Evaluation and Simulation Analysis of Mixing Performance for Gas Fuel Direct Injection Engine under Multiple Working Conditions

Abstract

:1. Introduction

2. Model and Research Method

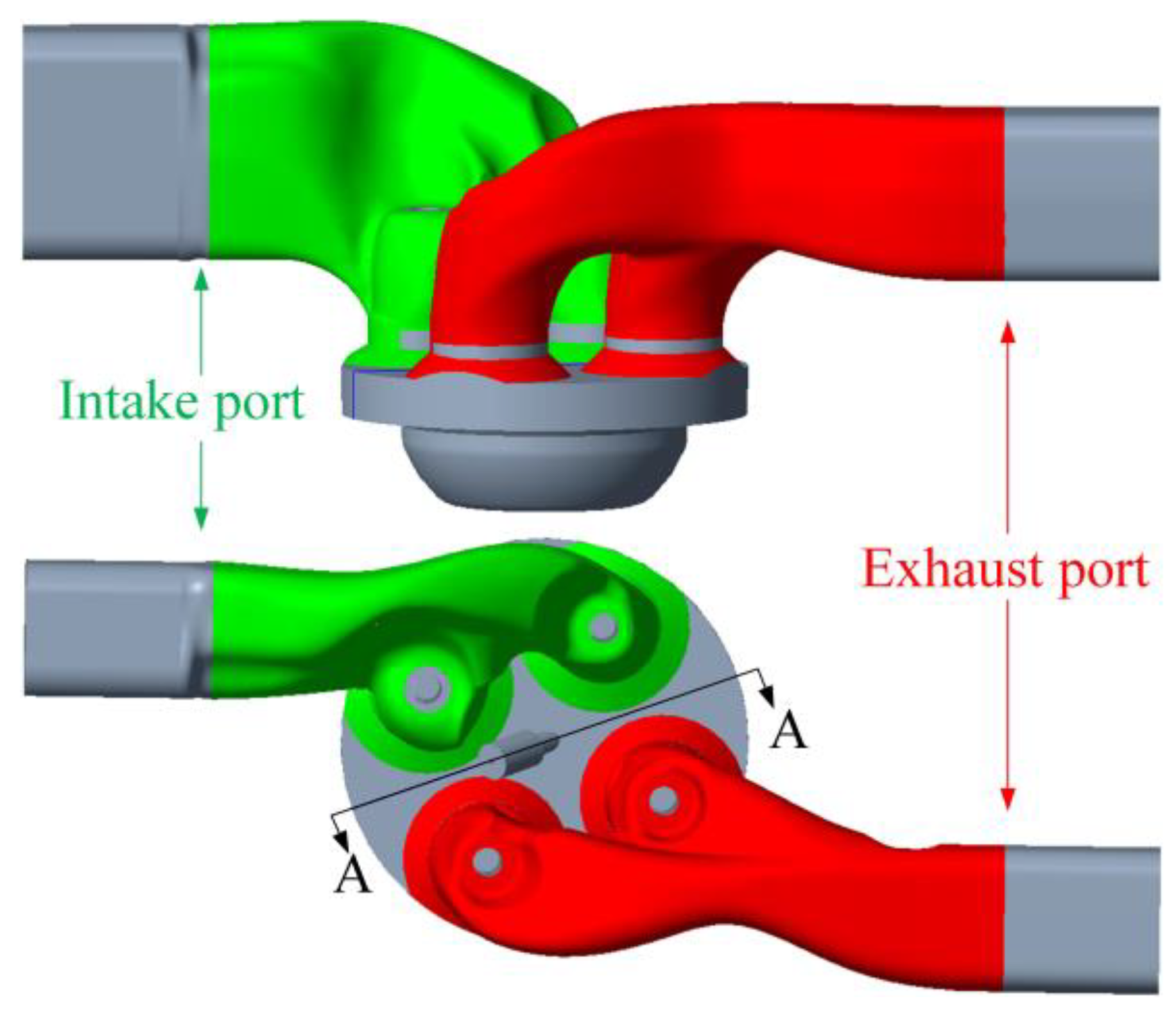

2.1. Model

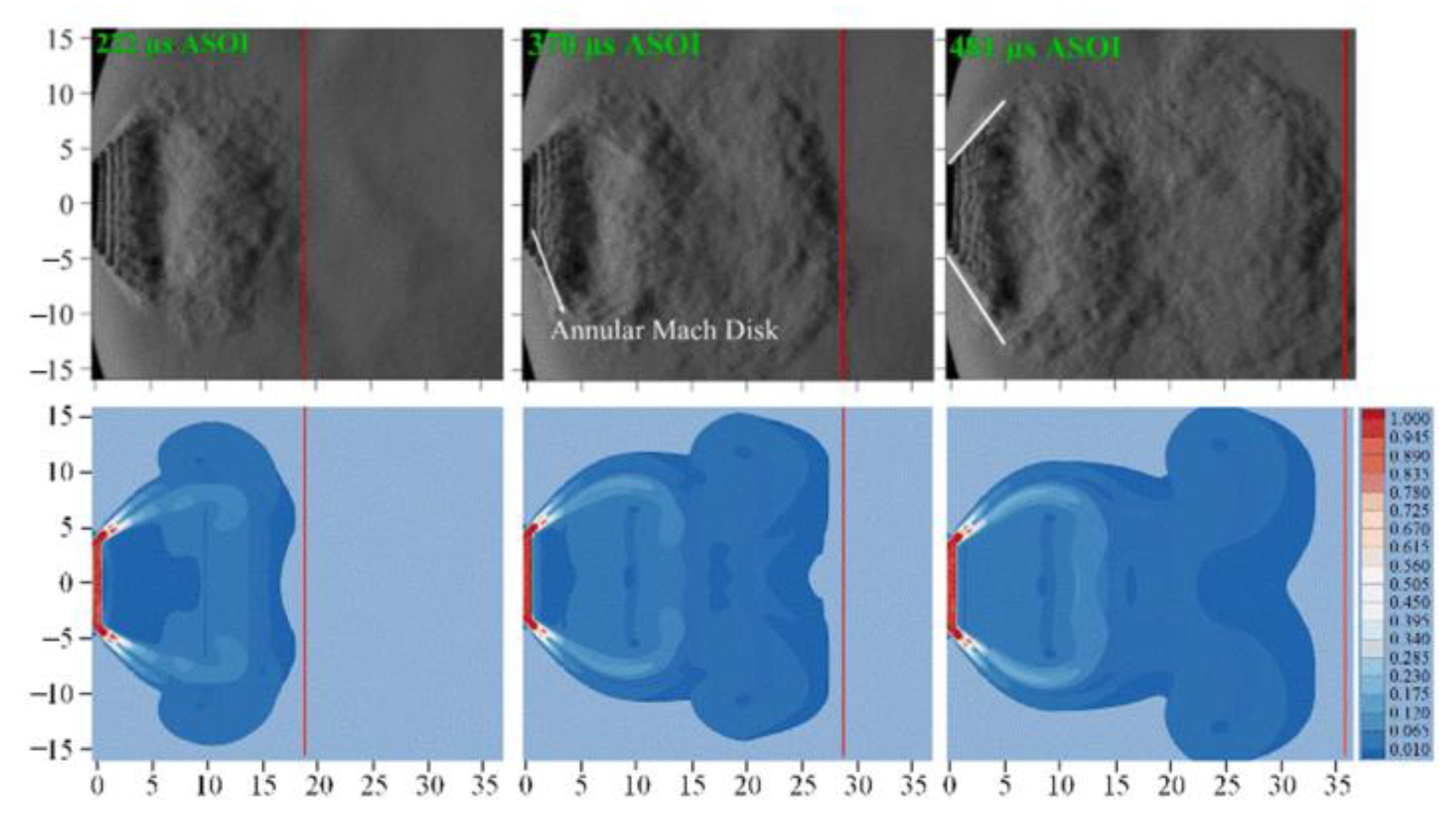

2.2. Transient CFD Model Verification

2.3. Research Method

3. Evaluation Methods for Mixing Performance

4. Results and Discussion

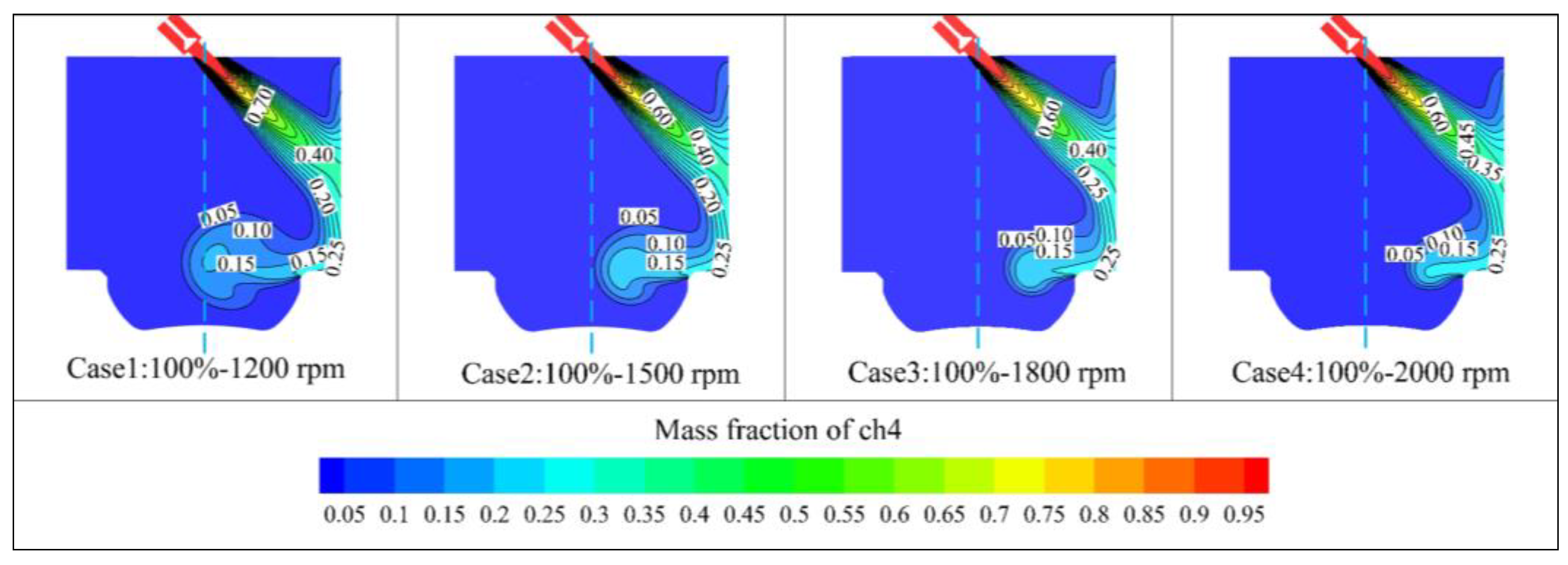

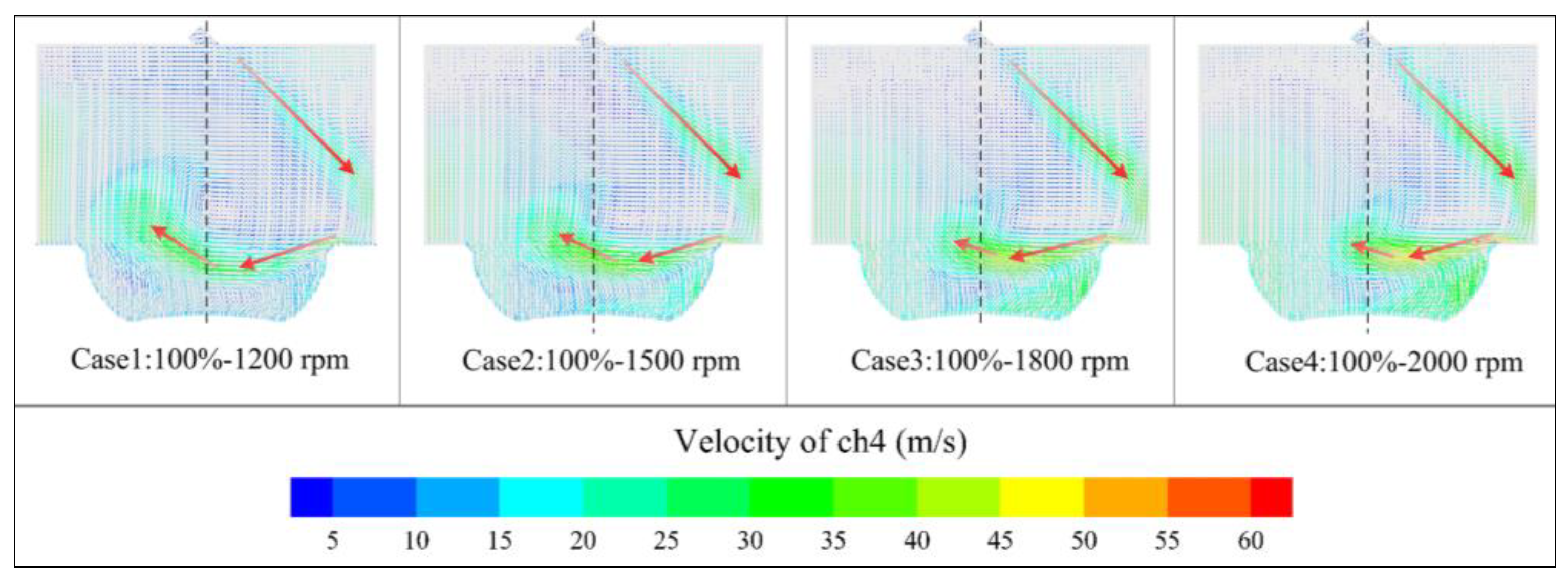

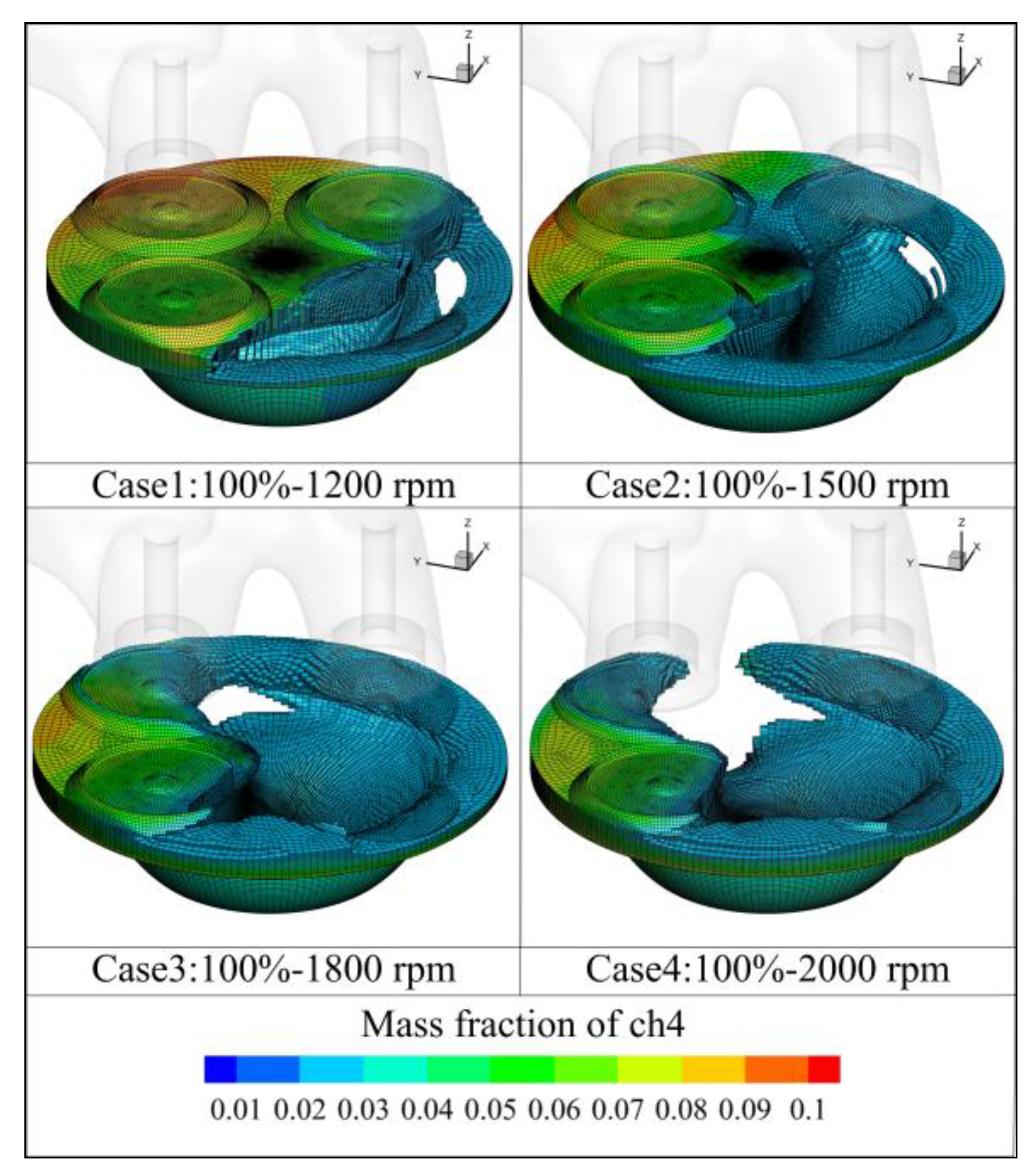

4.1. The Effect of Engine Speed

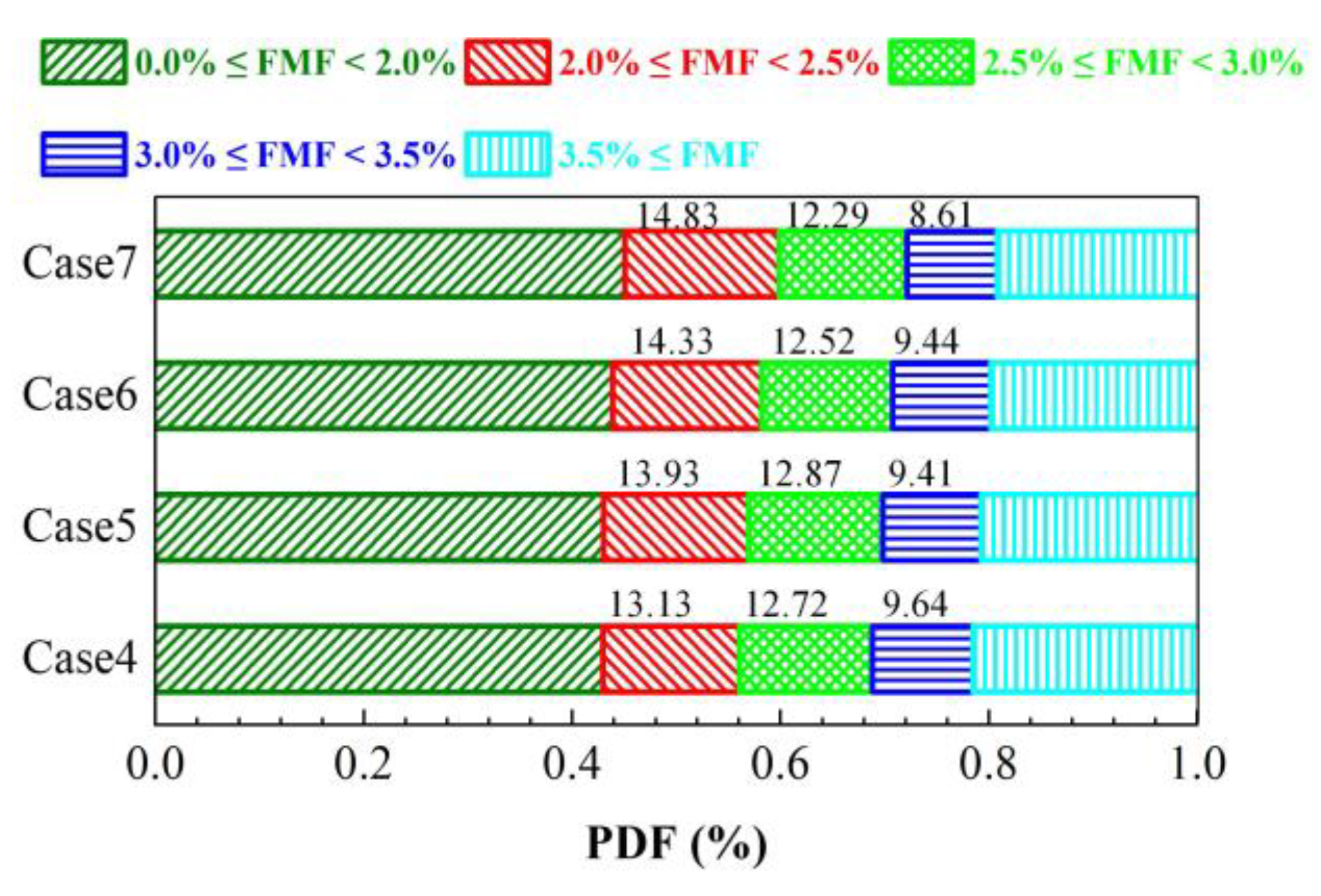

4.2. The Effect of Engine Load

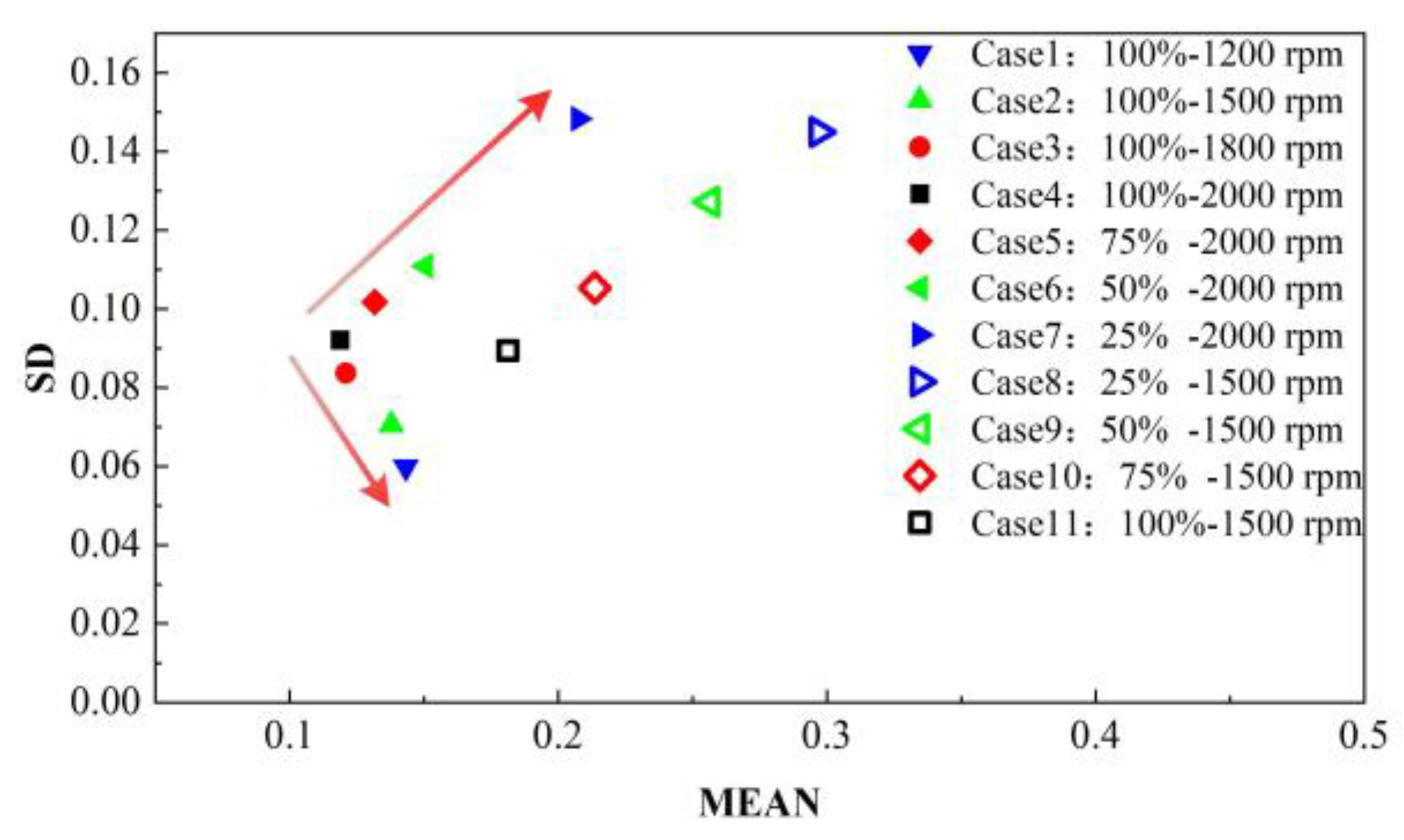

4.3. The Effect of Engine Multiple Working Conditions

5. Conclusions

- (1)

- Under the influence of engine speed, the characteristics of the gas fuel mixing process can be divided into three stages in the phase space. The gas fuel mixture rapidly occupies the cylinder volume in injection stage. During the transition stage, the gas fuel mixture is in a highly transient state. The diffusion stage is characterized by the continuous homogenization of the mixture.

- (2)

- In the phase space, the diffusion stage of the mixing stage shows a characteristic inflection point after the E moment. The gas fuel impinges on the left cylinder wall, forming a phenomenon of pushing back towards the in-cylinder centerline. This may be the reason for the emergence of characteristic inflection points.

- (3)

- The in-cylinder mixing process is influenced by the load factors too, and the mixing trend of the gas fuel in the phase space is the same. As the load decreases, the velocity of the gas fuel jet near the boundary of the vortex increases, making it more difficult for the energy of the vortex to dissipate. This leads to a greater variation in the gas fuel distribution in the cylinder.

- (4)

- The in-cylinder mixing performance at the end of compression stroke under different working conditions can be reflected in the phase space. As the engine load decreases, the MEAN increases, while the SD also increases, and the gas fuel mixture approaches the stratified mixture. As the engine speed decreases, the MEAN increases, while the SD decreases, and the gas fuel mixture approaches the homogeneous mixture.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CNG | compressed natural gas |

| DI | direct injection |

| PFI | port fuel injection |

| CFD | computational fluid dynamics |

| DOI | duration of injection |

| SOI | start of injection |

| EOI | end of injection |

| IVO | intake valve opening time |

| IVC | intake valve closing time |

| BTDC | before top dead center |

| ATDC | after top dead center |

| CA | crank angle |

| FMF | gas fuel mass fraction |

| probability distribution frequency | |

| BMCR | best mixture concentration region |

References

- IEA. Gas. Available online: https://www.iea.org/fuels-and-technologies/gas (accessed on 14 March 2023).

- Gideon, F.; Tarun, S.; Fionn, R. Exploring a case transition to low carbon fuel: Scenarios for natural gas vehicles in Irish road freight. SSRN Electron. J. 2021. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3855537 (accessed on 22 May 2023).

- Abdullah, N.N.; Anwar, G. An Empirical Analysis of Natural Gas as an Alternative Fuel for Internal Transportation. Int. J. Engl. Lit. Soc. Sci. 2021, 6, 479–485. [Google Scholar] [CrossRef]

- Tadeusz, D.; Przemysław, M.; Karolina, Z. Costs and benefits of using buses fuelled by natural gas in public transport. J. Clean. Prod. 2019, 225, 1134–1146. [Google Scholar]

- Mahendar, S.K.; Erlandsson, A.; Adlercreutz, L. Challenges for Spark Ignition Engines in Heavy Duty Application: A Review; SAE Technical Paper 2018-01-0907; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Abdullah, S.; Mahmood, W.; Aljamali, S.; Shamsudeen, S.A.A.A. Compressed Natural Gas Direct Injection: Comparison Between Homogeneous and Stratified Combustion. In Advances in Natural Gas Emerging Technologies; InTech Open: London, UK, 2017; pp. 153–169. [Google Scholar]

- Kakaee, A.-H.; Nasiri-Toosi, A.; Partovi, B.; Paykani, A. Effects of piston bowl geometry on combustion and emissions characteristics of a natural gas/diesel RCCI engine. Appl. Therm. Eng. 2016, 102, 1462–1472. [Google Scholar] [CrossRef]

- Chiodi, M.; Berner, H.-J.; Bargende, M. Investigation on Different Injection Strategies in a Direct-Injected Turbocharged CNG-Engine; SAE Technical Papers 2006-01-3000; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Spiegel, L.; Spicher, U. Mixture Formation and Combustion in a Spark Ignition Engine with Direct Fuel Injection. In International Congress and Exposition; SAE International: Warrendale, PA, USA, 1992; pp. 24–28. [Google Scholar]

- Yadollahi, B.; Boroomand, M. A Numerical Investigation of Combustion and Mixture Formation in a Compressed Natural Gas DISI Engine with Centrally Mounted Single-Hole Injector. J. Fluids Eng. 2013, 135, 091101. [Google Scholar] [CrossRef]

- Sankesh, D.; Lappas, P. Natural-Gas Direct-Injection for Spark-Ignition Engines—A Review on Late-Injection Studies; SAE Technical Paper 2017-26-0067; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Sankesh, D.; Edsell, J.; Mazlan, S.; Lappas, P. Comparative Study Between Early and Late Injection in a Natural-Gas Fueled Spark-Ignited Direct-Injection Engine. Energy Procedia 2017, 110, 275–280. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, X.; Zhang, J.; Hou, X. Numerical analysis of the influence of the fuel injection timing and ignition position in a direct-injection natural gas engine. Energy Convers. Manag. 2017, 149, 748–759. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M. Effect of diesel injection timing on the combustion of natural gas/diesel dual-fuel engine at low-high load and low-high speed conditions. Fuel 2018, 235, 838–846. [Google Scholar] [CrossRef]

- Keskinen, K.; Kaario, O.; Nuutinen, M.; Vuorinen, V.; Künsch, Z.; Liavåg, L.O.; Larmi, M. Mixture formation in a direct injection gas engine: Numerical study on nozzle type, injection pressure and injection timing effects. Energy 2016, 94, 542–556. [Google Scholar] [CrossRef]

- Addepalli, S.K.; Mallikarjuna, J.M. Quantitative Parametrization of Mixture Distribution in GDI Engines: A CFD Analysis. Arch. Comput. Methods Eng. 2018, 26, 639–662. [Google Scholar] [CrossRef]

- Mohammad, A.; Bashar, Q. Evaluating the in-cylinder gas mixture homogeneity in natural gas HCCI free piston engine under different engine parameters using 3D-CFD analysis. Energy Sources 2018, 40, 1097–1113. [Google Scholar]

- Baratta, M.; Misul, D.; Xu, J.; Fuerhapter, A.; Heindl, R.; Peletto, C.; Preuhs, J.; Salemi, P. Development of a High Performance Natural Gas Engine with Direct Gas Injection and Variable Valve Actuation. SAE Int. J. Engines 2017, 10, 2535–2551. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Chang, S. Effect of Injection Location and Multi-Hole Nozzle on Mixing Performance in a CNG-Fueled Engine with Port Gas Injection, Using CFD Analyses. MATEC Web Conf. EDP Sci. 2017, 95, 06003. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Zhang, L.; Li, L.; Wu, J.; Wang, H. Numerical Comparative Study on the In-Cylinder Mixing Performance of Port Fuel Injection and Direct Injection Gas-Fueled Engine. Energies 2022, 15, 5223. [Google Scholar] [CrossRef]

- Wang, T.; Wang, H.; Zhang, L.; Zheng, Y.; Li, L.; Chen, J.; Gong, W. A Numerical Study on the Transient Injection Characteristics of Gas Fuel Injection Devices for Direct-Injection Engines. Actuators 2023, 12, 102. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Zhang, J. Numerical analysis of flow, mixture formation and combustion in a direct injection natural gas engine. Fuel 2019, 259, 116268. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Bore (mm) × Stroke (mm) | 131 × 155 |

| Displacement volume(L) | 12.53 |

| Compression ratio | 11.5 |

| Rated power (kW)/speed (rpm) | 255/2000 |

| IVO/IVC(CA) | 30° BTDC/46° ATDC |

| EVO/EVC(CA) | 78° BTDC/30° ATDC |

| Parameter | Value |

|---|---|

| Outlet diameter (mm) | 7 |

| Valve lift (mm) | 1.5 |

| Injection pressure (MPa) | 1.0 |

| Case | Load | Rotate Speed, rpm | Inlet Pressure, bar | SOI, ° CA | EOI, ° CA | DOI, ° CA |

|---|---|---|---|---|---|---|

| 1 | 100% | 1200 | 2.0 | 584 | 635 | 51 |

| 2 | 100% | 1500 | 2.0 | 584 | 635 | 51 |

| 3 | 100% | 1800 | 2.0 | 584 | 635 | 51 |

| 4 | 100% | 2000 | 2.0 | 584 | 635 | 51 |

| 5 | 75% | 2000 | 1.7 | 588 | 635 | 47 |

| 6 | 50% | 2000 | 1.3 | 594 | 635 | 41 |

| 7 | 25% | 2000 | 0.8 | 601 | 635 | 34 |

| 8 | 25% | 1500 | 0.6 | 607 | 635 | 28 |

| 9 | 50% | 1500 | 0.8 | 603 | 635 | 32 |

| 10 | 75% | 1500 | 1.1 | 597 | 635 | 38 |

| 11 | 100% | 1500 | 1.4 | 593 | 635 | 42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wang, T.; Chen, J.; Zhang, L.; Zheng, Y.; Li, L.; Sun, Y. Evaluation and Simulation Analysis of Mixing Performance for Gas Fuel Direct Injection Engine under Multiple Working Conditions. Actuators 2023, 12, 239. https://doi.org/10.3390/act12060239

Wang H, Wang T, Chen J, Zhang L, Zheng Y, Li L, Sun Y. Evaluation and Simulation Analysis of Mixing Performance for Gas Fuel Direct Injection Engine under Multiple Working Conditions. Actuators. 2023; 12(6):239. https://doi.org/10.3390/act12060239

Chicago/Turabian StyleWang, Hongchen, Tianbo Wang, Jing Chen, Lanchun Zhang, Yan Zheng, Li Li, and Yanyun Sun. 2023. "Evaluation and Simulation Analysis of Mixing Performance for Gas Fuel Direct Injection Engine under Multiple Working Conditions" Actuators 12, no. 6: 239. https://doi.org/10.3390/act12060239

APA StyleWang, H., Wang, T., Chen, J., Zhang, L., Zheng, Y., Li, L., & Sun, Y. (2023). Evaluation and Simulation Analysis of Mixing Performance for Gas Fuel Direct Injection Engine under Multiple Working Conditions. Actuators, 12(6), 239. https://doi.org/10.3390/act12060239