4.1. Ventilation

In these studies, CO

2 is being used as an indicator of ventilation rates. Levels of CO

2 correlate well with human occupancy and levels above 1000 ppm are indicative of poor ventilation rates. The provenance of this is well evidenced [

12] and corresponds to a ventilation rate of 8 L/s per person [

13,

14]. This figure is also cited in a review of literature looking at the associations between ventilation rates and CO

2 levels with health outcomes, which concluded: “Almost all studies found that ventilation rates below 10 L/s per person in all building types were associated with statistically significant worsening in one or more health or perceived air quality outcomes” [

15]. Associations between health and CO

2 levels have been found in office buildings [

16] and associations between CO

2 levels and Total Volatile Organic Compounds (TVOCs) have been identified [

17]. Wargoki notes associations between CO

2 levels and health and concludes: “The ventilation rates above 0.4 ac/h or CO

2 below 900 ppm in homes seem to be the minimum level to protect against health risks based on the studies reported in the scientific literature” [

18].

A particular area of investigation therefore concerned ventilation and indoor air quality. Whilst it has been shown that MVHR can achieve energy reduction [

19], good air quality and associated health benefits [

20], recent research has identified a number of problems in relation to MVHR systems [

21].

In the pilot study conducted in 2011, a number of defects were identified in the MVHR system. These included crushed and damaged ducts, additional bends, a high amount of 100 mm flexible ducting being used, debris in the duct from construction, filters being dirty (

Figure 6), and the unit being connected using the horizontal spigots, which restrict airflow. The system had been re-commissioned prior to SC1, with some remedial work undertaken, but some areas of ductwork were inaccessible and could not be replaced or repaired.

Figure 6.

Mechanical Ventilation with Heat Recovery (MVHR) filters, dirt accumulation between scenarios.

Figure 6.

Mechanical Ventilation with Heat Recovery (MVHR) filters, dirt accumulation between scenarios.

Airflow testing of the MVHR was undertaken and the results are shown in

Table 3. This clearly shows that the systems remain out of balance, which will reduce the system efficiency. In addition to problems with the system itself, there are no door undercuts and therefore no means of enabling airflow through the building when bedroom or bathroom doors are closed.

Table 3.

Measured MVHR airflow rates.

Table 3.

Measured MVHR airflow rates.

| Room | Plot 1 | Plot 3 |

| Extract Positions | High Rate (L/s) | Low Rate (L/s) | High Rate (L/s) | Low Rate (L/s) |

| Utility/WC | 7.23 | 5.49 | 9.23 | 5.64 |

| Kitchen | 9.81 | 6.81 | 12.11 | 8 |

| Bathroom | 9.3 | 6.3 | 8.26 | 5.35 |

| Total | 26.34 | 18.6 | 29.6 | 18.99 |

| Supply Positions | High Rate (L/s) | Low Rate (L/s) | High Rate (L/s) | Low Rate (L/s) |

| Living Room | 5.64 | 4.51 | 7.27 | 7.34 |

| Bedroom 1 | 9.31 | 7.45 | 8.69 | 8.64 |

| Bedroom 2 | 8.13 | 6.23 | 6.53 | 6.9 |

| Bedroom 3 | 7.8 | 5.96 | 3.88 | 4.26 |

| Attic Room | 8.42 | 6.69 | 7.27 | 7.48 |

| Total | 39.3 | 30.84 | 33.64 | 34.62 |

| Difference | 12.98 | 12.24 | 4.04 | 15.63 |

Of note are the values for individual rooms compared with a desired ventilation rate of 8 L/s per person. Given that most rooms could reasonably be expected to have several occupants, this provision appears deficient. There is no other provision for background ventilation in the dwelling, so concerns were raised about consequences should the MVHR system fail or be disabled. Furthermore, the location of the unit in the loft will compromise regular and effective filter cleaning and general maintenance. It was also found that the filters quickly became dirty between scenarios, a period of weeks rather than months.

The effects of blockage and system failure were investigated in SC2, when the system was first occluded (simulating filter blockage) in week 1, and then turned off in week 2. Occupants were asked not to open windows during this period.

Whilst on the one hand this may seem like an extreme scenario, in fact there are a number of circumstances in which this may reflect real life. Firstly, there is evidence of MVHR systems being disabled for a number of reasons, including noise, lack of understanding and concerns over energy use [

22,

23]. Secondly, contemporary housing achieving greater airtightness still relies on trickle vents, which are frequently closed. A recent survey of 200 post-2010 regulation houses by the authors found that 80% kept trickle vents closed in the winter. Thirdly, in TSB BPE projects currently being monitored in Scotland, 12 out of 21 dwellings (57%) have “overshot” the building standards requirement (for mechanical ventilation) of 5 m

3/h·m

2, but do not have the required mechanical ventilation provision [

24].

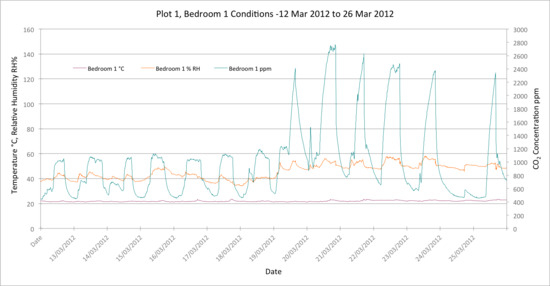

Conditions deteriorated in all apartments, but the effects were most marked in the bedrooms (

Figure 7 and

Figure 8). During the first week of occupation, the same diurnal relationship of CO

2 concentration and RH is evident through all apartments. In general, the peaks in CO

2 concentration are comparable to those seen in SC1 and this suggests that the impact on performance of the 50% occlusion is limited. Higher CO

2 levels are noted in the attic room, which had two occupants (

Figure 7). Measured airflow in this period was similar to the un-occluded period, suggesting that fan speed is increased (with a consequent energy penalty). In week 2, when the system was disabled, the impact on CO

2 is far more pronounced. The peaks in CO

2 concentration reach levels, particularly in bedrooms, that are indicative of very poor ventilation rates. This also extends to include water vapor as RH levels are seen to incrementally increase independent of the internal temperature.

In SC6, this problem was revisited, with more detailed investigation of effects on user comfort and perception, when comparing MVHR use with natural ventilation. In week 1, the dwellings were reliant on the MVHR system and in week 2 the system was again disabled, but window opening was allowed.

It is apparent that there is a marked deterioration in mean CO

2 levels in the dwellings between the two weeks (

Table 4). The living room effects are apparent where peaks of CO

2 are experienced during periods of high occupancy, but adaptive behaviour leading to window opening mitigates these (

Figure 9). However, the difference is marked when comparing the bedrooms, in which week 2 conditions are very much worse (

Figure 10).

Occupant perception of air quality in both dwellings and over both weeks is perceived as being generally good by the residents with values close to “4” with low standard deviation consistently achieved (

Table 5). Between the two weeks, there is very little change in perception of IAQ in Plot 3 while in Plot 1 the IAQ is seen to be less stuffy.

Figure 7.

(a) CO2 temp and RH levels SC2, Plot 1, Bedroom 1; (b) CO2 temp and RH levels SC2, Plot 3, Bedroom 1.

Figure 7.

(a) CO2 temp and RH levels SC2, Plot 1, Bedroom 1; (b) CO2 temp and RH levels SC2, Plot 3, Bedroom 1.

Figure 8.

(a) CO2 temp and levels SC2, Plot 1, Bedroom 4 (attic); (b) CO2 temp and RH levels SC2, Plot 3, Bedroom 4 (attic).

Figure 8.

(a) CO2 temp and levels SC2, Plot 1, Bedroom 4 (attic); (b) CO2 temp and RH levels SC2, Plot 3, Bedroom 4 (attic).

Table 4.

Whole house mean CO2 concentration SC6.

Table 4.

Whole house mean CO2 concentration SC6.

| Period | Mean CO2 Concentration |

|---|

| Plot 1 | Plot 3 |

|---|

| Week 1 | 822.6 ppm | 939.0 ppm |

| Week 2 | 1422.2 ppm | 1371.6 ppm |

Figure 9.

(a) CO2 temp and RH levels SC6, Plot 1, Living room; (b) CO2 temp and RH levels SC6, Plot 3, Living room.

Figure 9.

(a) CO2 temp and RH levels SC6, Plot 1, Living room; (b) CO2 temp and RH levels SC6, Plot 3, Living room.

Table 5.

Mean occupant internal air quality perception, SC6.

Table 5.

Mean occupant internal air quality perception, SC6.

| Period | Mean Internal Air Quality Perception (standard deviation) |

|---|

| Plot 1 | Plot 3 |

|---|

| Week 1 | 4.38 (0.14) | 4.75 (0.32) |

| Week 2 | 3.78 (0.22) | 4.79 (0.33) |

Figure 10.

(a) CO2 temp and RH levels SC6, Plot 1, Bedroom 1; (b) CO2 temp and RH levels SC6, Plot 3, Bedroom 1.

Figure 10.

(a) CO2 temp and RH levels SC6, Plot 1, Bedroom 1; (b) CO2 temp and RH levels SC6, Plot 3, Bedroom 1.

In the bedrooms, an identical pattern to the first week of SC2 was observed, with very high CO2 levels recorded overnight. From the monitored data it is clear that the actual Indoor Air Quality (IAQ) was markedly worse during the second week; therefore, it is worth considering why the residents would not perceive this.

The obvious explanation is the model of adaptive comfort [

25]; having the opportunity to ventilate directly made the occupants feel more in control and capable of altering the environment as they require. However, it would appear that this model does not apply to bedrooms overnight. Windows are not opened to ameliorate air quality—as might be expected, people who are asleep do not perceive and therefore act to change their environment. This is significant as not only are conditions very poor, but the occupants are exposed to them for long periods of time.

4.3. Temperature

In the original pilot study, the standard regime had set TRVs to 4 and the thermostat was set to 21 °C. This was found to produce temperatures that were uncomfortably high, despite very cold external conditions (

Figure 11) and there was an indication that the fabric of Plot 1 was becoming warm, with an increasing temperature profile during the week. To address this in the second week, the TRVs were set to 2 and the thermostat was set to 20 °C and the change in heating regime resulted in a more stable thermal environment.

However, despite the heating being controlled by TRVs and the thermostat, with no input from occupants, a rise in temperature in response to warmer external conditions is evident. This may suggest that the TRVs and thermostat are not exercising the degree of fine control that may be required to maintain thermal equanimity. The temperatures achieved in week 1 also suggest that the heating systems may be oversized for such thermally efficient dwellings, which if inadequately controlled would lead to overheating, or excessive energy use if (as was the case in the first week of the pilot study) occupants resorted to opening windows. Should the thermostat be set to higher temperatures and the TRVs turned to 5, very high temperatures would be achieved.

Figure 11.

Pilot study, average temperatures Plot 1 and Plot 3.

Figure 11.

Pilot study, average temperatures Plot 1 and Plot 3.

With the heating regimes that were set up in the test scenarios, the temperatures remained stable and at reasonable levels. In SC1 with TRVs set at 2 and the thermostat set at 18 C, temperatures were relatively cool, with living rooms having a mean of 15.83 °C for Plot 1 and 16.78 °C for Plot 3. The controls were adjusted for later scenarios with the thermostat at 20 °C. In SC3, which had a two period heating system, but continuous occupancy, living rooms had a mean of 20.31 °C in Plot 1 and 22.41 °C in Plot 3, and bedroom 1 had means of 21.58 °C in Plot 1 and 22.34 °C in Plot 3.

In SC5, which compared an intermittent heating regime in week 1 with a continuous heating in week 2, comfort polling asked residents to rate the thermal comfort at 8 pm each evening while in the dwelling. The ratings were based on a seven-point scale with 1 being much too cold and 7 much too warm, with a value of 4 identified as the “neutral” and most comfortable rating. This indicated that although both dwellings performed well, Plot 1 had an improved performance in the second week, despite the reduced energy consumption (

Table 7). This outcomes underpins findings from other scenarios, which tended to rate Plot 1 as being more comfortable and less prone to overheating.

Table 7.

Mean comfort levels SC5 week 1 and week 2.

Table 7.

Mean comfort levels SC5 week 1 and week 2.

| Mean Thermal Comfort (standard deviation) | Plot 1 | Plot 3 |

|---|

| Week 1 | 4.48 (0.60) | 4.61 (0.35) |

| Week 2 | 4.18 (0.48) | 4.45 (0.47) |

Effects on temperature due to the variation in ventilation regime were apparent in SC6. In the second week, there was a greater degree of window opening that appears to impact on temperature more in the thermally light Plot 3 than in Plot 1. In Plot 1, the living room had a mean temperature of 21.8 °C in week 1 and 21.4 °C in week 2. In Plot 3, the living room week 1 mean was 22.6 °C, which dropped to 19.8 °C in week 2. It is apparent that the fabric in Plot 1 retains its temperature with a more liberal window opening regime. Comparing the air and surface temperature in

Figure 12 clearly shows the relationship and is indicative of the benefits of the thermal mass at maintaining temperature with greater ventilation. This would have important implications for comfort and energy consumption, particularly in conjunction with a low level continuous heating regime.

Figure 12.

Comparison of air and surface temperatures SC6 (with MVHR vs. window opening).

Figure 12.

Comparison of air and surface temperatures SC6 (with MVHR vs. window opening).

The effects of thermal mass in the sunspace were also examined in SC4 and have been reported previously [

26]. In this scenario, an unoccupied profile was used to avoid incidental gains but the MVHR system was left running. The effect of thermal mass in the sunspaces was apparent (

Figure 13). Due to an irony of construction, in Plot 1 the sunspace is finished with white render on rigid board insulation, whilst in Plot 3 it is finished with a dark brindle brick outer leaf. The sunspaces are double height and temperatures readings were taken at both the lower and upper floor and shown in

Table 8.

Table 8.

Comparison of Plots 1 and 3 sunspace mean, maximum and minimum temperature values at two altitudes.

Table 8.

Comparison of Plots 1 and 3 sunspace mean, maximum and minimum temperature values at two altitudes.

| Location | Plot 1 | Plot 3 |

|---|

| Ground floor | Abs Max | 47.9 °C | 40.4 °C |

| Abs Min | 21.8 °C | 23.4 °C |

| Mean | 26.1 °C | 27.1 °C |

| Max/Min Range | 26.1 °C | 17.1 °C |

| First floor | Abs Max | 51.9 °C | 48.5 °C |

| Abs Min | 22.4 °C | 25.1 °C |

| Mean | 29.7 °C | 30.6 °C |

| Max/Min Range | 29.5 °C | 23.4 °C |

Figure 13.

SC4 sunspace temperatures ground floor/first floor Plot 1; ground floor/first floor Plot 3.

Figure 13.

SC4 sunspace temperatures ground floor/first floor Plot 1; ground floor/first floor Plot 3.

At present, there is no effective means of utilising these gains. There is no vent between the sunspace and the living or bedrooms, and so the only way to ensure air movement would be to open the door to these spaces, a relatively uncontrolled strategy.

Some issues of overheating were also identified. A particular—and avoidable—source of this was the hot water system. The commissioning tests identified that the pipework from the hot water and solar thermal system was uninsulated. The solar thermal store is located in a top floor plant space and temperatures here were seen to be remaining between 25 °C and 30 °C (

Figure 14).

Figure 14.

SC3 plant space temperatures Plots 1 and 2.

Figure 14.

SC3 plant space temperatures Plots 1 and 2.

Thermographic imaging revealed the impact of this on adjacent spaces, particularly the attic bedroom, which tended to experience higher average temperatures (

Table 9).

Table 9.

SC3 mean temperatures.

Table 9.

SC3 mean temperatures.

| Room | Plot 1 | Plot 3 |

|---|

| Living | 20.31 | 22.41 |

| Bed 1 | 21.58 | 22.34 |

| Bed 2 | 21.59 | 23.48 |

| Bed 3 | 21.06 | 23.34 |

| Attic | 21.84 | 23.85 |

| Plant | 28.38 | 26.87 |