Torque Characteristics Analysis of a Magnetorheological Brake with Double Brake Disc

Abstract

:1. Introduction

2. Design of Proposed MR Brake

2.1. Working Principle and Structural Design

2.2. Magnetic Circuit Analysis of the Proposed MR Brake

2.3. Mathematical Model of Braking Torque of the Proposed MR Brake

3. Finite Element Simulation of the Proposed MR Brake

4. Test and Analysis of Braking Torque Performance Characteristics

4.1. Prototype of Proposed MR Brake and Test Rig Setup

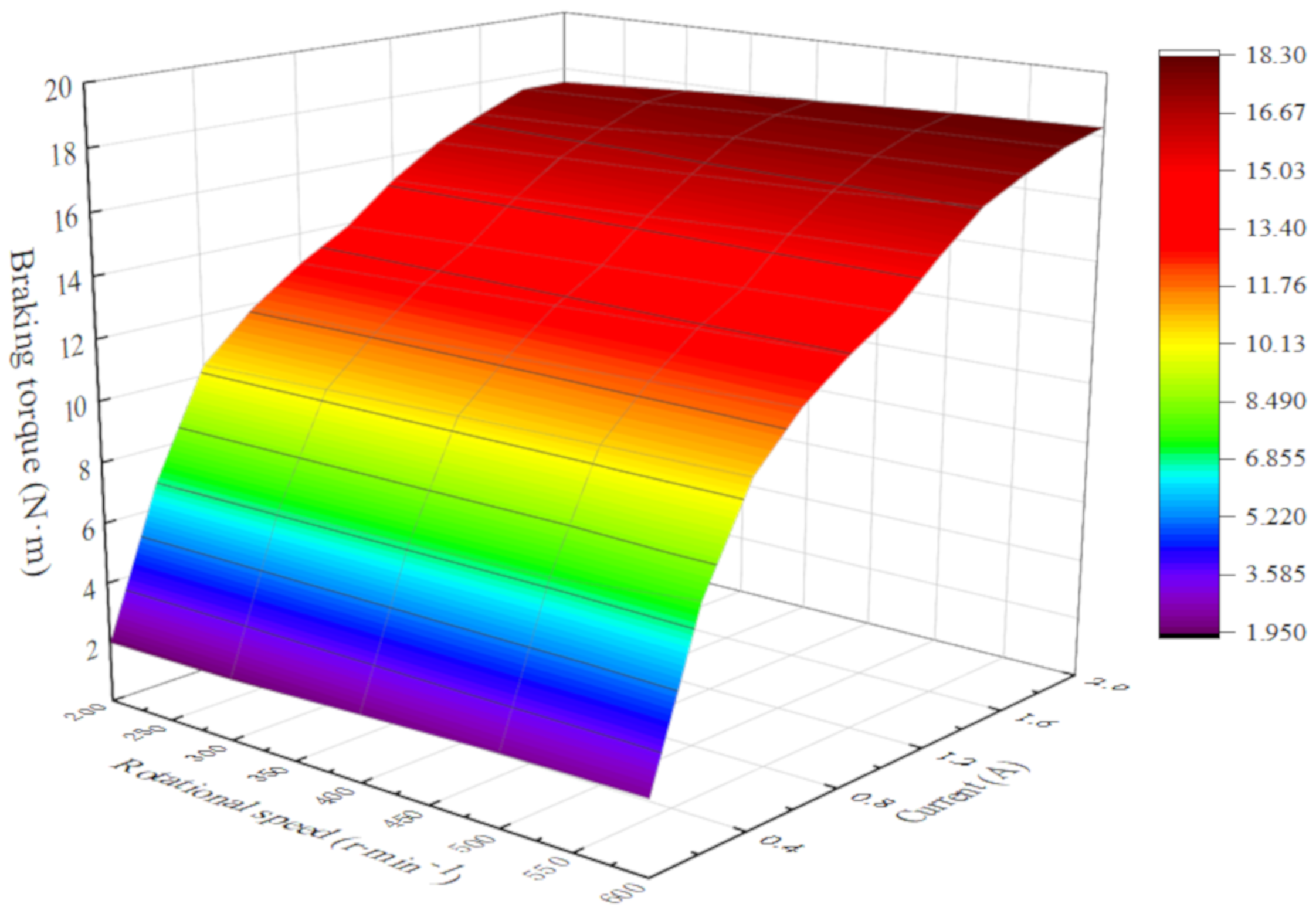

4.2. Experimental Analysis of Braking Torque Performance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, J.S.; Paul, P.S.; Raghunathan, G.; Alex, D.G. A review of challenges and solutions in the preparation and use of magnetorheological fluids. Int. J. Mech. Mater. Eng. 2019, 14, 1–18. [Google Scholar] [CrossRef]

- Jolly, M.R.; Bender, J.W.; Carlson, J.D. Properties and applications of commercial magnetorheological fluids. J. Intel. Mater. Syst. Struct. 1999, 10, 5–13. [Google Scholar] [CrossRef]

- Heo, Y.H.; Choi, D.; Yun, I.; Kim, S. A tiny haptic knob based on magnetorheological fluids. Appl. Sci. 2020, 10, 5118–5129. [Google Scholar] [CrossRef]

- Li, D.D.; Keogh, D.F.; Huang, K.; Chan, Q.N.; Yuen, A.C.Y.; Menictas, C.; Timchenko, V.; Yeoh, G.H. Modeling the response of magnetorheological fluid dampers under seismic conditions. Appl. Sci. 2019, 9, 4189–4204. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D.; Shi, X.X.; Liu, S.G.; Wang, F.H. Theoretical and experimental investigation on wave propagation in the periodic impedance layered structure modulated by magnetorheological fluid. J. Intell. Mater. Syst. Struct. 2020, 31, 882–896. [Google Scholar] [CrossRef]

- Kordonsky, W.I. Magnetorheological effect as a base of new devices and technologies. J. Magn. Magn. Mater. 1993, 122, 395–398. [Google Scholar] [CrossRef]

- Blake, J.; Gurocak, H.B. Haptic glove with MR brakes for virtual reality. IEEE/ASME Trans. Mech. 2009, 14, 606–615. [Google Scholar] [CrossRef]

- Qin, H.; Song, A.; Mo, Y. A hybrid actuator with hollowed multi-drum magnetorheological brake and direct-current micromotor for hysteresis compensation. J. Intel. Mat. Syst. Struct. 2019, 30, 1–12. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, J.; Zhong, F.; Yu, L. Performance evaluation of an improved radial magnetorheological valve and its application in the valve controlled cylinder system. Smart Mater. Struct. 2019, 28, 047003. [Google Scholar] [CrossRef]

- Keshav, M.; Bhagyarajan, A.; Chandramohan, S. Regression models for magnetic flux density using DoE techniques and geometric optimization of MR valve. Smart Mater. Struct. 2019, 28, 075008. [Google Scholar] [CrossRef]

- Kim, B.; Yoon, D.; Kim, G.; Choi, S.; Tan, A.S.; Sattel, T. Design of a novel magnetorheological damper adaptable to low and high stroke velocity of vehicle suspension system. Appl. Sci. 2020, 10, 5586–5602. [Google Scholar] [CrossRef]

- Bai, X.; Hu, W.; Wereley, N.M. Magnetorheological damper utilizing an inner bypass for ground vehicle suspensions. IEEE T. Magn. 2013, 4, 3422–3425. [Google Scholar] [CrossRef]

- Diep, B.T.; Nguyen, N.D.; Tran, T.T.; Nguyen, Q.H. Design and experimental validation of a 3-DOF force feedback system featuring spherical manipulator and magnetorheological actuators. Actuators 2020, 9, 19–39. [Google Scholar] [CrossRef] [Green Version]

- Qin, H.; Song, A.; Mo, Y. Performance evaluation of a hollowed multi-drum magnetorheological brake based on finite element analysis considering hollow casing radius. IEEE Access 2019, 7, 96070–96078. [Google Scholar] [CrossRef]

- Rizzo, R.; Musolino, A.; Bucchi, F.; Forte, P.; Frendo, F. Magnetic FEM design and experimental validation of an innovative fail-safe magnetorheological clutch excited by permanent magnets. IEEE Trans. Energy Conver. 2014, 29, 628–640. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Liu, Y.; Chen, J.; Li, Y.; Xu, L.; Peng, C.; Chen, S.; Liu, J.; Xu, C.; Cheng, G.; et al. A multi-mode rehabilitation robot with magnetorheological actuators based on human motion intention estimation. IEEE Trans. Neur. Sys. Reh. 2019, 27, 2216–2228. [Google Scholar] [CrossRef]

- Avraam, M.; Horodinca, M.; Romanescu, I.; Preumont, A. Computer controlled rotational MR-brake for wrist rehabilitation device. J. Intel. Mater. Syst. Struct. 2010, 21, 1543–1557. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Pang, J.; Wang, Z.; Zi, B. Development and control of an MR brake- based passive force feedback data glove. IEEE Access 2019, 7, 172477–172488. [Google Scholar] [CrossRef]

- Wang, N.; Liu, X.; Królczyk, G.; Li, Z.; Li, W. Effect of temperature on the transmission characteristics of high-torque magnetorheological brakes. Smart Mater. Struct. 2019, 28, 057002. [Google Scholar] [CrossRef]

- Shiao, Y.; Nguyen, Q. Torque enhancement for a new magnetorheological brake. Procedia Eng. 2014, 76, 12–23. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.M.; Hou, Y.F.; Tian, Z.Z. A novel high-torque magnetorheological brake with a water cooling method for heat dissipation. Smart mater. Struct. 2013, 22, 025019. [Google Scholar] [CrossRef]

- Wang, N.; Liu, X.; Sun, S.; Królczyk, G.; Li, Z.; Li, W. Microscopic characteristics of magnetorheological fluids subjected to magnetic fields. J. Magn. Magn. Mater. 2020, 501, 166443. [Google Scholar] [CrossRef]

- Patel, S.R.; Patel, D.M.; Upadhyay, R.V. Performance enhancement of MR brake using flake-shaped iron-particle–based magnetorheological fluid. J. Test. Eval. 2020, 48, 2396–2411. [Google Scholar] [CrossRef]

- Nam, T.H.; Ahn, K.K. A new structure of a magnetorheological brake with the waveform boundary of a rotary disk. Smart Mater. Struct. 2009, 18, 115029. [Google Scholar] [CrossRef]

- Qin, H.; Song, A.; Zeng, X.; Hu, S. Design and evaluation of a small-scale multi-drum magnetorheological brake. J. Intel. Mat. Syst. Struct. 2018, 29, 2607–2618. [Google Scholar] [CrossRef]

- Liu, B.; Li, W.; Kosasih, P.B.; Zhang, X. Development of an MR-brake-based haptic device. Smart Mater. Struct. 2006, 15, 1960. [Google Scholar] [CrossRef]

- Wang, S.; Song, W.; Li, H.; Wang, N. Modeling and multi-field simulation analysis of a multi-cylindrical magneto-rheological brake. Int. J. Appl. Electrom. Mech. 2018, 57, 399–414. [Google Scholar] [CrossRef]

- Hu, G.; Wu, L.; Li, L.; Yu, L. Performance analysis of rotary magnetorheological brake with multiple fluid flow channels. IEEE Access 2020, 8, 173323–173335. [Google Scholar] [CrossRef]

- Binyet, E.M.; Chang, J. Magnetohydrodynamics modelling of a permanent magnets activated MRF clutch–brake. Microsyst. Technol. 2020, 26, 3451–3457. [Google Scholar] [CrossRef]

- Mousavi, S.H.; Sayyaadi, H. Optimization and testing of a new prototype hybrid MR brake with arc form surface as a prosthetic knee. IEEE/ASME Trans. Mech. 2018, 23, 1204–1214. [Google Scholar] [CrossRef]

- Shiao, Y.; Ngoc, N.A.; Lai, C. Optimal design of a new multipole bilayer magnetorheological brake. Smart Mater. Struct. 2016, 25, 115015. [Google Scholar] [CrossRef]

- Shiao, Y.; Nguyen, Q.A. Development of a multi-pole magnetorheological brake. Smart Mater. Struct. 2013, 22, 065008. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Cui, H.; Yang, J. A new modified model for the rheological properties of magnetorheological fluids based on different magnetic field. J. Magn. Magn. Mater. 2020, 500, 166377. [Google Scholar] [CrossRef]

- Raul-Alexandru, S.; Daniela, S.R.; Sebastian, M.; Vékás, L. Magnetorheological Fluids Flow Modelling Used in A Magnetorheological Brake Configuration. In Proceedings of the 2019 International Conference on Energy and Environment, Timisoara, Romania, 17–18 October 2019; pp. 403–407. [Google Scholar]

- Bai, X.; Chen, P. On the Hysteresis mechanism of magnetorheological fluids. Front. Mater. 2019, 6, 36–44. [Google Scholar] [CrossRef] [Green Version]

- Bai, X.; Cai, F.; Chen, P. Resistor-capacitor (RC) operator-based hysteresis model for magnetorheological (MR) dampers. Mech. Syst. Signal Pr. 2019, 117, 157–169. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, G.; Wu, L.; Li, L. Torque Characteristics Analysis of a Magnetorheological Brake with Double Brake Disc. Actuators 2021, 10, 23. https://doi.org/10.3390/act10020023

Hu G, Wu L, Li L. Torque Characteristics Analysis of a Magnetorheological Brake with Double Brake Disc. Actuators. 2021; 10(2):23. https://doi.org/10.3390/act10020023

Chicago/Turabian StyleHu, Guoliang, Lifan Wu, and Linsen Li. 2021. "Torque Characteristics Analysis of a Magnetorheological Brake with Double Brake Disc" Actuators 10, no. 2: 23. https://doi.org/10.3390/act10020023

APA StyleHu, G., Wu, L., & Li, L. (2021). Torque Characteristics Analysis of a Magnetorheological Brake with Double Brake Disc. Actuators, 10(2), 23. https://doi.org/10.3390/act10020023