Experimental Research and Analysis of Influencing Factors on Hysteresis Properties of Common Steel Bars with Unbonded Sections

Abstract

:1. Introduction

2. Experimental Program

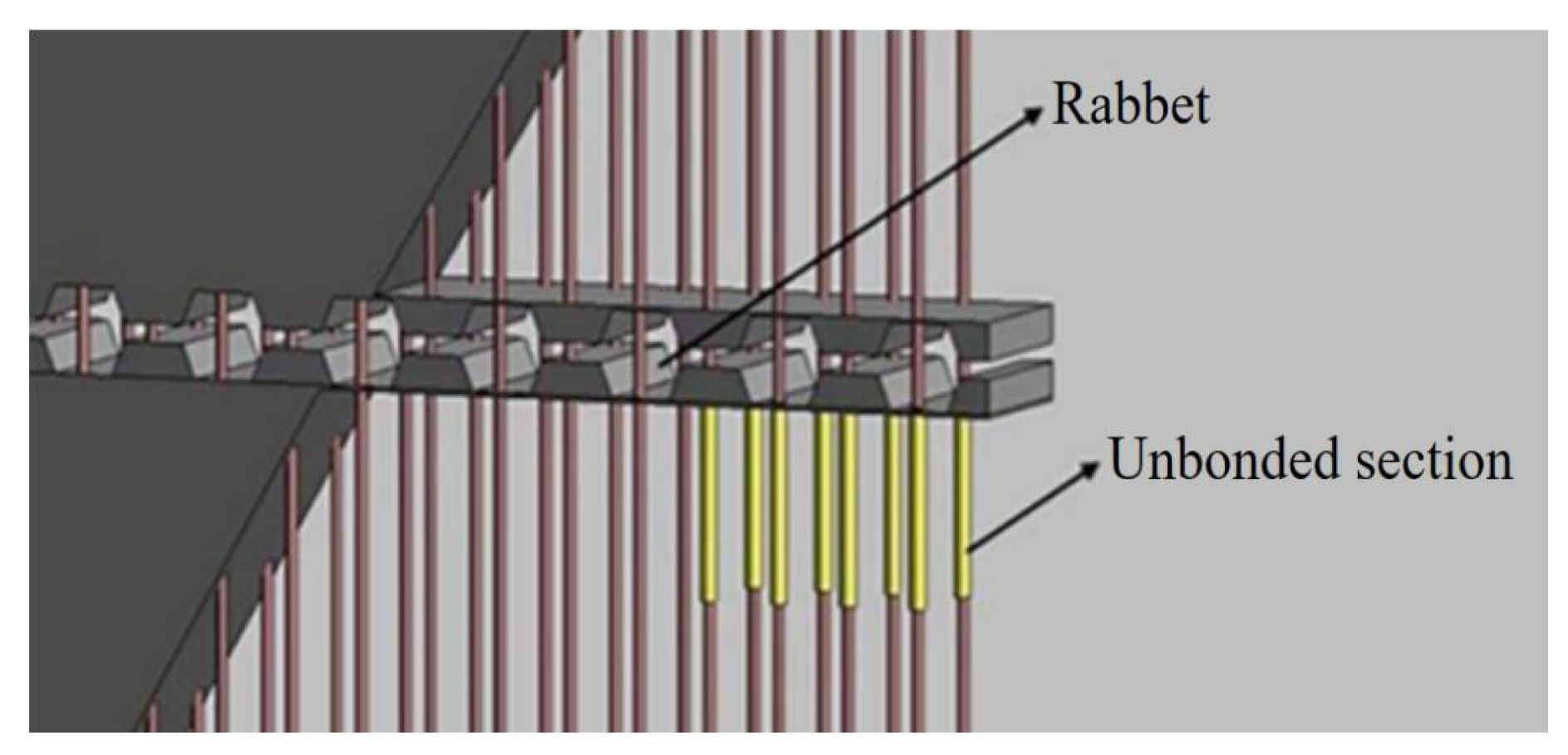

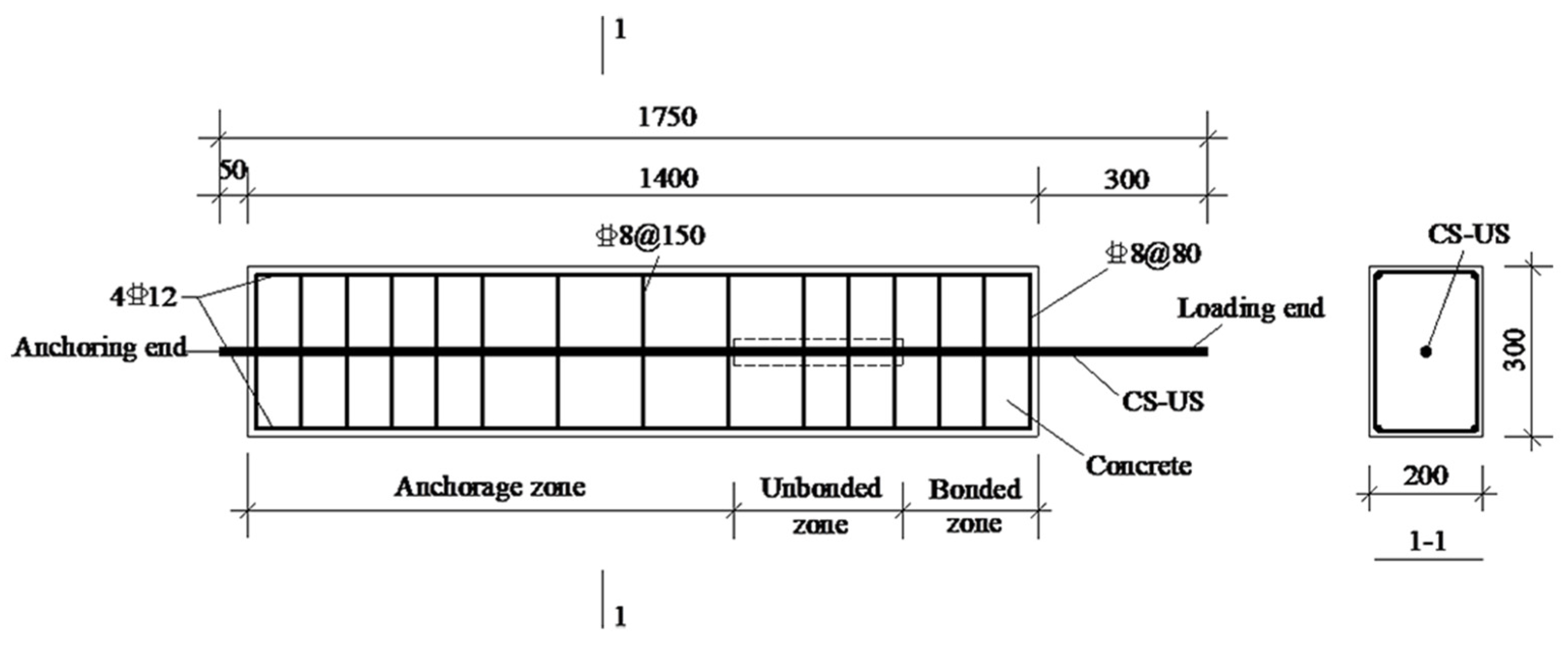

2.1. Specimen Design

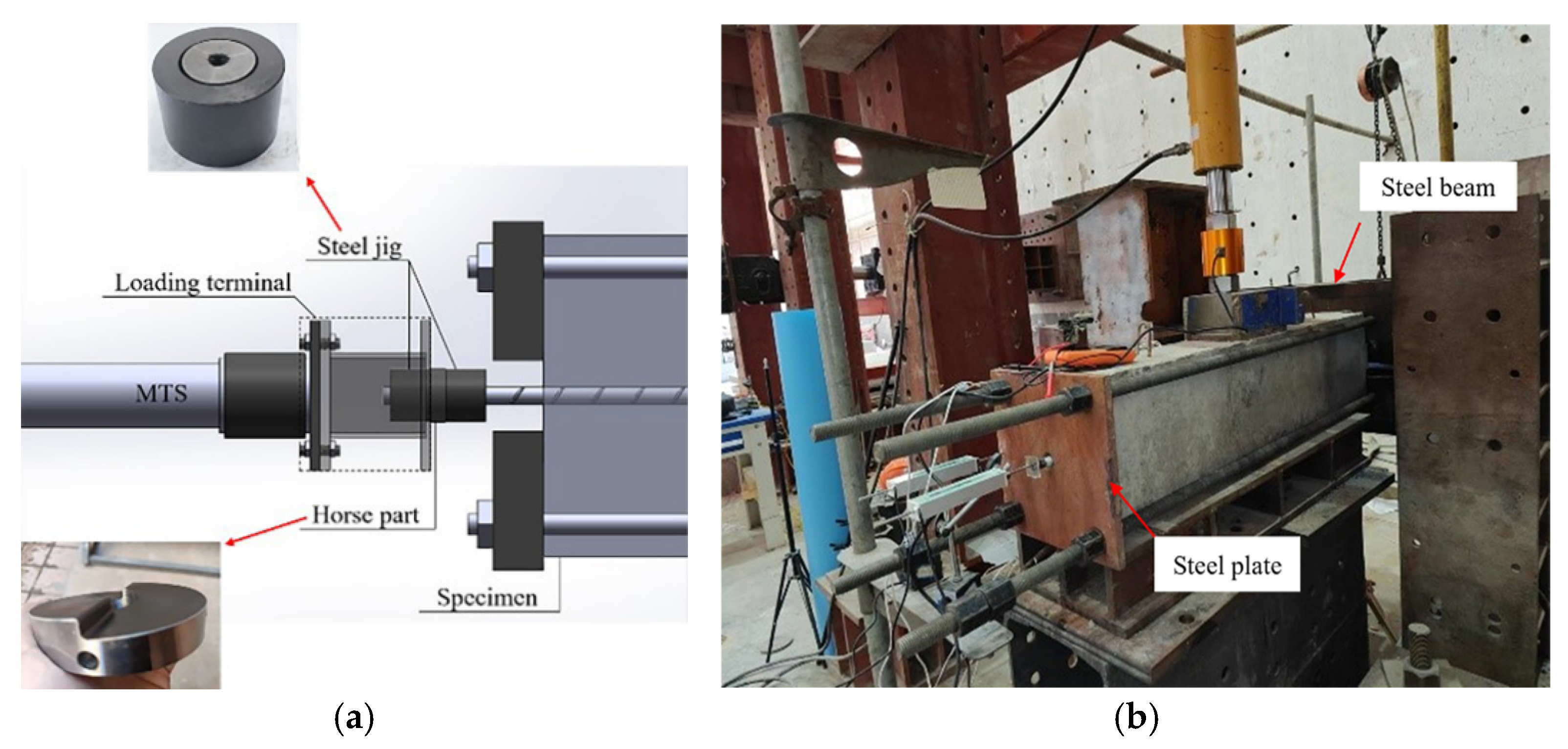

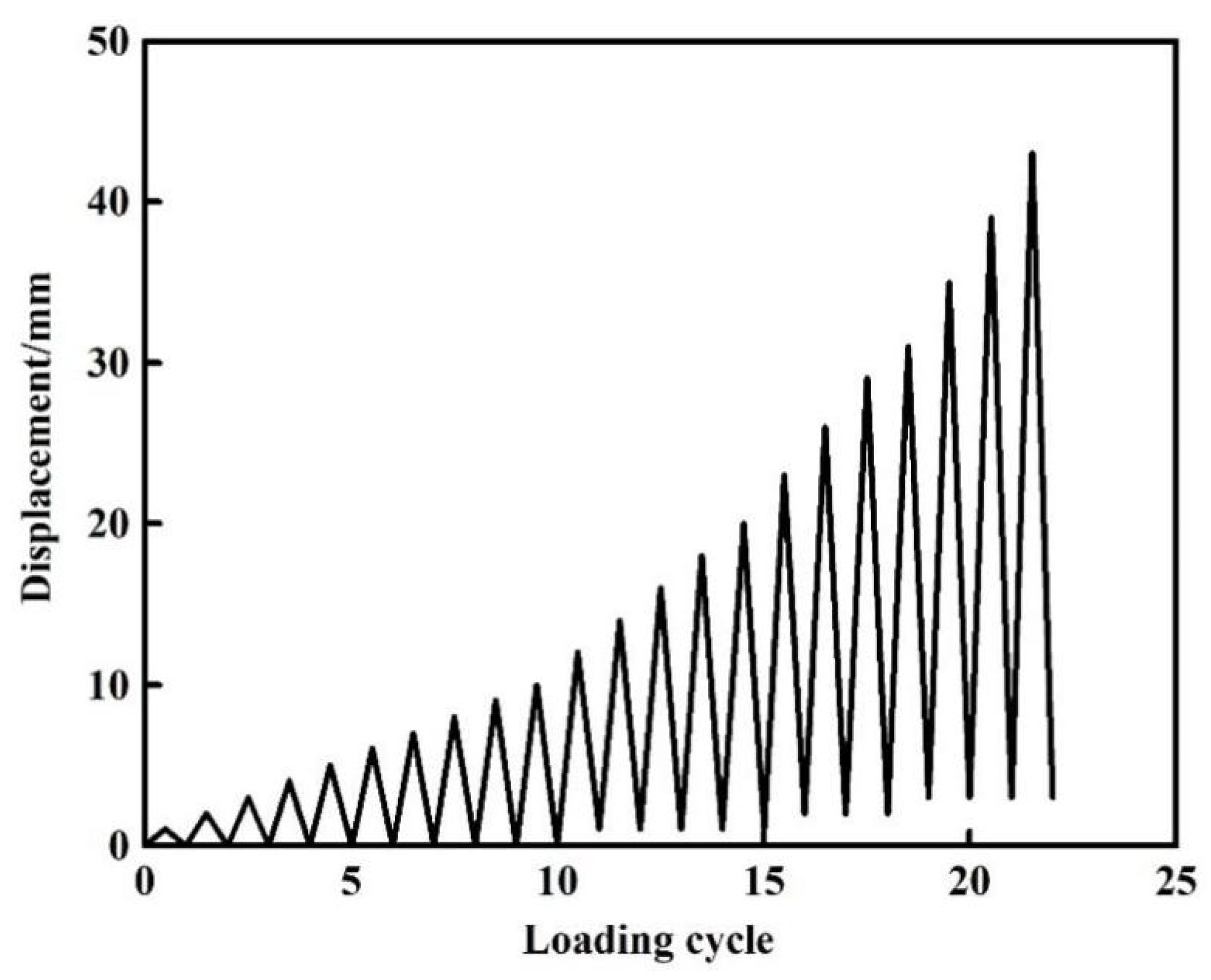

2.2. Test Setup and Loading Regime

3. Establishment and Verification of Finite Element Model

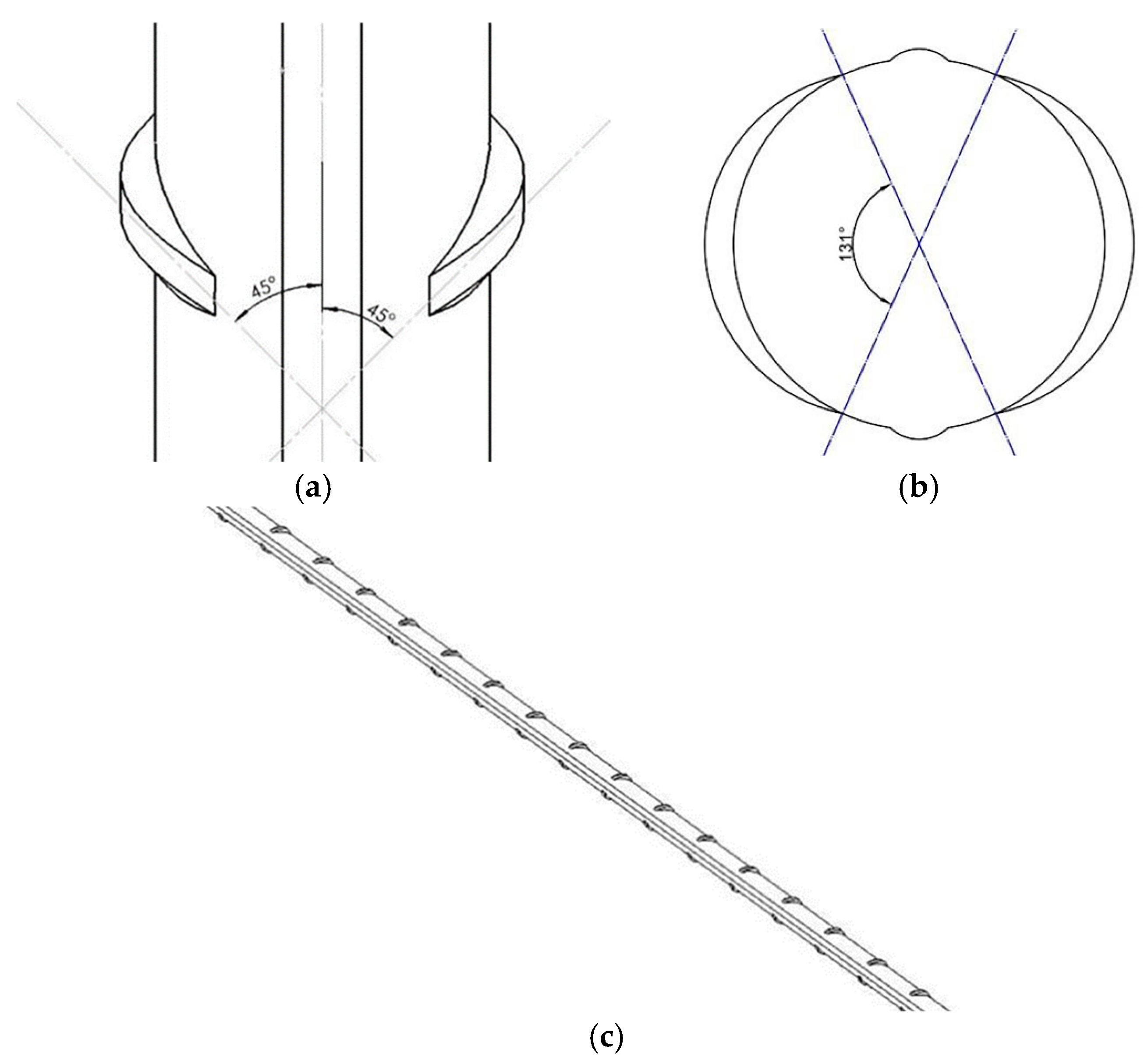

3.1. Contact Setting of CS-US with Concrete

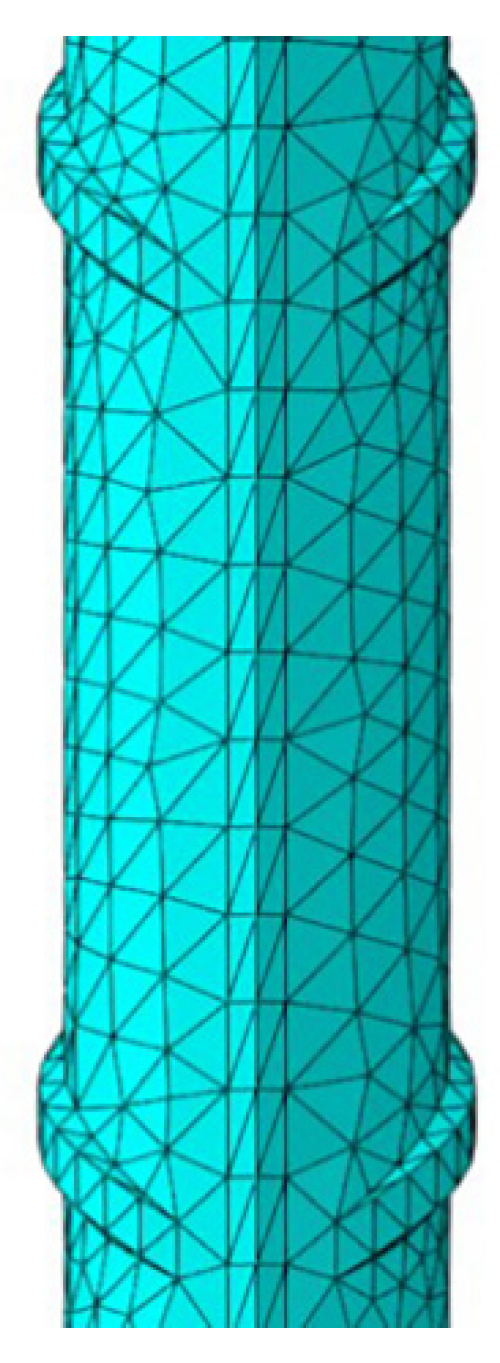

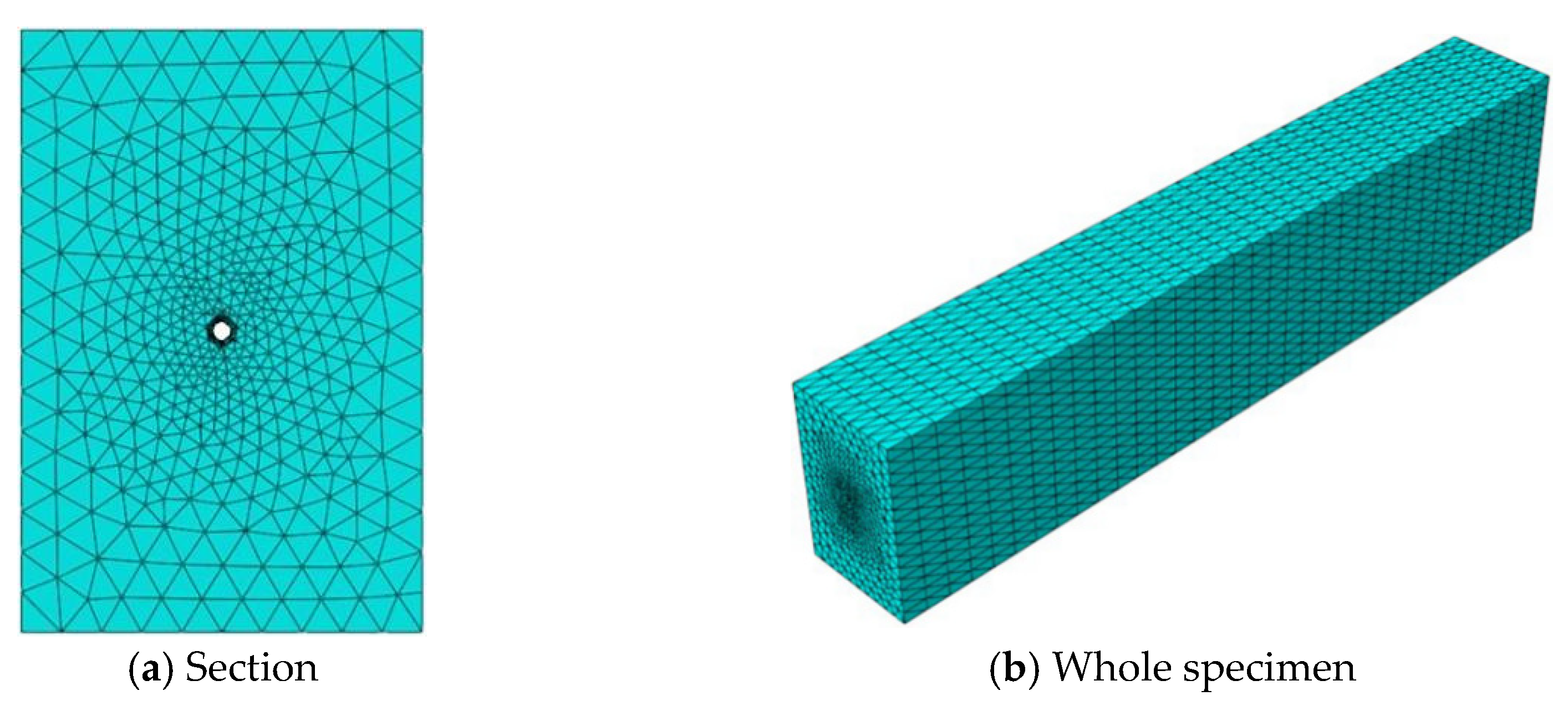

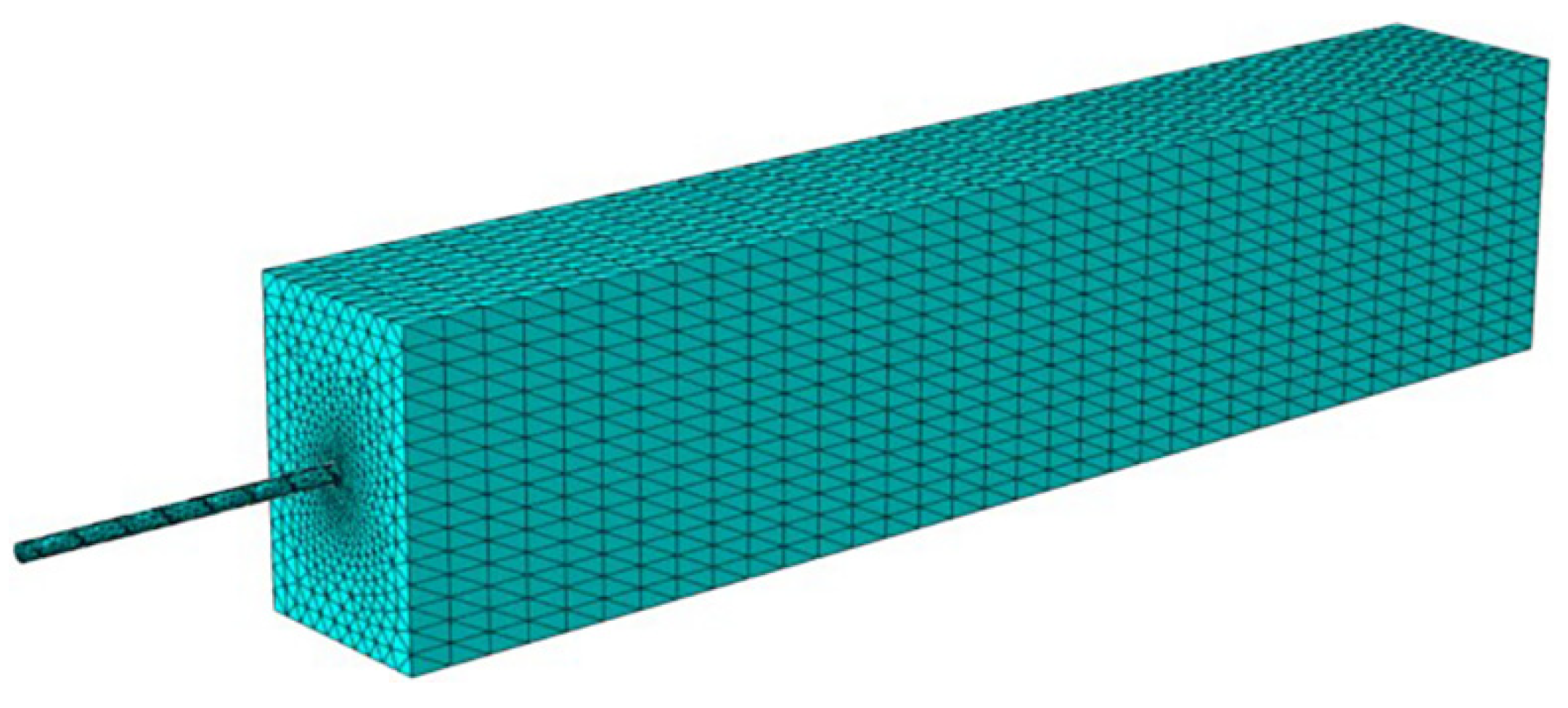

3.2. Unit Type and Size

- (1)

- CS-US

- (2)

- The Remaining Steel Bars and Concrete

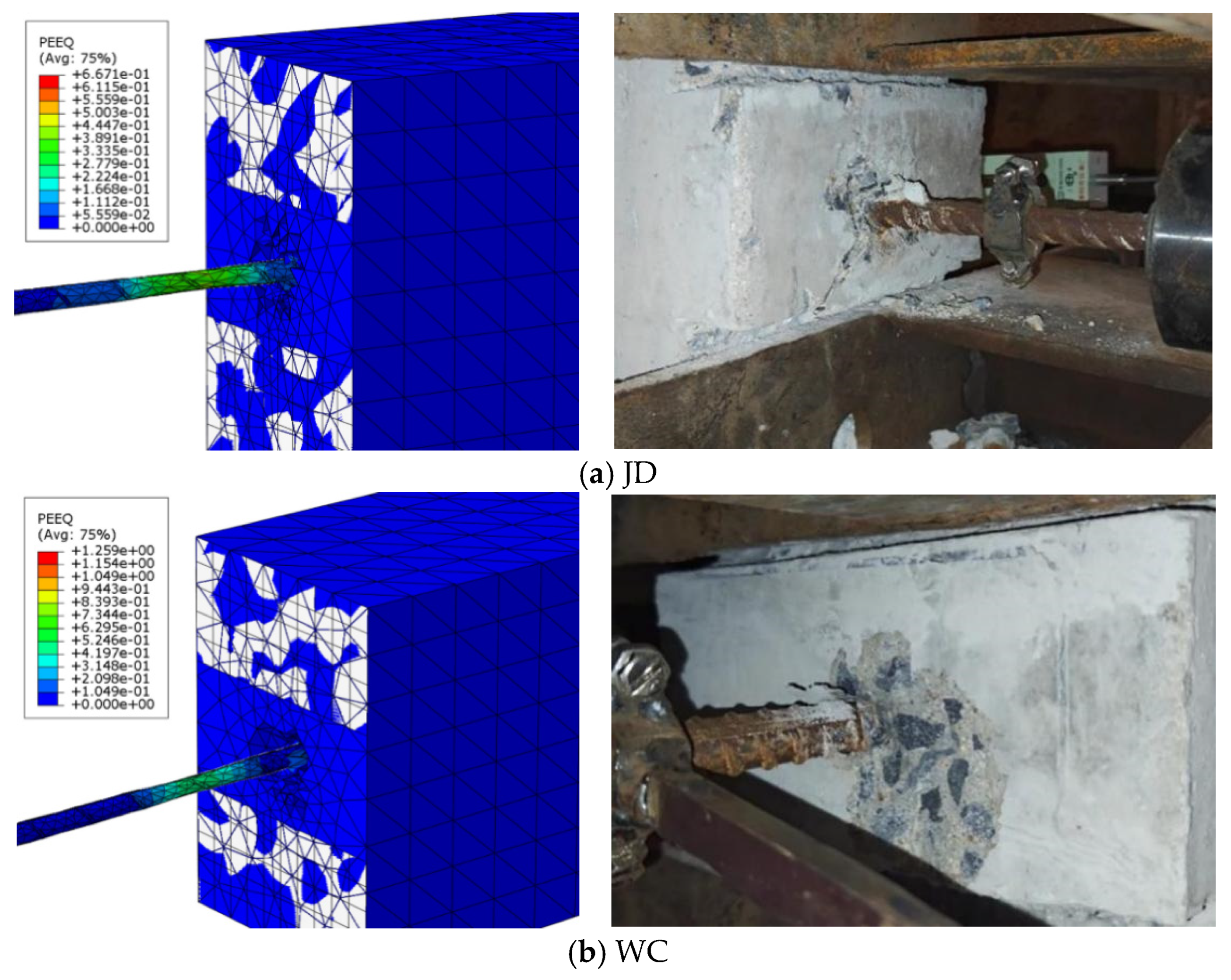

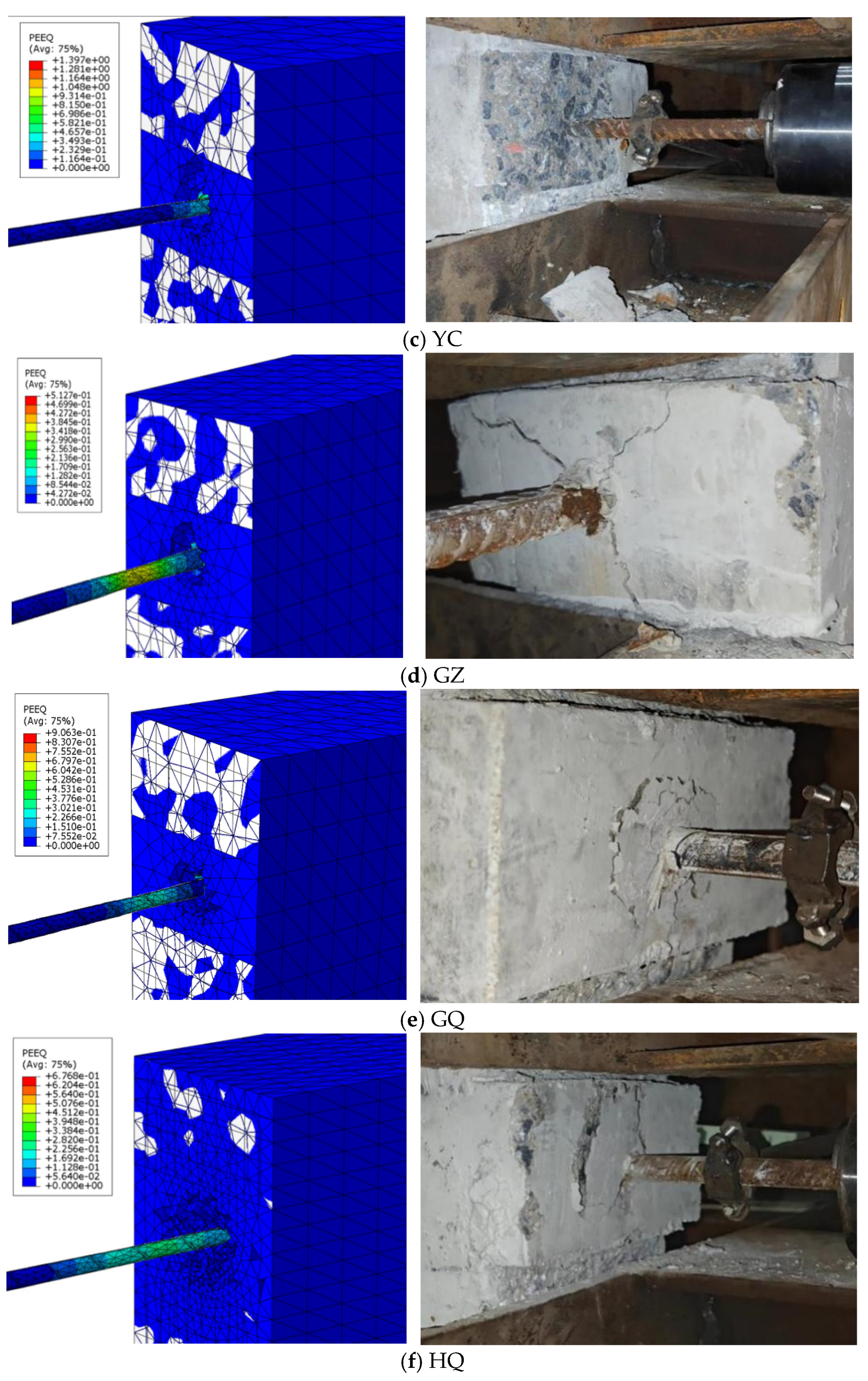

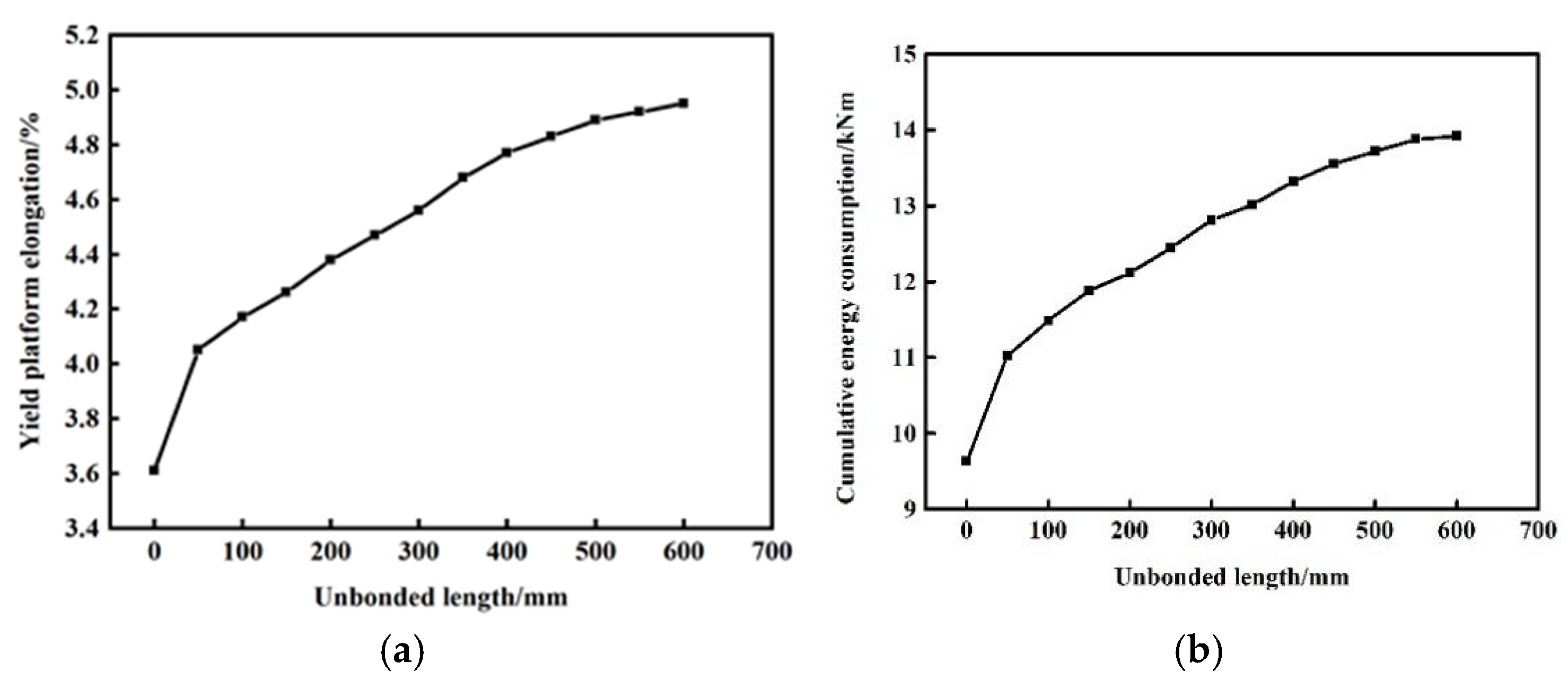

3.3. Verification of Finite Element Model

- (1)

- Failure pattern

- (2)

- Load–Displacement Curves

4. Parameter Analysis of CS-US Hysteresis Properties

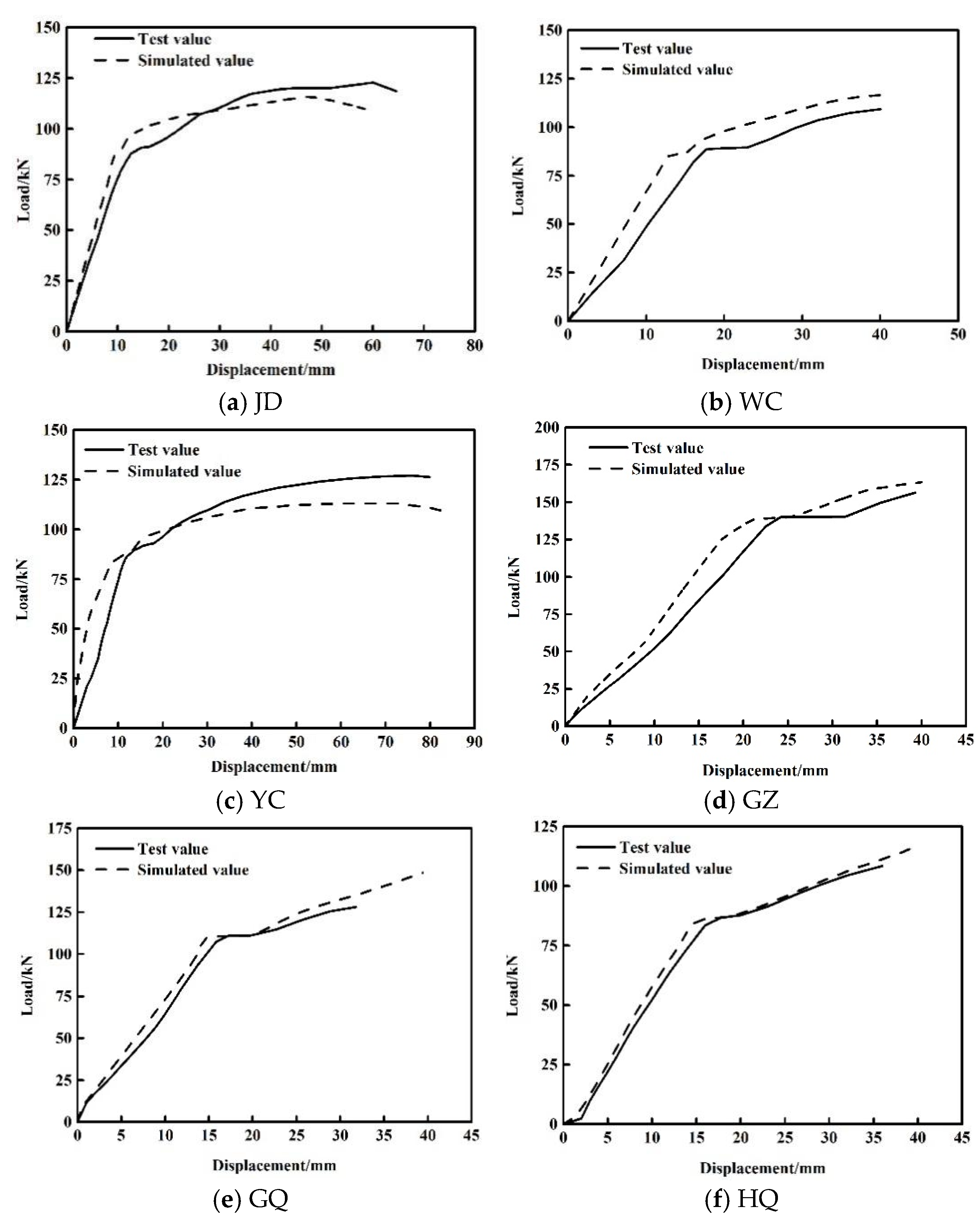

4.1. Unbonded Length

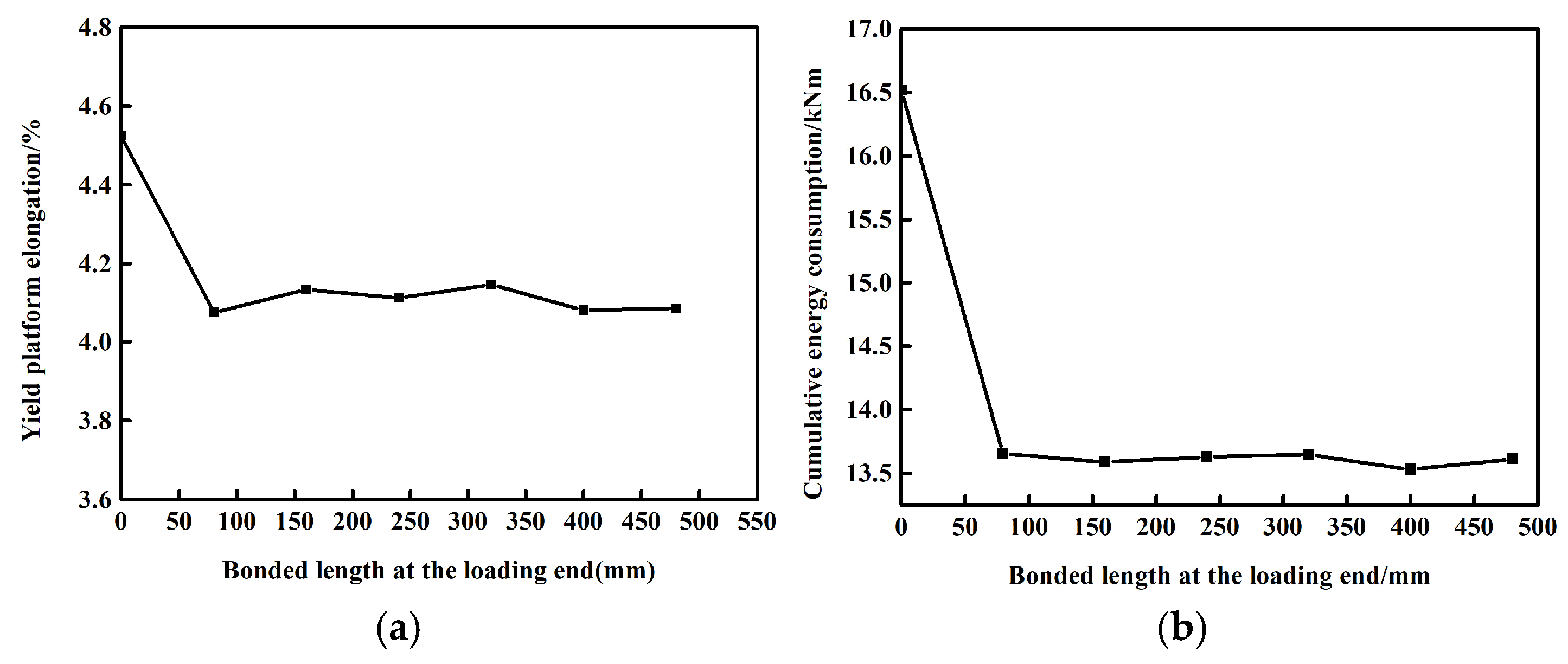

4.2. Location of Unbonded Section

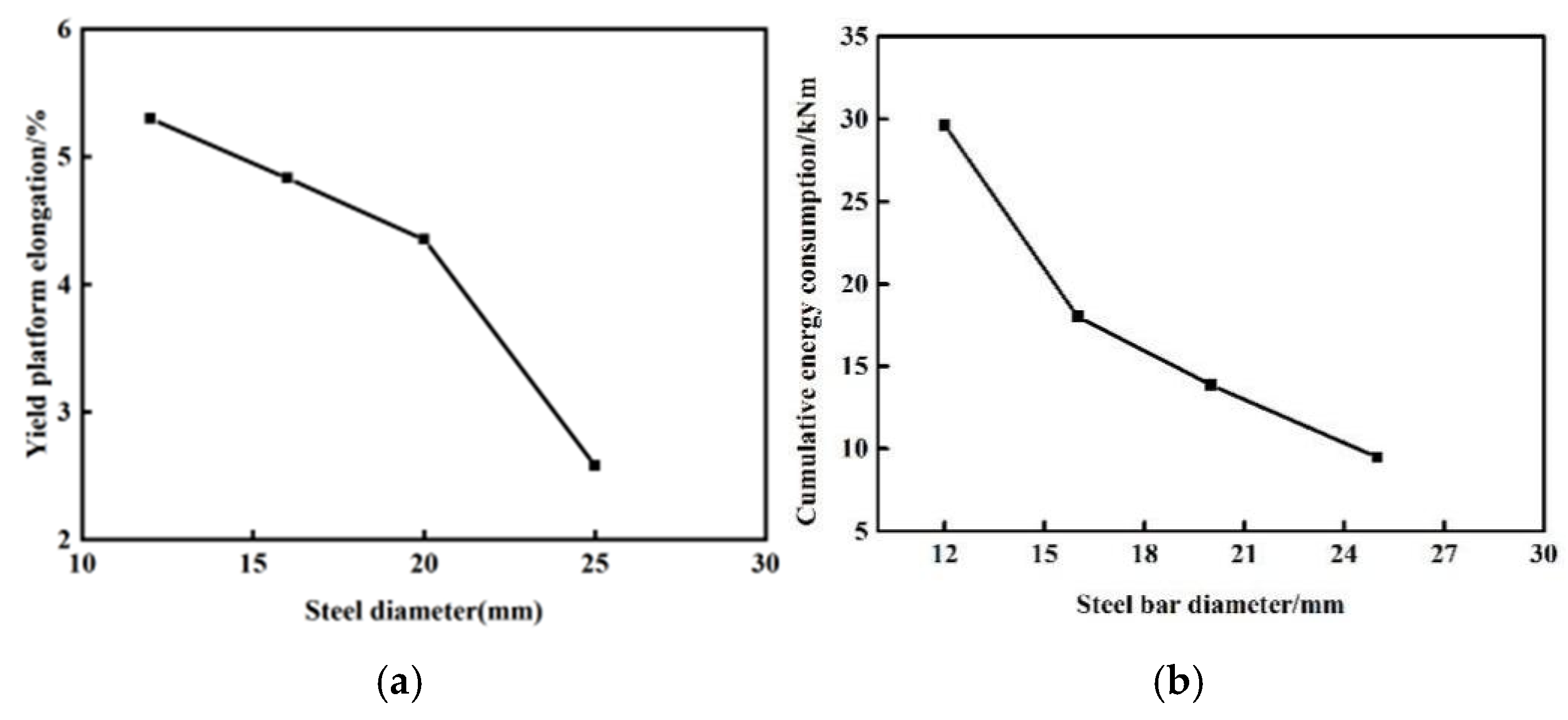

4.3. Steel Bar Diameter

4.4. Steel Bar Strength Grade

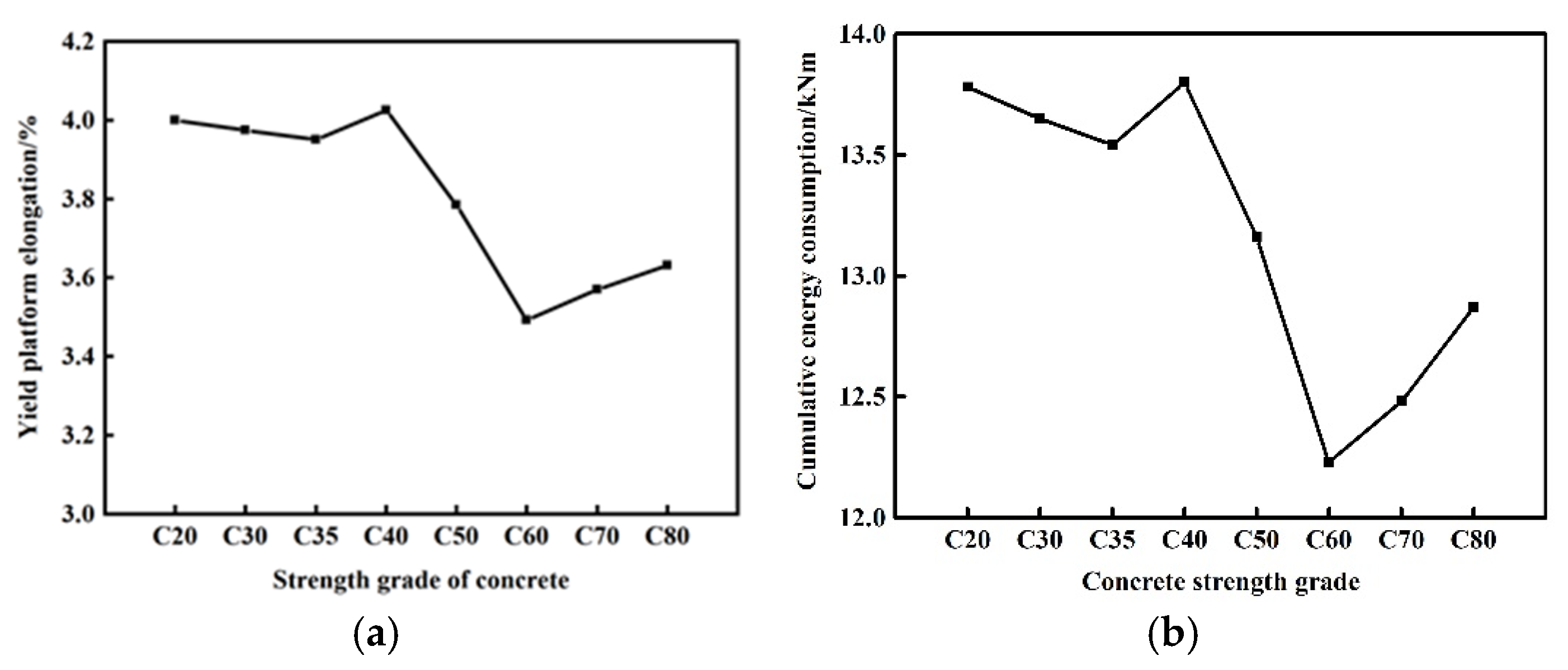

4.5. Concrete Strength Grade

4.6. Design Recommendations

5. Conclusions

- (1)

- The simulated values in the elastic phase are larger than the test values because of the necking of steel bars. Overall, the simulated values of the specimens are similar to the test values.

- (2)

- The efficacy of the unbonded section in enhancing the energy dissipation capacity and ductility of CS-US was demonstrated; furthermore, an increase in the unbonded length corresponds to enhancements in both energy dissipation capacity and ductility. When the unbonded length is in the range of 50 mm to 400 mm, the ductility and energy dissipation capacity of CS-US exhibit more pronounced increases, while in the range of 400 mm to 600 mm, the aforementioned properties of CS-US undergo a more gradual increase.

- (3)

- The setting of the bonded length at the loading end significantly reduces the energy dissipation capacity and ductility of CS-US, and its change has less influence on these parameters.

- (4)

- The larger the steel bar diameter is, the lower the energy dissipation capacity and ductility of CS-US are.

- (5)

- The larger the steel bar strength grade is, the lower the energy dissipation capacity and ductility of CS-US are.

- (6)

- When the concrete strength grade is below C40, the energy dissipation capacity and ductility of CS-US show minimal variations. However, when the concrete strength grade exceeds C40, the energy dissipation capacity and ductility of CS-US initially decrease and then increase, yet they remain lower than those observed in steel bars with concrete strength grades below C40.

- (7)

- Based on the influencing laws of the above parameters, the parameter design recommendations of CS-US are proposed as follows. The unbonded length should be selected within the range of 50–400 mm, and the concrete strength grade should be designated between C20 and C50. The bonded length at the loading end, the diameter of the steel bar, and the steel strength grade should be determined in accordance with the specific circumstances.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.B.; Zheng, S.S.; Dong, L.G.; Yang, S.; Zheng, Y.; Gao, X. Experimental study on bond behavior of corroded reinforcements in concrete under reversed cyclic loading. J. Build. Struct. 2024, 45, 237–248. (In Chinese) [Google Scholar] [CrossRef]

- Jin, L.; Zhang, X.W.; Guo, L.; Wu, J.; Du, X. Effect of loading rate on the bond capacity between the corroded reinforcing bars and concrete. Mater. Rev. 2024, 38, 154–162. (In Chinese) [Google Scholar] [CrossRef]

- Yang, T.; Xu, S.; Yuan, P.; Wang, D.; Liao, R.; Yang, Y.; Shao, R.; Wu, C. Bond performance and constitutive model of steel bar in G-UHPC under cyclic loading. Eng. Struct. 2024, 317, 118671. [Google Scholar] [CrossRef]

- Li, H.; Ping, K.L.; Chen, W.M.; Luo, Y.F.; Cao, Y.G. Study on bonding properties of steel bar and rubber concrete under different loading rates. J. Yangtze River Sci. Res. Inst. 2024, 41, 161–168. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, J.Q.; Tian, Q.L.; Ma, X.B.; Yao, S.F.; Liu, X. Study on influence of different test method on bond-anchorage properties of 630MPa high-strength reinforcement. Build. Struct. 2023, 53, 113–118. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhao, X.Q.; Yao, S.F.; Liu, X. Experiments on the performance of bond anchorage between high-strength variable rib reinforcement and concrete. J. Chongqing Univ. 2020, 43, 32–40. (In Chinese) [Google Scholar] [CrossRef]

- Hu, Z.J.; Ibrahim, S.Y.; Yao, P.F. Experimental and numerical study on interface bond strength and anchorage performance of steel bars within prefabricated concrete. Materials 2021, 14, 3713. [Google Scholar] [CrossRef]

- Niu, J.G.; Bian, Y.; Xie, C.B. Interfacial bond properties between recycled concrete and corroded steel bar. Sci. Technol. Eng. 2020, 20, 7845–7851. (In Chinese) [Google Scholar]

- He, H.N.; Chen, X.X.; Yang, M.M. Analysis of bond-slip performance between corroded steel bars and concrete at different positions of steel bars. J. Harbin Eng. Univ. 2023, 44, 1720–1731. (In Chinese) [Google Scholar] [CrossRef]

- Shang, H.S.; Chai, X. Experimental study on bond behavior of corroded steel bar to concrete under reciprocating load. Mater. Rev. 2023, 37, 133–138. (In Chinese) [Google Scholar] [CrossRef]

- ZHENG, Y.; ZHENG, S.-S.; YANG, L.; DONG, L.-G.; ZHANG, Y.-B. Experimental study and analytical model of the bond behavior of corroded reinforcing steel bars in concrete. Constr. Build. Mater. 2022, 327, 126991. [Google Scholar] [CrossRef]

- Qu, H.; Zhang, S.X.; Li, W.; Li, Y.J. Experimental study on hysteretic behaviors of stainless steel clad rebar considering buckling effect. Eng. Mech. 2024, 41, 106–115. (In Chinese) [Google Scholar] [CrossRef]

- Li, H.Y.; Wu, W.H.; Hou, N.; Li, R.; Deng, R.T.; Zhao, J. Study on bonding and anchoring properties of stainless steel bar and UHPC. J. Xi’an Univ. Architect. Technol. 2023, 55, 633–642. (In Chinese) [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Structural performance of stainless steel reinforced concrete members: A review. Constr. Build. Mater. 2022, 325, 126673. [Google Scholar] [CrossRef]

- Rabi, M. Bond prediction of stainless-steel reinforcement using artificial neural networks. Constr. Mater. 2024, 177, 87–97. [Google Scholar] [CrossRef]

- Rabi, M.; Cashell, K.A.; Shamass, R.; Desnerck, P. Bond behaviour of austenitic stainless steel reinforced concrete. Eng. Struct. 2020, 221, 111027. [Google Scholar] [CrossRef]

- Rabi, M.; Shamass, R.; Cashell, K.A. Description of the constitutive behaviour of stainless steel reinforcement. Case Stud. Constr. Mater. 2024, 20, e03013. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Li, A.; Lei, H. Experimental study on the bond performance of deformed steel bar in ultrahigh performance concrete. Case Stud. Constr. Mat. 2023, 18, e01874. [Google Scholar] [CrossRef]

- Lv, Y.; Zhang, J.; Han, W.; Su, M.; He, X.; Peng, H. Bond strength model between steel rebar and ultrahigh performance concrete containing coarse aggregates. Constr. Build. Mater. 2024, 421, 135710. [Google Scholar] [CrossRef]

- Wang, R.L.; Ma, B.; Chen, X. Experimental study on bond performance between UHPC and steel bars. J. Build. Eng. 2023, 79, 107861. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, L.; Deng, Z.; Zhang, C.; Zhang, Z.; Chen, C.; Pan, J.; Zhang, Y. Bond behavior between steel bars and 3D printed concrete: Effect of concrete rheological property, steel bar diameter and paste coating. Constr. Build. Mater. 2022, 349, 128708. [Google Scholar] [CrossRef]

- Li, Y.Y.; Zhao, Y.L.; Wu, K.; Wang, Q. Bond property and reliability analysis between high strength rebar and ultra-high-performance concrete. Eng. Mech. 2024, 1–10. (In Chinese) [Google Scholar] [CrossRef]

- Gao, X.-L.; Shen, S.-Y.; Wan, Y.; Qin, S.-W. Experimental study on bond behavior of steel bar embedded in thin UHPC. J. Build. Eng. 2024, 86, 108865. [Google Scholar] [CrossRef]

- Chen, Q.J.; Liu, S.T.; Wang, Y.J.; Wen, Y.H.; Kang, Y.K. Study on bonding properties of hybrid basalt-polypropylene fiber concrete and deformed bar. Build. Struct. 2023, 53, 1311–1318. (In Chinese) [Google Scholar] [CrossRef]

- Zhao, M.; Liu, G.; Liu, L.; Zhang, Y.; Shi, K.; Zhao, S. Bond of ribbed steel bar in high-performance steel fiber reinforced expanded-shale lightweight concrete. Buildings 2021, 11, 582. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Özkiliç, Y.O.; Mansour, W. Improving bond performance of ribbed steel bars embedded in recycled aggregate concrete using steel mesh fabric confinement. Constr. Build. Mater. 2023, 369, 130452. [Google Scholar] [CrossRef]

- Gao, D.Y.; Huang, Y.C.; Chen, G.; Yang, L. Bond stress distribution analysis between steel bar and steel fiber reinforced concrete using midpoint stress interpolation method. Constr. Build. Mater. 2020, 260, 119866. [Google Scholar] [CrossRef]

- Piotr, S. Study of bond strength of steel bars in basalt fiber reinforced high performance concrete. Crystals 2020, 10, 436. [Google Scholar] [CrossRef]

- Shamass, R.; Limbachiya, V.; Ajibade, O.; Rabi, M.; Lopez, H.U.L.; Zhou, X. Carbonated aggregates and basalt fiber-reinforced polymers: Advancing sustainable concrete for structural use. Buildings 2025, 15, 775. [Google Scholar] [CrossRef]

- Al-Kheetan, M.; Jweihan, Y.; Rabi, M.; Ghaffar, S.H. Durability enhancement of concrete with recycled concrete aggregate: The role of Nano-ZnO. Buildings 2024, 14, 353. [Google Scholar] [CrossRef]

- Hu, X.P.; Peng, G.; Niu, D.T.; Zhao, N. Bond characteristics of deformed steel bar in early-age frozen concrete during service period. Eng. Struct. 2019, 197, 109438. [Google Scholar] [CrossRef]

- Hu, X.P.; Peng, G.; Niu, D.T.; Wang, J. Experimental study on bond properties between early-age concrete and deformed steel bars. Constr. Build. Mater. 2020, 236, 117593. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Huo, J.S.; Li, Z. Experimental study and analysis on bond behaviour between steel bar and concrete. Build. Struct. 2019, 49, 76–80. (In Chinese) [Google Scholar] [CrossRef]

- Sun, C.-F.; Liang, S.-T.; Zhu, X.-J.; Li, H.; Guo, J.-M.; Li, G.; Song, Y.-M.; Wu, D.-Y. Experimental study and numerical simulation of precast shear wall with rabbet-unbonded horizontal connection. Int. J. Concr. Struct. Mater. 2020, 14, 6. [Google Scholar] [CrossRef]

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- Xu, W.H. Study on Bond Performance Between Corroded Steel Bar and Basalt Fiber Reinforced Concrete After Elevated Temperatures. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2023. (In Chinese). [Google Scholar] [CrossRef]

- Liu, H.F. Suggestion and discussion on the seismic steel property based on the ductility concrete structure. J. Qinghai Univ. 2011, 29, 4–8. (In Chinese) [Google Scholar] [CrossRef]

| Specimen Name | Unbonded Length (mm) | Bonded Length at Loading End (mm) | Steel Bar Diameter (mm) | Steel Bar Strength Grade | Concrete Strength Grade |

|---|---|---|---|---|---|

| JD | 300 | 240 | 16 | HRB400 | C35 |

| WC | 400 | 240 | 16 | HRB400 | C35 |

| YC | 300 | 320 | 16 | HRB400 | C35 |

| GZ | 300 | 240 | 20 | HRB400 | C35 |

| GQ | 300 | 240 | 16 | HRB500 | C35 |

| HQ | 300 | 240 | 16 | HRB400 | C30 |

| Steel Bar Strength Grade | Yield Platform Elongation (%) | Cumulative Energy Dissipation (kNm) |

|---|---|---|

| HRB335 | 4.9 | 15.4 |

| HRB400 | 4.4 | 13.8 |

| HRB500 | 3.8 | 12.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; Zhao, Z.; Dang, L.; Zhang, Z.; Song, Y. Experimental Research and Analysis of Influencing Factors on Hysteresis Properties of Common Steel Bars with Unbonded Sections. Buildings 2025, 15, 1276. https://doi.org/10.3390/buildings15081276

Sun C, Zhao Z, Dang L, Zhang Z, Song Y. Experimental Research and Analysis of Influencing Factors on Hysteresis Properties of Common Steel Bars with Unbonded Sections. Buildings. 2025; 15(8):1276. https://doi.org/10.3390/buildings15081276

Chicago/Turabian StyleSun, Chongfang, Zhipeng Zhao, Longji Dang, Zhenli Zhang, and Yamin Song. 2025. "Experimental Research and Analysis of Influencing Factors on Hysteresis Properties of Common Steel Bars with Unbonded Sections" Buildings 15, no. 8: 1276. https://doi.org/10.3390/buildings15081276

APA StyleSun, C., Zhao, Z., Dang, L., Zhang, Z., & Song, Y. (2025). Experimental Research and Analysis of Influencing Factors on Hysteresis Properties of Common Steel Bars with Unbonded Sections. Buildings, 15(8), 1276. https://doi.org/10.3390/buildings15081276