Soil Improvement Using Plastic Waste–Cement Mixture to Control Swelling and Compressibility of Clay Soils

Abstract

1. Introduction

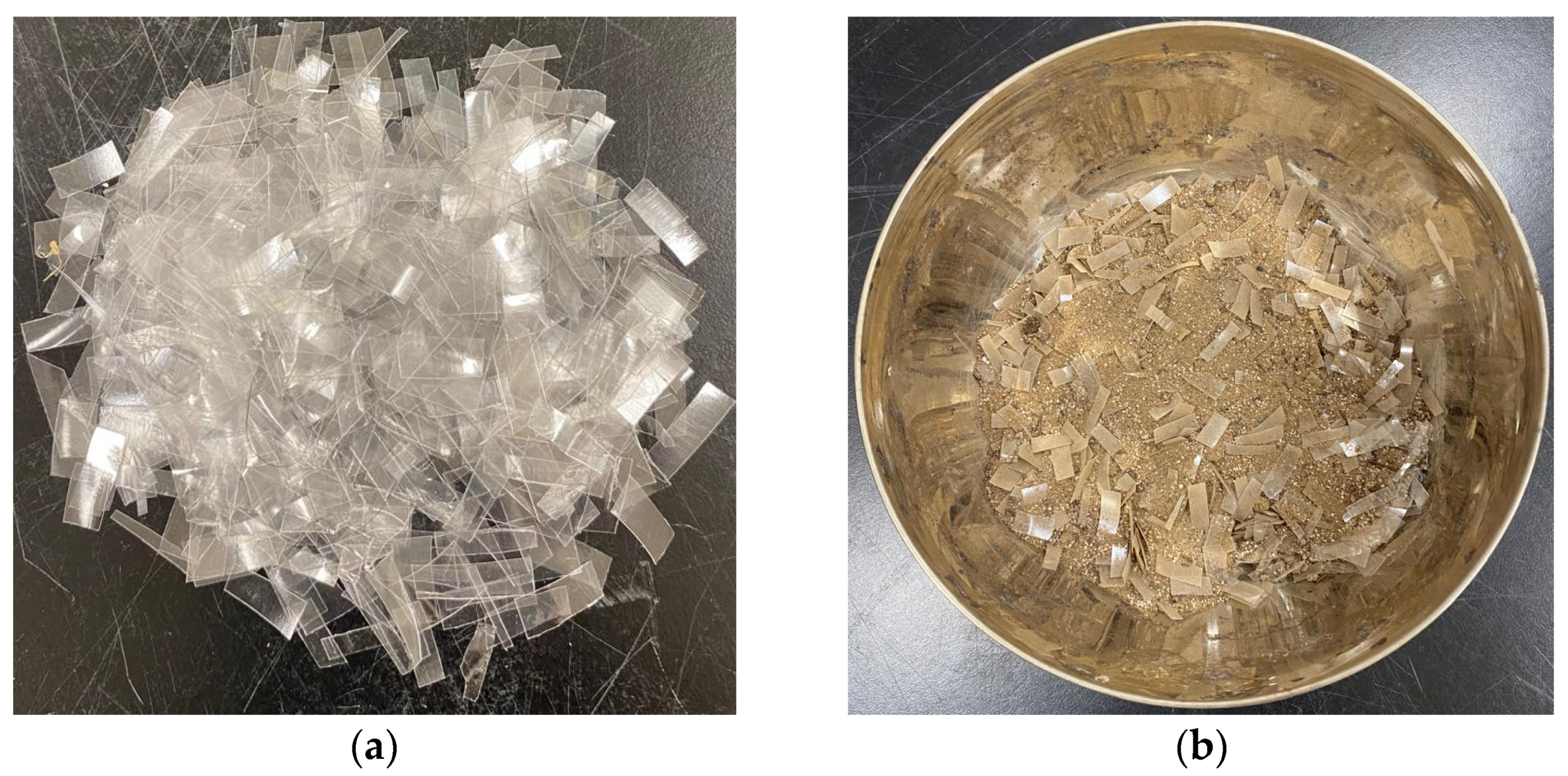

2. Materials and Testing Program

2.1. Soil Selection

2.2. Sample Preparation

2.3. Testing Procedures

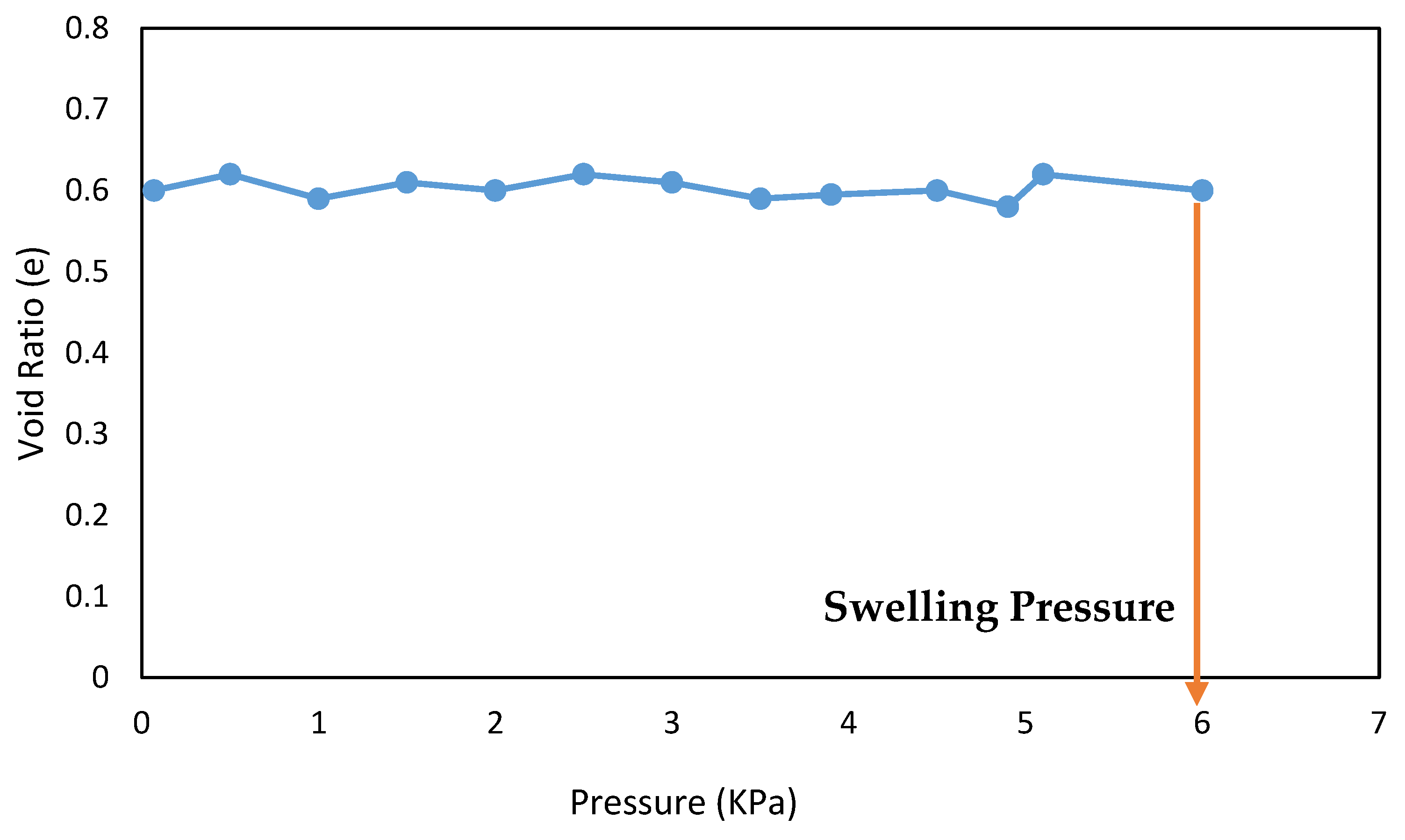

2.3.1. Swelling Test

2.3.2. California Bearing Ratio Test (CBR)

3. Results and Discussion

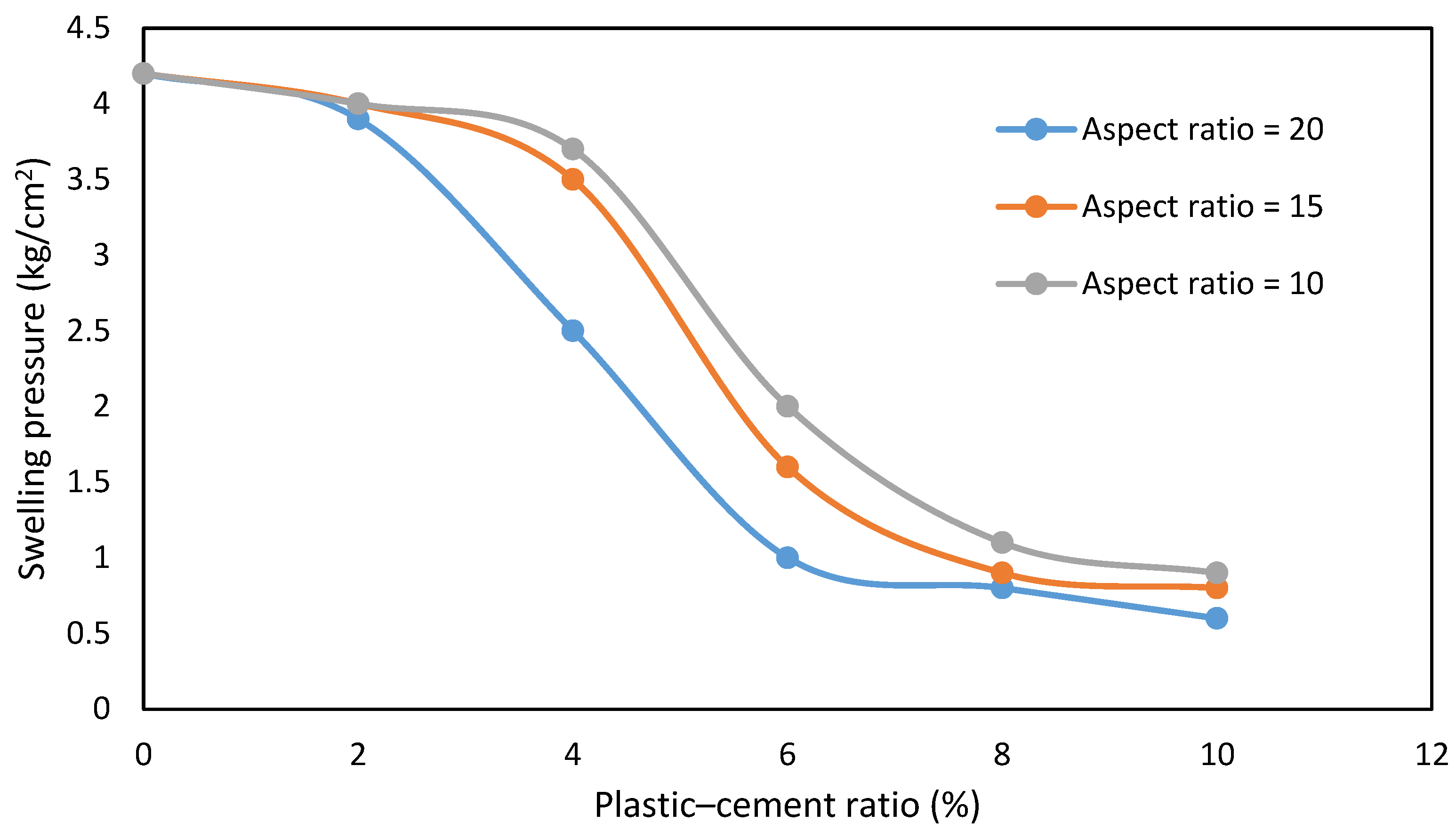

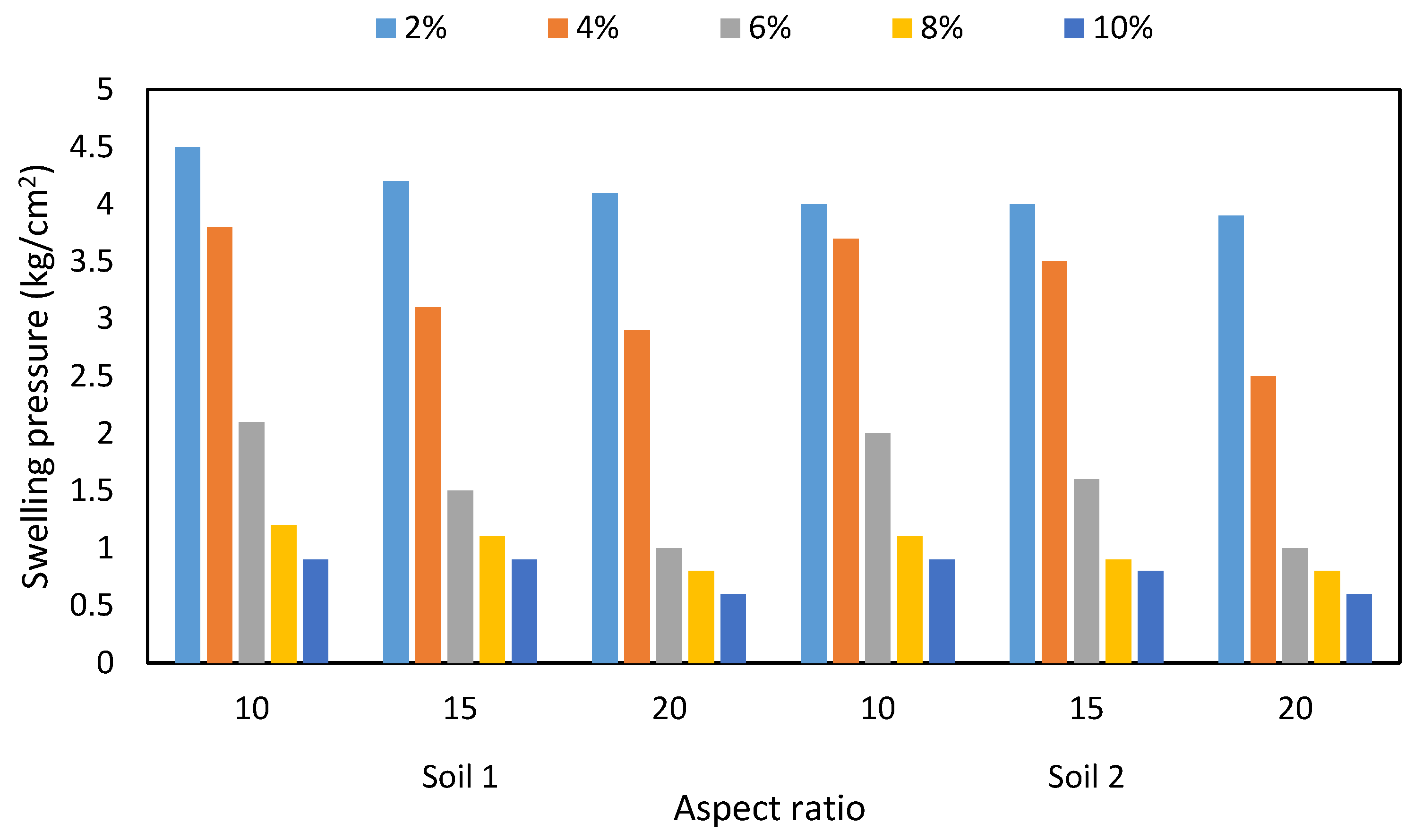

3.1. Effect of Plastic–Cement Blend on Swelling Pressure and Swell Potential

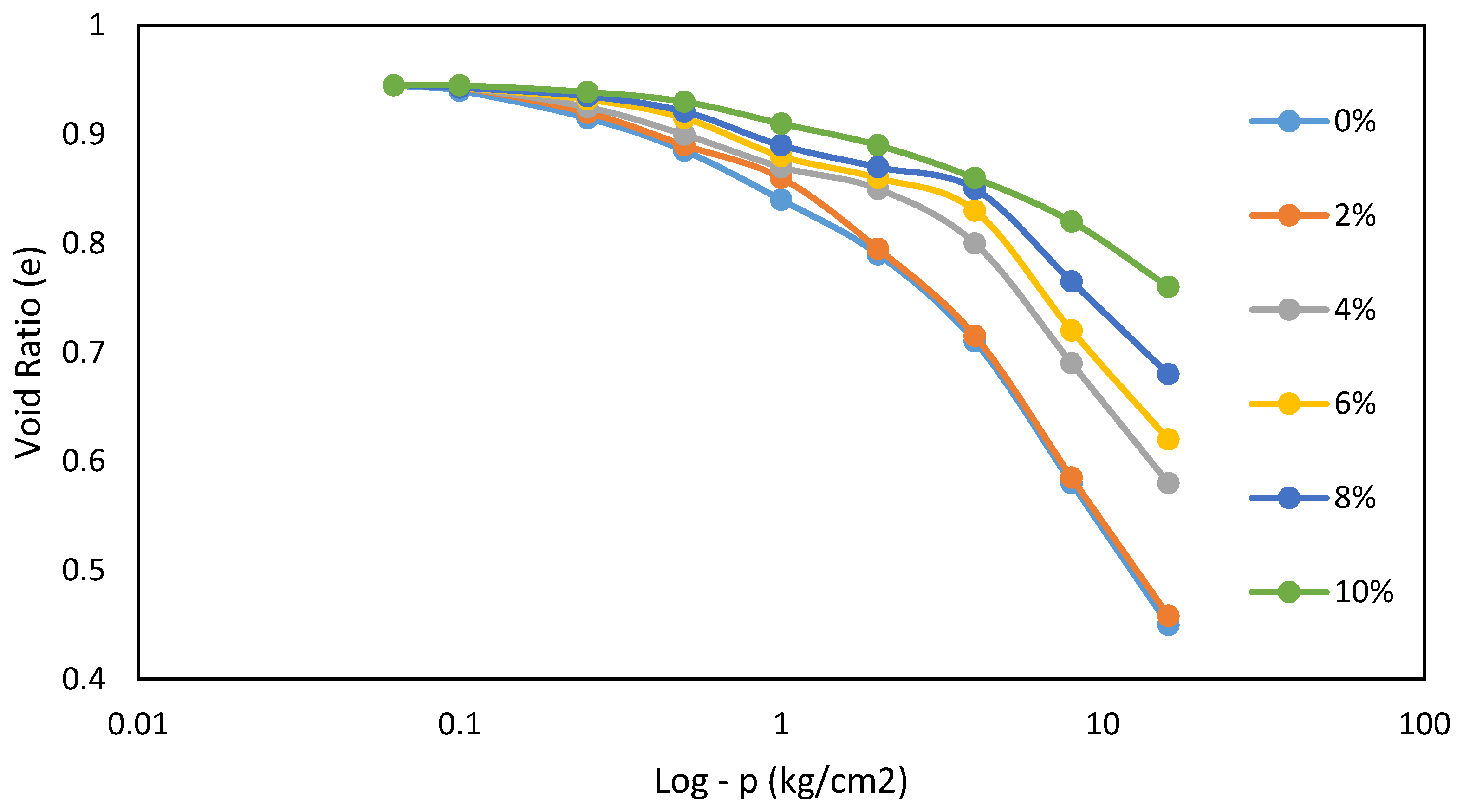

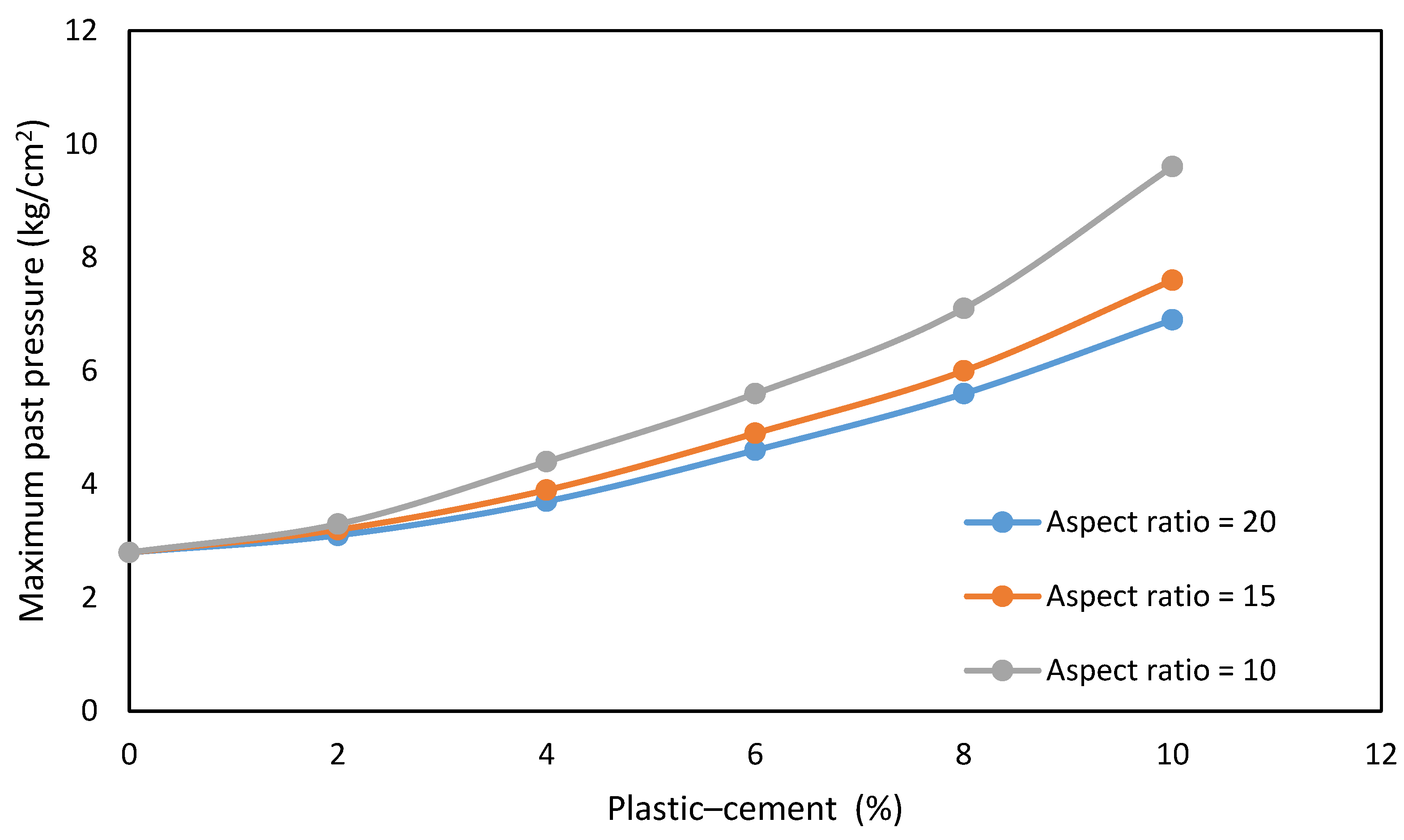

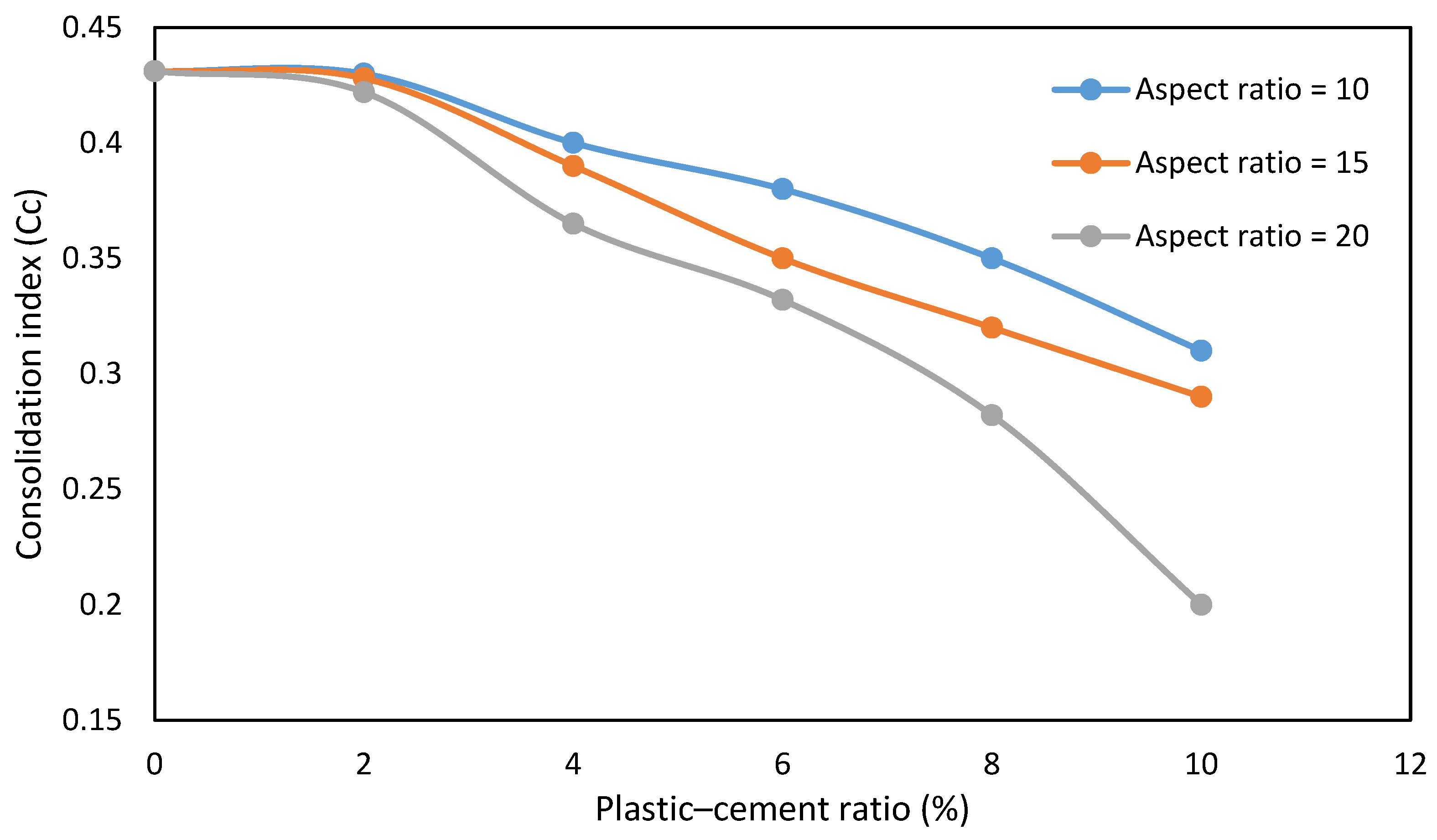

3.2. Effect of Plastic–Cement Blend on Consolidation Properties of Tested Clay Soils

3.3. Effect of Curing Time on Soil Stabilized with P-C Blend

3.4. California Bearing Ratio (CBR)

4. Conclusions

- The incorporation of the plastic waste–cement blend effectively reduces both the swelling pressure and swell potential of highly expansive soils, indicating improvement in the highly expansive soils.

- An optimal blend of 8% of plastic waste–cement significantly minimizes the expansive behavior of clay soils, offering a practical solution for the clay soils.

- The inclusion of shredded plastic waste in the soil mix leads to lower consolidation index values and a higher maximum past pressure, contributing to a more stable and less compressible soil structure.

- Increasing the aspect ratio of the plastic strips results in further reductions in swelling pressure, swell potential, and consolidation index, while simultaneously increasing the maximum past pressure, thereby enhancing the mechanical behavior of the soil.

- A curing time of 7 days is identified as the most effective duration for the plastic–cement blend to stabilize the soil.

- The results of the CBR tests reveal that adding shredded plastic waste significantly improves the soil’s bearing capacity, particularly under unsoaked conditions and at higher aspect ratios. An aspect ratio of 15 yields the most substantial improvements, with the CBR values increasing up to approximately 21% for soil 2 and 18% for soil 1 under unsoaked conditions with a 2% shredded plastic content.

- These findings suggest that plastic waste can serve as a viable material for soil stabilization, offering both engineering benefits and an environmentally friendly approach to reducing plastic waste disposal challenges.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amena, S.; Chakeri, D. A study on the effects of plastic waste strips and lime on strength characteristics of expansive soil. Adv. Civ. Eng. 2022, 2022, 6952525. [Google Scholar] [CrossRef]

- Gromko, G.J. Review of expansive soils. J. Geotech. Eng. Div. 1974, 100, 667–687. [Google Scholar] [CrossRef]

- Winterkorn, H.F.; Pamukcu, S. Soil stabilization and grouting. In Foundation Engineering Handbook; Springer: Berlin/Heidelberg, Germany, 1991; pp. 317–378. [Google Scholar]

- Yamin, M.; Attom, M.F.; Atabay, S.; Vandanapu, R. The Effect of Compaction Effort on Shear Strength Parameters of Low/High Plasticity Clay Soils. Geotech. Eng. 2021, 52, 1–8. [Google Scholar]

- Khalil, A.; Khan, Z.; Attom, M.; Khalafalla, O. Evaluation of Ground Improvement with Dynamic Replacement and Rapid Impact Compaction of an Artificial Island in the UAE—A Case Study. Geo-Congr. 2024, 2024, 116–125. [Google Scholar]

- Gangwar, P.; Tiwari, S. Stabilization of soil with waste plastic bottles. Mater. Today Proc. 2021, 47, 3802–3806. [Google Scholar] [CrossRef]

- Archibong, G.A.; Sunday, E.U.; Akudike, J.C.; Okeke, O.C.; Amadi, C. A review of the principles and methods of soil stabilization. Int. J. Adv. Acad. Res.|Sci. 2020, 6, 2488–9849. [Google Scholar]

- Banu, S.; Attom, M. Internal Erosion Stabilization of Cohesionless Soil Using Lime. Water 2023, 15, 1992. [Google Scholar] [CrossRef]

- Banu, S.A.; Attom, M.F. Effect of Curing Time on Lime-Stabilized Sandy Soil against Internal Erosion. Geosciences 2023, 13, 102. [Google Scholar] [CrossRef]

- Andavan, S.; Kumar, B.M. Case study on soil stabilization by using bitumen emulsions–A review. Mater. Today Proc. 2020, 22, 1200–1202. [Google Scholar] [CrossRef]

- Nayem, N.H. Enhancement of Soil Characteristics Using Different Stabilization Techniques. Environ. Eng. 2023, 8, 71–79. [Google Scholar]

- Amiralian, S.; Chegenizadeh, A.; Nikraz, H. A review on the lime and fly ash application in soil stabilization. Int. J. Biol. Ecol. Environ. Sci. 2012, 1, 124–126. [Google Scholar]

- Attom, M.; Mortula, M.M.; Munjed, A. Shear strength stabilization using burned sludge ash. Int. J. Adv. Mech. Civ. Eng. 2017, 4, 42–45. [Google Scholar]

- Zafar, T.; Ansari, M.A.; Husain, A. Soil stabilization by reinforcing natural and synthetic fibers–A state of the art review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Radwan, M.K.H.; Lee, F.W.; Woon, Y.B.; Yew, M.K.; Mo, K.H.; Wai, S.H. A study of the strength performance of peat soil: A modified cement-based stabilization agent using fly ash and polypropylene fiber. Polymers 2021, 13, 4059. [Google Scholar] [CrossRef]

- Khalil, A.; Khan, Z.; Attom, M.; Fattah, K.; Ali, T.; Mortula, M. Continuous Evaluation of Shear Wave Velocity from Bender Elements during Monotonic Triaxial Loading. Materials 2023, 16, 766. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.; Khan, Z.H.; Attom, M.; El Emam, M.; Fattah, K. Dynamic Properties of Calcareous Sands from Urban Areas of Abu Dhabi. Appl. Sci. 2022, 12, 3325. [Google Scholar] [CrossRef]

- Banu, S.; Attom, M.; Abed, F.; Vandanapu, R.; Astillo, P.V.; Al-Lozi, N.; Khalil, A. Numerical analysis of the ultimate bearing capacity of strip footing constructed on sand-over-clay sediment. Buildings 2024, 14, 1164. [Google Scholar] [CrossRef]

- Attom, M.F.; Vandanapu, R.; Khan, Z.; Yamin, M.; Astillo, P.V.; Eltayeb, A.; Khalil, A. Prediction of internal erosion parameters of clay soils using initial physical properties. Water 2024, 16, 232. [Google Scholar] [CrossRef]

- Wen, T.; Luo, Y.; Tang, M.; Chen, X.; Shao, L. Effects of representative elementary volume size on three-dimensional pore characteristics for modified granite residual soil. J. Hydrol. 2024, 643, 132006. [Google Scholar] [CrossRef]

- Majeed, M.; Tangri, A.P. Stabilization of soil using industrial wastes. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012018. [Google Scholar]

- Azni, I.; Katayon, S.; Ratnasamy, M.; Johari, M.M.N.M. Stabilization and utilization of hospital waste as road and asphalt aggregate. J. Mater. Cycles Waste Manag. 2005, 7, 33–37. [Google Scholar] [CrossRef]

- Ikara, I.A.; Kundiri, A.M.; Mohammed, A. Effects of waste glass (WG) on the strength characteristics of cement stabilized expansive soil. Am. J. Eng. Res. (AJER) 2015, 4, 33–41. [Google Scholar]

- Perera, S.T.A.M.; Saberian, M.; Zhu, J.; Roychand, R.; Li, J. Effect of crushed glass on the mechanical and microstructural behavior of highly expansive clay subgrade. Case Stud. Constr. Mater. 2022, 17, e01244. [Google Scholar] [CrossRef]

- Phanikumar, B.R. Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: A comparative study. Geomech. Geoengin. Int. J. 2009, 4, 175–181. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, B. A comparative study on shear strength and deformation behaviour of clayey and sandy soils reinforced with glass fibre. Geotech. Geol. Eng. 2020, 38, 4831–4845. [Google Scholar] [CrossRef]

- Almesfer, N.; Ingham, J. Effect of waste glass on the properties of concrete. J. Mater. Civ. Eng. 2014, 26, 06014022. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Characteristics of concrete with waste glass as fine aggregate replacement. Int. J. Eng. Tech. Res. 2014, 2, 11–17. [Google Scholar]

- Zuaiter, M.; Khalil, A.; Elkafrawy, M.; Hawileh, R.; AlHamaydeh, M.; Ayman, A.; Kim, T.Y. Effect of blending GGBS and silica fume on the mechanical properties of geopolymer concrete. Sci. Rep. 2025, 15, 9091. [Google Scholar] [CrossRef]

- Wong, S.L.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sustain. Energy Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Eltayeb, A.; Attom, M. The Use of Shredded Plastic Water Bottles in Soil Stabilization. Eurasia Proc. Sci. Technol. Eng. Math. 2021, 13, 37–44. [Google Scholar] [CrossRef]

- Awuchi, C.G.; Awuchi, C.G. Impacts of plastic pollution on the sustainability of seafood value chain and human health. Int. J. Adv. Acad. Res. 2019, 5, 46–138. [Google Scholar]

- Khoo, K.S.; Ho, L.Y.; Lim, H.R.; Leong, H.Y.; Chew, K.W. Plastic waste associated with the COVID-19 pandemic: Crisis or opportunity? J. Hazard. Mater. 2021, 417, 126108. [Google Scholar] [CrossRef] [PubMed]

- Law, K.L.; Starr, N.; Siegler, T.R.; Jambeck, J.R.; Mallos, N.J.; Leonard, G.H. The United States’ contribution of plastic waste to land and ocean. Sci. Adv. 2020, 6, eabd0288. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K. Characterisation of recycled mixed plastic solid wastes: Coupon and full-scale investigation. Waste Manag. 2016, 48, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and fragmentation of plastic debris in global environments. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1985–1998. [Google Scholar] [CrossRef]

- Peddaiah, S.; Burman, A.; Sreedeep, S. Experimental study on effect of waste plastic bottle strips in soil improvement. Geotech. Geol. Eng. 2018, 36, 2907–2920. [Google Scholar] [CrossRef]

- Kassa, R.B.; Workie, T.; Abdela, A.; Fekade, M.; Saleh, M.; Dejene, Y. Soil stabilization using waste plastic materials. Open J. Civ. Eng. 2020, 10, 55–68. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Jha, J.N.; Gill, K.S. Utilization of plastic wastes for improving the sub-grades in flexible pavements. In Paving Materials and Pavement Analysis; ASCE: Reston, VA, USA, 2010; pp. 320–326. [Google Scholar]

- Jaya, A.D.; Sunil, A.; Joseph, M.; Varghese, M.; Veena, M. Soil Stabilization Using Raw Plastic Bottles. In Proceedings of the Indian Geotechnical Conference, Kochi, India, 15–17 December 2011; pp. 15–17. [Google Scholar]

- Boobalan, S.C.; Anandakumar, P.K.; Sathasivam, M. Utilization of waste plastic sheets as soil stabilization materials. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Wani, I.A.; Sheikh, I.M.; Maqbool, T.; Kumar, V. Experimental investigation on using plastic wastes to enhance several engineering properties of soil through stabilization. Mater. Today Proc. 2021, 45, 4571–4574. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Methods for One-Dimensional Swell or Collapse of Soils; ASTM International: West Conshohocken, PA, USA, 1988. [Google Scholar]

- Seed, H.B.; Jr, R.J.W.; Lundgren, R. Prediction of swelling potential for compacted clays. J. Soil Mech. Found. Div. 1962, 88, 53–87. [Google Scholar] [CrossRef]

- Muci, R.; Skrame, K.; Fociro, O.; Mancini, M.; Gaudiosi, I.; Simionato, M. Effect of cement and fly-ash on the geotechnical properties of expansive clay soils. Ital. J. Geosci. 2021, 140, 108–120. [Google Scholar] [CrossRef]

- Tripathy, S.; Mishra, A.K. On the use of Skempton’s compression index equation. Geotech. Geol. Eng. 2011, 29, 129–135. [Google Scholar] [CrossRef]

- Eskisar, T. Influence of cement treatment on unconfined compressive strength and compressibility of lean clay with medium plasticity. Arab. J. Sci. Eng. 2015, 40, 763–772. [Google Scholar] [CrossRef]

- Pakbaz, M.S.; Keshani, A. Evaluation of time rate of swelling pressure development due to the presence of sulfate in clayey soils stabilized with lime. GEOMATE J. 2017, 12, 161–165. [Google Scholar]

- Shah, A.; Thaker, T. Utilization of post-consumer plastic water bottles as an admixture for improving the soil subgrade. In Geo-Congress 2024; ASCE: Reston, VA, USA; pp. 471–481.

- Solanki, Y.; Jambudia, M.; Shah, A. Analysis and modification of engineering behavior of soil using plastic waste materials. In Proceedings of the Indian Geotechnical Conference 2019: IGC-2019, Surat, India, 19–21 December 2019; Springer: Singapore, 2021; Volume III, pp. 661–669. [Google Scholar]

- Mandal, M.; Roy, N.; Bag, R. Effect of plastic waste on strength of clayey soil and clay mixed with fly ash. In Problematic Soils and Geoenvironmental Concerns: Proceedings of IGC 2018; Springer: Singapore, 2021; pp. 549–564. [Google Scholar]

| Soil 1 | Soil 2 | |

|---|---|---|

| Liquid Limit (%) | 81 | 63 |

| Plastic Limit | 26 | 22 |

| Plasticity Index | 53 | 41 |

| ɣdmax [kN/m3] | 13.1 | 13.7 |

| Water Optimum Content (%) | 41 | 33 |

| Sand (%) | 8 | 12 |

| Silt (%) | 18 | 27 |

| Clay (%) | 74 | 61 |

| Activity | 72 | 67 |

| Specific Gravity | 2.6 | 2.7 |

| Kaolinite (%) | 14.2 | 19.2 |

| Illite (%) | 31.2 | 27.1 |

| Montmorillonite (%) | 24.1 | 18.1 |

| Chlorite (%) | 14.8 | 16.7 |

| Classification (Unified Soil Classification System) | CH | CH |

| Blend Fraction (%) | Aspect Ratio | |||

|---|---|---|---|---|

| 10 | 15 | 20 | ||

| % Reduction | ||||

| Soil 1 | 2 | 6.3 | 12.5 | 14.6 |

| 4 | 20.8 | 35.4 | 39.6 | |

| 6 | 56.3 | 68.8 | 79.2 | |

| 8 | 75.0 | 77.1 | 83.3 | |

| 10 | 81.3 | 81.3 | 87.5 | |

| Soil 2 | 2 | 11.1 | 11.1 | 13.3 |

| 4 | 17.8 | 22.2 | 44.4 | |

| 6 | 55.6 | 64.4 | 77.8 | |

| 8 | 75.6 | 80.0 | 82.2 | |

| 10 | 80.0 | 82.2 | 86.7 | |

| Blend Fraction (%) | Swell Potential (%) | Percent Reduction (%) | |||||

|---|---|---|---|---|---|---|---|

| Aspect Ratio | Aspect Ratio | ||||||

| 10 | 15 | 20 | 10 | 15 | 20 | ||

| Soil 1 | 0 | 21 | 21 | 21 | 0 | 0 | 0 |

| 2 | 19 | 18 | 18 | 9.5 | 14.3 | 14.3 | |

| 4 | 13 | 11 | 9 | 38.1 | 47.6 | 57.1 | |

| 6 | 10 | 8 | 6 | 52.4 | 61.9 | 71.4 | |

| 8 | 6 | 6 | 4 | 71.4 | 71.4 | 81.0 | |

| 10 | 6 | 5 | 4 | 71.4 | 76.2 | 81.0 | |

| Soil 2 | 0 | 17 | 17 | 17 | 0.0 | 0.0 | 0.0 |

| 2 | 16 | 16 | 15 | 5.9 | 5.9 | 11.8 | |

| 4 | 14 | 12 | 9 | 17.6 | 29.4 | 47.1 | |

| 6 | 12 | 10 | 7 | 29.4 | 41.2 | 58.8 | |

| 8 | 8 | 6 | 4 | 52.9 | 64.7 | 76.5 | |

| 10 | 7 | 5 | 4 | 58.8 | 70.6 | 76.5 | |

| Soil | Mixture Percentage (%) | Consolidation Index | Maximum Past Pressure (kg/cm2) | ||||

|---|---|---|---|---|---|---|---|

| Aspect Ratio | Aspect Ratio | ||||||

| 10 | 15 | 20 | 10 | 15 | 20 | ||

| Soil 1 | 0 | 0.43 | 0.43 | 0.43 | 2.8 | 2.8 | 2.8 |

| 2 | 0.43 | 0.43 | 0.42 | 3.1 | 3.2 | 3.3 | |

| 4 | 0.4 | 0.39 | 0.37 | 3.7 | 3.9 | 4.4 | |

| 6 | 0.38 | 0.35 | 0.33 | 4.6 | 4.9 | 5.6 | |

| 8 | 0.35 | 0.32 | 0.28 | 5.6 | 6.0 | 7.1 | |

| 10 | 0.31 | 0.29 | 0.2 | 6.9 | 7.6 | 9.6 | |

| Soil 2 | 0 | 0.39 | 0.39 | 0.39 | 2.5 | 2.5 | 2.5 |

| 2 | 0.38 | 0.36 | 0.33 | 2.6 | 2.6 | 2.8 | |

| 4 | 0.36 | 0.34 | 0.3 | 3.5 | 3.7 | 3.9 | |

| 6 | 0.31 | 0.3 | 0.29 | 4.1 | 4.2 | 4.6 | |

| 8 | 0.30 | 0.28 | 0.27 | 4.5 | 5.0 | 5.7 | |

| 10 | 0.28 | 0.27 | 0.23 | 4.9 | 6.1 | 7.4 | |

| Soil Type | % of Plastic Waste | % Increase in CBR | ||

|---|---|---|---|---|

| Aspect Ratio = 5 | Aspect Ratio = 10 | Aspect Ratio = 15 | ||

| Soaked Soil 1 | 0.5 | 46.67 | 57.78 | 73.33 |

| 1 | 77.78 | 82.22 | 102.22 | |

| 1.5 | 106.67 | 124.44 | 162.22 | |

| 2 | 80.00 | 173.33 | 215.56 | |

| Unsoaked Soil 1 | 0.5 | 51.11 | 73.33 | 95.56 |

| 1 | 102.22 | 142.22 | 164.44 | |

| 1.5 | 120.00 | 193.33 | 231.11 | |

| 2 | 126.67 | 244.44 | 286.67 | |

| Soaked Soil 2 | 0.5 | 36.00 | 56.00 | 62.00 |

| 1 | 68.00 | 78.00 | 114.00 | |

| 1.5 | 96.00 | 124.00 | 172.00 | |

| 2 | 94.00 | 174.00 | 208.00 | |

| Unsoaked Soil 2 | 0.5 | 56.00 | 78.00 | 98.00 |

| 1 | 122.00 | 164.00 | 196.00 | |

| 1.5 | 162.00 | 218.00 | 256.00 | |

| 2 | 196.00 | 264.00 | 318.00 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Attom, M.; Al-Asheh, S.; Yamin, M.; Vandanapu, R.; Al-Lozi, N.; Khalil, A.; Eltayeb, A. Soil Improvement Using Plastic Waste–Cement Mixture to Control Swelling and Compressibility of Clay Soils. Buildings 2025, 15, 1387. https://doi.org/10.3390/buildings15081387

Attom M, Al-Asheh S, Yamin M, Vandanapu R, Al-Lozi N, Khalil A, Eltayeb A. Soil Improvement Using Plastic Waste–Cement Mixture to Control Swelling and Compressibility of Clay Soils. Buildings. 2025; 15(8):1387. https://doi.org/10.3390/buildings15081387

Chicago/Turabian StyleAttom, Mousa, Sameer Al-Asheh, Mohammad Yamin, Ramesh Vandanapu, Naser Al-Lozi, Ahmed Khalil, and Ahmed Eltayeb. 2025. "Soil Improvement Using Plastic Waste–Cement Mixture to Control Swelling and Compressibility of Clay Soils" Buildings 15, no. 8: 1387. https://doi.org/10.3390/buildings15081387

APA StyleAttom, M., Al-Asheh, S., Yamin, M., Vandanapu, R., Al-Lozi, N., Khalil, A., & Eltayeb, A. (2025). Soil Improvement Using Plastic Waste–Cement Mixture to Control Swelling and Compressibility of Clay Soils. Buildings, 15(8), 1387. https://doi.org/10.3390/buildings15081387