Renewable Energy Integration and Energy Efficiency Enhancement for a Net-Zero-Carbon Commercial Building

Abstract

1. Introduction

- Section 2 provides a detailed description of the proposed building and outlines the assumptions used for dynamic modelling;

- Section 3 outlines the methodology employed in the dynamic modelling, encompassing weather data, thermal comfort settings, building materials, the HVAC system, PV panels, and wind turbines;

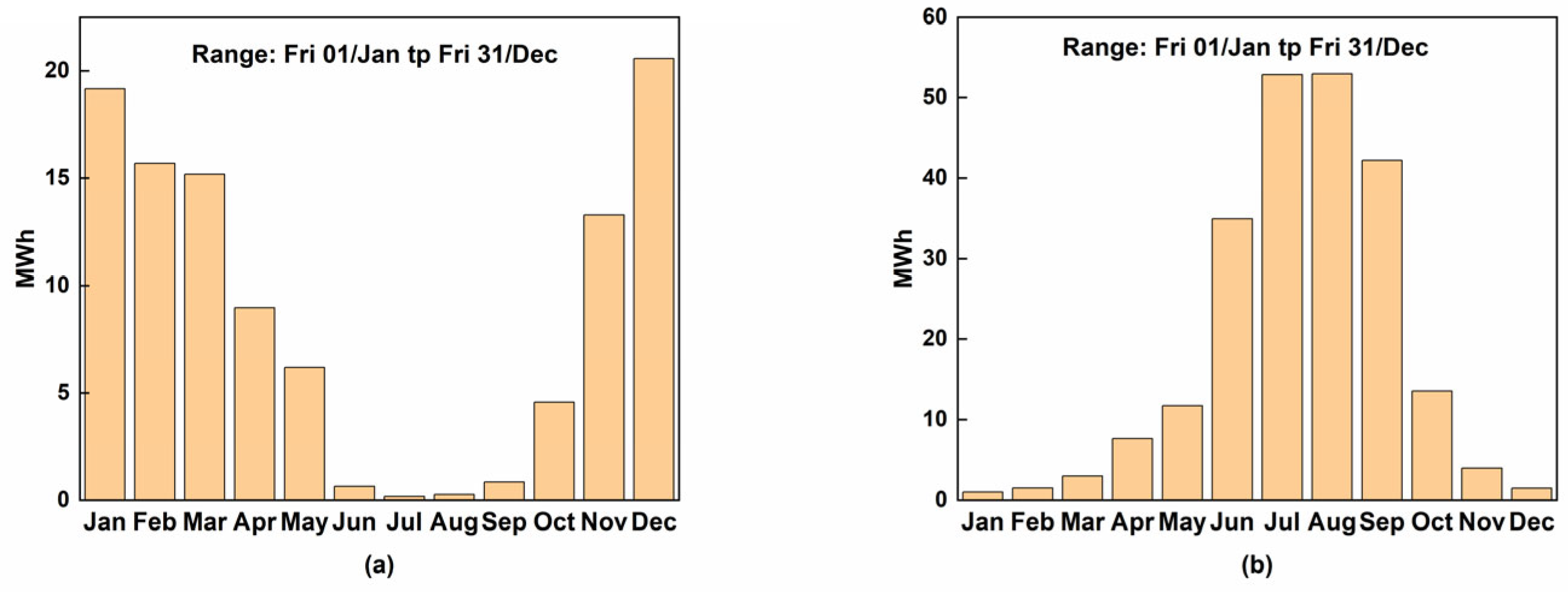

- Section 4 presents the results of the simulations, analysing solar energy, CO2 emissions, the annual space heating and cooling demand, the annual electricity demand, wind-generated electricity, and PV-generated electricity. Additionally, a comparison between the total electricity demand and on-site electricity generation is conducted;

- Section 5 summarises the key outcomes achieved from the dynamic simulations, highlighting the critical findings and insights derived from the analysis.

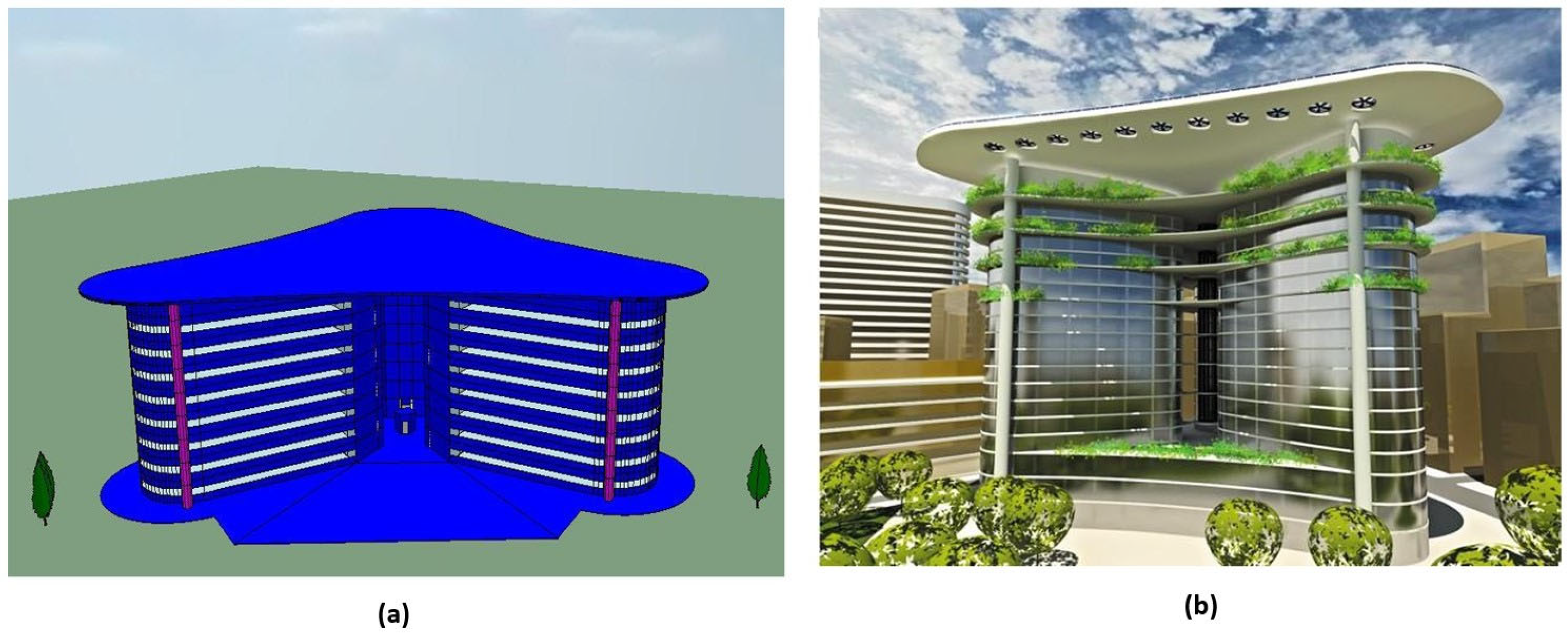

2. Overview of the Building and Assumptions

2.1. Description of the Building

2.2. Design Assumptions

- The selection of a location is explained in detail in Section 3.1. Though the location of the building eventually selected is outside of the UK, the design standards are taken from CIBSE Guides, UK National Calculation Methodology (NCM) templates, The Building Regulations 2010 Conservation of fuel and power Approved Document Part L Volume 2—Buildings other than dwellings, The Building Regulations 2010 Ventilation Approved Document Part F Volume 2—Buildings other than dwellings, the HM Government Non-Domestic Building Services Compliance Guide, etc;

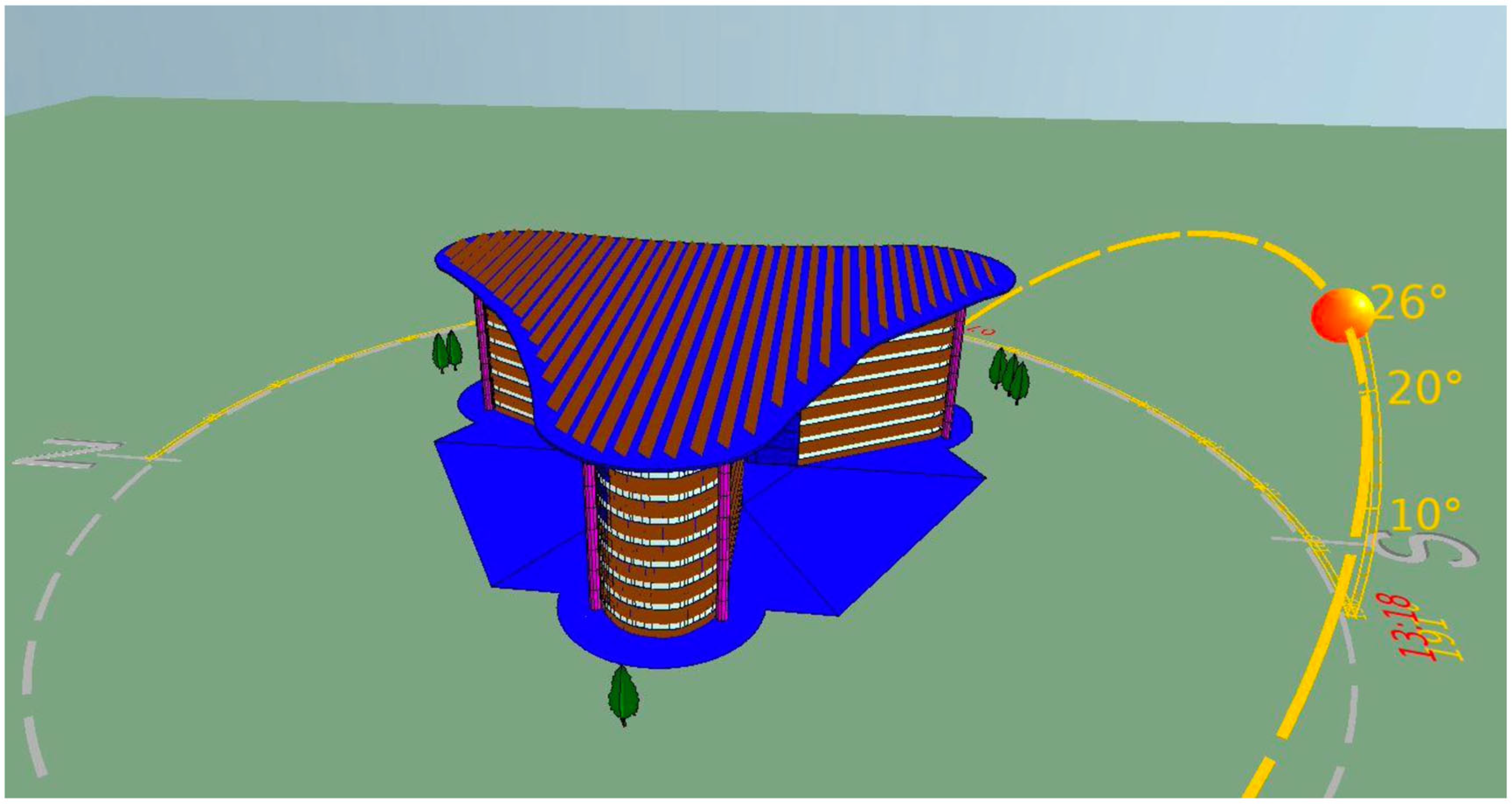

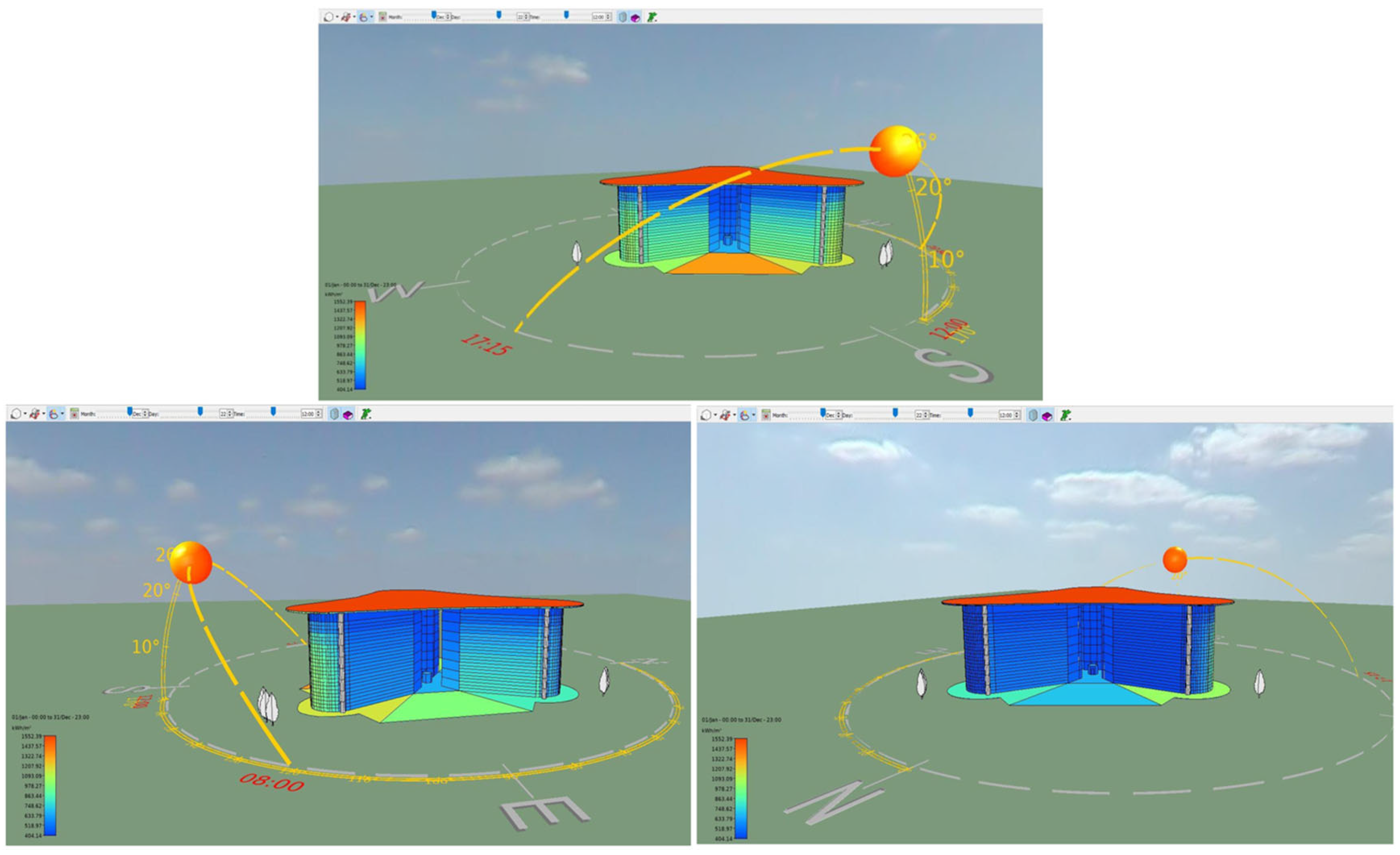

- As the building is still not built and is in the conceptual stage, the orientation of the building is assumed to be as illustrated in Figure 2;

- No adjacent/shading buildings are considered for the analysis of the Clover building model, since the goal of this study was to establish a baseline performance for the proposed design;

- Domestic hot water is not considered in this research due to its relatively small contribution to the overall energy demand in commercial buildings, unlike in residential buildings, where domestic hot water typically accounts for a significant portion of energy use.

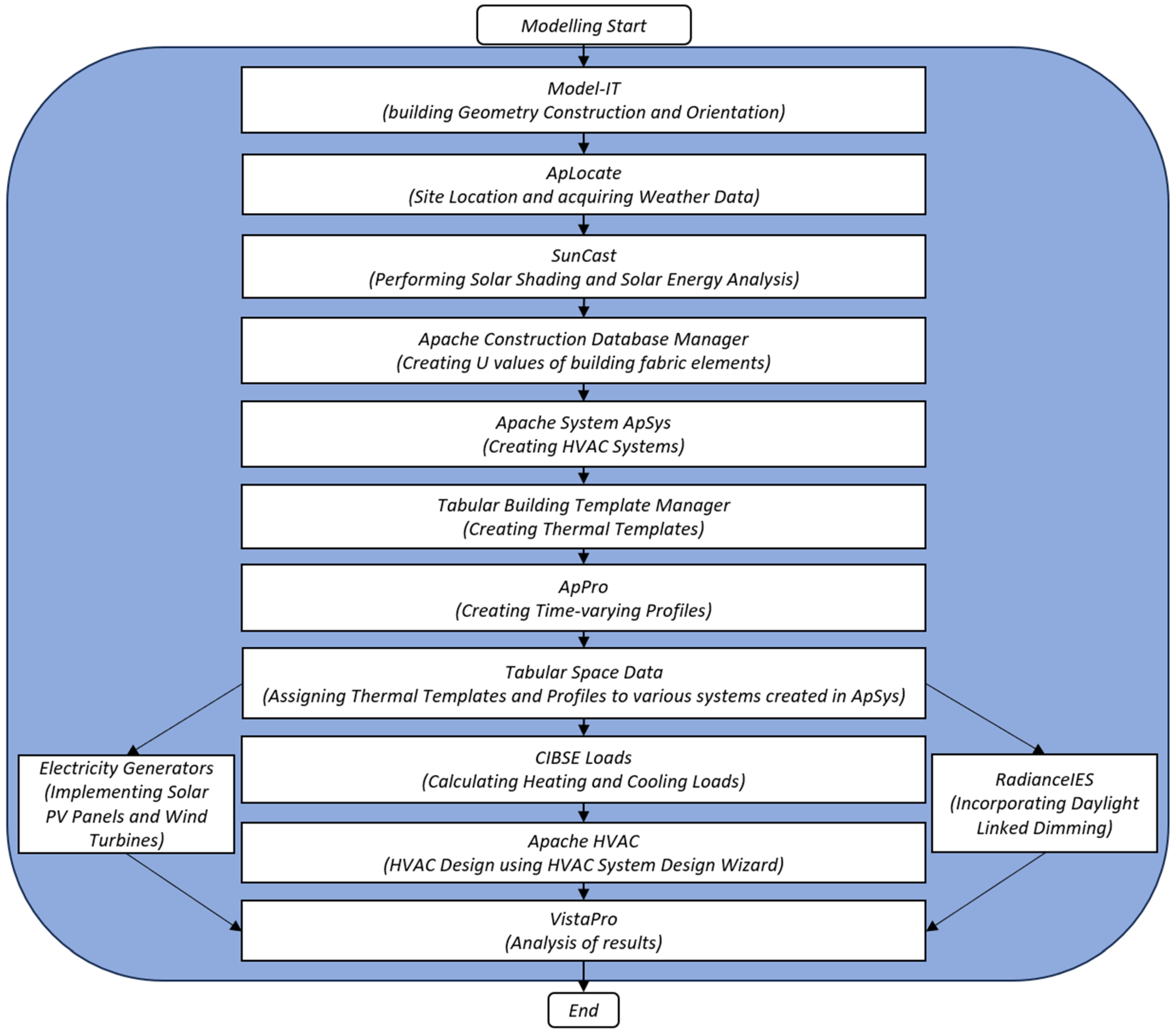

3. Methodology of the Dynamic Thermal Model

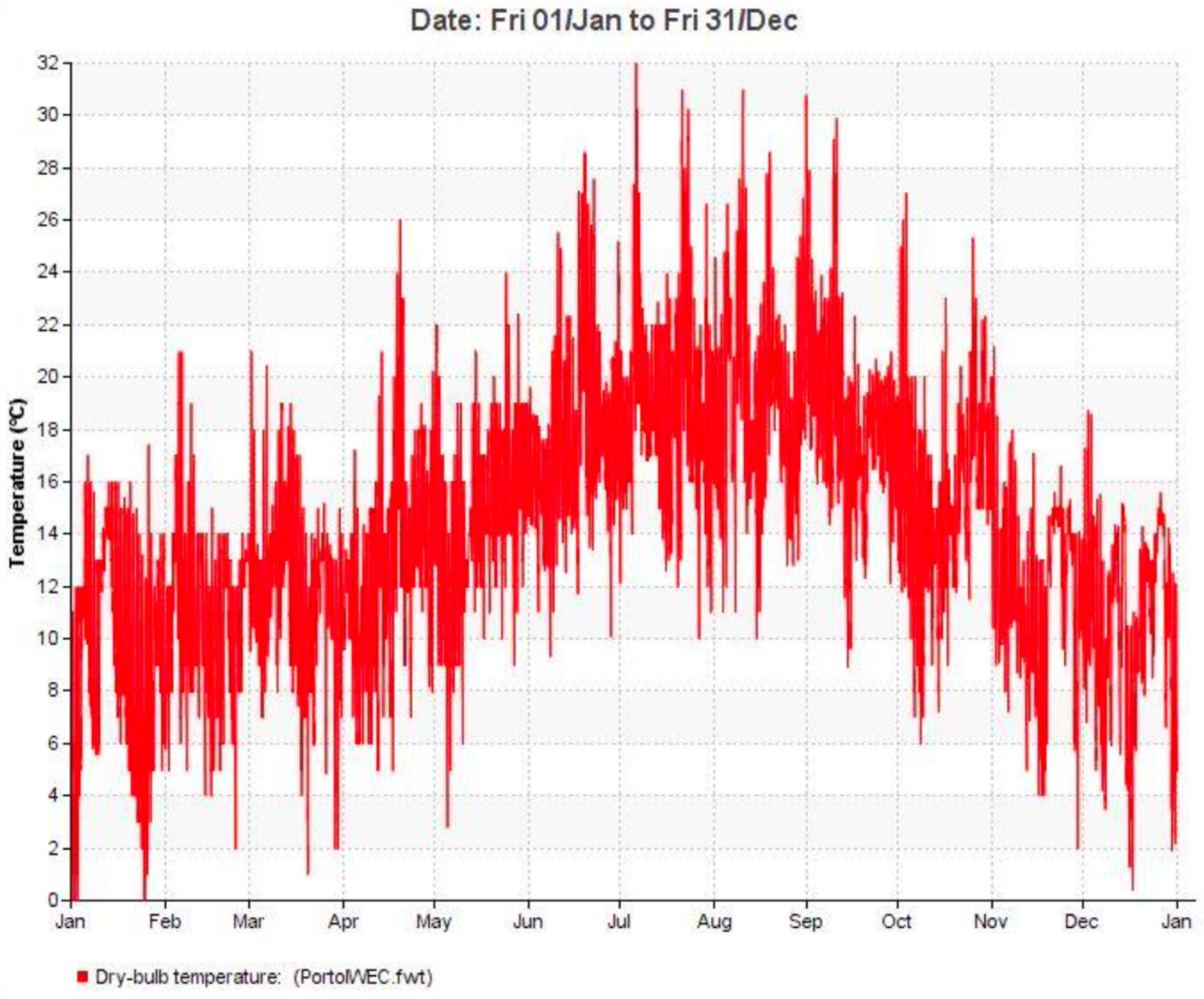

3.1. Weather Data

3.2. Thermal Comfort Model

3.2.1. Operative Temperature and Humidity

3.2.2. Internal Gains

3.2.3. Air Exchange Rates

3.2.4. Metabolic Rates and Clothing Insulation

3.3. Building Materials

3.4. HVAC System

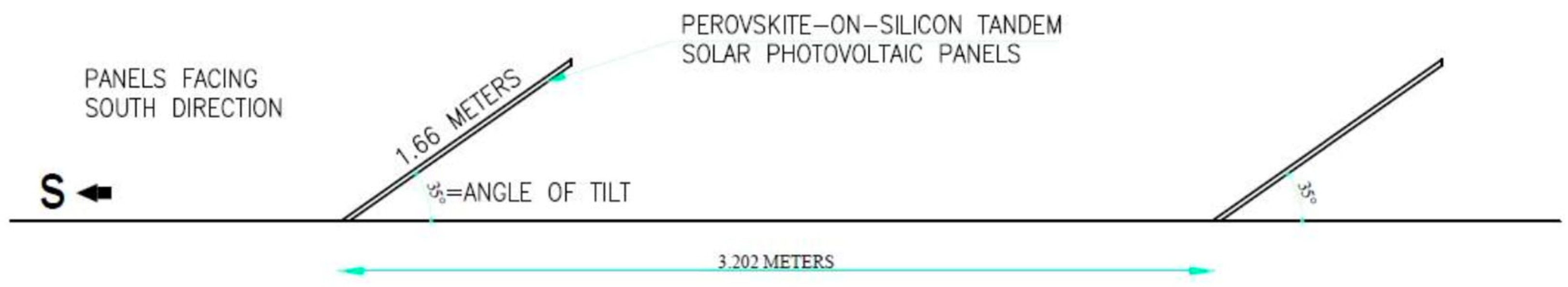

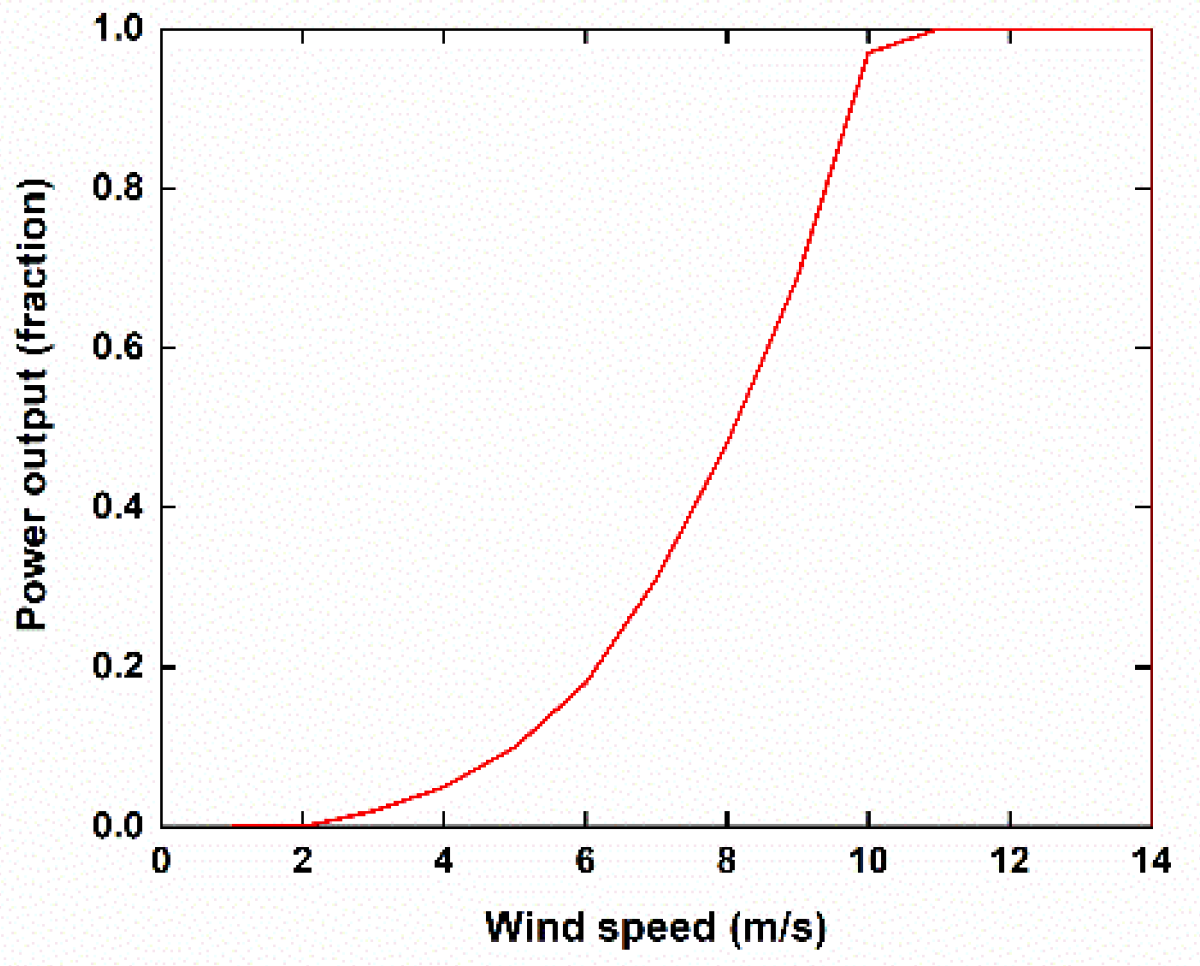

3.5. Photovoltaic Panels and Wind Turbines

4. Results

4.1. Validation of Internal Heat Gains

4.2. Solar Energy Analysis

4.3. Comparative Analysis for CO2 Emissions

4.4. Annual Space Heating and Cooling Demand

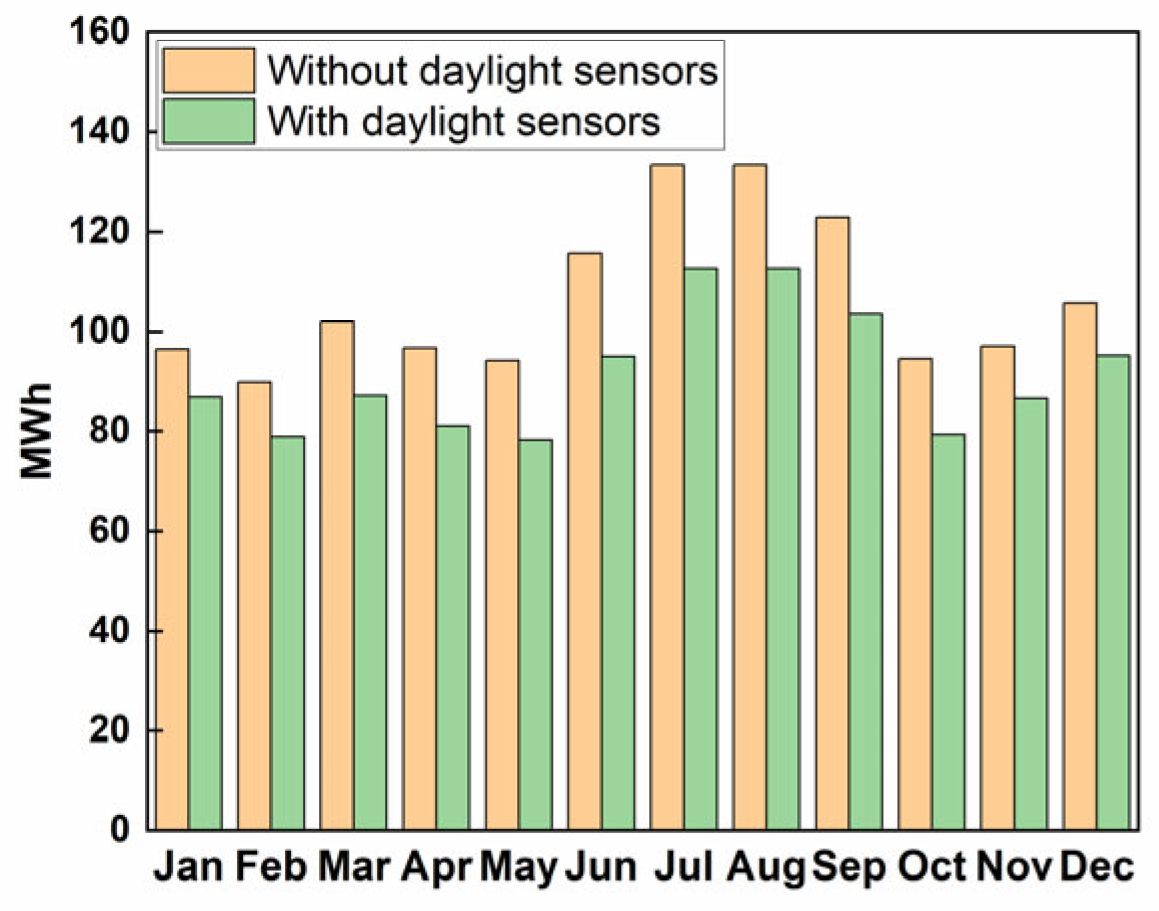

4.5. Annual Electricity Demand

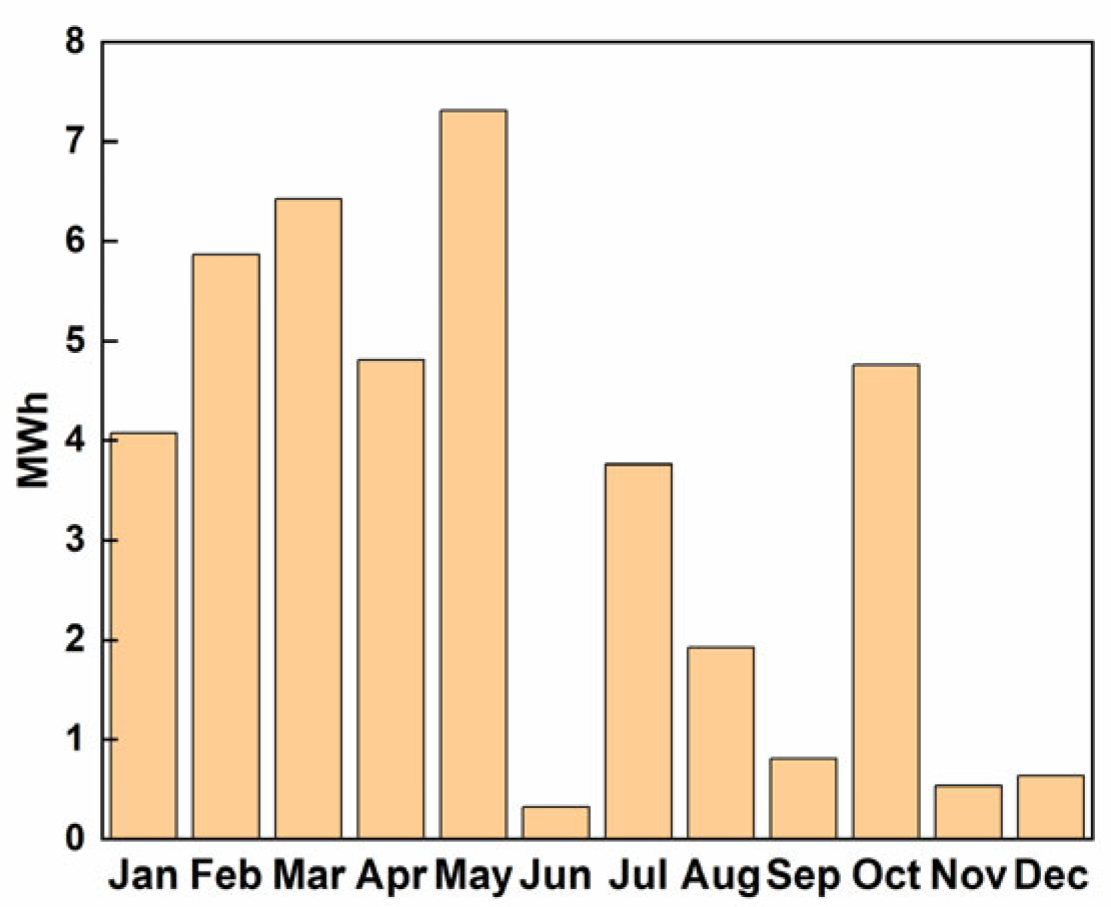

4.6. Wind-Generated Electricity

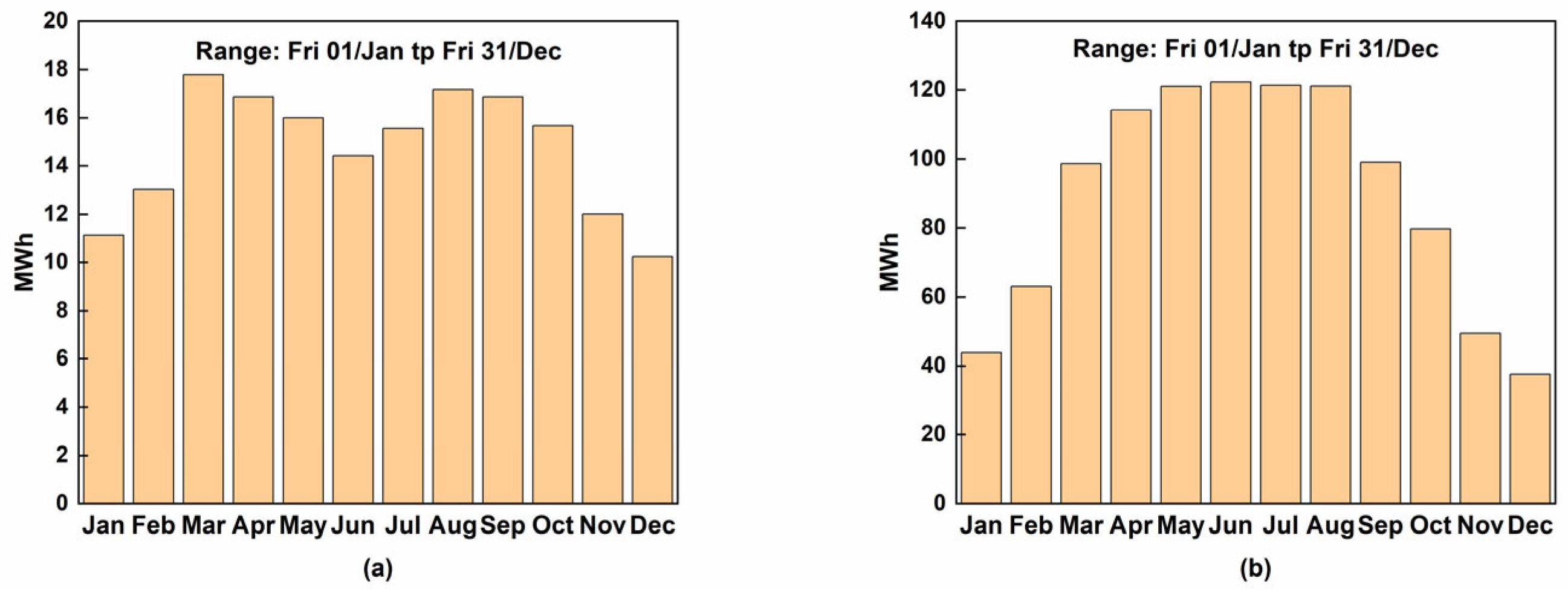

4.7. PV-Generated Electricity

4.8. Comparison of Total Electricity Demand vs. On-Site Electricity Generation

5. Conclusions

- This study compared the CO2 emissions of three building system configurations: traditional boiler and chiller systems, heat pump systems, and heat pumps integrated with PV panels and wind turbines. A 53% reduction in CO2 emissions was achieved when using the heat pump system instead of the boiler and chiller systems. Moreover, the CO2 emissions offset by renewable energy sources totalled approximately 300 tonnes, surpassing the emissions produced by the heat pump system. Consequently, the building design is capable of achieving net-zero carbon emissions;

- The implementation of passive design techniques, such as daylight sensors, significantly reduced the building’s annual electricity demand by 14.57%;

- The building’s total annual electricity demand was calculated to be 1093.5 MWh, while the combined annual electricity generation from PV panels and wind turbines reached 1285.14 MWh, resulting in a net electricity surplus of 191.64 MWh. This demonstrates that 100% on-site renewable energy generation is achievable, reducing the reliance on fossil fuels and contributing to the stability of the national electricity grid;

- “The Clover” is a net-zero-carbon building.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACH | air changes per hour |

| BESS | Battery Energy Storage System |

| BIPVs | building-integrated photovoltaic panels |

| COP | Coefficient of Performance |

| Clo | clothing insulation |

| DOAS | dedicated outside air system |

| EER | Energy Efficiency Ratio |

| GWP | Global Warming Potential |

| HAWT | horizontal-axis wind turbine |

| HVAC | heating, ventilation, and air conditioning |

| IES-VE | Integrated Environmental Solutions Virtual Environment |

| Met | metabolic rate |

| NCM | National Calculation Methodology |

| PV | photovoltaic |

| VAWT | vertical-axis wind turbine |

| VOCs | volatile organic compounds |

References

- Sangkakool, T.; Techato, K.; Zaman, R.; Brudermann, T. Prospects of green roofs in urban Thailand—A multi-criteria decision analysis. J. Clean. Prod. 2018, 196, 400–410. [Google Scholar] [CrossRef]

- Monna, S.; Juaidi, A.; Abdallah, R.; Albatayneh, A.; Dutournie, P.; Jeguirim, M. Towards sustainable energy retrofitting, a simulation for potential energy use reduction in residential buildings in palestine. Energies 2021, 14, 3876. [Google Scholar] [CrossRef]

- Bouckaert, S.; Pales, A.F.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector; OECD Publishing: Paris, France, 2021. [Google Scholar]

- Altan, H.; Hajibandeh, M.; Tabet Aoul, K.A.; Deep, A. Passive Design. ZEMCH: Toward the Delivery of Zero Energy Mass Custom Homes; Springer: Berlin/Heidelberg, Germany, 2016; pp. 209–236. [Google Scholar]

- Elaouzy, Y.; El Fadar, A. Energy, economic and environmental benefits of integrating passive design strategies into buildings: A review. Renew. Sustain. Energy Rev. 2022, 167, 112828. [Google Scholar] [CrossRef]

- Krarti, M. Optimal Design and Retrofit of Energy Efficient Buildings, Communities, and Urban Centers; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Chen, X.; Yang, H. Combined thermal and daylight analysis of a typical public rental housing development to fulfil green building guidance in Hong Kong. Energy Build. 2015, 108, 420–432. [Google Scholar] [CrossRef]

- Stevens, R.G.; Blask, D.E.; Brainard, G.C.; Hansen, J.; Lockley, S.W.; Provencio, I.; Rea, M.S.; Reinlib, L. Meeting report: The role of environmental lighting and circadian disruption in cancer and other diseases. Environ. Health Perspect. 2007, 115, 1357–1362. [Google Scholar] [CrossRef]

- Bui, V.; Liu, H.; Low, Y.; Tang, T.; Zhu, Q.; Shah, K.; Shidoji, E.; Lim, Y.; Koh, W. Evaluation of building glass performance metrics for the tropical climate. Energy Build. 2017, 157, 195–203. [Google Scholar] [CrossRef]

- Nandapala, K.; Chandra, M.S.; Halwatura, R.U. A study on the feasibility of a new roof slab insulation system in tropical climatic conditions. Energy Build. 2020, 208, 109653. [Google Scholar] [CrossRef]

- Rawat, M.; Singh, R.N. A study on the comparative review of cool roof thermal performance in various regions. Energy Built Environ. 2022, 3, 327–347. [Google Scholar] [CrossRef]

- Andric, I.; Kamal, A.; Al-Ghamdi, S.G. Efficiency of green roofs and green walls as climate change mitigation measures in extremely hot and dry climate: Case study of Qatar. Energy Rep. 2020, 6, 2476–2489. [Google Scholar] [CrossRef]

- Ng, T.S.; Yau, R.M.; Lam, T.N.; Cheng, V.S. Design and commission a zero-carbon building for hot and humid climate. Int. J. Low-Carbon Technol. 2016, 11, 222–234. [Google Scholar] [CrossRef]

- Aksamija, A. Regenerative design and adaptive reuse of existing commercial buildings for net-zero energy use. Sustain. Cities Soc. 2016, 27, 185–195. [Google Scholar] [CrossRef]

- Rabani, M.; Madessa, H.B.; Nord, N. Achieving zero-energy building performance with thermal and visual comfort enhancement through optimization of fenestration, envelope, shading device, and energy supply system. Sustain. Energy Technol. Assess. 2021, 44, 101020. [Google Scholar] [CrossRef]

- Aguacil, S.; Lufkin, S.; Rey, E. Active surfaces selection method for building-integrated photovoltaics (BIPV) in renovation projects based on self-consumption and self-sufficiency. Energy Build. 2019, 193, 15–28. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Peng, J. Energy optimization of high-rise commercial buildings integrated with photovoltaic facades in urban context. Energy 2019, 172, 1–17. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Jasek, J. The use of fresnel lenses to improve the efficiency of photovoltaic modules for building-integrated concentrating photovoltaic systems. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 415–426. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Bunthof, L.; Kreuwel, F.; Kaldenhoven, A.; Kin, S.; Corbeek, W.; Bauhuis, G.; Vlieg, E.; Schermer, J. Impact of shading on a flat CPV system for façade integration. Sol. Energy 2016, 140, 162–170. [Google Scholar] [CrossRef]

- Smyth, M.; Pugsley, A.; Hanna, G.; Zacharopoulos, A.; Mondol, J.; Besheer, A.; Savvides, A. Experimental perfor-mance characterisation of a hybrid photovoltaic/solar thermal façade module compared to a flat integrated collector storage solar water heater module. Renew. Energy 2019, 137, 137–143. [Google Scholar] [CrossRef]

- Dutton, A.G.; Halliday, J.A.; Blanch, M.J. The Feasibility of Building-Mounted/Integrated Wind Turbines (BUWTs): Achieving Their Potential for Carbon Emission Reductions; Energy Research Unit: Oxford, UK; CCLRC: Oxford, UK, 2005; pp. 77–83. [Google Scholar]

- Hyams, M.A. Wind energy in the built environment. In Metropolitan Sustainability; Woodhead Publishing: Cambridge, UK, 2012; pp. 457–499. [Google Scholar]

- Boyle, G. Renewable Energy Power for a Sustainable Future, 2nd ed.; Oxford University Press: Oxford, UK, 2004. [Google Scholar]

- Johari, M.K.; A Jalil, M.A.; Shariff, M.F.M. Comparison of horizontal axis wind turbine (HAWT) and vertical axis wind turbine (VAWT). Int. J. Eng. Technol. 2018, 7, 74–80. [Google Scholar] [CrossRef]

- Park, J.; Jung, H.J.; Lee, S.W.; Park, J. A new building-integrated wind turbine system utilizing the building. Energies 2015, 8, 11846–11870. [Google Scholar] [CrossRef]

- Singh, R.K.; Ahmed, M.R. Blade design and performance testing of a small wind turbine rotor for low wind speed applications. Renew. Energy 2013, 50, 812–819. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Bhaganagar, K. A pathway towards sustainable development of small capacity horizontal axis wind turbines—Identification of influencing design parameters & their role on performance analysis. Sustain. Energy Technol. Assess. 2021, 44, 101019. [Google Scholar] [CrossRef]

- Sari, D.P.; Cho, K.P. Performance Comparison of Different Building Shapes Using a Wind Tunnel and a Computa-tional Model. Buildings 2022, 12, 144. [Google Scholar] [CrossRef]

- Chaudhry, H.N.; Calautit, J.K.; Hughes, B.R. The Influence of Structural Morphology on the Efficiency of Building Integrated Wind Turbines (BIWT). AIMS Energy 2014, 2, 219–236. [Google Scholar] [CrossRef]

- Mao, Z.; Yang, G.; Zhang, T.; Tian, W. Aerodynamic performance analysis of a building-integrated savonius turbine. Energies 2020, 13, 2636. [Google Scholar] [CrossRef]

- Mohammed, G.; Ibrahim, A.; Kangiwa, U.M.; Wisdom, J.B. Design and testing of building integrated hybrid vertical axis wind turbine. J. Electr. Electron. Eng. 2021, 9, 69. [Google Scholar] [CrossRef]

- Nguyen, L.; Metzger, M. Optimization of a vertical axis wind turbine for application in an urban/suburban area. J. Renew. Sustain. Energy 2017, 9, 043302. [Google Scholar] [CrossRef]

- Irshad, A.S.; Kargar, N.; Elkholy, M.H.; Ludin, G.A.; Elias, S.; Hilali, A.; Senjyu, T.; Gamil, M.M.; Pinter, G. Tech-no-economic evaluation and comparison of the optimal PV/Wind and grid hybrid system with horizontal and vertical axis wind turbines. Energy Convers. Manag. X 2024, 23, 100638. [Google Scholar]

- Weeks, D. LAUNCH: RENEWABLES 2024 GLOBAL STATUS REPORT-GLOBAL OVERVIEW-REN21 Secretariat. 2024. Available online: https://policycommons.net/artifacts/12092387/launch/12986140/ (accessed on 22 January 2025).

- Attia, S.G.; Beltrán, L.; De Herde, A.; Hensen, J.L.M. “Architect friendly”: A comparison of ten different building performance simulation tools. In Proceedings of the 11th International IBPSA Building Simulation Conference (BS 2009), Glasgow, UK, 27–30 July 2009; International Building Performance Simulation Association (IBPSA): Brisbane, Australia, 2009; pp. 204–211. [Google Scholar]

- Lau, A.K.K.; Salleh, E.; Lim, C.H.; Sulaiman, M.Y. Potential of shading devices and glazing configurations on cooling energy savings for high-rise office buildings in hot-humid climates: The case of Malaysia. Int. J. Sustain. Built Environ. 2016, 5, 387–399. [Google Scholar] [CrossRef]

- Alnaqbi, A.K. Investigating Energy Savings Due to Implementing Green Roof on Existing Residential Buildings in UAE. Master’s Thesis, The British University in Dubai, Dubai, United Arab Emirates, 2013. [Google Scholar]

- Zoure, A.N.; Genovese, P.V. Implementing natural ventilation and daylighting strategies for thermal comfort and energy efficiency in office buildings in Burkina Faso. Energy Rep. 2023, 9, 3319–3342. [Google Scholar] [CrossRef]

- Race, G.L. How to Design a Heating System; CIBSE Publications: London, UK, 2006. [Google Scholar]

- Olesen, B.W.; Wang, H.; Kazanci, B.O. The Effect of Room Temperature Control By Air-or Operative Temperature on Thermal Comfort and Energy Use. In Proceedings of the Building Simulation 2019: 16th Conference of IBPSA Building Simulation 2019: 16th Conference of IBPSA, Rome, Italy, 2–4 September 2019; Volume 16, pp. 2086–2093. [Google Scholar]

- Race, G.L.; Mitchell, S. A Practical Guide to HVAC Building Services Calculations; BSRIA: Bracknell, UK, 2003. [Google Scholar]

- HM Government. The Building Regulations 2010 Ventilation Approved Document F Volume 2: Buildings Other than Dwellings. 2021. Available online: https://assets.publishing.service.gov.uk/media/62a761edd3bf7f03667c667e/ADF2_revised.pdf (accessed on 26 December 2024).

- Shen, B.; Li, Z.; Gluesenkamp, K.R. Experimental study of R452B and R454B as drop-in replacement for R410A in split heat pumps having tube-fin and microchannel heat exchangers. Appl. Therm. Eng. 2022, 204, 117930. [Google Scholar] [CrossRef]

- EasySolar. Shade Calculator—EasySolar. 2021. Available online: https://easysolar.app/en/shade-calculator/ (accessed on 3 April 2024).

- Ruya, E.; Augenbroe, G. Exploring thermal comfort acceptance criteria in energy modeling. In Proceedings of the 2018 Building Performance Analysis Conference and SimBuild Co-Organized by ASHRAE and IBPSA-USA, Chicago, IL, USA, 26–28 September 2018; pp. 258–265. [Google Scholar]

| System Type | Simulation Tool | Electrical Efficiency |

|---|---|---|

| BIPV [16] | BIM, 2018 | 0.17 |

| BIPV [17] | EnergyPlus, je +, R, GenOpt, 2018 | 0.06–0.15 |

| BIPV with Fresnel lens [18] | TRNSYS, 2016 | 0.22 |

| PV double-skin façade and PV insulating glass [19] | EnergyPlus | 0.05–0.07 |

| Concentrator solar PV [20] | 0.24 | |

| Hybrid photovoltaic/ solar thermal (HyPV/T) façade [21] | 0.08–0.23 |

| System Type | Method | Key Findings |

|---|---|---|

| HAWT [26] | CFD | The system contributed to 6.3% of building electricity supply. |

| HAWT [27] | Tests | The peak power coefficient attained by the 2-bladed rotor design at 6 m/s wind speed was 0.29. |

| HAWT [28] | QBlade software, 2016 | The design of a small horizontal wind turbine with three blades is suitable for low-wind-speed areas. |

| HAWT [29] | Experimental and CFD | Round-cornered buildings increased wind velocity by up to 34% compared to sharp-cornered structures, highlighting the significance of building shape in enhancing wind turbine performance. |

| HAWT [30] | CFD | A circular cross-section is the most viable building orientation, particularly suited to regions with a dominant prevailing wind direction, as a mean wind speed augmentation of 5% was achieved at the turbines. |

| VAWT [31] | CFD | An edge-mounted Savonius turbine has a higher coefficient of power than that operating in uniform flows; the average Cp of the turbine under 360-degree wind angles is 92.5% higher than that of the turbine operating in uniform flows. |

| VAWT [32] | Experimental | The building-integrated hybrid VAWT produced up to 63% more energy compared to a standalone hybrid VAWT, demonstrating the benefits of integration with building structures. |

| Location | Nearest Weather Station | Solar Insolation on Giant Roof (kWh/m2) | Annual Average Wind Speed (m/s) |

|---|---|---|---|

| London | London Heathrow | 922.16 | 4 |

| Alicante | Alicante Ap | 1613.64 | 3.2 |

| Peniche | Cabo Carvoeiro | 1552.39 | 4.9 |

| Catania | Catania Fontanarossa | 1664.91 | 3.4 |

| Perpignan | Perpignan Sud de France Ap | 1482.31 | 4.3 |

| Singapore | Singapore Paya Lebar | 1660.82 | 25 |

| Doha | Doha International | 2171.76 | 3.8 |

| Building Data | |

|---|---|

| Name | The Clover |

| Number of Storeys | Basement + ground + 7 |

| Application | Commercial office |

| Total Floor Area of Building | 20,250 m2 |

| Location Data | |

| Location | Peniche, Portugal |

| Nearest Weather Station | Cabo Carvoeiro, Portugal |

| Latitude | 39.36° N |

| Longitude | 9.41° W |

| Altitude/Elevation from Sea Level | 32 m |

| Time Zone | 0 h ahead of GMT |

| Daylight Saving Time | |

| Time Adjustment | 1 h |

| Span of Months | April to October |

| Site Data | |

| Summer Ground Reflectance | 0.2 |

| Winter Ground Reflectance | 0.2 |

| Terrain Type | Suburbs |

| External CO2 Concentration | 400 ppm |

| Wind Exposure | Normal |

| Design Weather Data | |

| Monthly Percentile for Heating Loads | 99.60% |

| Monthly Percentile for Cooling Loads | 0.40% |

| Barometric Pressure | 100,949.7 Pa |

| Reference Air Density | 1.2 kg/m3 |

| Air Specific Heat | 1.019 KJ/kg-K |

| Occupancy Heat Gains | |||||||

|---|---|---|---|---|---|---|---|

| Typical Application | Activity | Internal Dry Bulb Temperature (°C) | Sensible Heat (Watts/Person) | Latent Heat (Watts/Person) | References | Occupant Density (m2/Person) | References |

| Office | Seated, moderate work | 23 | 85 | 55 | CIBSE Guide A Table 6.3 page 344 of 404 | 12 | CIBSE Guide A Table 6.2 page 331 of 404 |

| Lighting Heat Gains from Different Spaces | |||||||

| Typical Application | Minimum Illuminance (lux) | Maximum Illuminance (lux) | References | Sensible Heat (Watts/person) | References | Radiant Fraction | |

| Open office | 300 | 500 | CIBSE Guide A Table 1.5 page 34 of 404 | 8 | CIBSE Guide A Table 6.2 page 331 of 404 | 0.45 | |

| Lift lobby | 100 | 200 | CIBSE Guide A Table 1.5 page 34 of 404 | 5.2 | UK NCM template imported in IES-VE | 0.45 | |

| Toilet | 200 | 200 | CIBSE Guide A Table 1.5 page 34 of 404 | 7.5 | UK NCM template imported in IES-VE | 0.45 | |

| Car park garage | 75 | 75 | CIBSE Guide A Table 1.5 page 34 of 404 | 3.9 | UK NCM template imported in IES-VE | 0.45 | |

| Equipment Heat Gain from Open Office | |||||||

| Typical Application | Sensible Heat Gain (Watts/m2) | References | Radiant Fraction | ||||

| Open office | 11.77 | UK NCM template imported in IES-VE | 0.22 | ||||

| External Wall | |||||||||||

| Element | Thickness (mm) | Thermal Conductivity (W/m-K) | Density (kg/m3) | Specific Heat Capacity (J/kg-K) | Thermal Resistance (m2-K/W) | ||||||

| Outer film of air | 0.04 | ||||||||||

| Brickwork outer leaf | 105 | 0.84 | 1700 | 800 | 125 | ||||||

| Polyurethane foam | 100 | 0.025 | 30 | 1400 | 4 | ||||||

| Brickwork inner leaf | 100 | 0.62 | 1700 | 800 | 0.161 | ||||||

| Gypsum plasterboard | 12.5 | 0.16 | 800 | 840 | 0.078 | ||||||

| Inner film of air | 0.13 | ||||||||||

| Overall heat transfer coefficient of external wall | 0.22 (W/m2-K) | ||||||||||

| Floor/Ceiling | |||||||||||

| Element | Thickness (mm) | Thermal Conductivity (W/m-K) | Density (kg/m3) | Specific Heat Capacity (J/kg-K) | Thermal Resistance (m2-K/W) | ||||||

| Inner film of air | 0.1 | ||||||||||

| Chipboard flooring | 18 | 0.14 | 600 | 1700 | 0.129 | ||||||

| Cellular polyurethane insulation | 100 | 0.023 | 24 | 1600 | 4.35 | ||||||

| Cast concrete | 75 | 0.14 | 370 | 840 | 0.536 | ||||||

| Gypsum plasterboard | 12.5 | 0.16 | 800 | 840 | 0.078 | ||||||

| Inner film of air | 0.1 | ||||||||||

| Overall heat transfer coefficient of external wall | 0.18 (W/m2-K) | ||||||||||

| Roof | |||||||||||

| Element | Thickness (mm) | Thermal Conductivity (W/m-K) | Density (kg/m3) | Specific Heat Capacity (J/kg-K) | Thermal Resistance (m2-K/W) | ||||||

| Outer film of air | 0.04 | ||||||||||

| Asphalt mastic roofing | 20 | 1.15 | 2330 | 840 | 0.017 | ||||||

| Polyurethane foam | 150 | 0.025 | 30 | 1400 | 6 | ||||||

| Screed | 50 | 0.46 | 1200 | 1000 | 0.109 | ||||||

| Concrete deck | 150 | 2 | 2400 | 1000 | 0.075 | ||||||

| Gypsum plasterboard | 12.5 | 0.16 | 800 | 840 | 0.078 | ||||||

| Inner film of air | 0.1 | ||||||||||

| Overall heat transfer coefficient of external wall | 0.16 (W/m2-K) | ||||||||||

| Glazing | |||||||||||

| Element | Thickness (mm) | Thermal Conductivity (W/m-K) | Gas | Convection Coefficient (W/m2-K) | Thermal Resistance (m2-K/W) | Transmittance | Outside Reflectance | Inside Reflectance | Refractive Index | Outside Emissivity | Inside Emissivity |

| Outer pane | 6 | 1.06 | 0.0057 | 0.409 | 0.289 | 0.414 | 1.526 | 0.837 | 0.042 | ||

| Cavity | 12 | Argon | 1.4033 | 0.6182 | |||||||

| Inner pane | 6 | 1.06 | 0.0057 | 0.783 | 0.072 | 0.072 | 1.526 | 0.837 | 0.837 | ||

| Cavity | 12 | Argon | 1.4033 | 0.196 | |||||||

| Inner pane | 6 | 1.06 | 0.0057 | 0.783 | 0.072 | 0.072 | 1.526 | 0.837 | 0.837 | ||

| Overall heat transfer coefficient of glass only | 0.9988 (W/m2-K) | ||||||||||

| Internal Heat Gains | Area | Occupancy Density | No. of People | Sensible Heat Gains (Watts/People) | Total Sensible Load | |

|---|---|---|---|---|---|---|

| Watts | kW | |||||

| People | 553.9 | 12 | 46 | 85 | 3923.46 | 3.92 |

| Internal heat gains | Area | - | Sensible heat gains (Watts/m2) | Total sensible load | ||

| Watts | kW | |||||

| Lighting | 553.9 | - | 8 | 4431.2 | 4.43 | |

| Equipment | 11.77 | 6519.4 | 6.52 | |||

| Total internal heat gains (sensible) | 14,874.06 | 14.87 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Ge, Y.; Patel, R.V. Renewable Energy Integration and Energy Efficiency Enhancement for a Net-Zero-Carbon Commercial Building. Buildings 2025, 15, 414. https://doi.org/10.3390/buildings15030414

Zhang X, Ge Y, Patel RV. Renewable Energy Integration and Energy Efficiency Enhancement for a Net-Zero-Carbon Commercial Building. Buildings. 2025; 15(3):414. https://doi.org/10.3390/buildings15030414

Chicago/Turabian StyleZhang, Xinyu, Yunting Ge, and Raj Vijay Patel. 2025. "Renewable Energy Integration and Energy Efficiency Enhancement for a Net-Zero-Carbon Commercial Building" Buildings 15, no. 3: 414. https://doi.org/10.3390/buildings15030414

APA StyleZhang, X., Ge, Y., & Patel, R. V. (2025). Renewable Energy Integration and Energy Efficiency Enhancement for a Net-Zero-Carbon Commercial Building. Buildings, 15(3), 414. https://doi.org/10.3390/buildings15030414