1. Introduction

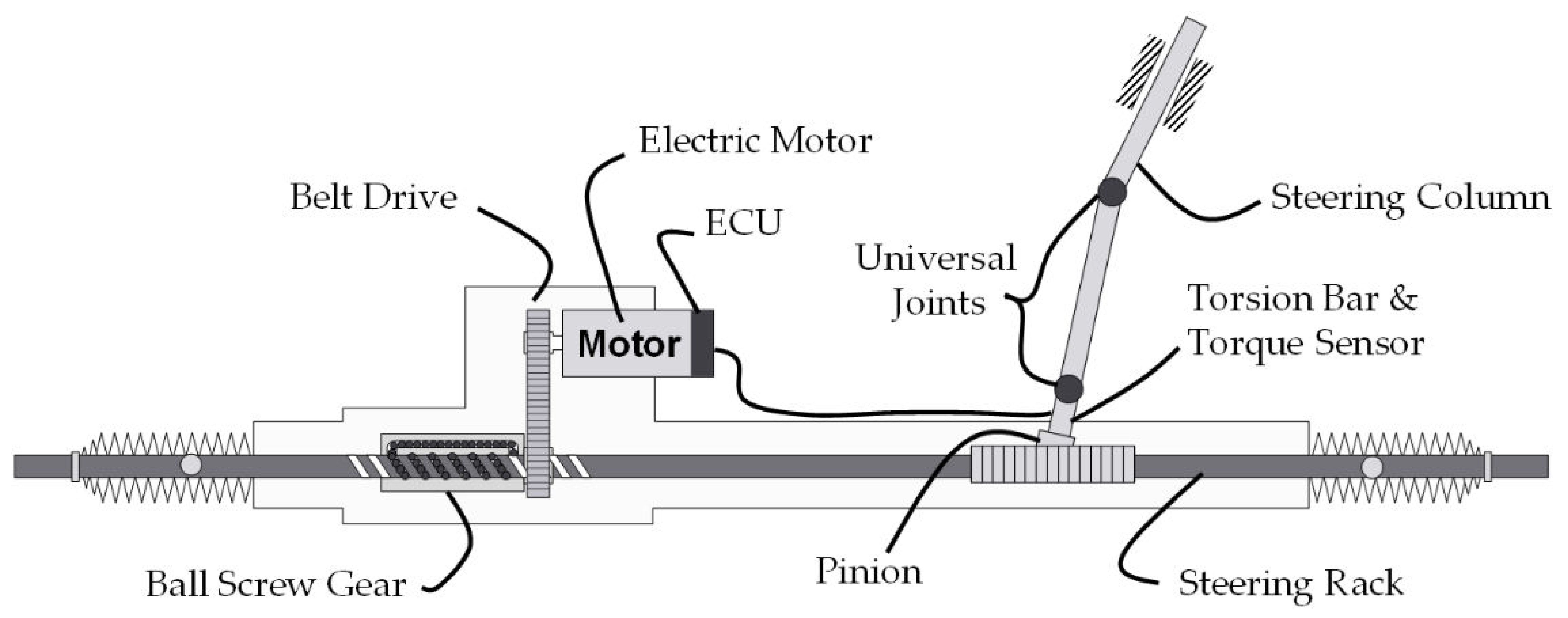

Modern steering systems for passenger vehicle cars possess an electric motor, which provides the necessary servo force to support the driver during steering maneuvers. During the automotive development process, the steering feel is improved, often in full vehicle tests. An alternative to road tests is the utilization of a steering system test bench, which allows the objective investigation of the steering system, without the requirement of a vehicle prototype.

Typical tests on steering test benches range from measurements of mechanical characteristics, such as the friction force of the steering gear, to approximations of full vehicle tests. Since electric power steering (EPS) systems exhibit large servo forces during parking, steering test benches for the investigation of such systems are required to provide sufficiently large actuator forces to imitate the wheel–road contact for real word applications. Currently, this goal is achieved by the usage of one or two permanent magnet linear synchronous motors (PMLSM).

Due to the high-power requirements, the utilized PMLSMs exhibit non-neglectable moving masses, deteriorating the dynamic behavior of the system. This is especially relevant when rapid steering wheel angle inputs are present. Furthermore, EPS systems represent nonlinear characteristics with friction, backlash, and natural frequencies within the investigated frequency range, which negatively influence the control performance, exemplarily when harmonic rack forces are introduced into the steering system. These shortcomings limit the applicability of steering test benches along the development process and require optimization.

Common approaches utilized to improve the dynamic control of regulated systems incorporate the inverse plant model into the control scheme [

1,

2]. In [

3,

4], a combined offline and online estimated transfer function is utilized to adapt the reference signal to the dynamics of the system under test, which is represented as a shaking table. For the online implementation, a recursive extended least square algorithm is used. A similar approach is described in [

5], wherein an online recursive extended least square algorithm adaptively alters the transfer function for acceleration, force and position control of a shaking table. Another force control approach is introduced in [

6], where the inverse model approach was successfully implemented within a flight simulator.

The estimation of a control transfer function on a steering test bench is connected to high efforts. Since the steering system represents an active component with friction, backlash and a variable driver input, steering systems are nonlinear systems. Consequently, the transfer function is only valid for one system state. Due to a great variety of variations in the system, transfer function-based approaches are not applicable for this purpose.

Similar, but alternative, approaches to control harmonic reference signals on a shaking table were introduced in [

7,

8]. Both methods utilize a least mean square filtering approach to weigh or adapt the input signal to compensate phase and amplitude deviation in the system response. Here, the adaptation occurs due to a comparison of the resulting and measured signals of the shaking table, without the explicit knowledge of the transfer function. Therefore, a similar approach can also be used on a steering test bench, where harmonic excitations are inserted into the steering rack.

Alternative approaches for the improvement of the dynamic characteristics of control systems are the usage of feedforward control signals based on velocity or acceleration information. In the discipline of hard disc drive control, there exist high requirements for the dynamic control performance, since the distance between a storage and the write/read pin needs to be small, but physical contact must not occur, even in the presence of external disturbances. For this purpose, [

9] introduced an acceleration feedforward control (AFC), which detects external disturbances to improve the control performance. In [

10], a similar approach was utilized to reduce the impact of external shocks to the drive system by an AFC in combination with a double disturbance observer, which successfully enhanced the control quality.

Within machining control applications, feedforward control approaches are exposed to changing boundary conditions, introduced by the workpiece characteristics, tool degradation and travel speed. Therefore, [

11] implemented an adaptive feedforward control based on the reference position signal and the occurring error together with friction compensation to reduce the resulting position error. Approaches for inertia compensation by a feedforward control are even further restricted since the workpiece and direction of excitation vary over time. Consequently, [

12] developed a velocity and AFC in combination with a jerk disturbance observer to compensate for varying inertia during the machining process. Similar approaches were conducted in [

13,

14,

15], where observers and artificial intelligence are implemented to estimate the current inertia of the system.

Previously described approaches for enhanced dynamics are implemented for position or velocity control and for predefined reference signals. A torque control application with feedforward control for friction and inertia compensation was proposed in [

16] on a rehabilitation device. The compensation is based on the currently measured angular velocity and the motor inertia, which successfully improves the control performance. A similar approach is also applicable for the implementation on a steering test bench, where the PMSLM is normally operated in force control mode.

Since steering system test benches are required to function within real-time applications, exemplarily together with a vehicle model, there are not only dynamic requirements in terms of magnitude accuracy but also concerning the time delay between the reference and measured signal. Such effects originate from dead time and the dynamic properties of the PMLSM control. A common method to deal with and improve the control performance of systems with dead time is the implementation of a Smith predictor [

17]. Here, a model of the process is utilized to derive a mathematical formulation without a delay in the system, enabling the use of standard PID control tuning processes for systems without dead time. The work in [

18] proposed an adaptation of a Smith predictor in combination with a fuzzy-PI controller on a brushless DC motor to account for modelling uncertainties, while an approach with an automatic dead time calculation is introduced in [

19].

Another method to improve the dynamic behavior of a brushless DC motor incorporates time-shifting the voltage signal according to the electrical characteristics of the motor in terms of inductance and resistance [

20]. The identification of the shifting time for the voltage signal is performed for different goals, such as performance [

20] or acoustics [

21]. A similar approach is proposed in [

22], wherein a phase delay compensation is utilized to improve the efficiency of the electric motor and its generated torque. Here, the optimum shifting time is estimated based on a Fourier series. These approaches utilize information of the current system state to alter the control strategy to improve performance. The basic principle is also applicable for steering test bench applications in real-time operation.

For PMLSMs implemented in steering system test benches, the prevailing operation mode is force control, which can be subdivided into two categories, based on the origin of the reference force signal. First, a reference force signal is provided in advance of the test to the PMLSM for the excitation of the steering system. This setup is exemplarily utilized for the harmonic force excitation of the steering rack. Second, the force is calculated based on a vehicle model, where the rack displacement measured within the PMLSM functions as the input for the reference rack force calculation. For the most basic case, the PMLSM operates as a virtual spring and, therefore, provides a reference force proportional to the measured rack displacement.

In this paper, drawbacks of the control performance occurring for both control categories are identified, and associated improvement approaches are proposed. For a previously known harmonic reference signal, a similar methodology as in [

7] is implemented to calculate a weighing factor to adapt the reference signal. Two additional methods, which are applicable for real-time testing, exemplarily combined with a vehicle model, use the steering wheel angle and steering rack-velocity information to provide the PMLSM control with a compensation signal for inertia and time delay.

The remaining article is structured as follows:

Section 2 gives an overview of the steering system and the relevant steering test bench, followed by a problem formulation and the proposal of compensation approaches in

Section 3. Results of the implemented control improvements are displayed and discussed in

Section 4.

Section 5 summarizes the conducted investigations.