1. Introduction

An aircraft anti-skid braking system (AABS) with good performance is an important guarantee for the successful completion of flight missions [

1]. It directly affects the safety of the aircraft and the crew on board. With the rapid development of the aviation industry, the demand for large-tonnage and high-velocity aircraft is increasing. In order to brake this type of aircraft in less time and over shorter distances, it is necessary to improve the efficiency and performance of AABS. Moreover, the AABS is highly non-linear and subject to many uncertainties including runway surface conditions, which makes the AABS controller design challenging [

2].

The conventional PID + PBM control [

3] method does not work well on runways with disturbances, and the aircraft suffers from low-speed slippage [

4,

5]. In response to these problems, many control schemes proposed by researchers have been widely applied in the field of AABS, such as mixed slip deceleration PID control [

6], backstepping dynamic surface control [

7], optimal fuzzy control [

8], self-learning fuzzy sliding mode control [

9], direct adaptive fuzzy–neural control [

10] and so on. Chen X. et al. proposed an asymmetric barrier Lyapunov-function-based wheel slip controller for AABS, and the braking system operating status was effectively constrained to the healthy region and the light slip region [

11]. Considering the need to make the brake control more resistant to disturbances, Li F. B. et al. designed a nonlinear observer for online estimation of disturbances and introduced a fast terminal sliding mode controller to track the optimal slip rate that changes in real time [

12]. Despite the above-mentioned works that have made an in-depth study on AABS control, the faults of electro-hydraulic actuators, speed sensors, and other system components are deemphasized, leaving AABS still with many security risks. Aiming to really improve the safety and reliability, the AABS can be designed and configured from the hardware level on the one hand [

13,

14,

15]. However, the demanding hardware experimental conditions limit the development of this method. On the other hand, as a popular branch of fault-tolerant control, reconfiguration control is widely applied to some safety-critical systems at present, especially in the field of aerospace engineering [

16,

17]. It seems reasonable and valid to introduce the concept of reconfiguration control into AABS. Moreover, this is also the future development direction of AABS and the key technology that needs urgent attention [

18]. Therefore, this paper attempts to design a reconfiguration controller for AABS to meet the higher performance requirements in fault conditions as well as those concerning demands related to reliability and safety.

Han J. inherited the essence of the classical PID controller and proposed an active-disturbance rejection control (ADRC) technique that requires low model accuracy and is easy to implement [

19,

20]. ADRC is capable of estimating internal and external system disturbances in real time and compensating for them. Since ADRC has obvious advantages in solving control problems for nonlinear models with uncertainty and strong disturbances, this allows ADRC to be applied on a wide variety of plants [

21,

22,

23]. Moreover, many excellent schemes combine ADRC with other advanced control methods, such as sliding mode ADRC [

24], adaptive ADRC [

25,

26], fuzzy ADRC [

27,

28,

29], Q-Learning ADRC [

30] and so on, which make the controllers much more robust and adept at anti-disturbance. Qi et al. [

31] proposed a BPNN-based adaptive ADRC controller wherein the ESO can be tuned online. Roman, R. C. et al. [

32] introduced an ADRC controller combined with Takagi–Sugeno Fuzzy control and verified it in a tower crane system, which greatly enhances the controller robustness and ability to handle nonlinearity. A fuzzy logic-based ADRC controller is presented by Gai J. et al. [

33] to improve the anti-load disturbance ability of permanent magnet synchronous motor. Currently, many researchers have used ADRC to solve the system component fault issues [

34,

35]. More importantly, ADRC has been introduced by Liu W. et al. for AABS and its good brake dynamic characteristics were validated [

36]. Thus, it seems that it is feasible to design a reconfiguration controller for AABS based on the ADRC technique.

Motivated by the above observations, in this paper, a reconfiguration controller-based adaptive fuzzy active-disturbance rejection control (AFADRC) has been developed for AABS subject to various component faults. The proposed reconfiguration control method is a remarkable control strategy compared to previous methods for four reasons:

- (i)

It is a robust control strategy, in which the AABS model is extended with a new state variable. This state variable is the sum of all unknown dynamics and disturbances that are not noticed in the fault-free plant description, and it is estimated online using the designed extended state observer (ESO), which indirectly simplifies the model to a significant extent.

- (ii)

An adaptive extended state observer (AESO) is proposed to estimate the new state variable. The method is based on online tuning of ESO parameters using an improved back propagation neural network (BPNN). It should be noted that the proposed AESO is an improvement on the one presented by Qi et al. [

31]. The application of AESO not only eliminates the tedious manual tuning of the parameters, but also greatly enhances the adaptiveness and robustness of the proposed method in the face of faults and disturbances.

- (iii)

Fuzzy logic is introduced into the nonlinear state error feedback (NLSEF). The performance of the ADRC is heavily related to the selection of NLSEF parameters. ADRC with fixed parameters has limited robustness and anti-disturbance. It may lead to an unacceptable performance or even divergence in different fault perturbation cases. NLSEF combined with fuzzy logic can adjust the control law parameters online autonomously to meet the control performance requirements, which thereby improves controller robustness and parameter adaptiveness. It is worth mentioning that fuzzy logic is data-driven, making it immune to model errors caused by imprecise modeling.

- (iv)

Additional fault detection and identification (FDI) modules are not required, and the controller parameters are adaptive. Therefore, the proposed AFADRC belongs to a novel combination of passive reconfiguration control and FDI-free reconfiguration control, which makes it an interesting solution in unknown fault conditions.

The paper is organized as follows.

Section 2 describes AABS dynamics. The reconfiguration controller based on AFADRC is presented in

Section 3. The simulation results are presented to demonstrate the merits of the proposed method in

Section 4, and conclusions are drawn in

Section 5.

3. Reconfiguration Controller Design

ADRC inherits the advantage of PID control, which is error-driven rather than model-based. There are some unique qualities in ADRC [

35,

39]: it offers an observer to estimate the disturbance; it combines the state feedbacks in a nonlinear way, allowing for a wide range of parameter adaptation; it is a digital control technique developed from the experimental platform rooted in computer simulations. The normal ADRC consists of a tracking differentiator (TD), a nonlinear state error feedback (NLSEF), and an extended state observer (ESO). However, the fixed controller parameters may not perform well in the face of faults that cause large jumps in model parameters. The normal ADRC requires many parameters to be tuned, which will increase the difficulty of engineering applications. Motivated by these facts, an AFADRC reconfiguration controller is proposed in this section—that is, using AESO instead of ESO to estimate the perturbations adaptively, and combining NLSEF with fuzzy logic to meet the control performance requirements under different fault and disturbance conditions.

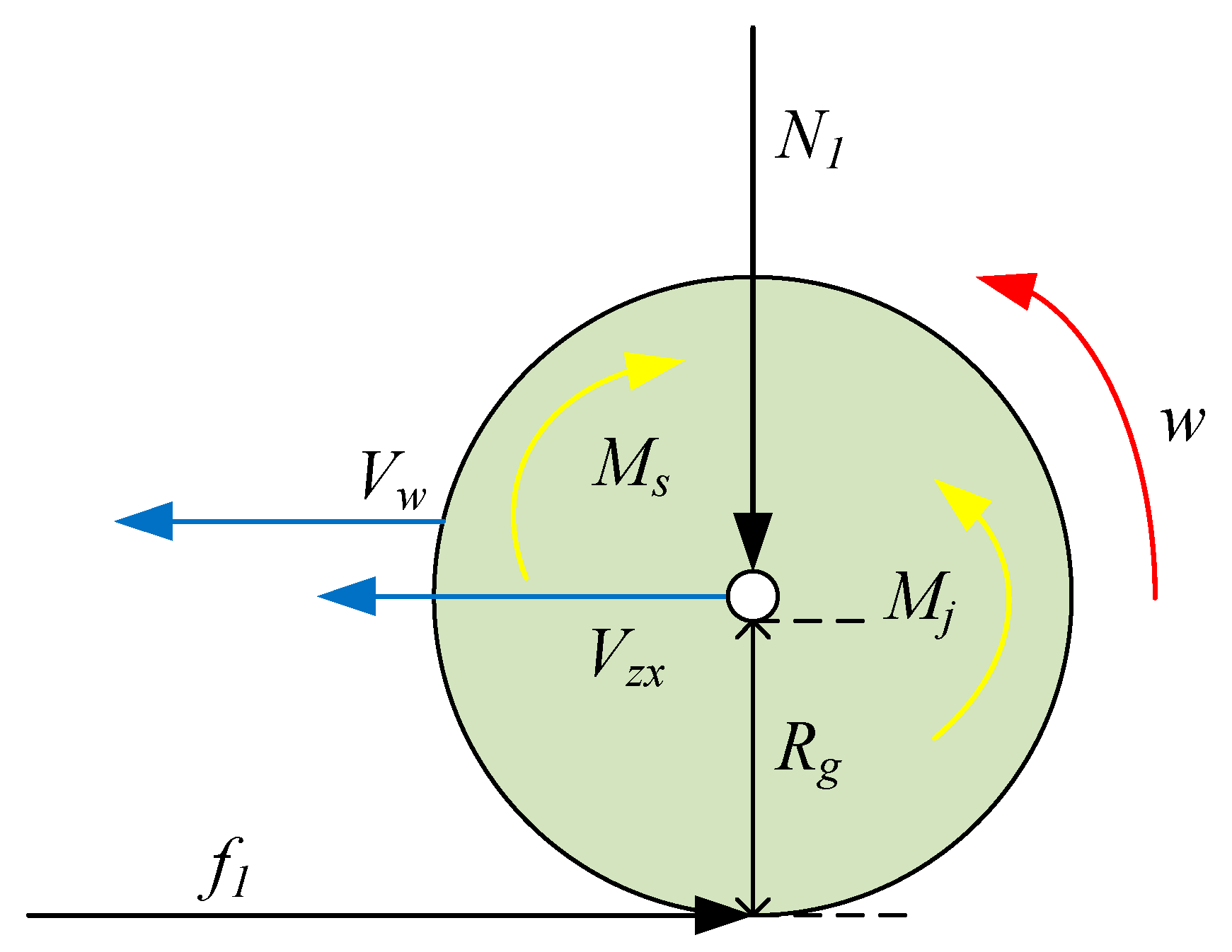

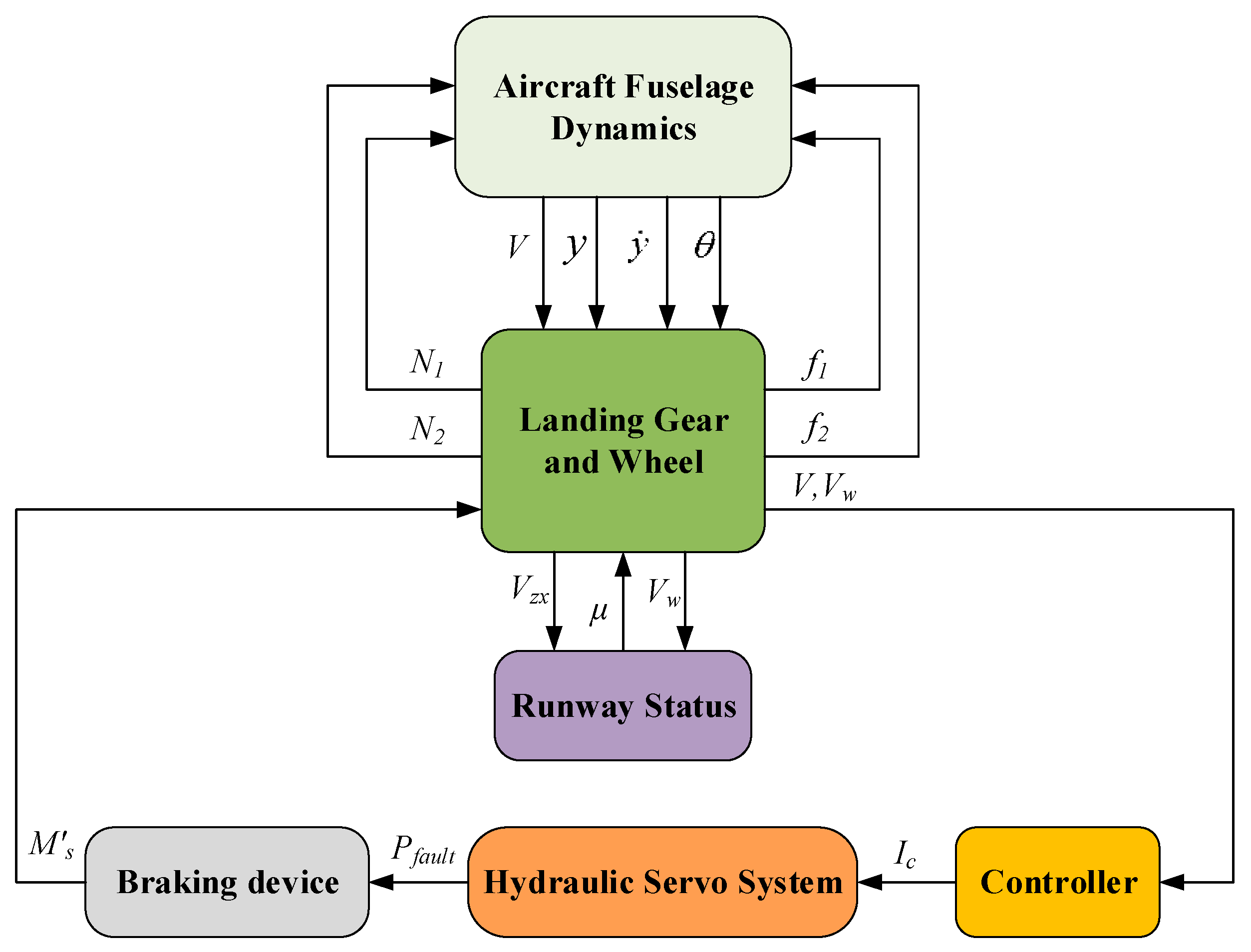

Although the aircraft has three degrees of freedom, only longitudinal taxiing is focused on in AABS. According to

Section 2, the AABS model can be written as follows:

where

is the uncertainty item,

represents the total perturbations,

. Since AABS in this paper adopts the slip speed control type [

1], system (15) can be rewritten as follows:

where

.

The structure of the AFADRC proposed in this paper is shown in

Figure 4. For AABS,

,

and

, where

denotes measurement noise. The design process is described in detail next.

3.1. Tracking-Differentiator (TD)

The main role of the TD is twofold: the first is to arrange the transition process for the system; the second is to filter the signal and obtain the differentiated signal. This effectively solves the conflict between rapidity and overshoot. A second-order TD can be designed as follows:

where

is the desired output,

is the transition process of

,

is the derivative of

,

and

are adjusted accordingly as filter coefficients. The function

is defined as follows:

with

3.2. Adaptive-Extended-State-Observer (AESO)

ESO is the core of ADRC, which estimates the system states and the total disturbance in real time based on the control quantity

and the plant output

. The normal ESO can be designed as follows:

where

is error of estimation,

is the estimated state,

is the derivative of

,

is the extended state which is an estimate of the total system perturbations,

is an adjustable parameter with a value close to

, and

are positive scalars; the function

is defined as follows:

From Equation (20), it can be seen that the three important parameters directly affect the accuracy of the estimated states . In particular, directly determines the perturbation compensation accuracy, which further comes to affect the overall control performance. For AABS with potential faults, the normal ESO may have the following issues:

- (i)

Manual tuning of parameters is tedious and not conducive to engineering applications.

- (ii)

An ESO with fixed may not accurately estimate the perturbations or even converge when faults occur.

- (iii)

If the ESO estimations are not optimal, this may result in less-than-satisfactory control.

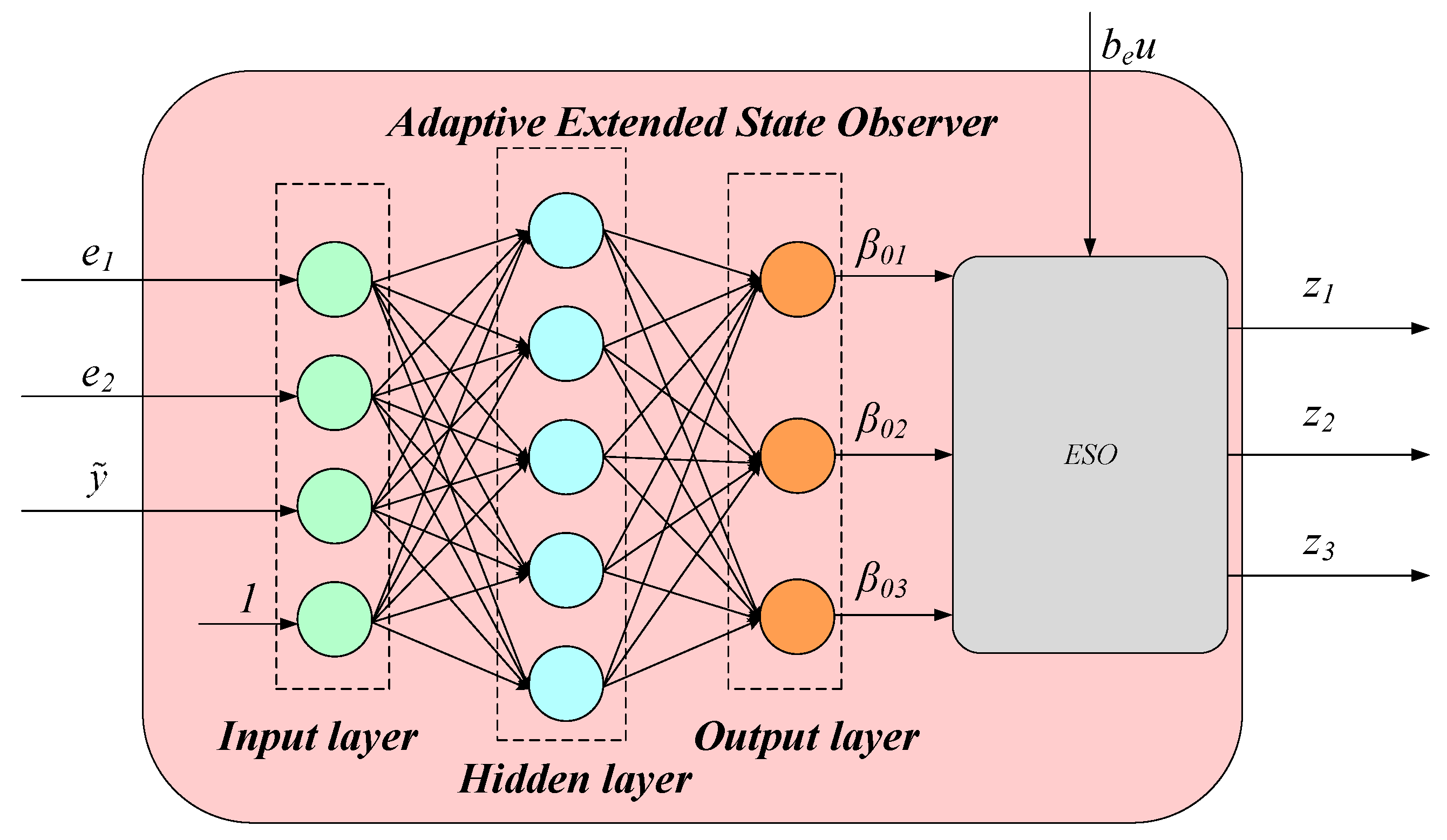

Motivated by the above analysis, in this paper, a three-layer BPNN-based AESO is designed that can be adaptively tuned to parameters with plant changes and disturbances. It is equivalent to system identification, which can improve the robustness, the estimated accuracy, and the control performance. The internal AESO structure is shown in

Figure 5.

and

are the input and output of the BPNN, respectively. The number of hidden nodes is determined to be 5 in combination with the plant and after several attempts.

The inputs of the input layer are:

and the input layer nodes correspond to

.

The inputs and outputs of the hidden layer are:

where

is the connection weight of the hidden layer.

The inputs and outputs of the output layer are:

where

is the connection weight of the output layer, the output layer nodes correspond to

, and the activation functions of neurons in the hidden layer and output layer are taken as follows:

To derive the error back-propagation process, the error energy function is defined as follows:

where

is system command value,

is system output, i.e.,

and

.

Slow learning speed and easy to fall into local minima are two typical disadvantages of traditional BPNN [

40]. In this paper, we introduce an adaptive learning rate

and an inertia term

that makes the search converge quickly to the full drama minimum. The connect weight can be adjusted by

in the negative gradient direction (steepest descent method), which can be defined as follows:

where

and

where

,

and

can be adjusted depending on the actual application system to ensure the stability of the network training process. This method has been proved to be effective in improving the network convergence speed [

41].

Since

is unknown, it can be approximated by

, where

. Then, the network output layer connect weight learning algorithm can be derived as:

Similarly, the network hidden layer connect weight learning algorithm can be obtained as follows:

After giving the initial values , AESO can update them autonomously to achieve the optimal estimation. This method is more convenient and has better observational performance than the traditional trial-and-error method.

3.3. Nonlinear-State-Error-Feedback (NLSEF) with Fuzzy Logic

NLSEF can be designed as follows:

where

and

are positive scalars,

and

,

is a positive scalar.

In normal applications, need to be tuned manually according to the actual situation. ADRC with fixed can perform well when the system is in normal operation. Once abrupt faults occur, large system parameter jumps are caused. At this point, the fixed may not maintain an acceptable performance. To improve the robustness and parameter adaptiveness of the controller, fuzzy logic is introduced to adjust the control law online. The controller thus has the reconfiguration capability to cope well with the fault conditions.

The details of the fuzzy logic are as follows:

are the fuzzy input variables, and

are the fuzzy output variables. In their domains, five language sets are defined as {“Negative Big (NB)”, “Negative Small (NS)”, “Zero (ZO)”, “Positive Small (PS)”, “Positive Big (PB)”}. Select input variables

for the Gaussian membership function, output variables

for the triangular membership function. In this paper, the basic domains of

are

,

, and the basic domains of

are

,

. The fuzzy reasoning uses Mamdani type and defuzzification is weight average method. Fuzzy rule table for

is established in

Table 7.

According to the above process, the gain of NLSEF can be obtained as follows:

where

are the initial values.

Remark 4. TD, AESO, and NLSEF with fuzzy logic together constitute the AFADRC controller. Compared to normal ADRC, AFADRC realizes the parameter adaption that makes the controller reconfigurable. The robustness and immunity are greatly improved. It can effectively compensate the adverse effects caused by the total perturbations including faults.

4. Simulation Results

To validate the fault recovery and disturbance rejection capabilities of the proposed reconfiguration controller for AABS, the corresponding simulations are performed in this section. AFADRC parameters are shown in

Table 8. The initial states of the aircraft are set as follows: (1) initial speed of aircraft landing

; (2) initial values of pitch angle and velocity

; (3) initial height of the center of gravity

; (4) initial speed of wheel

. The anti-skid brake control is considered to be over when

is less than

. To prevent deep wheel slippage as well as tire blowout, the wheel speed is kept to follow the aircraft speed quickly at first and the brake pressure is applied only after 1.5 s. This is also a concise protection measure.

In this paper, the pressure efficiency method [

42] is used to calculate the brake efficiency

, which can be described as follows:

where

is the square of the area between the peak point connection and the horizontal coordinate,

is the square of the area between the actual brake pressure trace and the horizontal coordinate. The details are shown in

Figure 6.

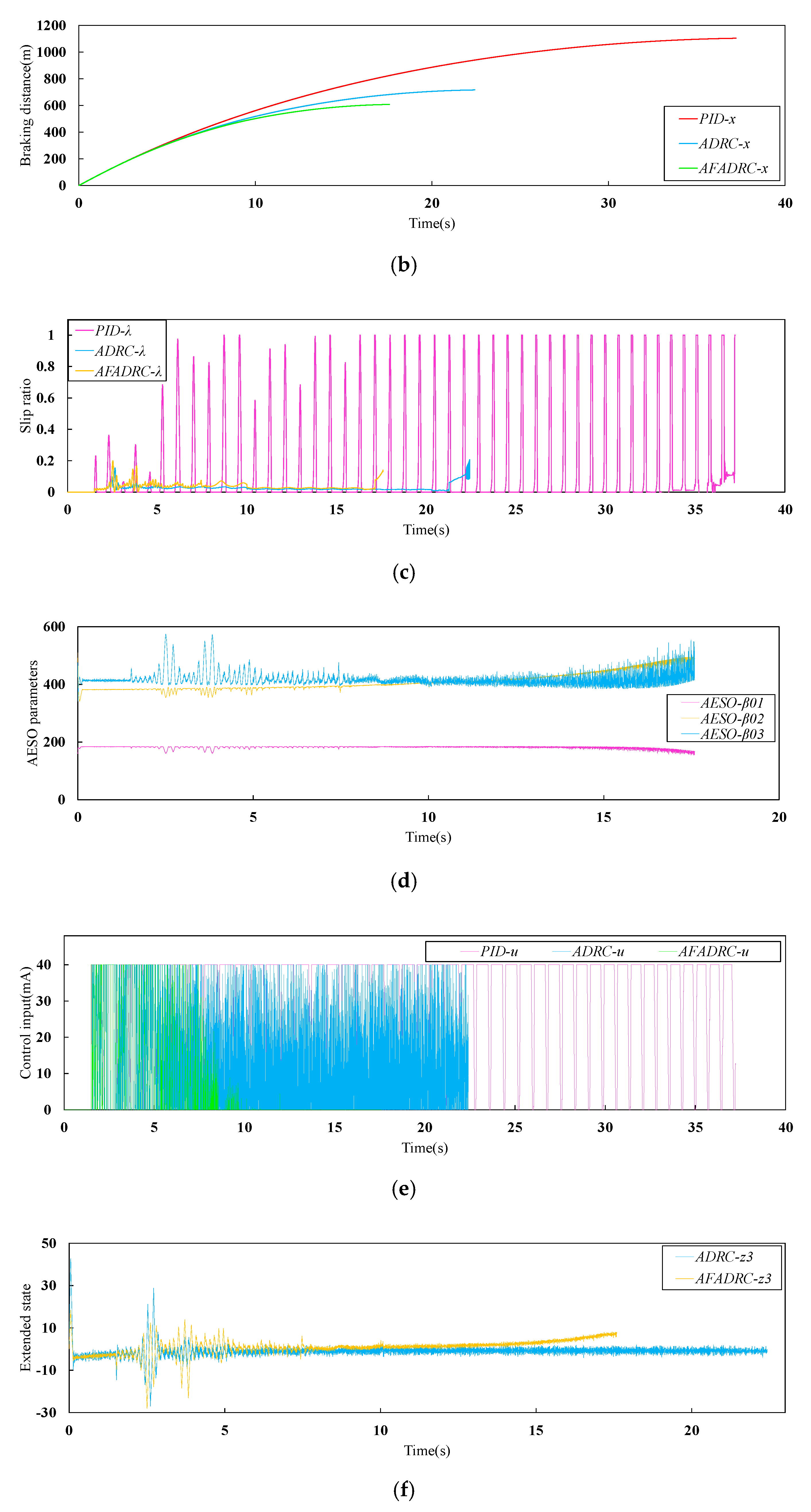

4.1. Case 1: Fault-Free and External Disturbance-Free in Dry Runway Condition

The simulation results of the dynamic braking process for different control schemes are shown in

Figure 7 and

Table 9. From

Figure 7a,b, compared with the traditional PID + PBM control, ADRC and AFADRC effectively shorten the braking time and the braking distance. In

Figure 7c the slip ratio is depicted. In the initial stage of braking, i.e., the high-speed phase of the wheel, there is a brief slippage of PID + PBM. In contrast, the braking efficiencies of ADRC and AFADRC are greatly improved, and the wheel slippages are clearly reduced with satisfactory control effects. As shown in

Figure 7d, AESO automatically adjusts the observer parameters during the braking process to achieve optimal observation. The control currents for the three methods are clearly shown in

Figure 7e. It can be seen that the controller is constantly performing release and brake operations during the braking process.

Figure 7f shows that ADRC and AFADRC can effectively estimate the disturbances generated inside the system during braking. It should be noted that AESO and fuzzy logic constantly update the parameters online to improve the estimation and compensation accuracy, which makes AFADRC braking performance better than ADRC.

4.2. Case 2: Actuator LOE Fault and Measurement Noise in Dry Runway Condition

The fault considered here assumes a 20% actuator LOE at 5 s and escalate to 40% LOE at 10 s. The band-limited white noise with noise power

is applied to describe the measurement noise. The simulation results are shown in

Figure 8 and

Table 10. As can be seen in

Figure 8a,b, the PID + PBM continuously performs a large braking and releasing operation under the combined effect of fault and disturbance. This makes braking much less efficient and risks dragging and flat tires. Although ADRC can maintain high braking efficiency, the braking time and distance are greatly increased. Moreover,

Figure 8c shows that there is a high frequency of wheel slip in the low-speed phase of the aircraft. In contrast, the proposed AFADRC can still efficiently and rapidly control the brakes, since it can remarkably handle the completely unknown uncertainties from both the internal and external. From

Figure 8d,f, it can be seen that these uncertainties are estimated fast and accurately based on AESO. Meanwhile, NLSEF with fuzzy logic adaptively adjusts the control law parameters according to the magnitude of the state errors and reconfigures the control to compensate for faults and measurement noise. The comparison between Case 1 and Case 2 illustrates that AFADRC not only ensures the braking performance of fault-free AABS, but also greatly improves the robustness and immunity of AABS in fault-perturbed conditions.

4.3. Case 3: Actuator LOE Fault and Measurement Noise in Mixed Runway Condition

The mixed runway structure is as follows: dry runway in the interval of 0–5 s, wet runway in the interval of 5–10 s, and snow runway after 10 s. Fault and disturbance conditions are the same as Case 2. The simulation results are shown in

Figure 9 and

Table 11. It can be clearly seen from

Figure 9a,b that the PID + PBM control cannot brake the aircraft to stop in a limited time, which may lead to serious consequences. Compared with ADRC, AFADRC can better adapt to the runway changes.

Figure 9d shows that AESO can still realize parameter adaption in the mixed runway case. The total perturbations can be accurately estimated: see

Figure 9f. Under fault-perturbed conditions, AFADRC can still brake fast with high efficiency, which improves the environmental adaptability and reliability of AABS.