3.1. Free-Run Experimental Results

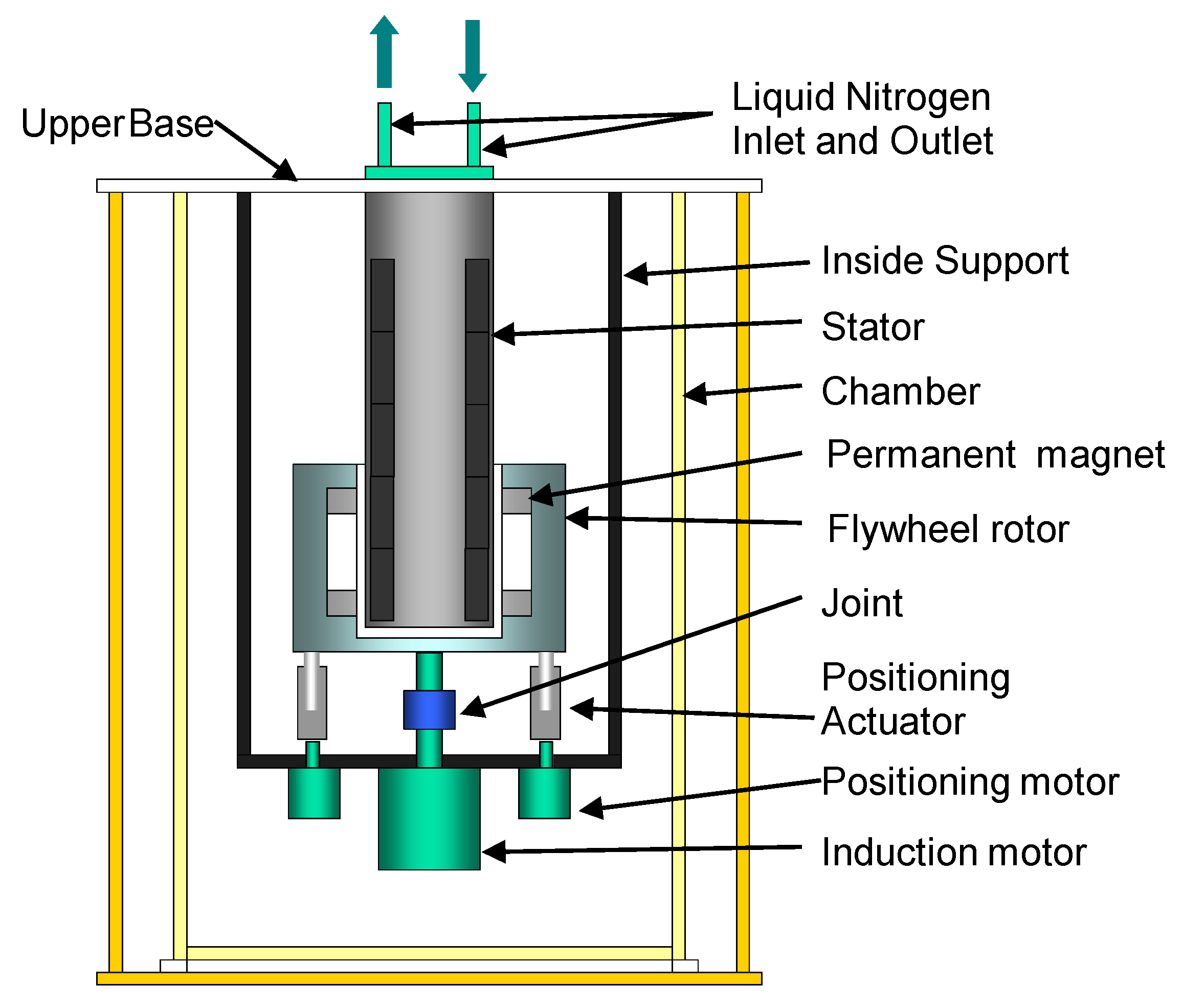

Figure 5 shows an experimental setup for a free-run experiment. The rotor is supported by four positioned linear actuators. The gap between the rotor and the stator is 0.75 mm. After field-cooling the superconductors with a gap of 0.75 mm, the actuators separate from the flywheel rotor. In this manner, the rotor can be levitated. The rotor is driven by the induction motor. The thick arrows near the joint show the rotation directions. Just after the rotation speed increases to 1000 rpm, the driving force of the motor stops. Then, the rotation speed and displacements of the rotor are measured. The displacements at the upper position of the rotor and the lower position of the rotor are measured by using two laser displacement sensors. During the experiment, the vacuum of the chamber is kept at

5 × 10

−3 Torr using a rotary vacuum pump. The chamber vacuum

5 × 10

−3 Torr is sufficient for the experiments performed here.

Figure 6 shows the free-run experimental results representing (a) the natural rotational decay curve, (b) displacement at an upper position of the rotor and (c) displacement at a lower position of the rotor. The rotation speed decays to zero from 1000 rpm for

1600 s. During the rotation, the displacement pattern of the upper rotor is almost the same as that of the lower rotor. There are resonance rotation speeds at

200 s and

900 s, which correspond to

800 rpm and

300 rpm, respectively. Except for these resonance rotation speeds, the displacement is less than 0.3 mm over a wide time range.

Figure 7 shows the free-run experimental results representing (a) displacements at the upper rotor (upper figure) and lower rotor (lower figure) at a speed of

300 rpm and (b) displacements at the upper rotor (upper figure) and lower rotor (lower figure) at a speed of

800 rpm. Both displacements, at the speeds of

300 rpm and

800 rpm, are less than 0.3 mm

o-p. The displacement phase of the upper figure in

Figure 7a is almost the same as the phase of the lower figure in

Figure 7a. This means that the flywheel rotor spins in a cylindrical motion at a speed of

300 rpm. Additionally, the displacement phase of the upper figure in

Figure 7b is almost the same as the phase of the lower figure in

Figure 7b. This means that the flywheel rotor also spins in the cylindrical motion at a speed of

800 rpm.

Figure 8 shows the free-run experimental results representing (a) a natural rotation decay curve, (b) displacement at the center position of the rotor and (c) displacement of the stator in just the upper position of the rotor. The rotation speed decays to zero from

1000 rpm for

1600 s. During the rotation, the displacement at the center position of the rotor is almost the same as those in

Figure 6a,b. Since the flywheel rotor has a cylindrical motion, the displacement at the center position of the rotor in

Figure 8b is almost the same as those in

Figure 7b.

Figure 8c shows that over a wide time range, the displacement of the stator in just the rotor’s upper position is less than 0.1 mm, except for the resonance rotation speeds, which are much smaller than that of the flywheel rotor in

Figure 8b. However, there are some displacement peaks at

250 s and

950 s. These peaks correspond to the resonance frequencies of the flywheel energy storage system.

Figure 9 shows the free-run experimental results representing (a) the displacements of the flywheel rotor (upper figure) and stator (lower figure) at a speed of

300 rpm and (b) displacements of the flywheel rotor (upper figure) and stator (lower figure) at a speed of

800 rpm. Both displacements, at speeds of

300 rpm, are less than 0.3 mm

o-p. The displacement phase of the flywheel rotor (upper figure in

Figure 9a) is almost the same as the phase of the stator (lower figure in

Figure 9a). This means that the displacement of the stator is caused by the vibration of the flywheel rotor. The displacement of the flywheel rotor (upper figure in

Figure 9b), at speeds of

800 rpm, is less than 0.2 mm

o-p. The displacement phase of the flywheel rotor (upper figure in

Figure 9b) is almost the same as the displacement phase of the stator (lower figure in

Figure 9b). This means that the displacement of the stator is caused by the vibration of the flywheel rotor. From the results from

Figure 6,

Figure 7,

Figure 8 and

Figure 9, it was found that the displacement of the stator is caused by the vibration of the flywheel rotor.

3.2. Free-Run Experimental Results in the Case of Fixed Stator

Since the displacement of the stator is caused by the vibration of the flywheel rotor, some experiments are performed with the stator fixed to the ground base.

Figure 10 shows the schematic illustration of the flywheel energy storage system in the case of a fixed stator. As shown in the figure, the stator is fixed to the base ground using some woods.

Figure 11 shows the free-run experimental results in the case of a fixed stator, representing (a) a natural rotation decay curve, (b) displacement at an upper position of the rotor and (c) displacement at a lower position of the rotor. The results in the case of the fixed stator in

Figure 11 correspond to the results in

Figure 6. In

Figure 6, the resonance rotation speeds at

300 rpm and

800 rpm are shown. However, there is no resonance rotation speed in

Figure 11, as the stator is fixed to the ground base. In the case of making such types of suspended systems, it is important to fix the stator to the base ground.

Figure 12 shows the free-run experimental results in the case of a fixed stator, representing (a) displacements of an upper position of the rotor (upper figure) and (b) displacements at a lower position of the rotor (lower figure) at a speed of

400 rpm. The displacement is less than 0.2 mm

o-p, which is smaller than the displacement in

Figure 6. The displacement phase of the upper figure in

Figure 12a is almost the same as the phase of the lower figure in

Figure 12a. This means that the flywheel rotor, in the case of a fixed stator, has the same cylindrical motion as that in the case of an unfixed stator.

3.3. Impulse Responses

The impulse responses are performed using the same setup as the free-run experiments performed in

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9. The impulses are applied to the center position of the rotor and the stator at just the upper position of the rotor. That is, the impulses are applied to the same positions as those in

Figure 8. The impulse responses for the stator and rotor are measured by using a fast Fourier transform (FFT) analyzer.

Figure 13 shows the impulse responses for (a) the rotor at a center position of the rotor in the case of an unfixed stator and for (b) the unfixed stator at just the upper position of the rotor, representing that the upper and lower figures show a displacement and power spectrum, respectively. As shown in the upper figure of

Figure 13a, the displacement amplitude decays to

10% of the initial value within

8.0 s. However, the decay does not occur monotonously. This is because there are two dominant vibration modes, and these modes are combined with each other in the upper figure of

Figure 13a. The lower figure of

Figure 13a shows the peaks at 6.0 Hz and 14.0 Hz. These correspond to the vibration modes shown in the upper figure of

Figure 13a. The peaks at 6.0 Hz and 14.0 Hz correspond to the vibration at 360 rpm and 840 rpm, respectively, as shown in

Figure 6 and

Figure 8. As shown in the lower figure of

Figure 13b, the displacement amplitude decays to

10% of the initial value within

8.0 s. The decay occurs in the same manner as that in

Figure 13a. This is also because there are two dominant vibration modes which are caused by the SMB.

Figure 14 shows the impulse response for the rotor at the center position of the rotor in the case of a fixed stator, representing (a) displacement and (b) the power spectrum. As shown in

Figure 14a, the natural damped vibration is observed, and the displacement amplitude decays to 10% of the initial value within

8.0 s. The result in

Figure 14a is different from the result in

Figure 13. In

Figure 14, there is just one vibration mode.

Figure 14b shows a large peak at 7.2 Hz, which corresponds to the vibration mode of SMB in

Figure 14a. From the result in

Figure 14, it was found that the peaks at 6.0 Hz and 14.0 Hz in

Figure 13 are regarded as the vibration modes of the stator and SMB.

3.4. Free-Run Experimental Results in the Case of Applied Load

Figure 15 shows the flywheel rotor with a load attached to the bottom end. The load is made of a laminated aluminum plate and measures 115 mm × 25 mm × 1 mm × 12 pieces and is 100 g in weight. The free-run experiments were performed using the flywheel rotor with a load.

Figure 16 shows the free-run experimental results using the flywheel rotor with 100 g in the case of the fixed stator, representing (a) a natural rotation decay curve, (b) displacements at the center position of the rotor and (c) displacements of the stator at just the upper position of the rotor. The results in

Figure 16 correspond to the results in

Figure 11. During the natural rotation decay, a resonance rotation speed at

300 rpm is observed in

Figure 16b,c, although there is no resonance rotation speed in

Figure 11. This is caused by the attached load of 100 g. In other words, the load of 100 g amplifies the vibration of SMB. In the case of making this type of suspended system, it seems that it is important to fix the stator end.

Figure 17 shows free-run experimental result showing (a) displacements at upper position of rotor and (b) displacements at lower position of rotor at a speed of

370 rpm.