Discussion on the Stiffness of the Drive Chain in the Legs of Biped Robots

Abstract

:1. Introduction

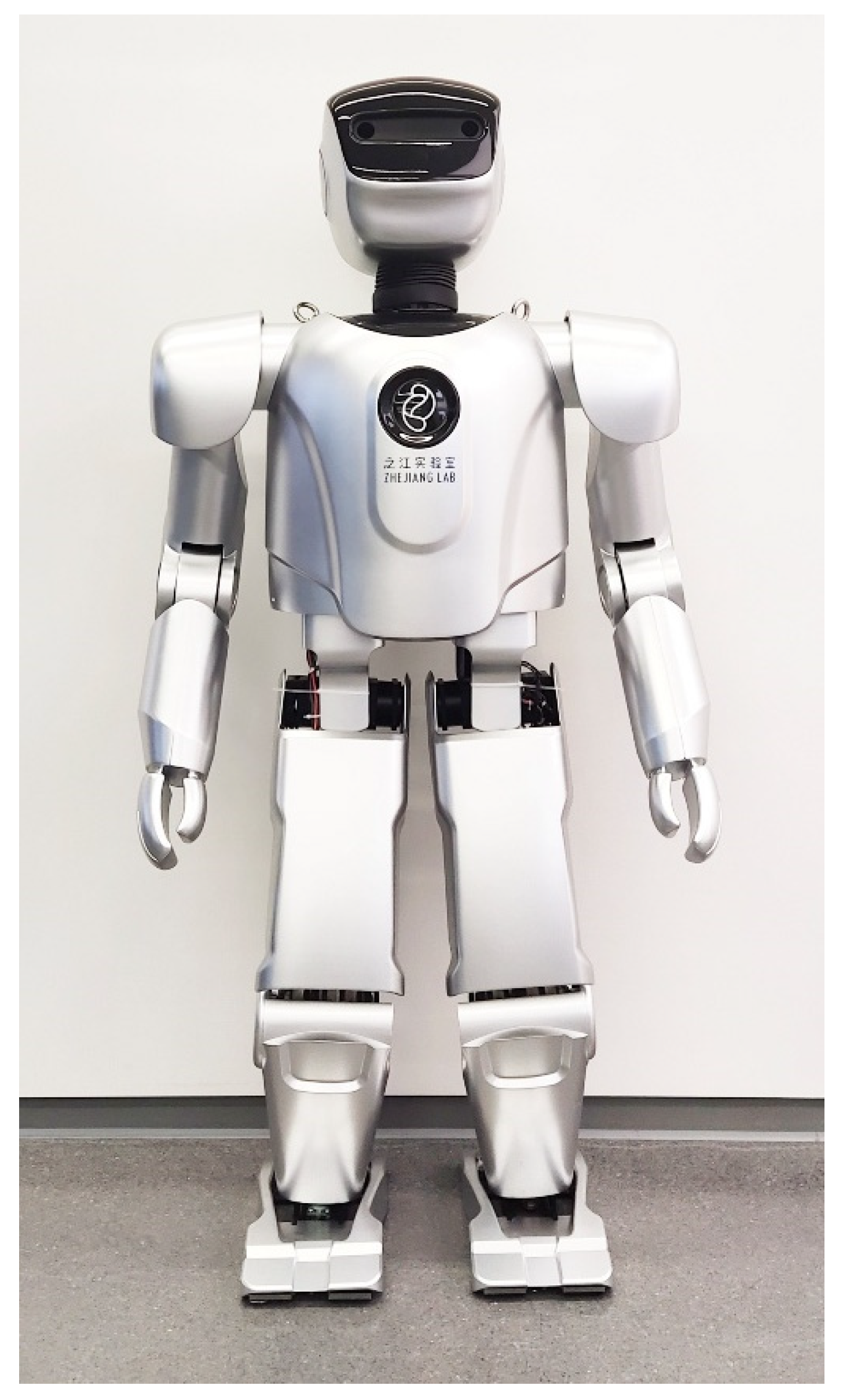

2. Description of the Biped Robot AIRO

3. Mathematical Modelling for the Knee Motion

3.1. Spring-Mass Models for the Knee Motion

3.2. Determination of Parameters

3.3. Numerical Solution of the Mathematical Model

4. Simulation Results on the Stiffness

4.1. Performance of the Stance and Swing Phase

4.2. Influence of the Stiffness for Stance Phase

4.3. Influence of the Legs’ Asymmetry

5. Experiments

6. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Yang, X.; She, H.; Lu, H.; Fukuda, T.; Shen, Y. State of the Art: Bipedal Robots for Lower Limb Rehabilitation. Appl. Sci. 2017, 7, 1182. [Google Scholar] [CrossRef] [Green Version]

- Nelson, G.; Saunders, A.; Neville, N.; Swilling, B.; Bondaryk, J.; Billings, D.; Lee, C.; Playter, R.; Raibert, M. Petman: A humanoid robot for testing chemical protective clothing. J. Rob. Soc. Jpn. 2012, 30, 372–377. [Google Scholar] [CrossRef] [Green Version]

- Abate, A. Mechanical Design for Robot Locomotion. Ph.D. Thesis, School of Mechanical, Industrial, and Manufacturing Engineering, Oregon State University, Corvallis, OR, USA, 2018. [Google Scholar]

- Hirose, M.; Ogawa, K. Honda humanoid robots development. Philos. Trans. A Math. Phys. Eng. Sci. 2007, 365, 11–19. [Google Scholar] [CrossRef]

- Tsagarakis, N.G.; Caldwell, D.G.; Negrello, F.; Choi, W.; Baccelliere, L.; Loc, V.G.; Noorden, J.; Muratore, L.; Margan, A.; Cardellino, A.; et al. Walk-man: A high-performance humanoid platform for realistic environments. J. Field Robot. 2017, 34, 1225–1259. [Google Scholar] [CrossRef]

- Yuan, H.; Song, S.; Du, R.; Zhao, M.; Zhu, S.; Gu, J. A Capturability-based Control Framework for the Underactuated Bipedal Walking. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021. [Google Scholar]

- Park, I.W.; Kim, J.Y.; Lee, J.; Oh, J.H. Mechanical design of the humanoid robot platform, HUBO. Adv. Robot. 2007, 21, 1305–1322. [Google Scholar] [CrossRef]

- Hurst, J.W.; Chestnutt, J.E.; Rizzi, A.A. An actuator with physically variable stiffness for highly dynamic legged locomotion. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004. [Google Scholar]

- Li, X.; Zhou, H.; Zhang, S.; Feng, H.; Fu, Y. WLR-II, a hose-less hydraulic wheel-legged robot. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; pp. 4339–4346. [Google Scholar]

- Zhou, H.; Du, R.; Xie, A.; Yang, H. Theoretical Analysis for the Flow Ripple of a Tandem Crescent Pump with Index Angles. Appl. Sci. 2017, 7, 1148. [Google Scholar] [CrossRef] [Green Version]

- Vanderborght, B.; Verrelst, B.; Van Ham, R.; Naudet, J.; Vermeulen, J.; Lefeber, D.; Daerden, F. LUCY, a bipedal walking robot with pneumatic artificial muscles. In Proceedings of the IEEE Conference on Mechatronics and Robotics, Singapore, 1–3 December 2004; pp. 106–114. [Google Scholar]

- Ahmad Sharbafi, M.; Shin, H.; Zhao, G.; Hosoda, K.; Seyfarth, A. Electric-Pneumatic Actuator: A New Muscle for Locomotion. Actuators 2017, 6, 30. [Google Scholar] [CrossRef] [Green Version]

- Song, S.; Tang, C.; Wang, Z.; Yan, G. Active disturbance rejection controller design for stable walking of a compass-like biped. Trans. Institute Meas. Control 2018, 40, 4063–4077. [Google Scholar] [CrossRef]

- Yuan, H.; Ge, Y.; Gan, C. Control strategy for gait transition of an underactuated 3D bipedal robot. Front. Inform. Technol. Electron. Eng. 2019, 20, 1026–1035. [Google Scholar] [CrossRef]

- Gong, Y.; Hartley, R.; Da, X.; Hereid, A.; Harib, O.; Huang, J.K.; Grizzle, J. Feedback control of a cassie bipedal robot: Walking, standing, and riding a segway. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019. [Google Scholar]

- Carbone, G.; Lim, H.; Takanishi, A.; Ceccarelli, M. Stiffness analysis of biped humanoid robot WABIAN-RIV. Mech. Mach. Theory 2006, 41, 17–40. [Google Scholar] [CrossRef]

- Carbone, G.; Lim, H.; Takanishi, A.; Ceccarelli, M. Stiffness analysis of the humanoid robot WABIAN-RIV: Modelling. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation (ICRA), Taiwan, China, 14–19 September 2003. [Google Scholar]

- Carbone, G.; Lim, H.; Takanishi, A.; Ceccarelli, M. Numerical and experimental estimation of stiffness performances for the humanoid robot WABIAN-RV. In Proceedings of the 2003 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Kobe, Japan, 20–24 July 2003. [Google Scholar]

- Kwon, W.; Kim, H.; Park, J.; Roh, C.H.; Lee, J.; Park, J.; Kim, W.K.; Roh, K. Biped humanoid robot Mahru III. In Proceedings of the 2007 7th IEEE-RAS International Conference on Humanoid Robots, Pittsburgh, PA, USA, 29 November–1 December 2007. [Google Scholar]

- Kim, J.; Lee, Y.; Kwon, S.; Seo, K.; Roh, K. Development of the lower limbs for a humanoid robot. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Algarve, Portugal, 7–12 October 2012. [Google Scholar]

- Lohmeier, S. Design and Realization of a Humanoid Robot for Fast and Autonomous Bipedal Locomotion. Ph.D. Thesis, Technische Universität München, München, Germany, 2010. [Google Scholar]

- Lohmeier, S.; Thomas, B.; Heinz, U. Humanoid robot LOLA. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation (ICRA), Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Lohmeier, S.; Buschmann, T.; Schwienbacher, M.; Ulbrich, H.; Pfeiffer, F. Leg design for a humanoid walking robot. In Proceedings of the 2006 6th IEEE-RAS International Conference on Humanoid Robots, Genova, Italy, 4–6 December 2006. [Google Scholar]

- Xiong, X.; Ames, A.D. Bipedal hopping: Reduced-order model embedding via optimization-based control. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Xiong, X.; Ames, A.D. Coupling reduced order models via feedback control for 3d underactuated bipedal robotic walking. In Proceedings of the 2018 IEEE-RAS 18th International Conference on Humanoid Robots (Humanoids), Beijing, China, 6–9 November 2018. [Google Scholar]

- De Luca, A.; Book, W. Robots with Flexible Elements. In Springer Handbook of Robotics; Springer: Cham, Switzerland, 2016; pp. 243–282. [Google Scholar]

- Ma, Z.; Zuom, S.; Chen, B.; Liu, J. Friction prediction and validation of a variable stiffness lower limb exosuit based on finite element analysis. Actuators 2021, 10, 151. [Google Scholar] [CrossRef]

- Palli, G.; Melchiorri, C.; De Luca, A. On the feedback linearization of robots with variable joint stiffness. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation (ICRA), Pasadena, CA, USA, 19–23 May 2008. [Google Scholar]

- Klimchik, A.; Caro, S.; Furet, B.; Pashkevich, A. Complete stiffness model for a serial robot. In Proceedings of the 2014 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Vienna, Austria, 2–4 September 2014. [Google Scholar]

- Pashkevich, A.; Klimchik, A.; Chablat, D. Enhanced stiffness modeling of manipulators with passive joints. Mech. Mach. Theory 2011, 46, 662–679. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Park, J.; Kim, J.; Kim, M.; Lee, D. Stiffness decomposition and design optimization of under-actuated tendon-driven robotic systems. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018. [Google Scholar]

- Geeroms, J.; Flynn, L.; Jimenez-Fabian, R.; Vanderborght, B.; Lefeber, B. Design and energetic evaluation of a prosthetic knee joint actuator with a lockable parallel spring. Bioinspir. Biomim. 2017, 12, 026002. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, R.; Song, S.; Yuan, H.; Nie, D.; Gu, J. Discussion on the Stiffness of the Drive Chain in the Legs of Biped Robots. Actuators 2022, 11, 79. https://doi.org/10.3390/act11030079

Du R, Song S, Yuan H, Nie D, Gu J. Discussion on the Stiffness of the Drive Chain in the Legs of Biped Robots. Actuators. 2022; 11(3):79. https://doi.org/10.3390/act11030079

Chicago/Turabian StyleDu, Ruilong, Sumian Song, Haihui Yuan, Daming Nie, and Jason Gu. 2022. "Discussion on the Stiffness of the Drive Chain in the Legs of Biped Robots" Actuators 11, no. 3: 79. https://doi.org/10.3390/act11030079

APA StyleDu, R., Song, S., Yuan, H., Nie, D., & Gu, J. (2022). Discussion on the Stiffness of the Drive Chain in the Legs of Biped Robots. Actuators, 11(3), 79. https://doi.org/10.3390/act11030079