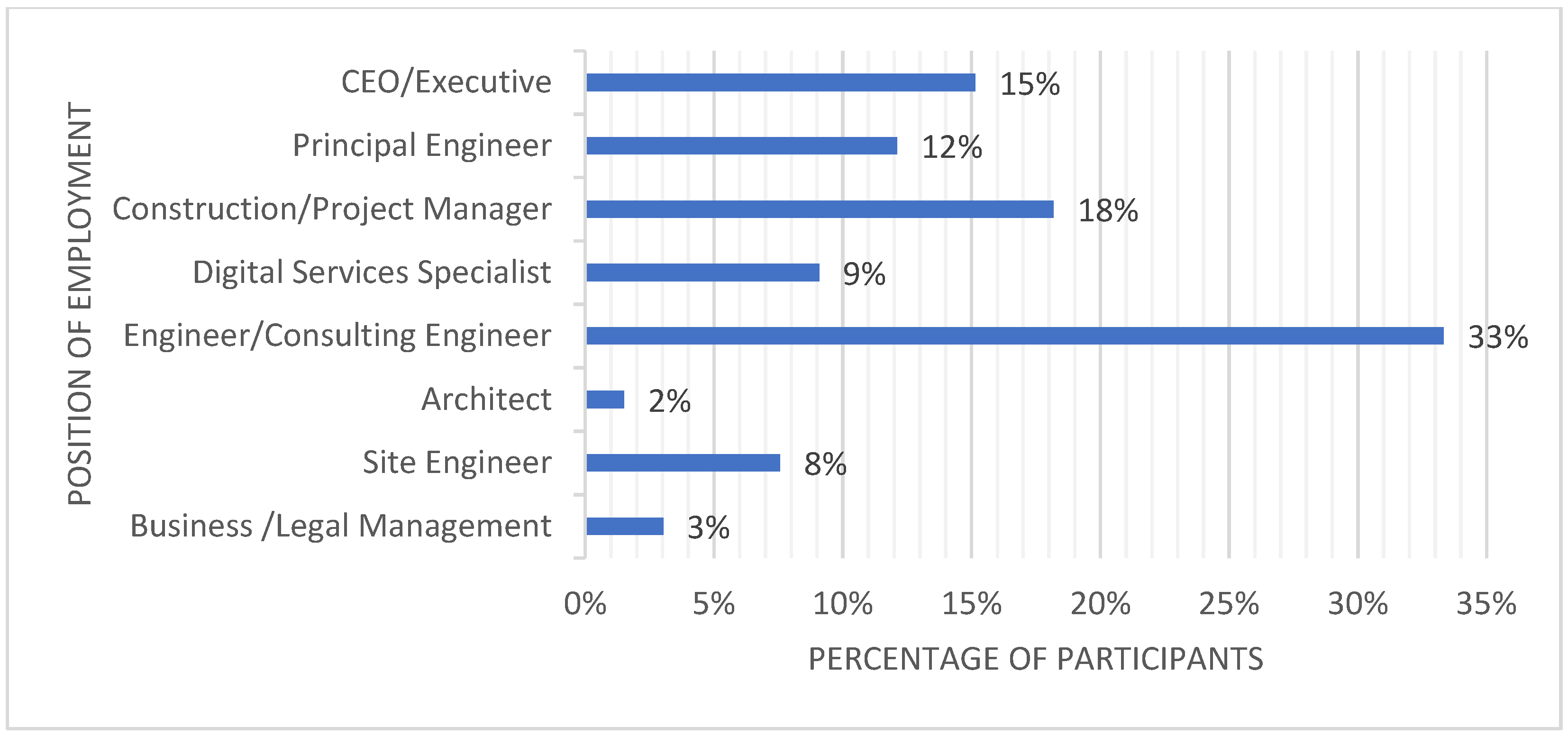

3.4.4. Target Audience of the Online Survey

4. Results and Discussion

4.1. Literature Review on Different Survey Styles

4.1.1. Interpreting the Interview Results

4.1.2. Analysing the Qualitative Data Using Thematic Analysis

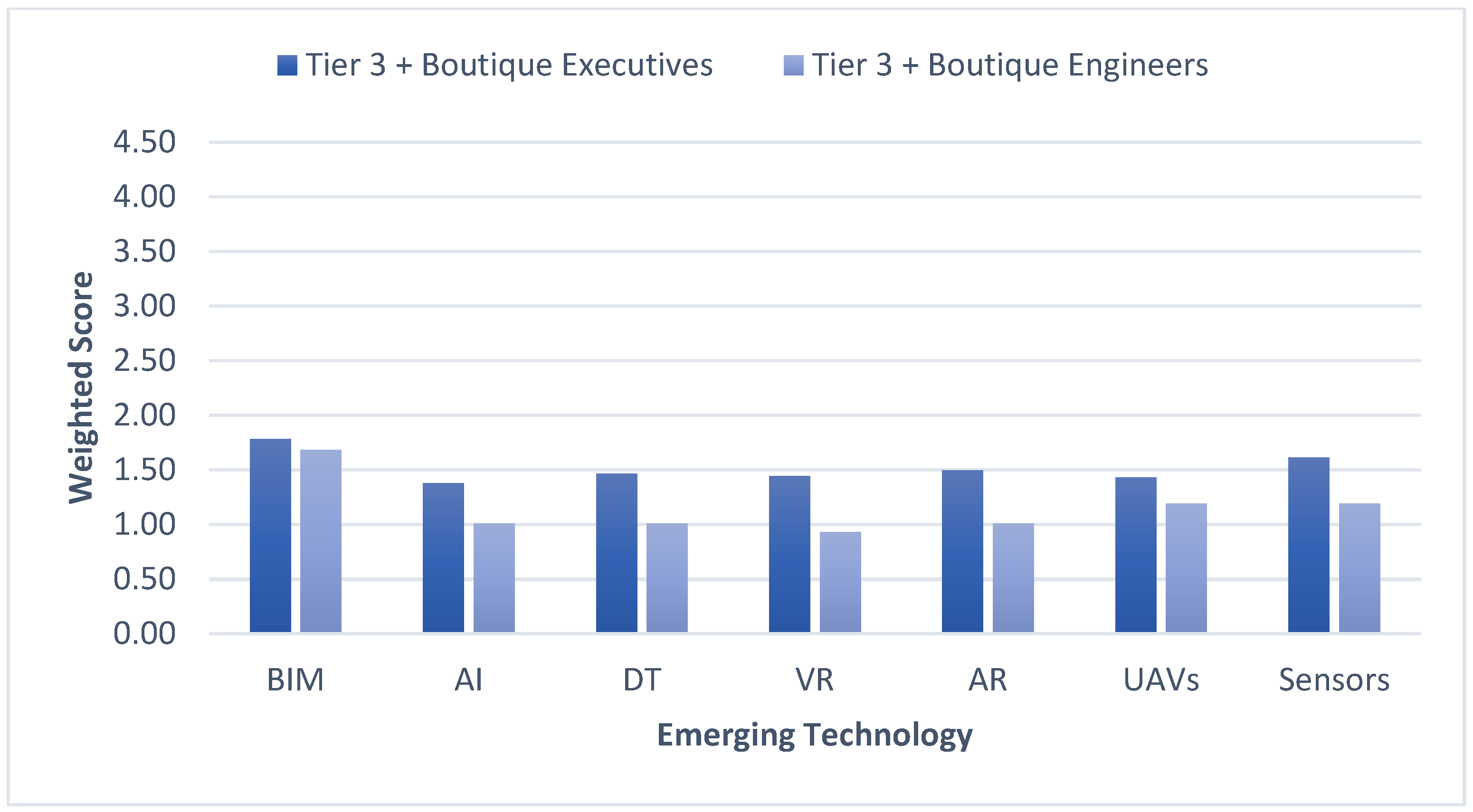

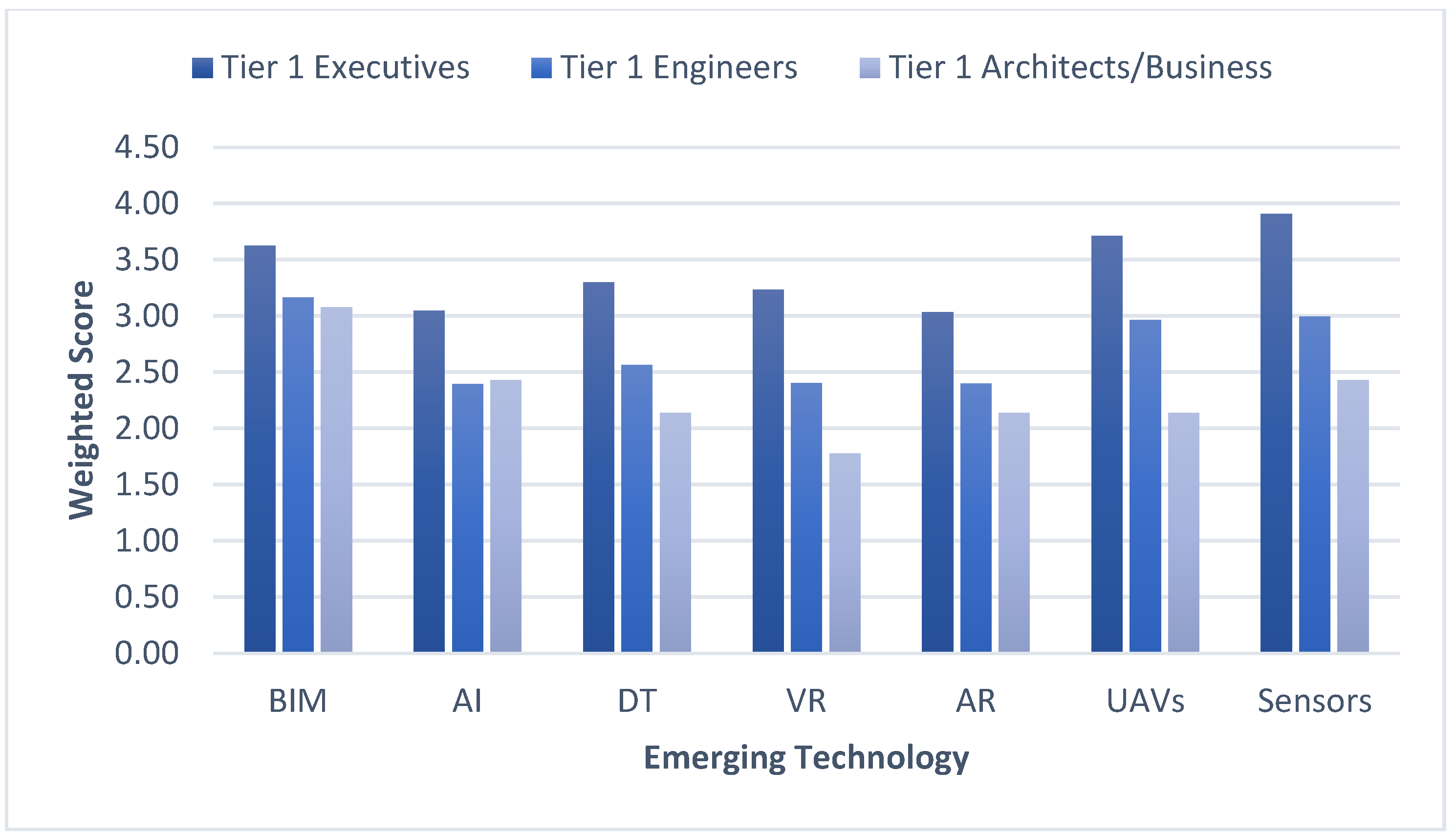

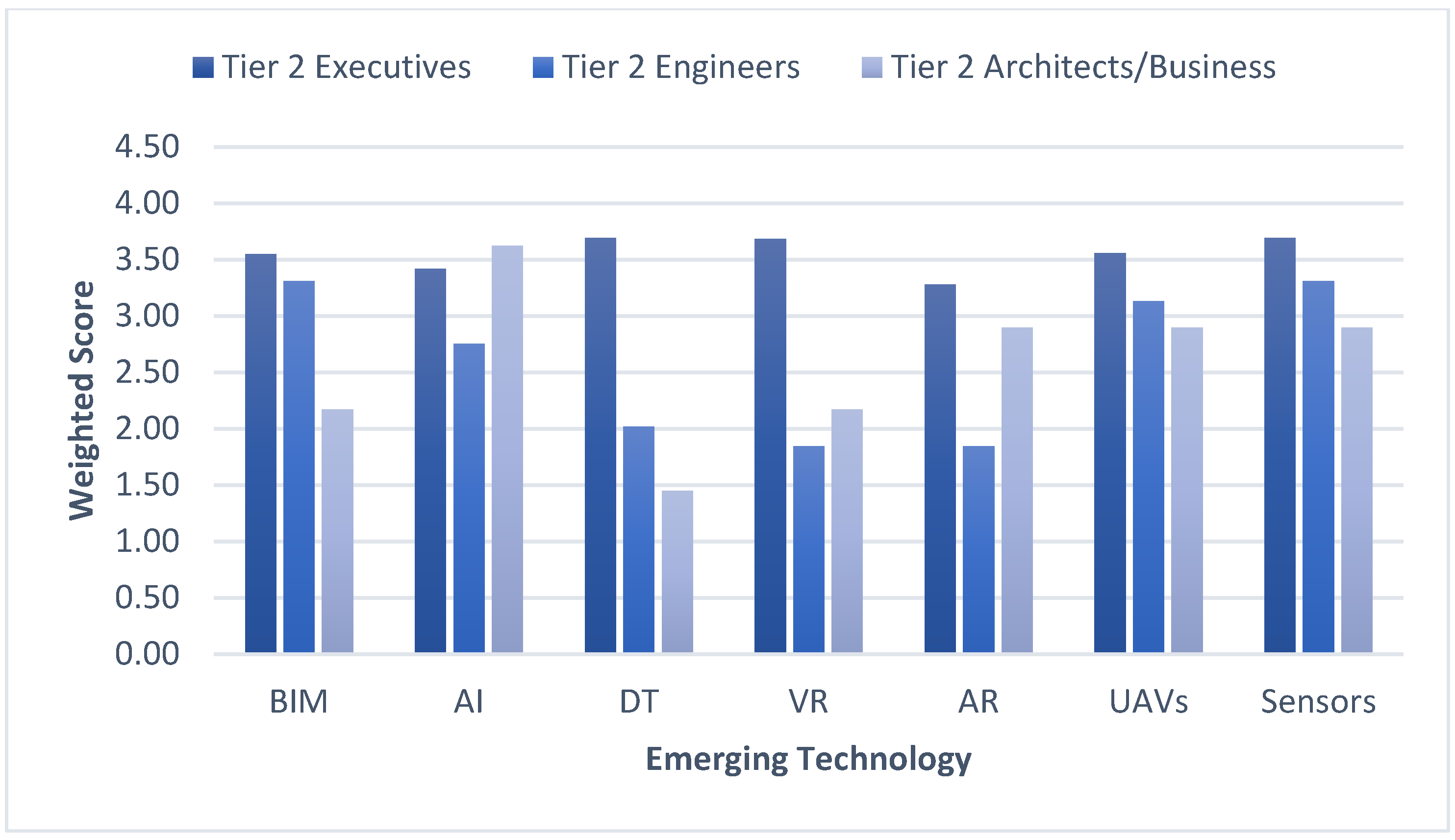

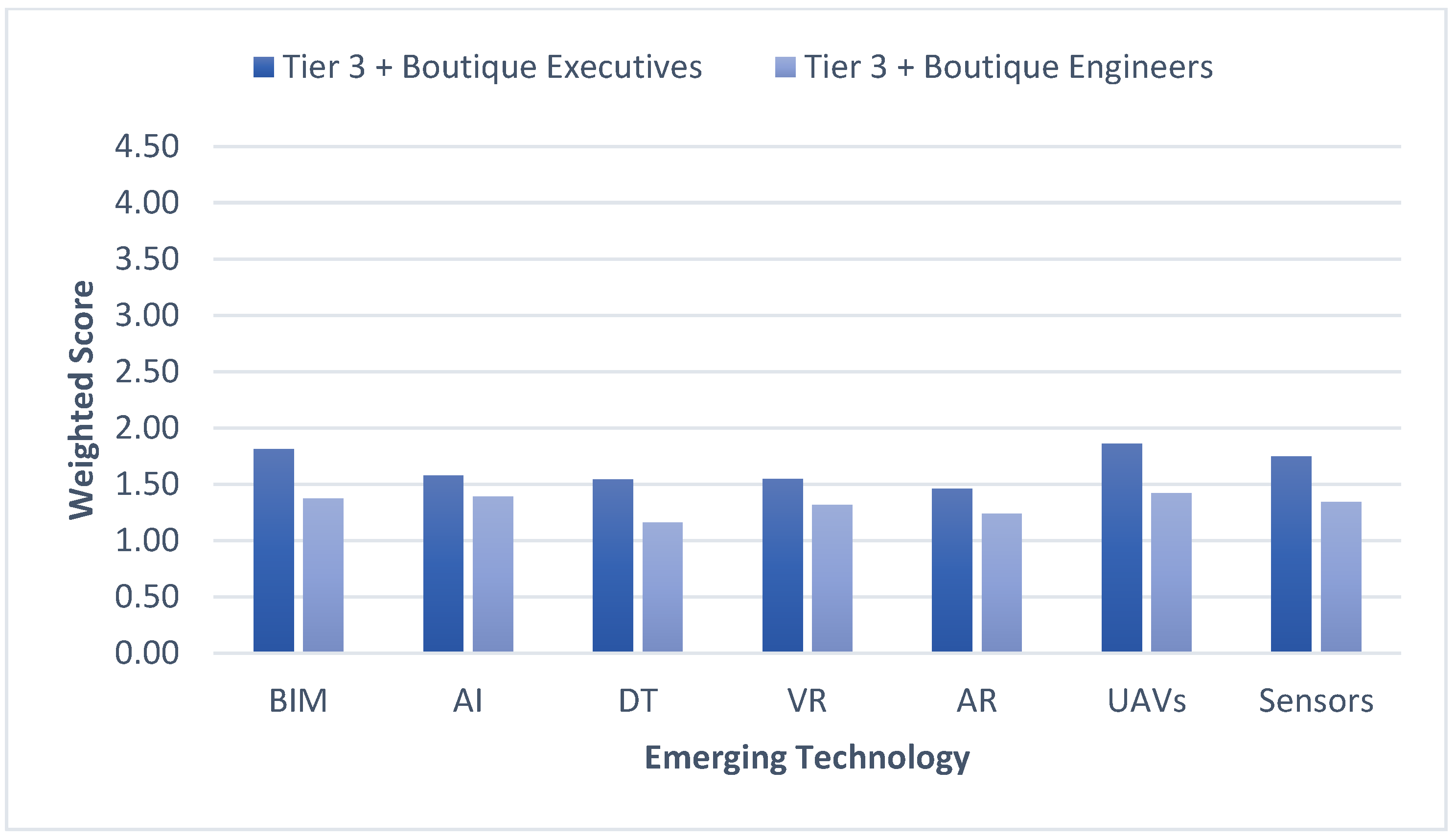

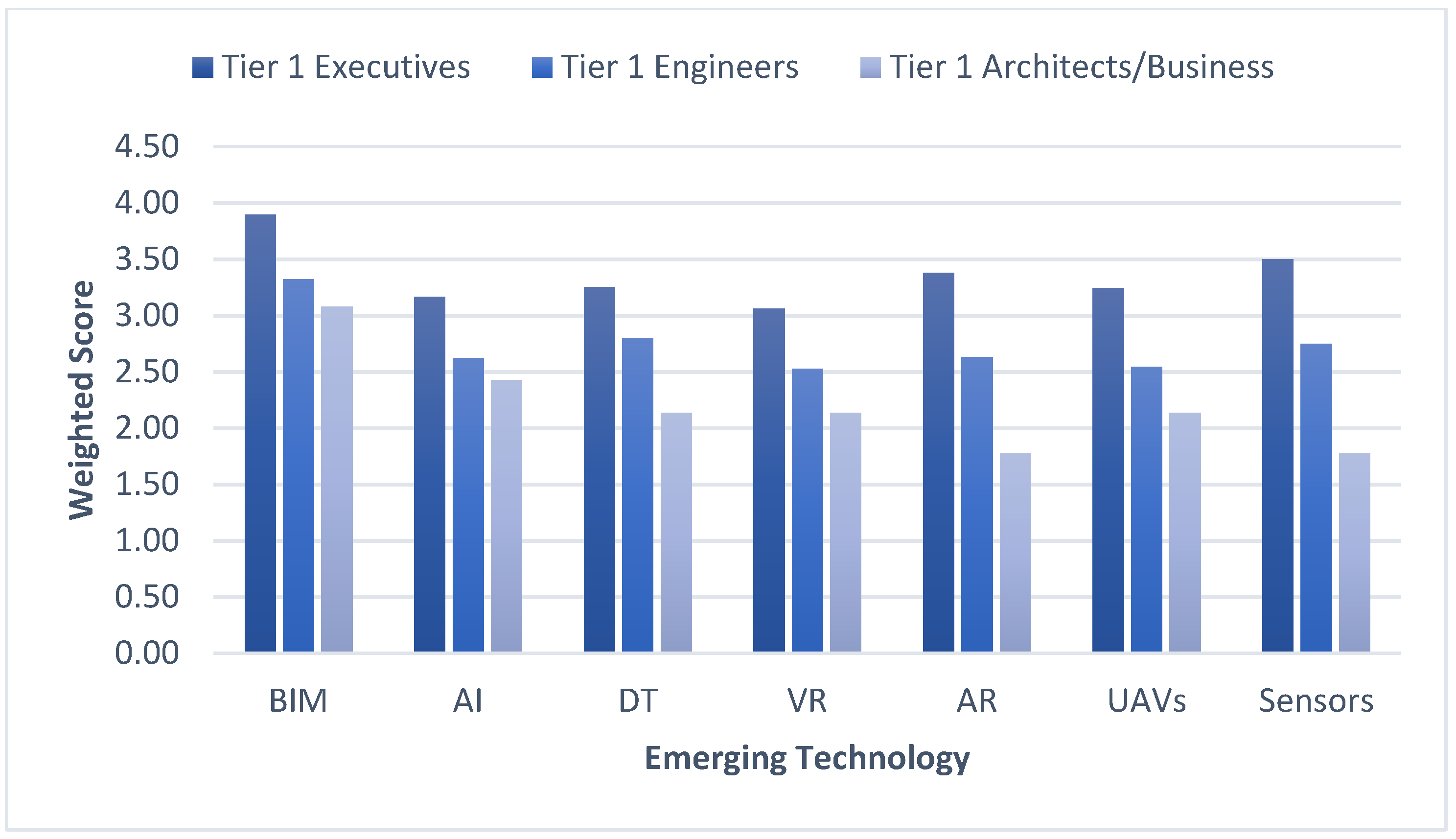

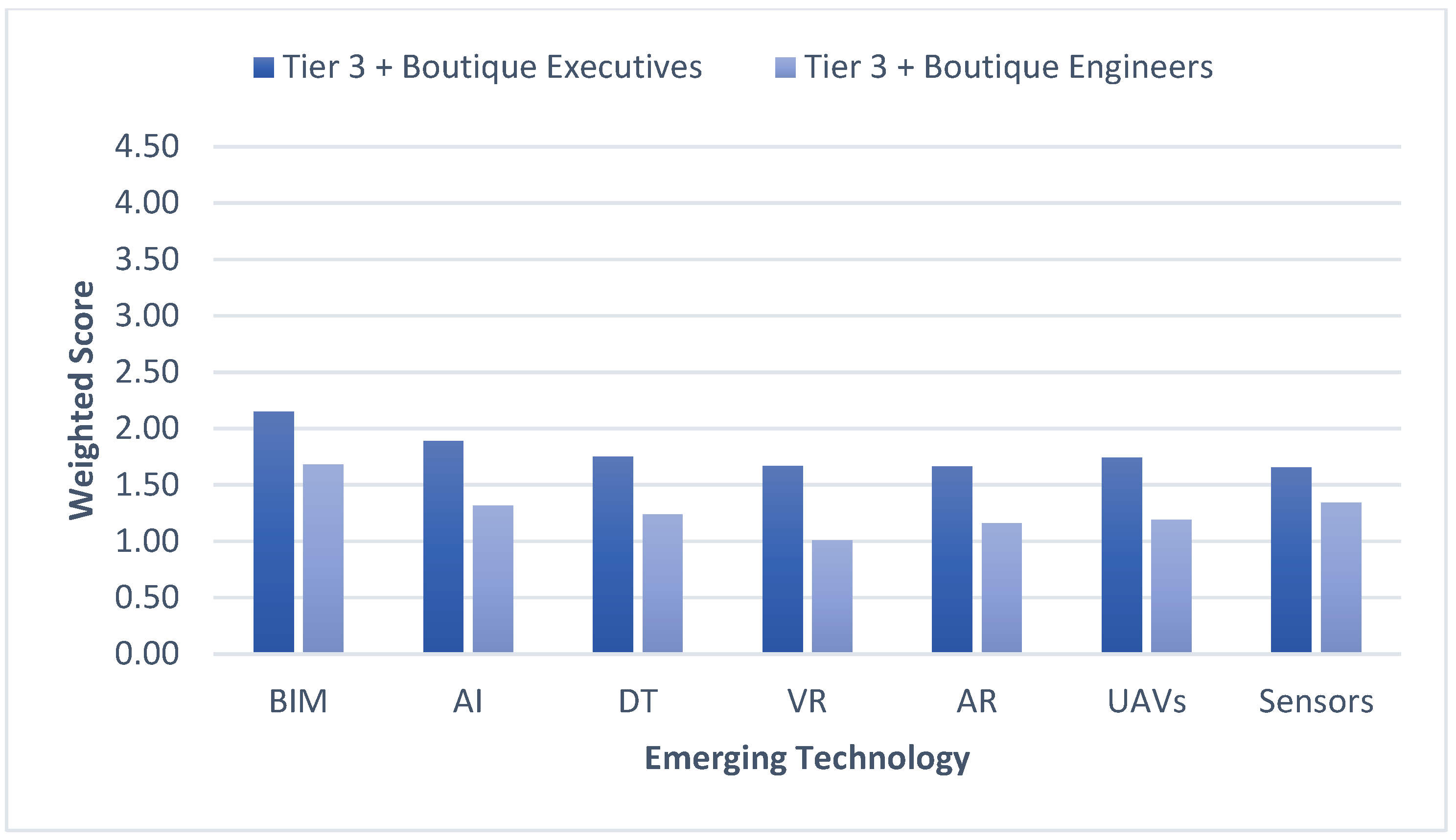

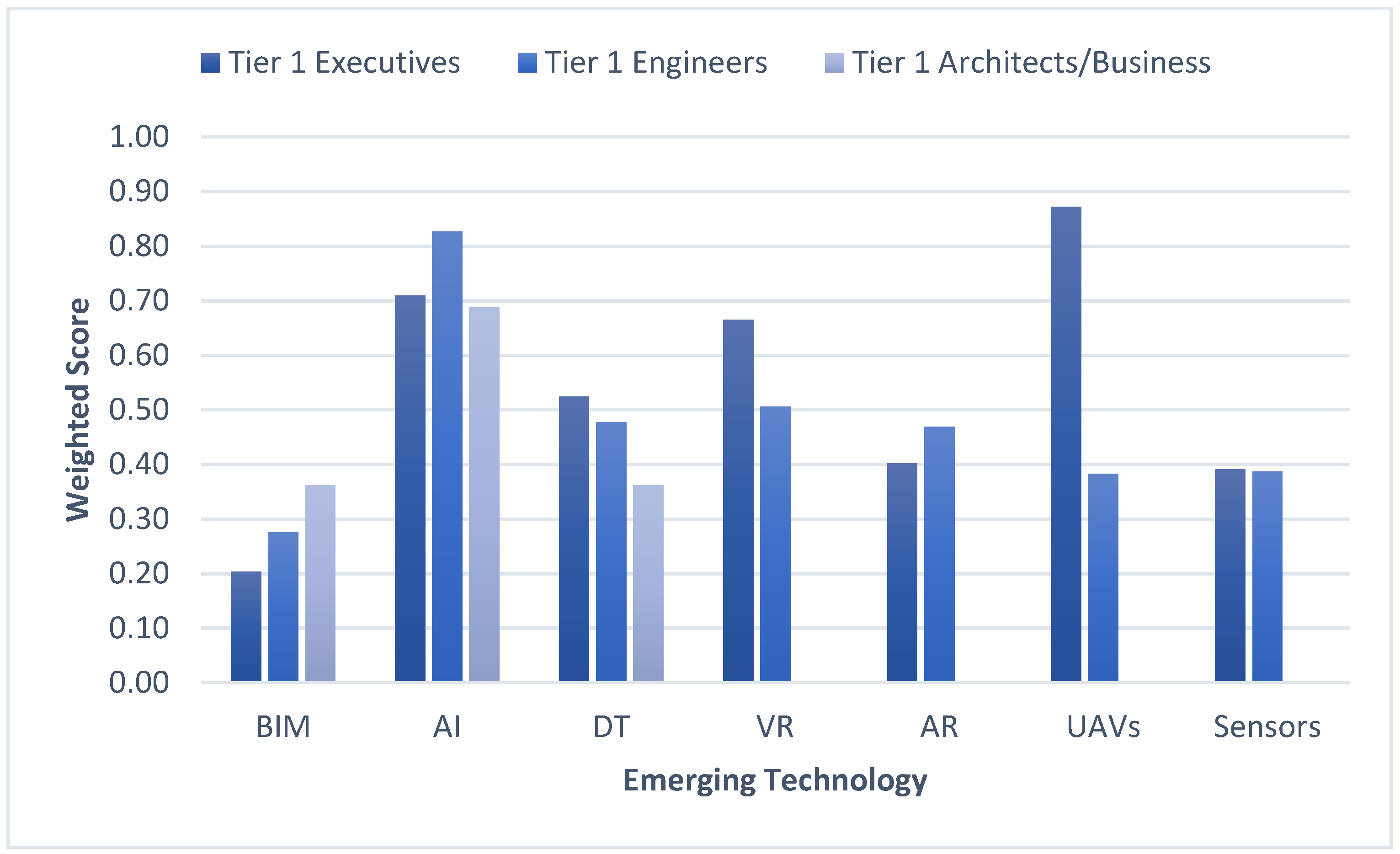

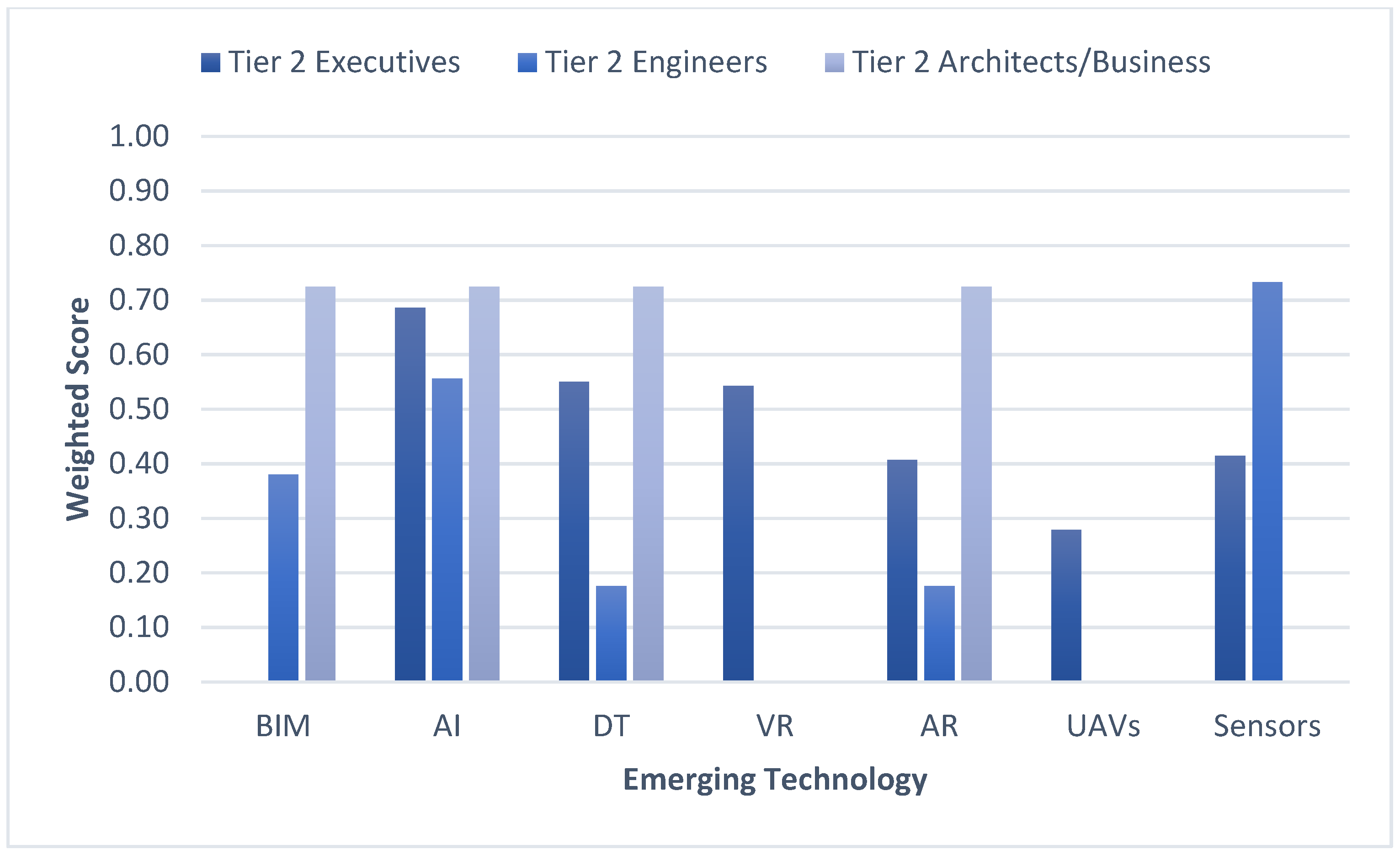

4.2. Interpreting the Survey Results

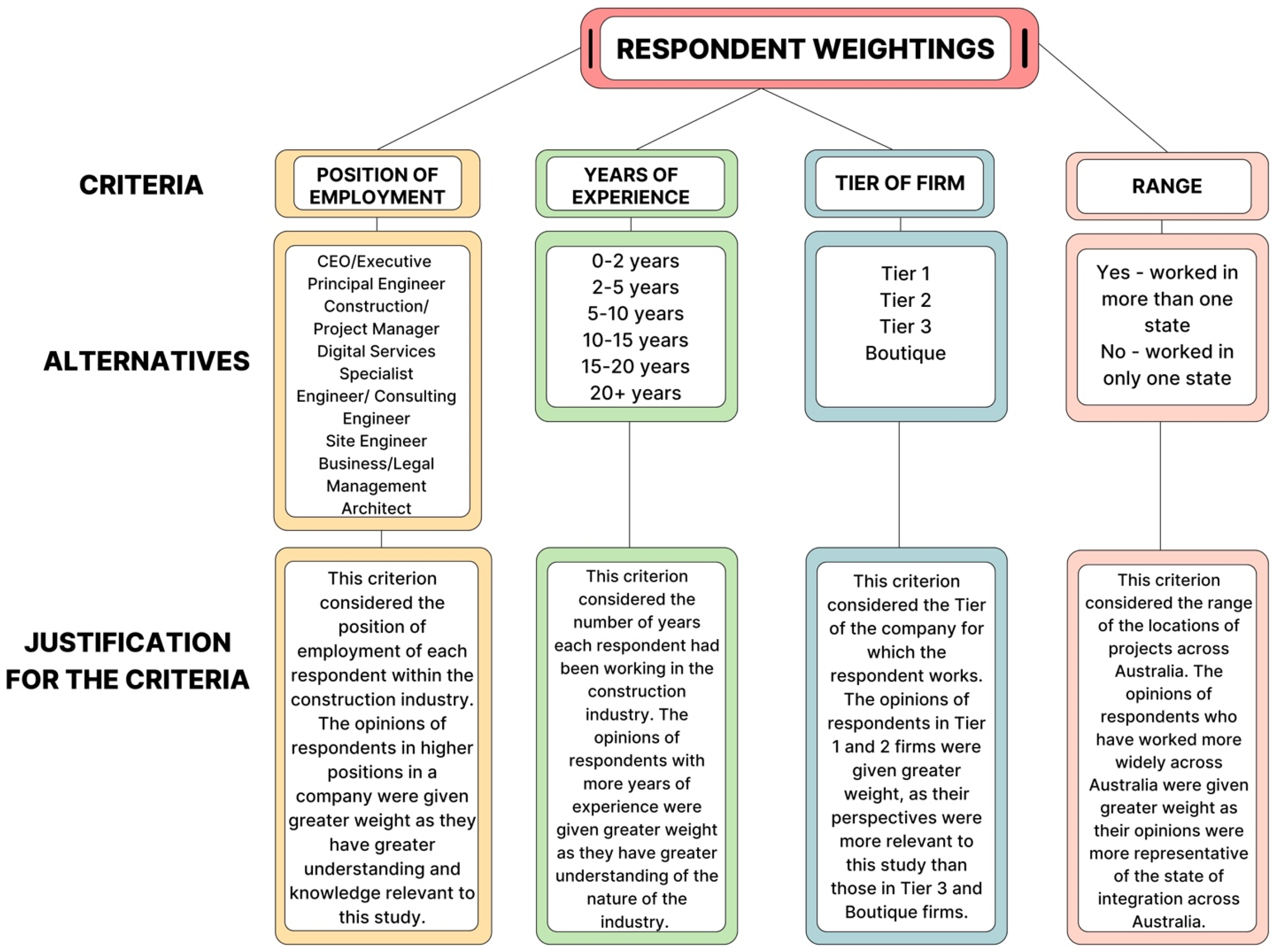

Analysing the Qualitative Data Using Thematic Analysis

- An n × n matrix was created, where n = number of criteria.

- Pairwise comparisons were completed between each combination of criteria, as per Table 1. The comparison is based on a relative importance scale of 1–9, where 1 indicates the criteria are of equal importance, and 9 indicates that one criterion is of extreme importance relative to the comparative criterion. As the matrix is inversely symmetrical, the reciprocal of each rating was applied above the diagonal of the matrix [97]. The value for each pairwise comparison constitutes an eigenvector. Table 2 below summarises the reasoning behind the relative weightings of the criteria.

- A standardised matrix was produced by dividing each eigenvector in Table 1 by the sum of the eigenvectors for each Criterion.

- The average of each row of the standardised eigenvectors for each criterion was calculated [97]. This average constitutes the value of the weighted eigenvector (respondent weighting).

- Steps 1–4 were repeated for the alternatives for . The n × n matrix contains the alternatives for each criterion.

- The Consistency index (S) of each matrix was calculated using the equation , where = number of alternatives and = average of the priority eigenvectors.

- To calculate , the priority eigenvectors were required. A priority eigenvector matrix was created by multiplying each pairwise comparison eigenvalue by its corresponding weighted eigenvector. The priority eigenvector was then calculated by dividing the sum of all priority vectors by its corresponding weighted eigenvector [93].

- The consistency ratio was calculated using the equation , where = the random consistency index [97].

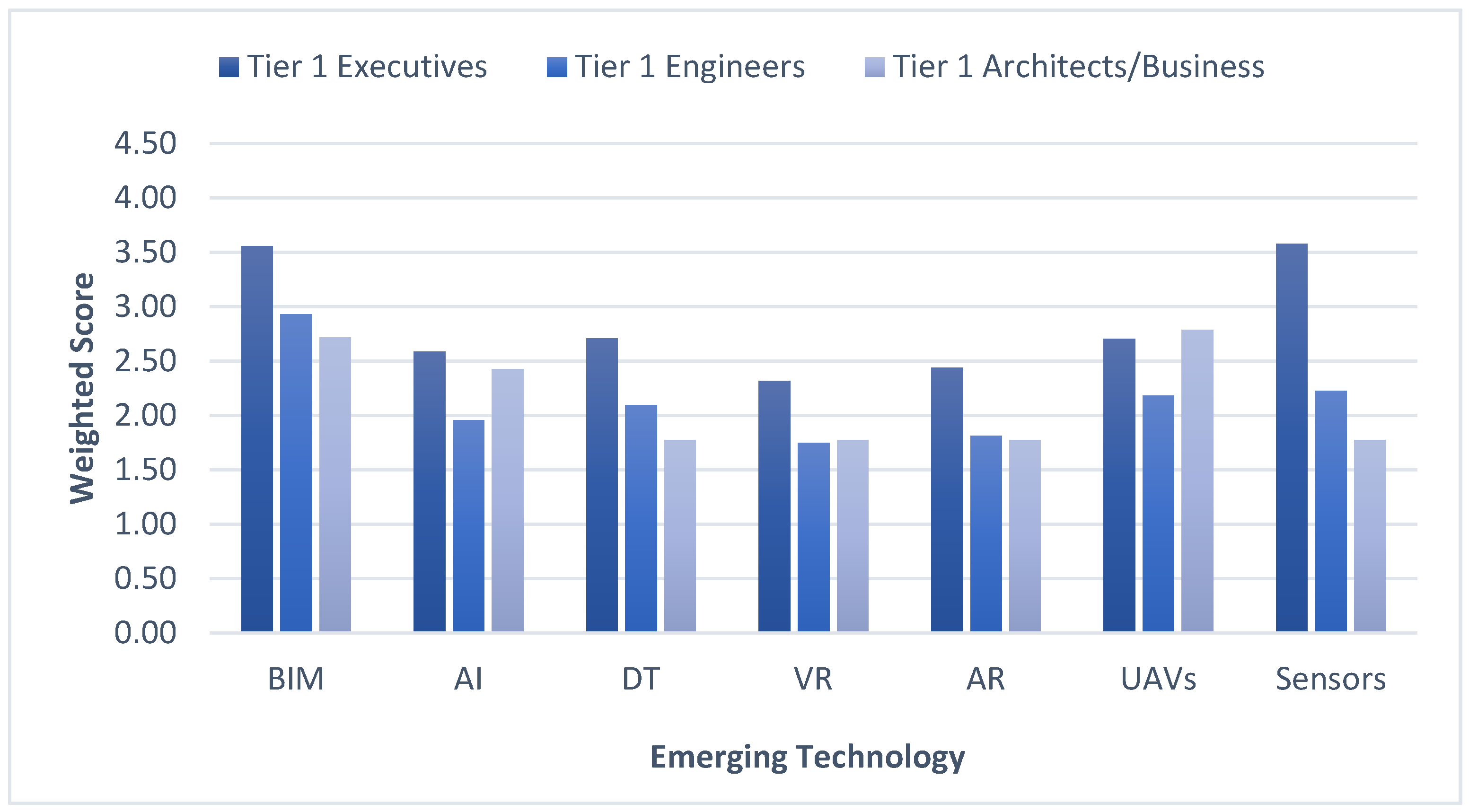

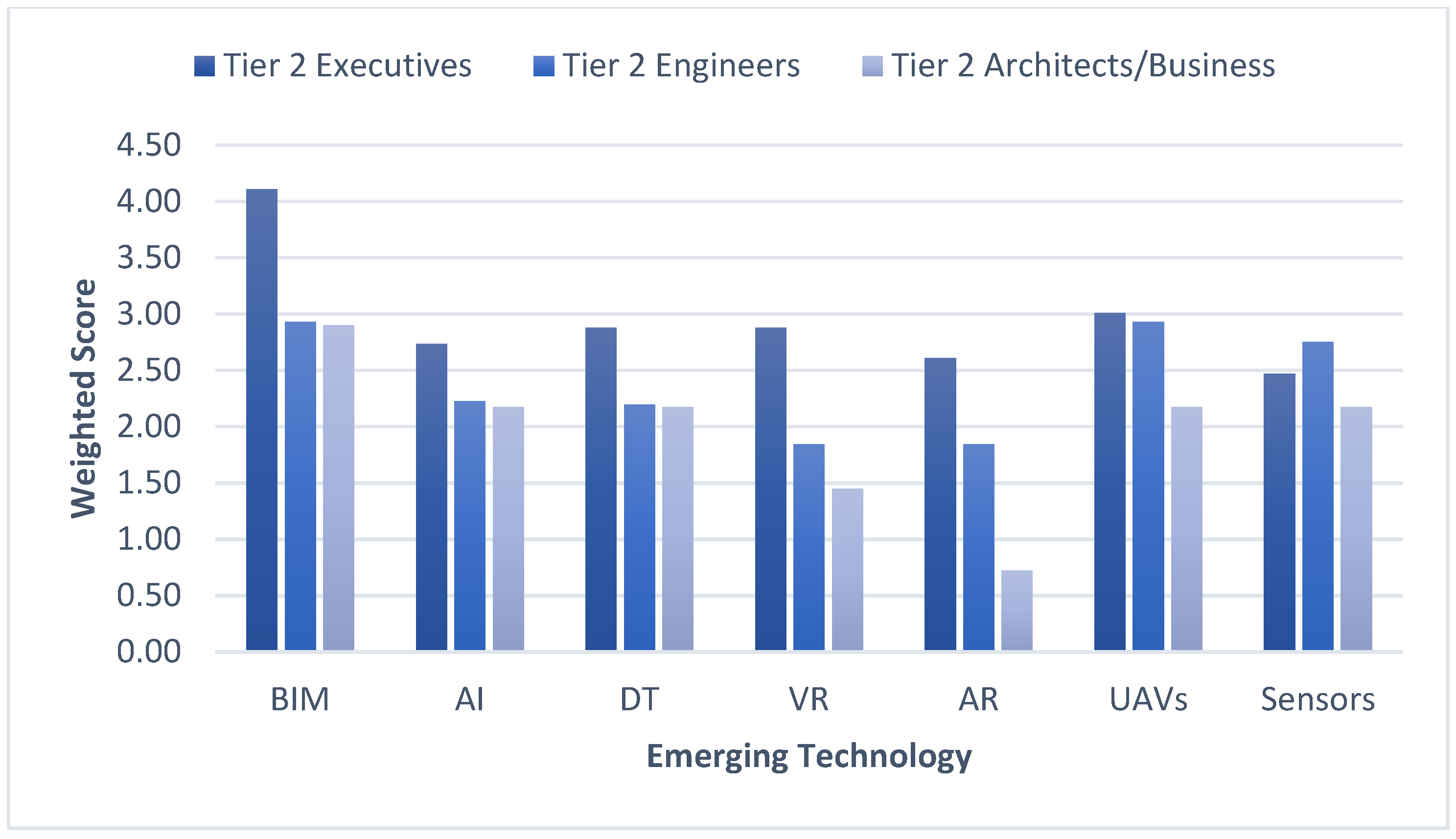

4.3. Discussion of Results

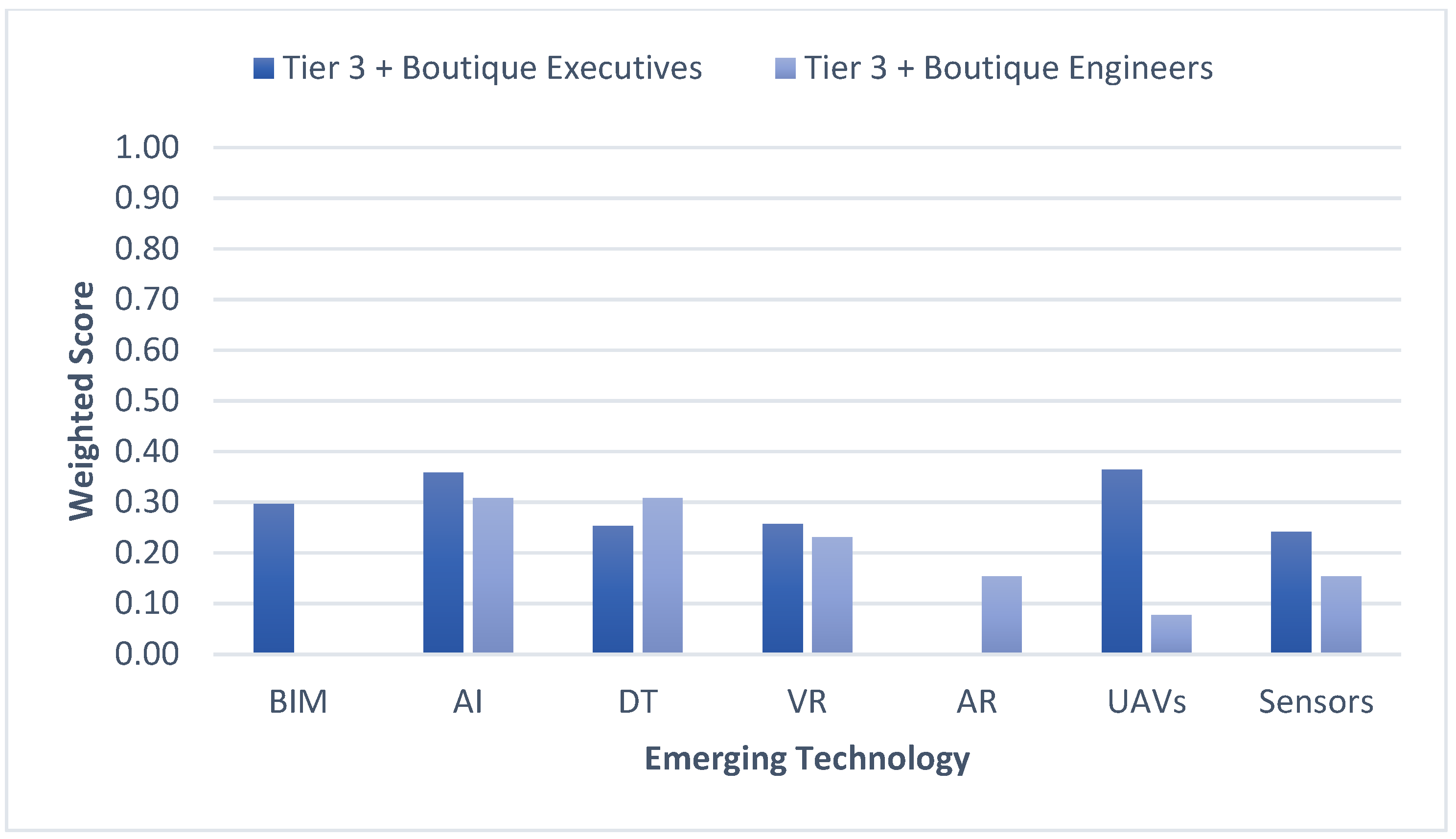

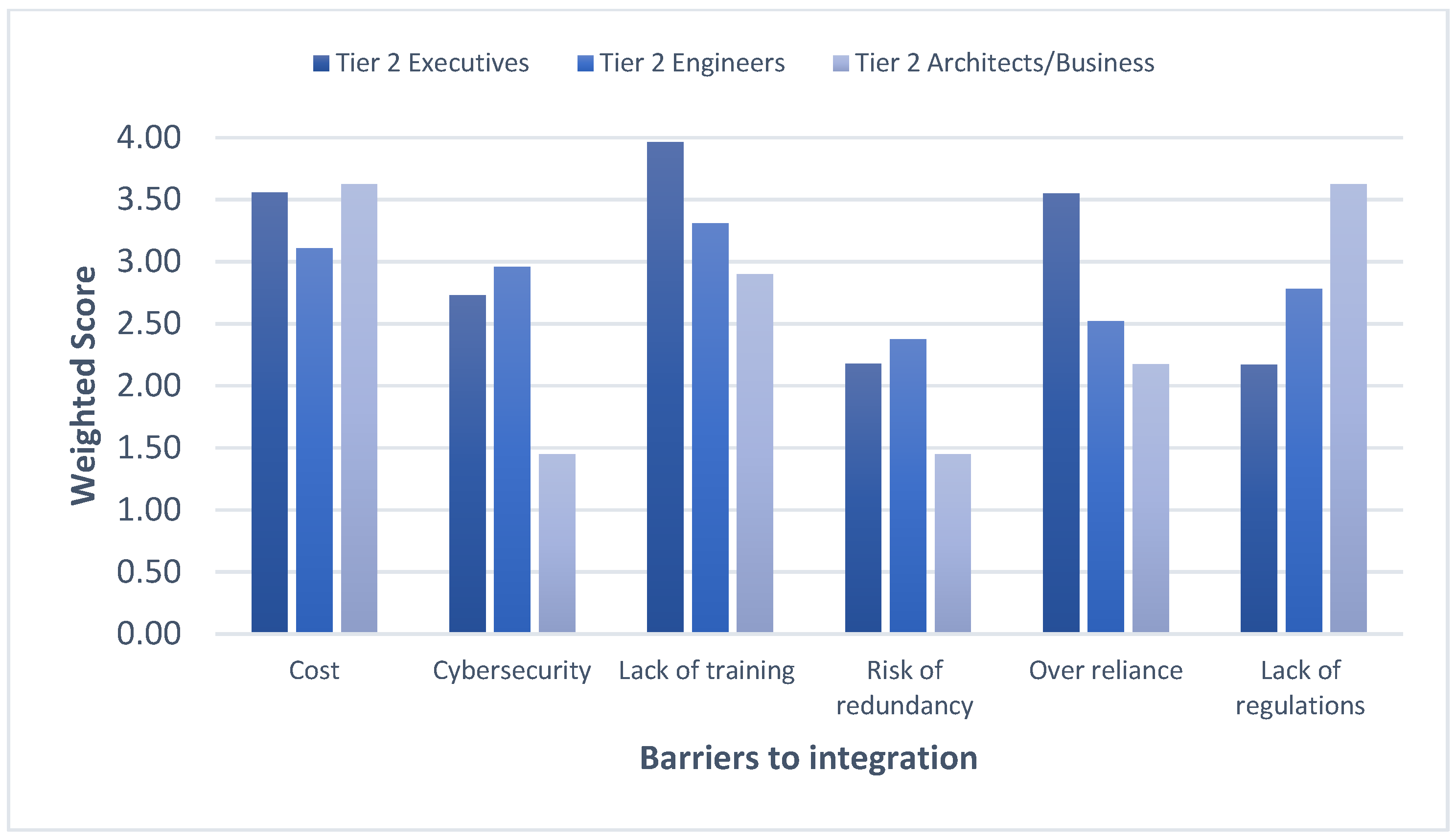

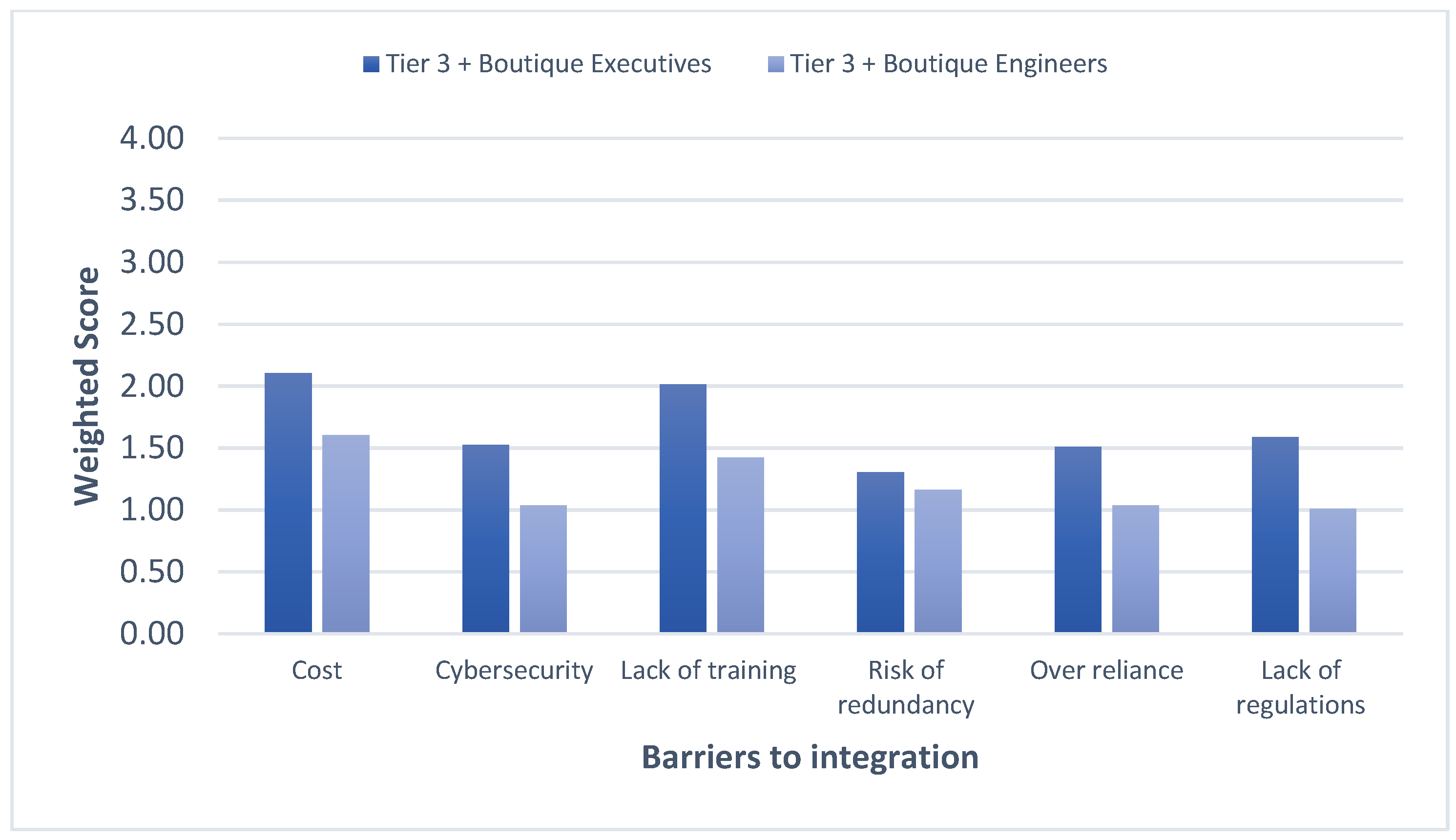

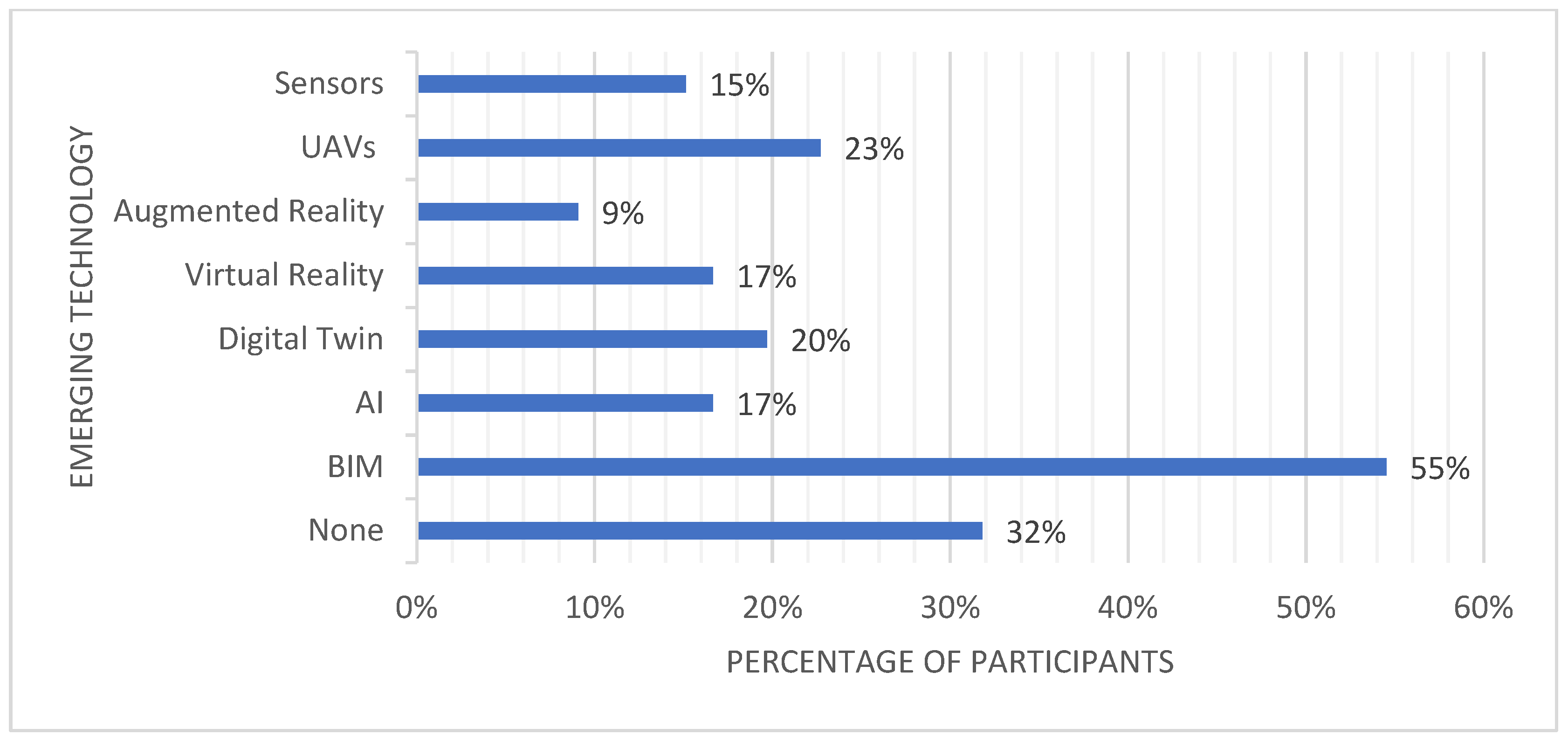

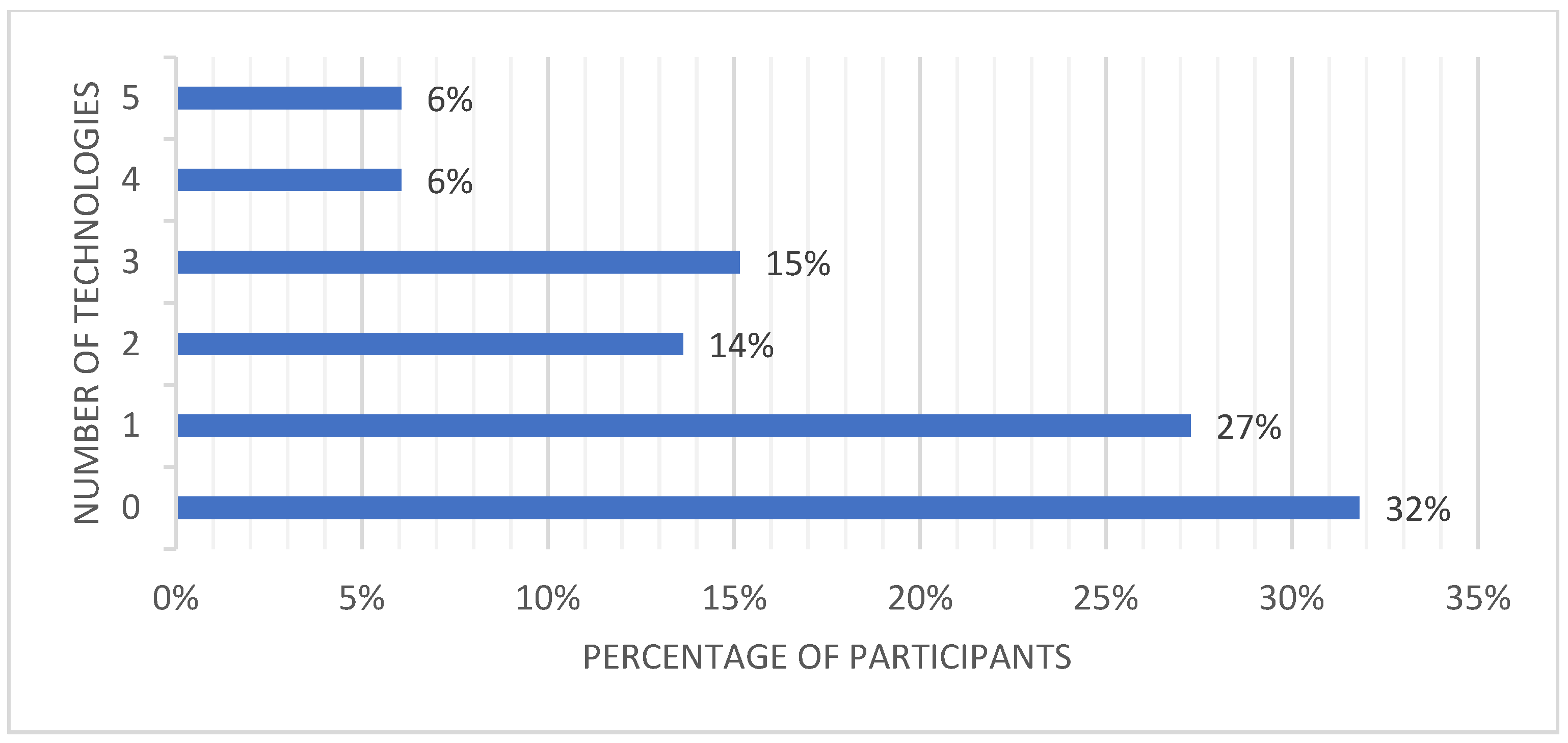

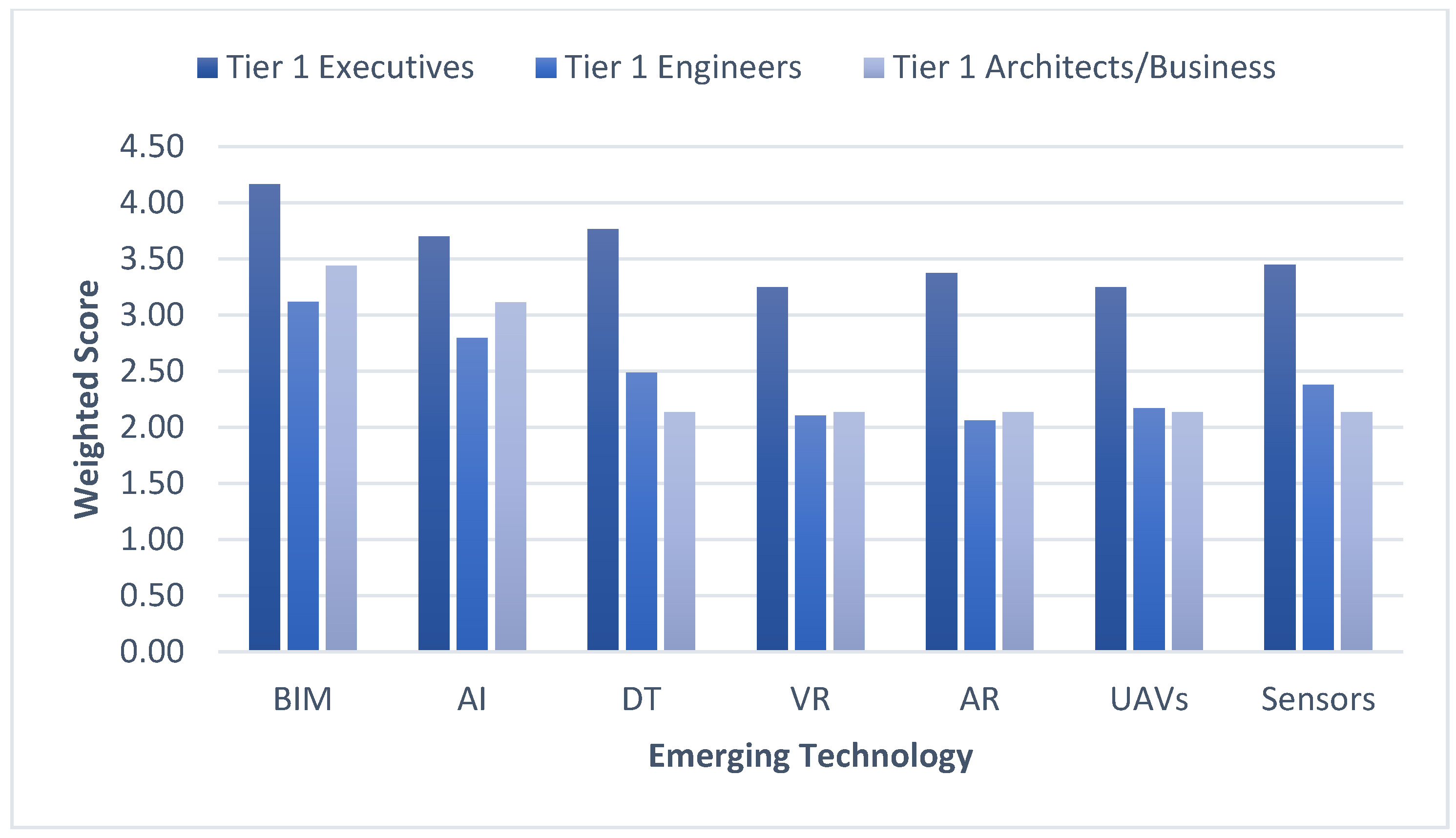

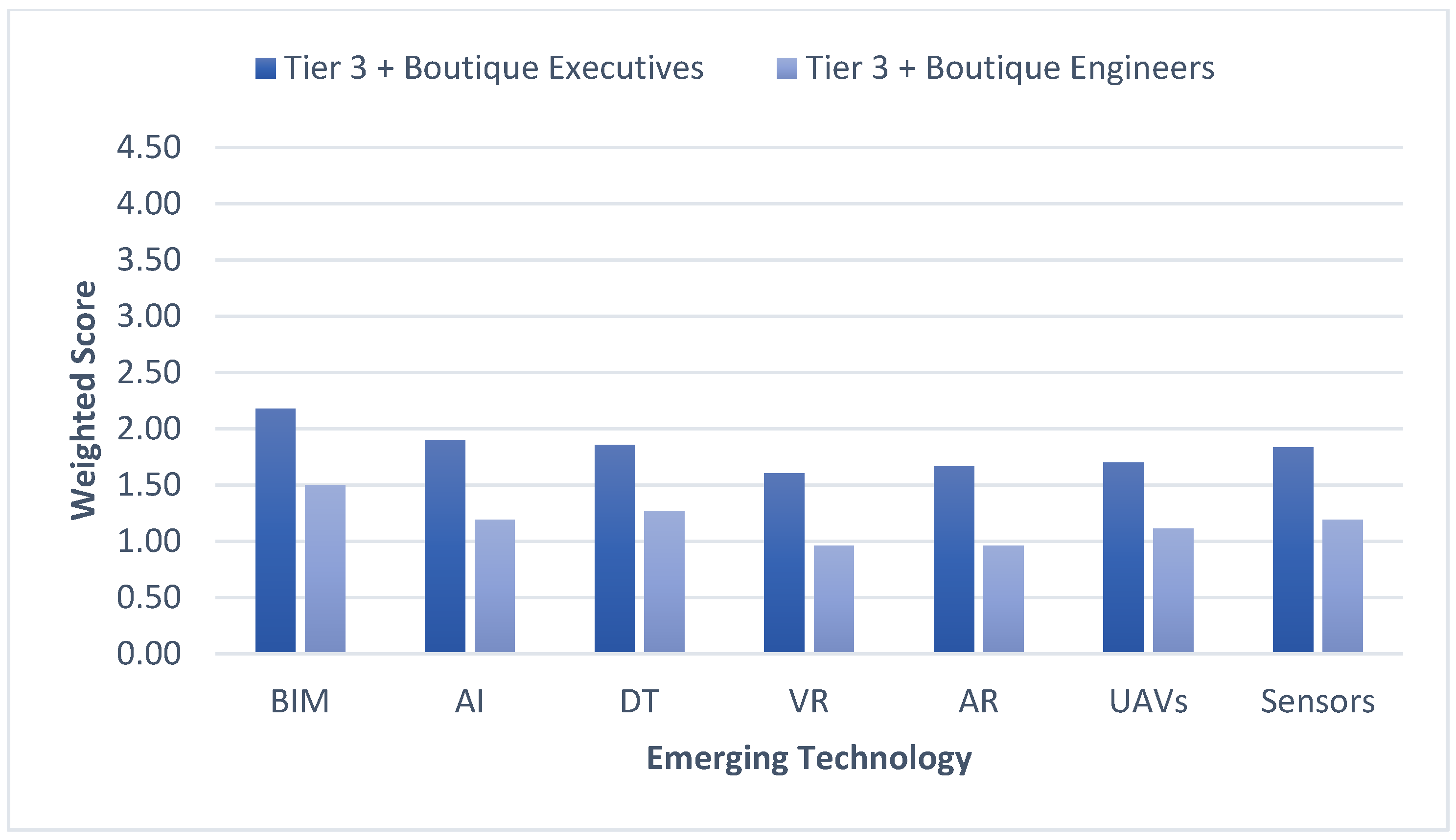

4.3.1. Current Integration of Emerging Technologies in Construction Projects

4.3.2. Integration of Emerging Technologies to Improve Construction Practices

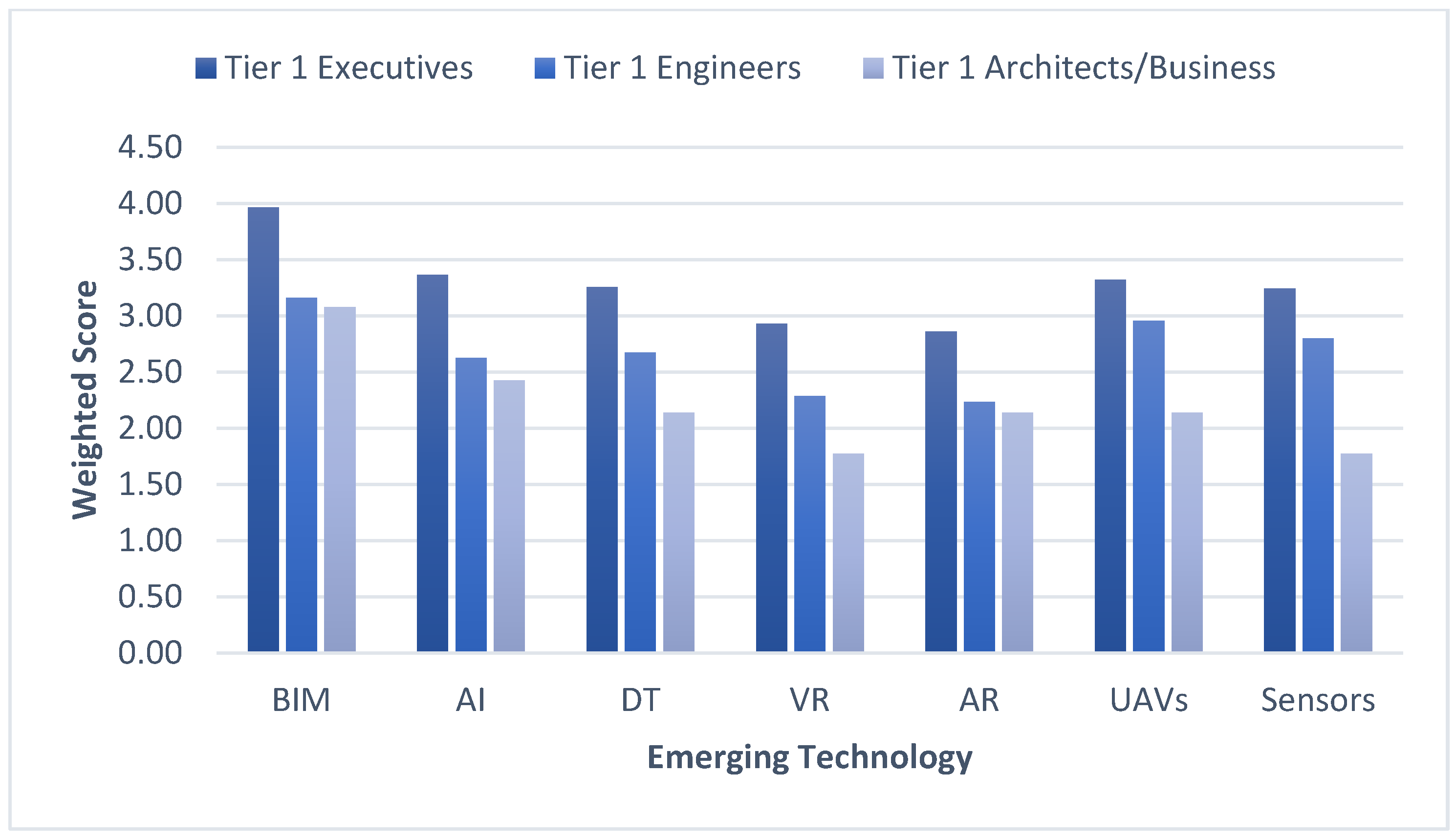

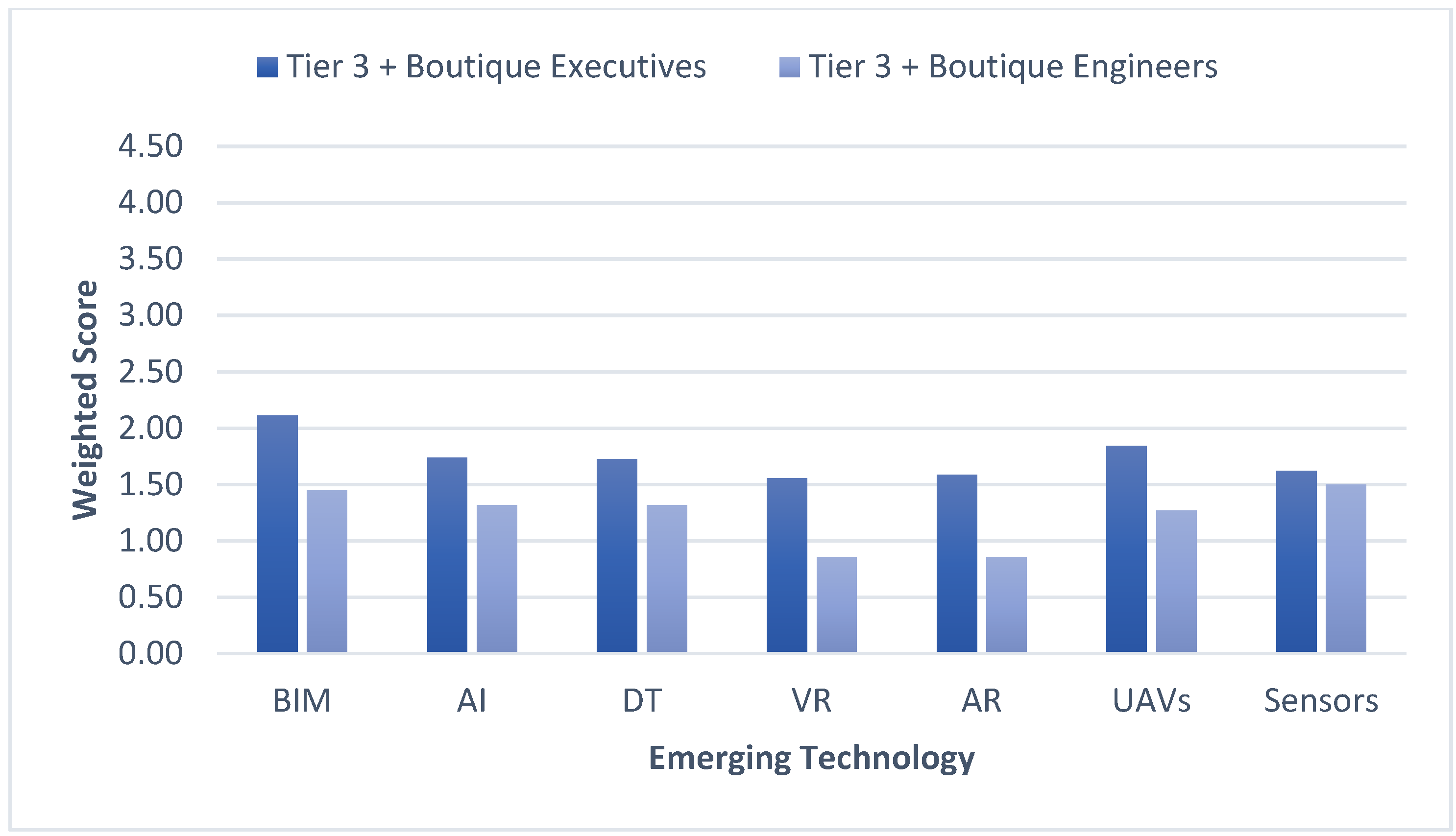

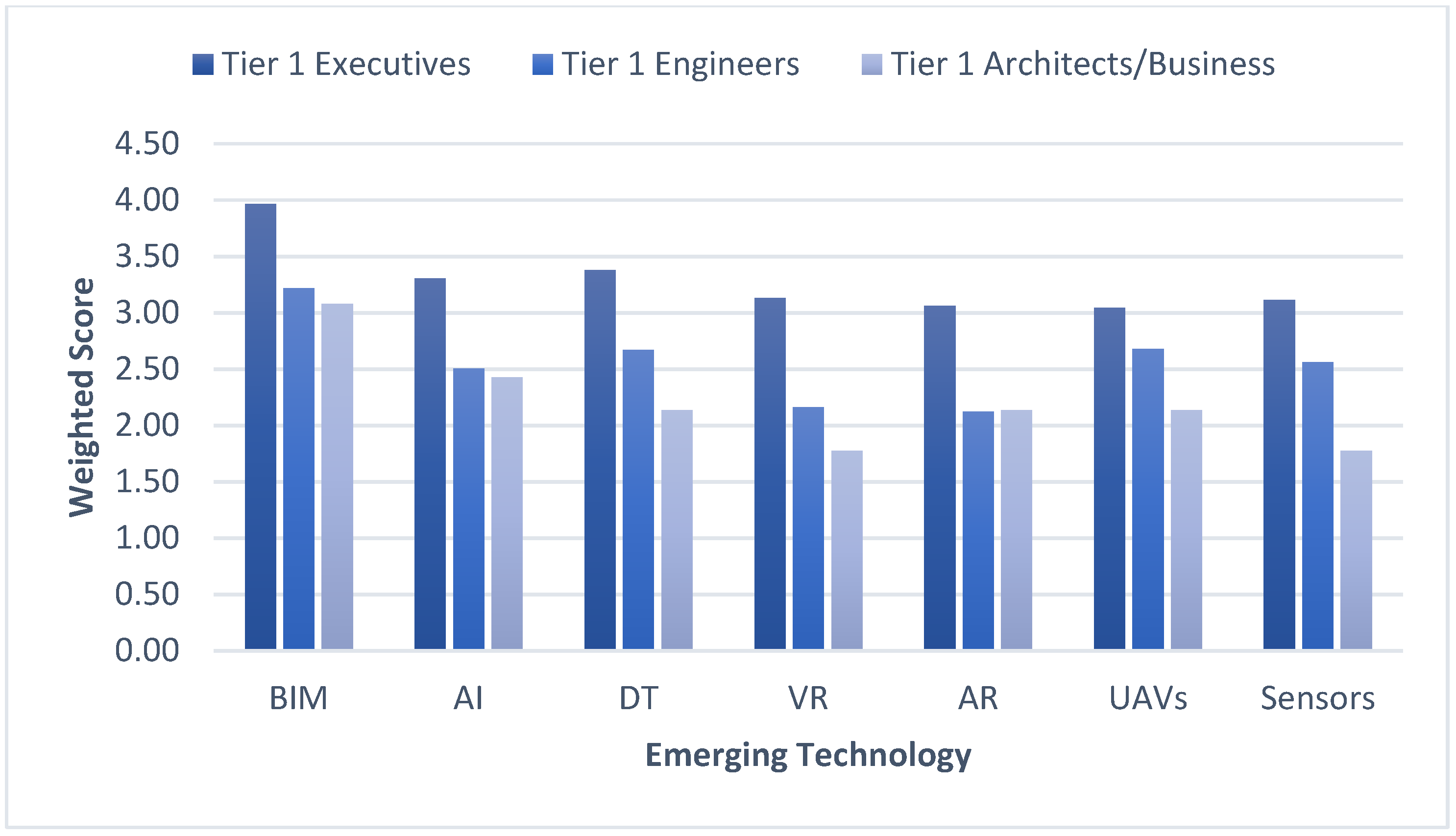

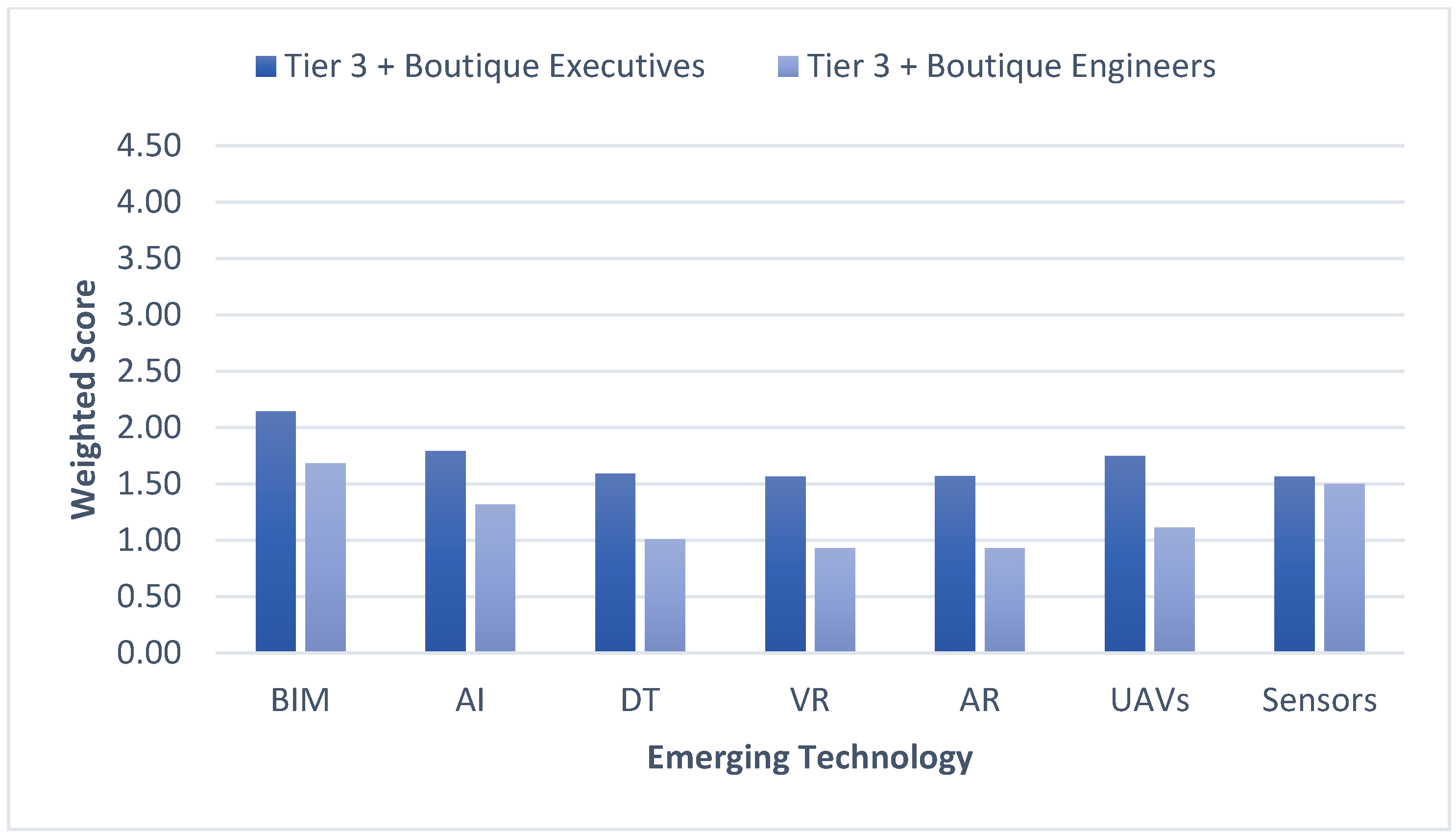

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reserve Bank of Australia. Composition of the Australian Economy Snapshot|Education. 21 March 2024. Available online: https://www.rba.gov.au/education/resources/snapshots/economy-composition-snapshot/ (accessed on 1 December 2024).

- BIS Oxford Economics. Australia ACA Construction Industry Productivity Report; BIS Oxford Economics: Sydney, Australia, 2023. [Google Scholar]

- Australian Constructors Association. Disrupt or Die: Australia’s Construction Industry is at a Crossroads. 2023. Available online: https://www.constructors.com.au/disrupt-or-die-australias-construction-industry-is-at-a-crossroads/ (accessed on 20 January 2025).

- Build Australia. Severe Shortage of Skilled Construction Workers Despite More Apprentices Than Ever. 2023. Available online: https://www.buildaustralia.com.au/news_article/severe-shortage-of-skilled-construction-workers-despite-more-apprentices-than-ever/ (accessed on 1 December 2024).

- Safe Work Australia. Key Work Health and Safety Statistics Australia, 2023. 2023. Available online: https://data.safeworkaustralia.gov.au/insights/key-whs-stats-2023 (accessed on 1 December 2024).

- Equity Economics. The Cost of Building Defects; Equity Economics: Sydney, Australia, 2023. [Google Scholar]

- Soltani, S.; Maxwell, D.; Rashidi, A. The State of Industry 4.0 in the Australian Construction Industry: An Examination of Industry and Academic Point of View. Buildings 2023, 13, 2324. [Google Scholar] [CrossRef]

- Osunsanmi, T.; Aigbavboa, C.; Oke, A. Construction 4.0: The Future of the Construction Industry in South Africa. Int. J. Civ. Environ. Eng. 2018, 12, 206–212. [Google Scholar]

- Talbi, A.; Souad, S.B. Industry 4.0 in construction organization of a mega projects: A bibliometric analysis. Procedia Comput. Sci. 2022, 204, 524–531. [Google Scholar] [CrossRef]

- Atuahene, B.; Kanjanabootra, S.; Gajendran, T. Benefits of Big Data Application Experienced in the Construction Industry: A Case of an Australian Construction Company. In Proceedings of the Conference: Proceedings of the 36th Annual Association of Rresearchers in Construction Management (ARCOM) Conference, London, UK, 7–8 September 2020. [Google Scholar]

- Phua, F.T.T. Construction management research at the individual level of analysis: Current status, gaps and future directions. Constr. Manag. Econ. 2013, 31, 167–179. [Google Scholar] [CrossRef]

- Rajendran, S.; Clarke, B.; Whelan, M.L. Contract Issues & Construction Safety Management. Prof. Saf. 2013, 58, 56–61. [Google Scholar]

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Bigham, G.F.; Adamtey, S.; Onsarigo, L.; Jha, N. Artificial Intelligence for Construction Safety: Mitigation of the Risk of Fall. In Intelligent Systems and Applications; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar]

- Perera, S.; Xiaohua, J.; Samaratunga, M.; Gunasekara, K. Drivers and barriers to digitalisation: A cross-analysis of the views of designers and builders in the construction industry. J. Inf. Technol. Constr. 2023, 28, 87–106. [Google Scholar] [CrossRef]

- Chen, X.; Chang-Richards, A.Y.; Yiu, T.W.; Ling, F.Y.Y.; Pelosi, A.; Yang, N. A multivariate regression analysis of barriers to digital technologies adoption in the construction industry. Eng. Constr. Archit. Manag. 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Obiso, J.-J.; Himang, C.; Ocampo, L.; Bongo, M.; Caballes, S.; Abellana, D.P.; Deocaris, C.; Padua, R.; Ancheta, R., Jr. Management of Industry 4.0—Reviewing intrinsic and extrinsic adoption drivers and barriers. Int. J. Technol. Manag. 2019, 81, 210. [Google Scholar] [CrossRef]

- Temel, S.; Durst, S. Knowledge risk prevention strategies for handling new technological innovations in small businesses. VINE J. Inf. Knowl. Manag. Syst. 2021, 51, 655–673. [Google Scholar] [CrossRef]

- Dubois, A.; Gadde, L.-E. The Construction Industry as a Loosely Coupled System: Implications for Productivity and Innovation. Constr. Manag. Econ. 2002, 20, 621–631. [Google Scholar] [CrossRef]

- Hardie, M.; Newell, G. Factors influencing technical innovation in construction SMEs: An Australian perspective. Eng. Constr. Archit. Manag. 2011, 18, 618–636. [Google Scholar] [CrossRef]

- Blayse, A.M.; Manley, K. Key influences on construction innovation. Constr. Innov. 2004, 4, 143–154. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Okpala, I.; Nnaji, C.; Karakhan, A.A. Utilizing Emerging Technologies for Construction Safety Risk Mitigation. Pract. Period. Struct. Des. Constr. 2020, 25, 04020002. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.F.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Lin, L.; Wu, S.; Kang, Y.; Sepasgozar, S. Exploring the Benefits and Limitations of Digital Twin Technology in Building Energy. Appl. Sci. 2023, 13, 8814. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, Y.; Wu, X.; Skibniewski, M.J. Artificial Intelligence in Construction Engineering and Management, 1st ed.; Lecture Notes in Cvil Engineering; Springer: Singapore, 2022; p. 263. [Google Scholar]

- Yaqot, M.; Menezes, B. The Good, the Bad, and the Ugly: Review on the Social Impacts of Unmanned Aerial Vehicles (UAVs); Springer International Publishing: Cham, Switzerland, 2022; pp. 413–422. [Google Scholar]

- Yap, J.B.H.; Skitmore, M.; Lam, C.G.Y.; Lee, W.P.; Lew, Y.L. Advanced technologies for enhanced construction safety management: Investigating Malaysian perspectives. Int. J. Constr. Manag. 2024, 24, 633–642. [Google Scholar] [CrossRef]

- Choi, B.; Hwang, S.; Lee, S. What drives construction workers’ acceptance of wearable technologies in the workplace?: Indoor localization and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Caffaro, F.; Micheletti Cremasco, M.; Bagagiolo, G.; Vigoroso, L.; Cavallo, E. Effectiveness of occupational safety and health training for migrant farmworkers: A scoping review. Public Health 2018, 160, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Polmear, M.; Simmons, D.R. Industry Perspective on the Role of Visualization Technology in Construction Safety Training. Int. J. Constr. Educ. Res. 2022, 18, 352–373. [Google Scholar] [CrossRef]

- Tender, M.; Couto, J.P.; Gibb, A.; Fuller, P.; Yeomans, S. Emerging Technologies for Health, Safety and Well-being in Construction Industry. In Industry 4.0 for the Built Environment: Methodologies, Technologies and Skills; Bolpagni, M., Gavina, R., Ribeiro, D., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 369–390. [Google Scholar]

- Lingard, H.; Pink, S.; Harley, J.; Edirisinghe, R. Looking and learning: Using participatory video to improve health and safety in the construction industry. Constr. Manag. Econ. 2015, 33, 740–751. [Google Scholar] [CrossRef]

- Stewart, R.A.; Mohamed, S.; Marosszeky, M. An empirical investigation into the link between information technology implementation barriers and coping strategies in the Australian construction industry. Constr. Innov. 2004, 4, 155–171. [Google Scholar] [CrossRef]

- Schneiderova-Heralova, R. Importance of life cycle costing for construction projects. Eng. Rural. Dev. 2018, 17, 1223–1227. [Google Scholar]

- Uchenna Sampson, I.; Mohamad, S.; Mat Dzahir, M.A.; Asibuodu, U.; Ajayi, O. Acceptance of contemporary technologies for cost management of construction projects. J. Inf. Technol. Constr. 2022, 27, 864–883. [Google Scholar] [CrossRef]

- Vasista, T.; Aboneh, A. Benefits, Barriers and Applications of Information Communication Technology in Construction Industry: A Contemporary Study. Int. J. Eng. Technol. UAE 2018, 7, 492–499. [Google Scholar] [CrossRef]

- Kulkarni, S.B.; Mhetar, G. Cost Control Technique Using Building Information Modeling (BIM) For a Residential Building. Int. J. Eng. Res. Technol. 2017, 10, 324–330. [Google Scholar]

- BigRentz Inc. 6 Ways Augmented Reality Can Change Construction; BigRentz Inc.: Irvine, CA, USA, 2019. [Google Scholar]

- Gondia, A.; Siam, A.; El-Dakhakhni, W.; Nassar Ayman, H. Machine Learning Algorithms for Construction Projects Delay Risk Prediction. J. Constr. Eng. Manag. 2020, 146, 04019085. [Google Scholar] [CrossRef]

- Rivera, A.; Le, N.; Kashiwagi, J.; Kashiwagi, D. Identifying the Global Performance of the Construction Industry. J. Adv. Perform. Inf. Value 2016, 8, 7. [Google Scholar] [CrossRef]

- Assaf, S.A.; Al-Hejji, S. Causes of delay in large construction projects. Int. J. Proj. Manag. 2006, 24, 349–357. [Google Scholar] [CrossRef]

- Arcadis. 2021 Global Construction Disputes Report: The Road to Early Resolution; Arcadis: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Btoush, M.; Harun, A.T. Minimizing delays in the Jordanian construction industry by adopting BIM technology. IOP Conf. Ser. Mater. Sci. Eng. 2017, 271, 012041. [Google Scholar] [CrossRef]

- Gurgun, A.P.; Koc, K.; Kunkcu, H. Exploring the adoption of technology against delays in construction projects. Eng. Constr. Archit. Manag. 2024, 31, 1222–1253. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Heidari, A.; Peyvastehgar, Y.; Amanzadegan, M. A systematic review of the BIM in construction: From smart building management to interoperability of BIM & AI. Archit. Sci. Rev. 2024, 67, 237–254. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Liu, Y.; Yu, F. Application of Emerging Technologies to Improve Construction Performance. Buildings 2023, 13, 1147. [Google Scholar] [CrossRef]

- Yıldırım, M.; Giran, O. Digital Twin in Construction. In Digital Twin Driven Intelligent Systems and Emerging Metaverse; Karaarslan, E., Aydin, Ö., Cali, Ü., Challenger, M., Eds.; Springer Nature: Singapore, 2023; pp. 249–267. [Google Scholar]

- Sepasgozar, S.M.E.; Khan, A.A.; Smith, K.; Romero, J.G.; Shen, X.; Shirowzhan, S.; Li, H.; Tahmasebinia, F. BIM and Digital Twin for Developing Convergence Technologies as Future of Digital Construction. Buildings 2023, 13, 441. [Google Scholar] [CrossRef]

- Blanco, J.L.; Fuchs, S.; Parsons, M.; Ribeirinho, M.J. Artificial intelligence: Construction technology’s next frontier. Build. Econ. 2018, 7–13. [Google Scholar]

- Koretsky, M.D.; Magana, A.J. Using Technology to Enhance Learning and Engagement in Engineering. Adv. Eng. Educ. 2019, 53. [Google Scholar]

- Ahmed, S. Barriers to Implementation of Building Information Modeling (BIM) to the Construction Industry: A Review. J. Civ. Eng. Constr. 2018, 7, 107–113. [Google Scholar] [CrossRef]

- Suprun, E.; Perisic, N.; Stewart, R.; Mostafa, S. Preparing the Next Generation of Civil Engineering Graduates: Identifying and Combating the Digital Skills Gap. In Proceedings of the 30th Annual Conference for the Australasian Association for Engineering Education (AAEE 2019): Educators Becoming Agents of Change: Innovate, Integrate, Motivate, Brisbane, Australia, 8–11 December 2019. [Google Scholar]

- Elzomor, M.; Pradhananga, P. Scaling Construction Autonomous Technologies and Robotics within the Construction Industry; 2021. [Google Scholar]

- Laguador, J.; Chavez-Prinsipe, N.; Castro, E. Employability Skill Development Needs of Engineering Students and Employers’ Feedback on Their Internship Performance. Univers. J. Educ. Res. 2020, 8, 3097–3108. [Google Scholar] [CrossRef]

- Zaheer, M.I.; Ajayi, S.O.; Zulu, S.L.; Oyegoke, A.; Kazemi, H. Understanding the key competencies of market-ready building surveying graduates from employers’ perspectives. J. Eng. Des. Technol. 2021, 19, 291–314. [Google Scholar] [CrossRef]

- Broo, D.G.; Schooling, J. Digital twins in infrastructure: Definitions, current practices, challenges and strategies. Int. J. Constr. Manag. 2023, 23, 1254–1263. [Google Scholar] [CrossRef]

- Fitriani, H.; Ajayi, S. Preparing Indonesian civil engineering graduates for the world of work. Ind. High. Educ. 2022, 36, 471–487. [Google Scholar] [CrossRef]

- Jadallah, H.; Friedland, C.J.; Nahmens, I.; Pecquet, C.; Berryman, C.; Zhu, Y. Educational Theory-Integrated Construction Industry Training: State-of-the-Art Review. Front. Built Environ. 2021, 7, 635978. [Google Scholar] [CrossRef]

- Kazaz, A.; Manisali, E.; Ulubeyli, S. Effect of basic motivational factors on construction workforce productivity in Turkey. J. Civ. Eng. Manag. 2008, 14, 95–106. [Google Scholar] [CrossRef]

- Department of Employment and Workplace Relations. Digital Capability for Workforce Skills—Final Report 2022; Australian Government: Canberra, Australia, 2022.

- RMIT University. Inquiry into the Digital Transformation of Workplaces. In RMIT Submission to House Standing Committee on Employment, Education and Training; RMIT University: Melbourne, Australia, 2024. [Google Scholar]

- Australian Workforce and Productivity Agency. Future focus: Australia’s Skills and Workforce Development Needs: A Discussion Paper for the 2012 National Workforce Development Strategy; Australian Workforce and Productivity Agency: Melbourne, Australia, 2012. [Google Scholar]

- Detsimas, N.; Coffey, V.; Sadiqi, Z.; Li, M. Workplace training and generic and technical skill development in the Australian construction industry. J. Manag. Dev. 2016, 35, 486–504. [Google Scholar] [CrossRef]

- Francis, V.; Paton-Cole, V. Innovation and Immersive Vocational Education Training for Construction Site Supervisors. In Proceedings of the 11th International Conference on Construction in the 21st Century, London, UK, 9–11 September 2019; Springer: Berlin/Heidelberg, Germany, 2021; pp. 179–183. [Google Scholar]

- Department of Education and Training. Victorian Employer Skills and Training Survey 2017. 2017. Available online: https://www.education.vic.gov.au/Documents/training/employers/industry/SkillsandTrainingEmployerSurvey2017InfographicTransport.pdf (accessed on 1 December 2024).

- Digital Transformation Expert Panel. The Learning Country: Digital Transformation Skills Strategy; Australian Industry Standards: Sydney, Australia, 2021; p. 82. [Google Scholar]

- Madanayake, U.; Young, B.; Seidu, R.D. Upeksha Madanayake; Bert Ediale Young; Seidu, R.D. Investigating the Skills and Knowledge Requirements for IOT implementation in Construction. In Proceedings of the 5th NA International Conference on Industrial Engineering and Operations Management, Detroit, MI, USA, 10–14 August 2020. [Google Scholar]

- Solis, F.A.M.; Howe, J.; O’Brien, W.J. Integration of Information Technologies into Field Managers’ Activities: A Cognitive Perspective. J. Manag. Eng. 2015, 31, A4014001. [Google Scholar] [CrossRef]

- Olanipekun, A.O.; Sutrisna, M. Facilitating Digital Transformation in Construction—A Systematic Review of the Current State of the Art. Front. Built Environ. 2021, 7, 660758. [Google Scholar] [CrossRef]

- Douglas Omoregie Aghimien; Clinton Ohis Aigbavboa; Oke, A.E. Critical success factors for digital partnering of construction organisations—A Delphi study. Eng. Constr. Archit. Manag. 2020, 27, 3171–3188. [Google Scholar] [CrossRef]

- Mueller, A.; Segal, D. Structured Versus Semistructured Versus Unstructured Interviews; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Brinkmann, S. The Oxford Handbook of Qualitative Research; Leavy, P., Ed.; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- DeJonckheere, M.; Vaughn, L.M. Semistructured interviewing in primary care research: A balance of relationship and rigour. Fam. Med. Community Health 2019, 7, e000057. [Google Scholar] [CrossRef]

- Kakilla, C. Strengths and Weaknesses of Semi-Structured Interviews in Qualitative Research: A Critical Essay. 2021; preprint. [Google Scholar]

- McBride, K.A.; MacMillan, F.; George, E.S.; Steiner, G.Z. The Use of Mixed Methods in Research. In Handbook of Research Methods in Health Social Sciences; Liamputtong, P., Ed.; Springer: Singapore, 2019; pp. 695–713. [Google Scholar]

- Joshi, A.; Kale, S.; Chandel, S.; Pal, D.K. Likert scale: Explored and explained. Br. J. Appl. Sci. Technol. 2015, 7, 396–403. [Google Scholar] [CrossRef]

- Taylor-Powell, E.; Hermann, C. Collecting Evaluation Data: Surveys; University of Wisconsin-Extension: Madison, WI, USA, 2000. [Google Scholar]

- Dillman, D.A.; Smyth, J.D.; Christian, L.M. Internet, Phone, Mail, and Mixed-Mode Surveys: The Tailored Design Method; John Wiley & Sons, Inc.: Newark, NJ, USA, 2014. [Google Scholar]

- Lee, R.M.; Fielding, N.G.; Blank, G. The SAGE Handbook of Online Research Methods; SAGE Publications Ltd.: London, UK, 2017. [Google Scholar]

- Wright, K.B. Researching Internet-Based Populations: Advantages and Disadvantages of Online Survey Research, Online Questionnaire Authoring Software Packages, and Web Survey Services. J. Comput.-Mediat. Commun. 2017, 10, JCMC1034. [Google Scholar] [CrossRef]

- Wu, M.-J.; Zhao, K.; Fils-Aime, F. Response rates of online surveys in published research: A meta-analysis. Comput. Hum. Behav. Rep. 2022, 7, 100206. [Google Scholar] [CrossRef]

- Antoun, C.; Couper, M.P.; Conrad, F.G. Effects of Mobile Versus PC Web on Survey Response Quality: A Crossover Experiment in a Probability Web Panel. Public Opin. Q. 2017, 81, 280–306. [Google Scholar] [CrossRef]

- Kusmaryono, I.; Wijayanti, D.; Risqi, H. Number of Response Options, Reliability, Validity, and Potential Bias in the Use of the Likert Scale Education and Social Science Research: A Literature Review. Başlık 2022, 8, 625–637. [Google Scholar] [CrossRef]

- Microsoft Forms Team. Create and Analyze Forms and Quizzes from Mobile; Microsoft: Redmond, WA, USA, 2022. [Google Scholar]

- Revilla, M.; Couper, M.P.; Ochoa, C. Willingness of Online Panelists to Perform Additional Tasks. Methods Data Anal. A J. Quant. Methods Surv. Methodol. 2019, 2019, 13. [Google Scholar]

- Bekele, W.; Yohannes, F. Sample Size for Interview in Qualitative Research in Social Sciences: A Guide to Novice Researchers. Res. Educ. Policy Manag. 2022, 4, 42–50. [Google Scholar] [CrossRef]

- Trigueros-Cervantes, C.; Rivera-García, E.; Rivera-Trigueros, I. The Use of NVivo in the Different Stages of Qualitative Research; Springer International Publishing: Cham, Switzerland, 2018; pp. 381–392. [Google Scholar]

- Kuckartz, U. Qualitative Text Analysis: A Systematic Approach. In Compendium for Early Career Researchers in Mathematics Education; Kaiser, G., Presmeg, N., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 181–197. [Google Scholar]

- Fugard, A.; Potts, H. Thematic Analysis; Springer: London, UK, 2019. [Google Scholar]

- Saaty, T.L. How to make a decision: The analytic hierarchy process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Brunelli, M. Priority vector and consistency. In Introduction to the Analytic Hierarchy Process; International Series in Operations Research & Management Science, v.175; Springer International Publishing: Cham, Switzerland, 2015; pp. 17–31. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process, 2nd ed.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Saaty, T.; Vargas, L.; St, C. The Analytic Hierarchy Process; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Leal, J.E. AHP-express: A simplified version of the analytical hierarchy process method. MethodsX 2020, 7, 100748. [Google Scholar] [CrossRef] [PubMed]

- Podvezko, V. Application of AHP technique. J. Bus. Econ. Manag. 2009, 10, 181–189. [Google Scholar] [CrossRef]

- Vafaei, N.; Ribeiro, R.A.; Camarinha-Matos, L.M. Normalization Techniques for Multi-Criteria Decision Making: Analytical Hierarchy Process Case Study; Springer International Publishing: Cham, Switzerland, 2016; pp. 261–269. [Google Scholar]

- Mu, E.; Pereyra-Rojas, M. Understanding the Analytic Hierarchy Process. In Practical Decision Making: An Introduction to the Analytic Hierarchy Process (AHP) Using Super Decisions V2; Springer International Publishing: Cham, Switzerland, 2017; pp. 7–22. [Google Scholar]

- Moore, H.F.; Gheisari, M. A Review of Virtual and Mixed Reality Applications in Construction Safety Literature. Safety 2019, 5, 51. [Google Scholar] [CrossRef]

- Afolabi, A.O.; Nnaji, C.; Okoro, C. Immersive Technology Implementation in the Construction Industry: Modeling Paths of Risk. Buildings 2022, 12, 363. [Google Scholar] [CrossRef]

- Boje, C.; Guerriero, A.; Kubicki, S.; Rezgui, Y. Towards a semantic Construction Digital Twin: Directions for future research. Autom. Constr. 2020, 114, 103179. [Google Scholar] [CrossRef]

| 1.00 | 3.00 | 0.50 | 4.00 | |

| 0.33 | 1.00 | 0.25 | 6.00 | |

| 2.00 | 4.00 | 1.00 | 9.00 | |

| 0.25 | 0.17 | 0.11 | 1.00 | |

| Total | 3.58 | 8.17 | 1.86 | 20.00 |

| Criteria 1 | Criteria 2 | More Important Criteria | Reasoning |

|---|---|---|---|

| Position | Experience | Position | Position of employment is considered more important as individuals in higher executive roles, such as CEOs, are required to stay informed about the adoption of new technologies. While individuals with over 20 years of experience may possess substantial knowledge, if their role has remained limited to lower, more confined positions, they may lack a broad exposure or interest in learning about newer technologies. |

| Tier | Position | Tier | Tier is more important than position as the target audience for the research and expert system being created is Tier 1 and 2 companies. The responses of participants from these Tiers are more valuable in understanding the current state of industry practices. |

| Range | Tier | Tier | Tier is more important than occupation as the target audience for the research and expert system being created is Tier 1 and 2 companies. Further, Tier 1 and 2 firms are at the forefront of technological adoption, so their insights are more relevant to the study, regardless of their geographical scope. |

| Criteria | Weight of Criteria |

|---|---|

| Position () | 0.279 |

| Experience () | 0.162 |

| Tier () | 0.509 |

| Range () | 0.050 |

| Criteria | Alternatives | Weight of Alternatives |

|---|---|---|

| Position of Employment | CEO/Executive | 0.184 |

| Principal Engineer | 0.184 | |

| Construction/Project Manager | 0.184 | |

| Digital Services Specialist | 0.184 | |

| Engineer/Consulting Engineer | 0.097 | |

| Site Engineer | 0.097 | |

| Business/Legal Management | 0.035 | |

| Architect | 0.035 | |

| Years of Experience | 0–2 years | 0.082 |

| 2–5 years | 0.082 | |

| 5–10 years | 0.149 | |

| 10–15 years | 0.149 | |

| 15–20 years | 0.269 | |

| 20+ years | 0.269 | |

| Tier of Employment Firm | Tier 1 | 0.425 |

| Tier 2 | 0.425 | |

| Tier 3 | 0.094 | |

| Boutique | 0.056 | |

| Range | Yes | 1.000 |

| No | 0.000 |

| Group 1 (‘Executives’) | Group 2 (‘Engineers’) | Group 3 (‘Architects/Business’) |

|---|---|---|

| Position of Employment | CEO/Executive | 0.184 |

| Principal Engineer | 0.184 | |

| Construction/Project Manager | 0.184 | |

| Digital Services Specialist | 0.184 | |

| Engineer/Consulting Engineer | 0.097 | |

| Site Engineer | 0.097 | |

| Business/Legal Management | 0.035 | |

| Architect | 0.035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaaya, M.L.; Sarkis, L.M.; Tahmasebinia, F. Integration of Emerging Technologies with Construction Practices in Australia. Buildings 2025, 15, 396. https://doi.org/10.3390/buildings15030396

Chaaya ML, Sarkis LM, Tahmasebinia F. Integration of Emerging Technologies with Construction Practices in Australia. Buildings. 2025; 15(3):396. https://doi.org/10.3390/buildings15030396

Chicago/Turabian StyleChaaya, Mia L., Lucia M. Sarkis, and Faham Tahmasebinia. 2025. "Integration of Emerging Technologies with Construction Practices in Australia" Buildings 15, no. 3: 396. https://doi.org/10.3390/buildings15030396

APA StyleChaaya, M. L., Sarkis, L. M., & Tahmasebinia, F. (2025). Integration of Emerging Technologies with Construction Practices in Australia. Buildings, 15(3), 396. https://doi.org/10.3390/buildings15030396