Representing Small Commercial Building Faults in EnergyPlus, Part II: Model Validation

Abstract

1. Introduction

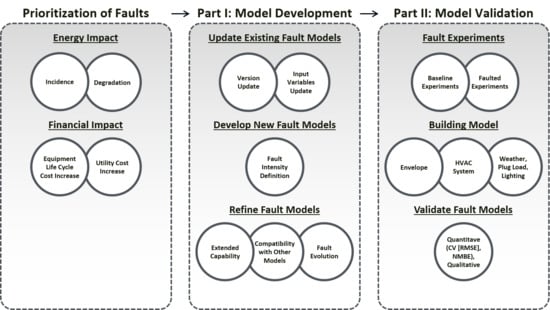

2. Methodology

2.1. Overall Workflow

2.2. Physical Experiments

2.3. Validation Workflow

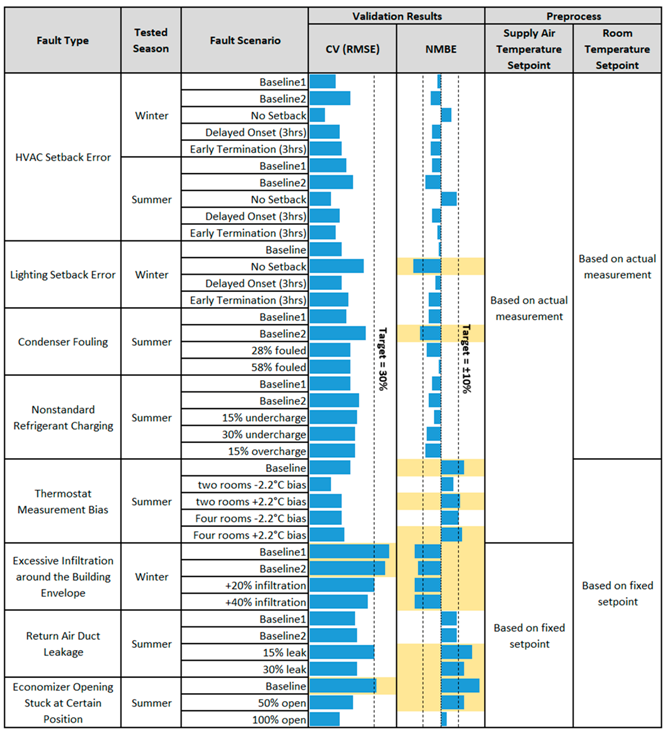

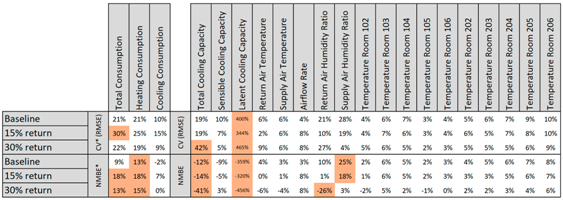

- The CV (RMSE) of the predicted hourly energy consumption shall not exceed 30%.

- The NMBE of the predicted hourly energy consumption shall not exceed ±10%.

2.4. Building Model Tuning and Validation Process Modifications

2.4.1. Supply Duct Leakage and VAV Box Configurations

2.4.2. Infiltration in Return Air Plenum

2.4.3. Diffuse Horizontal Irradiance Calculation

2.4.4. Other Preprocess Modifications

3. Fault Model Validation Results

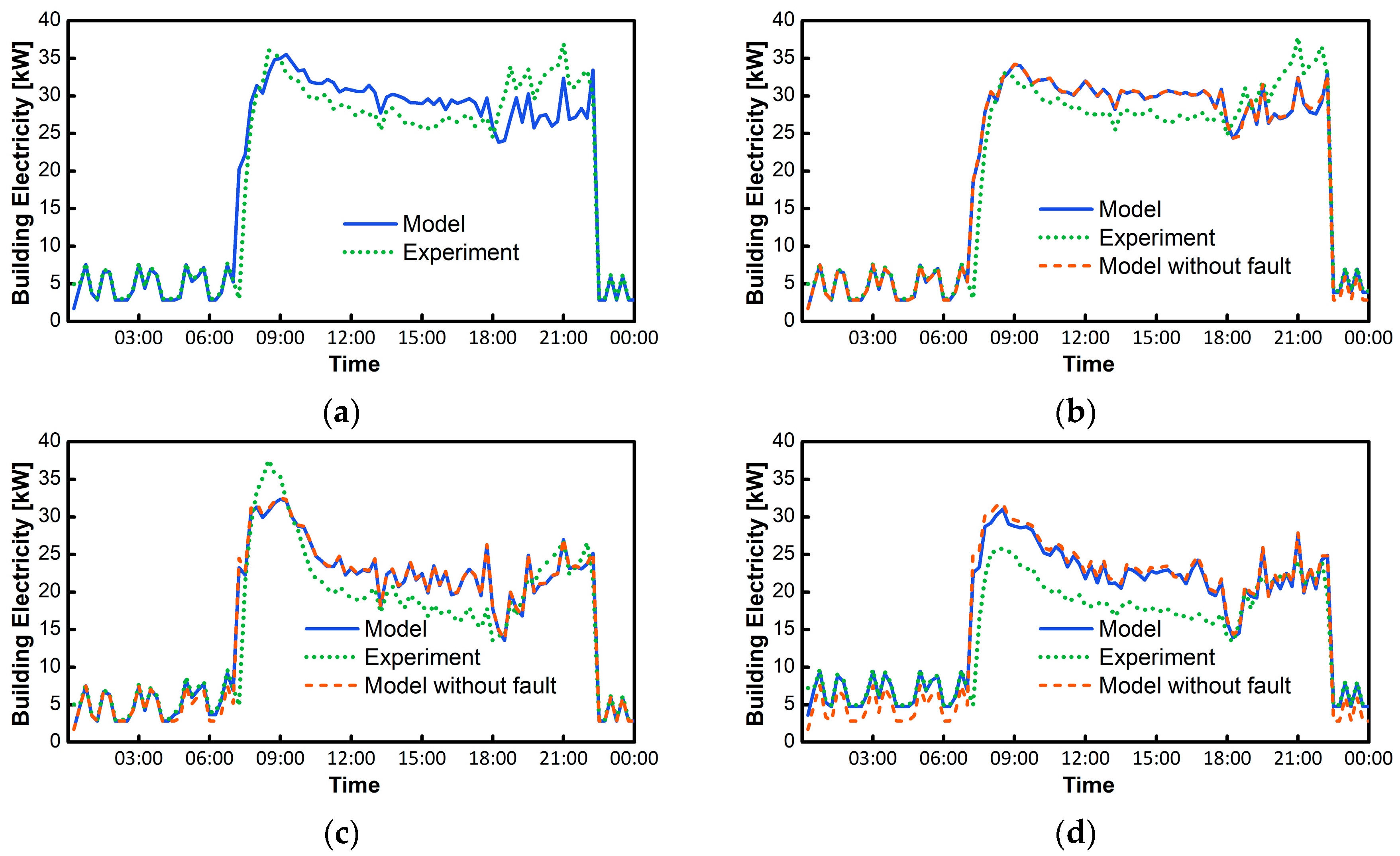

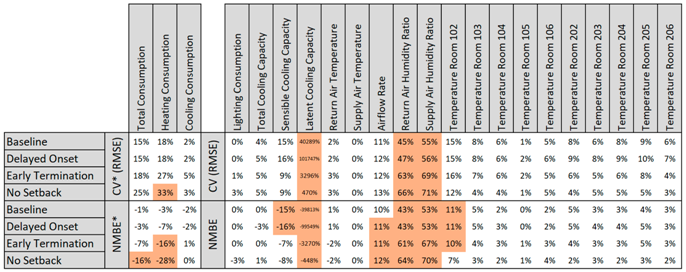

3.1. HVAC Setback Error

3.2. Lighting Setback Error

3.3. Condenser Fouling

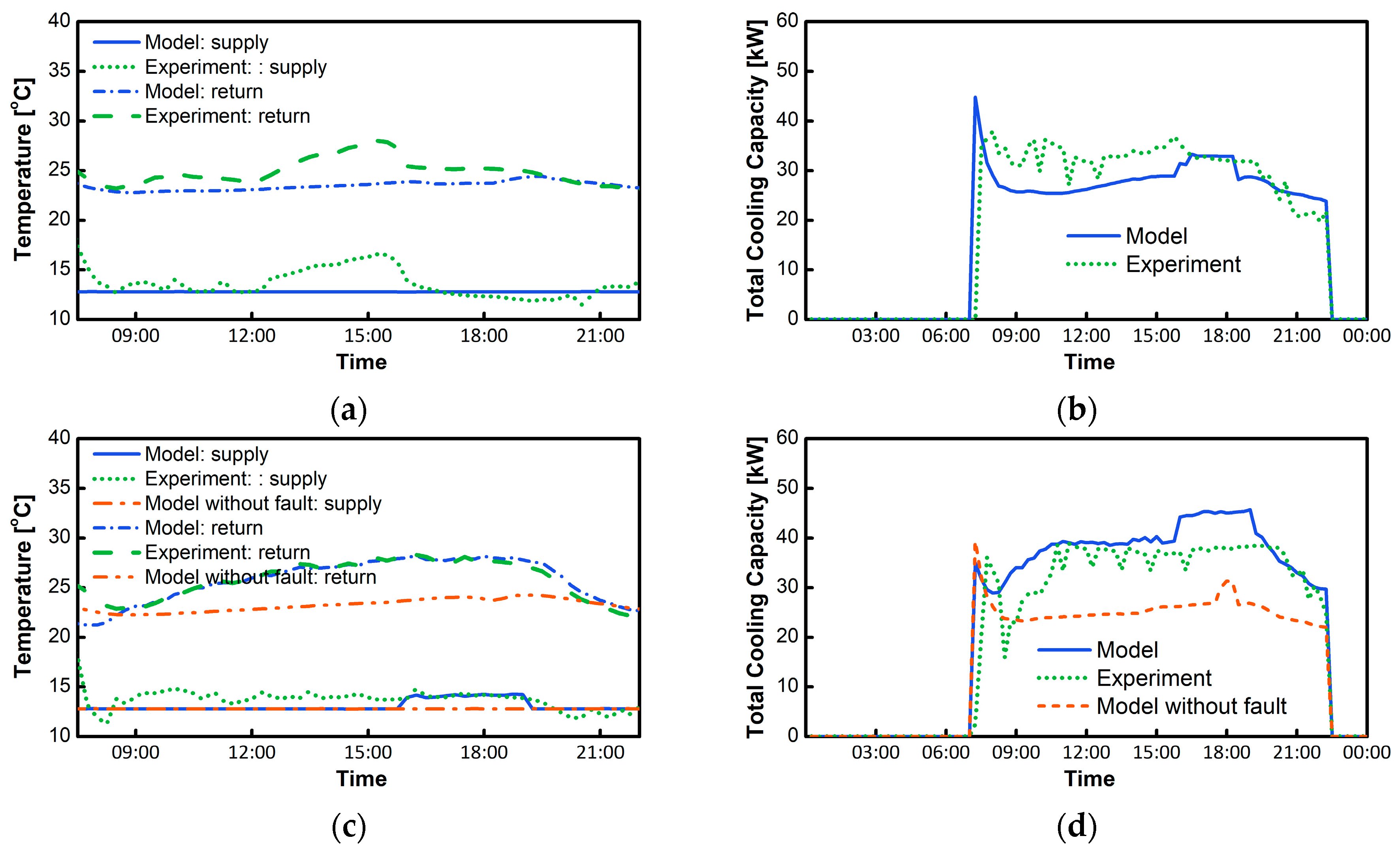

3.4. Nonstandard Refrigerant Charging

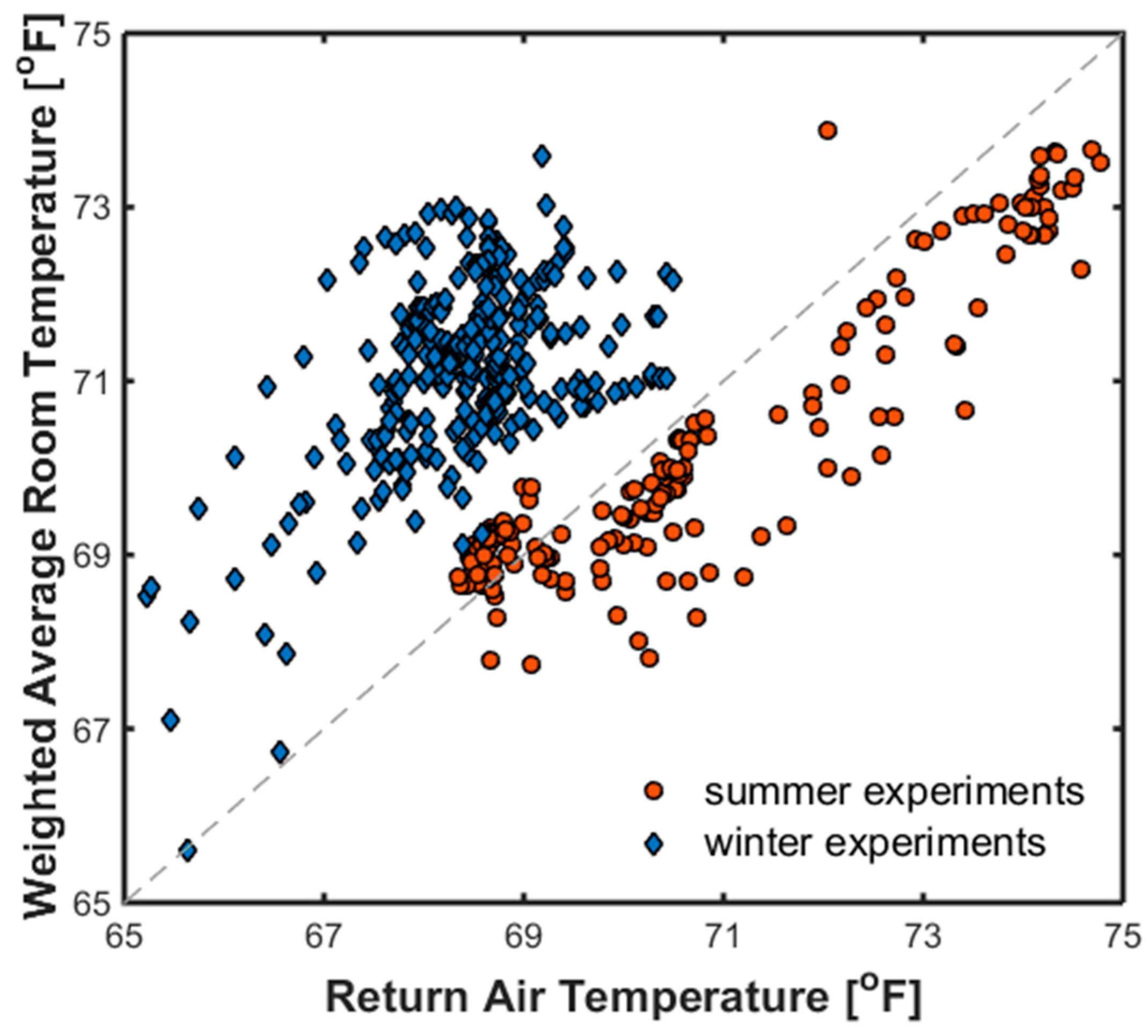

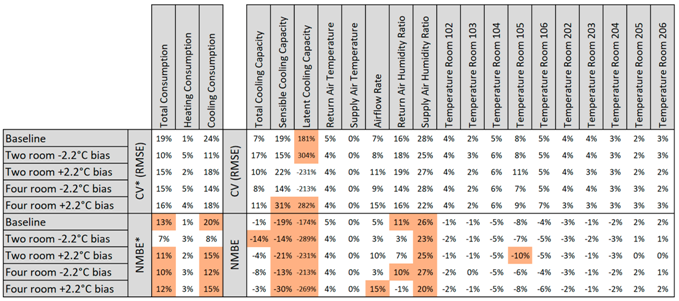

3.5. Thermostat Measurement Bias

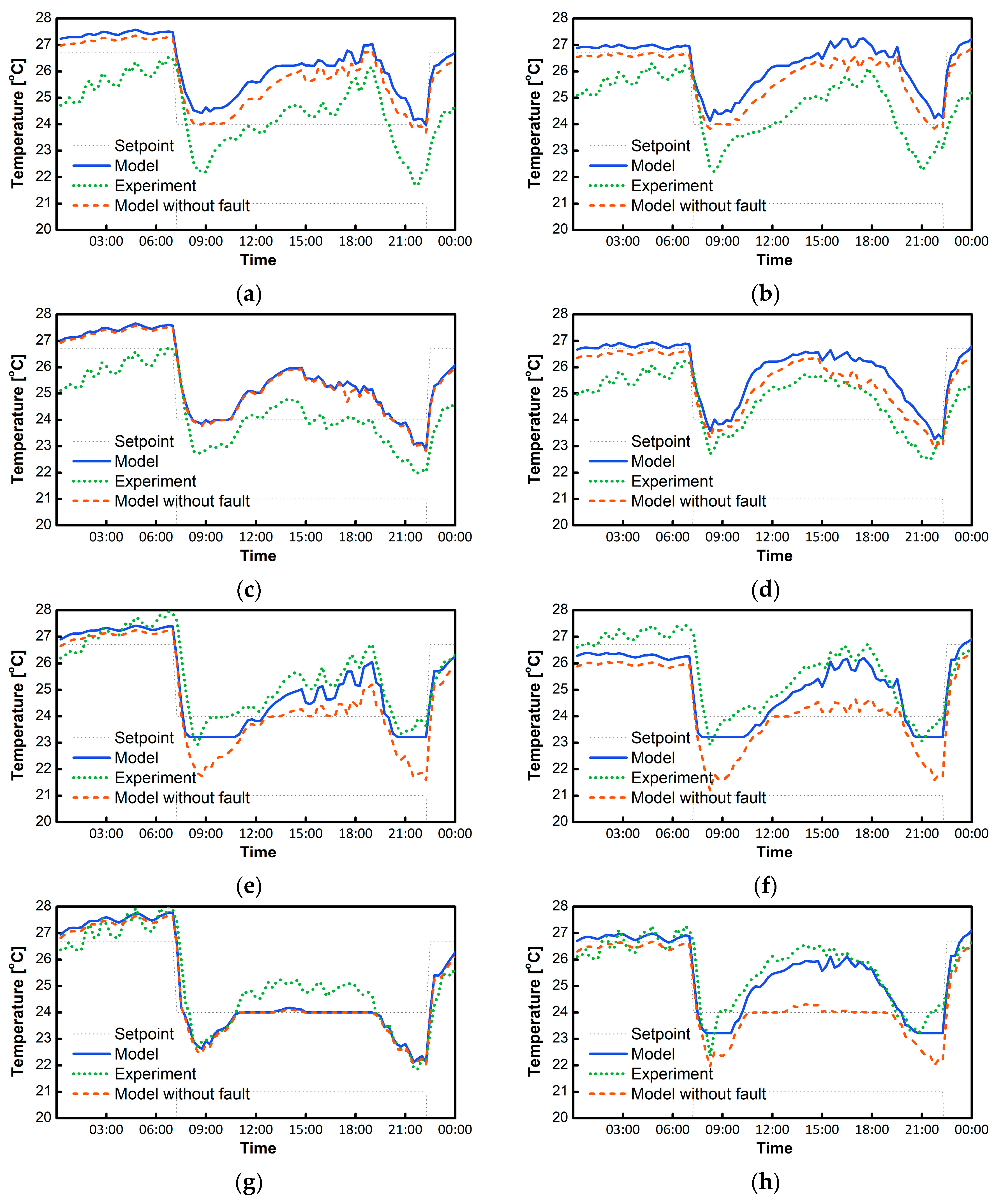

3.6. Excessive Infiltration Through the Building Envelope

3.7. Economizer Opening Stuck at a Fixed Position

3.8. Return Air Duct Leakage

4. Discussion, Limitations, and Future Work

- -

- In order to precisely estimate the impacts of faults on the building, and especially for fault models that only modify existing variables in EnergyPlus, the building model requires a more rigorous calibration process to precisely reflect the thermal behavior of the building. Although poor humidity level prediction in the building model did not have a significant impact on the building’s overall performance (because the absolute scale of the latent load was already small), the difference in the rate of temperature decay during the unoccupied hours did lead to significant overprediction of heating energy consumption for the winter season simulation.

- -

- Fault models for predicting the degradation of the RTU performance (e.g., condenser fouling and nonstandard refrigerant charging) were developed by estimating the relative deviation from the nominal equipment’s performance. Although the nonstandard refrigerant charging model showed good agreement against measurements, the condenser fouling model requires additional improvement based on validation results. Additionally, a more accurate DX unit model (or cooling coil model in EnergyPlus) is necessary to accurately estimate both sensible and latent cooling performances of the unit.

- -

- The stuck economizer damper and return air duct leakage faults are modeled by linearly introducing the outdoor air into the air system depending on the definition of the fault intensity. However, measurements showed that the impacts from a stuck damper and return air duct leakage are nonlinear. While pressure-based airflow network models can be used for improved prediction of outdoor air introduced into the air system, this type of model typically requires high computational requirements that are not suitable in building energy simulation tools. Thus, these two fault models also need improvements for capturing nonlinearities.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Greek symbols | |

| ∆ | difference in time |

| solar zenith angle, rad | |

| Acronyms | |

| AFDD | automated fault detection and diagnosis |

| C | air leakage coefficient of the airflow power law |

| CFM 50 | airflow measured with a blower door test with 50 pascals, cfm |

| COP | coefficient of performance |

| CV (RMSE) | coefficient of variation of the root-mean-square error, % |

| DHI | diffuse horizontal irradiance, W/m2 |

| DNI | direct normal irradiance, W/m2 |

| DX | direct expansion |

| ELA | effective leakage area, in2 |

| FRP | flexible research platform |

| GHI | global horizontal irradiance, W/m2 |

| HVAC | heating, ventilating, and air conditioning |

| K | constant of proportionality dependent upon orifice area |

| N | pressure exponent of the airflow power law |

| n | total number of data points |

| NMBE | normalized mean bias error, % |

| NSRDB | National Solar Radiation Database |

| PAT | Parametric Analysis Tool |

| P | Pressure, in.w.g. |

| q | airflow, cfm |

| RTU | rooftop unit |

| y | actual metered value |

| predicted value | |

| average of metered value | |

| VAV | variable air volume |

Appendix A

| HVAC Setback Error | Scenario | Baseline | 3 h delayed onset | 3 h early termination | No setback | ||||||

| Fault intensity definition | - | Delay in onset of overnight HVAC setback, in hours | Early termination of overnight HVAC setback, in hours | Absence of overnight HVAC setback (binary) | |||||||

| Fault imposition method | - | Modify the control programming to either delay/terminate/remove the setback schedules. | |||||||||

| Tested date | 30/11/2017 | 7-8/8/2018 | 1/12/2017 | 5/8/2018 | 3/12/2017 | 4/8/2018 | 20/12/2017 | 28/8/2018 | |||

| Average daily ambient temperature | 9.0 °C | 26.1 °C | 9.1 °C | 25.7 °C | 10.5 °C | 25.4 °C | 11.6 °C | 26.1 °C | |||

| Exception | - | Fault imposed earlier and removed later than other fault experiments to avoid transient effects during transitions. | |||||||||

| Lighting Setback Error | Scenario | Baseline | 3 h delayed onset | 3 h early termination | No setback | ||||||

| Fault intensity definition | - | Delay in onset of overnight lighting setback, in hours | Early termination of overnight lighting setback, in hours | Absence of overnight HVAC setback (binary) | |||||||

| Fault imposition method | - | Modify the control programming to either delay/terminate/remove the setback schedules. | |||||||||

| Tested date | 5/2/2019 | 7/2/2018 | 9/2/2018 | 18/2/2018 | |||||||

| Average daily ambient temperature | 4.3 °C | 3.1 °C | 1.6 °C | 7.4 °C | |||||||

| Exception | - | Fault imposed earlier and removed later than other fault experiments to avoid transient effects during transitions. | |||||||||

| Condenser Fouling | Scenario | Baseline | 28% fouling | 58% fouling | |||||||

| Fault intensity definition | - | Percent reduction in condenser coil airflow at full load. | |||||||||

| Fault imposition method | - | Cover the condenser face using pretested blocking media. | |||||||||

| Tested date | 2/9/2019 | 27/8/2017 | 29/8/2017 | ||||||||

| Average daily ambient temperature | 16.4 °C | 22.9 °C | 22.1 °C | ||||||||

| Exception | - | RTU operated in full load (supply fan in 100% speed) and all VAV dampers fully open. | |||||||||

| Nonstandard Refrigerant Charging | Scenario | Baseline | 15% undercharge | 30% undercharge | 15% overcharge | ||||||

| Fault intensity definition | - | Fraction of refrigerant charge level deviated from normal charge. | |||||||||

| Fault imposition method | - | Add or remove refrigerant to the refrigerant circuit. | |||||||||

| Tested date | 22-23/8/2019 | 14/8/2018 | 16/8/2018 | 18/8/2018 | |||||||

| Average daily ambient temperature | 23.4 °C | 24.1 °C | 24.4 °C | 24.8 °C | |||||||

| Exception | - | No exception. Based on normal operating conditions and schedule. | |||||||||

| Thermostat Measurement Bias | Scenario | Baseline | −2.2 °C bias in room 105 and 205 | +2.2 °C bias in room 105 and 205 | −2.2 °C bias in room 105, 205, 106, and 206 | +2.2 °C bias in room 105, 205, 106, and 206 | |||||

| Fault intensity definition | - | Zone thermostat measurement deviation from correct value in °C (e.g., positive fault intensity = measurement reading higher than actual). | |||||||||

| Fault imposition method | - | Adjust temperature setpoints of rooms by a number of degrees equal in magnitude and opposite in sign to the fault intensity. | |||||||||

| Tested date | 9/8/2019 | 10/8/2019 | 14/8/2019 | 12/8/2019 | 13/8/2019 | ||||||

| Average daily ambient temperature | 26.0 °C | 26.6 °C | 25.7 °C | 25.5 °C | 26.6 °C | ||||||

| Exception | - | No exception. Based on normal operating condition and schedule. | |||||||||

| Excessive Infiltration Through the Building Envelope | Scenario | Baseline | +20% infiltration | +40% infiltration | |||||||

| Fault intensity definition | - | Effective infiltration area as a percentage of the nominal value. | |||||||||

| Fault imposition method | - | Open windows to achieve target infiltration area. | |||||||||

| Tested date | 9-10/12/2019 | 7/12/2017 | 14/12/2017 | ||||||||

| Average daily ambient temperature | 1.2 °C | 3.8 °C | 0.6 °C | ||||||||

| Exception | - | Baseline and fault tests conducted only when daily average ambient temperature was less than 7.2 °C in order to increase the fault impact. | |||||||||

| Economizer Opening Stuck at a Fixed Position | Scenario | Baseline | Damper 50% open | Damper 100% open | |||||||

| Fault intensity definition | - | Ratio of economizer damper at the stuck position (0 = fully closed, 1 = fully open). | |||||||||

| Fault imposition method | - | Modify the control programming to override the position of the outdoor air damper. | |||||||||

| Tested date | 20/8/2019 | 15/8/2019 | 19/8/2019 | ||||||||

| Average daily ambient temperature | 27.4 °C | 25.4 °C | 26.4 °C | ||||||||

| Exception | - | No exception. Based on normal operating condition and schedule. | |||||||||

| Return Air Duct Leakage | Scenario | Baseline | 15% return duct leakage | 30% return duct leakage | |||||||

| Fault intensity definition | - | Unconditioned air introduced into the return air stream at full load condition as a percent of the design airflow rate. | |||||||||

| Fault imposition method | - | Insert an adjustable opening in the return duct at the RTU and adjust this to achieve the target air-leakage rate. | |||||||||

| Tested date | 21-22/6/2019 | 15/6/2018 | 19/6/2018 | ||||||||

| Average daily ambient temperature | 24.1 °C | 25.6 °C | 27.4 °C | ||||||||

| Exception | - | RTU operated under full load (supply fan at 100% speed) and all VAV dampers fully open. | |||||||||

References

- Kim, J.; Frank, S.; Braun, J.E.; Goldwasser, D. Representing small commercial building faults in energyplus, Part I: Model development. Buildings 2019, 9, 233. [Google Scholar] [CrossRef]

- Kim, J.; Cai, J.; Braun, J.E. Common Faults and Their Prioritization in Small Commercial Buildings; Common Faults and Their Prioritization in Small Commercial Buildings: February 2017–December 2017. 2018. Available online: https://www.nrel.gov/docs/fy18osti/70136.pdf (accessed on 12 November 2019).

- Roth, K.W.; Westphalen, D.; Feng, M.Y.; Llana, P.; Quartararo, L. Energy Impact of Commercial Building Controls and Performance Diagnostics: Market Characterization, Energy Impact of Building Faults and Energy Savings Potential; Building Technologies Program; National Technical Reports Library: Washington, DC, USA, 2005. [Google Scholar]

- Frank, S.; Heaney, M.; Jin, X.; Robertson, J.; Cheung, H.; Elmore, R.; Henze, G. Hybrid Model-Based and Data-Driven Fault Detection and Diagnostics for Commercial Buildings; American Council for an Energy-Efficient Economy (ACEEE): Washington, DC, USA, 2016. [Google Scholar]

- Kim, W.; Katipamula, S. A review of fault detection and diagnostics methods for building systems. Sci. Technol. Built Environ. 2018, 24, 3–21. [Google Scholar] [CrossRef]

- Yu, Y.; Yuill, D.; Behfar, A. Fault Detection and Diagnostics (FDD) Methods for Supermarkets-Phase 1; ASHRAE: Omaha, NE, USA, 2017. [Google Scholar]

- Yuill, D.P.; Braun, J.E. Evaluating the performance of fault detection and diagnostics protocols applied to air-cooled unitary air-conditioning equipment. HVAC&R Res. 2013, 19, 882–891. [Google Scholar]

- Yuill, D.P.; Braun, J.E. Effect of the distribution of faults and operating conditions on AFDD performance evaluations. Appl. Therm. Eng. 2016, 106, 1329–1336. [Google Scholar] [CrossRef]

- Ali, A.H.H.; Ismail, I.M. Evaporator air-side fouling: Effect on performance of room air conditioners and impact on indoor air quality. HVAC&R Res. 2008, 14, 209–219. [Google Scholar]

- Aydin, C.; Ozerdem, B. Air leakage measurement and analysis in duct systems. Energy Build. 2006, 38, 207–213. [Google Scholar] [CrossRef][Green Version]

- Bell, I.H.; Groll, E.A. Air-side particulate fouling of microchannel heat exchangers: Experimental comparison of air-side pressure drop and heat transfer with plate-fin heat exchanger. Appl. Therm. Eng. 2011, 31, 742–749. [Google Scholar] [CrossRef]

- Cho, S.-H.; Yang, H.-C.; Zaheer-uddin, M.; Ahn, B.-C. Transient pattern analysis for fault detection and diagnosis of HVAC systems. Energy Convers. Manag. 2005, 46, 3103–3116. [Google Scholar] [CrossRef]

- Comstock, M.C.; Braun, J.E.; Groll, E.A. The sensitivity of chiller performance to common faults. HVAC&R Res. 2001, 7, 263–279. [Google Scholar]

- Goswami, D.Y.; Ek, G.; Leung, M.; Jotshi, C.K.; Sherif, S.A.; Colacino, F. Effect of refrigerant charge on the performance of air-conditioning systems. In Proceedings of the IECEC-97 Proceedings of the Thirty-Second Intersociety Energy Conversion Engineering Conference (Cat. No.97CH6203), Honolulu, HI, USA, 27 July–1 August 1997; Volume 3, pp. 1635–1640. [Google Scholar]

- Kim, M.; Payne, W.V.; Domanski, P.A.; Yoon, S.H.; Hermes, C.J.L. Performance of a residential heat pump operating in the cooling mode with single faults imposed. Appl. Therm. Eng. 2009, 29, 770–778. [Google Scholar] [CrossRef]

- Kim, W.; Braun, J.E. Evaluation of the impacts of refrigerant charge on air conditioner and heat pump performance. Int. J. Refrig. 2012, 35, 1805–1814. [Google Scholar] [CrossRef]

- Mukhopadhyaya, P.; Bomberg, M.; Kumaran, M.K.; Drouin, M.; Lackey, J.C.; Van Reenen, D.; Normandin, N. Long-term thermal resistance of polyisocyanurate foam insulation with gas barrier. In Proceedings of the IX International Conference on Performance of Exterior Envelopes of Whole Buildings, Clearwater Beach, FL, USA, 5–10 December 2004. [Google Scholar]

- O’Neal, D.L.; Farzad, M. The effect of improper refrigerant charging on the performance of an air conditioner with capillary tube expansion. Energy Build. 1990, 14, 363–371. [Google Scholar] [CrossRef]

- Pak, B.C.; Groll, E.A.; Braun, J.E. Impact of fouling and cleaning on plate fin and spine fin heat exchanger performance. ASHRAE Trans. 2005, 111, 496–504. [Google Scholar] [CrossRef]

- Palmiter, L.; Kim, J.-H.; Larson, B.; Francisco, P.W.; Groll, E.A.; Braun, J.E. Measured effect of airflow and refrigerant charge on the seasonal performance of an air-source heat pump using R-410A. Energy Build. 2011, 43, 1802–1810. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. The impact of fouling on the condenser of a vapor compression refrigeration system: An experimental observation. Int. J. Refrig. 2014, 38, 260–266. [Google Scholar] [CrossRef]

- Rice, C.K. The Effect of Void Fraction Correlation and Heat Flux Assumption on Refrigerant Charge Inventory Predictions; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1987. [Google Scholar]

- Siegel, J.A.; Nazaroff, W.W. Predicting particle deposition on HVAC heat exchangers. Atmos. Environ. 2003, 37, 5587–5596. [Google Scholar] [CrossRef]

- Simmler, H.; Brunner, S. Vacuum insulation panels for building application: Basic properties, aging mechanisms and service life. Energy Build. 2005, 37, 1122–1131. [Google Scholar] [CrossRef]

- Wallace, L.A.; Emmerich, S.J.; Howard-Reed, C. Continuous measurements of air change rates in an occupied house for 1 year: The effect of temperature, wind, fans, and windows. J. Expo. Anal. Environ. Epidemiol. Princet. 2002, 12, 296–306. [Google Scholar] [CrossRef]

- Wichman, A.; Braun, J. Fault detection and diagnostics for commercial coolers and freezers. HVAC&R Res. 2008, 15:1, 77–99. [Google Scholar] [CrossRef]

- Woradechjumroen, D.; Yu, Y.; Li, H.; Yu, D.; Yang, H. Analysis of HVAC system oversizing in commercial buildings through field measurements. Energy Build. 2014, 69, 131–143. [Google Scholar] [CrossRef]

- Zirkelbach, D.; Schafaczek, B.; Künzel, H.M. Thermal performance degradation of foam insulation in inverted roofs due to moisture accumulation. In Proceedings of the XII DBMC 2011, 12th International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011; Volume 1, pp. 529–536. [Google Scholar]

- Cheung, H.; Braun, J.E. Simulation of fault impacts for vapor compression systems by inverse modeling. Part I: Component modeling and validation. HVAC&R Res. 2013, 19, 892–906. [Google Scholar]

- Cheung, H.; Braun, J.E. Simulation of fault impacts for vapor compression systems by inverse modeling. Part II: System modeling and validation. HVAC&R Res. 2013, 19, 907–921. [Google Scholar]

- Cheung, H.; Braun, J.E. Empirical modeling of the impacts of faults on water-cooled chiller power consumption for use in building simulation programs. Appl. Therm. Eng. 2016, 99, 756–764. [Google Scholar] [CrossRef]

- Dey, M.; Rana, S.P.; Dudley, S. Smart building creation in large scale HVAC environments through automated fault detection and diagnosis. Future Gener. Comput. Syst. 2018. [Google Scholar] [CrossRef]

- Farzad, M. Modeling the Effects of Refrigerant Charging on Air Conditioner Performance Characteristics for Three Expansion Devices. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 1990. [Google Scholar]

- Guo, Y.; Tan, Z.; Chen, H.; Li, G.; Wang, J.; Huang, R.; Liu, J.; Ahmad, T. Deep learning-based fault diagnosis of variable refrigerant flow air-conditioning system for building energy saving. Appl. Energy 2018, 225, 732–745. [Google Scholar] [CrossRef]

- Harms, T.M. Charge Inventory System Modeling and Validation for Unitary Air Conditioners. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2002. [Google Scholar]

- Inamdar, H.V.; Groll, E.A.; Weibel, J.A.; Garimella, S.V. Prediction of air-side particulate fouling of HVAC&R heat exchangers. Appl. Therm. Eng. 2016, 104, 720–733. [Google Scholar]

- Li, S.; Wen, J. Application of pattern matching method for detecting faults in air handling unit system. Autom. Constr. 2014, 43, 49–58. [Google Scholar] [CrossRef]

- Reddy, T.A. Application of a generic evaluation methodology to assess four different chiller FDD methods (RP-1275). HVAC&R Res. 2007, 13, 711–729. [Google Scholar]

- Rossi, T.M. Detection, Diagnosis, and Evaluation of Faults in Vapor Compression Equipment. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 1995. [Google Scholar]

- Shen, B.; Braun, J.E.; Groll, E.A. Improved methodologies for simulating unitary air conditioners at off-design conditions. Int. J. Refrig. 2009, 32, 1837–1849. [Google Scholar] [CrossRef]

- NREL Open Studio Fault Models. Available online: https://github.com/NREL/OpenStudio-fault-models (accessed on 23 May 2019).

- Cheung, H.; Braun, J.E. Development of Fault Models for Hybrid Fault Detection and Diagnostics Algorithm; National Renewable Energy Laboratory: Golden, CO, USA, 2015. [Google Scholar]

- Im, P.; Bhandari, M.S.; New, J.R. Multiyear Plan for Validation of EnergyPlus Multi-Zone HVAC System Modeling using ORNL’s Flexible Research Platform; Oak Ridge National Lab (ORNL), Building Technologies Research and Integration Center (BTRIC): Oak Ridge, TN, USA, 2016. [Google Scholar]

- Goldwasser, D.; Ball, B.L.; Farthing, A.D.; Frank, S.M.; Im, P. Advances in Calibration of Building Energy Models to Time Series Data: Preprint; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [Google Scholar]

- Kim, J.; Im, P.; Leach, M. Curated Test Fault Data Set. Available online: https://openei.org/doe-opendata/dataset/curated-test-fault-data-set (accessed on 16 November 2019).

- National Renewable Energy Laboratory. OpenStudio. Available online: https://www.openstudio.net/ (accessed on 20 November 2019).

- Goldwasser, D.; Macumber, D.; Parker, A.; Lee, E.; Guglielmetti, R.; Brackney, L. The Life Cycle of an OpenStudio Measure: Development, Testing, Distribution, and Application; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2016. [Google Scholar]

- ASHRAE. ASHRAE Guideline 14-2014—Measurement of Energy, Demand, and Water Savings; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE): Atlanta, GA, USA, 2014. [Google Scholar]

- National Solar Radiation Database (NSRDB). Available online: https://nsrdb.nrel.gov/ (accessed on 5 September 2019).

- Wheeler, G.; Kozubal, E.; Judkoff, R. Experimental design and laboratory characterization of a medium- and high-efficiency rooftop unit for use in building energy simulations. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, Indiana, 9–12 August 2018; Purdue University. [Google Scholar]

| Location | Oak Ridge, Tennessee |

|---|---|

| Building width | 44 ft (13.4 m) (outside dimension with 1′4″ (0.4 m) exterior wall thickness) |

| Building length | 44 ft (13.4 m) |

| Floor to floor height | 14 ft (4.3 m) |

| Floor to ceiling height | 9 ft (2.7 m) |

| Number of floors | 2 |

| Number of thermal zones | 10 (8 perimeter and 2 core) conditioned zones |

| Occupied hours | 7 a.m. to 10 p.m. |

| Temperature setpoints | Supply air temperature: 12.7 °C (cooling)/18.3 °C (heating) Zone temperature (occupied): 24 °C (cooling)/21 °C (heating) Zone temperature (unoccupied): 26.7 °C (cooling)/15.6 °C (heating) |

| Building envelope | Wall structure: Concrete masonry units with face brick Wall insulation: Fiberglass RUS-11 (Btu/hr-°F-ft2)/RSI-1.9 (W/m-K) Floor: Slab-on-grade Roof structure: Metal deck with polyisocyanurate and ethylene proplylene diene monomer Roof insulation: Polyisocyanurate RUS-18/RSI-3.17 Windows: Aluminum frame, double-pane, clear glazing Window-to-wall ratio: 28% |

| HVAC system | Rooftop unit: DX unit (12.5 ton, energy efficiency ratio 9.6), furnace (natural gas fired, AFUE 81%) Variable air volume (VAV) system (electric reheat coil) |

| Plug load | Lighting power density: 0.85 W/ft2 (9.2 W/m2) with lighting on/off schedule Equipment power density: 1.3 W/ft2 (14.0 W/m2) with on/off schedule |

| Room | Measurement | Model | ||

|---|---|---|---|---|

| Minimum Airflow, CFM | Maximum Airflow, CFM | Minimum Airflow, CFM | Maximum Airflow, CFM | |

| 102 | 98 | 160 | 98 | 280 |

| 103 | 90 | 218 | 90 | 400 |

| 104 | 297 | 352 | 297 | 560 |

| 105 | 274 | 317 | 274 | 600 |

| 106 | 276 | 401 | 276 | 600 |

| 202 | 161 | 280 | 161 | 450 |

| 203 | 118 | 164 | 118 | 250 |

| 204 | 268 | 473 | 268 | 600 |

| 205 | 272 | 408 | 272 | 600 |

| 206 | 285 | 415 | 285 | 630 |

| Total (downstream) | 2139 | 3188 | 2139 | 4970 |

| Total (upstream) | 3170 | 4447 | - | - |

| Leak % | 33% | 28% | - | - |

| Test | Baseline Test | +20% Infiltration | +40% Infiltration |

|---|---|---|---|

| CFM 50 | 1364.32 | 1648.82 | 1868.11 |

| ELA | 75.038 | 90.69 | 102.75 |

| C | 107.30 | 129.67 | 146.92 |

| N | 0.65 | 0.65 | 0.65 |

| Window opening | Closed | Room 106: 2 ¼″ Room 204: 1 ¾″ | Room 106: 4 ¾″ Room 204: 3 ¾″ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Frank, S.; Im, P.; Braun, J.E.; Goldwasser, D.; Leach, M. Representing Small Commercial Building Faults in EnergyPlus, Part II: Model Validation. Buildings 2019, 9, 239. https://doi.org/10.3390/buildings9120239

Kim J, Frank S, Im P, Braun JE, Goldwasser D, Leach M. Representing Small Commercial Building Faults in EnergyPlus, Part II: Model Validation. Buildings. 2019; 9(12):239. https://doi.org/10.3390/buildings9120239

Chicago/Turabian StyleKim, Janghyun, Stephen Frank, Piljae Im, James E. Braun, David Goldwasser, and Matt Leach. 2019. "Representing Small Commercial Building Faults in EnergyPlus, Part II: Model Validation" Buildings 9, no. 12: 239. https://doi.org/10.3390/buildings9120239

APA StyleKim, J., Frank, S., Im, P., Braun, J. E., Goldwasser, D., & Leach, M. (2019). Representing Small Commercial Building Faults in EnergyPlus, Part II: Model Validation. Buildings, 9(12), 239. https://doi.org/10.3390/buildings9120239