Abstract

This article sheds light on the materialization and operation of residential partitioning wall components in relation to circular and flexible performance. The hypothesis is twofold: (1) A stronger integration of materialization and operation aspects is indispensable in establishing sustainable value-models, and (2) recent innovations, concerning the reversibility of material connections, will help disrupting the status-quo in that respect. Attention is drawn to renewable natural fibre composites (NFC), reversible adhesives, and biodegradable insulation materials. After a background sketch regarding the notion of time, change, and material circularity in design and planning, the housing challenge in the Amsterdam metropolitan area (AMA, the Netherlands) is described. Next, a design conceptualization stage is introduced, informed by two methods and tools in particular: Circ-Flex assessment, and activity-based spatial material flow analysis. Results of the conceptualization stage are presented regarding materialization and operation, culminating in Circ-Flex partitioning components, more specifically: Side panels and insulation. It was found that NFC can tackle current issues relating, most prominently, to circularity performance. Associated modifications in the value-chain occur, above all, in raw material sourcing, manufacturing, reutilization logistics, and data-sharing. The outcomes are valid for multiple building components other than indoor partitioning, such as kitchens and furniture, but also insulation—and interior side-sheeting—of walls and roofs in energy-renovations.

1. Introduction

This article departs from adaptability and flexibility as indicators of housing-quality, with respect to changing needs and requirements of the end-user. This relates to multi-family building structures that accommodate virtually endless flexibility in the individual home-unit infill. Although this notion has been adopted in architectural design and development, it has not delivered the anticipated practical, large scale results [1,2]. Also in the Netherlands, traditional housing design and building paradigms prevail, giving priority to generic-uniform- rather than specific-pluriform-design. The current traction in the Netherlands around the concept of circular building provides leverage for change in this respect [3]. Circular building (CB) and flexible building (FB) are essentially two sides of the same coin: Flexibility of the housing unit—specifically relating the infill—can accommodate a bespoke and up-to-date indoor materialization in line with the user requirements. This, in turn, opens up to new product supply and service models that serve a circular economy, integrating design, manufacturing, use, operation, and reutilization. In practice, however, integration of the latter three steps—use, operation and reutilization—is usually insufficiently secured due to engrained technical and organisational patterns, leading to underachieving value models [4,5]. This article aims to shed more light on the materialization and operation of partitioning wall components in relation to circular and flexible (Circ-Flex) performance, as introduced by Geldermans et al. [5]. The hypothesis is twofold: (1) A stronger integration of materialization and operation aspects is indispensable in establishing sustainable value-models, and (2) recent innovations concerning the reversibility of material connections will help disrupting the status-quo in this respect. Particular attention is drawn to natural fiber composites, reversible adhesives, and biodegradable insulation materials, all with inherent renewability potential. Innovations in this direction may lead to a broadening of the product range for partitioning configurations, anticipating healthy, circular, and flexible resource systems. The geographical context is the Netherlands, in particular the Amsterdam metropolitan area, based on its articulated ambitions regarding circular economy implementation, and the associated policies deployed [6].

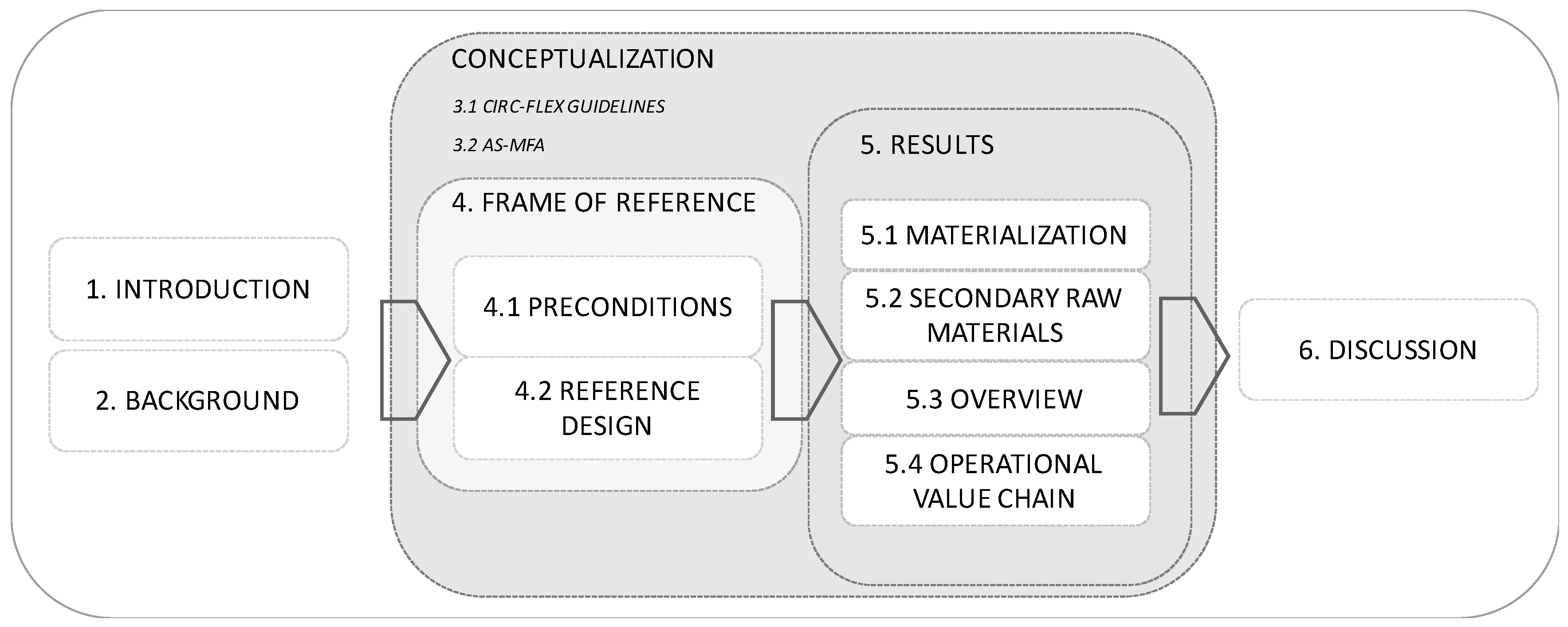

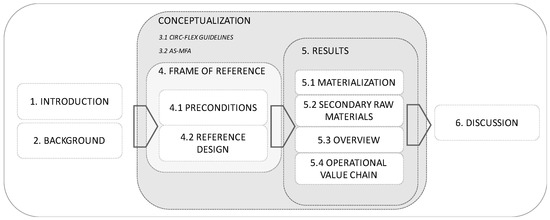

The structure of this paper is as follows. First, a background sketch is provided with regard to the notion of time, change, and material circularity in design and planning. Second, the housing challenge in the Amsterdam metropolitan area is described, as well as the way in which the concept of circularity has found its way into the municipal and regional policies. Next, the design conceptualization stage is explained, including two methods and tools: Circ-Flex assessment, and Activity-based spatial material flow analysis. Subsequently, results of the conceptualization stage are presented regarding materialization and operation, culminating in a circular–flexible partitioning configuration based on side-panel and insulation innovations. Finally, the results are reflected upon from technical and organisational vantage points. Figure 1 visualises the methodological structure.

Figure 1.

Methodological structure of the research.

2. Background

2.1. Time, Change, and Circularity

The notion of time in architectural design and planning in relation to quality and change, is captured well by the ‘timeless way of building,’ put forward by Christopher Alexander in the 1970s [7]. Alexander’s ‘timeless way’ accommodates a quality that is essential to life and living, but can only be described by its surrounding and constituent characteristics. Thus, Alexander describes it as a ‘quality without a name’ [7]. A similar quality can be detected in the concept of open building, first introduced by John Habraken in the early 1960s, relating to mass housing [8]. Habraken distinguishes the structural support of a building from the non-structural infill. The latter is the domain of the end-user, and should be treated accordingly in associated design and decision-making. The crux being that ever evolving individual patterns of living thrive when optimally supported by the environment in which they take place. People attach meaning to objects and environments through interactions that occur within spaces, and those meanings affect perceptions and subsequent interactions [9,10,11,12,13,14]. The physical space can thus be seen as a backdrop for changing activities and interrelations.

The concept of buildings being assemblies of dynamic layers with diverging functional and temporal identities has also been elaborated by Stewart Brand, who introduced six shearing layers: Site, structure, skin, services, space plan, and stuff [15]. Alexander, Habraken, and Brand all touch upon the awareness that the built environment is inextricably part of larger systems, comprised of countless interrelated processes that operate in complex configurations. One aspect of this complexity—analogous with nature—is that processes and their associated material manifestations have different timescales with little or no exchange (of energy/mass/information) between them [16]. Translated to building design, this implies that ‘faster layers’ (shorter material turnovers) are not obstructed by slower ones (longer material turnovers). An important theoretical framework supporting this notion is design for disassembly (DfD). DfD allows for easy modifications of spatial typologies and disassembly of building parts [17,18]. DfD thus facilitates future change, as well as the recovery of building parts on various levels: Building, sub-systems, building components, and materials [19,20].

Flexibility can be seen as a precondition—and accelerator—of a circular economy in relation to construction and planning [21,22,23]. Flexible characteristics concern those aspects that allow easy rearrangement of building components, accommodating changing lifestyles, needs, and/or functions. Circular characteristics concern the dynamic total of associated processes, materials and stakeholders that accommodate renewable flows of building materials and products at optimal rates and utilities. Although the theoretical and practical attention for circular economy in the built environment is growing, it has not yet yielded much literature concerning the inherent systemic nature, integrating materialization, and operation of circular value models.

2.2. The Amsterdam Context

The Amsterdam metropolitan area (AMA) has a high ambition with regard to shifting from a linear to a circular society [6,24,25]. Simultaneously, there are other challenges with regard to the built environment in the AMA. The housing demand faces a steep increase. Roughly 200,000 new housing units should be built in the AMA by 2040, and at the same time, vacant office spaces will be transformed into spaces for residential or mixed functions. On top of that, a large share of the existing building stock is not up to standard with regard to housing quality and energetic performance. This necessitates huge renovation efforts, not least by the housing associations that own about 40–45% of the stock [26]. Like elsewhere, the AMA deals with demographic changes, that also resonate in the housing requirements; for example, with regard to an ageing population and increase in single households [27,28]. Such developments underscore the notion that the building stock, new as well as renovated or transformed, needs to accommodate for changing functions and lifestyles. The housing challenge in the AMA is an opportunity to bring ambitions regarding circularity and flexibility into practice.

Within the AMA, multiple initiatives are and have been taking place in anticipation of the shift from linear to circular. For example, the municipality of Amsterdam developed the Circular Innovation Program to accelerate insights in the transition towards a circular economy [29]. Several key value chains were pinpointed as high-potential, with special attention for the construction value chain and the biomass value chain [24,29]. In an evaluation of the Circular Innovation Program, it was observed that high-value reuse of building materials is hindered by business-as-usual approaches merely aimed at linear optimization, and that current value chains are thus closed in a low-value manner [30]. Furthermore, the need was identified to deploy a more integrated approach to logistics, land use, spatial planning, financing, and regulations in order to achieve a successful upscaling of value chains [25,30]. As such, Amsterdam and its metropolitan area give shape to its ambition to be a global leader, aiming to prove that the circular economy is a realistic and viable concept [31].

3. Conceptualization, Methods, and Tools

In this section, two methods and tools are introduced that are applied within the conceptualization stage. First, in Section 3.1, Circ-Flex assessment guidelines are introduced, which inform the design preconditions. Next, in Section 3.2, a method is presented to track waste and secondary raw material flows at a local scale: The activity-based spatial material flow analysis. The conceptualization stage consists of three clusters. First, design preconditions are introduced and the frame of reference is provided. Next, regular materialization and operation pathways are analysed. This builds up to a specific circular and flexible non-bearing partitioning configuration, which is described in the last step.

3.1. Circ-Flex Potential

Circ-Flex assessment guidelines were determined with the aim to establish a more integrated and inclusive approach to the transition from linear to circular built environments, tying in with recent calls for a more comprehensive evidence-base to better inform the policy debate, in the light of the interrelated Sustainable Development Goals [32]. Circ-Flex can be understood as a systems approach rooted in the synergistic liaison between circular and flexible characteristics. Circular characteristics concern the dynamic total of associated processes, materials, and stakeholders that accommodate circular flows of building materials and products at optimal utilities, rates, and spatial scales [3,5]. Flexible characteristics concern the building designs and activities that allow for easy rearrangement of infill components, accommodating the potentially changing needs of occupants [3,5]. Geldermans et al. [5] coupled those characteristics to issues of end-user health and well-being, in response to the gaps that exist in research and practice concerning this linkage. After an exploration of multiple assessment methods and frameworks, the Circ-Flex assessment guidelines were derived from three schemes in particular: Cradle to Cradle™ Certified, WELL™ Certified, and Pre-Returnable Procurement®. Overlapping and complementary features of those schemes provided the basis for an integrated assessment of Circ-Flex potential and residential health impact of infill products. One of the main findings was related to what Geldermans et al. referred to as “orphan operational processes;” i.e., those processes that are likely to play a decisive role in determining the Circ-Flex potential, but are not, or are insufficiently addressed, in assessment schemes [5]. Circ-Flex requires accurate monitoring in order to anticipate changes over time, whilst becoming more than a theoretical possibility. This means that appropriate measures need to be taken at the right moment in time by the right stakeholder, instrumentalizing, amongst others, design, contracting, (dynamic) resource passports, and software. Table 1 lists Circ-Flex assessment guidelines as synthesized by Geldermans et al., excluding the additional embodied-impact categories concerning social fairness, and embodied energy and carbon [5]. In this paper, the accent is on the first two categories of Table 1, albeit in anticipation of the other four.

Table 1.

Circ-Flex assessment guidelines excluding embodied impacts [5].

3.2. Activity-Based Spatial Material Flow Analysis

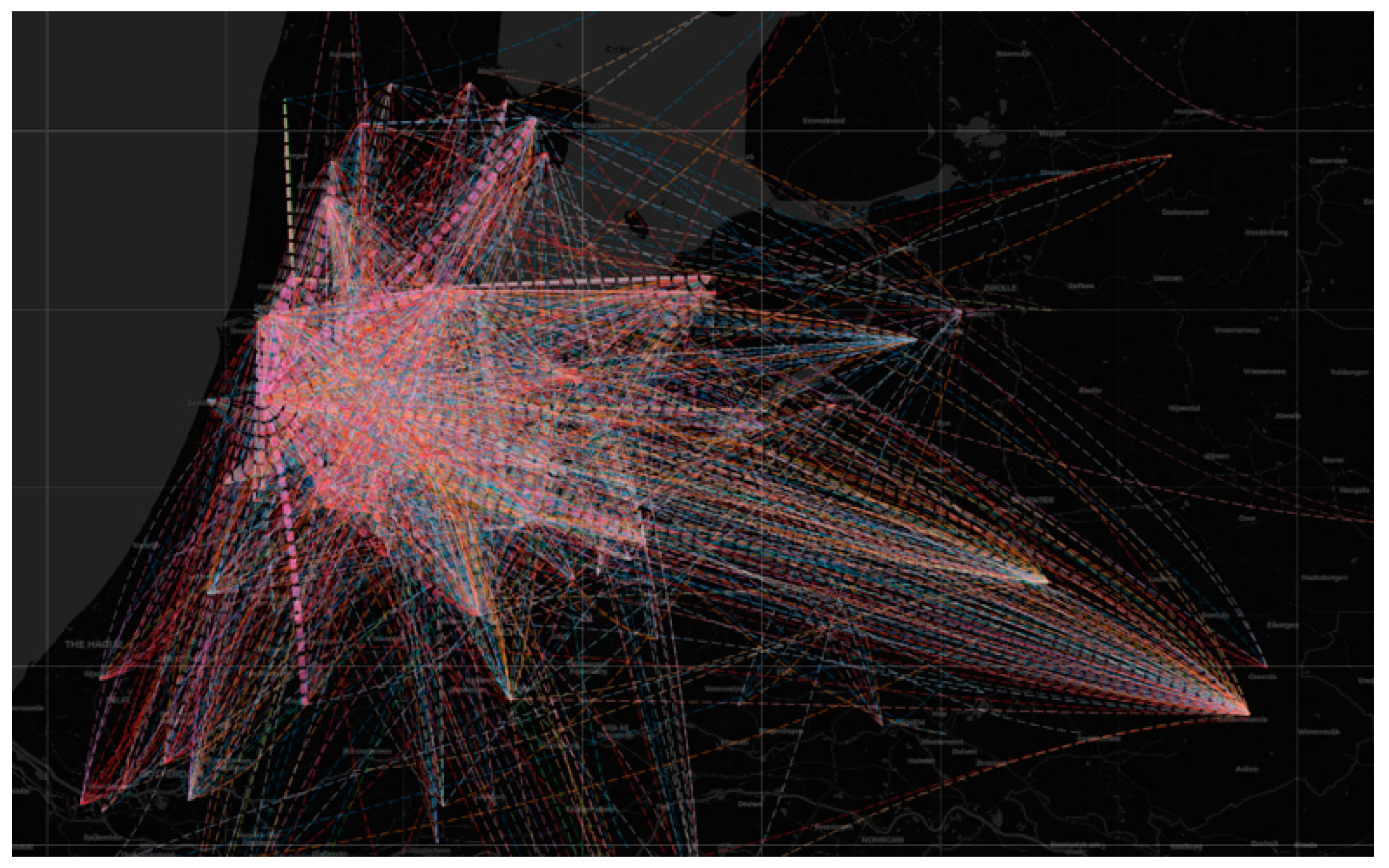

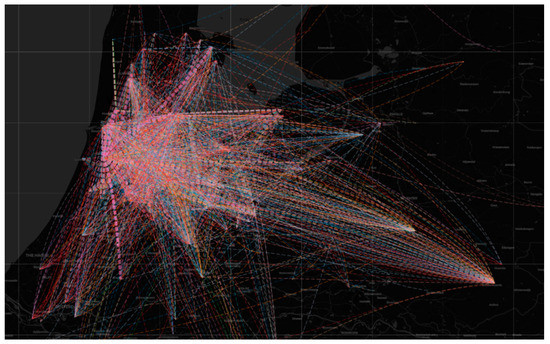

Material flow analysis (MFA), as an analytical tool, is closely linked to the fields of industrial ecology and urban metabolism. Both fields of science depart from the realization that the ways and rates in which-urban-territories mobilize, consume, and transform resources, are not sustainable, nor is the resulting waste and pollution [33,34,35,36]. Recently, there have been initiatives to enrich the scope of MFA, providing more grip on the inner workings of analyzed systems. Those inner workings include the role of key players and processes, as well as the impact on territorial quality [37,38]. This helps decision makers to establish integrated strategies for the shift from linear to circular urban development [37,39]. The activity-based spatial MFA (AS-MFA) is a novel approach to help identifying site-specific leverage points for eco-innovative solutions [39]. AS-MFA has been developed as part of the EU Horizon 2020 research project ‘Resource management in Peri-urban Areas’ (REPAiR). The aim of AS-MFA is to identify and map specific economic activities relating material flows and stocks from waste production in cities’ sub-systems, as well as the involved actors and their interrelations. In doing so, AS-MFA connects material, spatial, and social analyses, in anticipation of, on the one hand, lifecycle-based sustainability impacts, and on the other, circular solution routes, as sought by public and private stakeholders in the six European case-study areas (Amsterdam, Hamburg, Napels, Pécs, Łódź, and Ghent) [39]. The method follows a six-step iteration: (1) Determination of material scope; (2) definition of the associated supply chain; (3) selection of geographic and spatial scales; (4) definition of case-specific value chain; (5) modelling of the mass flows; (6) mapping and visualization of the results. With regard to data, AS-MFA adheres to EU-wide classification systems, as well as national and local sources. For the Amsterdam case-study, the AS-MFA was applied to construction and demolition waste (CDW), and food waste. Building materials currently ‘in stock, locked inside the built fabric,’ were included in anticipation of future material-release during renovation or demolition stages. Figure 2 is an example of AS-MFA results, generated through a digital tool, developed as part of the REPAiR project. The tool is open source and can be accessed via the link: https://gdse.h2020repair.bk.tudelft.nl. The full AS-MFA methodology is described in the publication REPAiR D3.3: Process model for the two pilot cases [39].

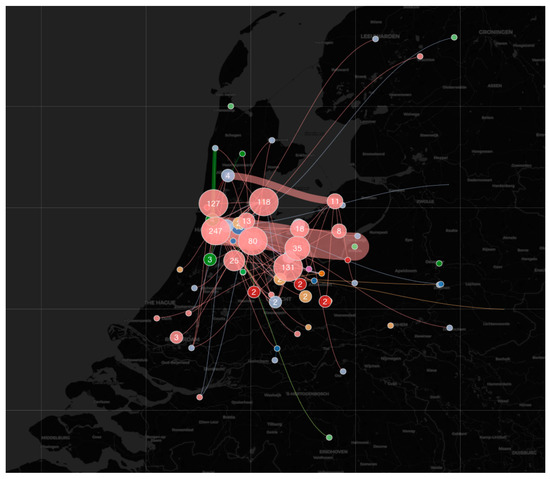

Figure 2.

Example of an activity-based spatial material flow analysis (AS-MFA) result, concerning construction and demolition waster (CDW) originating in the Amsterdam metropolitan area (AMA), in tons/year, from origin (disposal location) to destination (storage or treatment location). Each color represents a CDW category.

4. Design Preconditions and Frame of Reference

4.1. Design Preconditions

In this section, preconditions are formulated. The starting point is the assumption that a critical level of flexibility is accommodated by the super-structural design of a multi-family property. The residents of each individual housing unit are free to define the whole infill layout, and thus also the type and location of room dividing partition walls. In order to anticipate change, the partition walls should not obstruct any potential future intervention, be it due to infill rearrangements, maintenance, repair, replacement, or upgrades. Circularity of associated parts-building components, materials, and raw materials-needs to be respected at all times. Those parts can thus not be seen in isolation but always in relation to provenance and destination, underscoring the relevance of value chains and the distribution of control. The design brief takes a user-centered approach, adhering to healthy building and renovation concepts that allow for a high level of flexibility regarding the space layout, whilst striving for high circularity potential of the associated materials. The focus is on a non-bearing partition wall. Below, specific preconditions are listed that integrate intrinsic properties of the partitioning part, as well as relational properties, with regard to user experience, physical context, and value chain performance, based on Geldermans et al. [3,5].

- The partitioning wall unlocks flexibility-capacity, through ease of assembly, disassembly, reassembly, and reutilization;

- The partitioning wall unlocks circularity capacity, through the ease of maintenance, reuse, redistribution, remanufacturing, recycling, and/or facilitating biological cycles;

- The partitioning wall unlocks user capacity, by an inclusive approach that takes account of willingness to engage, freedom of choice, and the health and well-being of end-users;

- The partitioning wall supports coordination between subsystems, particularly in regard to installations and electric or data provisions;

- The partitioning wall accommodates multiple duty ratings.

All preconditions originate in Circ-Flex assessment guidelines, although preconditions one to three are more explicitly addressed than four and five. The latter two, however, represent aspects that are no less relevant for the conceptualization exercise. Precondition 4 highlights the fact that partitions ‘communicate’ with adjacent parts, such as doors and ceilings, as well as mechanical, electric, plumbing (MEP), and information and communication technology (ICT) infrastructure. Precondition five is based on the level of duty the partition should be able to support, in case present or new-users and/or functions require a different performance profile. For example, when compartments change from a domestic duty to office functions. Although the options are virtually limitless, and heavier duties could be imagined with regard to the required performance, a typical ‘medium duty’ is assumed, compatible with categories A and B of the Eurocode “Action on Structures” [40,41]. This resonates in, amongst others, fire, thermal, and robustness performance. Precondition five implies a certain level of product-familiarity: Neutral enough to withstand forces of change, both from the perspective of users and building owners.

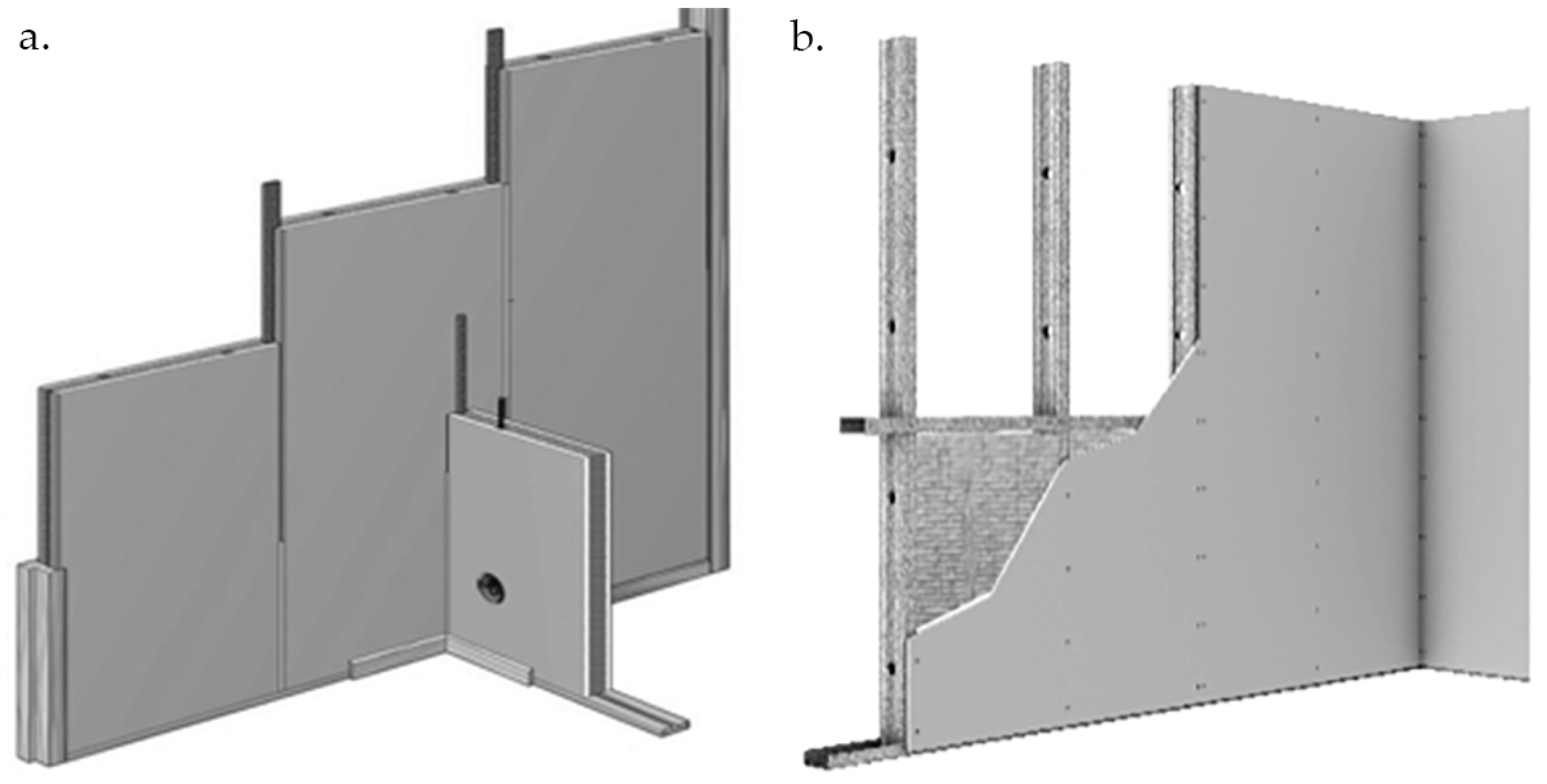

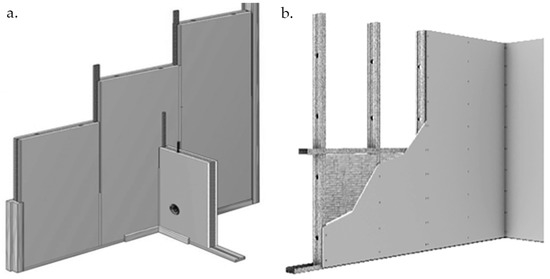

4.2. Frame of Reference

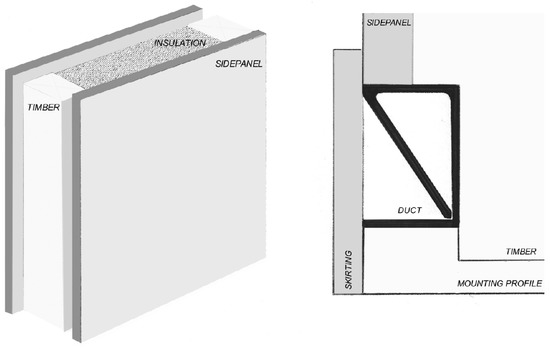

The design conceptualization departs from familiar examples of residential floor to ceiling wall systems that are easy to assemble, disassemble, and re-assemble, but robust enough to function in a (semi-)fixed setting. In the Dutch context, two primary partitioning variants apply in this respect: A configuration based on-homogeneous or heterogeneous-solid wall modules, in which framework, insulation and cladding are incorporated, and a hollow variant based on a studwork with separate side-panels and insulation. In the latter configuration, the framework is comprised of either timber or metal studs. Eventual finishing layers are not part of the conceptualization, even though these may have a strong impact on circularity, flexibility, and health performance. This will be addressed in the discussion section. Figure 3 displays a solid partitioning wall configuration (a), and its hollow counterpart (in the metal stud variety) (b).

Figure 3.

Solid partitioning wall configuration (a) and its hollow-wall counterpart (b).

Considerations concerning changing requirements for cables and wires have been addressed in the past, and solutions have found their way to the market. Infill Systems BV (with a branch in The Netherlands and the United States of America), for example, has patented multiple variations relating to “invisibly arranging cabling in an indoor space defined wholly or partially by non-load-bearing partition walls” [42]. Those patents are rooted in the notion of open building and the flexibility of the space layout, as addressed in Section 2.1, with a long history of research and implementation [43,44,45,46,47,48,49]. Moreover, several manufacturers of partitioning products have integrated those notions into their products. An example is the ‘Cable Stud,’ by the aforementioned Infill Systems BV, especially developed for hollow metal stud wall configurations that anticipate optimal freedom for positioning of installations and associated infrastructure. Variations on this innovation can be found in, amongst others, the Knauf BoWall system, and the Faay KBL system. The latter is developed for a solid wall system. In contrast to hollow-wall systems, solid walls reduce the flexibility with regard to placement of, for example, MEP and ICT provisions.

Regarding the materialization of hollow-wall partitioning, the main roles are claimed by the boards used for side-panelling and the insulation material within the cavity between two boards. A primary product with regard to side-panelling is gypsum board, which is widely used for partitions [50]. Gypsum boards are an example of materials that can function in circular models, consisting primarily of recyclable calcium sulfate dihydrate (CaSO4·2H2O). Although recycling rates are still relatively low on a European scale, the Netherlands shows increasingly high scores, induced by more stringent regulations that prevent transboundary landfilling [51]. Yet, an orchestrated effort is still required to fully capitalize on the recycling potential of gypsum-based waste. A recent study into the benefits of deconstruction (and segregated disposal) versus demolition (and disposal in mixed waste) showed that the latter is significantly more costly [50].

A small percentage of the weight of the gypsum board product (usually 1–5% for a basic board, but more if specific properties are required) consists of additives, such as binding agents, process accelerants and retardants, fillers, reinforcement fibers, fire retardants, and foaming agents [52]. Those additives are not regenerated to their initial quality, and become an impurity in the gypsum-recycling process. Moreover, other impurities may accumulate in the secondary gypsum flow along the way, adding up to about 10% of impurities in total. Although most substances can safely be integrated in the production processes, a certain level of gypsum-purity is required [53]. This necessitates the addition of purer gypsum. Gypsum recycling is thus essentially downcycling.

Flue gas desulphurization (FGD) gypsum is currently the main raw material in gypsum boards for the Dutch market [54]. In light of the imminent phase-out of coal-fired power-plants as the primary source of FGD gypsum, other sources need to be explored, apart from increasing the share of recycled gypsum [54]. Most likely, this will lead to natural mines in, for example, Morocco, Spain, or France. Another source would be so-called Phosphogypsum, formed as by-product in fertilizer production. This raw material, however, is controversial due to its-weak-radioactivity, and is currently not broadly accepted as a safe alternative [55].

Concerning insulation materials, mineral wool (or man-made vitreous fibres: MMVFs) is—and has been—widely applied in Dutch construction. In current demolition flows, rock wool is more common than glass wool, as the latter entered the market later [56]. There are reported health threats associated with mineral wool, in particular in manufacturing, construction, and deconstruction or demolition stages, but exposure may also occur during do-it-yourself home remodeling activities [57]. As yet, there is no substantial evidence regarding human toxicology of mineral wool. Certain MMVFs have been classified as carcinogenic in the past, by the World Health Organization. However, this classification was withdrawn after the manufacturing industry altered the composition of their product [58]. Currently, multiple sources report the statis: ‘Reasonably anticipated to be human carcinogenic’ for glass wool [59,60]. In the Netherlands, there are several facilities that recycle mineral wool at a high-grade. This requires appropriate disposal and logistical management, which is not widely applied yet, neither in the Netherlands nor in Europe as a whole [61,62,63]. Although nowadays not as widely used as their mineral counterpart, cellulose wool has been applied in partitionings’ constituents for a long time, whilst becoming increasingly sophisticated [64]. Not many data are available with regard to whole lifecycle performance of contemporary cellulose materials, but LCA-based studies detect advantages and disadvantages regarding the—environmental—performance for cellulose insulation products, such as paper wool [64,65,66]. From the viewpoint of flexibility and circularity, uncertainties regarding the end-of-life stage are promonent obstacles, whereas—human and environmental—health issues are related to dust and additives [64,65,66]. A Dutch manufacturer of recycled paper insulation products (Everuse®), has tackled the end-of-life issue to some extent, by retaining ownership and taking back the products after an agreed functional life [67]. The issue relating additives, however, remains unsolved.

5. Results: Materialization and Operation Analysis

In this section, components of hollow non-bearing partitions are presented, in line with the design preconditions. The primary vantage points are related to materialization and operation. First, materialization of side-panels and insulation is described, primarily focusing on biobased innovations. Next, local secondary material flows are addressed, in relation to raw material sourcing. Subsequently, a materialization overview is provided, focusing on two variants of side panel and insulation products for hollow-wall partitioning. This overview includes a range of properties, such as material composition, product and material origin, recycling potential, and technical specifications. In the final subsection, operational value chain aspects of two specific materials and products are described.

5.1. Materialization

Distinguishing multiple material levels (from raw materials to building components) is required for determining circularity and flexibility potential, as well as the distribution of control in the value chain. Several materials and products are explored, aimed at proven technologies and new innovations, and based on the availability of data. Starting points for these explorations are two databases in particular: The Cradle to Cradle® Products Innovation Institute, and the Materials Passport Platform (prototype) [68,69]. These sources are estimated to be most reliable with regard to conscientious adherence to the given preconditions and underlying assessment guidelines. Additional data were sourced from product suppliers. Subsequently, the scope was narrowed down to biobased products for, both, side-panels and insulation.

5.1.1. Side Panels

Natural fiber composites (NFCs) are engineered products that comprise organic fibers in, either, a lignin and hemicellulose matrix (intrinsic part of woody materials), or a combination with synthetic or biobased resins. Engineered fiber boards can provide a cheaper alternative, with more uniform properties than wood [70]. From our angle, products and production techniques that lead to composites with irreversible-thermosetting-bonds between raw materials are problematic. This is valid for most NFCs currently used in interior partitioning functions. Besides the irreversibility, binding substances are often based on volatile organic compounds, such as formaldehyde, potentially leading to harmful emissions over time [71]. Regardless of the enhancements in the last decade, influenced by an increasing awareness of industry and regulatory frameworks regarding potential health effects, those characteristics are not compatible with the Circ-Flex ambition of the underlying article. Even when theoretically renewable bio-based binding agents are applied successfully, irreversibility remains an issue. What is more, the environmental and social impacts of raw materials for those alternative glues—often wheat or corn-based—are still up for debate [72,73]. Processes related to those innovations are rather opaque. Sustainable land use, natural biosphere protection, and food-competition, amongst others, are issues that require more elaboration [72]. Important progress is made in the industry, with regard to sustainability performance, specifically concerning recycled and recyclable content [74]. When shredded after one or more service lives, fibers can be used in new boards with little quality loss. This extends the life significantly, but is not circular on a raw material level: Neither binding agents nor fibers are regenerated to a quality-profile that is similar to—or higher than—their initial states.

An alternative for wood-based panels that recently emerged on the market, and that tackles aforementioned issues, is based on the conversion of cellulose fibers with pressure and heat. This technology was introduced by Noble Environmental Technologies. The Cradle-to-Cradle (Silver) certified product is referred to as ECOR®. It concerns a platform technology, allowing for many different types of fibers as raw materials, whilst ‘upcycling’ low/no value residues to a high value product [75]. ECOR is made in single (FlatCOR) and multiply woodpanels, as well as three dimensional assemblies with a honeycomb core, and can be applied for non-bearing indoor partitions, amongst others [76]. As a raw panel ECOR is free of additives. However, in many building applications some form of treatment is required. E.g., for resistance against fire, moisture, or biological decay. Although ecologically sound alternatives for potentially damaging chemicals are often available, implementation takes time, due to the heavy engagement that is required from material manufacturers and the chemical industry [77]. An example is the Molecular Heat Eater® (MHE) technology. MHE concerns a non-toxic, biodegradable flame retardant technology based on food-grade chemicals, that functions in multiple ways to slow or extinguish a fire [78]. Raw materials can be sourced from organic residues, local to the production facility, such as agricultural, horticultural, and food waste [79]. ECOR has recently teamed up with DSM-Niaga, focusing on a reversible adhesive technology. ECOR and DSM-Niaga developed a laminated panel that can be brought back to its separate parts by “un-clicking” the adhesive. Subsequently, the adhesive can be recycled, as can the individual ECOR panels. This innovation, referred to as NEP (Niaga Ecor Panel), is currently aimed at the furniture domain, but indoor building applications are explored. Being at a Technology Readiness Level of 6–7, the innovation still needs to be demonstrated in an operational environment. In concept, however, the technology could work well for indoor partitioning. Given that adhesives and binders are primary concerns for Circ-Flex applications, the disruptive potential of NEP is significant [80,81].

5.1.2. Insulation

Acoustic and thermal performance are important requirements for the partition, enhanced by an insulating part of the wall system. When focusing on insulation materials for a hollow wall system, and taking account of flexibility, circularity and health, two main categories can be distinguished: Synthetic and organic core materials. An example of the former is Calostat®, a thermal insulation board based on silicon dioxide, that renders it incombustible. Although not many data are readily available regarding this product, it performs very well on the Cradle to Cradle product scorecard, with ‘Gold’ scores for four out of five categories, and ‘Platinum’ (the highest score) for Material Health [82]. As such, it outperforms other mineral insulation products. Flax, hemp, cellulose, and seaweed based insulation products are examples of the organic variety [83,84]. Enhancing specific properties, such as fireproofing, necessitates the use of additives, which impacts the associated barriers in-reutilization pathways. In that respect, the ecological fire-retardant mentioned in the preceding paragraph is no less applicable to these insulation materials. An innovation that received increasing attention over the last decade concerns a type of bio-composite that is self-growing, renewable, and can be locally produced [85]. This bio-composite comprises a substrate that is inoculated-and bound together-by fungal mycelium; i.e., the filamentous “root” structure of fungi. The substrate can consist of organic fibers; for example, agricultural by-products, such as switchgrass, flax shives, or hemp [86]. Mycelium is said to have superior intrinsic fire retardant characteristics compared to many other insulation products [87,88]. Studies into their functional performance—as insulation materials—are limited, and the results vary, depending on fungal species and fiber substrate. Therefore, more tests—and consistent testing methods—are required before solid claims can be made [89,90]. However, the outlook is promising regarding intrinsic fire retarding, thermal, and acoustic properties, and excellent life-cycle performance: Multiple locally sourced feedstocks can be applied, energy requirements are low, and at the end of its service-life, mycelium-based material is fully biodegradable [89]. It is estimated that, in light of the steady progress, the material will soon be cost competitive as well [87,91].

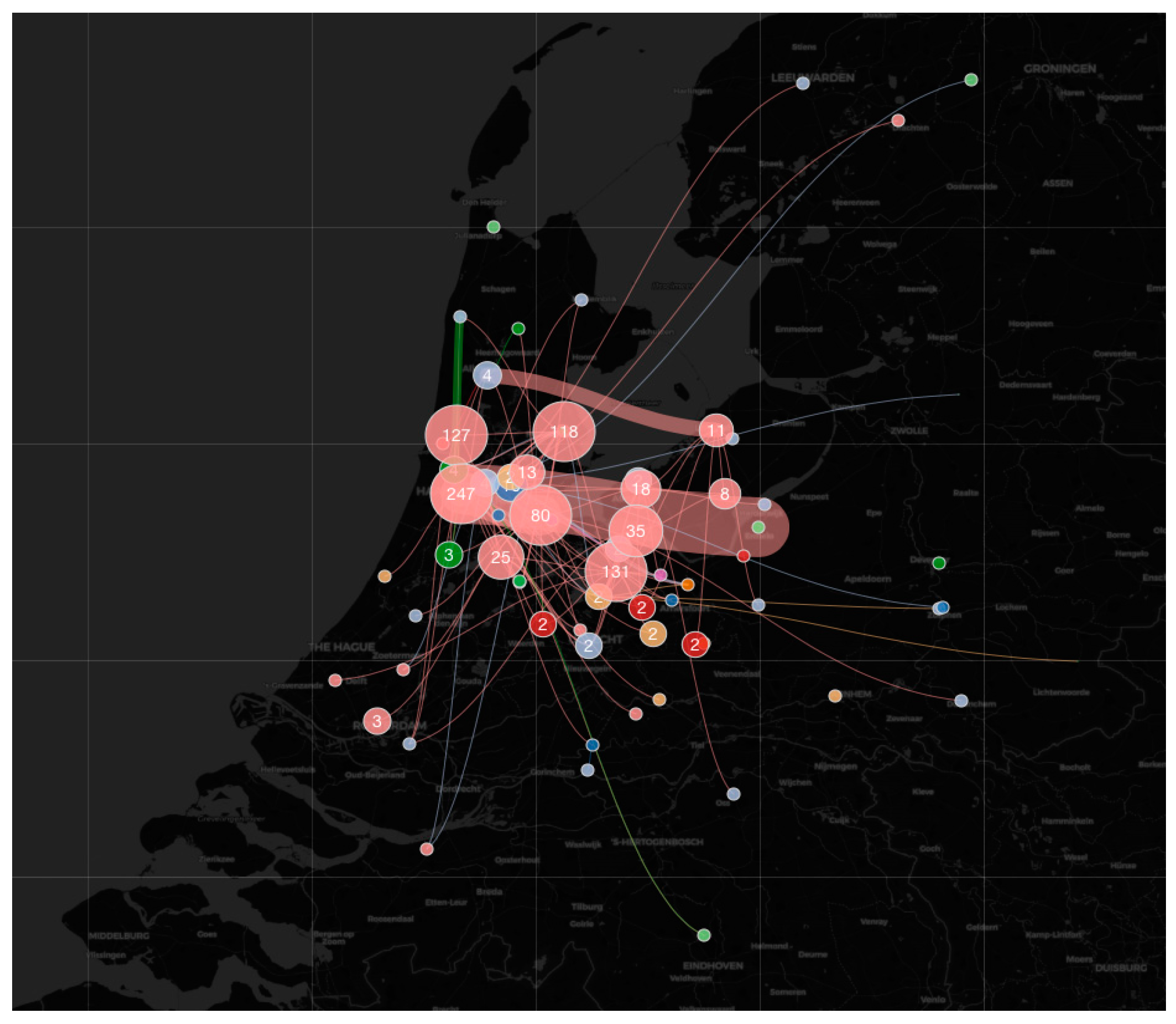

5.2. Secondary Raw Materials and Waste

The renewability of (raw) materials is an essential aspect of Circ-Flex performance. In this section, waste and potential secondary raw materials associated with the AMA are addressed, following the AS-MFA method. This links to both biological and technical cycles, whilst necessitating a more advanced stance towards the secondary material market. On the one hand, specific waste flows can be avoided by adhering to renewable models, and on the other, current waste flows can be applied as feedstock for new materials. The AS-MFA tool helps to identify secondary flows, as a precursor for both those aspects. Figure 4 shows, as an example, the wood waste stream in the AMA, associated with the year 2016. In Figure 4, the actors (represented by circles and numbers) are linked to activity groups, following the level-1 categorization of the Nomenclature des Activités économiques dans la Communauté Européenne (NACE) [92]. The lines—with widths relative to amount—represent wood that is disposed of as a waste stream per activity group, clustered by geographical location, as well as its treatment location. This concerns a flow of roughly 15,000 t in the year 2016. Secondary wood with a high enough level of purity (excluding, for example, wood in mixed waste) that currently ends up in low-grade-linear-pathways, such as incineration, might be an appropriate source of fibers for Circ-Flex partitioning configurations. About half of the flows in Figure 4, ~7.5 kton, is currently incinerated [93]. AS-MFA also provides a grasp of materials currently locked inside the built stock. For wood, this is estimated to be approximately 9000 kton. AS-MFA can be paired with other territorial ‘layers’ to identify local/regional areas that can play a role in the value chain. For example, by exploiting degraded land, underused fields, or urban territories in transition [94]. Such territories can be applied as temporary or permanent production areas, locations for processing facilities, and/or the storage of building materials, in order to establish local synergies between supply and demand. Finally, other materials can be integrated into the flow model as well [39].

Figure 4.

Wood materials as part of the CDW flow in the Amsterdam metropolitan area (2016).

5.3. Materialization Overview

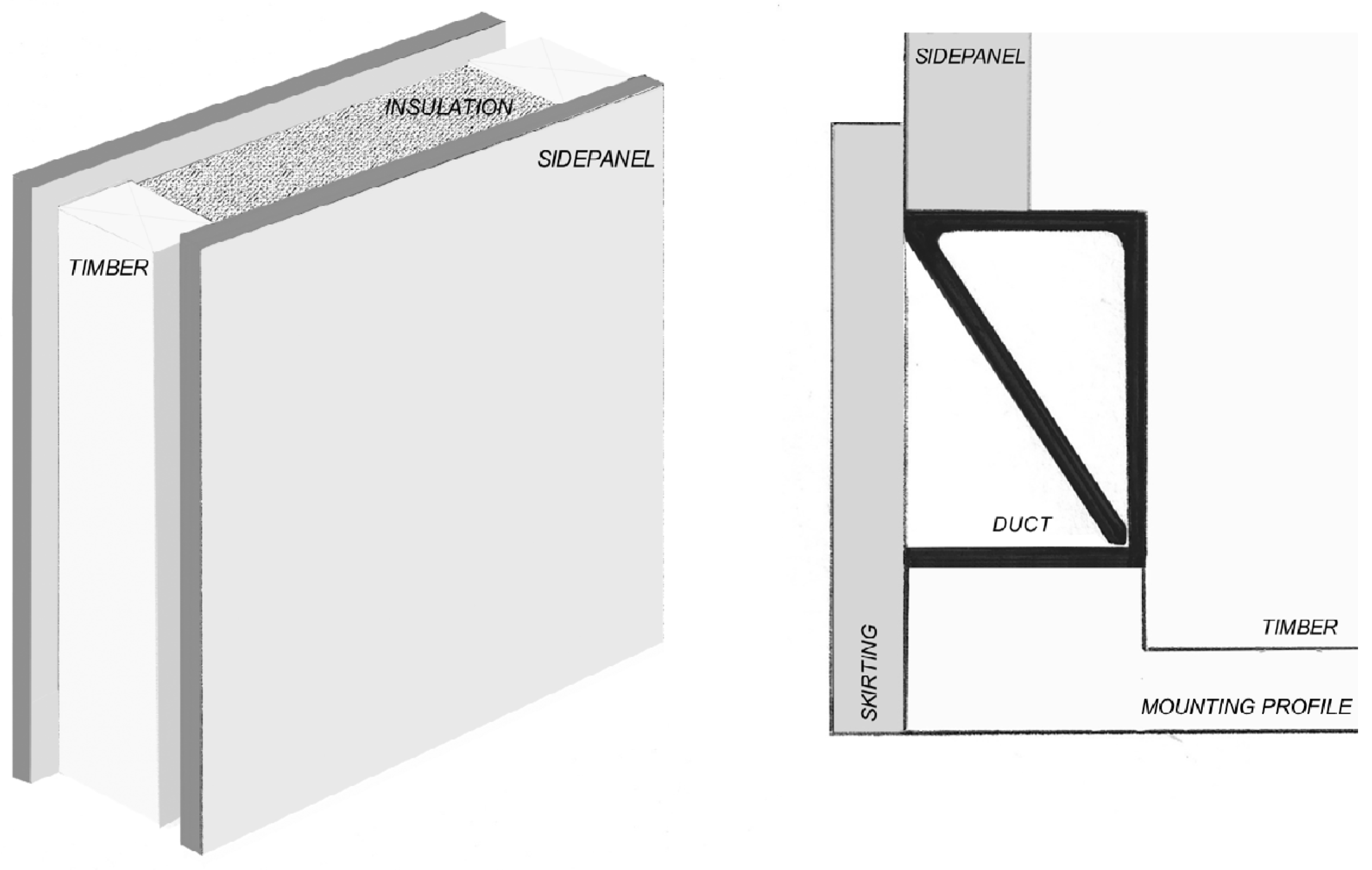

Figure 5 displays rudimentary sketches of a partition wall design, consisting of a stud framework (timber in this example), two side-panels, and insulation within the cavity. The cavity allows for cables and wires in order to position electrical and data provisions wherever desired. To facilitate that, a cable duct is foreseen at the bottom (depicted on the right in Figure 5), adapted from aforementioned groundwork by Infill Systems BV [42]. These devices are fitted into the vertical member. The vertical members slot into timber or metal mounting profiles on ceiling and floor. The skirting board can be taken off in order to reach cables and wires. The materialization facilitates personalized (re)configurations, allowing for many variations. Materials can either be pre-cut in various standard sizes or customized on-site. Lastly, for this exercise we assume the use of common-additional-fasteners for dry, direct connections, even though this restricts reuse and recycling to some extent [18].

Figure 5.

Basic partition wall configuration (left) and detail of the cable duct behind skirting board (right).

Table 2 brings together data for two variants of the components, side panels and insulation, focusing on materialization, origin, and reutilization. Table 3 assembles technical specifications and a price indication. Table 2 and Table 3 do not aim to provide a complete set of parameters to assess Circ-Flex performance, but rather first insights from the analysis into the material and operational performance of the products and their functions in the intended scope. Table 2 particularly refers back to the categories ‘Material Health and Transparency’ and ‘Material Reutilization’ of Table 1, whilst anticipating AS-MFA aspects concerning secondary materials and georeferencing. Table 3 combines product specifications to facilitate a quickscan regarding functional performance of partitioning components, and to identify any remarkable differences from the study’s perspective. Apart from basic product performance, Table 3 ties in with the category ‘Perceived Performance’ as part of the Circ-Flex assessment guidelines. The data are based on information from manufacturers and literature. In the case that data are unavailable, it is indicated in the given column.

Table 2.

Side-panels and insulation: Materialization, origin, and reutilization.

Table 3.

Side-panels and insulation—selected technical specifications and price indications.

5.4. Operational Value-Chain

From the materialization matrix of Table 2, various changes to the regular value chain can be observed. For example, in the case of gypsum-board, the most apparent shift is related to the sourcing of gypsum with a high enough level of purity. The share of FGD gypsum will decrease, due to the closure of coal-fired power-plants. This likely leads to an increase of both recycled and natural gypsum, whilst applying modifications to the manufacturing process to safeguard the required product quality [95]. Furthermore, the gypsum-board product is comprised of multiple additives sourced via regular channels. Although the associated European (chemical) industry is the primary supplier, market mechanisms are increasingly a global game [109]. Moreover, in anticipation of changing partitioning requirements, a basic gypsum-board is not sufficient. Enhancing the properties, such as robustness, has a direct, negative effect on the recyclability. In the case of insulation, a main observation is the difference in end-of-life scenarios, linked to take-back systems as part of a supplier’s business model, but also additives that provide restrictions in this respect. Lack of data made it difficult to fully assess the Everuse® product with regard to such aspects.

5.4.1. Niaga ECOR Panel

With regard to primary/secondary production of fibers for the NEP, raw materials can be found locally. Apart from post-industrial and post-consumer residual flows, agricultural by-products could apply. Based on proximity, sourcing beyond national boundaries may apply, depending on the manufacturing location. At this moment, ECOR manufactures their FlatCOR panels in Serbia, while a NEP production facility is set-up in Venlo, the Netherlands. Raw materials-fibers and polymers-are transported to that location. The polyester polymers, based on regular chemical feedstock (carboxylic acid and glycol), are produced in Germany and transported in big bags of granulate pellets [99]. Next, the panels are transported to wholesale or retail locations if not directly to the site. Temporary storage is also an option. ECOR currently develops a ‘product-as-service’ business model for the NEP that takes account of the take-back stage, so that materials are recovered and reutilized [99]. This activity can be deployed by ECOR itself or be outsourced to another service-provider. Concerning the service life of NEP, no data exist yet, but based on estimations of similar products, approximately 30 years can be assumed [105,106,110]. Within this period, the material can, theoretically, be reused and remanufactured several times before it is recycled.

5.4.2. Mycelium Fiber Composite Insulation

The raw materials for mycelium-fiber composites can be divided into: Fungal mycelium, fibers and—potentially—additives. Fibrous agricultural residues are cleaned and pasteurized before being introduced to mycelium in standardized moulds [89]. These moulds—ideally transparent and plastic for reasons of control and hygiene—are essential in the cultivation process, but are not included in underlying exploration of (raw) material use. The mycelium grows due to its symbiotic relationship with the fibers that feed it, forming a strong yet flexible composite. A process accelerator may be added, such as wheat flour [91,101]. The binding process takes up several days, after which the panel is dried and the growing process stopped [85]. Fungal species, suitable for the MFC process, can be found on the global market or be cultivated in local laboratories [89,91,101]. For this exercise, we assume the fungal strain comes from a local source. The wheat flour, that may be used in the process, is a ubiquitous agricultural commodity. Although this raw material can come from local (Dutch or European) sources, the wheat market is essentially a global market. Wheat on the Dutch market is 50% from domestic origin and 50% from abroad [111]. The largest share, in weight, are the fibrous raw materials. Multiple substrates have provided good results in terms of mechanical, thermal, fire, and acoustic performance [89]. A pioneering company, with a head-start in mycelium technology, has brought an insulation product to the market based on hemp [88]. The ratio is 95% hemp residues and 5% mycelium. No use of additives is reported for this product. A Dutch associate of this American company has successfully applied combinations with other substrates, such as cattail reed [101]. Production of the MFC can be done locally, close to the area of distribution, use, and recycling. For example, in proximity to fibrous residues from agriculture or public land maintenance.

6. Discussion of the Results

6.1. Technical Reflection

6.1.1. Fasteners and Coatings

The focus has been on products that may radically alter value chains, but not so much the interaction with users and contractors. Both, NEP and MFC can be applied in common implementation configurations. The underlying study did not prominently include fasteners. Common fasteners were anticipated, also in relation to screw tightness. Disassembly of the NEP cannot be done without minor damage to the product due to screw holes. Although this may lead to initial decrease in value with regard to flexibility and inner cycles, such as reuse and remanufacturing, it has no impact on the recycling stage provided the NEP retains—or regains—its purity. The latter aspect is closely linked to the application of coatings and finishing layers. Finishing was not part of the scope but clearly an essential intervention in the light of health, flexibility, and circulation, as stated in Section 4.2. The Niaga technology can be combined with various materials. The expectation is that coatings can also be compatible in this respect. Several manufacturers of coatings, known to comply with the ethics of health and circularity, make use of readily available natural products and processes that can safely be recycled with the ecor fibers [68,69]. However, being in the development and experimentation stage, evidence is still scarce. What is more, a limited range of applicable products will impact the user’s freedom of choice. Research, innovation, and marketing efforts in this direction are thus required.

6.1.2. Properties

The NEP is currently in a pilot phase aimed at the furniture sector. From Table 3 it can be derived that multiple tests are required to steer production towards interior partitioning components. The performance of the FlatCOR product indicates that robustness will not be a main concern for the NEP, but dimensional stability may be, specifically in respect to relative humidity fluctuations. Furthermore, Table 3 displays unknowns with regard to fire safety and thermal performance, which thus requires further testing in these areas. Another relevant factor, not included in Table 3, is acoustic performance. This is best tested on a whole wall module rather than on separate materials. Potential changes in function of space over time need to be taken into consideration. For example, shifting from residential uses—such as living rooms or bedrooms—to meeting-rooms or working spaces. If a regular drywall performance is assumed, ranging between softly spoken and normal conversation, extra measures may be necessary. For example, by doubling the side-panels or applying a thicker alternative, ideally with a honeycomb core to reduce weight and raw material requirements [96,97,98,99]. Specific attention in this respect should go to the connection with adjacent parts, such as ceilings, floors, and doors. Holes at the partition heads and cable duct cavities will have a substantial negative effect on acoustic performance. Additional materials may thus apply, with an inherent impact on the Circ-Flex performance.

With regard to the MFC insulation, specific attention should go to the service life. Based on estimations, approximately 20 years is anticipated. This is shorter than that of regular insulation products and side-panels, which may lead to undesirable effects regarding replacement interventions.

6.1.3. Raw Materials

The NEP technology allows for multiple fiber feedstocks. Focusing on Dutch biogenic residues that apply, but are currently incinerated, it can be assumed that supply-risk is not a main concern. As an example, Annevelink et al. [112] calculated roughly 170 kton clean fibrous biogenic residues per year from agriculture alone, that is currently incinerated but could be used at a higher utility. Addtionally, about 6000 kton of similar material—albeit in diverse qualities—from other sectors, most notably households (2750 kton), and trade/services/government (1300 kton), are incinerated [112]. A rough calculation (dividing 170 kton by 25 kg per m2, based on Table 2) indicates this residual flow could provide raw material for seven million meters squared. Regardless of the crudeness of this calculation, it provides a favourable order of magnitude regarding supply-security. Biogenic residues are also relevant in relation to the mycelium fiber composites. With regard to the shift from linear to circular value chains in the construction sector, the application of MFC has been studied before in the AMA context [113]. Designated buffer-zones for temporary water storage were identified as high potential territories for growing crops (grasses, reeds), capitalizing on local opportunities for renewable insulation materials and other ecosystem services [114]. Production of the MFC can take place in local facilities at temperatures between 20 °C (for growing) and 80 °C (for baking). Main issues are (1) the time it takes for the mycelium to bind the fibers and for the material to dry, and (2) the space it takes for those processes. Automatisation will have a decisive impact on production volumes per m2 land used [101].

6.1.4. Mould

Lastly, mould control is addressed—particularly important with regard to transportation, storage, use, and maintenance conditions [5]. As in the reference case, the products themselves need to be in line with the standards. However, this may imply additional additives which can compromise the performance concerning circularity, flexibility and/or health. Further testing is required, not least in relation to the use of coatings, as mentioned earlier. Moreover, consistent quality control is indispensable throughout the whole operational cycle.

6.2. Organisational Reflection

6.2.1. Value-Chain Modifications

In order to adhere to familiar use and construction models in the design conceptualization, it was decided to not deviate too much from existing partitioning configurations. However, radical changes occur with regard to raw material sourcing, manufacturing, reutilization, and data-sharing. The use of secondary raw materials, of a renewable nature, contributes greatly to the potential of the design. Moreover, it can add a local narrative to the value-chain. Even if that narrative was to play no role of importance in the end-user’s perception, it is estimated meaningful for other networked partners in the value chain [99]. Acting collectively can make a big difference in opening up market barriers, knowing that innovative building materials and concepts often encounter critical hurdles in the implementation stage and fail to become proper innovations [115,116]. Proximity, both culturally and geographically, and a shared understanding of value creation, can drive that collective act, lubricating the social process through which innovations spread throughout an industry [117,118,119]. The Amsterdam metropolitan area and its articulated ambitions with respect to circularity in the built environment provides fertile ground in that respect. At least in theory. If raw material supply, manufacturing, supply, operation, and reverse supply logistics are aligned, the chain still needs to be activated by a key actor; namely, the client. This could be the end-users but also—and arguably more importantly at this stage—public or private organisations, such as housing associations, in close conjunction with local authorities. Finally, it can be expected that the prices and availability of materials remain decisive factors in the value model, based on current purchasing behaviour [120,121]. In the that case a take-back service is integrated in the value proposition, the manufacturer, retailer, or another appointed intermediary might claim ownership and the customer has access to the performance without responsibilities concerning material cycling [122]. Otherwise, a specialized secondary material ‘broker’ is likely to manage appropriate processing routes.

6.2.2. Data and Communication

Alongside design, material and manufacturing aspects, appropriate use and operational processes are vital for establishing healthy material cycles in flexible applications. This strongly links to aspects of co-creation and performance evaluations, as incorporated in the Circ-Flex assessment guidelines (Table 1), whilst necessitating advanced data exchange and communication. Knowing how a product or material functions within a value chain requires meticulous and consistent monitoring. Feedback loops are an essential part of the model in this respect and dynamic data-sets (for instance in the form of material passports) are crucial carriers of information. The latter are also valid for streamlining moments of intervention and associated transport movements, which puts an emphasis on activities of storage and logistics. The role of logistics is thus expected to intensify in the circular model. This aspect underscores the necessity to establish value chains in which the various stakeholders are well-connected, both concerning data-sharing and relational bonds.

6.2.3. Tenant Satisfaction

The construction, use, and maintenance stage of the value chain represents a wide diversity of actors, such as users, contractors, housing associations, and service companies. Focusing on multi-family housing in the AMA, a main role is reserved for housing associations. Multiple housing associations in the AMA are exploring ways to integrate circularity. However, at this moment, there is not much experience to build on yet. One example, related to circular kitchen concepts, showed that outsourcing—parts of—kitchen implementation, maintenance and repair cycles had incentivized housing associations to think along in this direction [123]. A preference was reported for a ‘hybrid concept,’ in which the housing association provided a basic kitchen-module, whereas additions and adjustments were left to the tenants and external suppliers [123]. Success rates depend on the DIY capacity of the tenant and on the viability of contracts with suppliers or external service providers. Such developments are only in their infancy, and substantial conclusions cannot be drawn yet. That said, the beginnings of new relationships are tangible with regard to the (circular) value chain around a building’s infill. The importance of tenant-satisfaction for housing associations plays a key role. The kitchen example revealed that primary concerns of tenants were freedom of choice, costs, and “hassle-free” systems [124]. This is probably no different for partitioning, and as such, is an important focus for further steps based on the design conceptualization in this paper.

6.2.4. Validity in Other Contexts

The Amsterdam metropolitan area has been the main geographical reference point. A fair question is related to the validity for other contexts. From a technical and materialization point of view, there is not much reason to expect highly diverging results between geographical contexts. With regard to applied methods, the REPAiR project has shown that the generic AS-MFA (beta version) works well in six different European case-study areas, leading to context-specific results. The Circ-Flex guidelines have not been applied to other contexts yet, although this tool integrates categories from internationally applied assessment methods, notably C2C CertifiedTM and WELL CertifiedTM. Recognized barriers are related to data-availability, data-sharing, and continuous value-chain collaboration [5]. This relates to multiple factors, with an apparent emphasis on organisational capacity, although technology-absorption can also be an issue. Follow-up research in this direction should provide more insight in that respect.

Amsterdam has positioned itself at the forefront of CE development, in anticipation of National and European goals. It can be assumed that cities or city regions with high ambitions in this direction might be more inclined than others to embark on implementation adventures. Implementation generally requires ‘harder’ engagement from multiple perspectives and actors. Safeguarding the appropriate circulation of materials necessitates commitment from, for example, waste logistics and processing companies, to become secondary material ‘brokers’ and producers. It is believed that this requires an intrinsic motivation, as well as financial and regulatory incentives. It will depend case by case to what extent subsystems relating waste and resource management provide leeway for such shifts. Moreover, the value proposition embedded in the partitioning innovation revolves around co-creation between networked partners, with strong user-centered accents. There may be contexts where such an approach finds more fertile ground than elsewhere. With regard to the AMA, developments in this direction are in their infancy [125].

7. Conclusions

The aim of this article was to shed more light on materialization and operation of partitioning wall components in relation to Circ-Flex performance. The hypotheses were, that: (1) A stronger integration of materialization and operational aspects is indispensable in establishing sustainable value-models, and (2) recent innovations, concerning the reversibility of material connections, will help disrupt the status-quo. It was found that the presented materialization, based on renewable and reversible natural fiber composites, can tackle issues that are found in current value-chains, most prominently regarding circularity performance. For example relating gypsum-board, particle board, and mineral wool manufacturing and reutilization-logistics, as addressed in Section 4 and Section 5. The increased circularity performance does not compromise material health, and could even provide solutions for current bottlenecks. With regard to flexibility performance, potential damages during disassembly and reassembly may compromise reuse and remanufacturing cycles. At the same time, flexibility for the user is facilitated when it comes to ease of assembly, disassembly, and design freedom. As in any other partition system, finishing layers are desicive factors in the overal performance.

Modifications in the value-chain occur, above all, in raw material sourcing, manufacturing, reutilization logistics, and data-sharing. Raw materials for the components can be secured by local supply, reducing the dependency on international markets. Value-chain integration is essential to streamline logistics and data-sharing. Although this research did not focus on financial aspects, it is assumed that the innovative products and materials could fit in, both, regular transaction models and product-service systems. It is expected that the benefits in this respect are not so much for the user, but for the supplier or secondary material ‘broker.’ The outcomes are estimated to be valid for multiple building components, other than indoor partitioning, such as kitchens and furniture, but also insulation, and the interior side-sheeting, of walls and roofs in energy-renovations. Focus areas for further research are related to the facts that multiple tests are still needed to assess the technical performance, and substantial efforts are required to engage key actors in bringing such innovations to scale.

Author Contributions

Conceptualization, B.G.; Data curation, B.G.; Formal analysis, B.G.; Investigation, B.G.; Methodology, B.G.; Project administration, B.G.; Resources, B.G.; Supervision, M.T. and P.L.; Validation, B.G.; Visualization, B.G.; Writing—original draft, B.G.; Writing—review & editing, B.G., M.T. and P.L.

Funding

This research received no external funding.

Acknowledgments

This study has benefitted from the kind information input of the following companies: Biomimetic Technology Ltd.; DSM-Niaga; Ecovative Design LLC; Faay Vianen B.V.; Infill Systems B.V.; Krown-Design; Noble Environmental Technologies/ECOR Europe; Siniat/Etex B.V.; Unilin Panels. No dependencies, financial or otherwise, exist between the authors and those companies. Furthermore, the AS-MFA method is developed within the framework of the project Resource management in Peri-urban Areas (REPAiR). This project has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement No 688920.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Laberge, R. Design criteria for adequate and affordable housing towards current social, demographic and economic trends. In Proceedings of the International Conference on Adequate and Affordable Housing for All, Toronto, ON, Canada, 24–27 June 2004. [Google Scholar]

- Oorschot, J.H.; Durmisevic, E.; Halman, J.I. Implementation of innovation: The inertia of implementing the open building concept in practice. In Proceedings of the International Conference on Management and Innovation for a Sustainable Built Environment, Amsterdam, The Netherlands, 20–23 June 2011. [Google Scholar]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Circular and Flexible Infill Concepts: Integration of the Residential User Perspective. Sustainability 2019, 11, 261. [Google Scholar] [CrossRef]

- Habraken, N.J. The Use of Levels; Keynote Address Unesco Regional Seminar on Shelter for the Homeless Seoul 1988; Open House International: Gateshead, UK, 2002; Volume 27. [Google Scholar]

- Geldermans, B.; Tenpierik, M.; Luscuere, P. Human Health and Well-Being in Relation to Circular and Flexible Infill Design: Assessment Criteria on the Operational Level. Sustainability 2019, 11, 1984. [Google Scholar] [CrossRef]

- Hendriksen, L.; de Graaf, J. Ontwikkelplan Circulaire Economie Metropoolregio Amsterdam; Metropoolregio Amsterdam: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Alexander, C. The Timeless Way of Building; Oxford University Press: Oxford, UK, 1977; ISBN 0195019199. [Google Scholar]

- Habraken, N.J. De Dragers en de Mensen—Het Einde van de Massawoningbouw; Scheltema & Holkema: Amsterdam, The Netherlands, 1961. [Google Scholar]

- Poldma, T. Transforming Interior Spaces: Enriching Subjective Experiences Through Design Research. J. Res. Pract. 2010, 6, M13. [Google Scholar]

- Poldma, T. Dwelling futures and lived experience: Transforming interior space. Des. Philos. Pap. 2008, 6, 141–155. [Google Scholar] [CrossRef]

- Poldma, T. Adapting the Interior Environment: A Case Study Using Light, Color and Research as Catalysts for Interior Design Problem-Solving; Interiors + Sources: Cedar Rapids, IA, USA, 2006. [Google Scholar]

- Vaikla-Poldma, T. An Investigation of Learning and Teaching Processes in an Interior Design Class: An Interpretive and Contextual Inquiry. Unpublished Doctoral Dissertation, McGill University, Montreal, QC, Canada, 2003. [Google Scholar]

- Mitchell, C.T. Refining Designing: From Form to Experience; Van Nostrand Reinhold: New York, NY, USA, 1993. [Google Scholar]

- Malnar, J.M.; Vodvarka, F. The Interior Dimension: A Theoretical Approach to Enclosed Space; John Wiley: New York, NY, USA, 1992. [Google Scholar]

- Brand, S. How Buildings Learn; Viking: New York, NY, USA, 1994; ISBN 9780670835157. [Google Scholar]

- O’Neill, R.V.; De Angelis, D.L.; Waide, J.B.; Allen, T.F.H. A Hierarchical Concept of Ecosystems; Princeton University Press: Princeton, NJ, USA, 1986. [Google Scholar]

- Guy, B.; Ciarimboli, N. Design for Disassembly in the Built Environment: A Guide to Closed Loop Design and Building; Hamer Centre for Community Design: State College, PA, USA, 2008. [Google Scholar]

- Durmisevic, E. Transformable Building Structures, Design for Disassembly as a Way to Introduce Sustainable Engineering to Building Design & Construction; Delft University of Technology: Delft, The Netherlands, 2006. [Google Scholar]

- Kendall, S. Notes on ‘open systems’ in building technology. Build. Environ. 1987, 22, 93–100. [Google Scholar] [CrossRef]

- Nicolic, J. Building “with the Systems” vs. Building “in the System” of IMS Open Technology of Prefabricated Construction: Challenges for New “Infill” Industry for Massive Housing Retrofitting. Energies 2018, 11, 1128. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle, Remaking the Ways We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Debacker, W.; Manshoven, S. Synthesis of the State of the Art: Key Barriers and Opportunities for Materials Passports and Reversible Building Design in the Current System; Buildings as Material Banks: Brussels, Belgium, 2016. [Google Scholar]

- Geldermans, R.J. Design for change and circularity: Accommodating circular material & product flows in construction. Energy Procedia 2016, 96, 301–311. [Google Scholar]

- Circle Economy and Fabric. Circular Amsterdam—A Vision and Action Agenda for the City and Metropolitan Area; Municipality of Amsterdam: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Amsterdam Smart City. Perspectief op Amsterdam als Circulaire Stad; ASC: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Booi, H.; Ahamiane, S.; De Graaff, L.; Schmitz, D.; Sleutjes, B.; Smits, A.; Tepic, M. Factsheet Wonen in Amsterdam 2017; Gemeente Amsterdam: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Ministry of the Interior and Kingdom Relations. Cijfers over Wonen en Bouwen 2016; Ministerie BZK: The Hague, The Netherlands, 2016.

- Buys, A.; Reijden, H.; Van der Hagen, L. Rapportage Raming Woningbehoefte Metropoolregio Amsterdam 2017–2015; RIGO: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Municipality of Amsterdam. Circulair Innovatie Programma; Municipality Amsterdam: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Municipality of Amsterdam and Circle Economy. Amsterdam Circulair—Evaluatie en Handelingsperspectieven; Municipality Amsterdam: Amsterdam, The Netherlands, 2018. [Google Scholar]

- C40 Cities Climate Leadership Group and Climate-KIC Circular Cities. Mapping Municipality-Led Circular Economy Case Studies; C40 Cities: London, UK, 2018. [Google Scholar]

- World Health Organization. Circular Economy and Health: Opportunities and Risks; World Health Organization Regional Office for Europe: Copenhagen, Denmark, 2018; ISBN 9789289053341. [Google Scholar]

- Girardet, H. Regenerative Cities. In Green Economy Reader: Lectures in Ecological Economics and Sustainability; Shmelev, S., Ed.; Springer: Cham, Switzerland, 2017; pp. 183–204. [Google Scholar]

- Barles, S. Comprendre et maîtriser le métabolisme urbain et l’empreinte environnementale des villes. In Responsabilité et Environnement; Annales des Mines: Paris, France, 2008; Volume 52, pp. 21–26. [Google Scholar]

- Kennedy, C.; Pincetl, S.; Bunje, P. The Study of Urban Metabolism and Its Applications to Urban Planning and Design. Environ. Pollut. 2011, 159, 1965–1973. [Google Scholar] [CrossRef]

- Allen, A.; Broto, V.C.; Rapoport, E. Interdisciplinary Perspectives on Urban Metabolism: A review of the literature. J. Ind. Ecol. 2012, 16, 851–861. [Google Scholar]

- Van der Leer, J.; van Timmeren, A.; Wandl, A. Social-Ecological-Technical systems in urban planning for a circular economy: An opportunity for horizontal integration. Archit. Sci. Rev. 2018, 61, 298–304. [Google Scholar] [CrossRef]

- Minx, J.C.; Baiocchi, G. Time use and sustainability. In Handbook for Input–Output Economics in Industrial Ecology; Suh, S., Ed.; Springer: Dordrecht, The Netherland, 2009; pp. 819–846. [Google Scholar]

- Geldermans, B.; Wandl, A.; Steenmeijer, M.; Furlan, C.; Streefland, T.; Formato, E.; Cerreta, M.; Amenta, L.; Varju, V.; Inglese, P.; et al. REPAiR: REsource Management in Peri-urban AReas: Going Beyond Urban Metabolism: D3.3 Process Model for the Two Pilot Cases: Amsterdam, The Netherlands & Naples, Italy; Revised Version 30 April 2019; Delft University of Technology: Delft, The Netherlands, 2019. [Google Scholar]

- Association of Interior Specialists. Best Practice Guide Installation of Partitioning; AIS: Solihull, UK, 2013. [Google Scholar]

- Holicky, M.; Materna, A.; Sedlacek, G.; Arteaga, A.; Sanpaolesi, L.; Vrouwenvelder, T.; Kovse, I.; Gulvanessian, H. Implementation of Eurocodes, Handbook 3 Action effects for Buildings; Leonardo da Vinci Pilot Project CZ/02/B/F/PP-134007; University of Technology Aachen: Aachen, Germany, 2005. [Google Scholar]

- European Patent Office. Method and System for Invisibly Arranging Cabling in a Room; Infill Systems B.V.: Delft, The Netherlands, 2016. [Google Scholar]

- Post, J.M. Van ‘Aap, Noot, Mies, Huis’ Naar ‘Zon, Wind en Water’; Technische Universiteit Eindhoven: Eindhoven, The Netherland, 2010. [Google Scholar]

- Koskela, L. An Exploration Towards a Production Theory and Its Application to Construction. Ph.D. Thesis, VTT Building Technology, Helsinki, Finland, 2010. [Google Scholar]

- Durmisevic, E.; Linthorst, P. Industrialization of housing (Building with systems). In Proceedings of the Continuous Customization in Housing, Tokyo, Japan, 16–18 October 2000. [Google Scholar]

- Vreedenburgh, E.; Mooij, M.; van Randen, A. Leidingsystematiek in Relatie tot Flexibiliteit, Verslag IOP-Onderzoek ‘Leidingen’; Werkgroep OBOM, Technische Universiteit Delft: Delft, The Netherlands, 1990. [Google Scholar]

- Schneider, T.; Till, T. Flexible housing: Opportunities and limits. Archit. Res. Q. 2005, 9, 157–166. [Google Scholar] [CrossRef]

- Smith, R.E. Prefab Architecture, A Guide to Modular Design and Construction; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Habraken, N.J. The Control of Complexity. Places 1987, 4, 3–15. [Google Scholar]

- European Commission. BIO by Deloitte Resource efficient use of mixed wastes. In Case Study Gypsum-to-Gypsum, from Production to Recycling, A Circular Economy for the European Gypsum Industry with the Demolition and Recycling Industry; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Ministry of Infrastructure and Water. LAP3, Deel B: Afvalbeheer en Overbrenging; DGMI: The Hague, The Netherlands, 2017.

- Sávoly, A.; Dawn, E. Gypsum Wallboard Chemical Additives; GEO Specialty Chemicals: Southhampton, UK, 2015. [Google Scholar]

- Mueller, M.; Hampel, C. Influence of the Gypsum Raw Material on the Performance of PCE-based HRWRA during Gypsum Board Production. In Proceedings of the Global Gypsum Conference, Paris, France, 25–26 October 2010. [Google Scholar]

- Zeeg, E.; Geldermans, B. (Siniat, Delfzijl, The Netherlands). Personal communication, 2019.

- Van der Veen, H.C.J. Het Effect van Milieubeleid op Locatiebeslissingen van Bedrijven. Ph.D. Thesis, University of Groningen, Groningen, The Netherland, 2004. [Google Scholar]

- Bodemrichtlijn Rijksoverheid. Bouwstoffase Isolatiemateriaal. Available online: https://www.bodemrichtlijn.nl/Bibliotheek/bouwstoffen-en-afvalstoffen/isolatiemateriaal/bouwstoffase-isolatiemateriaal (accessed on 8 May 2019).

- Lunn, R.; Jahnke, G.; Spencer, D.; Jameson, C.W.; Garner, S.; Atwood, S.; Carter, G.; Ewens, A.; Greenwood, D.; Ratcliffe, J.; et al. Final Report on Carcinogens Background Document for Glass Wool Fibers; National Toxicology Program: Durham, NC, USA, 2009.

- Cartwright, G. Is It Time to Legislate the Mineral Wool Industry More Tightly at EU Level? EU Today Ltd.: London, UK, 2018. [Google Scholar]

- Environmental Protection Agency. Fact Sheet Fine Mineral Fibers; EPA: Washington, DC, USA, 2016.

- National Toxicology Program. Certain Glass Wool Fibers (Inhalable)—Report on Carcinogens Status; National Institute of Environmental Health Sciences: Durham, NC, USA, 2011.

- Ministry of Infrastructure and Environment. Background Document Sector Plan 84: Other Recyclable Monoflows (National Waste Management Plan); Update 28 November 2017; Ministry of Infrastructure and Environment: The Hague, The Netherlands, 2017.

- Väntsi, O.; Kärki, T. Mineral wool waste in Europe: A review of mineral wool waste quantity, quality, and current recycling methods. J. Mater. Cycles Waste Manag. 2013, 16, 62–72. [Google Scholar] [CrossRef]

- Vercalsteren, A.; van der Linden, A.; Gillabel, J. Onderzoek over het Sluiten van de Materiaalketen van Minerale wol; Steunpunt Duurzaam Materialen Beheer: Heverlee, Belgium, 2014. [Google Scholar]

- Lopez Hurtado, P.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Schmidt, A.; Clausen, A.U.; Astrup Jensen, A.; Kamstrup, O. A Comparative Life Cycle Assessment of Building Insulation Products made of Stone Wool, Paper Wool and Flax: Part 1: Background, Goal and Scope, Life Cycle Inventory, Impact Assessment and Interpretation. Int. J. Life Cycle Assess. 2004, 9, 53–66. [Google Scholar] [CrossRef]

- Silvestre, J.D.; de Brito, J.; Pinheiro, M.D. Life-cycle assessment of thermal insulation materials for external walls of buildings. In Proceedings of the International Conference of Constructions, Innsbruck, Austria, 27–28 May 2011. [Google Scholar]

- Everuse. Circulaire Isolatieplaat. Available online: https://www.everuse.com/everuse-circulaire-isolatieplaat (accessed on 20 May 2019).

- C2C Certified Products Registry. Available online: https://www.c2ccertified.org/products/registry (accessed on 20 April 2019).

- Material Passport Platform (Prototype). Available online: https://passports.bamb2020.eu/#!/products (accessed on 20 April 2019).

- Irle, M.; Barbu, M.C. Wood-Based Panel Technology. In Wood-Based Panels, An Introduction for Specialists; Thoemen, H., Irle, M., Sernek, M., Eds.; Brunel University Press: London, UK, 2010. [Google Scholar]

- Ross, R.J. Wood Handbook—Wood as an Engineering Material; General Technical Report; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010.

- Carus, M.; Dammer, L. Food or Non-Food: Which Agricultural Feedstocks Are Best for Industrial Uses? Ind. Biotechnol. 2013, 9. [Google Scholar] [CrossRef]

- Gerbinet, S.; Briard, V.; Pigeolet, J.P.; Hampson, C.; Belboom, S.; Groslambert, S.; Léonard, A. Use of a Bio-Based Binder in the Building Sector; University of Liège: Liège, Belgium, 2017. [Google Scholar]

- Saravia Cortez, A.M.; Herva, M.; Garcia-Dieguez, C.; Roca, E. Assessing environmental sustainability of particleboard production process by ecological footprint. J. Clean. Prod. 2013, 52, 301–308. [Google Scholar] [CrossRef]

- Noble Environmental Technologies. ECOR. Available online: https://ecorglobal.com (accessed on 3 April and 24 May 2019).

- Noble Environmental Technologies. ECOR Core Catalog Guide; Noble Environmental Technologies: San Diego, CA, USA, 2011. [Google Scholar]

- Pauli, G. The Blue Economy; Academic Foundation: New Delhi, India, 2015. [Google Scholar]

- Hahs, R. System Reset—Part 3: Flame Retardants from Food. Available online: https://www.thinkbiomimicry.com/2017/03/02/systemreset-part-3-flame-retardants-from-food/ (accessed on 2 March 2019).

- Nilsson, M. (Biomimetic Technology Ltd., Toronto, ON, Canada). Personal communication, 2019.

- Wouters, M.; Burghoorn, M.; Ingenhut, B.; Timmer, K.; Rentrop, C.; Bots, T.; Oosterhuis, G.; Fischer, H. Tuneable adhesion through novel binder technologies. Progress Org. Coat. 2011, 72, 152–158. [Google Scholar] [CrossRef]

- Tichelaar, M.P.; Koning, C.E.; Udding, J.H.; Westerhof, W.; Reutelingsperger, C. Methods for Producing Textile Products, Products Obtainable Therefrom and Method to Reclaim the Product. US Patent US2017/0152417A1, 1 June 2017. [Google Scholar]

- Evonik. Calostat High Performance Insulation Material; Evonik: Hanau, Germany, 2018. [Google Scholar]

- Leefmilieu Brussel. Thermische en Akoestische Isolatie—Infofiche Ecoconstructie voor Particulieren MAT14; Brussels Instituut voor Milieubeheer: Brussels, Belgium, 2009. [Google Scholar]

- Van Dam, J.E.G.; van den Oever, M.J.A. Catalogus Biobased Bouwmaterialen; Wageningen UR—Food & Biobased Research—118: Wageningen, The Netherlands, 2012. [Google Scholar]

- McIntyre, G. Presentation: Ecovative, We Grow Materials; World Materials Forum: Nancy, France, 2016. [Google Scholar]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Bayer, E.; McIntyre, G. An evaluation study of mycelium-based acoustic absorbers grown on agricultural by-product substrates. Ind. Crops Prod. 2013, 51, 480–485. [Google Scholar] [CrossRef]

- Jones, M.P.; Wang, C.H.; Bhat, T.; Moinuddin KJohn, S. Thermal degradation and fire reaction properties of mycelium composites. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Ecovative. MycoComposite Specifications Sheet. Available online: https://s3-us-west-2.amazonaws.com/ecovative-website-production/documents/MycoComposite029.pdf (accessed on 23 May 2019).

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Critical Concrete. Producing Mycelium Insulation. Available online: https://criticalconcrete.com/category/summer-school-2018/ (accessed on 24 May 2019).

- Eurostat. NACE Rev. 2—Statistical Classification of Economic Activities in the European Community; Eurostat: Brussels, Belgium, 2008; ISBN 978-92-79-04741-1. [Google Scholar]

- Duijvestein, P.; Roemers, G. De Metropoolregio Amsterdam als circulaire grondstoffen hub, Database bouw-en sloopafval in de MRA; Metabolic and D2R New Economy: Amsterdam, The Netherlands; The Hague, The Netherlands, 2018. [Google Scholar]

- Amenta, L.; van Timmeren, A. Beyond Wastescapes: Towards Circular Landscapes. Addressing the Spatial Dimension of Circularity through the Regeneration of Wastescapes. Sustainability 2018, 10, 4740. [Google Scholar] [CrossRef]

- British Gypsum. White-Book CO2 Technical Performance, Updated Version; British Gyspum: Loughborough, UK, 2019. [Google Scholar]

- Siniat. LaDura Premium Technical Specifications; Etex Building Performance B.V.: Delfzijl, The Netherlands, 2015. [Google Scholar]