Building with Snow: Technical Exploration and Practice of Snow Materials and Snow Architecture

Abstract

1. Origin and Preliminary Exploration of Snow Architecture

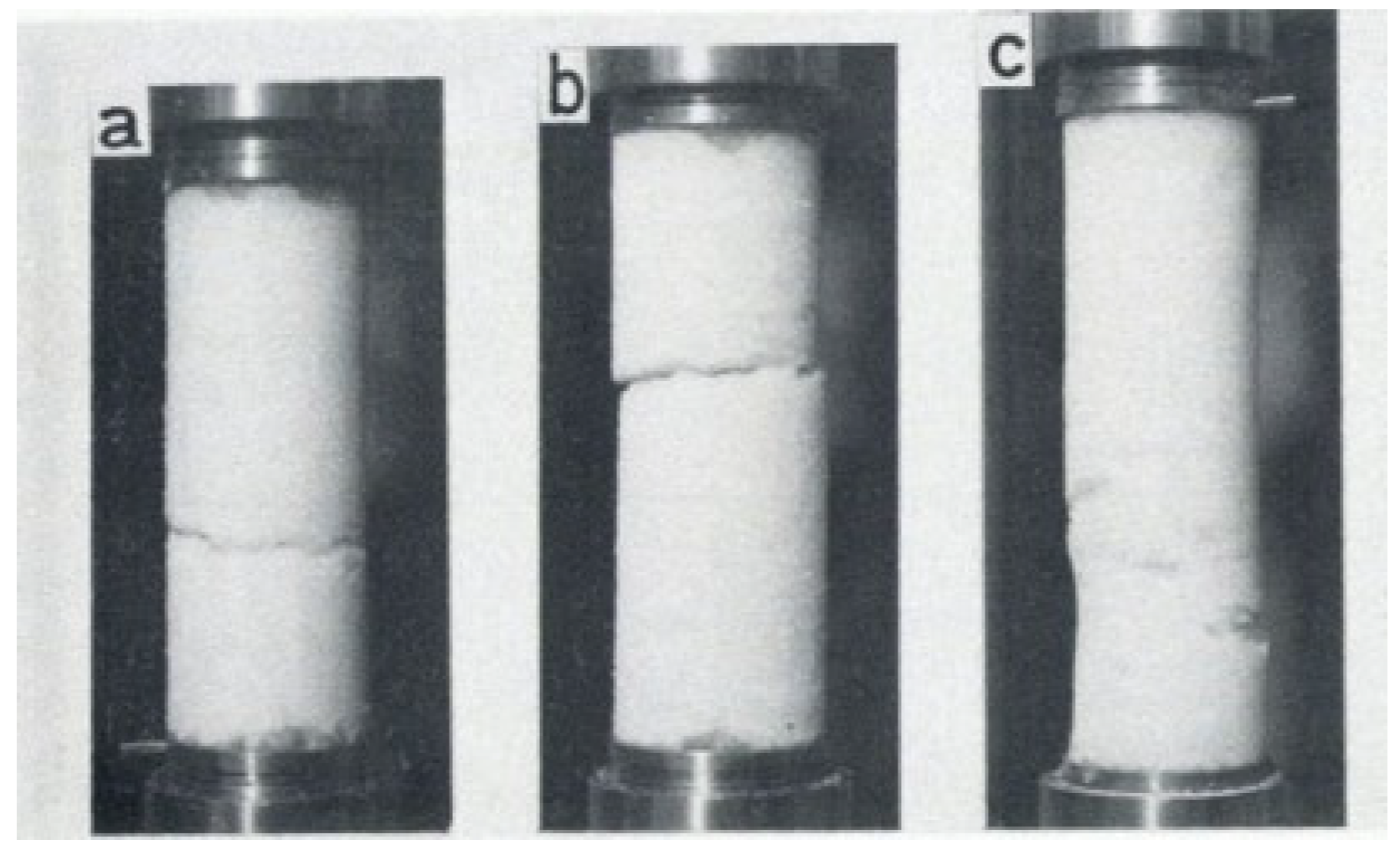

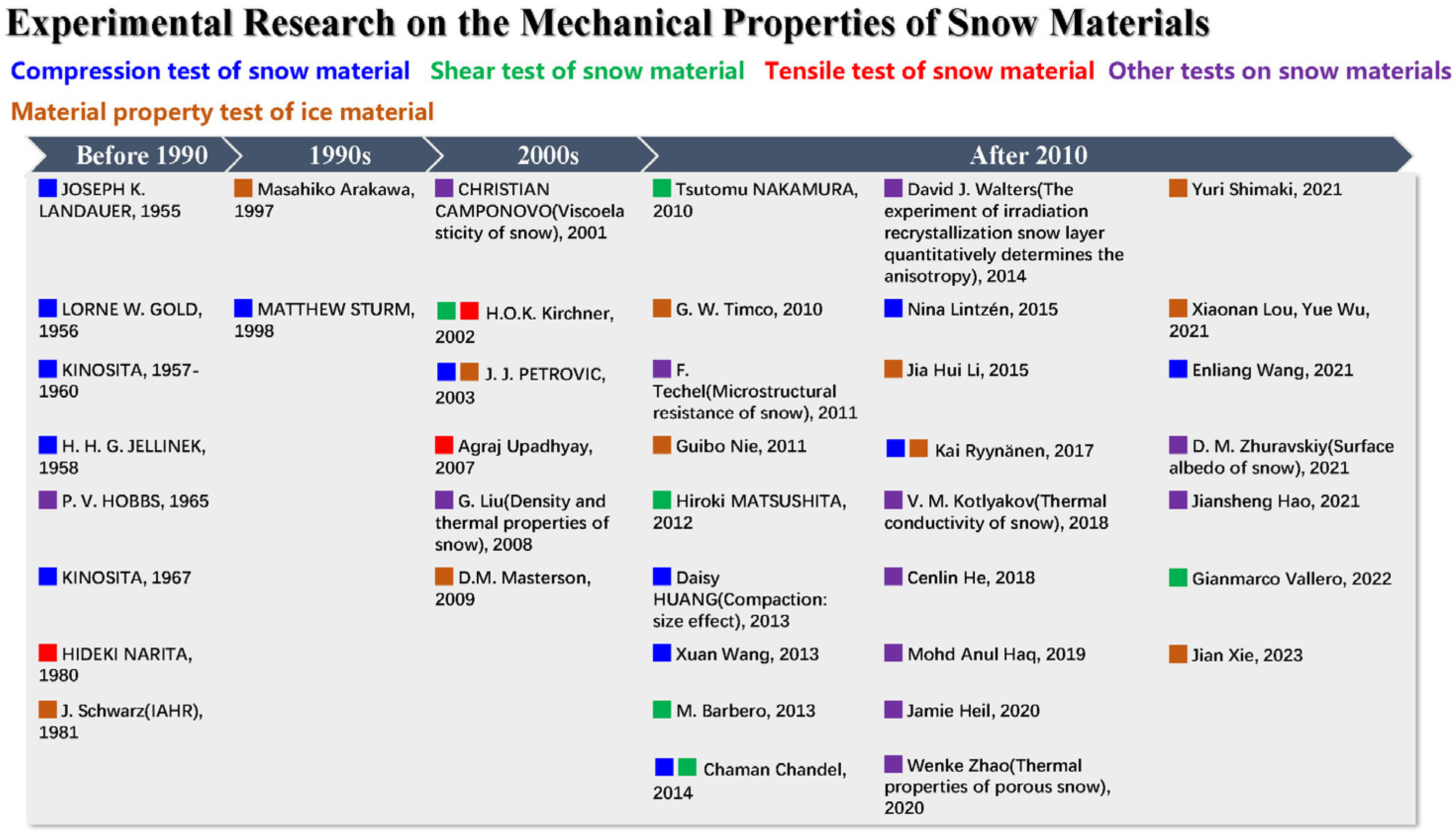

2. Research Status of Snow Materials

3. The Current State of Snow Architecture Design Research

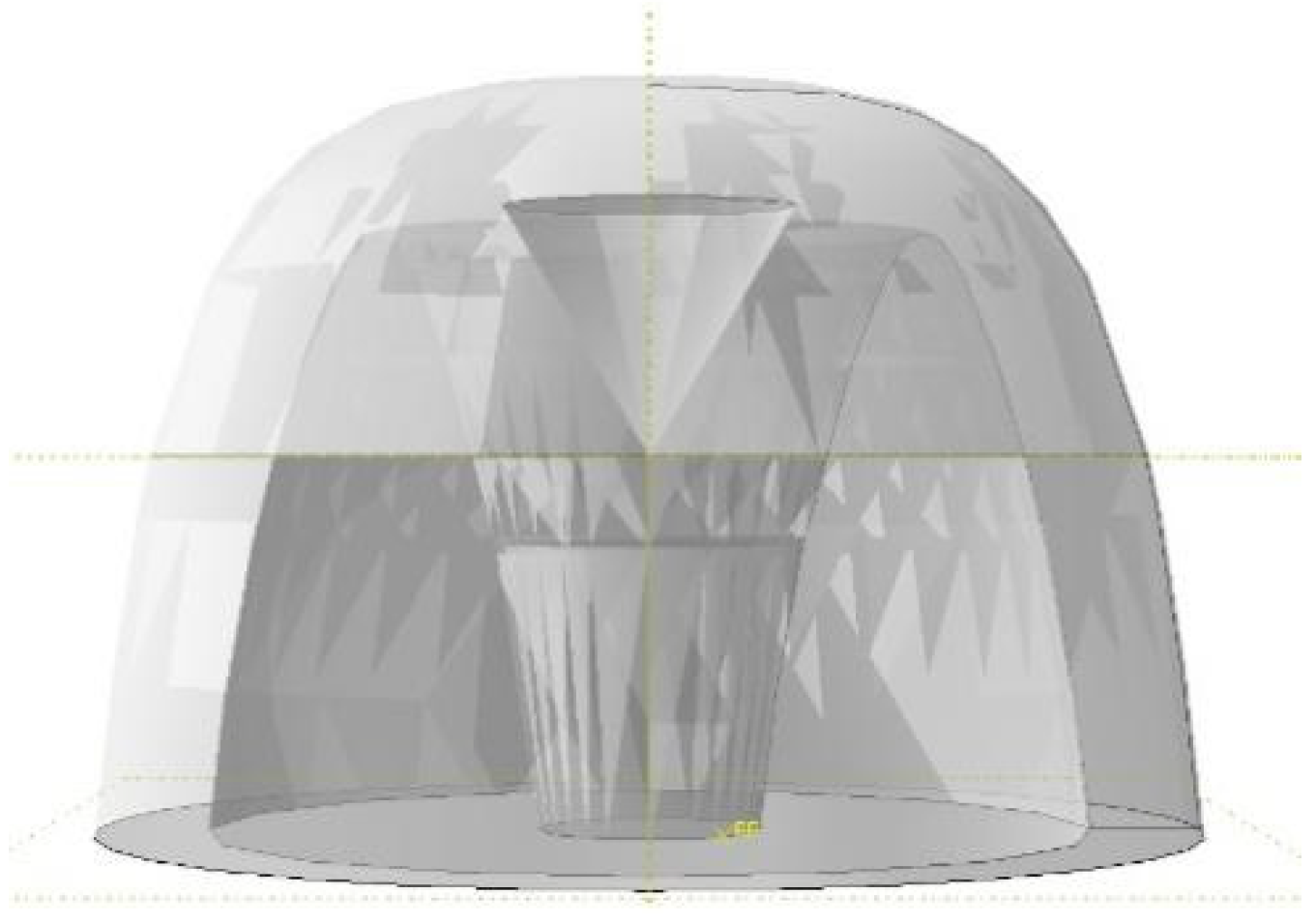

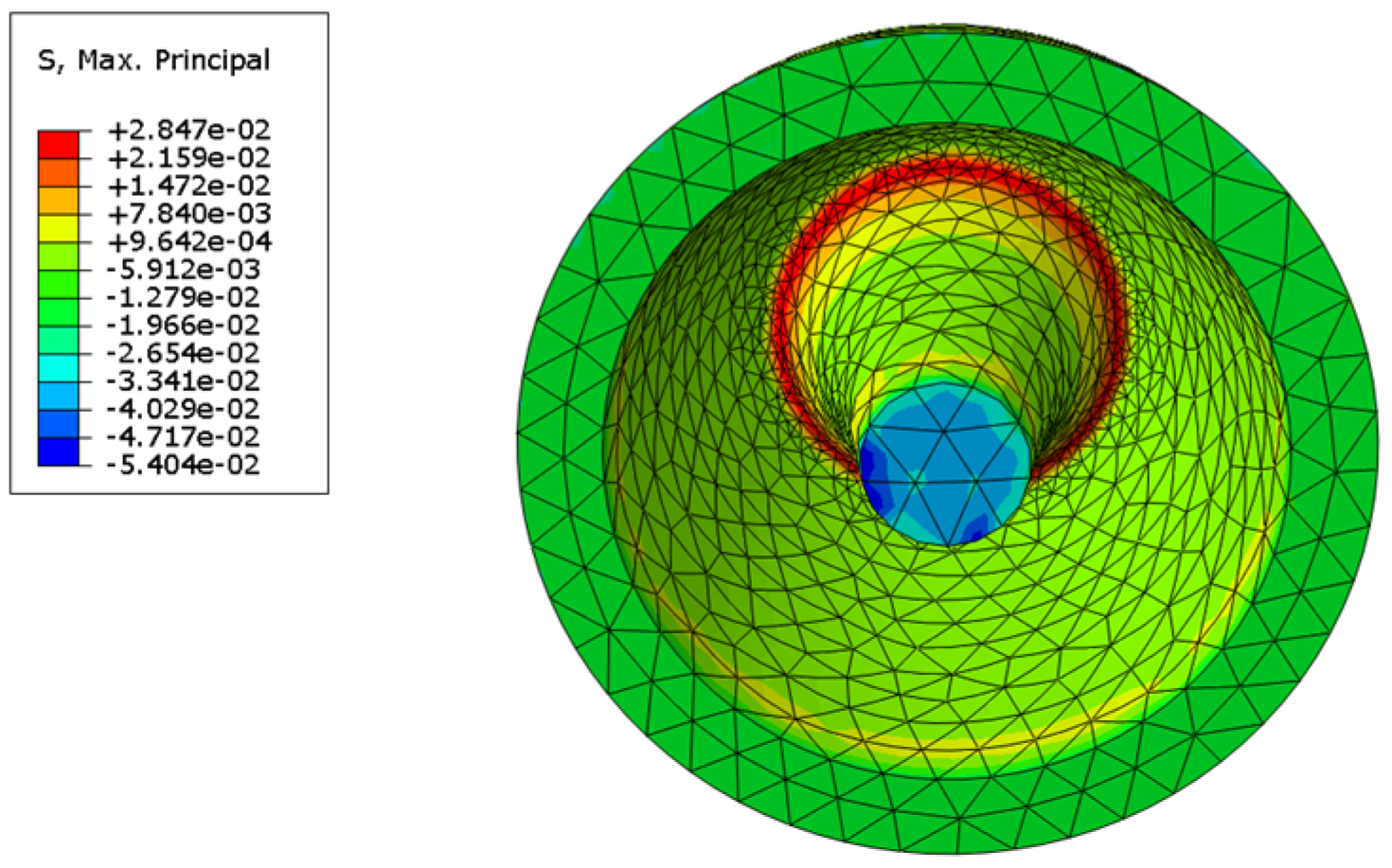

4. Research Status of Snow Architecture Structure and Construction Technology

5. Technical Exploration and Practice of Snow Architecture

6. Conclusions and Future Outlook

Funding

Conflicts of Interest

References

- Li, J.H.; Wei, Z.; Wu, C. Preparation and properties of novel building materials at low temperature. Cold Reg. Sci. Technol. 2015, 67, 464–468. [Google Scholar] [CrossRef]

- Chu, X. Saga Dzong Snow Building and Its Characteristics. Shanxi Archit. 2009, 35, 34–36. [Google Scholar]

- Wang, J. Foreign Snow Buildings. Theory Learn. 2008, 1, 72–73. [Google Scholar]

- Golubev, V.N.; Frolov, A.D. Model of structure and mechanical properties of dry granular snow. Ann. Glaciol. 2000, 31, 434–438. [Google Scholar] [CrossRef]

- Barnett, T.P.; Dümenil, L.; Schlese, U.; Roeckner, E.; Latif, M. The Effect of Eurasian Snow Cover on Regional and Global Climate Variations. J. Atmos. Sci. 1989, 46, 661–686. [Google Scholar] [CrossRef]

- Petrovic, J.J. Mechanical properties of ice and snow. J. Mater. Sci. 2003, 38, 1–6. [Google Scholar] [CrossRef]

- Masterson, D.M. State of the art of ice bearing capacity and ice construction. Cold Reg. Sci. Technol. 2009, 58, 99–112. [Google Scholar] [CrossRef]

- Landauer, J.K. Stress-Strain Relations in Snow under Uniaxial Compression. J. Appl. Phys. 1955, 26, 1493–1497. [Google Scholar] [CrossRef]

- Lintzén, N.; Edeskär, T. Uniaxial Strength and Deformation Properties of Machine-Made Snow. J. Cold Reg. Eng. 2015, 29, 04014020. [Google Scholar] [CrossRef]

- Lou, X.; Wu, Y.; Huang, J.; Chen, Z. The tensile mechanical properties and constitutive model of plain ice and fiber-reinforced ice for construction. Constr. Build. Mater. 2023, 394, 132050. [Google Scholar] [CrossRef]

- Gold, L.W. The Strength of Snow in Compression. J. Glaciol. 1956, 2, 719–725. [Google Scholar] [CrossRef]

- Huo, H.F.; Hu, B.; Li, T. DEM analyses of mesoscopic failure mechanism and stress bearing mechanism of compacted snow subjected to unconfined compressive loading. Cold Reg. Sci. Technol. 2023, 216, 103993. [Google Scholar] [CrossRef]

- Huo, H.; Chen, Q.; Xiao, E.; Li, H.; Xu, H.; Li, T.; Tang, X. Long-term one-dimensional compression tests and fractional creep model of compacted snow. Cold Reg. Sci. Technol. 2024, 228, 104326. [Google Scholar] [CrossRef]

- Kinoshita, S. The Relation between the Deformation Velocity of Snow and Two Types of its Deformation (Plastic and Destructive). Low temperature science. Ser. A Phys. Sci. 1957, 16, 139–166. [Google Scholar]

- Kinoshita, S. The Relation between the Deformation Velocity of Snow and the Types of its Deformation II. Low temperature science. Ser. A Phys. Sci. 1958, 17, 11–30. [Google Scholar]

- Kinoshita, S. The Relation between the Deformation Velocity of Snow and the Types of its Deformation III. Low temperature science. Ser. A Phys. Sci. 1960, 19, 135–146. [Google Scholar]

- Narita, H. Mechanical behavior and structure of snow under uniaxial tensile stress. J. Glaciol. 1980, 26, 275–282. [Google Scholar] [CrossRef]

- Kirchner, H.; Michot, G.; Schweizer, J. Fracture toughness of snow in shear and tension. Scr. Mater. 2002, 46, 425–429. [Google Scholar] [CrossRef]

- Kinoshita, S. Compression of Snow at Constant Speed. Phys. Snow Ice Proc. 1967, 1, 911–927. [Google Scholar]

- Jellinek, H.H.G. Compressive Strength Properties of Snow. J. Glaciol. 1959, 3, 345–354. [Google Scholar] [CrossRef]

- Huang, D.; Lee, J.H. Mechanical properties of snow using indentation tests: Size effects. J. Glaciol. 2013, 59, 35–46. [Google Scholar] [CrossRef]

- Chandel, C.; Mahajan, P.; Srivastava, P.K.; Kumar, V. The behaviour of snow under the effect of combined compressive and shear loading. Curr. Sci. A Fortn. J. Res. 2014, 107, 888–894. [Google Scholar]

- Libbrecht, K.G. The physics of snow crystals. Rep. Prog. Phys. 2005, 68, 855–895. [Google Scholar] [CrossRef]

- Theodore, R. Butkovich. Strength studies of high-density snows. Trans. Am. Geophys. Union 1958, 39, 305–312. [Google Scholar]

- Matsushita, H.; Matsuzawa, M.; Abe, O. The influences of temperature and normal load on the shear strength of snow consisting of precipitation particles. Ann. Glaciol. 2012, 53, 31–38. [Google Scholar] [CrossRef]

- Golubev, V.N.; Frolov, A.D. Modelling the change in structure and mechanical properties in dry snow densification to ice. Ann. Glaciol. 1998, 26, 45–50. [Google Scholar] [CrossRef]

- Wang, X.; Baker, I. Observation of the microstructural evolution of snow under uniaxial compression using X-ray computed microtomography. J. Geophys. Res. D Atmos. JGR 2013, 118, 12371–12382. [Google Scholar] [CrossRef]

- Haq, M.A.; Ghosh, A.; Rahaman, G.; Baral, P. Artificial neural network-based modeling of snow properties using field data and hyperspectal imagery. Nat. Resour. Model. 2019, 32, e12229. [Google Scholar] [CrossRef]

- Arakawa, M.; Maeno, N. Mechanical strength of polycrystalline ice under uniaxial compression. Cold Reg. Sci. Technol. 1997, 26, 215–229. [Google Scholar] [CrossRef]

- Afzali, S.; Taylor, R.; Sarracino, R. Experimental investigation on the tensile strength of freshwater freeze-bonds. Cold Reg. Sci. Technol. 2023, 210, 103823. [Google Scholar] [CrossRef]

- Hagenmuller, P.; Theile, T.C.; Schneebeli, M. Numerical simulation of microstructural damage and tensile strength of snow. Geophys. Res. Lett. 2014, 41, 86–89. [Google Scholar] [CrossRef]

- Golubev, V.N.; Frolov, A.D. On the correlation between tensile strength and stress wave velocities of dry coherent snow based on its structural model. Ann. Glaciol. 2001, 32, 70–74. [Google Scholar] [CrossRef][Green Version]

- Sturm, M.; Holmgren, J. Differences in compaction behavior of three climate classes of snow. Ann. Glaciol. 1998, 26, 125–130. [Google Scholar] [CrossRef]

- Brown, R.D.; Goodison, B.E. Interannual variability in reconstructed Canadian snow cover, 1915–1992. J. Clim. 1996, 9, 1299–1318. [Google Scholar] [CrossRef]

- Vallero, G.; Barbero, M.; Barpi, F.; Borri-Brunetto, M.; De Biagi, V.; Ito, Y.; Yamaguchi, S. Experimental study of the shear strength of a snow-mortar interface. Cold Reg. Sci. Technol. 2022, 193, 103430. [Google Scholar] [CrossRef]

- De La Chapelle, S.; Milsch, H.; Castelnau, O.; Duval, P. Compressive creep of ice containing a liquid intergranular phase rate-controlling processes in the dislocation creep regime. Geophys. Res. Lett. 1999, 26, 251–254. [Google Scholar] [CrossRef]

- De La Chapelle, S.; Duval, P.; Baudelet, B. Compressive creep of polycrystalline ice containing a liquid phase. Saipta Metall. Mater. 1995, 33, 447–450. [Google Scholar] [CrossRef]

- Rixen, C.; Haeberli, W.; Stoeckli, V. Ground Temperatures under Ski Pistes with Artificial and Natural Snow. Arct. Antarct. Alp. Res. 2004, 36, 419–427. [Google Scholar] [CrossRef]

- Wang, E.; Fu, X.; Han, H.; Liu, X.; Xiao, Y.; Leng, Y. Study on the mechanical properties of compacted snow under uniaxial compression and analysis of influencing factors. Cold Reg. Sci. Technol. 2021, 182, 103215. [Google Scholar] [CrossRef]

- Kotlyakov, V.M.; Sosnovskiy, A.V.; Osokin, N.I. Estimation of thermal conductivity of snow by its density and hardness in Svalbard. Ice Snow 2018, 58, 343–352. [Google Scholar] [CrossRef]

- West, B.; Hodgdon, T.; O’Connor, D.; Parno, J.; Courville, Z. Peridynamic modeling of the micromechanical response of snow under high strain rates. Cold Reg. Sci. Technol. 2024, 218, 104055. [Google Scholar] [CrossRef]

- Lou, X.; Wu, Y. Splitting tensile mechanical properties of plain ice and fiber—Reinforced ice. Cold Reg. Sci. Technol. 2021, 192, 103381. [Google Scholar] [CrossRef]

- Mccallum, A.B.; Wiegand, A. Simple Method for Estimating Snow Strength Using CPT Sleeve Friction Data. J. Cold Reg. Eng. 2018, 32, 04018013. [Google Scholar] [CrossRef]

- Johnson, J.B.; Schneebeli, M. Characterizing the microstructural and micromechanical properties of snow. Cold Reg. Sci. Technol. 1999, 30, 91–100. [Google Scholar] [CrossRef]

- Wei, X. Research on Solar Snow (Ice) Melting Technology of Cement Concrete Pavements in High Cold Areas of Tibet; Chang’an University: Xi’an, China, 2013. [Google Scholar]

- Mulak, D.; Gaume, J. Numerical investigation of the mixed-mode failure of snow. Comput. Part. Mech. 2019, 6, 439–447. [Google Scholar] [CrossRef]

- Nie, G.; Zhi, X.; Fan, F.; Kokawa, T.; Niu, S.; Yu, Z.W. Construction and Experiment of the Harbin Ice Shell. Adv. Mater. Res. 2011, 168–170, 398–403. [Google Scholar] [CrossRef]

- Shimaki, Y.; Arakawa, M. Tensile strength and elastic properties of fine-grained ice aggregates: Implications for crater formation on small icy bodies. Icarus 2021, 369, 114646. [Google Scholar] [CrossRef]

- Ryynänen, K. Safe Snow and Ice Construction to Arctic Conditions. In The Interconnected Arctic—UArctic Congress 2016; Springer International Publishing: Cham, Switzerland, 2017; Volume 28, pp. 277–282. [Google Scholar]

- Hobbs, P.V. The effect of time on the physical properties of deposited snow. J. Geophys. Res. 1965, 70, 3903–3907. [Google Scholar] [CrossRef]

- Barbero, M.; Barpi, F.; Borri-Brunetto, M.; Pallara, O. An Apparatus for In Situ Direct Shear Tests on Snow. Exp. Tech. 2016, 40, 149–158. [Google Scholar] [CrossRef]

- Walters, D.J.; Adams, E.E. Quantifying anisotropy from experimental testing of radiation recrystallized snow layers. Cold Reg. Sci. Technol. 2014, 97, 72–80. [Google Scholar] [CrossRef]

- Hao, J.; Mind’je, R.; Feng, T.; Li, L. Performance of snow density measurement systems in snow stratigraphies. Hydrol. Res. 2021, 52, 834–846. [Google Scholar] [CrossRef]

- Schwarz, J.; Frederking, R.; Gavrillo, V.; Petrov, I.; Hirayama, K.-I.; Mellor, M.; Tryde, P.; Vaudrey, K. Standardized Testing Methods for Measuring Mechanical Properties of Ice. Cold Reg. Sci. Technol. 1981, 4, 245–253. [Google Scholar] [CrossRef]

- Techel, F.; Pielmeier, C.; Schneebeli, M. Microstructural resistance of snow following first wetting. Cold Reg. Sci. Technol. 2011, 65, 382–391. [Google Scholar] [CrossRef]

- Liu, G.; Si, B.C. Dual-probe heat pulse method for snow density and thermal properties measurement. Geophys. Res. Lett. 2008, 35, L16404. [Google Scholar] [CrossRef]

- Heil, J.; Mohammadian, B.; Sarayloo, M.; Bruns, K.; Sojoudi, H. Relationships between Surface Properties and Snow Adhesion and Its Shedding Mechanisms. Appl. Sci. 2020, 10, 5407. [Google Scholar] [CrossRef]

- He, C.; Liou, K.N.; Takano, Y.; Yang, P.; Qi, L.; Chen, F. Impact of Grain Shape and Multiple Black Carbon Internal Mixing on Snow Albedo: Parame-terization and Radiative Effect Analysis. J. Geophys. Res. Atmos. 2018, 123, 1253–1268. [Google Scholar] [CrossRef]

- Camponovo, C.; Schweizer, J. Rheological measurements of the viscoelastic properties of snow. Ann. Glaciol. 2001, 32, 44–50. [Google Scholar] [CrossRef][Green Version]

- Upadhyay, A.; Joshi, S.K.; Chandel, C. Tensile Strength of Snow using Centrifugal Technique. Def. Sci. J. 2007, 57, 787–795. [Google Scholar] [CrossRef]

- Nakamura, T.; Abe, O.; Hashimoto, R.; Ohta, T. A dynamic method to measure the shear strength of snow. J. Glaciol. 2010, 56, 333–338. [Google Scholar] [CrossRef]

- Zhao, W.; Li, L.; Wang, W.; Zhang, Y.; Su, W.; Chen, X.; Li, B. Thermal performances of porous snow by a hydronic heating system at different weather conditions. J. Therm. Anal. Calorim. 2020, 141, 1519–1528. [Google Scholar] [CrossRef]

- Zhuravskiy, D.M.; Ivanov, B.V. A Technique for Photogra metric Estimation of Albedo of Snow–Ice Surfaces. Izv. Atmos. Ocean. Phys. 2021, 57, 1561–1565. [Google Scholar] [CrossRef]

- Xie, J.; Yan, M.; Yan, J. Experimental study on PVA reinforced salt-water ice under uniaxial-compression at arctic low temperatures. Cold Reg. Sci. Technol. 2023, 206, 103751. [Google Scholar] [CrossRef]

- Theile, T.; Löwe, H.; Theile, T.C.; Schneebeli, M. Simulating creep of snow based on microstructure and the anisotropic deformation of ice. Acta Mater. 2011, 59, 7104–7113. [Google Scholar] [CrossRef]

- Timco, G.W.; Weeks, W.F. A review of the engineering properties of sea ice. Cold Reg. Sci. Technol. 2010, 60, 107–129. [Google Scholar] [CrossRef]

- Li, W.; Sun, S.; Wang, B.; Liu, X. Numerical Simulation of Sensitivities of Snow Melting to Spectral Composition of the Incoming Solar Radiation. Adv. Atmos. Sci. 2009, 26, 403–412. [Google Scholar] [CrossRef]

- Xu, H. Fluid Heating Road Snow Melting System—Coupled Moisture and Temperature Snow Melting Model and Simulation Analysis; Harbin Institute of Technology: Harbin, China, 2012. [Google Scholar]

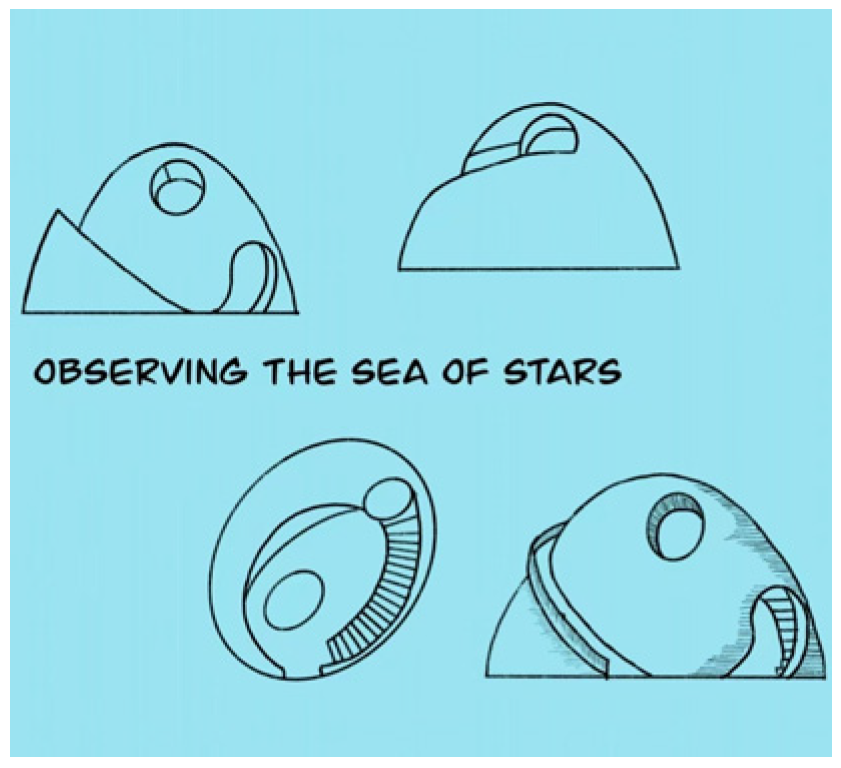

- Xin, C.; Luo, P.; Yang, S.; Sun, J. Deduction of Natural Attributes—Exploration of Contemporary Snow Architecture Innovation Practice. Contemp. Archit. 2023, S1, 47–52. [Google Scholar]

- Wang, Y.; Yao, S.W.; Yang, H.W. A fractal derivative model for snow’s thermal insulation property. Therm. Sci. 2019, 23, 2351–2354. [Google Scholar] [CrossRef]

- Mellor, M. Snow concentration and effective air density during snow-falls. J. Glaciol. 1983, 29, 505–507. [Google Scholar] [CrossRef]

- Yang, J. Characteristics, Design, and Construction of Snow Buildings. Heilongjiang Sci. Technol. Inf. 2001, 01, 46. [Google Scholar]

- Yan, M.L.; Xie, J.; Yan, J.B. Mode I fracture behaviors of plain and PVA reinforced ice at Arctic low temperatures. Cold Reg. Sci. Technol. 2023, 216, 104012. [Google Scholar] [CrossRef]

- Kirchner, H.O.K.; Peterlik, H.; Michot, G. Size independence of the strength of snow. Phys. Rev. E 2004, 69, 011306. [Google Scholar] [CrossRef] [PubMed]

- Wergin, W.P.; Rango, A.; Erbe, E.F. Observations of Snow Crystals Using Low-Temperature Scanning Electron Microscopy. Scanning 1995, 17, 41–49. [Google Scholar] [CrossRef]

- GB51202-2016; Technical Standard for Ice and Snow Landscape Architecture. China Architecture Industry Press: Beijing, China, 2016.

- Wu, J.Y.; Li, J.; Faria, R. An energy release rate-based plastic-damage model for concrete. Int. J. Solids Struct. 2006, 43, 583–612. [Google Scholar] [CrossRef]

- Abdel-Tawab, K.; Rodin, G.J. Analysis of primary creep of S2 fresh-water and saline ice. Cold Reg. Sci. Technol. 1997, 26, 83–96. [Google Scholar] [CrossRef]

- Yue, P. Discrete Element Method Numerical Simulation Study on the Formation and Release Mechanism of Avalanches; Lanzhou University: Lanzhou, China, 2022. [Google Scholar]

- Bamzai, A.S.; Shukla, J. Relation between Eurasian Snow Cover, Snow Depth, and the Indian Summer Monsoon: An Observational Study. J. Clim. 1999, 12, 3117–3132. [Google Scholar] [CrossRef]

- Mellor, M.; Testa, R. Creep of ice under low stress. J. Glaciol. 1969, 8, 147–152. [Google Scholar] [CrossRef]

- Wilkinson, D.S. A pressure sintering model for the densification of polar firn and glacier ice. J. Glaciol. 1988, 34, 40–45. [Google Scholar] [CrossRef]

- Shazly, M.; Prakash, V.; Lerch, B.A. High strain-rate behavior of ice under uniaxial compression. Int. J. Solids Struct. 2009, 46, 1499–1515. [Google Scholar] [CrossRef]

- Song, M.; Cole, D.M.; Baker, I. An investigation of the effects of particles on creep of polycrystalline ice. Scr. Mate-Rialia 2006, 55, 91–94. [Google Scholar] [CrossRef]

- Song, M. An evaluation of the rate-controlling flow process in Newtonian creep of polycrystalline ice. Mater. Sci. Eng. A 2008, 486, 27–31. [Google Scholar] [CrossRef]

- Hagenmuller, P.; Chambon, G.; Naaim, M. Microstructure-based modeling of snow mechanics: A discrete element approach. Cryosphere 2015, 9, 1969–1982. [Google Scholar] [CrossRef]

- Song, M.; Cole, D.M.; Baker, I. Initial experiments on the effects of particles at grain boundaries on the anelasticity and creep behavior of granular ice. Ann. Glaciol. 2004, 39, 397–401. [Google Scholar] [CrossRef]

- Dai, H.; Di, S.; Xue, Y.Z. Microscopic mechanism of plastic heterogeneous deformation of columnar-grained polycrystalline ice. Cold Reg. Sci. Technol. 2024, 222, 104183. [Google Scholar] [CrossRef]

- Lou, X.; Wu, Y.; Liu, X.M. A double scalar elastic damage constitutive model of ice materials. Int. J. Mech. Cal Sci. 2023, 237, 107807. [Google Scholar] [CrossRef]

- Wei, P.; Zhuang, D.; Zheng, Y.Y.; Zaoui, A.; Ma, W. Temperature and pressure effect on tensile behavior of ice-Ih under low strain rate: A molecular dynamics study. J. Mol. Liq. 2022, 355, 118945. [Google Scholar] [CrossRef]

- Dong, C.; Meng, Y.; Liu, Y.; Huang, Z.; Ma, L. Study on the ice friction characteristics. Cold Reg. Sci. Technol. 2023, 216, 104010. [Google Scholar] [CrossRef]

- Liu, R.; Xue, Y.; Han, D.; Ni, B. Studies on model-scale ice using micro-potential-based peridynamics. Ocean Eng. 2021, 221, 108504. [Google Scholar] [CrossRef]

- McClung, D. Comparison of analytical snow pressure models. Can. Geotech. J. 1993, 30, 947–952. [Google Scholar] [CrossRef]

- Barrett, J.W.; Garcke, H.; Nürnberg, R. Numerical computations of facetted pattern formation in snow crystal growth. Phys. Rev. E 2012, 86, 011604. [Google Scholar] [CrossRef]

- Miller, D.; Adams, E.; Schmidt, D.; Brown, R. Preliminary experimental evidence of heating at the running surface of avalanching snow. Cold Reg. Sci. Technol. 2003, 37, 421–427. [Google Scholar] [CrossRef]

| Research Methods | Specific Content | Relevant Evaluation |

|---|---|---|

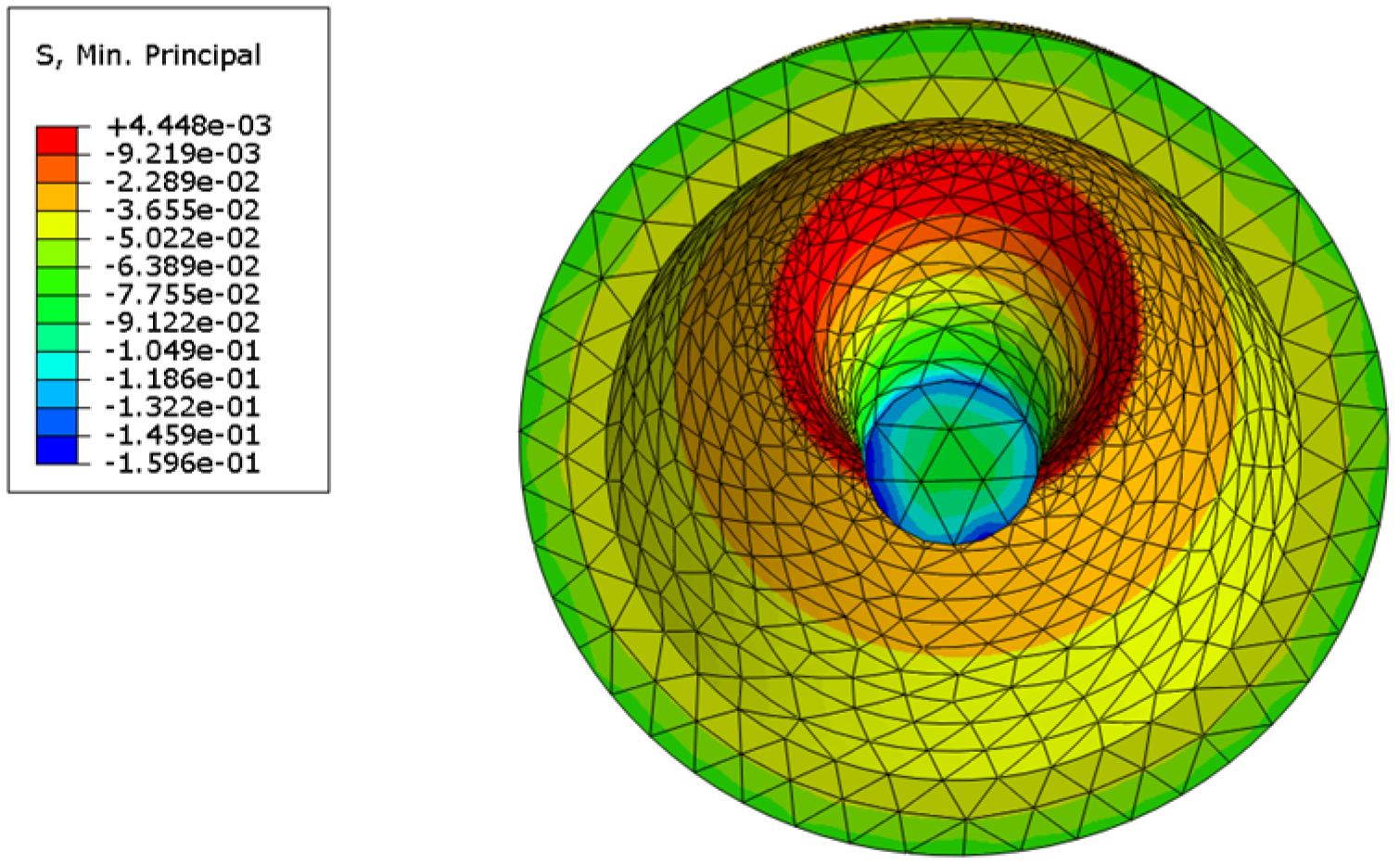

| Finite element method | Snow with a density greater than 0.6 can be considered a continuous medium. | Elastic–plastic + thermal damage |

| Discrete element method | Using discrete element software analysis, a bond between particles is established. | Critical strain of snow-to-ice transformation |

| Near-field dynamics | Snowflake shapes, type I-h single-crystal ice, snow is modeled as an ensemble of ice single crystals with random orientations, isotropic Norton creep law. | Constitutive model of ice material |

| Parameter Name | Parameter Value |

|---|---|

| Material density | 510 kg/m3 |

| Modulus of elasticity | 162 MPa |

| Poisson’s ratio | 0.3 |

| Calculate the thickness of the structure | 1.5 m |

| −15 °C tensile strength | 0.043 MPa |

| −15 °C compressive strength | 0.164 MPa |

| Serial Number | Detect Content | Control Indicators | |

|---|---|---|---|

| 1 | Structural morphometry | Structural span | The comparison deviation with the design model is less than 10%. |

| Height of structure | |||

| 2 | Measurement of structural thickness | Thickness of snow shell | The thickness of the snow shell structure at different positions should not be less than that required by the construction drawings. |

| 3 | Material strength test | Compressive strength | Controlling the uniaxial compressive strength of artificial and natural snow. |

| Tensile strength | Controlling the uniaxial tensile strength of artificial and natural snow. | ||

| Dimension (m) | Snow Shell Design Scheme | Actual Snow Shell Structure | Deviation |

|---|---|---|---|

| Inner diameter | 1.8 | 1.65 | 8% |

| Height | 2.3 | 2.2 | 4% |

| Snow Shell | Elevation (m) | Design Thickness (mm) | Measuring Point | Measured Thickness (mm) |

|---|---|---|---|---|

| Kamakura | +0.600 | 170.0 | J-Z1, J-Z2, J-Z33, J-Z34 | Left side 218, Right side 151 |

| +0.800 | 160.0 | J-Z3, J-Z4, J-Z31, J-Z32 | Left side 240, Right side 161 | |

| +1.200 | 150.0 | J-Z5, J-Z6, J-Z29, J-Z30 | Left side 275, Right side 170 | |

| +1.400 | 140.0 | J-Z7, J-Z8, J-Z27, J-Z28 | Left side 278, Right side 155 | |

| +1.600 | 130.0 | J-Z9, J-Z10, J-Z25, J-Z26 | Left side 258, Right side 80 | |

| +1.800 | 120.0 | J-Z11, J-Z12, J-Z23, J-Z24 | Left side 200, Right side 108 | |

| +2.000 | 110.0 | J-Z13, J-Z14, J-Z21, J-Z22 | Left side 148, Right side 140 |

| Test Conditions | Material | Compressive Strength (MPa) | Tensile Strength (MPa) | ||

|---|---|---|---|---|---|

| Design Value | Standard Value | Design Value | Standard Value | ||

| −15 °C 550 kg/m3 | Machine-made snow | 0.213 | 0.405 | 0.055 | 0.104 |

| −15 °C 410 kg/m3 | Natural snow | 0.138 | 0.262 | 0.043 | 0.082 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Zhang, Q.; Zhang, G.; Fan, F. Building with Snow: Technical Exploration and Practice of Snow Materials and Snow Architecture. Buildings 2025, 15, 1277. https://doi.org/10.3390/buildings15081277

Sun J, Zhang Q, Zhang G, Fan F. Building with Snow: Technical Exploration and Practice of Snow Materials and Snow Architecture. Buildings. 2025; 15(8):1277. https://doi.org/10.3390/buildings15081277

Chicago/Turabian StyleSun, Jianfeng, Qingwen Zhang, Guolong Zhang, and Feng Fan. 2025. "Building with Snow: Technical Exploration and Practice of Snow Materials and Snow Architecture" Buildings 15, no. 8: 1277. https://doi.org/10.3390/buildings15081277

APA StyleSun, J., Zhang, Q., Zhang, G., & Fan, F. (2025). Building with Snow: Technical Exploration and Practice of Snow Materials and Snow Architecture. Buildings, 15(8), 1277. https://doi.org/10.3390/buildings15081277