Abstract

The increasing environmental impact of industrial waste, particularly from the textile sector, has driven efforts to integrate alternative materials into road construction. This study explores the feasibility of incorporating recycled cotton textile fibers into Stone Mastic Asphalt (SMA) mixtures to enhance their mechanical performance and sustainability. The bituminous mixture SMA 11 surf 35/50 was designed with 0.3% textile fibers, a dosage optimized to prevent binder drainage while maintaining adequate structural properties. Laboratory tests were conducted to evaluate bulk and maximum density, air void content, water sensitivity, and resistance to permanent deformation. The results demonstrated that the inclusion of 0.3% textile fibers significantly reduced binder drainage, improved moisture resistance with an ITSR of 96.30%, and enhanced stability under traffic loads. Although the WTSAIR value of 0.12 mm/1000 cycles did not fully comply with PG-3 requirements for T2 traffic, slight adjustments in binder content or composition could optimize performance. Beyond technical benefits, this study highlights the environmental and economic advantages of repurposing locally generated textile waste, reducing landfill accumulation, and fostering synergies between industries. Future research should focus on optimizing bitumen content, conducting fatigue and aging tests, and validating field performance under real traffic and environmental conditions to ensure long-term durability and compliance with road specifications.

1. Introduction

Transport, particularly the road sector, has a significant environmental impact due to its energy consumption and greenhouse gas emissions. Authorities must address this challenge through sustainable practices in road construction and maintenance. The European Union promotes the circular economy, which includes the reuse and recycling of waste materials, such as construction and demolition waste (CDW) and textile waste.

To enhance environmental quality and promote the sustainable development of transport infrastructure, it is essential to implement sustainable strategies in pavement construction and rehabilitation. The benefits of using large quantities of recycled materials include (i) the reduction in natural resource consumption, (ii) the elimination of waste materials otherwise destined for disposal, (iii) the reduction in energy and water consumption, and (iv) the decrease in greenhouse gas emissions [1].

However, the textile industry is one of the most polluting sectors, generating a significant amount of waste. This waste is produced not only during garment manufacturing but also during the dyeing process. To prevent textile industry waste from ending up in landfills, one of the key innovations of Directive 2018/851/EU is that companies will be required to pay for the waste they generate and will no longer be allowed to destroy or incinerate it.

In the field of road construction, research has explored the potential use of various types of waste as substitutes for natural aggregates in pavement and granular layers and even as a partial replacement for bitumen. In this context, one of the most commonly reused materials is reclaimed asphalt pavement (RAP) [2], along with construction and demolition waste (CDW) [3,4]. Other waste materials that have been studied include those from the steel industry [5], plastics [6], and rubber [7], which have shown potential to improve performance or reduce environmental impact. Other waste materials that have been studied include those from the steel industry and plastics. However, very few studies have assessed the benefits of incorporating textile waste into bituminous mixtures, which could enhance durability by contributing to a more resilient structural framework.

Since the late 19th century, asphalt has been widely used in road construction [8]. SMA mixtures, introduced in Germany in the 1960s, are recognized for their high performance and durability, making them ideal for heavy traffic pavements [9]. These mixtures offer fatigue resistance and long-term stability [9], requiring a higher asphalt binder content (6–7%) compared to conventional mixtures (4–7%) [10].

Although SMA mixtures have a higher initial cost, their long-term benefits—such as enhanced durability, resistance to studded tires, wear, and plastic deformation—justify their widespread adoption worldwide, especially for high-traffic roads. Despite certain challenges like binder exudation, additional advantages including improved drainage and noise reduction make SMA mixtures a cost-effective solution in the long run [9,11,12,13].

Fibers play a fundamental role in Stone Mastic Asphalt (SMA) mixtures, as they stabilize the binder and prevent segregation. In addition to enhancing mechanical performance by increasing resistance to fatigue and deformation, they also contribute significantly to reducing cracking and help delay and control the appearance of reflective cracks [14]. This reinforces the suitability of SMA as an effective solution for high-traffic roads. Different additives such as cellulose, polyester, lignin, and glass fibers have been studied for their ability to enhance the dynamic modulus, moisture tolerance, and fatigue resistance of SMA, while also reducing binder segregation [15,16,17]. Studies have shown that cellulose fiber, when added in proportions of approximately 0.30% by weight of the mixture, significantly reduces drainage effects and improves mechanical properties [18].

Numerous studies have demonstrated that the incorporation of cellulose fibers into SMA mixtures significantly enhances their mechanical properties and durability. These fibers, typically added in proportions around 0.3% by weight of the total mixture, are effective in stabilizing the binder and preventing drainage due to their high absorption capacity and structural integrity. For instance, Putman and Amirkhanian [19] reported over 30% reduction in binder drainage and significant improvements in resistance to permanent deformation upon using cellulose fibers. Similarly, Behbahani et al. [20] observed reductions of approximately 30% in rutting compared to mixtures without fibers. Additional research by Qian and Lu [21] confirmed improvements in indirect tensile strength and binder cohesion. These findings underscore the functional role of fibers in improving performance under traffic loads and environmental stresses. Despite these advances, most existing research focuses on commercial cellulose fibers. There is a clear gap in assessing alternative fibrous materials—such as recycled textile waste—that may offer comparable stabilizing effects while contributing to environmental sustainability, thereby justifying the present investigation.

Hybrid modifications of SMA using different fibers have yielded promising results. For instance, cellulose fibers improve exudation capacity, ductility, and fatigue resistance, while basalt fibers reduce permanent deformation and increase stress resistance [22]. Other studies have tested alternative fibers such as palm oil-derived cellulose, which, when combined with ground tire rubber, enhances pavement performance [23]. Recycled tire textile fibers (WTTF) have also been investigated as a replacement for commercial additives, demonstrating similar mechanical properties to traditional SMA blends [15,24].

Although various materials have been studied to absorb excess binder in SMA mixtures, including cellulose, basalt, pumice, paper, palm oil fibers, and synthetic fibers such as tire textiles and cigarette filters, there is limited knowledge regarding the use of textile waste fibers in SMA mixtures [25].

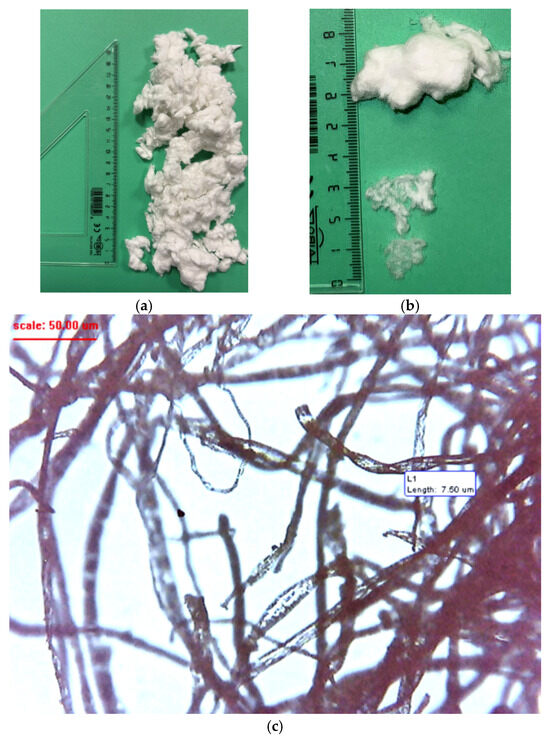

The textile industry generates a wide variety of waste throughout its production chain, including fiber remnants, fabric scraps, threads, and byproducts from textile recycling. Among these, cotton fibrous waste generated during the mechanical cutting and processing of recycled textiles stands out. This type of waste, which is homogeneous in nature and composed exclusively of natural fibers, has a length ranging from 0 to 5 mm, making it particularly suitable for use as an additive in bituminous mixtures.

In this study, a cotton fibrous waste discarded by the textile industry itself—due to its non-reusability in spinning processes—was selected. Its choice is based both on technical suitability—given its ability to stabilize the bituminous binder and reduce drainage—and on sustainability criteria, as it is a locally available waste that currently lacks a valorization pathway. Its incorporation into SMA-type mixtures contributes to a more sustainable paving model, promoting the reuse of industrial waste and reducing reliance on virgin raw materials.

Previous research suggests that local materials could replace cellulose fibers, but further investigation is required. In this context, the Valencian Community, a key textile production region in Spain, generates approximately 150,000 tonnes of textile waste annually, with cities like Alcoy, Ontinyent, and Elche being major contributors. Alcoy alone reports that 25% of its industrial waste is textile-based. In response, the region has launched initiatives such as the ReFashion project, promoted by the Instituto Valenciano de Competitividad Empresarial (IVACE), to recycle and reuse textile materials, reducing landfill disposal. Additionally, local companies are adopting more sustainable technologies, creating approximately 500 new jobs in the last five years.

One promising solution is the incorporation of textile waste into asphalt mixtures, which can enhance mechanical properties, increase durability, and reduce maintenance costs. By integrating textile waste into asphalt, the demand for virgin materials decreases, lowering environmental impact while promoting a circular economy. Investing in innovative recycling strategies and fostering collaboration between government, businesses, and society are crucial steps toward a more sustainable textile industry.

Objective and Contribution

The primary objective of this study is to analyze the feasibility of using textile waste fibers as an alternative to commercial cellulose fibers in SMA mixtures. This includes defining optimal component proportions and conducting laboratory tests to evaluate the suitability of the formulated mixtures. The bituminous mixtures were characterized through volumetric and performance-based tests, assessing fundamental properties such as void content, water sensitivity, and resistance to permanent deformation.

By incorporating textile waste fibers into SMA, this study not only explores a novel recycling approach but also contributes to a circular economy by reducing waste disposal and improving pavement durability. Additionally, this research aligns with sustainability goals by reducing reliance on virgin materials and promoting the reuse of industrial byproducts.

Therefore, this paper investigates the potential of using textile waste fibers as a sustainable additive in Stone Mastic Asphalt (SMA) mixtures, aiming to evaluate their effectiveness as a substitute for commercial cellulose fibers. The study includes a comprehensive experimental program to assess the mechanical performance of the modified mixtures. The findings contribute to advancing circular economy strategies in pavement engineering while addressing a significant environmental challenge posed by the textile industry.

2. Materials and Methods

2.1. Materials

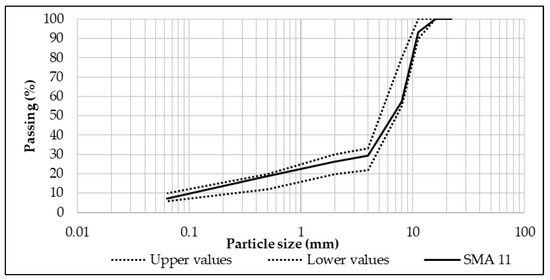

The selected asphalt mixture for this study is SMA 11 surf 35/50, which was modified with recycled cotton fibers to obtain the final product. The composition of the aggregates used in the mixture are as follows: (i) filler or mineral powder smaller than 0.063 mm; (ii) a 0/6 mm fraction consisting of fine limestone aggregate; and (iii) a 6/12 mm fraction of coarse porphyritic aggregate. Upon receipt of the aggregates in the laboratory, granulometric tests were conducted following the UNE-EN 933-2 [26] standard to determine the particle size distribution (see Table 1). The aggregates were supplied by Guerola Áridos y Hormigones, S.L., based in Ontinyent, Alicante (Spain).

Table 1.

Particle size distribution of materials.

The bitumen used in the production of the SMA 11 mixture was 35/50 penetration grade, supplied by the Spanish company Cepsa. This bitumen meets the required properties for a wearing course up to a traffic category T2 (AADT < 800 veh/day), according to Spanish road specifications (PG-3) [10]. The main characteristics of the bitumen are presented in Table 2.

Table 2.

Specifications of conventional bitumen 35/50.

According to the manufacturer’s recommendations, the working temperatures for the asphalt mixture are as follows (Figure 1):

Figure 1.

Laboratory heated mixer.

- Mixing temperature: 155–165 °C;

- Binder working temperature: 155–165 °C;

- Compaction temperature: 150–160 °C;

- Maximum heating temperature: 170 °C.

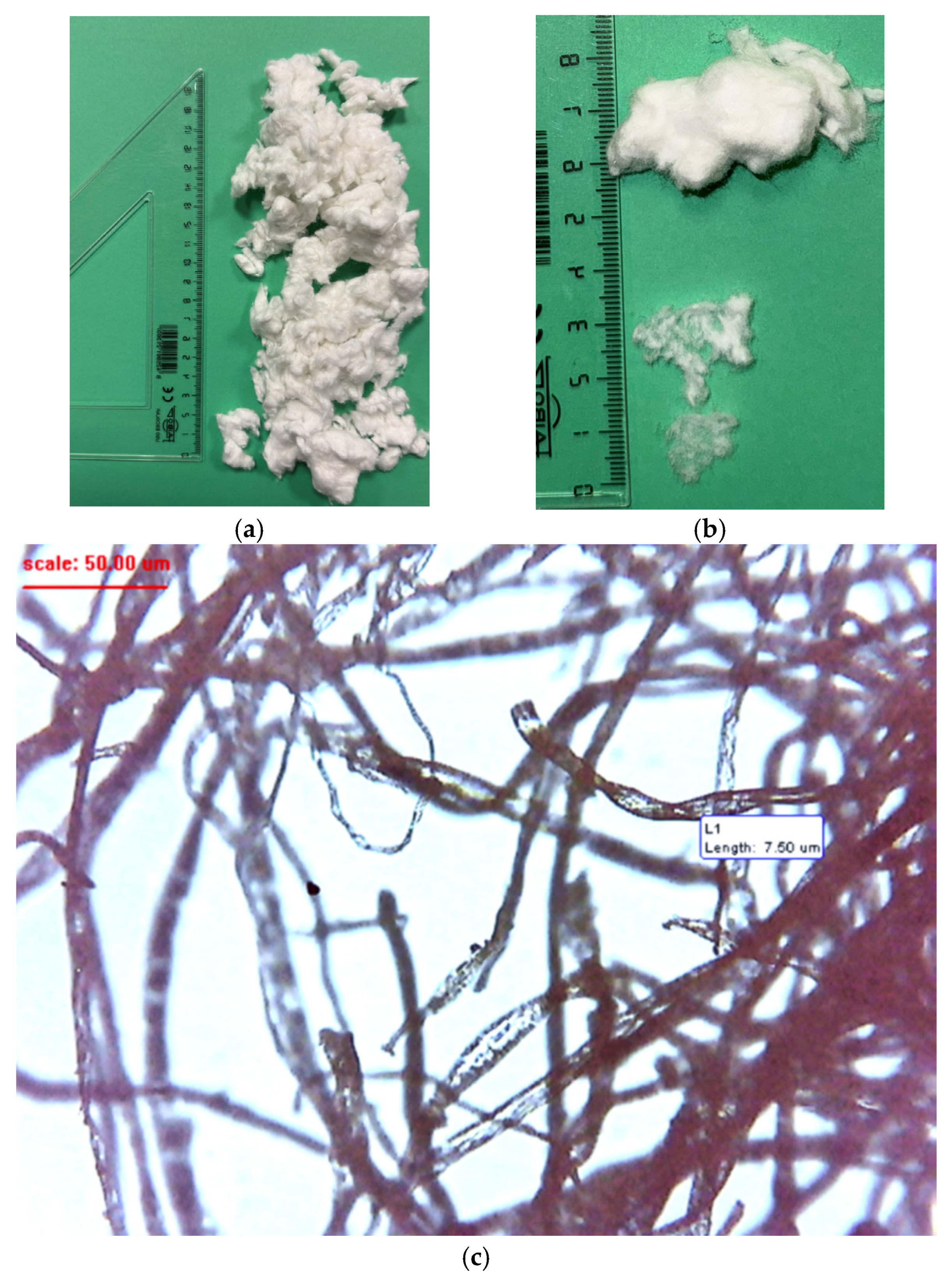

The addition of recycled cotton textile fibers modifies the rheological properties of bitumen by increasing viscosity and enhancing resistance to binder drainage, thus improving overall mixture cohesion. Traditionally, fibers are incorporated into asphalt mixtures to minimize binder drainage. The fibers were provided by Recover Textile Systems, S.L., a company specializing in processing textile waste located in Banyeres de Mariola, Alicante (Spain). According to analyses conducted by this company, the cotton powder consists of 100% cotton fibers, ensuring the absence of harmful substances or compounds that could pose health risks. The fibrous particles in this waste ranged in length from 0 to 5 mm and originated exclusively from cutting residues generated during the manufacturing of new recycled cotton fibers (see Figure 2). In this study, the fibers used were approximately 5 mm in length. This controlled production process guarantees the homogeneity of the subproduct, making it a consistent and reliable material for asphalt applications. Recycled cotton fibers are specifically utilized due to their local availability, as the Valencian Community is a significant center for textile waste generation, particularly from cities such as Alcoy, Ontinyent, and Elche. This provides considerable logistical and environmental advantages by reducing transportation-related costs and minimizing the carbon footprint associated with material transportation. By employing these local wastes in asphalt mixtures, abundant regional resources are utilized, contributing to local economic development, enhancing synergies among nearby industries, and effectively promoting the implementation of a circular economy in the road construction sector.

Figure 2.

Recycled cotton textile fibers: (a) general photo, (b) detail photo, and (c) micrograph image.

Based on these materials and the granulometric spindles specified in Article 544 of the Spanish road specifications (PG-3) [10], which defines the composition of SMA 11 surf 35/50, the minimum bitumen content for the mixture is set at 5.8%. However, if the aggregate density differs from 2.65 g/cm3, a correction factor (α = 2.65/ρd) could be applied. Given that the aggregates supplied have a density of 2.9 g/cm3, the adjusted minimum bitumen content is 5.3%.

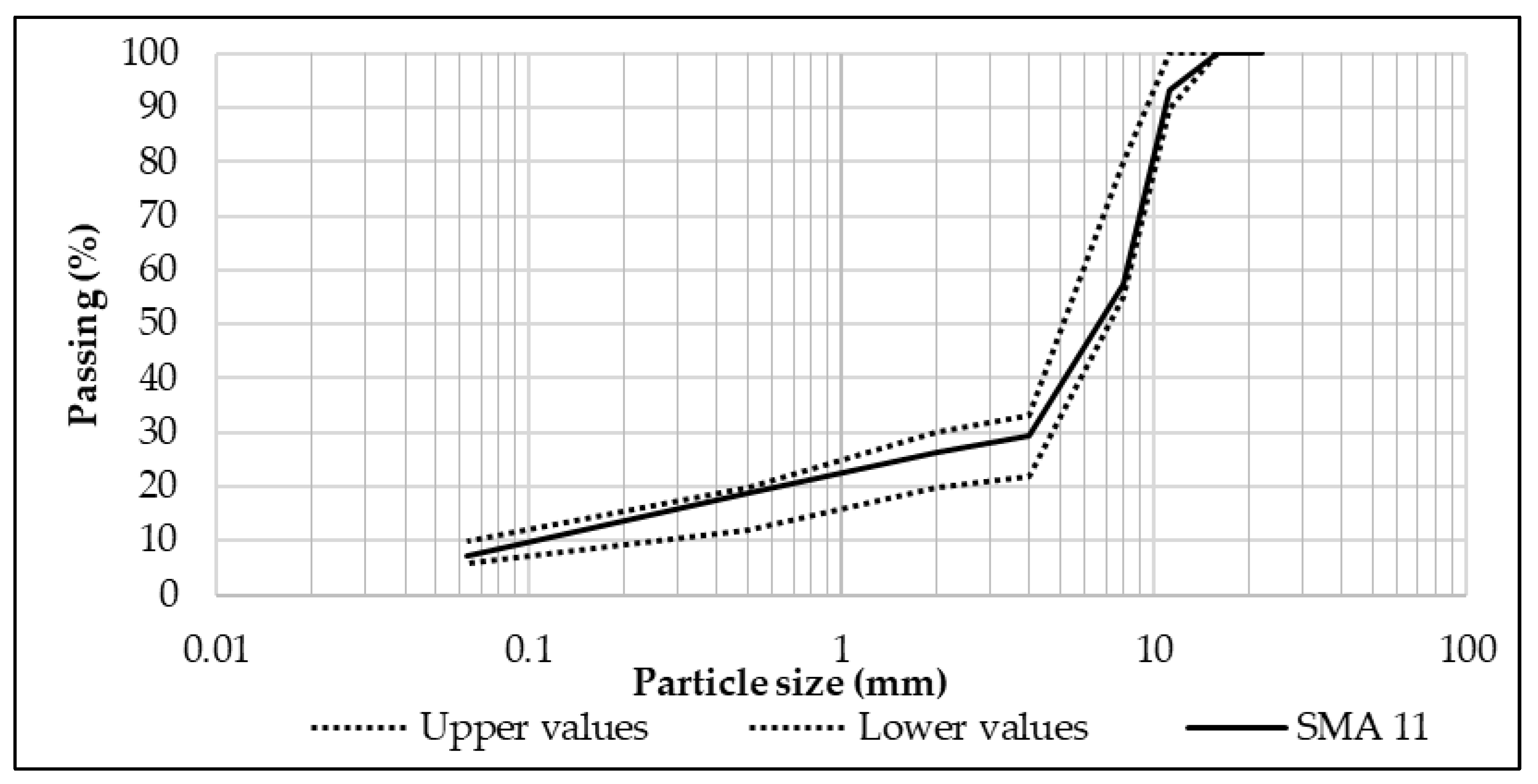

Three bituminous mixtures were produced, incorporating 0.0%, 0.3%, and 0.6% cotton textile fibers. The proportions of aggregate and filler used in each mixture are detailed in Table 3 and Figure 3.

Table 3.

Percentages of materials in the dosed mixtures.

Figure 3.

Particle size distribution.

2.2. Fabrication and Preparation of Test Specimens

First, the binder drainage test was carried out. Three samples were prepared, containing 0.0%, 0.3%, and 0.6% of cotton textile fibers, respectively.

For the selection of these fiber percentages, it has been considered that Article 544.2.4 of PG-3 [10] specifies that, in the case of mixtures using fibers, their content must not be lower than 0.3%. Therefore, we decided to test a mixture without fibers, a mixture with the minimum amount of fibers allowed by Spanish regulations, and a mixture with 0.6% fibers.

The preparation of eight cylindrical specimens (Ø 101.6 mm and height 63.5 mm) was carried out using impact compaction, applying 50 blows to each face, to determine the bulk density. Additionally, an extra amount of material was prepared to determine the maximum density. Based on the density values and the bitumen and additive content, the air void content of the mixture was estimated.

Subsequently, the water sensitivity test was conducted to determine the ITSR index. For this purpose, other eight cylindrical specimens were prepared and then divided into two batches: dry and wet.

Additionally, based on the obtained air void values, four prismatic specimens (410 mm × 260 mm × 40 mm) were fabricated using a plate compactor for the wheel tracking test, allowing for the determination of plastic deformations.

2.3. Characterization of the SMA

2.3.1. Binder Drainage

To determine the optimal textile fiber content, as specified in Article 544 of PG-3 [10], the binder drainage test was conducted in accordance with the UNE-EN 12697-18 [34] standard, using the beaker method.

The method consists of evaluating the amount of binder lost due to drainage after one hour at a representative temperature. To do this, the empty beaker (m0) is weighed and, subsequently, a sample of the bituminous mixture is placed in the glass, also obtaining the overall weight (m2). After one hour in the oven at the representative temperature, the glass is emptied by tipping the bituminous mixture material and the empty vessel (m1) is weighed again. The difference between the weight of the beaker after (m1) and before (m0) corresponds to the amount of binder drained. Finally, the binder flow (BD) is expressed as a percentage using Equation (1).

The test was carried out three times for each mixture, corresponding to the different textile fibers contents under evaluation.

2.3.2. Bulk Density, Maximum Density, and Air Voids

The bulk density of the SMA mixtures was determined following the UNE-EN 12697-6 [35] standard, using Method A—Immersion in water. This method is based on Archimedes’ principle, where the specimen is submerged in water to determine its volume by displacement. The process consists of the following steps:

- Sample preparation:

- Drying: The specimen is dried at room temperature until a constant weight is achieved.

- Weighing in Air: The dry specimen is weighed, recording its mass as m1.

- Heavy underwater:

- The specimen is immersed in deaerated water at 25 ± 1 °C.

- The submerged saturated mass is recorded as m2.

- The saturated surface-dry mass is recorded as m3.

- Calculation of bulk density:

The maximum density of the asphalt mixtures was determined in accordance with the UNE-EN 12697-5 [36] standard. This parameter is essential for evaluating the compaction quality of asphalt mixtures and ensuring proper pavement performance, as it allows for the subsequent calculation of the air void content in the mixture.

The method used was Procedure A—Volumetric Procedure, which involves measuring the sample volume using a pycnometer filled with water. This approach provides an accurate determination of the maximum density by applying Archimedes’ principle to measure the displaced water volume.

The maximum density was determined following a structured procedure to ensure accuracy. The process consists of the following steps:

- Sample Preparation:

- A representative sample of the bituminous mixture is selected.

- The sample is dried at room temperature to eliminate any surface moisture.

- Weighing the Sample:

- The empty and dry pycnometer is weighed (m1).

- The test sample is placed inside the pycnometer, and the total mass is recorded (m2).

- The pycnometer is then filled with de-aired water up to the calibration mark, and the combined mass is recorded (m3).

- Calculation of Maximum Density:

The air void content (Va) in the mixture was determined according to the UNE-EN 12697-8 [37] standard. This parameter is calculated using the maximum density () and the bulk density () of the specimens by applying Equation (4).

Additionally, the void content in aggregates (VMA) and the void content filled with a binder (VFB) can be determined using the following expressions:

where Va is the air void content in the bituminous specimen (%), VFB is the percentage of voids filled with binder (%), VMA is the void content in aggregates (%), is the maximum density of the mixture (g/cm3), is the bulk density of the specimen (g/cm3), B is the binder percentage in the specimen (%), and is the binder density (g/cm3).

The results must comply with the limits established in Table 544.10 of PG-3 [10] to ensure the required compaction and durability of the SMA-type mixtures (see Table 4).

Table 4.

Air void content limits for SMA-type bituminous mixtures according to PG-3 [10].

2.3.3. Water Sensitivity Test

The water sensitivity of the bituminous mixtures was evaluated according to the UNE-EN 12697-12 [38] standard, using Method A, which is based on the UNE-EN 12697-23 [39] standard for determining the indirect tensile strength of bituminous specimens.

For this test, eight cylindrical specimens (Ø 101.6 mm, height 63.5 mm) were compacted using the impact method (UNE-EN 12697-30) [40], applying 50 blows per face. After fabrication, the specimens were divided into two groups: a dry group and a wet group. The difference in average apparent densities between both groups was required to remain below 0.015 g/cm3 to ensure consistency in the results.

The dry specimens were stored upright on a flat surface at (20 ± 5) °C. The wet specimens underwent a vacuum saturation process and were subsequently immersed in a water bath at (40 ± 2) °C for (72 ± 2) hours.

The test temperature was set at 15 °C. To achieve this temperature, the dry specimens were placed in a thermally controlled air chamber, while the wet specimens were submerged in a water bath for at least four hours before testing.

Finally, the indirect tensile strength (ITS) of both specimen batches was measured according to the UNE-EN 12697-23 [39]. The indirect tensile strength ratio (ITSR), which quantifies the effect of moisture on the mechanical properties of the mixture, was calculated using Equation (7).

where ITSR is the indirect tensile strength ratio, in percentage (%); ITSw is the average indirect tensile strength of the wet batch, in kPa; and ITSd is the average indirect tensile strength of the dry batch, in kPa.

2.3.4. Wheel Tracking Test

To evaluate the susceptibility of bituminous mixtures to deformation under load, the test defined in the UNE-EN 12697-22 [41] standard was conducted. This required the fabrication of four prismatic specimens with dimensions of 410 mm × 260 mm × 40–60 mm, following the UNE-EN 12697-33 [42] standard for specimen preparation using a plate compactor.

After manufacturing and compacting the mixture, it was allowed to cool before being demolded. The specimens were then stored on a flat surface for at least two days to ensure proper stabilization before testing.

The test was carried out using a testing machine where a loaded wheel repeatedly moves over a securely fixed pavement sample. It was performed following Procedure B in air, at a controlled temperature of 60 °C, with a total duration of 10,000 cycles.

3. Results

3.1. Binder Drainage

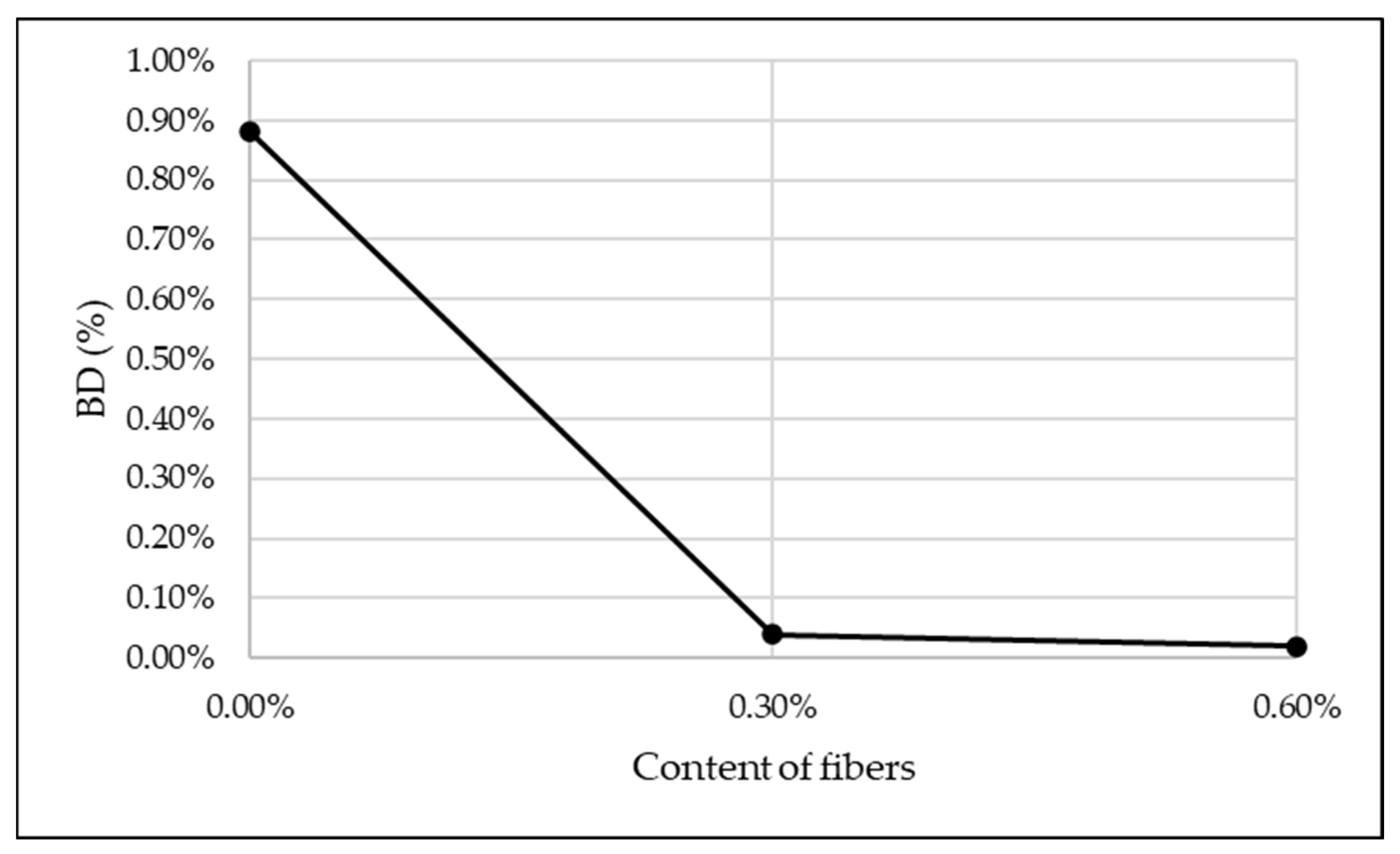

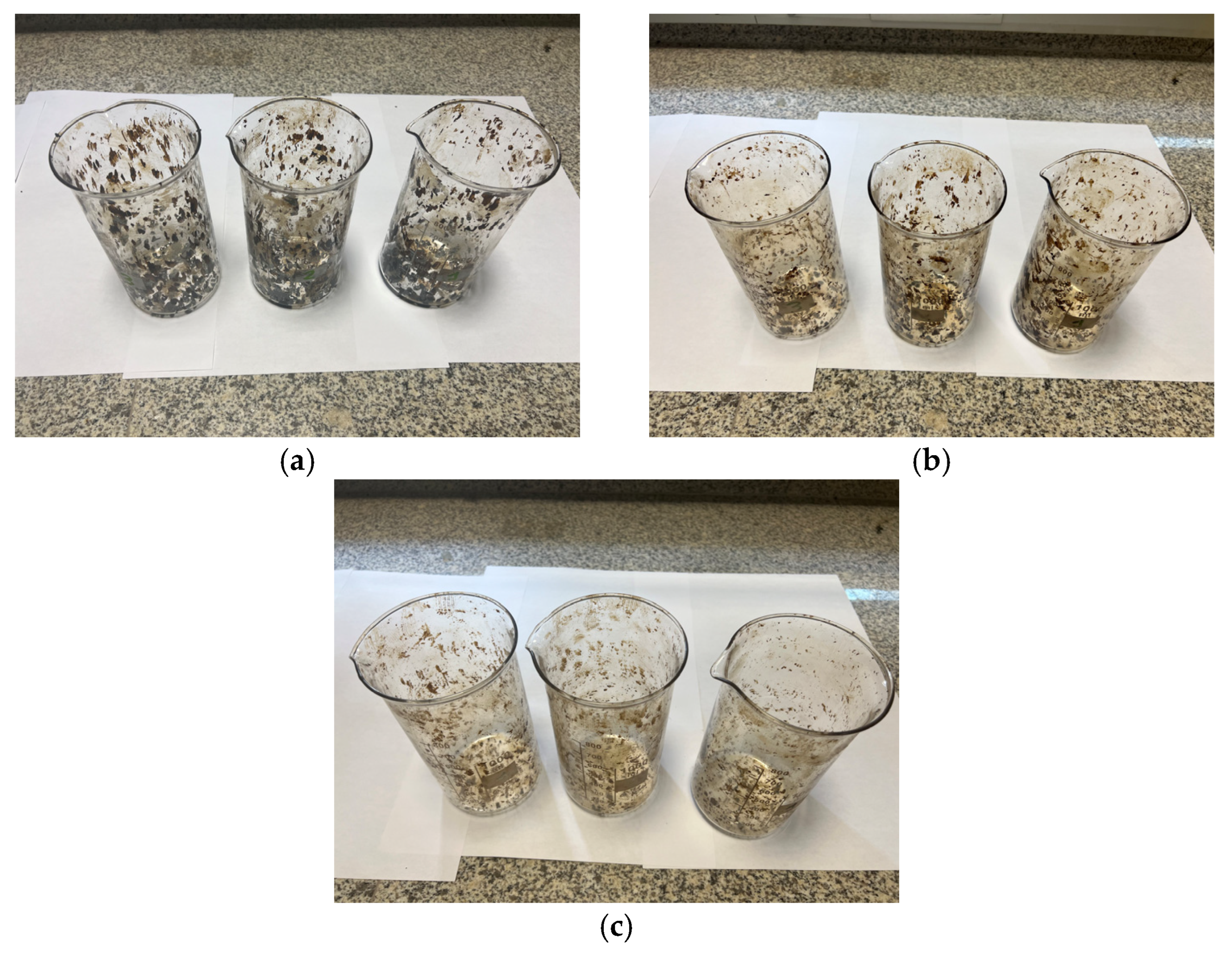

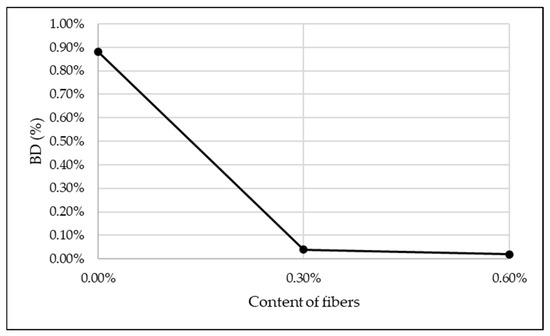

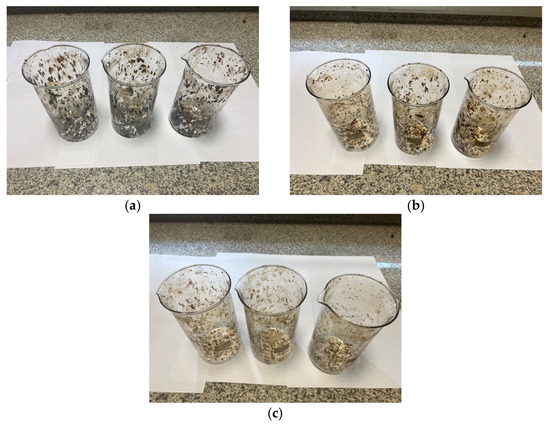

Figure 4 and Figure 5 present the results obtained from the binder drainage test, conducted according to the UNE-EN 12697-18 [34] standard. As can be observed, the incorporation of recycled textile fibers significantly reduces binder drainage. With the addition of 0.3% fibers, drainage is almost entirely eliminated, as illustrated in Figure 4.

Figure 4.

Binder drainage depending on content of fibers.

Figure 5.

Results of the binder drainage test: (a) 0.0% fibers, (b) 0.3% fibers, and (c) 0.6% fibers.

The results confirm that the addition of 0.3% recycled textile fibers to the bituminous mixture is effective in mitigating binder drainage and complies with the limits established in PG-3 [10]. Article 544.5.1.5 states that for SMA 11 mixtures, binder drainage, determined using the beaker method UNE-EN 12697-18 [34], must be below 0.3%, with a recorded value of 0.04%.

3.2. Air Voids

The bulk density of the SMA 11 surf 35/50 mixture with 0.3% fibers was determined from eight specimens, obtaining an average value of 2.462 g/cm3. The maximum density was calculated from two samples, yielding an average value of 2.602 g/cm3.

Using these density values, the air void content (Va) was computed (see Table 5). On average, the SMA 11 surf 35/50 mixture with 0.3% fibers and a bitumen content of 5.3% exhibited an air void content of 5.4%, which falls within the 4% to 6% range specified in Article 544 of the PG-3 [10] for this type of mixture.

Table 5.

Air void content of SMA 11 surf 35/50 with 0.3% fibers.

Additionally, the voids in the mineral aggregate (VMA) and the voids filled with bitumen (VFB) were analyzed. The obtained values indicate that the mixture maintains the necessary balance between void structure and binder content, ensuring adequate performance and durability. The average VMA was 18.0%, while the VFB was 70.0%, confirming that the mix design meets the required compaction and stability criteria.

These results demonstrate that incorporating 0.3% recycled textile fibers contributes to an optimized air void content while maintaining compliance with road construction specifications.

3.3. Water Sensitivity Test

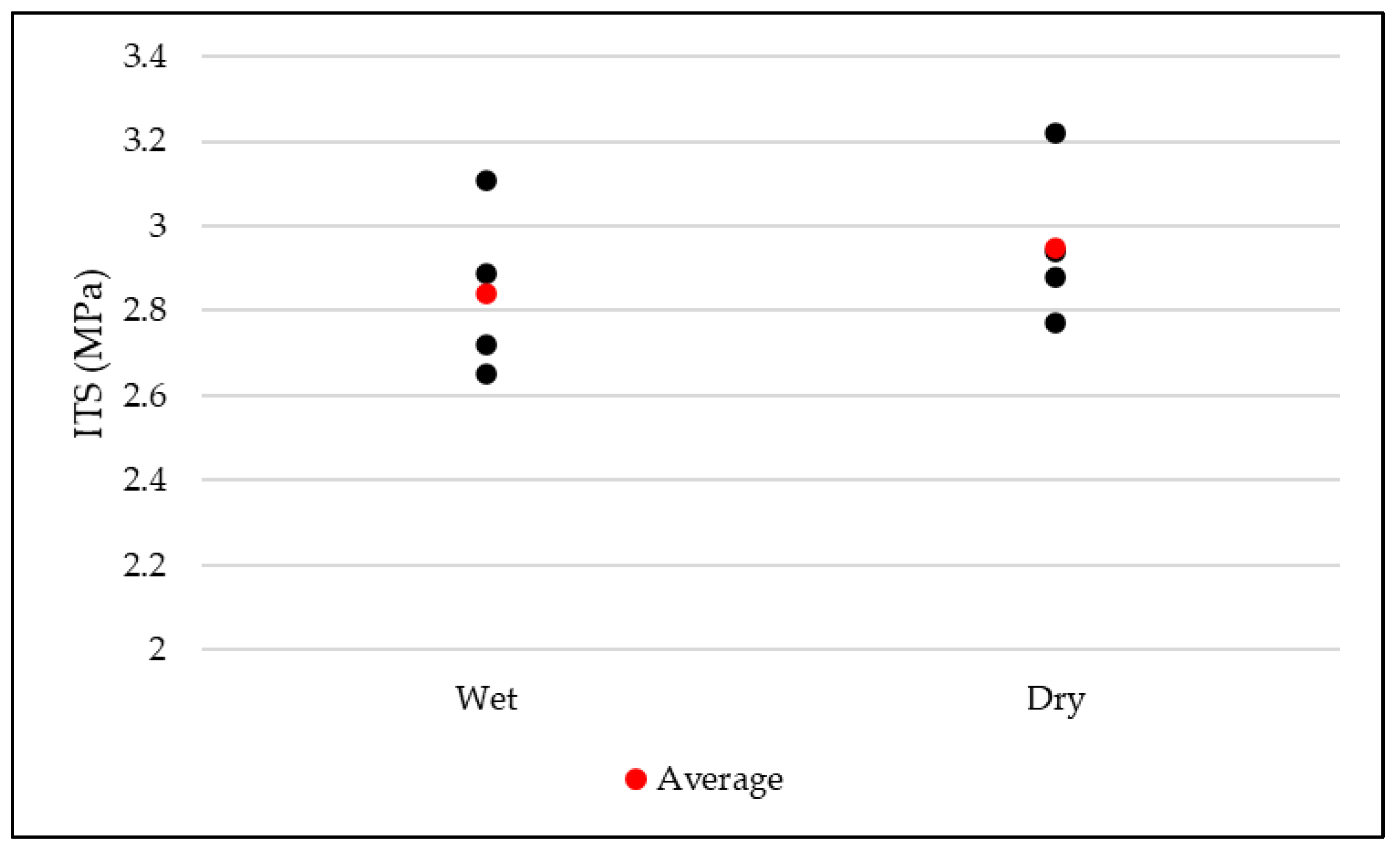

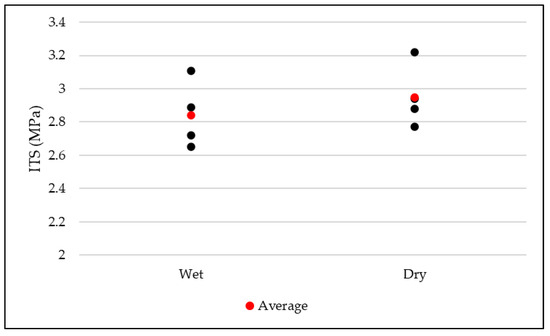

The results obtained from the water sensitivity test are presented in Figure 6, which illustrates the indirect tensile strength (ITS) values for both wet and dry specimens.

Figure 6.

Results of the water sensitivity test.

The average ITS value for the dry specimens was 2.95 kPa, while the wet specimens achieved an average of 2.84 kPa. Using these values and applying the corresponding formula, the indirect tensile strength ratio (ITSR) was calculated to be 96.30%.

According to PG-3 [10], the ITSR value for this type of mixture must be greater than 90% to ensure sufficient resistance to moisture damage. The obtained ITSR of 96.30% confirms that the SMA 11 surf 35/50 mixture with 0.3% recycled textile fibers meets the required specifications, demonstrating excellent water resistance and mechanical stability under moisture exposure.

These results indicate that the incorporation of recycled textile fibers does not compromise the mixture’s ability to withstand water-induced damage, making it a viable and durable alternative for road construction.

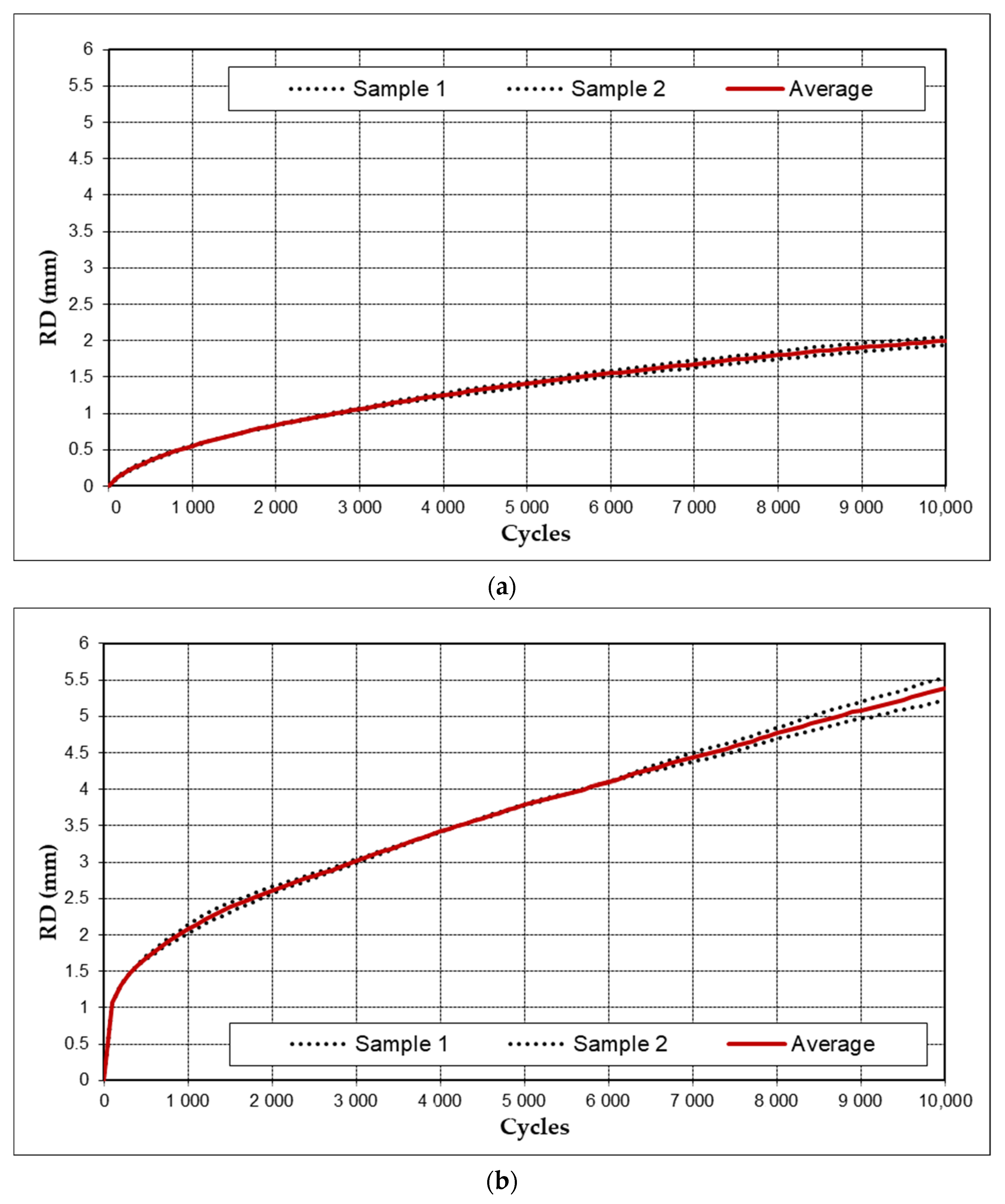

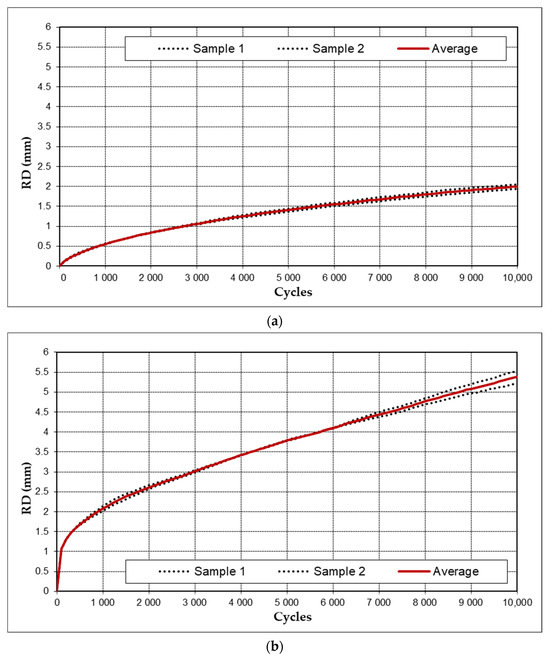

3.4. Wheel Tracking Test

The results obtained from the wheel tracking test are presented in Figure 7 and Table 6. According to Article 544 of the PG-3 [10], an SMA-type mixture intended for surface courses must have a WTSAIR value lower than 0.10 mm/1000 cycles for moderate and low heavy traffic categories (≤T2) and a lower than 0.07 mm/1000 cycles for significant heavy traffic categories (≥T1).

Figure 7.

Track test results for SMA: (a) without fibers and (b) with 0.3% fibers.

Table 6.

Track test results.

The SMA 11 mixture without fibers exhibited a WTSAIR value of 0.32 mm/1000 cycles, while the mixture containing 0.3% recycled textile fibers achieved a significantly lower value of 0.12 mm/1000 cycles. Although this value does not fully comply with the PG-3 requirements [10], it is close to the specified threshold.

These results suggest that further optimization of the mix design, such as adjusting the binder content or modifying the binder type, could enhance the resistance to permanent deformation, ensuring full compliance with the standard. Despite not meeting the exact limit, the significant reduction in rutting potential with fiber incorporation highlights the positive effect of recycled textile fibers in improving the mixture’s performance.

4. Discussion

The results obtained in this study confirm the feasibility of incorporating textile industry waste into bituminous mixtures as a substitute for conventional fibers to mitigate binder drainage while maintaining structural integrity. As established in the introduction, the textile industry is one of the most polluting sectors, generating a high volume of waste that is difficult to reintegrate into its own production cycle. This study demonstrates that recycled cotton textile fibers provide an effective alternative, reinforcing the potential of cross-industry waste utilization to enhance sustainability in road construction.

The inclusion of 0.3% recycled textile fibers in the SMA 11 surf 35/50 mixture proved to be the most effective dosage, offering optimal binder stabilization and mechanical performance. Higher fiber contents, such as 0.6%, resulted in material dispersion issues that negatively affected cohesion and structural integrity The fibers tend to clump together and are not homogeneously distributed within the mixture, resulting in fragile points due to the accumulation of textile fibers. Conversely, mixtures without textile waste (0.0% fibers) exhibited excessive binder drainage, compromising the stability of the mixture and confirming the necessity of fiber reinforcement.

This outcome aligns with prior research highlighting the role of fibers in reducing asphalt binder exudation and improving mechanical stability [13]. Moreover, the results reinforce previous findings that cellulose and textile fibers can effectively replace synthetic stabilizers in SMA mixtures while enhancing performance against mechanical stresses and environmental conditions [15].

The designed mixture met the requirements of Article 544 of the PG-3 [10] in terms of air void content, which was 5.4%, well within the specified 4% to 6% range. The measured maximum density (2.602 g/cm3) and bulk density (2.462 g/cm3) confirm that the mixture maintains the necessary compactability for road applications.

Regarding moisture resistance, the water sensitivity test showed an ITSR of 96.30%, exceeding the 90% minimum requirement PG-3 [10]. These results confirm the low susceptibility of the mixture to water-induced damage, ensuring long-term durability. However, the wheel tracking test indicated that while the WTSAIR value of 0.12 mm/1000 cycles for the fiber-reinforced mixture did not fully comply with the ≤0.10 mm/1000 cycles limit for T2 traffic, it represents a significant improvement over the 0.32 mm/1000 cycles of the fiber-free mixture. This suggests that slight adjustments in binder type or dosage could enable full compliance with PG-3 standards [10].

In addition to the technical benefits demonstrated through this study, the incorporation of recycled textile fibers into SMA mixtures offers clear economic and environmental advantages. From an economic perspective, the bitumen commonly used in SMA wearing courses has an approximate cost of EUR 650 per tonne [43]. Considering a typical bitumen content of 5.5% by weight for this type of mixture, its contribution to the total cost is estimated at approximately EUR 35.75 per tonne of mixture, representing between 22% and 23% of the overall cost. In contrast, commercial cellulose fibers usually account for 4% to 6% of the total cost, with an average value of EUR 8 per tonne of mixture. Replacing them with recycled textile fibers—particularly when sourced from local waste streams, as in this case study—can significantly reduce the overall cost of the final product.

From an environmental standpoint, this strategy enables the valorization of a waste product that is massively generated in regions such as the Valencian Community, where approximately 150,000 tonnes of textile waste are produced annually [44]. Unlike other materials that can be reintegrated into their original industry, textile waste often lacks effective reintegration routes, leading to accumulation in landfills [16]. Integrating these materials into bituminous mixtures transforms an environmental liability into a valuable engineering resource, aligning with circular economy principles and reducing dependence on virgin raw materials.

Furthermore, sourcing recycled fibers from local textile production hubs minimizes logistical costs and emissions associated with material transport. Since many asphalt plants are located near industrial zones, the incorporation of locally generated textile waste strengthens regional sustainability and fosters synergies between productive sectors. This connection between the textile industry and the road construction sector paves the way for more sustainable solutions, from technical, environmental, and economic perspectives.

The findings of this study confirm that recycled cotton textile fibers can successfully replace traditional stabilizers in SMA mixtures, offering technical, environmental, and economic benefits. The 0.3% fiber dosage was found to be the optimal balance between binder stabilization, mechanical strength, and regulatory compliance. While slight modifications may be required to fully meet the WTSAIR standard for T2 traffic, the results suggest that textile waste incorporation is a viable and scalable strategy for enhancing asphalt mixture performance while contributing to waste reduction and circular economy goals.

The cross-sector utilization of industrial waste offers a sustainable pathway for the pavement industry, demonstrating that materials traditionally deemed non-recyclable in their primary sector can be successfully repurposed to improve infrastructure resilience and environmental sustainability.

Although the results are promising, certain limitations must be acknowledged, and further research is needed to optimize the performance of these mixtures. While the study focused on a fixed bitumen content of 5.3%, adjusting this parameter could improve mechanical resistance and rutting performance, particularly for applications in higher traffic categories. Future studies should investigate the ideal bitumen–fiber balance to maximize performance. The research evaluated binder drainage, water sensitivity, and wheel tracking resistance, but further mechanical tests are needed to assess long-term durability. In particular, tests on fatigue resistance, stiffness modulus, and thermal susceptibility would provide a more comprehensive understanding of the material’s behavior under real-world conditions. While laboratory tests provide valuable insights, the next step is to validate these mixtures under real traffic and environmental conditions. Long-term monitoring of trial sections would allow for assessing structural integrity, aging behavior, and maintenance needs over time. Beyond SMA mixtures for surface layers, future research should examine the potential use of textile waste in other asphalt applications, such as base layers, porous asphalt for noise reduction, and warm mix asphalt technologies to enhance sustainability further.

5. Conclusions

This study evaluated the incorporation of recycled cotton textile fibers into SMA mixtures, aiming to enhance mechanical performance and sustainability in road construction.

- These mixtures are suitable for moderate-traffic categories (T2 or lower), especially for secondary roads, urban streets, rural paths, and controlled-traffic industrial areas.

- Textile fibers (0.3%) significantly reduce binder drainage compared to mixtures without fibers.

- High resistance to moisture damage was confirmed (ITSR = 96.3%), ideal for temperate and humid climates.

- The inclusion of textile fibers provides environmental benefits such as waste reduction, lower carbon footprint, and promotion of a circular economy through local resource reuse.

- Wheel tracking tests indicate rutting resistance (0.12 mm/1000 cycles) close to PG-3 limits [10], suggesting potential for further optimization.

Overall, the integration of recycled textile fibers into SMA mixtures is technically feasible and provides substantial environmental and economic benefits, making it a promising sustainable practice for road infrastructure.

Author Contributions

Conceptualization, C.A.-T. and D.L.-C.; methodology, C.A.-T. and D.L.-C.; formal analysis, C.A.-T. and D.L.-C.; investigation, C.A.-T.; data curation, D.L.-C.; writing—original draft preparation, B.O.-C. and C.A.-T.; writing—review and editing, and D.L.-C.; visualization, B.O.-C.; supervision, D.L.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Guerola Áridos y Hormigones, S.L.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- National Academies of Sciences, Engineering, and Medicine. Recycling and Reclamation of Asphalt Pavements Using in-Place Methods; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Llopis-Castelló, D.; Alonso-Troyano, C.; Álvarez-Troncoso, P.; Marzá-Beltrán, A.; García, A. Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates. Sustainability 2022, 14, 15777. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using waste plastics as asphalt modifier: A review. Materials 2021, 15, 110. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. A review on using crumb rubber in reinforcement of asphalt pavement. Sci. World J. 2014, 2014, 214612. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Koting, S.; Sulong, N.H.R.; Karim, M.R.; AlMashjary, B.M. Performance evaluation of stone mastic asphalt (SMA) mixtures with palm oil clinker (POC) as fine aggregate replacement. Constr. Build. Mater. 2020, 262, 120546. [Google Scholar] [CrossRef]

- Babalghaith, A.M.; Koting, S.; Ibrahim, M.R.; Mohd, N.S.; Rozali, S.; Muhamad, M.R.; Yusoff, N.I.M. Effect of Black PET Fiber as Additive on the Mechanical Properties of Stone Mastic Asphalt (SMA) Mixtures. In Advances in Civil Engineering Materials: Selected Articles from the International Conference on Architecture and Civil Engineering (ICACE2020); Springer: Singapore, 2021; pp. 249–260. [Google Scholar]

- Spanish Ministry of Public Works. Pliego de Prescripciones Técnicas Generales Para Obras de Carreteras Y Puentes de La Dirección General de Carreteras (PG-3); Ministerio de Fomento, Dirección General de Carreteras; Spanish Ministry of Public Works: Madrid, Spain, 2008. [Google Scholar]

- Lugeiyamu, L.; Kunlin, M.; Mensahn, E.S.; Faraz, A. Utilization of waste polyethylene terephthalate (PET) as partial replacement of bitumen in stone mastic asphalt. Constr. Build. Mater. 2021, 309, 125176. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Subhy, A.; Lo Presti, D.; Airey, G.; Widyatmoko, I. Rutting analysis of different rubberised stone mastic asphalt mixtures: From binders to mixtures. Road Mater. Pavement Des. 2022, 23, 2098–2114. [Google Scholar] [CrossRef]

- Maurer, D.A.; Malasheskie, G.J. Field performance of fabrics and fibers to retard reflective cracking. Geotext. Geomembr. 1989, 8, 239–267. [Google Scholar] [CrossRef]

- Valdés-Vidal, G.; Calabi-Floody, A.; Mignolet-Garrido, C.; Díaz-Montecinos, C. Effect of a new additive based on textile fibres from end-of-life tyres (ELT) on the mechanical properties of stone mastic asphalt. Polymers 2023, 15, 1705. [Google Scholar] [CrossRef]

- Mokhtari, A.; Nejad, F.M. Mechanistic approach for fiber and polymer modified SMA mixtures. Constr. Build. Mater. 2012, 36, 381–390. [Google Scholar] [CrossRef]

- Yin, J.; Wu, W. Utilization of waste nylon wire in stone matrix asphalt mixtures. Waste Manag. 2018, 78, 948–954. [Google Scholar] [CrossRef] [PubMed]

- Brown, E.R. Designing Stone Matrix Asphalt Mixtures for Rut-Resistant Pavements; Transportation Research Board: Washington, DC, USA, 1999; pp. 425–430. [Google Scholar]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- Behbahani, H.; Nowbakht, S.; Fazaeli, H.; Rahmani, J. Effects of fiber type and content on the rutting performance of stone matrix asphalt. J. Appl. Sci. 2009, 9, 1980–1984. [Google Scholar] [CrossRef]

- Qian, Z.; Lu, Q. Design and laboratory evaluation of small particle porous epoxy asphalt surface mixture for roadway pavements. Constr. Build. Mater. 2015, 77, 110–116. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Z.; Liu, L.; Zhang, Y.; Xu, Q. Hybrid modification of stone mastic asphalt with cellulose and basalt fiber. Adv. Mater. Sci. Eng. 2020, 2020, 5671256. [Google Scholar] [CrossRef]

- Muniandy, R.; Selim, A.A.; Hassim, S.; Omar, H. Laboratory Evaluation of Ground Tire Rubber in Stone Mastic Asphalt. J. Eng. Res. 2004, 1, 53–58. [Google Scholar] [CrossRef]

- Rodríguez, W.; Rivera, J.; Sevillano, M.; Torres, T. Performance evaluation of Stone Mastic Asphalt (SMA) mixtures with textile waste fibres. Constr. Build. Mater. 2024, 455, 139125. [Google Scholar] [CrossRef]

- Tataranni, P.; Sangiorgi, C. A preliminary laboratory evaluation on the use of shredded cigarette filters as stabilizing fibers for stone mastic asphalts. Appl. Sci. 2021, 11, 5674. [Google Scholar] [CrossRef]

- UNE-EN 933-2; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2022.

- UNE-EN 1426; Bitumen and Bituminous Binders. Determination of Needle Penetration. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2016.

- UNE-EN 1427; Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball Method. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2015.

- UNE-EN 12591; Bitumen and Bituminous Binders. Specifications for Paving Grade Bitumens. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2009.

- UNE-EN 12593; Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2015.

- UNE-EN 12592; Bitumen and Bituminous Binders—Determination of Solubility. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2015.

- UNE-EN 2592; Petroleum and Related Products—Determination of Flash and Fire Points. Cleveland Open Cup Method. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2018.

- UNE-EN 12607-1; Bitumen and Bituminous Binders—Determination of the Resistance to Hardening Under Influence of Heat and Air—Part 1: RTFOT Method. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2015.

- UNE-EN 12697-18; Bituminous Mixtures—Test Methods—Part 18: Binder Drainage. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2017.

- UNE-EN 12697-6; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 6: Determination of Bulk Density of Bituminous Specimen. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2020.

- UNE-EN 12697-5; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 5: Determination of the Maximum Density. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2018.

- UNE-EN 12697-8; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 8: Determination of Void Characteristics of Bituminous Specimens. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2018.

- UNE-EN 12697-12; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 12: Determination of the Water Sensitivity of Bituminous Specimens. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2018.

- UNE-EN 12697-23; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2018.

- UNE-EN 12697-30; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 30: Specimen Preparation by Impact Compactor. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2019.

- UNE-EN 12697-22; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 22: Wheel Tracking. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2020.

- UNE-EN 12697-33; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 33: Specimen Prepared by Roller Compactor. Spanish Association for Standardization and Certification (AENOR): Madrid, Spain, 2019.

- Ministry of Transport and Sustainable Mobility. OC 4/2023: Procedure for Price Justification and Support Base 2023; Government of Spain: Madrid, Spain, 2023.

- Valencian Institute of Business Competitiveness (IVACE). ReFashion Project: Textile Recycling and Waste Recovery in the Valencian Community; Valencian Institute of Business Competitiveness: Valencia, Spain, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).