Fabrication of a Polyimide Film Pneumatic Actuator by Molding and Welding Processes

Abstract

:1. Introduction

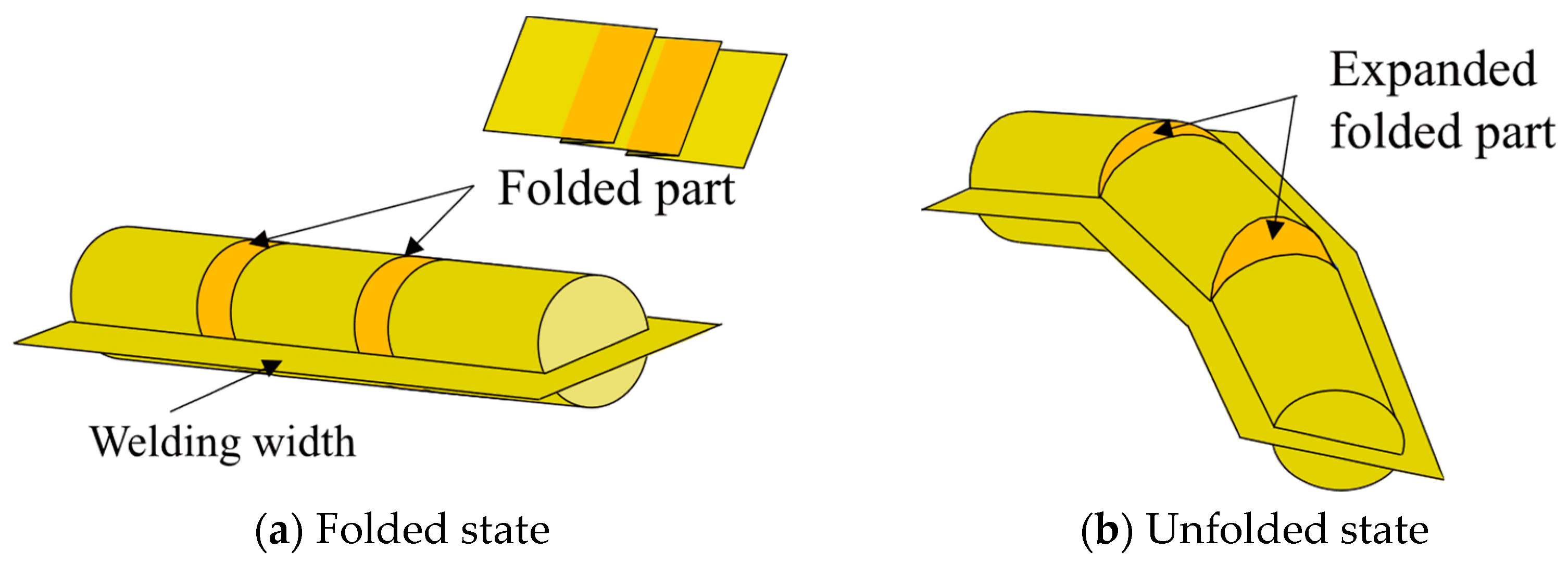

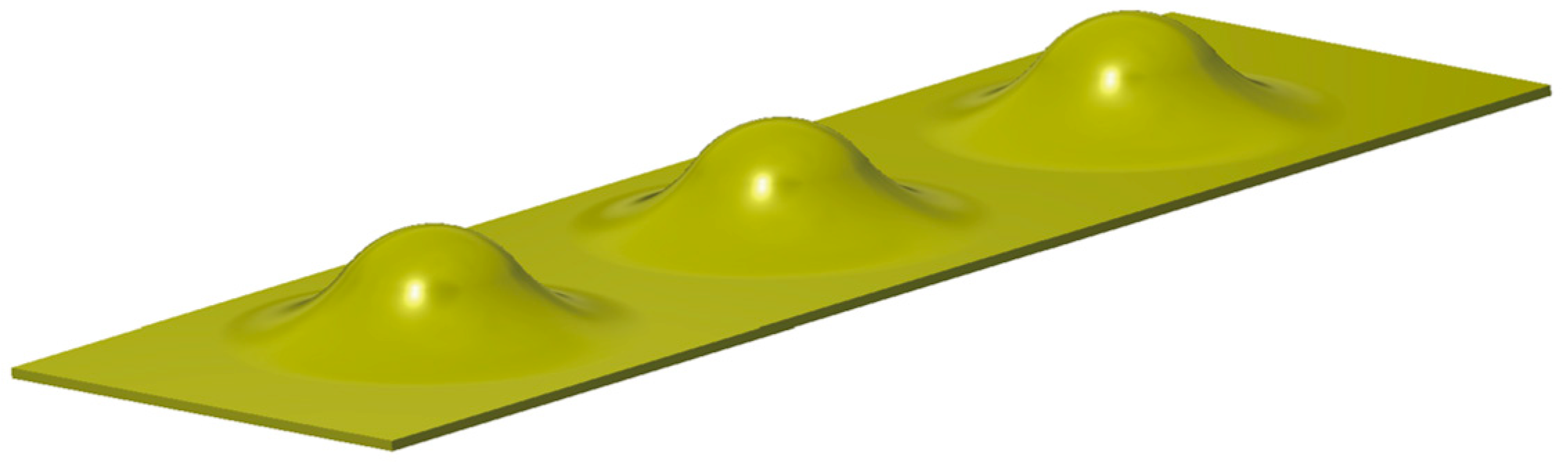

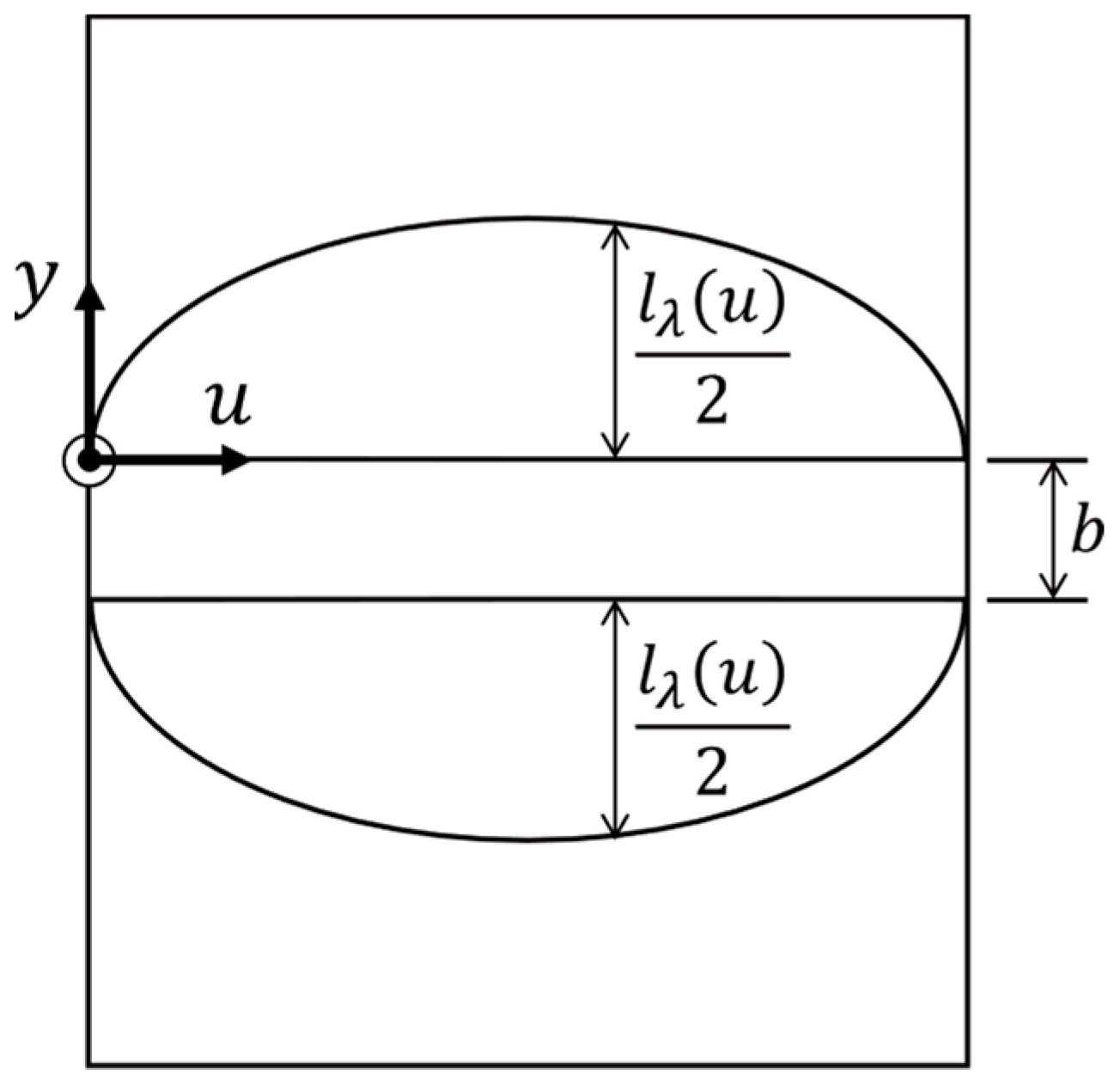

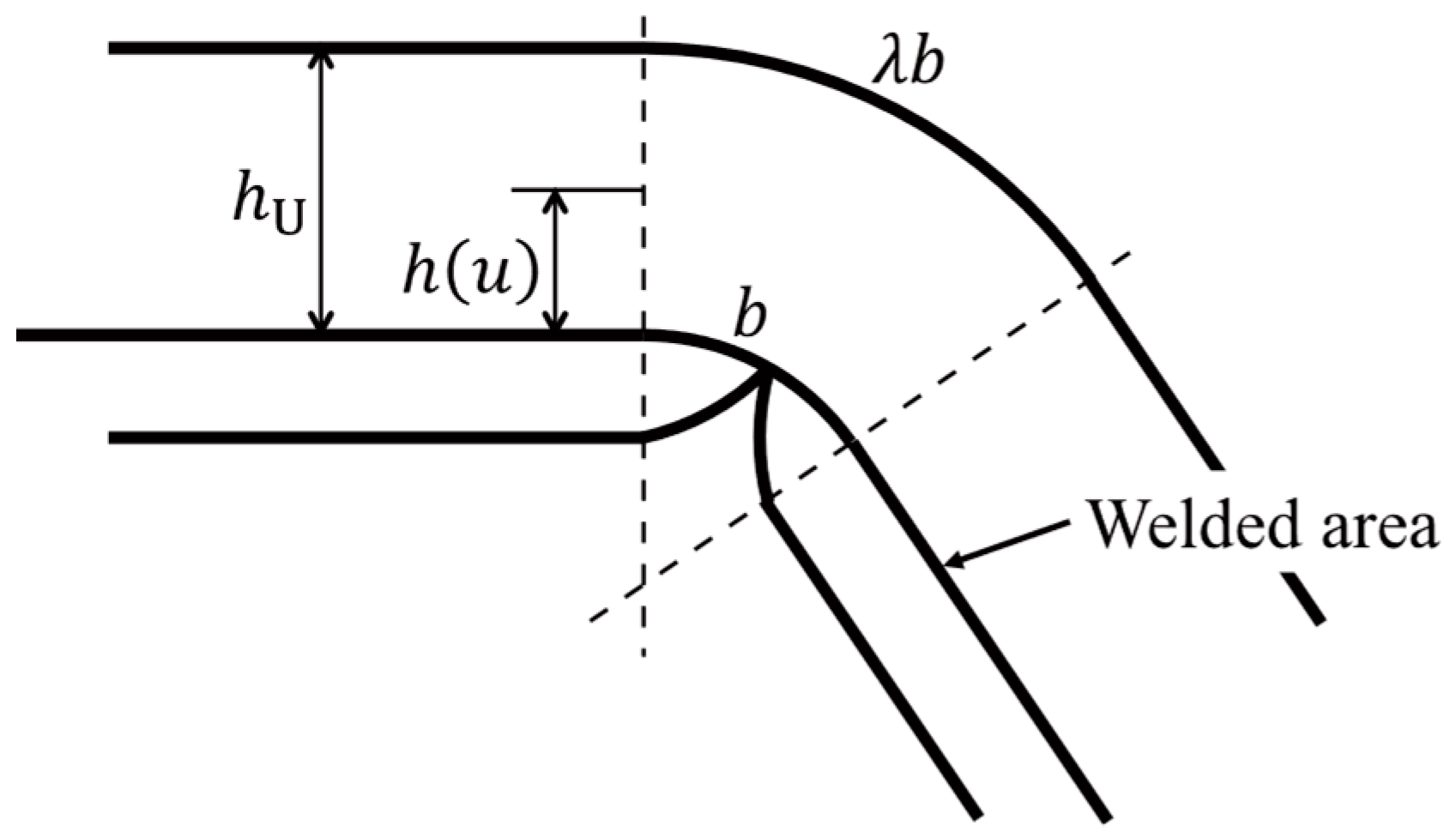

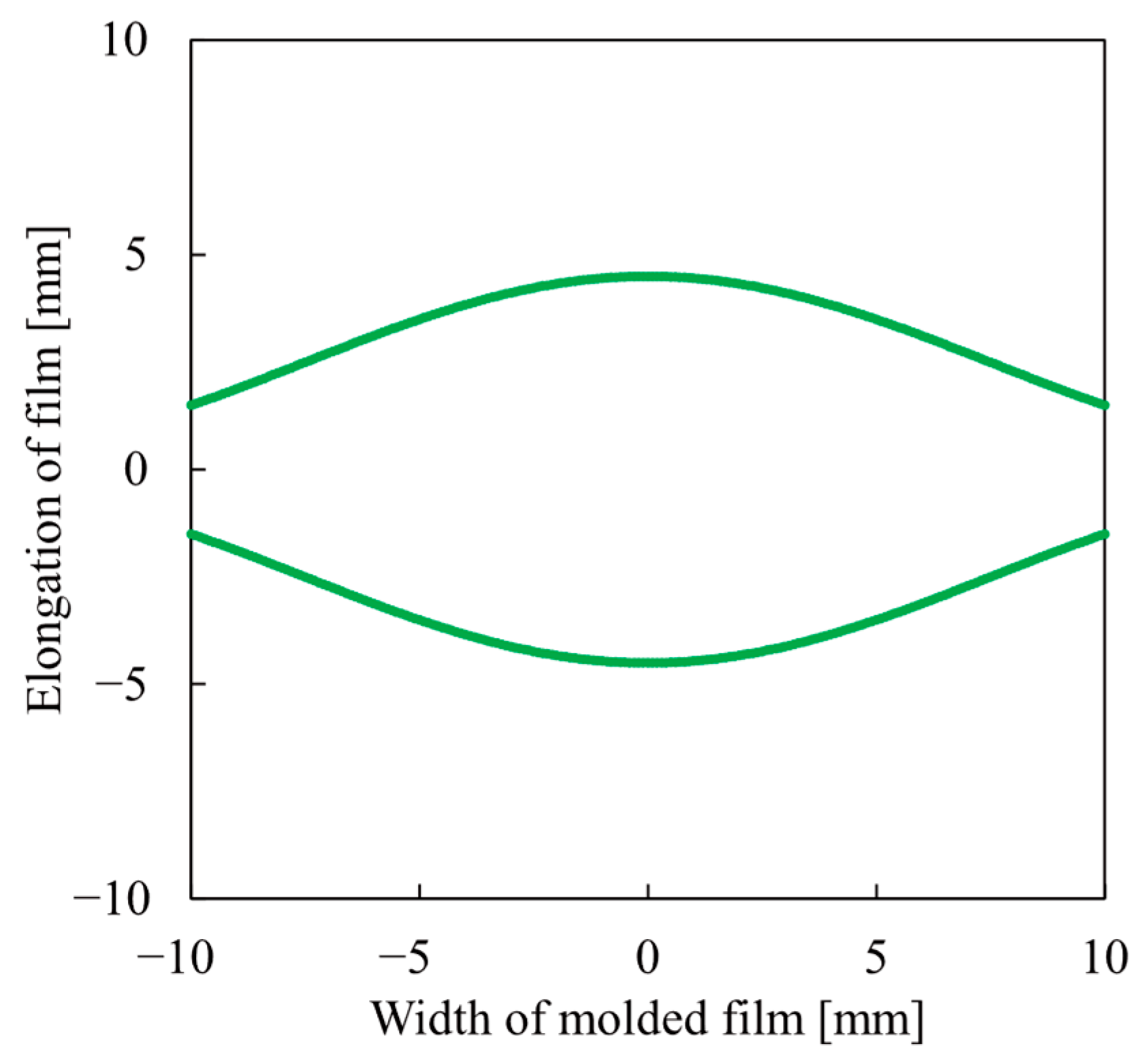

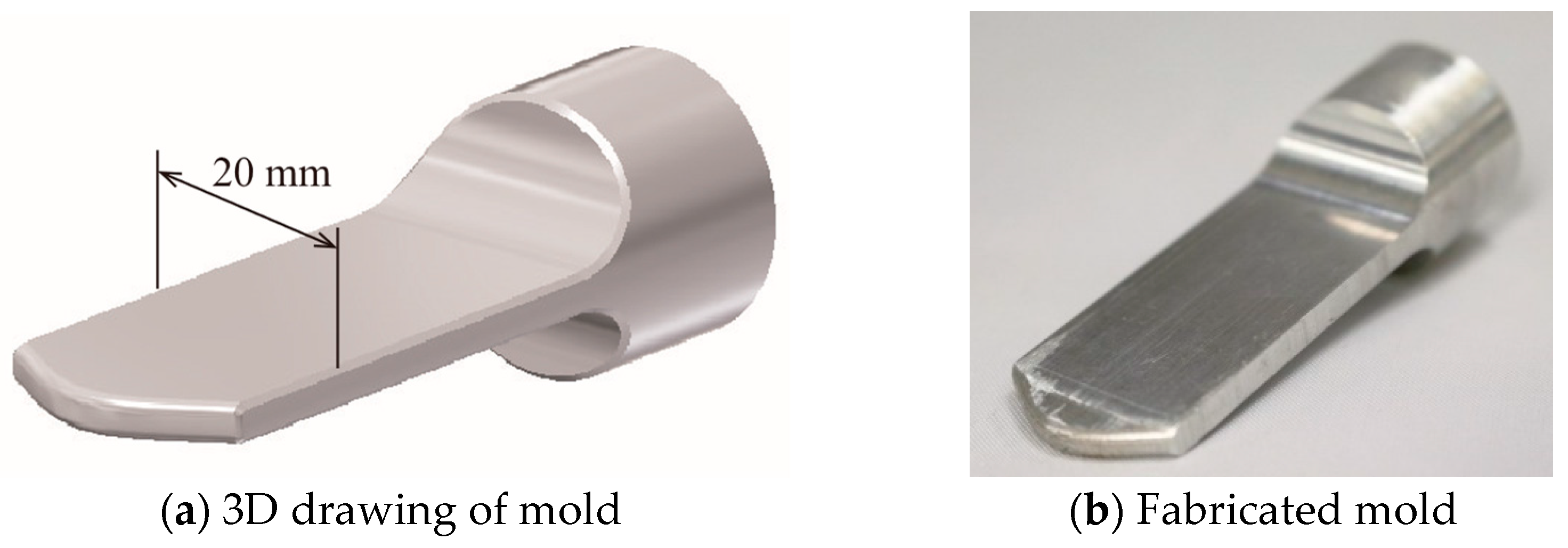

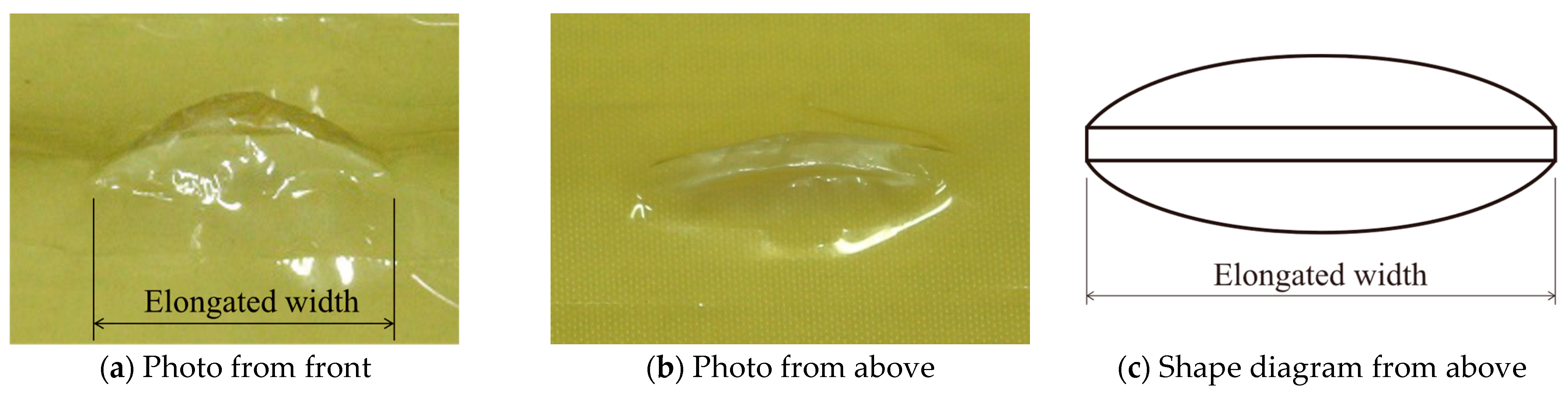

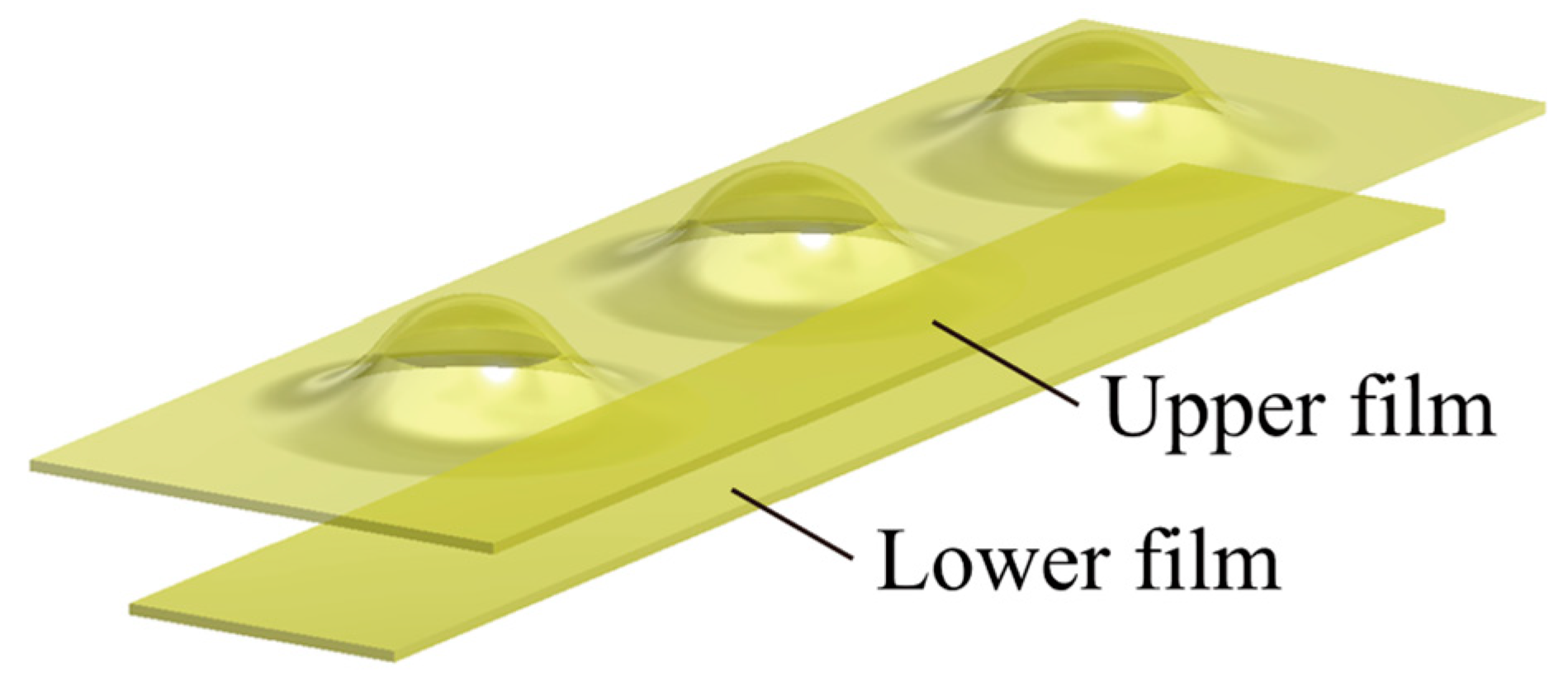

2. Design of Structure

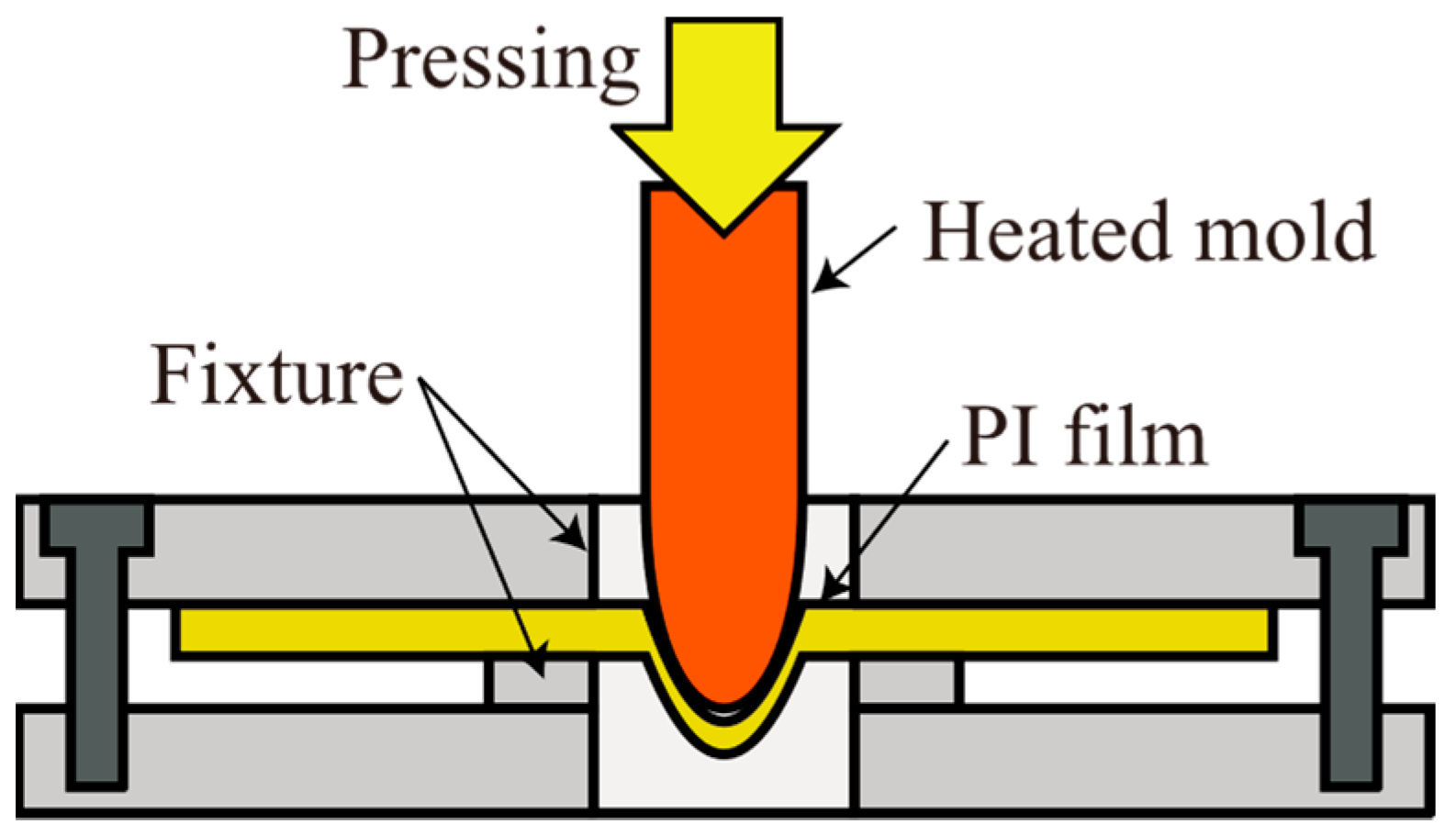

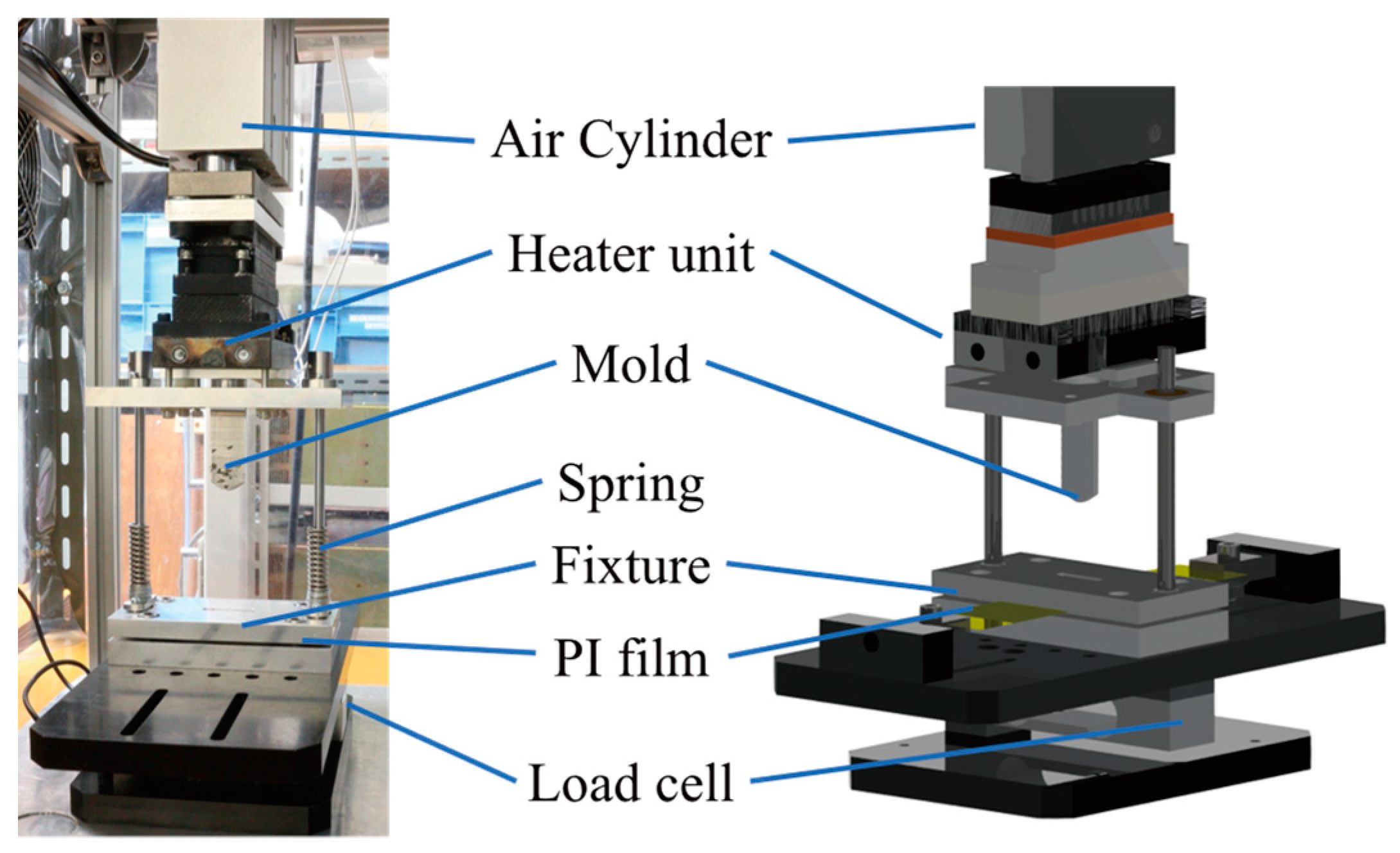

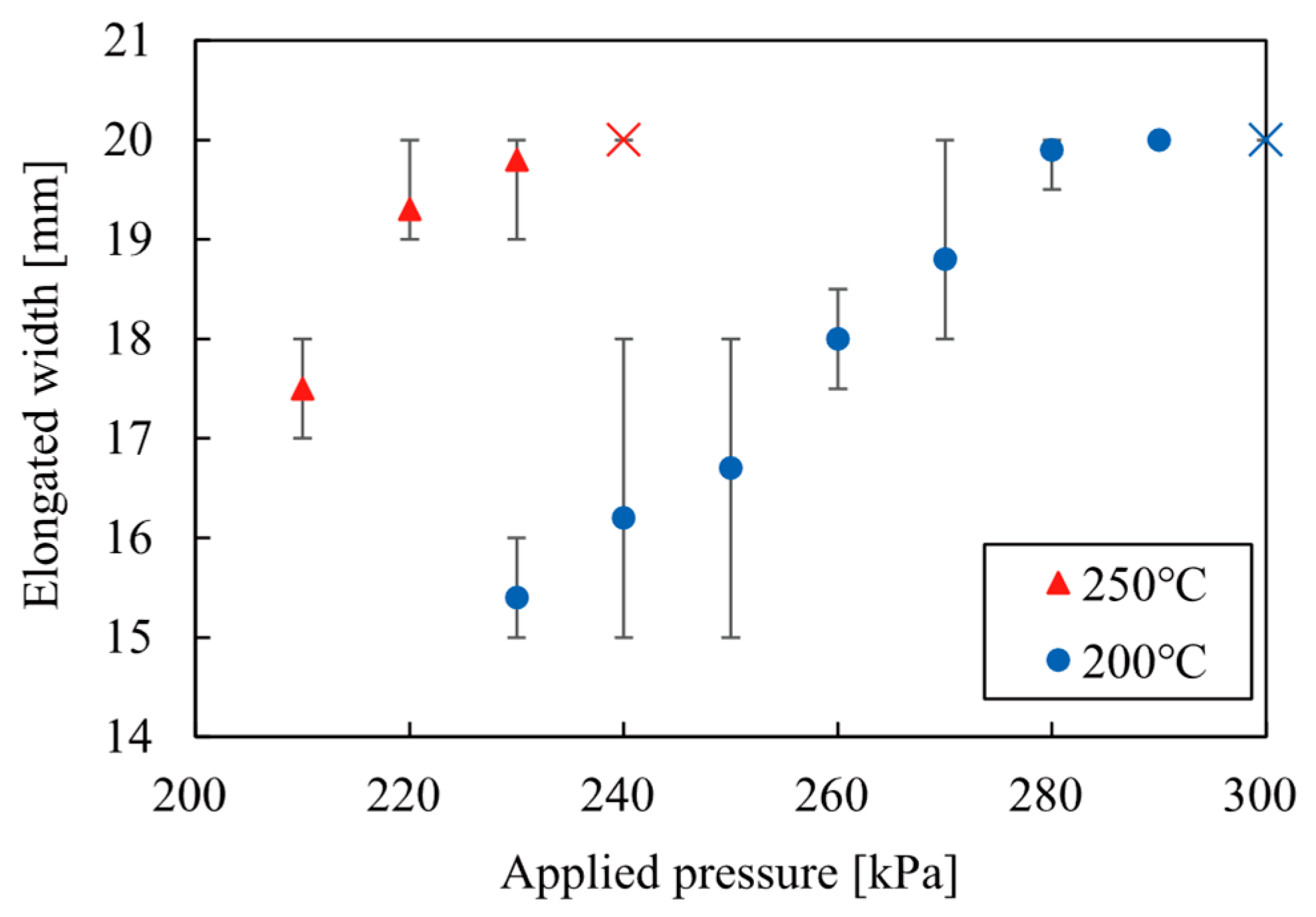

3. Fabrication of Pod Structure

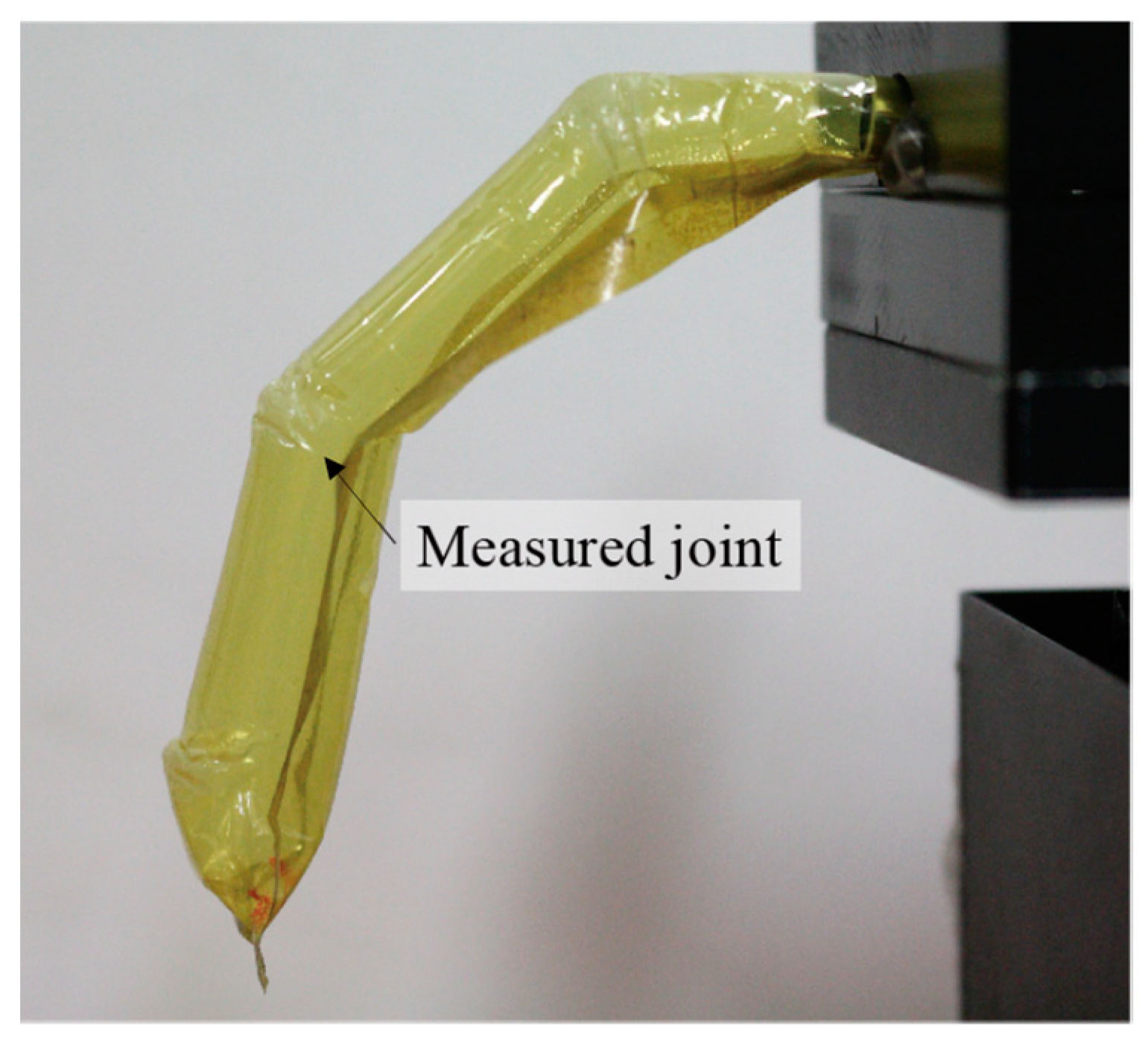

4. Fabrication of Actuator

5. Evaluation of Actuators

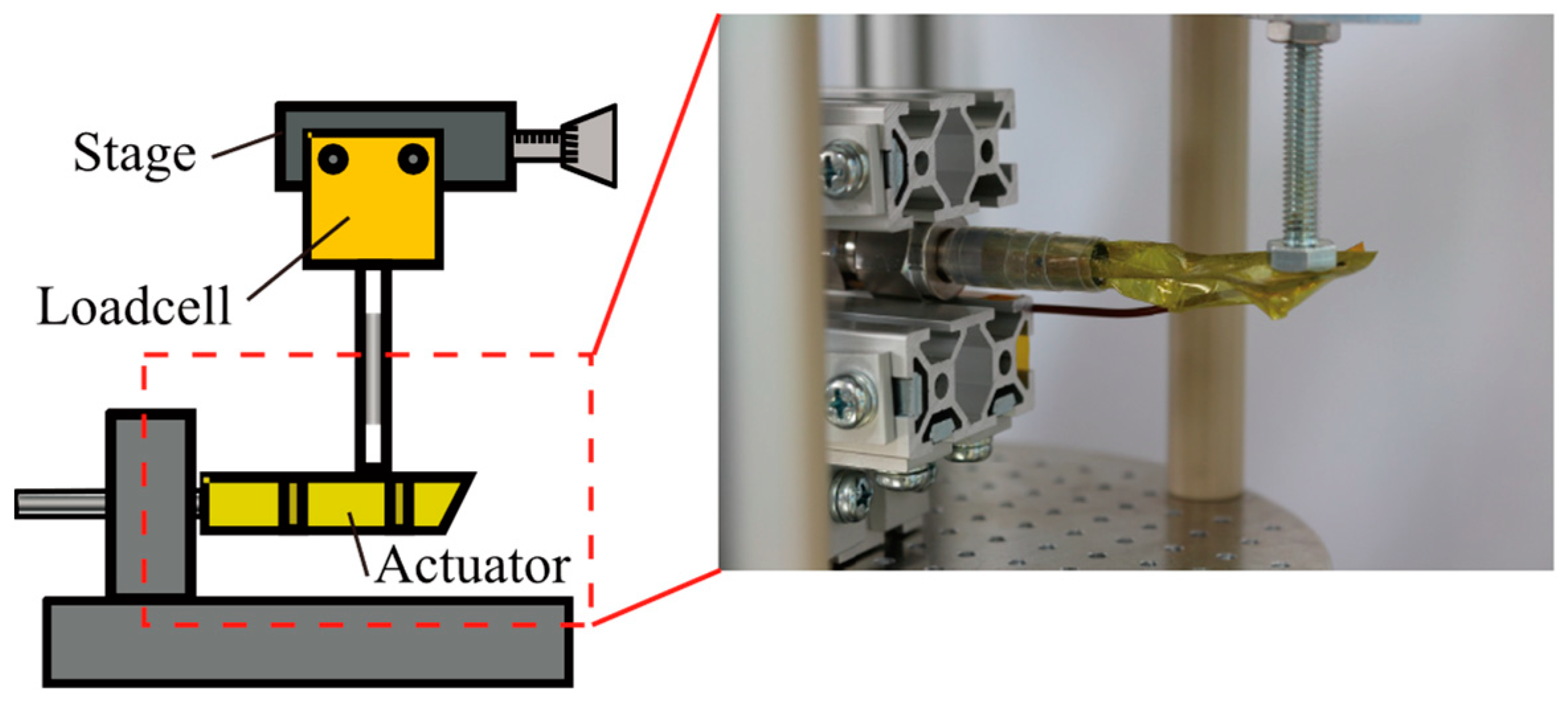

5.1. Output Characteristics

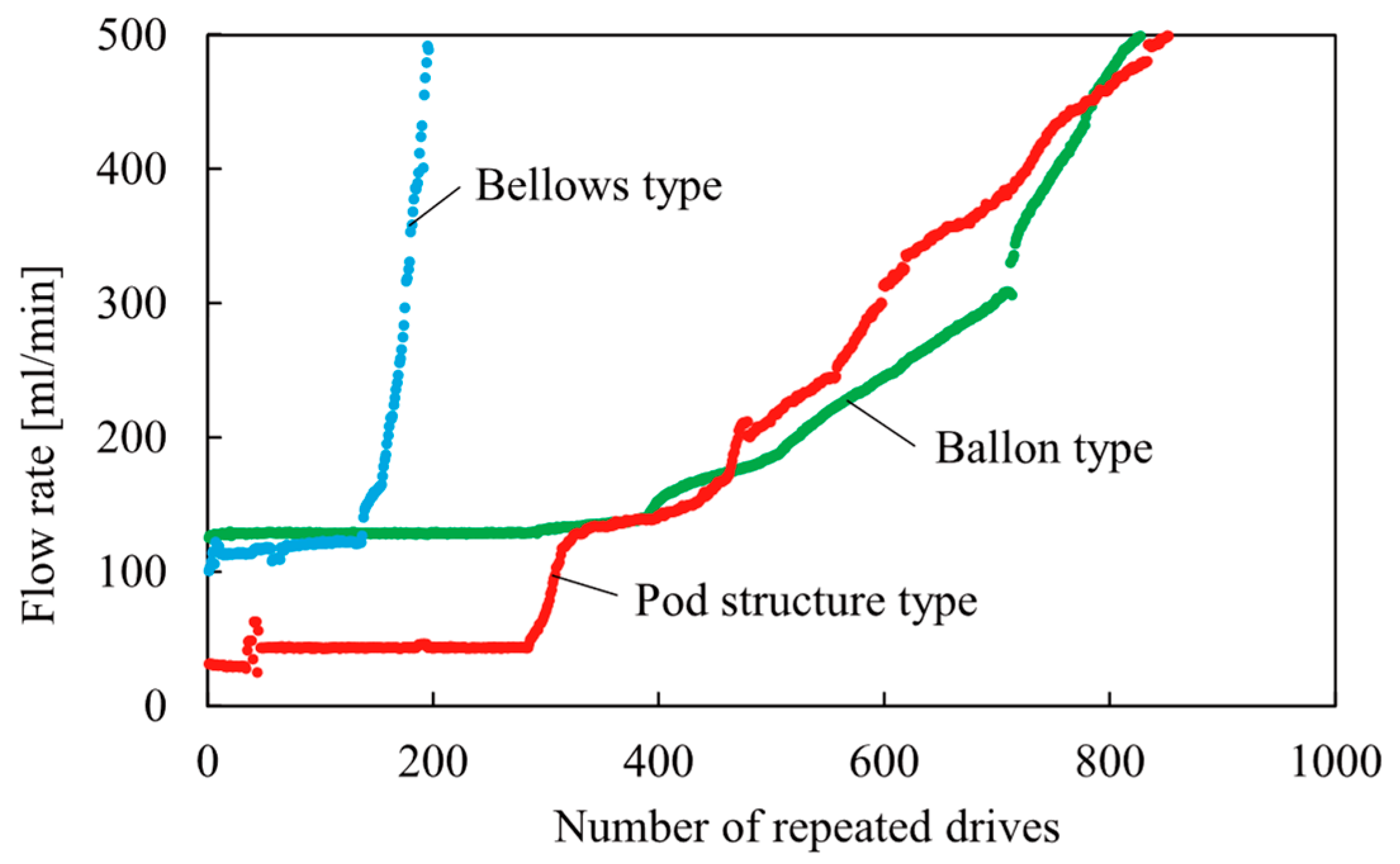

5.2. Repeated Durability

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schmitt, F.; Piccin, O.; Barbé, L.; Bayle, B. Soft Robots Manufacturing: A Review. Front. Robot. AI 2018, 31, 84. [Google Scholar] [CrossRef] [Green Version]

- Walker, J.; Zidek, T.; Harbel, C.; Yoon, S.; Strickland, F.S.; Kumar, S.; Shin, M. Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators. Actuators 2020, 9, 3. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Li, Y.; Elsamadisi, A.; Shepherd, R. Scalable Manufacturing of High Force Wearable Soft Actuators. Extrem. Mech. Lett. 2015, 3, 89–104. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of Robotic Soft Actuators with Programmable Bioinspired Architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef] [PubMed]

- Suzumori, K.; Iikura, S.; Tanaka, H. Development of Flexible Microactuator and Its Applications to Robotic Mechanisms. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 9–11 April 1991. [Google Scholar]

- Sasaki, D.; Noritsugu, T.; Takaiwa, M. Development of High Contractile Pneumatic Artificial Rubber Muscle for Power Assist Device. J. Robot. Mechatron. 2012, 24, 150–157. [Google Scholar] [CrossRef]

- Furukawa, S.; Wakimoto, S.; Kanda, T.; Hagihara, H. A Soft Master-Slave Robot Mimicking Octopus Arm Structure Using Thin Artificial Muscles and Wire Encoders. Actuators 2019, 8, 40. [Google Scholar] [CrossRef] [Green Version]

- Jones, B.; McMahan, W.; Walker, I. Design and Analysis of a Novel Pneumatic Manipulator. Int. Fed. Acc. Mechatron. Syst. 2004, 37, 687–692. [Google Scholar] [CrossRef]

- Hughe, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft Manipulators and Grippers: A Review. Front. Robot. AI 2016, 3, 69. [Google Scholar] [CrossRef] [Green Version]

- Elmoughni, H.M.; Yilmaz, A.F.; Ozlem, K.; Khalilbayli, F.; Cappello, L.; Atalay, A.T.; Ince, G.; Atalay, O. Machine-Knitted Seamless Pneumatic Actuators for Soft Robotics: Design, Fabrication, and Characterization. Actuators 2021, 10, 94. [Google Scholar] [CrossRef]

- Sasaki, D.; Noritsugu, T.; Takaiwa, M. Development of Pneumatic Soft Robot Hand for Human Friendly Robot. J. Robot. Mechatron. 2003, 15, 164–171. [Google Scholar] [CrossRef]

- Wanga, B.; McDaida, A.; Biglari-Abharib, M.; Giffneya, T.; Aw, K. A Bimorph Pneumatic Bending Actuator by Control of Fiber Braiding Angle. Sens. Actuators A Phys. 2017, 257, 173–184. [Google Scholar] [CrossRef]

- Hu, H.; Mutlu, R.; Li, W.; Alici, G. A Structural Optimisation Method for a Soft Pneumatic Actuator. Robotics 2018, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, T.; Shinohara, H. Position and Force Control Based on Mathematical Models of Pneumatic Artificial Muscles Reinforced by Straight Glass Fibers. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007. [Google Scholar]

- Kawamura, S.; Sudani, M.; Deng, M.; Noge, Y.; Wakimoto, S. Modeling and System Integration for a Thin Pneumatic Rubber 3-DOF Actuator. Actuators 2019, 8, 32. [Google Scholar] [CrossRef] [Green Version]

- Shapiro, Y.; Wolf, A.; Gabor, K. Bi-bellows: Pneumatic Bending Actuator. Sens. Actuators A Phys. 2011, 167, 484–494. [Google Scholar] [CrossRef]

- Sudani, M.; Deng, M.; Wakimoto, S. Modelling and Operator-Based Nonlinear Control for a Miniature Pneumatic Bending Rubber Actuator Considering Bellows. Actuators 2018, 7, 26. [Google Scholar] [CrossRef] [Green Version]

- Wakimoto, S.; Suzumori, K.; Ogura, K. Miniature Pneumatic Curling Rubber Actuator Generating Bidirectional Motion with One Air-supply Tube. Adv. Robot. 2011, 25, 1311–1330. [Google Scholar] [CrossRef] [Green Version]

- Daerden, F.; Lefeber, D. Pneumatic Artificial Muscles: Actuators for Robotics and Automation. Eur. J. Mech. Environ. Eng. 2000, 47, 10–21. [Google Scholar]

- Kurumaya, S.; Nabae, H.; Endo, G.; Suzumori, K. Design of Thin McKibben Muscle and Multifilament Structure. Sens. Actuators A Phys. 2017, 261, 66–74. [Google Scholar] [CrossRef]

- Kumar, V.; Ko, U.H.; Zhou, Y.; Hoque, J.; Arya, G.; Varghese, S. Microengineered Materials with Self-Healing Features for Soft Robotics. Adv. Intell. Syst. 2021, 3, 2100005. [Google Scholar] [CrossRef]

- Choi, J.; Lee, S.; Kim, J.; Lee, M.; Kim, K.; In, H. Development of a pneumatically-driven Growing Sling to assist patient transfer. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020. [Google Scholar]

- Troise, M.; Gaidano, M.; Palmieri, P.; Mauro, S. Preliminary Analysis of a Lightweight and Deployable Soft Robot for Space Applications. Appl. Sci. 2021, 11, 2558. [Google Scholar] [CrossRef]

- Takahashi, I.; Fujita, K. Deformation Mechanism Formulation of Differential-Stiffness-Films-Laminated Pouch Motor. In Proceedings of the 2020 IEEE/SICE International Symposium on System Integration (SII), Honolulu, HI, USA, 12–15 January 2020. [Google Scholar]

- Jung, J.C.; Jang, J.H.; Rodrigue, H. Inflatable L-shaped Prisms as Soft Actuators for Soft Exogloves. Eng. Res. Express 2019, 1, 025009. [Google Scholar] [CrossRef]

- Jung, J.C.; Rodrigue, H. Film-based Anisotropic Balloon Inflatable Bending Actuator. J. Mech. Sci. Technol. 2019, 33, 4469–4476. [Google Scholar] [CrossRef]

- Niiyama, R.; Sun, X.; Sung, C.; An, B.; Rus, D.; Kim, S. Pouch Motors: Printable Soft Actuators Integrated with Computational Design. Soft Robot. 2015, 2, 59–70. [Google Scholar] [CrossRef]

- Sato, T.; Saito, N.; Ogasawara, T.; Sato, T. Development of Rubberless Artificial Muscle and Fundamental Characteristics. In Proceedings of the 37th Annual Conference of the IEEE IES, Melbourne, VIC, Australia, 7–10 November 2011. [Google Scholar]

- Maruyama, D.; Kimura, H.; Koseki, M.; Inou, N. Driving Force and Structural Strength Evaluation of a Flexible Mechanical System with a Hydrostatic Skeleton. J. Zhejiang Univ. Sci. A 2010, 11, 255–262. [Google Scholar] [CrossRef]

- Sun, X.; Felton, S.M.; Niiyama, R.; Wood, R.J.; Kim, S. Self-folding and Self-actuating Robots: A Pneumatic Approach. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015. [Google Scholar]

- Nishioka, Y.; Uesu, M.; Tsuboi, H.; Kawamura, S.; Masuda, W.; Yasuda, T.; Yamano, M. Development of a Pneumatic Soft Actuator with Pleated Inflatable Structures. Adv. Robot. 2017, 31, 753–762. [Google Scholar] [CrossRef]

- Yamaguchi, D.; Hanaki, T.; Ishino, Y.; Hara, M.; Takasaki, M.; Mizuno, T. Concept and Prototype of Soft Actuator for Liquid Nitrogen Temperature Environments. J. Robot. Mechatron. 2020, 32, 1019–1026. [Google Scholar] [CrossRef]

- Hanaki, T.; Yamaguchi, D.; Ishino, Y.; Hara, M.; Takasaki, M.; Mizuno, T. Evaluation of Leakage Caused by Bending Cycle of Soft Film Actuator for Ultra-low Temperature. In Proceedings of the Conference on JSPE 2016 Autumn, Ibaraki, Japan, 6–8 September 2016. (In Japanese). [Google Scholar]

| Properties | Symbol | Value |

|---|---|---|

| Width of upper film | 20 mm | |

| Width of lower film | 10 mm | |

| Standard molding width | b | 3 mm |

| Curvature ratio | λ | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamaguchi, D.; Hanaki, T.; Ishino, Y.; Takasaki, M.; Mizuno, T. Fabrication of a Polyimide Film Pneumatic Actuator by Molding and Welding Processes. Actuators 2021, 10, 177. https://doi.org/10.3390/act10080177

Yamaguchi D, Hanaki T, Ishino Y, Takasaki M, Mizuno T. Fabrication of a Polyimide Film Pneumatic Actuator by Molding and Welding Processes. Actuators. 2021; 10(8):177. https://doi.org/10.3390/act10080177

Chicago/Turabian StyleYamaguchi, Daisuke, Tatsuya Hanaki, Yuji Ishino, Masaya Takasaki, and Takeshi Mizuno. 2021. "Fabrication of a Polyimide Film Pneumatic Actuator by Molding and Welding Processes" Actuators 10, no. 8: 177. https://doi.org/10.3390/act10080177

APA StyleYamaguchi, D., Hanaki, T., Ishino, Y., Takasaki, M., & Mizuno, T. (2021). Fabrication of a Polyimide Film Pneumatic Actuator by Molding and Welding Processes. Actuators, 10(8), 177. https://doi.org/10.3390/act10080177