Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials

Abstract

1. Introduction

2. State of the Art and Research Objectives

2.1. Literature Survey of 3D Printable Mixture

2.2. Research Objectives: Experimental Framework for Printability

3. Material and Method

3.1. Materials and Mix Design

3.2. Printability Evaluation

3.2.1. Material Distribution Flowability

3.2.2. Shape Stability of Material Buildability

3.2.3. Printability Windows (Open Time)

3.3. Tests and Procedures

3.3.1. Mini Slump Test

- S’: dimensionless slump;

- S: slump (mm);

- H0: initial mini-slump height (mm).

3.3.2. Cone Penetrometer

- σ: penetration resistance,

- : applied load, (m mass),

- θ: half the cone apex angle (15° for the used cone in this study),

- : penetrated side area of the used cone in contact with mortar,

- h: penetration depth.

3.4. Mortar Printing System

4. Results and Discussion

4.1. Flowability Evaluation

4.2. Buildability Evaluation

4.3. Optimal Printability Coefficient

- S: slump (mm);

- Smin: minimum slump of the mixture (mm);

- Smax: maximum slump of the mixture (mm).

- σ: stress (MPa);

- σmin: minimum stress of the mixture (MPa);

- σmax: maximum stress of the mixture (MPa).

- : flowability coefficient;

- : buildability coefficient;

- The printability coefficient properties are presented as:

- P > 0: flowability property is predominant.

- P < 0: buildability property is predominant.

- P = 0: the two properties are balanced, and Figure 9 highlights an optimal time, Toptimal, which represents the optimal time to start printing (12 min after mixing).

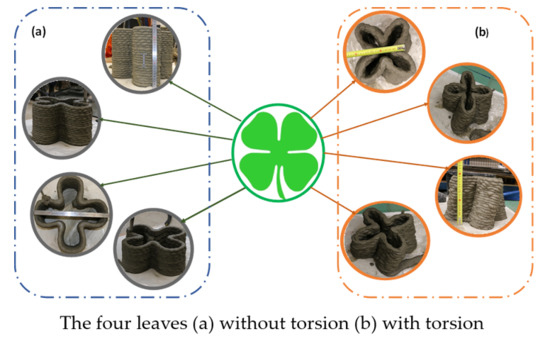

5. 3D Printing Test of the Optimal Formulation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Technology. Position Paper Smart Systems for the Automated Factory; European Technology Platform on Smart Systems Integration: Steinplatz, Berlin, Germany, 2018. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Piazza, M.C.; Alexander, S.E. Additive Manufacturing: A Summary of the Literature Center for Economic Development; Urban Publication, Cleveland State University: Cleveland, OH, USA, 2015. [Google Scholar]

- Bhargav, A.; Sanjairaj, V.; Rosa, V.; Feng, L.W.; Fuh Yh, J. Applications of additive manufacturing in dentistry: A review. J. Biomed. Mater. Res. B Appl. Biomater. 2018, 106, 2058–2064. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Meas. J. Int. Meas. Confed. 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Buswell, R.A.; Soar, R.C.; Gibb, A.G.F.; Thorpe, A. The Potential of Freeform Construction Processes. In Proceedings of the 16th International Symposium on Solid Freeform Fabrication, Austin, TX, USA, 13–15 August 2018; pp. 503–512. [Google Scholar]

- Krimi, I.; Lafhaj, Z.; Ducoulombier, L. Prospective study on the integration of additive manufacturing to building industry—Case of a French construction company. Addit. Manuf. 2017, 16, 107–114. [Google Scholar] [CrossRef]

- RBuswell, R.A.; Soar, R.C.; Gibb, A.G.F.; Thorpe, A. Freeform Construction: Mega-scale Rapid Manufacturing for construction. Autom. Constr. 2007, 16, 224–231. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Rouhana, C.M.; Aoun, M.S.; Faek, F.S.; Eljazzar, M.S.; Hamzeh, F.R. The reduction of construction duration by implementing contourontour crafting (3D printing). In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, IGLC 2014, Oslo, Norway, 25–27 June 2014; pp. 1031–1042. [Google Scholar]

- Lloret, E.; Shahab, A.R.; Linus, M.; Flatt, R.J.; Gramazio, F.; Kohler, M.; Langenberg, S. Complex concrete structures: Merging existing casting techniques with digital fabrication. Comput. Aided Des. 2015, 60, 40–49. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital Concrete: Opportunities and Challenges. RILEM Tech. Lett. 2016, 1, 67. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- De Laubier, R.; Wunder, M.; Sven, W.; Rothballer, C. Will 3D Printing Remodel the Construction Industry? Boston Consult. Group 2018, 21. [Google Scholar]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Jebli, M.; Jamin, F.; Pelissou, C.; Malachanne, E.; Garcia-Diaz, E.; Youssoufi, M.S.E. Leaching effect on mechanical properties of cement-aggregate interface. Cem. Concr. Compos. 2018, 87, 10–19. [Google Scholar] [CrossRef]

- Figueiredo, S.C.; Rodríguez, C.R.; Ahmed, Z.Y.; Bos, D.H.; Xu, Y.; Salet, T.M.; Çopuroğlu, O.; Schlangen, E.; Bos, F.P. An approach to develop printable strain hardening cementitious composites. Mater. Des. 2019, 169, 107651. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. Constr. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2018, 95, 260–270. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 382–400. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Rabenantoandro, A.Z.; Krimi, I.; Dakhli, Z. 3D Printing in Construction: Application Framework for a Robotic Arm Based on the Extrusion Technique. In Proceedings of the International conference on Smart Sustanaible and Sensous Settlement (3SSettlement), Technical University of Munich, Munich, Germany, 7–8 March 2018; pp. 199–206. [Google Scholar]

- Lafhaj, Z.; Dakhli, Z. Performance indicators of printed construction materials: A durability-based approach. Buildings 2019, 9, 97. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Weng, Y.; Wong, T.N.; Tan, M.J. Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Constr. Build. Mater. 2019, 198, 245–255. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Sultangaliyeva, F.; Carré, H.; la Borderie, C.; Roussel, N. Effect of the Addition of Polypropylene Fibers on the Rheological Behaviour of Fresh Fluid Cementitious Materials. In Proceedings of the 12th fib International PhD Symposium in Civil Engineering, Prague, Czech Republic, 29–31 August 2018; pp. 161–168. [Google Scholar]

- Popescu, M.; Reiter, L.; Liew, A.; van Mele, T.; Flatt, R.J.; Block, P. Building in Concrete with an Ultra-lightweight Knitted Stay-in-place Formwork: Prototype of a Concrete Shell Bridge. Structures 2018, 14, 322–332. [Google Scholar] [CrossRef]

- Kim, B.G.; Jiang, S.P.; Aïtcin, P.C. Slump improvement mechanism of alkalies in PNS superplasticized cement pastes. Mater. Struct. 2000, 33, 363–369. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Meier, R.; Khoshnevis, B. Performance-Based Testing of Portland Cement Concrete for Construction-Scale 3D Printing. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 13–35. [Google Scholar]

- Papachristoforou, M.; Mitsopoulos, V.; Stefanidou, M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct. Integr. 2018, 10, 155–162. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Hosseini, E.; Zakertabrizi, M.; Korayem, A.H.; Xu, G. A novel method to enhance the interlayer bonding of 3D printing concrete: An experimental and computational investigation. Cem. Concr. Compos. 2019, 99, 112–119. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J.; Xia, M. Method of enhancing interlayer bond strength in construction scale 3D printing with mortar by effective bond area amplification. Mater. Des. 2019, 169, 107684. [Google Scholar] [CrossRef]

- Hwang, D.; Khoshnevis, B. An innovative construction process-contour crafting (CC). In Proceedings of the 22nd International Symposium on Automation and Robotics in Construction, ISARC 2005, Ferrara, Italy, 11–14 September 2005. [Google Scholar]

- Malaeb, Z.; Hachem, H.; Tourbah, A.; Maalouf, T.; el Zarwi, N.; Hamzeh, F. 3D Concrete Printing: Machine and Mix Design. Int. J. Civ. Eng. Technol. 2015, 6, 14–22. [Google Scholar]

- Tay, Y.W.; Panda, B.; Paul, S.C.; Tan, M.J.; Qian, S.Z.; Leong, K.F.; Chua, C.K. Processing and properties of construction materials for 3D printing. Mater. Sci. Forum. 2016, 861, 177–181. [Google Scholar] [CrossRef]

- Nerella, V.N.; Mechtcherine, V. Studying the Printability of Fresh Concrete for Formwork-Free Concrete Onsite 3D Printing Technology (CONPrint3D). In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 333–347. [Google Scholar]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. B Eng. 2019, 165, 75–83. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. In Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2018; Volume 163, pp. 600–610. [Google Scholar]

- Banfill, P.F.G. Rheology of Fresh Cement and Concrete; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Feys, D.; Khayat, K.H.; Khatib, R. How do concrete rheology, tribology, flow rate and pipe radius influence pumping pressure? Cem. Concr. Compos. 2016, 66, 38–46. [Google Scholar] [CrossRef]

- Hu, C.; de Larrard, F.; Sedran, T.; Boulay, C.; Bosc, F.; Deflorenne, F. Validation of BTRHEOM, the new rheometer for soft-to-fluid concrete. Mater. Struct. Constr. 1996, 29, 620–631. [Google Scholar] [CrossRef]

- Banfill, P.F.G.; Beaupre, D.; Chapdelaine, F.; de Larrard, F.; Domone, P.L.J.; Nachbaur, L.; Sedran, T.; Wallevik, O.; Wallevik, J.E. Comparison of Concrete Rheometers: International Tests at LCPC (Nantes, France) in October 2000; NISTIR 6819: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Alhozaimy, A.M. Effect of absorption of limestone aggregates on strength and slump loss of concrete. Cem. Concr. Compos. 2009, 31, 470–473. [Google Scholar] [CrossRef]

- Vickers, T.M., Jr.; Farrington, S.A.; Bury, J.R.; Brower, L.E. Influence of dispersant structure and mixing speed on concrete slump retention. Cem. Concr. Res. 2005, 35, 1882–1890. [Google Scholar] [CrossRef]

- Kovler, K.; Roussel, N. Properties of fresh and hardened concrete. Cem. Concr. Res. 2011, 41, 775–792. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Elaty, M.A.A.A.; Ghazy, M.F. Evaluation of consistency properties of freshly mixed concrete by cone penetration test. HBRC J. 2016, 12, 1–12. [Google Scholar] [CrossRef][Green Version]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. Constr. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

| Criterion | Description | Control | Measurement |

|---|---|---|---|

| Flowability | Easy pumpability in the delivery, pumping system and easy deposition | Continuous grading of fine particles, use of powders additions (fly ash) and use of chemical additives (superplasticizers) | Direct measurement: rheological parameters by rheometers Indirect measurement: slump, slump flow, Slump and V-funnel |

| Extrudability | Ability of material to be delivered continuously through small pipes and nozzles without interruption | Fine particles, continuous grading, round shape and ratio nozzle diameter/maximal | Print test: the maximum length of printed filaments without blockage and without cracks. Ram extrusion |

| Buildability | Ability of the material to retain its shape just after deposition | Use of mineral additives, chemical additives (setting accelerator and rheology modifiers VMA (viscosity modifier agent)) | Assessment of mechanical properties at early age: penetration under constant load |

| Interlayer adhesion | Material ability to bond to subsequent layers. | Adjusted vertical print speed and use of admixtures (set retarder) | Hardened mechanical performance of inter-layers: direct tensile test and shear test |

| Open time | Defined as the time interval beyond which material extrudability property decrease not to confuse with setting time of the material. | As it is related to extrudability, Open time control been found by other researchers to varies using of powders additions, an increase in GGBS content, use of chemical additives that usually decreases cement setting time | Assessed with a Vicat apparatus to determine the initial and final setting time |

| Research’s Team | Cement (kg) | Silica Fume (kg) | Fly Ash (kg) | Sand (kg) | Water (kg) | W/C | Superplasticizer (% of Cement Weight) | Plasticizer (% of Cement Weight) | Retarder (% of Cement Weight) | Accelerator (% of Cement Weight) |

|---|---|---|---|---|---|---|---|---|---|---|

| B. Khoshnevis et al. [42] | 888 | _ | _ | 984 | 456 | 0.51 | 3 | _ | _ | _ |

| S. Lim et al. [23] | 579 | 83 | 165 | 1241 | 232 | 0.28 | 1 | 1.2 | 0.5 | _ |

| Z. Malaeb et al. [43] | 125 | _ | _ | 240 | 49 | 0.39 | _ | _ | 0.8 | 1.25 |

| B. Panda et al. [44] | 253 | 61 | 192 | 810 | 152 | 0.30 | 1.05 | _ | _ | _ |

| M. Krause et al. [45] | 430 | 180 | 170 | 1240 | 180 | 0.23 | 1.2 | _ | _ | _ |

| L. Wang et al. [31] | 1680 | 240 | 480 | _ | 270 | 0.27 | 1.08 | 1.2 | _ | _ |

| Production Factory | Clinker ≥ 95% | SO3 | S2− | Na2O Active Equivalent | ||

|---|---|---|---|---|---|---|

| C3A | C3S | C2S | ||||

| Beaucaire | 2.3 | - | 10.2 | 2 | 0.01 | 0.32 |

| Production Factory | Mechanical Resistance MPa | Finesse | Cement Pure Paste | Beginning of Setting | |||

|---|---|---|---|---|---|---|---|

| 1j | 2j | 28j | Blaine (cm2/g) | Refus (%) 40 µm | |||

| Beaucaire | 18 | 31 | 63 | 4280 | - | 28.6 | 3h10 |

| Chemical Characteristic | Chemical Element | Composition (%) | Physical Property | Physical Properties | Value |

| SiO2 | 99.30 | Bulk density | 2.65 | ||

| Fe2O3 | 0.016 | pH | 7 | ||

| Al2O3 | 0.150 | Apparent density | 1.6 | ||

| TiO2 | 0.017 | Pyroscopic resistance | 1750 °C | ||

| CaO | 0.006 | CU (D60/D10) | 1.65 | ||

| K2O | 0.130 | Fire loss | Max 0.20% |

| Mixture | Cement % | Sand % | Water % | W/C |

|---|---|---|---|---|

| M1 | 35 | 53 | 12 | 0.36 |

| M2 | 35 | 52 | 13 | 0.38 |

| M3 | 35 | 51 | 14 | 0.40 |

| Parameter | Abrams Cone | Mini Cone |

|---|---|---|

| (mm) | 300 | 150 |

| (mm) | 100 | 50 |

| (mm) | 200 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lafhaj, Z.; Rabenantoandro, A.Z.; el Moussaoui, S.; Dakhli, Z.; Youssef, N. Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials. Buildings 2019, 9, 245. https://doi.org/10.3390/buildings9120245

Lafhaj Z, Rabenantoandro AZ, el Moussaoui S, Dakhli Z, Youssef N. Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials. Buildings. 2019; 9(12):245. https://doi.org/10.3390/buildings9120245

Chicago/Turabian StyleLafhaj, Zoubeir, Andry Zaid Rabenantoandro, Soufiane el Moussaoui, Zakaria Dakhli, and Nicolas Youssef. 2019. "Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials" Buildings 9, no. 12: 245. https://doi.org/10.3390/buildings9120245

APA StyleLafhaj, Z., Rabenantoandro, A. Z., el Moussaoui, S., Dakhli, Z., & Youssef, N. (2019). Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials. Buildings, 9(12), 245. https://doi.org/10.3390/buildings9120245