Optimizing the Mixture Design of Manufactured Sand Concrete for Highway Guardrails in Mountainous Terrain

Abstract

:1. Introduction

2. Materials and Methods

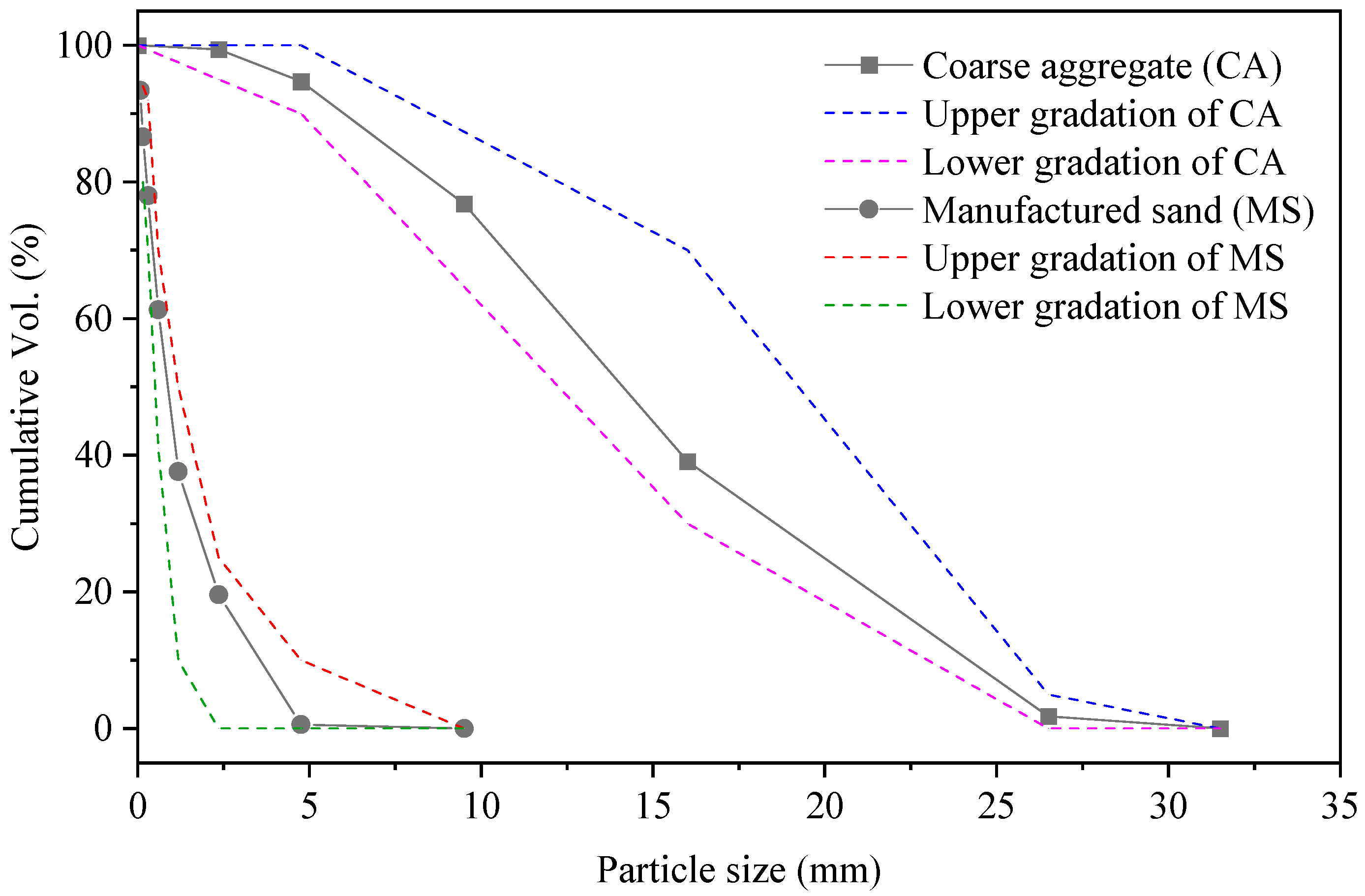

2.1. Raw Materials

2.2. Mix Design and Concrete Preparation

2.3. Testing Methods

3. Results and Discussion

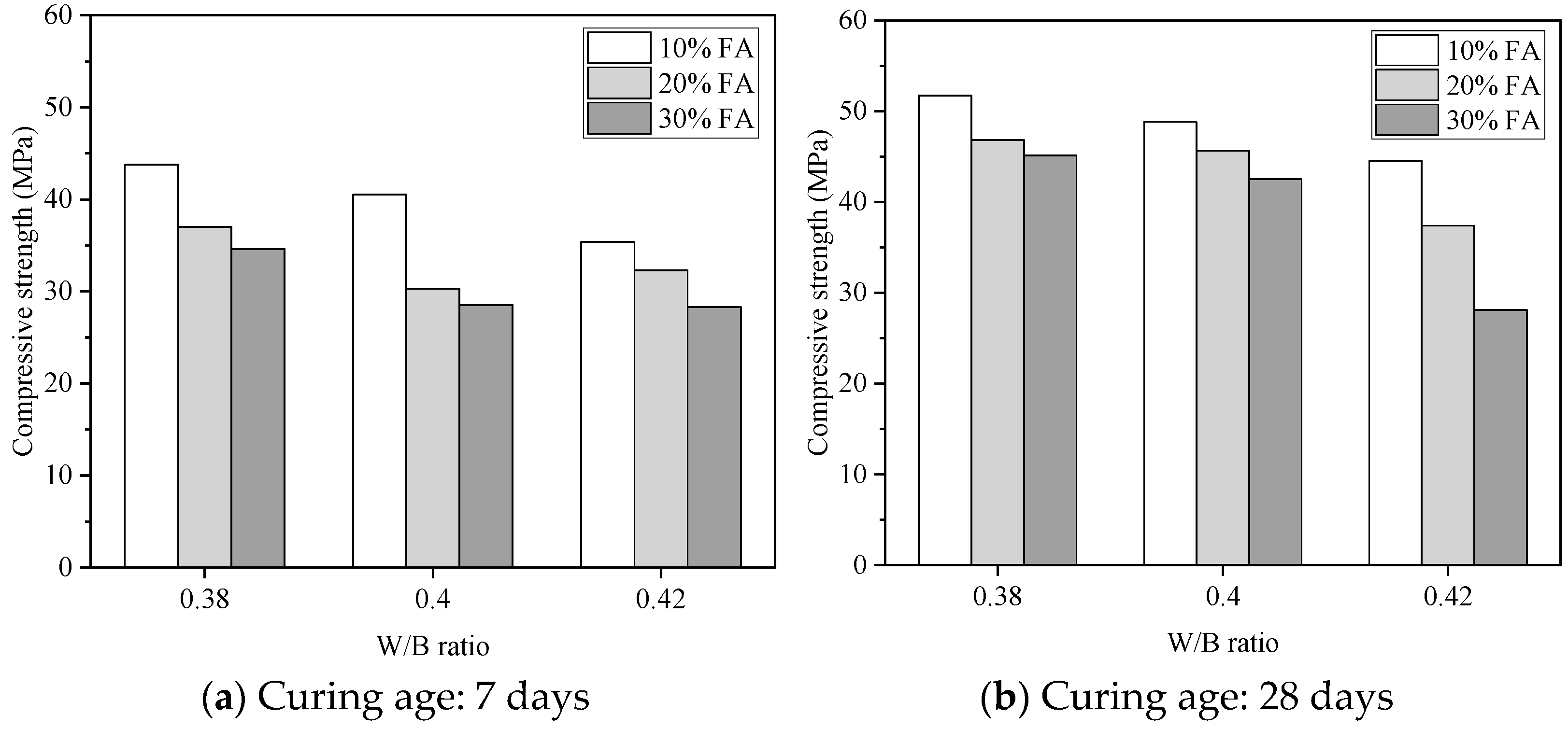

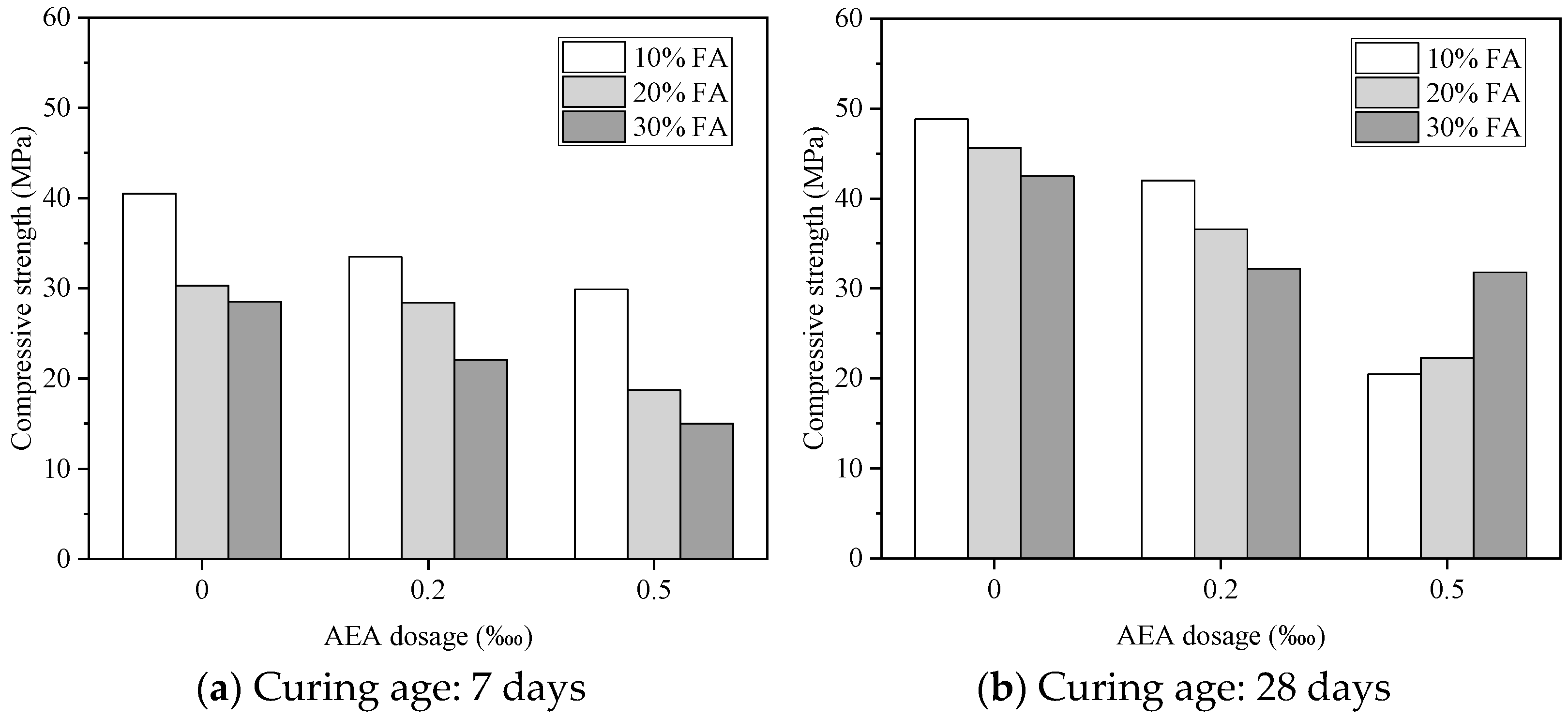

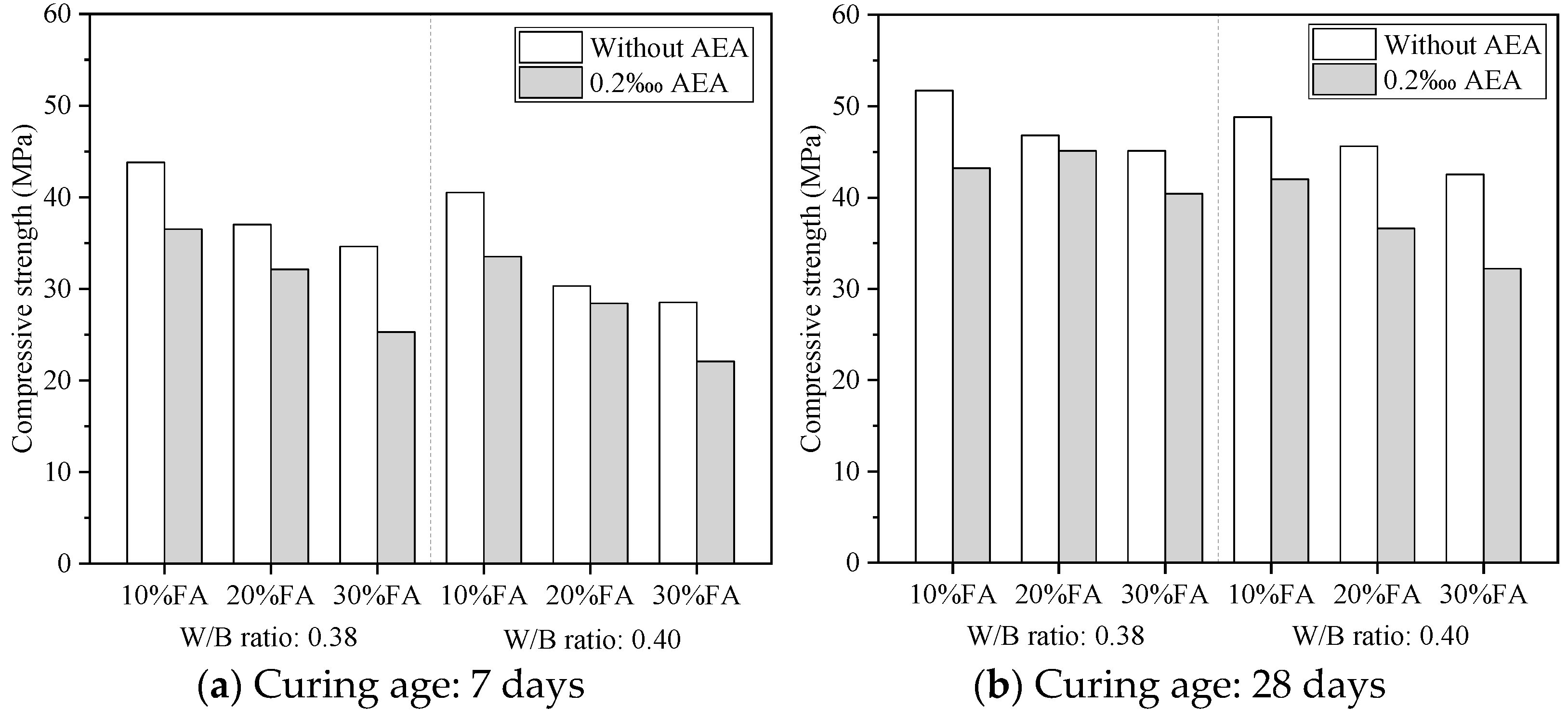

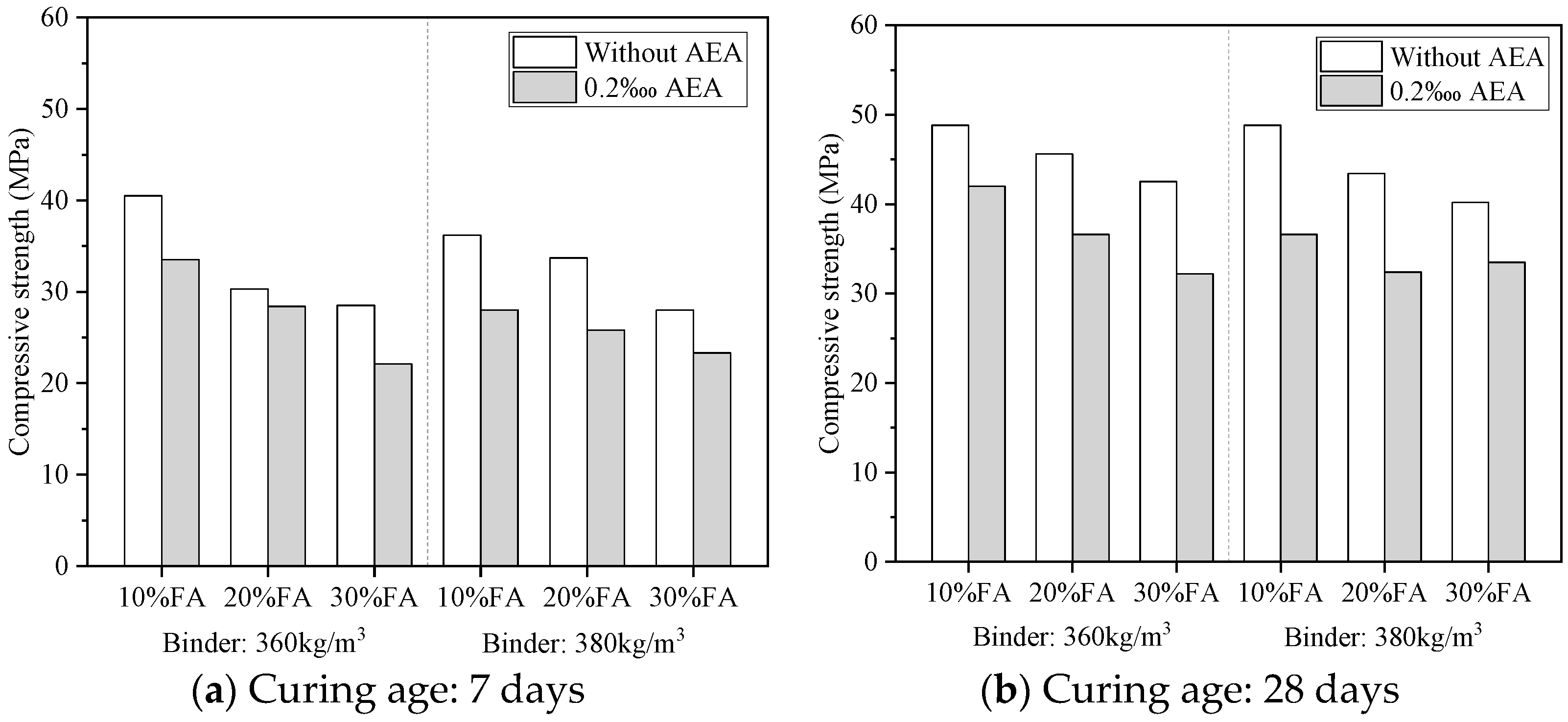

3.1. Compressive Strength

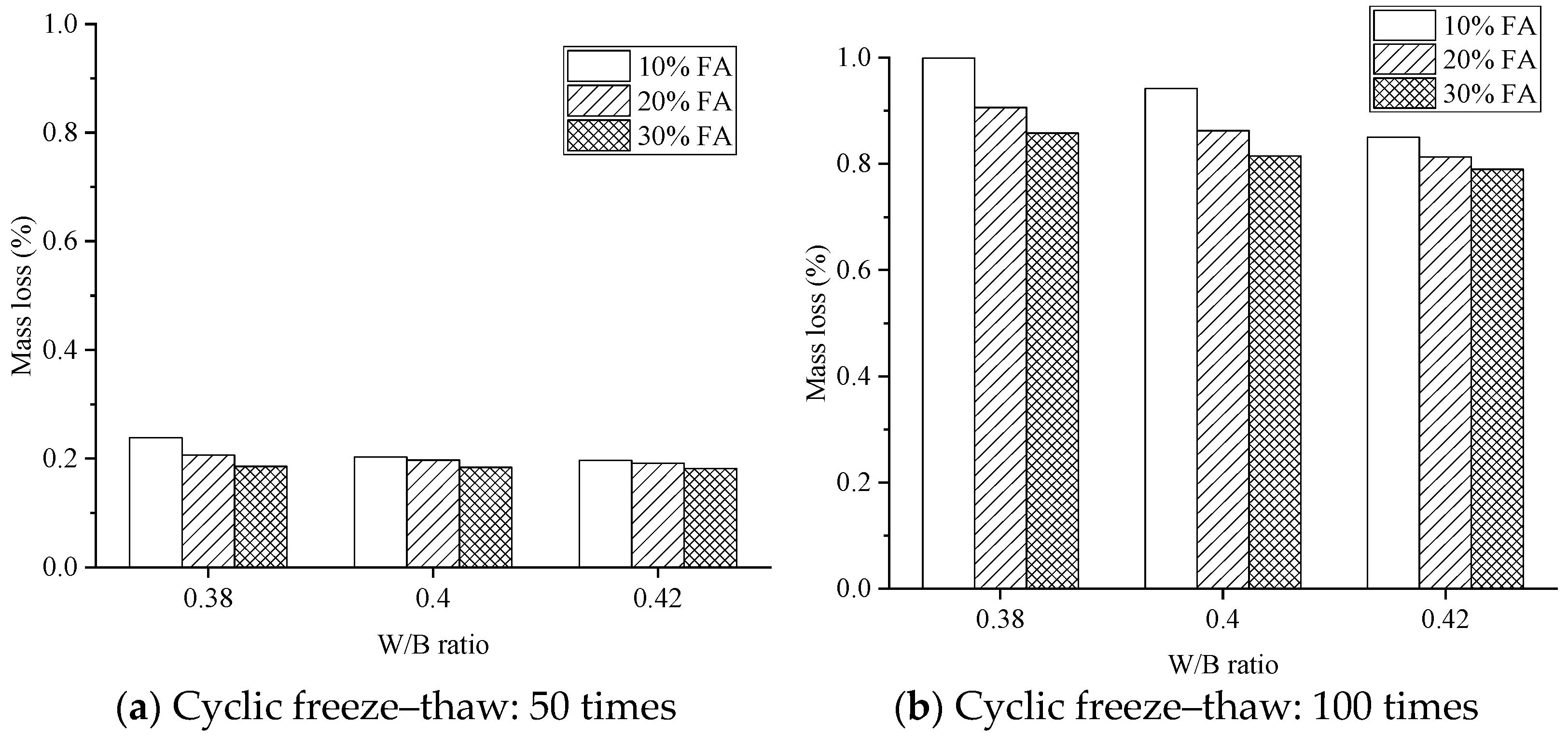

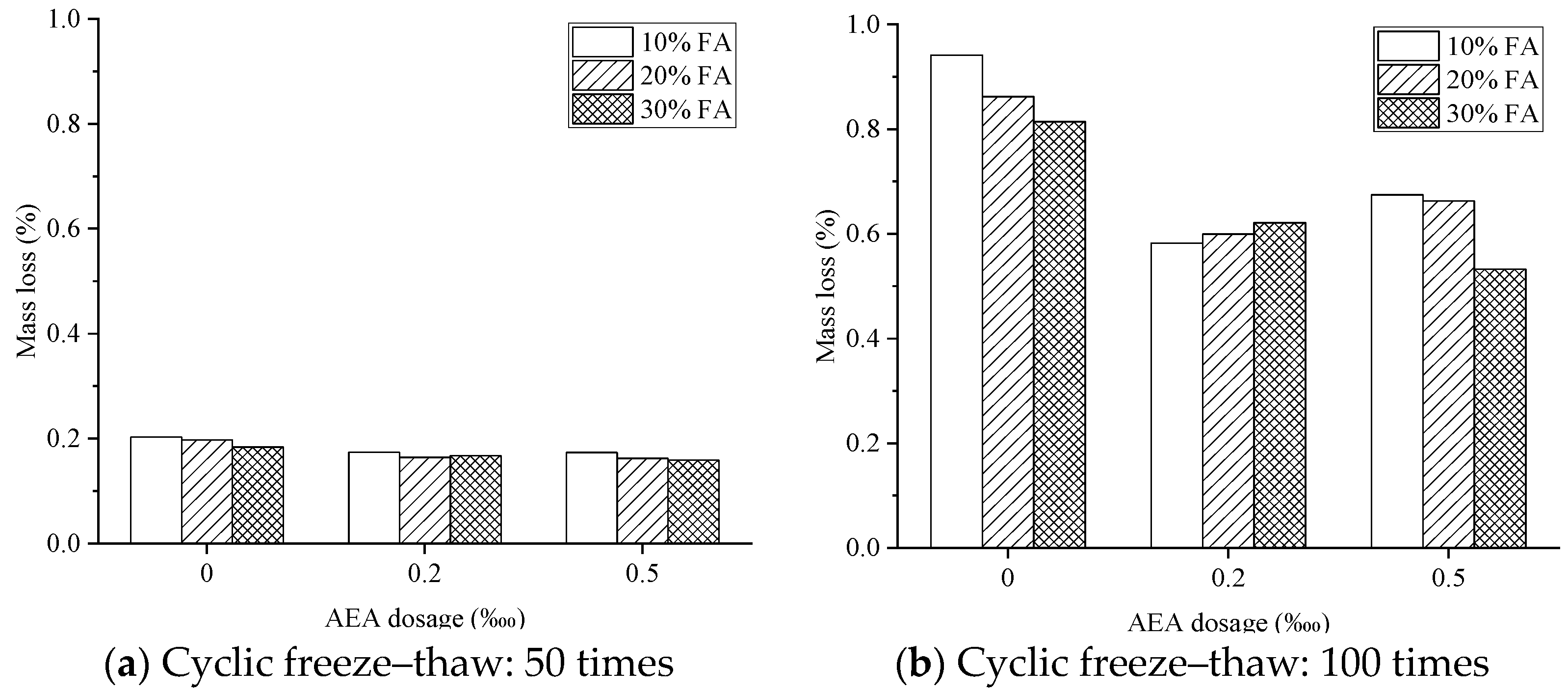

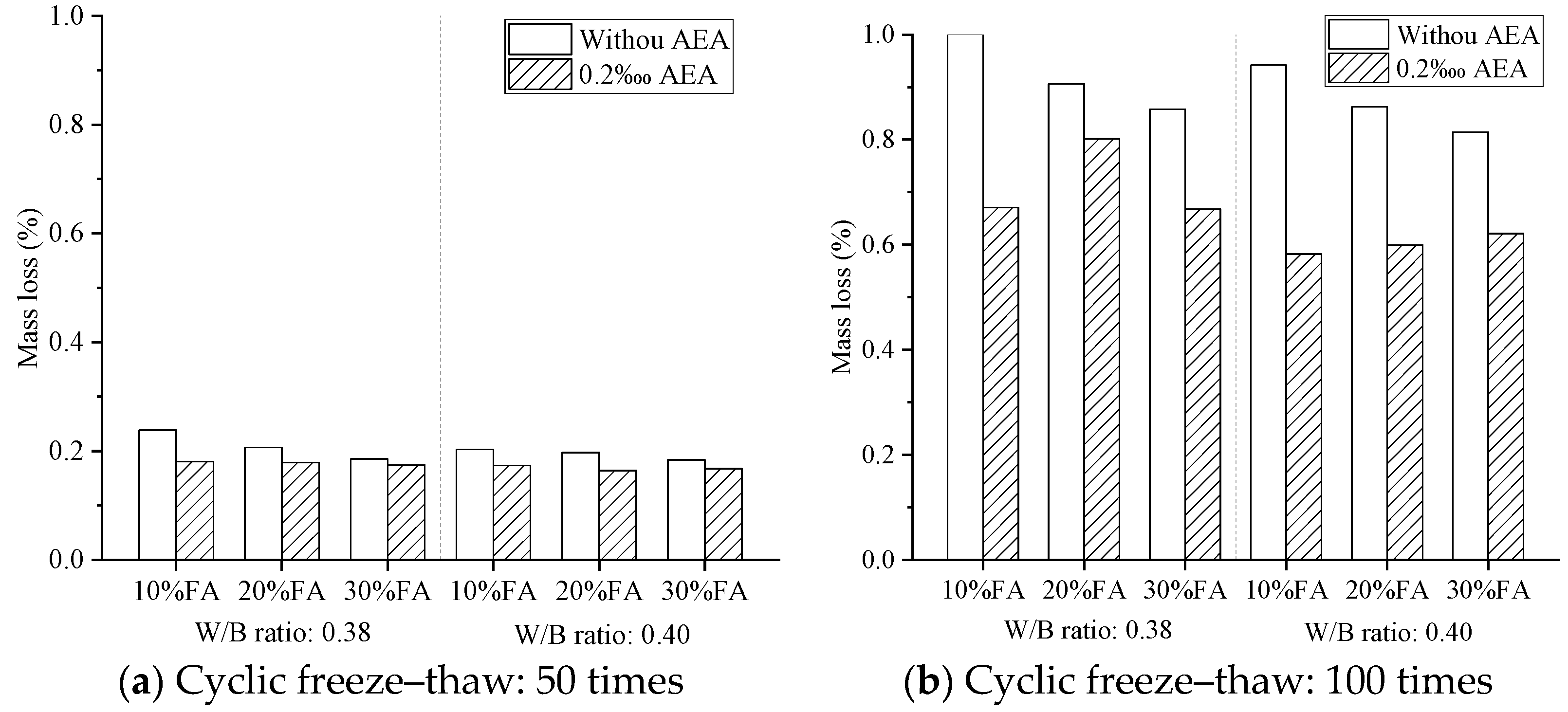

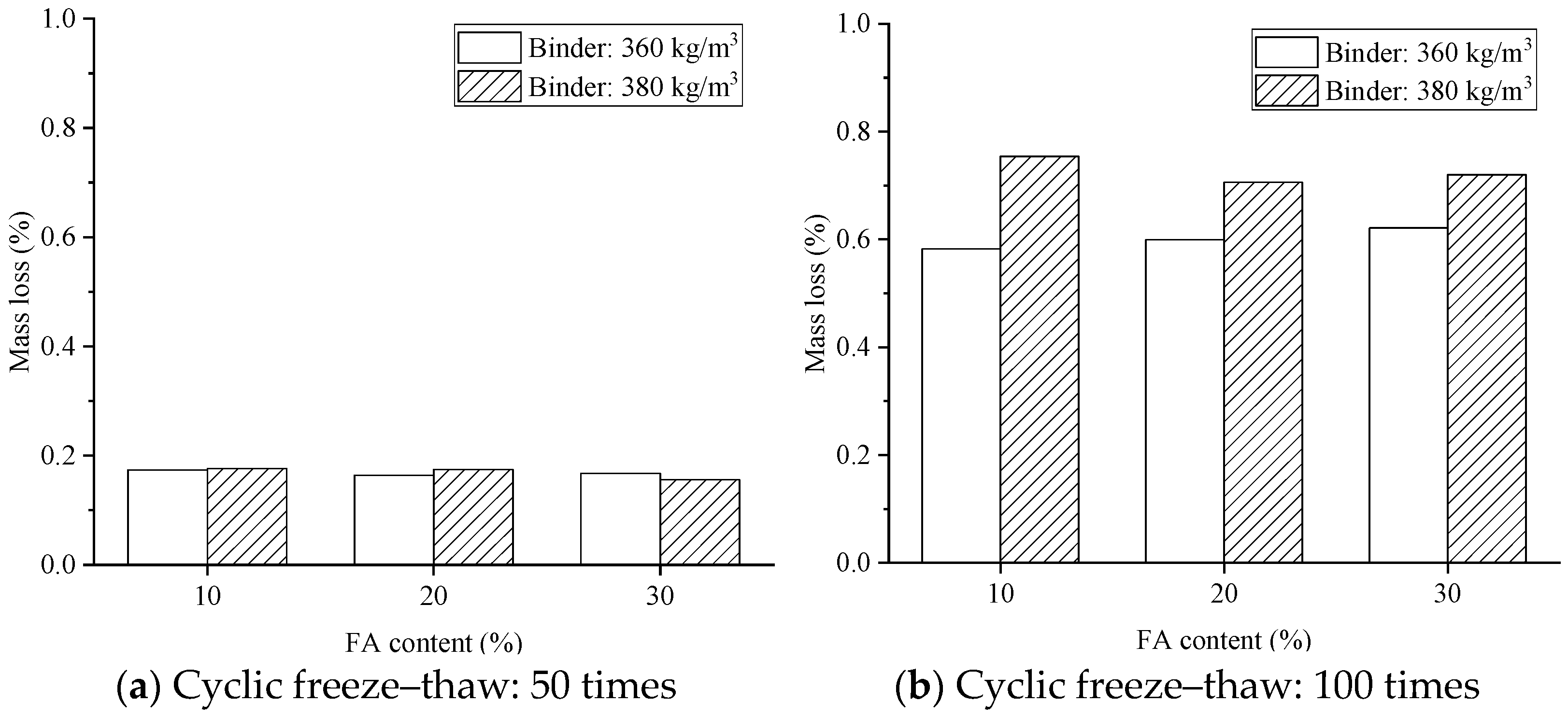

3.2. Freeze–Thaw Resistance

3.3. Pore Size Distribution

3.4. Microstructural Observation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, S.; Bai, T.; Guo, M.; Wei, Y.; Ma, W. Impact of freeze-thaw cycles on the long-term performance of concrete pavement and related improvement measures: A review. Materials 2022, 15, 4568. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Xu, H.; Li, J.; Luo, N. Has highway construction narrowed the urban–rural income gap? Evidence from Chinese cities. Pap. Reg. Sci. 2020, 99, 705–723. [Google Scholar] [CrossRef]

- Huang, X.; Wang, S.; Zhou, Y. Soil organic carbon change relating to the prevention and control of rocky desertification in Guizhou Province, SW China. Int. J. Glob. Warm. 2018, 15, 315–332. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Furszyfer Del Rio, D.D.; Foley, A.M.; Bazilian, M.D.; Kim, J.; Uratani, J.M. Decarbonizing the cement and concrete industry: A systematic review of socio-technical systems, technological innovations, and policy options. Renew. Sustain. Energy Rev. 2023, 180, 113291. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, H.; Gu, C.; Shao, C.; Jiang, Z.; Wang, Y.; Chen, X. Analysis of concrete damage evolution in cold regions under combined freeze-thaw cycle-crack effect. Constr. Build. Mater. 2024, 456, 139296. [Google Scholar] [CrossRef]

- Shen, W.; Liu, Y.; Wang, Z.; Cao, L.; Wu, D.; Wang, Y.; Ji, X. Influence of manufactured sand’s characteristics on its concrete performance. Constr. Build. Mater. 2018, 172, 574–583. [Google Scholar] [CrossRef]

- Cortes, D.D.; Kim, H.K.; Palomino, A.M.; Santamarina, J.C. Rheological and mechanical properties of mortars prepared with natural and manufactured sands. Cem. Concr. Res. 2008, 38, 1142–1147. [Google Scholar] [CrossRef]

- Leleu, S.L.; Valdes, J.R. Experimental study of the influence of mineral composition on sand crushing. Geotechnique 2007, 57, 313–317. [Google Scholar] [CrossRef]

- Gonçalves, J.P.; Tavares, L.M.; Toledo Filho, R.D.; Fairbairn, E.M.R.; Cunha, E.R. Comparison of natural and manufactured fine aggregates in cement mortars. Cem. Concr. Res. 2007, 37, 924–932. [Google Scholar] [CrossRef]

- Safiddine, S.; Debieb, F.; Kadri, E.H.; Menadi, B.; Soualhi, H. Effect of crushed sand and limestone crushed sand dust on the rheology of cement mortar. Appl. Rheol. 2017, 27, 12–20. [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y.; Li, F.L.; Zhao, S.B. Experimental study on long-term compressive strength of concrete with manufactured sand. Constr. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Li, B.X.; Ke, G.J.; Zhou, M.K. Influence of manufactured sand characteristics on strength and abrasion resistance of pavement cement concrete. Constr. Build. Mater. 2011, 25, 3849–3853. [Google Scholar] [CrossRef]

- Benabed, B.; Kadri, E.-H.; Azzouz, L.; Kenai, S. Properties of self-compacting mortar made with various types of sand. Cem. Concr. Compos. 2012, 34, 1167–1173. [Google Scholar] [CrossRef]

- Singh, D.; Zaman, M.; Commuri, S. Inclusion of aggregate angularity, texture, and form in estimating dynamic modulus of asphalt mixes. Road Mater. Pavement Des. 2012, 13, 327–344. [Google Scholar] [CrossRef]

- Menadi, B.; Kenai, S.; Khatib, J.; Ait-Mokhtar, A. Strength and durability of concrete incorporating crushed limestone sand. Constr. Build. Mater. 2009, 23, 625–633. [Google Scholar] [CrossRef]

- Bederina, M.; Makhloufi, Z.; Bounoua, A.; Bouziani, T.; Quéneudec, M. Effect of partial and total replacement of siliceous river sand with limestone crushed sand on the durability of mortars exposed to chemical solutions. Constr. Build. Mater. 2013, 47, 146–158. [Google Scholar] [CrossRef]

- Ren, Q.; De Schutter, G.; Jiang, Z.; Chen, Q. Multi-level diffusion model for manufactured sand mortar considering particle shape and limestone powder effects. Constr. Build. Mater. 2019, 207, 218–227. [Google Scholar] [CrossRef]

- Liu, J.; Xu, L.; Liu, J.; Wang, W.; He, R. Experimental study on manufactured sand concrete containing mineral admixture under freeze-thaw cycles. Constr. Build. Mater. 2024, 453, 138759. [Google Scholar] [CrossRef]

- Li, W. Analysis of the influence water-cement ratio on concrete strength. E3S Web Conf. 2021, 283, 01016. [Google Scholar] [CrossRef]

- Peng, R.; Qiu, W.; Teng, F. Three-dimensional meso-numerical simulation of heterogeneous concrete under freeze-thaw. Constr. Build. Mater. 2020, 250, 118573. [Google Scholar] [CrossRef]

- Zhang, S.; Fan, Y.; Shah, S. Study on deformation characteristics and damage model of NMK concrete under cold environment. Buildings 2022, 12, 1431. [Google Scholar] [CrossRef]

- Gu, C.; Sun, W.; Guo, L.; Wang, Q.; Liu, J.; Yang, Y.; Shi, T. Investigation of microstructural damage in ultrahigh-performance concrete under freezing-thawing action. Adv. Mater. Sci. Eng. 2018, 2018, 3701682. [Google Scholar] [CrossRef]

- Oyunbileg, D.; Amgalan, J.; Batbaatar, T.; Temuujin, J. Evaluation of thermal and freeze-thaw resistances of the concretes with the silica fume addition at different water-cement ratio. Case Stud. Constr. Mater. 2023, 19, e02633. [Google Scholar] [CrossRef]

- Chen, C.; Lu, C.; Lu, C.; Wei, S.; Guo, Z.; Zhou, Q.; Wang, W. Synergetic effect of fly ash and ground-granulated blast slag on improving the chloride permeability and freeze–thaw resistance of recycled aggregate concrete. Constr. Build. Mater. 2023, 365, 130015. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze–thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Pushpalal, D.; Danzandorj, S.; Narantogtokh, B.; Nishiwaki, T.; Sashka, U.; Erdenebat, S.; Sambuu, C. Freezing-thawing durability and chemical characteristics of air-entrained sustainable concrete incorporated high-calcium fly ash in high-volume. J. Build. Eng. 2024, 89, 109307. [Google Scholar] [CrossRef]

- Gonzalez, D.C.; Mena, A.; Minguez, J.; Vicente, M.A. Influence of air-entraining agent and freeze-thaw action on pore structure in high-strength concrete by using CT-Scan technology. Cold Reg. Sci. Technol. 2021, 192, 103397. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Entrained air and freeze-thaw durability of concrete incorporating nano-fibrillated cellulose (NFC). Cem. Concr. Compos. 2024, 150, 105582. [Google Scholar] [CrossRef]

- WawrzeĔczyk, J.; Juszczak, T.; Molendowska, A. Effect of binder composition on the structure of cement paste and on physical properties and freeze-thaw resistance of concrete. Procedia Eng. 2016, 161, 73–78. [Google Scholar] [CrossRef]

- Ugurlu, A.I.; Karakoç, M.B.; Ozcan, A. Effect of binder content and recycled concrete aggregate on freeze-thaw and sulfate resistance of GGBFS based geopolymer concretes. Constr. Build. Mater. 2021, 301, 124246. [Google Scholar] [CrossRef]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International Committee: West Conshohocken, PA, USA, 2018.

- ASTM C666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International Committee: West Conshohocken, PA, USA, 2008.

- Izadifar, M.; Dolado, J.S.; Thissen, P.; Ukrainczyk, N.; Koenders, E.; Ayuela, A. Theoretical elastic constants of tobermorite enhanced with reduced graphene oxide through hydroxyl vs epoxy functionalization: A first-principles study. J. Phys. Chem. C 2023, 127, 18117–18126. [Google Scholar] [CrossRef]

| Density (g/cm3) | Specific Area (m2/kg) | Water Consumption (%) | Setting Time (min) | Stability (mm) | Flexural Strength (MPa) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3d | 28d | 3d | 28d | ||||

| 3.11 | 318 | 27.2 | 198 | 325 | 0.5 | 5.0 | 7.8 | 30.5 | 50.6 |

| Water Demand (%) | Finneess (%) | Reactive Index (%) | SO3 (%) | f-CaO (%) | LOI (%) |

|---|---|---|---|---|---|

| 98 | 20 | 73 | 1.58 | 0.32 | 5.38 |

| Mud Content (%) | MB Value (g/kg) | Stone Powder Content (%) | Crushing Index (%) | Apparent Density (kg/m3) | Packing Density (kg/m3) | Porosity (%) |

|---|---|---|---|---|---|---|

| 0.2 | 0.5 | 7.3 | 20 | 2716 | 1656 | 39.0 |

| Mud Content (%) | Flatness and Elongation Ratio (%) | Crushing Index (%) | Apparent Density (kg/m3) |

|---|---|---|---|

| 0.1 | 3.5 | 8 | 2708 |

| Mixture Notation | Binder (kg/m3) | W/B Ratio | FA (%) | AEA (‱) | Mass Ratio of Concrete (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC | FA | Sand | Coarse Aggregate | WRA | Water | ||||||

| 5–10 mm | 5–25 mm | ||||||||||

| F10W1 | 360 | 0.38 | 10 | - | 324 | 36 | 874 | 103 | 923 | 3.6 | 136.8 |

| F20W1 | 360 | 0.38 | 20 | - | 288 | 72 | 874 | 103 | 923 | 3.6 | 136.8 |

| F30W1 | 360 | 0.38 | 30 | - | 252 | 108 | 874 | 103 | 923 | 3.6 | 136.8 |

| F10 | 360 | 0.40 | 10 | - | 324 | 36 | 874 | 103 | 923 | 3.6 | 144 |

| F20 | 360 | 0.40 | 20 | - | 288 | 72 | 874 | 103 | 923 | 3.6 | 144 |

| F30 | 360 | 0.40 | 30 | - | 252 | 108 | 874 | 103 | 923 | 3.6 | 144 |

| F10W2 | 360 | 0.42 | 10 | - | 324 | 36 | 874 | 103 | 923 | 3.6 | 151.2 |

| F20W2 | 360 | 0.42 | 20 | - | 288 | 72 | 874 | 103 | 923 | 3.6 | 151.2 |

| F30W2 | 360 | 0.42 | 30 | - | 252 | 108 | 874 | 103 | 923 | 3.6 | 151.2 |

| F10Y1 | 360 | 0.40 | 10 | 0.2 | 324 | 36 | 874 | 103 | 923 | 3.6 | 144 |

| F20Y1 | 360 | 0.40 | 20 | 0.2 | 288 | 72 | 874 | 103 | 923 | 3.6 | 144 |

| F30Y1 | 360 | 0.40 | 30 | 0.2 | 252 | 108 | 874 | 103 | 923 | 3.6 | 144 |

| F10Y2 | 360 | 0.40 | 10 | 0.5 | 324 | 36 | 874 | 103 | 923 | 3.6 | 144 |

| F20Y2 | 360 | 0.40 | 20 | 0.5 | 288 | 72 | 874 | 103 | 923 | 3.6 | 144 |

| F30Y2 | 360 | 0.40 | 30 | 0.5 | 252 | 108 | 874 | 103 | 923 | 3.6 | 144 |

| F10J | 380 | 0.40 | 10 | 0.2 | 342 | 38 | 874 | 103 | 923 | 3.8 | 152 |

| F20J | 380 | 0.40 | 20 | 0.2 | 304 | 76 | 874 | 103 | 923 | 3.8 | 152 |

| F30J | 380 | 0.40 | 30 | 0.2 | 266 | 114 | 874 | 103 | 923 | 3.8 | 152 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Zhou, P.; Zhao, S.; Yang, Q.; Gu, K.; Song, Q.; Jiang, Z. Optimizing the Mixture Design of Manufactured Sand Concrete for Highway Guardrails in Mountainous Terrain. Buildings 2025, 15, 1436. https://doi.org/10.3390/buildings15091436

Gao J, Zhou P, Zhao S, Yang Q, Gu K, Song Q, Jiang Z. Optimizing the Mixture Design of Manufactured Sand Concrete for Highway Guardrails in Mountainous Terrain. Buildings. 2025; 15(9):1436. https://doi.org/10.3390/buildings15091436

Chicago/Turabian StyleGao, Jianping, Pan Zhou, Sigui Zhao, Qian Yang, Kang Gu, Qingnan Song, and Zhengwu Jiang. 2025. "Optimizing the Mixture Design of Manufactured Sand Concrete for Highway Guardrails in Mountainous Terrain" Buildings 15, no. 9: 1436. https://doi.org/10.3390/buildings15091436

APA StyleGao, J., Zhou, P., Zhao, S., Yang, Q., Gu, K., Song, Q., & Jiang, Z. (2025). Optimizing the Mixture Design of Manufactured Sand Concrete for Highway Guardrails in Mountainous Terrain. Buildings, 15(9), 1436. https://doi.org/10.3390/buildings15091436