2.1. Magnetic Field Simulations

The magnetic field was modeled for the magnetic nanofluid, depending on the Duty Cycle

Da and different flux path distances, considered above the two E cores and inside the magnetic nanofluid rectangle. Here, Duty Cycle

Da is dimensionless and represents the ratio between the power transistor conduction time

and oscillation period

.

is the power transistor off time or the time when the current passes through the diode. Oscillation period

can be determined from a frequency interval of 0.5…25 Hz. The magnetic nanofluid was represented for three different geometries, as a 3 × 42 mm, 4 × 42 mm and 6 × 42 mm rectangle that is situated above the two E cores. Of course, these geometrical configurations are valid only when the magnetic nanofluid is not moving or when each configuration can be assimilated as a single frame (in time) that is only a part of the whole magnetic nanofluid movement (see

Figure 1 and

Figure 2).

It can be seen below that the Duty Cycle has a major influence on the average voltage and current and can directly control the magnetic field amplitude and the magnetic pushing force. One geometrical configuration was considered in FEMM for ferrites: two E cores aligned on the entire 42 mm inner box space length and separated by a 2 mm spacer.

The second E core was added because it registered a small additional influence on the magnetic field amplitude and on magnetic nanofluid behavior. Almost no influence was observed when the oscillating frequency was changed from 0 Hz to 3 Hz. Therefore, it cannot be distinguished between a DC power supply and an AC power source at very low frequencies (<3 Hz). It is important to consider a variable thickness between 2 and 6 mm for the magnetic nanofluid and to compare each result to identify where the magnetic field stops changing. The magnetic nanofluid characteristics are described in

Appendix A. Moreover, the magnetic nanofluid synthesis, coprecipitation method, treatment with oleic acid (as surfactant) and the final mixture with transformer oil (as stabilizing and carrier agent) are presented in

Appendix A. The magnetic nanofluid M

H curve Equation (A6), shown in

Appendix A, was approximated from the vibrating magnetometer experimental values of magnetization. Then, these values were converted from A/m to T, resulting in

JH and

BH interpolation curves.

The magnetic nanofluid

BH curve was introduced in FEMM 4.2 material library. For 0.0018 T, the magnetic field intensity was 1 kA/m; for 0.0148 T, it was 4 kA/m; for 27 mT, it was 10 kA/m; for 45 mT, 20 kA/m; for 90 mT, 50 kA/m; for 124 mT, 75 kA/m; for 211 mT, 140 kA/m; for 289 mT, 200 kA/m; and for 417 mT, it was 300 kA/m. From 475 kA/m, the magnetic field increased very slowly to 0.640 T, and when starting from 500 kA/m, the magnetic field remained almost constant at 0.67–0.685 T. The saturation magnetization of the magnetic nanofluid is present here at over 500 kA/m for a measured magnetic field of 0.67–0.685 T. From the above simulations (see

Figure 2a and

Table 1) the highest magnetic field of 45 mT is situated in the vicinity of the coil, at the center and near ferrite edges. Just above the ferrite cores from 0.01 to 0.5 mm distance, inside the magnetic nanofluid and for

Da = 0.9 Duty Cycle, the magnetic nanofluid reaches the saturation magnetization of 45 mT. The magnetic field decreases as the viewer moves further away from the ferrites, down to 30 mT, at a 1.5 mm distance.

The maximum magnetic field inside the magnetic nanofluid approaches 44 mT (the scientific notation 4.4e-002 is same as 4.4 × 10

−2) for 0.72 Duty Cycle and at 0.01 mm distance from E ferrite cores (see

Figure 2b). At a 0.5 mm distance and at the same Duty Cycle, the magnetic field is 40 mT. The saturation magnetization can only be avoided from 0.7 Duty Cycle down to 0.2 Duty Cycle.

When one E core electromagnet is activated, the magnetic field encloses, such as in simulations, and the magnetic nanofluid inflates and follows the magnetic field lines. The straight line and rectangular geometry of magnetic nanofluid is only an approximation but can give fast and good results. All simulations were made by using Dirichlet boundary conditions. Seven small boundary layers were used to obtain precise results.

An estimation of the average current passing through the coils and the electronic power scheme is described in

Appendix B.

By replacing

and

, from Equations (A12) and (A13) (

Appendix B), inside Equations (A10) and (A11) respectively, Equation (A14) can be rearranged. Equation (1), the final expression for the average current, is obtained by simplifying the exponential terms from Equation (A14).

The calculated average current that depends on the Duty Cycle value and that was also introduced in the simulation is:

Please note that is an arbitrary time that contains all previous periods or cycles k (for a single cycle k = 1), and is the inductive load time constant. If this constant is too big, the current will not have time to rise completely for the given oscillation period, . In our case, , so all exponential terms can be ignored, .

It can be observed that this formula was extracted after calculating the current when the transistor is in conduction mode (On) and in (Off) position. In (Off) position, the current passing through the diode is equal to the inductive load current. It is important to see that the average current was obtained by integrating and summing , the current passing through the transistor in conduction mode, with , which is exactly the load and diode current when the voltage supply is cut off. Without applying integration for [tk…tk + DaTosc] on conduction state interval or off state [tk + DaTosc…tk + Tosc] interval, the average voltage or Da Duty Cycle will be ignored.

The average current (see Equations (A14) and (1) for different Duty Cycles) was obtained by considering the resistance and inductance of the coil, 309 Ω and 0.127 H, respectively. From this given initial data, the load time constant can be extracted, which was much lower than the pulses’ oscillation period .

In the experimental section, a peak voltage of U = 15 V from the rectangular pulse was applied to the coil. In simulations, an average or RMS (root mean square) current must be used to activate the coil.

The voltage and current can be changed by modifying the Duty Cycle to be between 5 and 95%. Depending on how much the transistors were in conduction mode, the pulse was longer in duration, and the average voltage had increased proportionally.

The magnetic field situated at 0.5 mm above E cores was presented in

Figure 3a,b, for

Da = 0.9 Duty Cycle and

Da = 0.72 Duty Cycle. The maximum magnetic field at 0.5 mm distance (

Da = 0.9, 2 mm thick magnetic nanofluid) from ferrites increases from 0.04 T, as seen in

Figure 3a, up to 0.044 T at 0.5 mm distance (

Da = 0.9, 6 mm thick magnetic nanofluid) (see

Table 1). The magnetic field remains at the same value of 0.044 T between 4 mm and 6 mm magnetic nanofluid thickness, which means that no additional magnetic nanofluid is needed above the E cores. The 4 mm magnetic nanofluid thickness is the optimum inflation limit.

Moreover, the magnetic field at 0.5 mm above E ferrite cores and inside the magnetic nanofluid is shown in

Figure 4. These magnetic field values were also introduced in

Table 1 (for

Da = 0.2). Ins

Table 1, all magnetic field values at different distances above E cores and for selected Duty Cycles (

Da), 0.2, 0.5, 0.72 and 0.9, are presented.

If the Duty Cycle is decreased to be under 0.2, the magnetic field amplitude will decrease under 10 mT, and the magnetic nanofluid will no longer inflate, or the inflation will not be visible (see

Figure 4a,b). An optimum magnetic nanofluid control will be realized if the Duty Cycle is adjusted between

. For

the average current is 10 mA. For

, the maximum recommended value used in simulations, the average current is 35 mA, and the magnetic field will not increase above 27 mT. If

the average current will increase to 44–48 mA, and the magnetic field will exceed 44 mT.

The magnetic nanofluid was simulated by the BH hysteresis curve that is rising up to the saturation point of 0.045 T. From the simulations, it can be seen that the magnetic field inside the magnetic nanofluid is very close to 44–45 mT, under 0.5 mm distance above the core and for . To avoid the saturation point of the magnetic nanofluid, the Duty Cycle can be limited electronically, not to exceed the maximum 0.7 value.

The optimum magnetic nanofluid control can be realized between 0.5 and 0.7 Duty Cycle (see

Figure 5 and

Figure 6). The Fe-Ni-Zn-V ferrite core type has a magnetization curve that grows from 68 mT and 44 A/m, 0.2 T and 150 A/m, 0.31 T and 1359 A/m, 0.48 T and 63 kA/m, and 0.67 T and 197 kA/m and starts to saturate at 0.83 T and 324 kA/m.

If the values of the magnetic field distribution along the two ferrite cores, for

Da = 0.5 (

Figure 7), are compared with the obtained magnetic field density for two E ferrite cores at

Da = 0.72 (see

Figure 8), it can be seen that the magnetic field induction has changed from 15 to 17 mT (at 3–4 mm distance), up to 23–25 mT.

The magnetic field along ferrites, at 1 mm distance above E cores, reaches 22 mT for

Da = 0.5 and 30 mT for

Da = 0.72 (see

Figure 8 and

Figure 9). The magnetic field at the first E core center drops down to 5 mT. Moreover, the magnetic field near the secondary E core is very small, about 2 mT. These observations bring us to the conclusion that the secondary E core with no active coil has little influence on the magnetic field path and also on the magnetic nanofluid present above the secondary non-acting core. As it can be seen later from the magnetic nanofluid actuation process, although the magnetic field lines are mainly surrounding the active coil and the E core, forming a magnetic nanofluid dome, the other three non-acting E cores are still keeping a part of the magnetic nanofluid upwards, but at a much lower height. This time, as it can be observed in the density plots, the magnetic nanofluid stays near the edges of the acting E core, where the magnetic field is bigger. In the active E core center, the magnetic field is low, under 5 mT, and is forming a hole.

At 3.5 mm above the E cores (

Figure 8), the magnetic field remains near 20 mT. This is also the real limit to where the magnetic nanofluid bubble is rising. The magnetic fluid will rise and form a hemisphere around the active coil until the force of gravity is equilibrated by the magnetic force.

The magnetic field falls below 2 mT when the observer is looking further away from the second non-active coil and E core center. The previous simulations were able to give important information about magnetic field variation with distance considered above the E core (where the magnetic nanofluid is situated), magnetic nanofluid thickness, average current and Duty Cycle.

The magnetic field was investigated for at least four cases, where the Duty Cycle was 0.2, 0.5, 0.72 and 0.9. From these simulations, it can be concluded that is the optimum working interval. Frequency has little or no effect on current because and the magnetic nanofluid will not inflate over 4 mm because the magnetic field amplitude will remain the same at 3.5–4 mm, 0.02 T (), no matter whether the magnetic nanofluid thickness is 4, 6 or 10 mm. The magnetic field amplitude will only start to increase a little over 25 mT when the magnetic nanofluid thickness is 3 mm.

For a maximum of 44–48 mA current, the magnetic nanofluid will be in the saturation region.

2.2. Electronic Drive Circuit

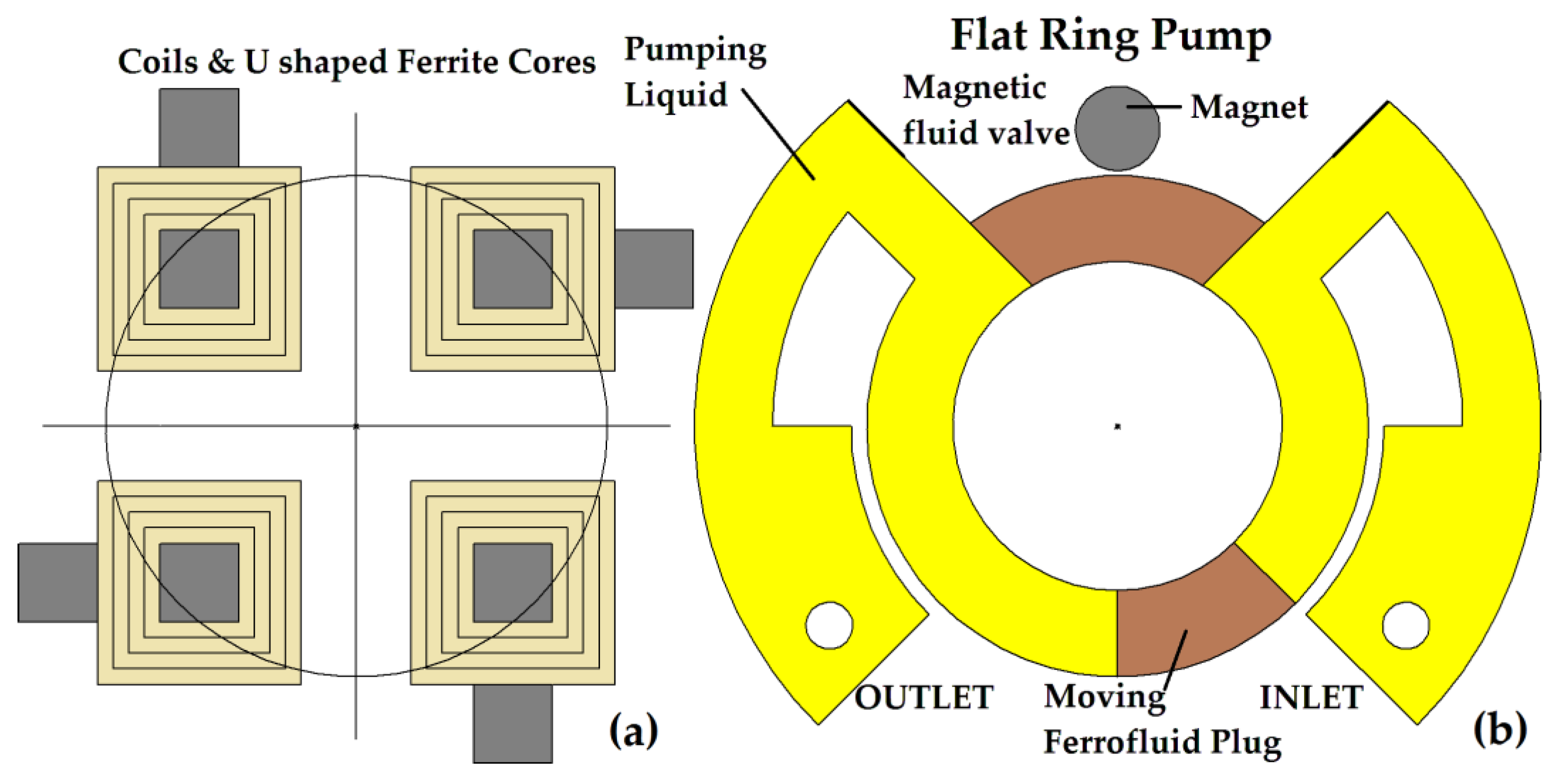

The main role of the electronic drive circuit is to ensure precise control of magnetic field intensity and induction produced by each of the four coils. These four coils, L1, L2, L3 and L4, are activated by rectangular pulse trains, such as in

Figure 9a,b.

The first CD4047 oscillator generates a rectangular V

osc voltage signal with a frequency between 4 and 100 Hz. As the CD4047 oscillator is set as an astable multivibrator τ

osc = 4.4

R1 C1, the variable resistance limits must be calculated accordingly to Equations (2)–(4). The

C1 has a fixed capacitance value of 100 nF. It results in

fmax = 100 Hz and

fmin = 4 Hz.

However, if and C1 = 100 nF, it can be determined that R10 = 22.7 kΩ and = 528 kΩ. A 500 kΩ potentiometer must be chosen and connected in series with a 20 or 22 kΩ fixed resistor and one 100 nF capacitor to adjust the oscillator frequency to be between 4.3 and 113 Hz (see Equations (2)–(4)).

A 74HC4017D or CD4017 Johnson decade counter with internal flip-flops logic circuits was used to create the train of four pulses, with the timing presented in the datasheet and as seen in previous pictures. The timing pulse sequence of the first Q1 flip-flop logic gate was followed by the secondary pulse sequence of the Q2 flip-flop gate until all Q1…Q9 carry-out signals formed a decade sequence. From this sequence, only four signals, Q1, Q2, Q3 and Q4, were chosen to be useful signals for the 4066 digital switching circuit and to control L1, L2, L3 and L4 coils. As can be noticed in the datasheet, the decade counter takes the clock signal frequency given by the CD 4047 oscillator and decreases it by two times for each flip-flop gate. Moreover, each CD4047 chip has an internal frequency divider (by 2) for both astable and monostable modes. If the signals from pin 10 are used for the output of the oscillator, it should be taken into account that the oscillator frequency will be divided by 4 and will be applied to the transistor gates by using channels 1…4. Power transistors switch on and off at a pulsed repetition frequency situated between 0.5 and 25 Hz, initiating or interrupting the power supply for each coil according to the previous timing sequence.

While the oscillator is generating and sending a V

OSC signal at the Johnson clock terminal, the same Vosc signal is reformed by two series inverting NAND (4011 chip) or NOT (4041) logic gates and applied to the triggering entrance of a monostable CD4047 chip. This integrated circuit arranged in a monostable configuration is used for modifying the Duty Cycle factor between 5 and 95%. This monostable circuit allows the pulses to pass only in the selected positive edge signal window, established by the Duty Cycle factor and monostable

τmon = 2.48

R2 C6 triggering time.

If

C6 capacitance is set to 100 nF, the variable

R*2 potentiometer value limits can be calculated.

The Duty Cycle

Da has an adjusting interval between 5% and 95%. If the minimum Duty Cycle

Damin = 5% and the maximum

fmax = 100 Hz oscillator frequency, we should be able to determine the variable resistance R

2 lower limit. The potentiometer

R*2 minimum value will be:

If the maximum Duty Cycle is chosen to be 95% and the minimum

fmin = 4 Hz oscillator frequency, the variable resistance R

2 higher limit can be determined. The maximum value of the potentiometer

will be:

Equations (5)–(8) resulted in R2min = 2…50 kΩ and R2max = 957 kΩ; these are the variable resistance limits that are necessary to keep the Duty Cycle inside 5–95% interval for frequencies variating between 4 and 100 Hz. Overall, a 1 MΩ variable potentiometer was needed to cover the entire Duty Cycle range.

If R

20 = 47 kΩ is selected to be a minimum series resistance in order to keep the Duty Cycle inside a 5% lower limit, for 4 Hz frequencies, it will be impossible to set the Duty Cycle to be 5% for higher frequencies, such as at 100 Hz. Moreover, if

R20 = 1.8 kΩ, the Duty Cycle can be set to a minimum of 0.18% at 4 Hz. The Duty Cycle can now be set to 5% at 100 Hz.

From Equation (9), it can be concluded that .

The load of IGBT transistors is represented by the inductance coils L1, L2,…,L4. Thus, the coils can be controlled using a rectangular voltage with variable “f” frequency in the range of 1 Hz ÷ 25 Hz.

At the exit pins of each digital switch from the 4066 chip, a train of rectangular pulses U1, U2,…, U4 is obtained, such as in

Figure 10 and

Figure 11. These train pulses are used to control the power IGBT groups (Q5, Q6), (Q11, Q12), (Q17, Q18) and (Q23, Q24). Each group of two power transistors has a buffer circuit where the gates are connected. The buffer consists of one 2N1711 NPN transistor; two BD139, BD 140, NPN and PNP transistors pair arranged in series connection; and one smaller G7N60C3D IGBT rated at 600 V and 14 A to bring the gate to the ground and disconnect the group of power IGBT’s. The buffer acts depending on the channel’s signals; when the channel signal is on or HIGH, the 2N1711 transistor brings the gates of these two BD139 and BD140 complementary transistors to the ground. The BD140 PNP transistor switches on, and BD139 switches off, meaning that the G7N60C3D IGBT gate will also be connected to the ground, and the G7N60C3D IGBT will be turned off. In this case, the gates of the power IGBT’s pair stay positive, and the corresponding coil is supplied with current.

When the channel signal is LOW, the 2N1711 transistor keeps the gates of these two BD139 and BD140 complementary transistors to the positive side. The BD140 PNP transistor switches off, and the BD139 NPN transistor switches on, meaning that the G7N60C3D IGBT gate will also be connected to the positive side, and the G7N60C3D IGBT will be turned on, bringing the power IGBT gates to the ground. In this case, the power IGBT pair will be turned off, and no current will pass through the corresponding coil.

Each buffer will act similarly to allow or block the current flowing path from the 15 V voltage source.

In

Figure 10 and

Figure 11, the electronic scheme is presented for controlling coils L1, L2, L3 and L4. The inductive kick overvoltage can be 3 to 4 times higher than the supply voltage. In our case, the activating pulse frequency is small, 1–25 Hz, so only a high inductance could cause a rapid voltage spike. The coil’s inductances with the E ferrite cores were measured at different frequencies between 20 and 100 Hz, and all four inductances were 0.126–0.127 H. The electronic power scheme is described in

Appendix B.

2.3. Actuator Fabrication and Experiments

An ABS box was 3D printed to be used as a support for both E-type ferrite cores and to retain the magnetic fluid (see

Figure 1). This box is composed of four equal squared compartments 20 mm in length. The 3D-printed wall has a thickness of 2 mm. E-type ferrite cores also have the same length of 20 mm, and each central leg has a squared surface of 5 × 5 mm

2. Each lateral leg has a surface of 5 × 3.5 mm

2. The overall ferrite height is 10 mm, and the space between legs is 4 mm. This space was used to mount the coils. Each coil support has a 6 mm squared hole to be suited to the leg surface, and the useful winding surface is 4 × 6 mm

2. The coil support has a height of 6 mm. The coil winding wire had a diameter of 0.06 mm, and the coil had a number of 1534 turns. The same 2 mm wall thickness was used as a spacer in simulations. The inner box height was 16 mm to let the magnetic nanofluid be poured a little above the coils and E ferrite cores and to have space to observe the magnetic nanofluid 3–4 mm inflation without spilling the fluid across the outside walls. Any E-type soft ferrite with a total flux path length of 20 mm could be used, but the recommended core materials for lower than 200 kHz frequencies are 3C81, 3C90…93.

The laboratory equipment used for magnetic fluid experiments was the following:

- -

Agilent E4980 A LCR Meter;

- -

Keysight 53210 A RF Counter;

- -

FLUKE 281 40 Ms/s Arbitrary Waveform Generator;

- -

Agilent 34461 A 6 ½ Digit Multimeter;

- -

Tektronix TDS 2014 B Digital Storage Oscilloscope;

- -

NI LabVIEW Signal Express Tektronix Edition;

- -

AC/DC Current Probe FLUKE 80i-110s, Sensitivity 100 mV/A.

Measurements were made at room temperature (22 ± 3 °C) and humidity of 48.2 RH.

Coil inductance measurements from

Table 2 were made with Agilent E4980 A LCR Meter at different frequencies. Because this actuator is controlled at frequencies below 20 Hz, the coil inductance has little influence on series impedance Z. The coil resistance with 309 Ω and the 15 V coil average supply voltage values were used for current estimation and as an input parameter in previous simulations. It is known that frequency, total 1534 number of turns and average current must be introduced in FEMM 4.2 as input parameters, besides the soft magnetic materials and copper strands selection.

As the FLUKE 80i-110s current probe had a sensitivity of 100 mV/A, and it was observed that on channel 2 from the oscilloscope, there are 10 mV/division, about 8 mV were measured with the current probe.

That means a 0.08 A peak-to-peak current and a 50 mA average current were measured for a 0.9 Duty Cycle. For 0.72 Duty Cycle, a 0.06 A peak-to-peak current was measured, which means 38 mA average value. These measured currents are in agreement with the ones used in simulations.

Here, in

Figure 12, a higher 72% Duty Cycle and 9 Hz frequency was chosen for both voltage and current measurements because higher values should be more easily acquired by the oscilloscope. The inductive load and IGBT transistor will stay in the conduction state for longer, allowing the electronic circuit to be supplied with more power.

In

Figure 13, the measurements of actuator coils supply voltage and the current passing through this coils, at 1.5 Hz and with a 72% Duty Cycle were shown.

Average power of 0.6 W is supplied to a single inductive load at 72% Duty Cycle (see

Figure 12). The magnetic fluid actuator does not need more than 1 W of continuous power to operate. As the Duty Cycle decreases, the current passing through the coil also decreases; in this way, the magnetic field falls towards a lower limit until the actuator stator stops pushing the mobile part. A lower magnetic field passing through the magnetic nanofluid means less magnetic fluid displacement, and lower magnetic fluid bubble inflations are to be obtained in this case.

The actuator temperature measurement carried out with the FLUKE TI 20 equipment revealed that the level of heating is negligible,

Figure 14. The maximum measured temperature value was 46 °C after 30 min of operation and was located just above the active coil and E core center, where the white mist is present. Above non-active coils, the temperature decreased by only 2 °C. This temperature map can explain that magnetic nanofluids also have enhanced heat transfer characteristics. Various types of oil magnetic nanofluids were used in power transformers to improve the cooling system; however, the thermal self-pumping property of a magnetic fluid was also exploited to recirculate the fluid inside the cooling tubes.

It can be noticed that the temperature inside the magnetic nanofluid and actuator coils increases up to 46 °C. The measured room temperature was around 20 °C, and near the box walls, the temperature increased slightly to 28 °C.

From these four frames (see

Figure 15a–d) selected from a video recording of the phenomena, the Johnson counter command cycle that is used for magnetic fluid inflation and translation movement can be distinguished. When the first coil is activated, an elevation appears in the right down side stator corner and stays up until the second timing sequence starts. When the second rectangular signal appears, the first coil is shuttled down, and the coil from the upper side right corner is activated. Much of the magnetic nanofluid that was present down side will now be attracted to the upper side; therefore, a translation movement is executed, and at the same time, the magnetic nanofluid forms a half bubble in the upper side. The same process described earlier is repeated four times for each group of two coils. At the end of the rotation cycle, inflation appears in the left down side stator corner, and the fourth coil is activated. The magnetic fluid stays up in this region until the first coil is activated again and the rotation cycle is completed. Three movies were made at different driving frequencies, at 9 Hz; 3.4 Hz; and at the lowest frequency, 1.5 Hz. The most important frames were selected to describe the magnetic fluid rotation or translation movements at 1.5 Hz driving frequency (

Supplementary Materials).