Abstract

High-performance electroactive polymer actuators with large bending, fast response, and high durability have gained attention in the development of micromanipulators and multifunctional bionic soft robots. Herein, we developed high-performance electroactive soft actuators fabricated with ultrathin free-standing microfibrillated cellulose (MFC)-reinforced poly(3,4-ethylenedioxythiophene)/poly(4-styrenesulfonate) (PEDOT/PSS) with multi-walled carbon nanotube (MWCNT)-doped composite electrode films and ion-exchange Nafion membranes by a hot-pressing method. The prepared PEDOT/PSS-MFC-MWCNT electrodes have good film-forming properties with a Young’s modulus of 448 MPa and an electrical conductivity of 75 S/cm. The proposed PEDOT/PSS-MFC-MWCNT/Nafion soft actuators have a sustained peak displacement of 2.1 mm and a long-term cyclic stability of 94% with no degradation over 1 h at 1.0 V, 0.1 Hz. Furthermore, we fabricated soft micro-grippers based on the actuators for mimicking actual finger actions for grasping, pointing, and counting, which introduces new possibilities for the next-generation development of micromanipulators and bionic soft robotics.

1. Introduction

Multifunctional microrobots hold great promise for micromanipulation applications such as single-cell manipulation and surgery procedures, targeted therapy, and drug release [1,2,3,4,5]. In targeted therapy, microrobots can be designed to deliver medication directly to the site of the disease, enhancing treatment efficacy and minimizing side effects by reducing the dosage required and avoiding the exposure of healthy tissues to the therapeutic agents. Moreover, the controlled release of drugs can be achieved with microrobots, allowing for a more precise temporal and spatial management of the drug administration.

Generally, micro-operating soft robot systems require efficient active components, specifically actuators, to achieve precise and efficient movements. Ionic electroactive polymers (IEAPs) are advanced intelligent materials that exhibit the unique property of deformation in response to electrical stimulation. The IEAP actuators are potential candidates for active components in microrobots due to their softness, large bending, fast response, and low operating voltages (<5 V) [6,7,8,9].

A common example of IEAP is an ionic polymer metal composite (IPMC), which has a sandwich structure with an intermediate ion-exchange membrane (e.g., Nafion, PVDF-g-PSS) and chemically plated metal electrodes (e.g., Pt, Pd, Ag, Au) on both sides [10,11,12,13,14,15,16,17,18,19]. The bending deformation of IPMC is caused by the migration of internally hydrated cations under the action of the excitation voltage [20]. The IPMC with high deformability and low density can highly mimic the movement patterns and properties of biological muscle tissues [21,22,23,24,25], offering promising prospects for applications in bionics, artificial muscles, sensors, biomedical engineering, and soft robotics [26,27,28,29,30,31,32,33]. However, IPMC electrodes treated with electroless plating are prone to issues including rough surfaces, poor adhesion, multiple repeated plating, and time-consuming preparation, which thus negatively impact the charging efficiency and reduce the electromechanical properties of IPMC actuators. Thus, the fabrication of flexible electrode films with high conductivity, superior film-forming capabilities, high water-retaining capacity, and strong adhesion with an ion-exchange layer is essential for the advancement of high-performance IEAP soft actuators.

The commercially available flexible electrodes named poly(3,4-ethylenedioxythiophene)/poly(4-styrenesulfonic acid) (PEDOT/PSS) are an ideal conductive polymer. Since PEDOT/PSS electrodes possess excellent conductivity, flexibility, high electrochemical stability, and processing simplicity [34,35,36,37,38], recent studies have developed IEAP actuators based on PEDOT/PSS electrodes via drop-casting [39], dip-casting [40,41], spin-coating [42,43], and hot-pressing methods [44,45]. However, the drop or dip casting method is susceptible to generating uneven electrode surfaces. The spin coating produces waste because the solution is easily flung out of the coating, and it is challenging to control the film thickness during high-speed spinning. The self-standing electrode film needed for hot pressing is not easily formed by the commercially available PEDOT/PSS solution.

The natural green cellulose known as microfibrillated cellulose (MFC) has drawn a lot of scientific interest owing to its dense network structure, hydrophilicity, nontoxic, renewable nature, and biocompatibility [46,47]. Microfibrillated cellulose can be considered a reinforcing material for the PEDOT/PSS electrode to improve the film-forming properties and water-retaining capacity. Multi-walled carbon nanotubes (MWCNTs) with a large aspect ratio and high electrical conductivity can be used as nano-reinforcements to improve mechanical properties and electrical conductivities of PEDOT/PSS electrodes. [48,49,50,51].

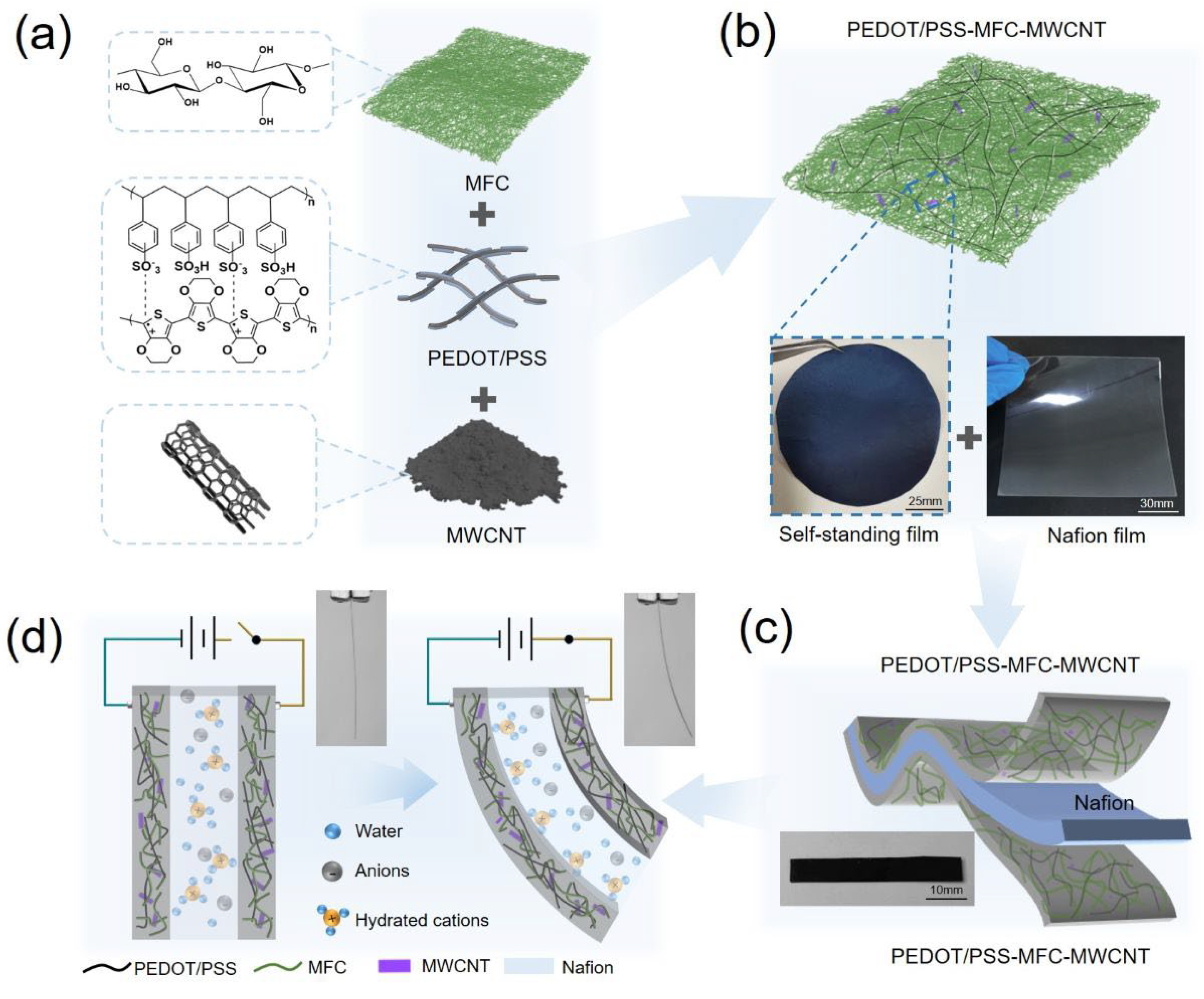

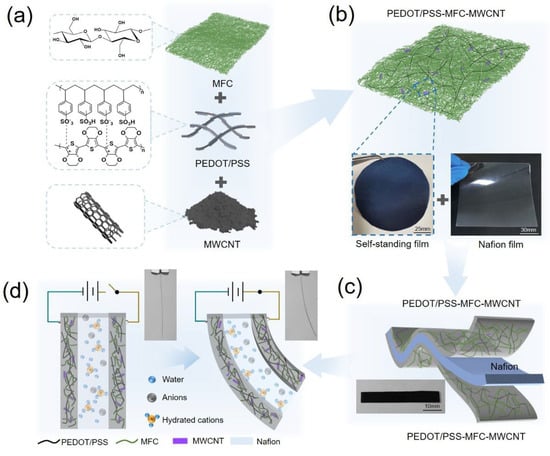

Here, we introduce advanced sandwich-structure ionic electroactive polymer actuators based on free-standing MFC-reinforced MWCNT-doped PEDOT/PSS composite electrode films and Nafion membranes by a hot-pressing method (Figure 1). The addition of MFC with a dense network structure and high specific surface to the PEDOT/PSS electrode could improve the contact surface between the electrode film and Nafion film via hot-pressing, which is beneficial to increasing the interface adhesion. Furthermore, the hydrophilic MFC has a high capacity for retaining water, which further supports the long-term actuation performance of the ionic actuator. In addition, MFC has a biodegradable nature and compatibility, and the development of eco-friendly MFC-reinforced PEDOT/PSS biocomposite-based ionic actuators with high performance remains a meaningful challenge. Our study aims to leverage the inherent benefits of MFC and MWCNT to enhance the performance of PEDOT/PSS electrode film for developing advanced ionic actuators. In our work, the proposed PEDOT/PSS-MFC-MWCNT actuator was assessed in terms of its morphologies, chemical structures, thermal stability, mechanical properties, electrical conductivity, and electromechanical actuation characteristics with various electrical inputs (voltages: ±0.5, ±1, ±1.5, ±2, and ±3.0 V; frequencies:1, 0.5, 0.3, and 0.1 Hz). Additionally, we evaluated the impacts of the addition of MFC and MWCNT on PEDOT/PSS electrode membranes. Finally, we demonstrated the actuators’ prospective application as soft micro-grippers for mimicking actual finger actions for grasping, pointing, and counting actions, which creates new possibilities for the next-generation development of flexible manipulators and bionic soft robotics.

Figure 1.

Development of the PEDOT/PSS-MFC-MWCNT actuator. (a) Chemical structures of MFC, PEDOT/PSS, and MWCNT. (b) A self-supported PEDOT/PSS-MFC-MWCNT electrode film. (c) Hot-pressed three-layer PEDOT/PSS-MFC-MWCNT/Nafion actuator. (d) Ionic soft actuator’s working principle.

2. Experimental Section

2.1. Materials

Aqueous PEDOT/PSS dispersion (CLEVIOS™ F ET, viscosity: 20–80 mPa·s at 20 °C, solids content: 3.0–4.0%) from Heraeus was utilized as a conductive electrode. Micro-fibrillated cellulose (MFC, 2%, diameter: 0.1–1.0 µm, PH: 7–8, Guilin Qihong Tech Co., Ltd., Guilin, China) dispersion was employed as reinforcement. Multi-walled carbon nanotube (MWCNT, length: 0.5–2 µm, diameter: <8 nm) was provided by XFNANO Tech Co., Ltd., Nanjing, China. Polyethylene glycol monoallyl ether (PEGM, n = approx.20) was used as a surfactant additive produced by Tokyo Chemical Industry Co., Ltd., Tokyo, Japan. Ion-exchange Nafion N212 film (thickness: 50 μm) was supplied by DuPont.

2.2. Development of PEDOT/PSS-MFC-MWCNT Electrode Film

First, 10 g MFC paste with 40 g water were mixed together. Then, 20 g PEDOTPSS and 1wt% PEGM were introduced to the mixture while stirring for 30 min. Secondly, 0.005 g MWCNT was added to the PEDOT/PSS-MFC electrode dispersion and stirred at 700 rpm for 8 h. Subsequently, the composite was subjected to sonication for 1 h to effectively disperse the MWCNTs throughout the matrix. Following this, the PEDOT/PSS-MFC- MWCNT composite dispersion was vacuum-degassed for 30 min to remove air bubbles. Finally, the composite dispersion was cast onto a polytetrafluoroethylene evaporation dish (Ø 100 mm) and heated at 65 °C for 10 h to obtain a self-supported PEDOT/PSS- MFC-MWCNT electrode film with a thickness of 35 μm (Figure 1a,b).

2.3. Fabrication of the PEDOT/PSS-MFC-MWCNT Actuator

The ionic electronic soft actuator was fabricated with an ion-exchanged Nafion-N212 film sandwiched between two prepared self-supporting PEDOT/PSS-MFC-MWCNT electrode films by a hot press (ST-15YP, Kunshan Lugong Precision Instrument Co., Ltd., Kunshan, China) under 70 °C for 5 min with a pressure of 20 MPa (Figure 1c). Ultimately, a 105 μm thick hot-pressed PEDOT/PSS-MFC-MWCNT/Nafion soft actuator was obtained and then sliced into 40 mm long and 5 mm wide strips.

2.4. Characterization

In order to investigate the characterization of the prepared samples, the morphological properties were analyzed by a GeminiSEM 500 Field Emission Scanning Electron Microscope (FE-SEM, manufactured by Carl Zeiss, Oberkochen, Germany) under an acceleration voltage of 2 kV. A cross-section of the three-layer PEDOT/PSS-MFC-MWCNT /Nafion actuator was produced through a freeze-fracture technique under liquid nitrogen. The chemical interaction and crystallinity were analyzed by a Nicolet iS20 Fourier transform infrared spectroscopy (FT-IR) with a broad wavelength range of 500–4000 cm−1 and a D8 discover X-ray diffractometer (XRD, Bruker AXS Co., Billerica, MA., USA) using Cu Kα radiation (λ = 1.5418 Å) with a scan rate of 0.02° in the range of 5–80°. The thermal stability was measured by a TG209F3 Thermogravimetric Analyzer (TGA, Netzsch Co., Selb, Germany) with a temperature range of 30–600 °C in a nitrogen atmosphere condition, while the tensile properties were measured from a tensile tester (QT-6203A) with a tensile rate of 10 mm min–1. The electrical conductivity was assessed using a ST2258C four-point probe.

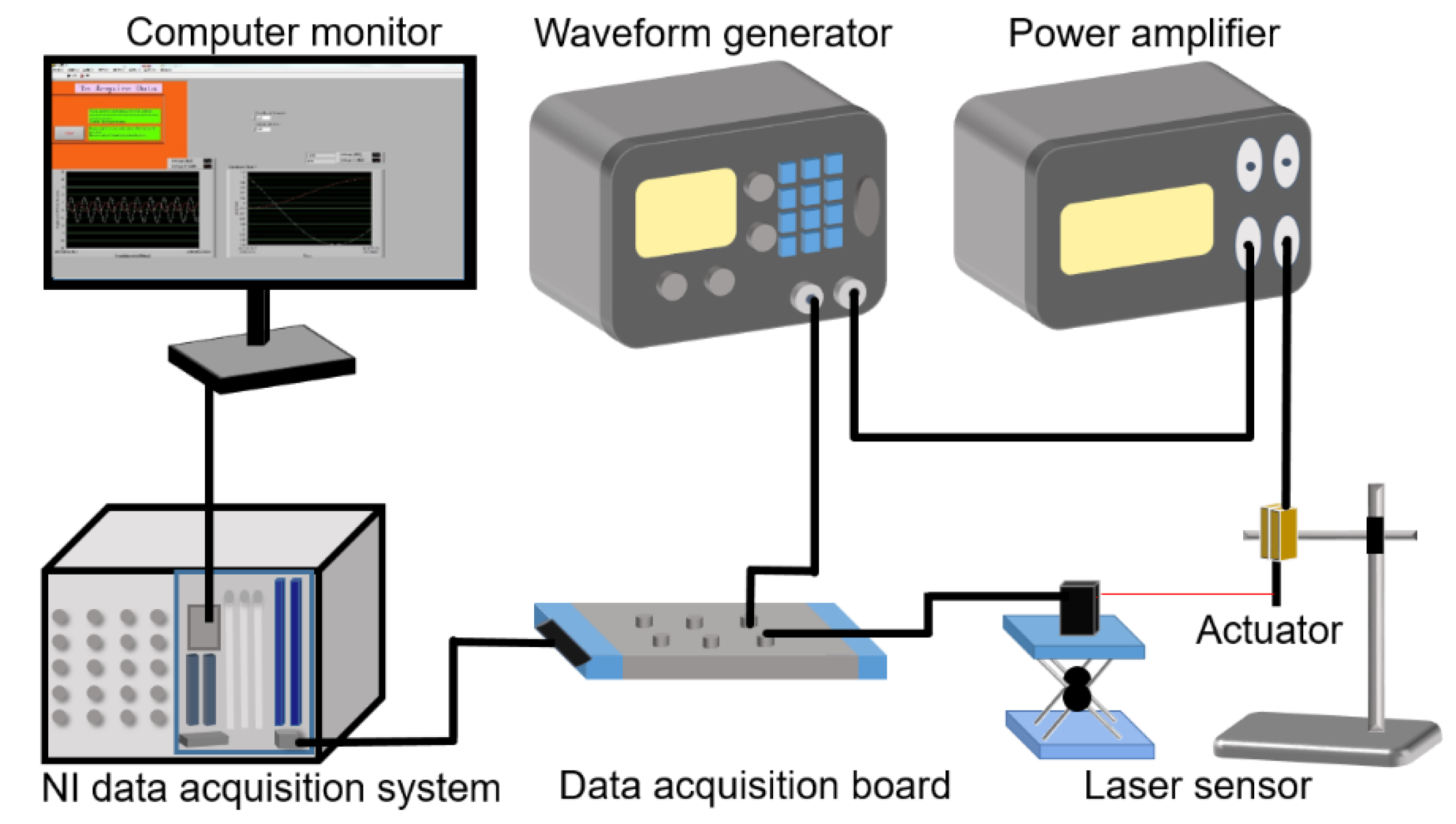

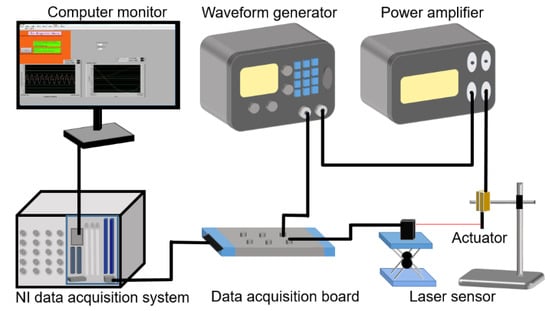

The actuator bending displacement testing system, as shown in Figure 2, includes a laser displacement sensor (IL-300, Keyence Co., Osaka, Japan), a power amplifier (FPA2000, Feel Tech Co., Zhengzhou, China), a signal generator (33500B, Keysight Tech Co., Santa Rosa, CA., USA), a data acquisition system (NI Pxle1078, National Instruments Co., Texas, TX, USA), and a computer monitor. In this experiment, the prepared actuator was fastened to a beam by clamping a 5 mm length off its upper end. The actuator length in operation was 35 mm. Kelvin clips were used to clip the copper electrodes and connect the device to the test system. The actuator strip was subjected to alternating sinusoidal voltages (±0.5, ±1, ±1.5, and ±2 V) and frequencies (1, 0.5, 0.3, and 0.1 Hz). The laser displacement sensor was used to record the tested actuator’s electromechanical deformation simultaneously. Moreover, the bending strain ε was determined with the equation: ε = 2dt/(d2 + l2), where d, t, and l stand for peak displacement, thickness, and free length, respectively.

Figure 2.

The actuation displacement testing system of the actuator.

3. Results and Discussion

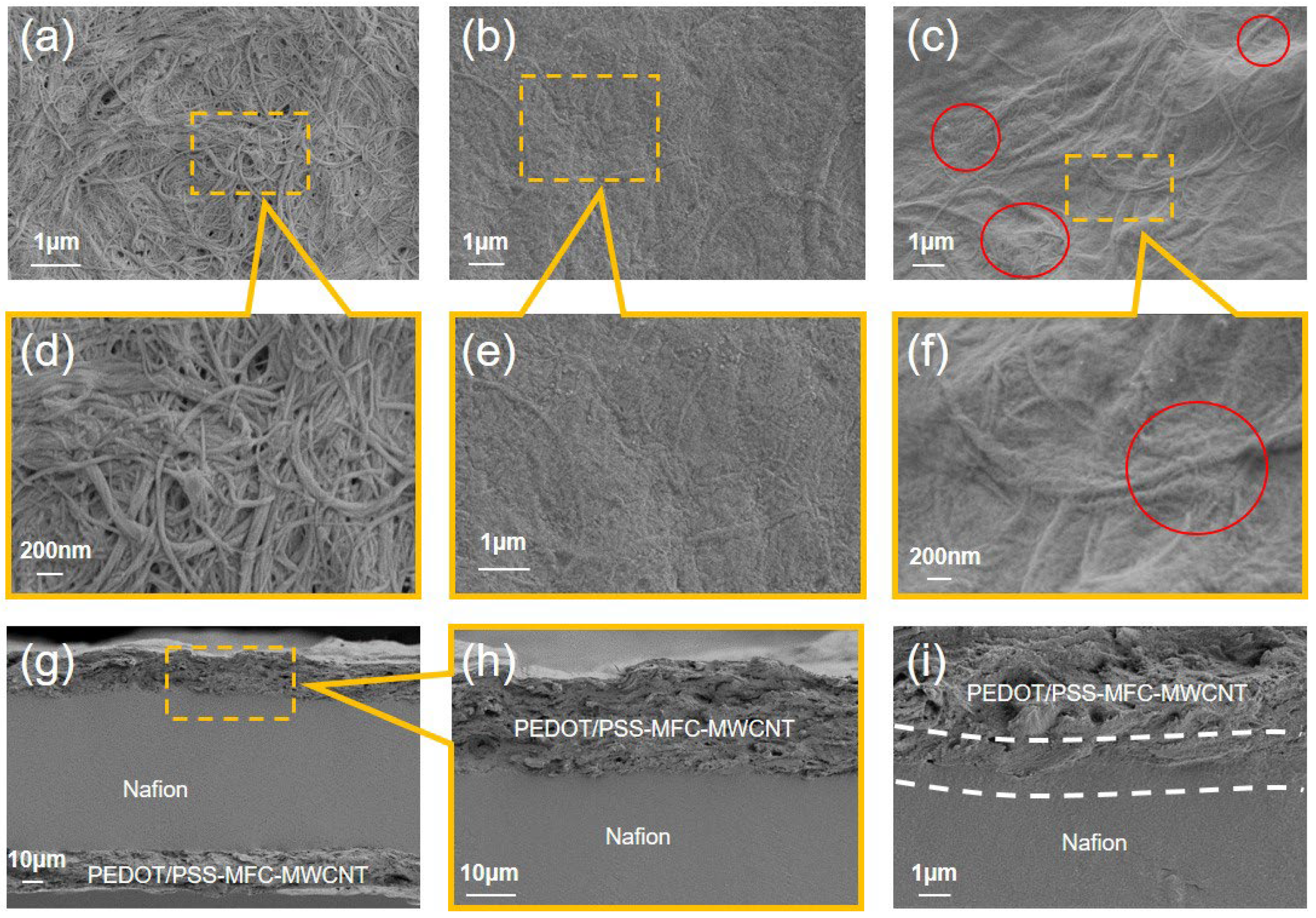

3.1. Scanning Electron Microscope

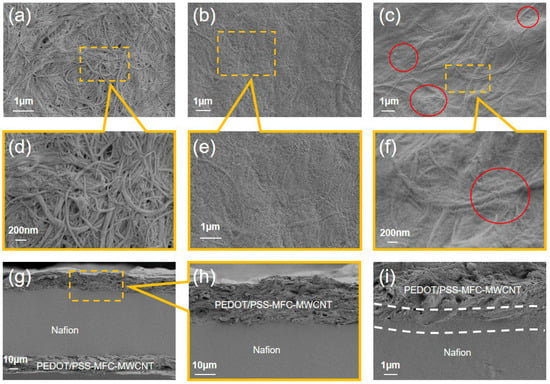

The morphologies of MFC, PEDOT/PSS-MFC, and PEDOT/PSS-MFC-MWCNT film were evaluated by FE-SEM. Figure 3a,d show the morphologies of the prepared MFC film with a natural dense microfibrous network structure. MFC-reinforced PEDOT/PSS electrode films have a comparatively homogeneous surface with microfibrous structures (Figure 3b,e). Following doping with MWCNT containing nanopore structures (Figure 3c,f), the PEDOT/PSS-MFC-MWCNT electrode surface displays a relatively uniform distribution without significant particle aggregation, and the locations in the composite where MWCNTs may be incorporated are marked with circles. Figure 3g–i show the cross-sectional SEM images of the hot-pressed PEDOT/PSS-MFC-MWCNT actuator with a sandwich structure. Importantly, the composite electrode films attached well to the Nafion film without delamination. A densification interface layer is clearly visible in Figure 3i resulting from the solidification and mutual compression caused by heating and pressure. Additionally, using a hot-pressing method, the microfibre surface of the PEDOT/PSS-MFC-MWCNT electrode has a porous and dense structure that improves adhesion and allows for a large bonding area with Nafion. In this case, a strong interface adhesion is essential to enhance the electromechanical characteristics of the actuator.

Figure 3.

SEM images of (a,d) MFC film, (b,e) PEDOT/PSS-MFC film, (c,f) PEDOT/PSS-MFC- MWCNT film, and (g,h) hot-pressed three-layer PEDOT/PSS-MFC-MWCNT/Nafion actuator’s cross-section. (i) Interface adhesion between electrode film and Nafion film via hot-pressing.

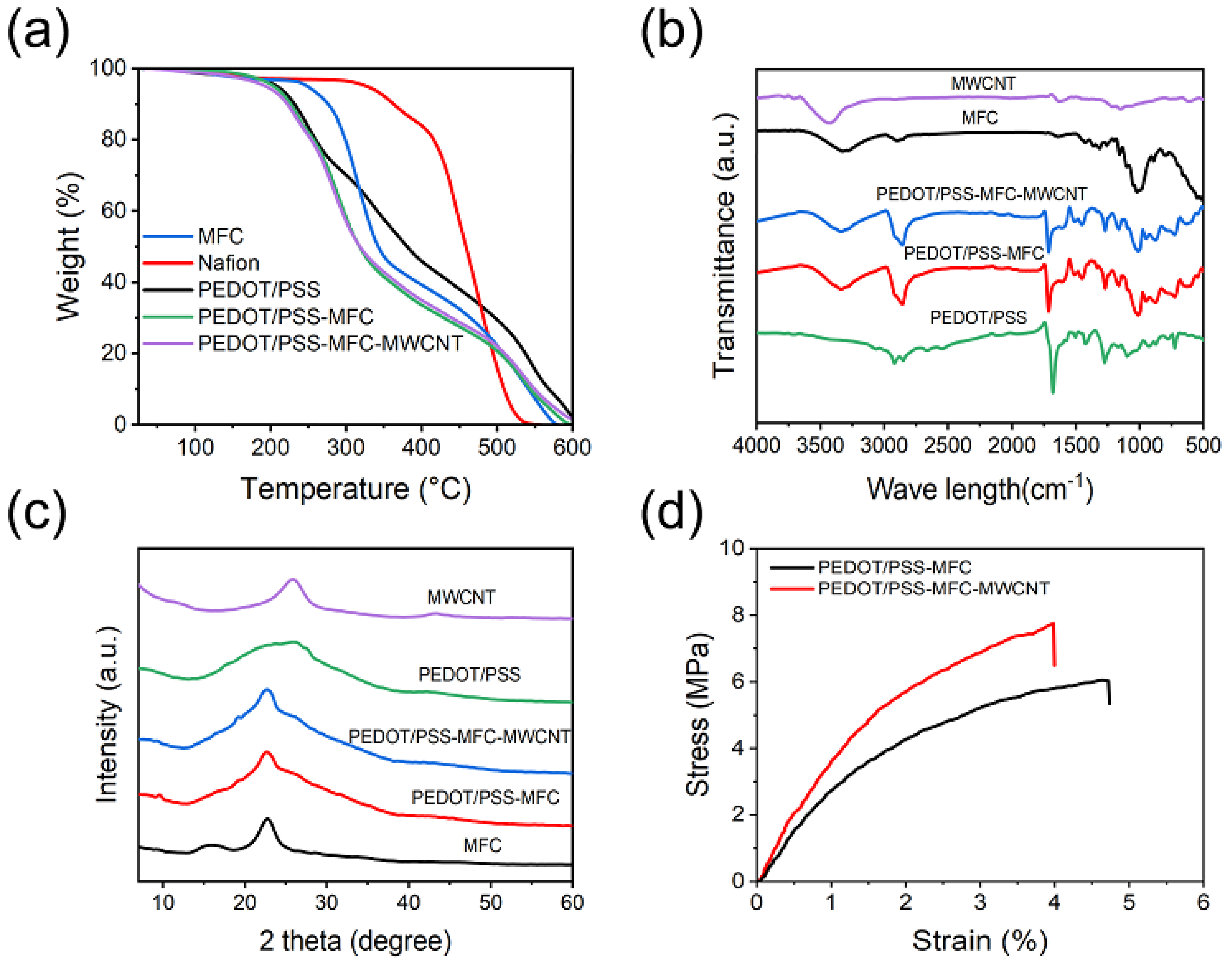

3.2. Thermogravimetric Analyzer

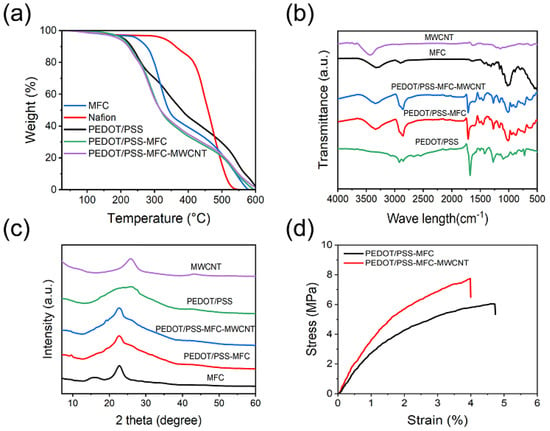

Figure 4a shows the thermal stability of the obtained PEDOT/PSS-MFC-MWCNT actuators. The first weight loss occurs from 30 to 200 °C owing to the evaporation of water, while the second (200–350 °C) significant weight fall is related to the decomposition of PSS and the main-chain degradation of MFC. The three stages (350–600 °C) are attributed to the breakdown of the main backbone PEDOT conjugated systems and the elimination of residual MFC molecular chains. The thermogravimetric analyzer shows that there is no observable chemical degradation of the PEDOT/PSS-MFC-MWCNT actuator for the preparation conditions (drying at 65 °C for 10 h and hot-pressing at 70 °C for 5 min).

Figure 4.

(a) TGA curves, (b) FT-IR spectra, (c) XRD patterns, and (d) tensile properties of the prepared PEDOT/PSS-MFC and PEDOT/PSS-MFC-MWCNT films.

3.3. Fourier Transform Infrared Spectroscopy

In order to confirm the interactions and chemical structures between MFC, MWCNT, and PEDOT/PSS, FT-IR spectra of PEDOT/PSS, MFC, MWCNT, MFC-PEDOT/PSS, and PEDOT/PSS-MFC-MWCNT were investigated in Figure 4b. The characteristic peaks of MFC at 3326, 2869, 1329, and 1029 cm−1 were attributed to O-H stretching, C-H stretching, and vibrational wobble of CH2 and -CO groups, respectively [52,53]. The absorption peaks of PEDOT/PSS at 3242, 1640, 1029, and 952 cm−1 are O-H stretching, C-C bonding in thiophene ring, C-O-C bending, and C-S-C stretching vibration, respectively [54]. More obvious characteristic peaks of MFC-reinforced PEDOT/PSS films at 2869 and 1645 cm−1 are observed, attributed to C-H stretching and the presence of C-C bonds in the thiophene ring. Two new characteristic peaks occurred at 1641 and 1163 cm−1 after the addition of MWCNT because of the O-H and C-O-C stretching vibrations of the aromatic C=C. The FT-IR analyses illustrate the strong interactions and chemical crosslinking of PEDOT/PSS, MFC, and MWCNT.

3.4. X-ray Diffractometer

The XRD in Figure 4c shows that MFC and MWCNT significantly impacted the crystallinity of PEDOT/PSS. The MFC shows typical features of cellulose I structure. The characteristic peaks of MFC at 2θ = 16.1° and 22.6° correspond to characteristic diffraction peaks in the (110) and (200) planes, respectively [55]. The diffraction peak at 2θ = 22.6° rises significantly following the addition of high crystallinity MFC in PEDOT/PSS electrode compared with pure PEDOT/PSS. Furthermore, the peak of PEDOT/PSS-MFC doped with MWCNT appears at 2θ = 43.4°due to the characteristic diffraction peak of MWCNT in the (100) plane [56]. Moreover, the crystallinities of the samples were calculated using the crystallization index (CI): CI = (Imax - Imin)/Imax, where Imax is the maximum peak intensity and Imin is the minimum peak intensity. The crystallinity of MFC, PEDOT/PSS, PEDOT/PSS-MFC, and PEDOT/PSS-MFC-MWCNT was 60%, 43%, 55%, and 53%, respectively. The crystallinity of MFC with the addition of PEDOT/PSS and MWCNT decreased significantly due to the strong interaction and crosslinking between PEDOT/PSS, MFC, and MWCNT, which suggests that the crystallinity of the electrode film was discernibly impacted by the MFC and MWCNT.

3.5. Tensile Testing

Figure 4d shows the mechanical properties of the prepared PEDOT/PSS-MFC and PEDOT/PSS-MFC-MWCNT electrode films. The Young’s modulus of the MFC-reinforced PEDOT/PSS electrode film is 310 MPa. After doping with MWCNT, the PEDOT/PSS-MFC-MWCNT electrode film displays a higher Young’s modulus of 448 MPa. The self-supporting PEDOT/PSS-MFC-MWCNT composite electrode films with higher mechanical strength and good film-forming capabilities are beneficial for the actuator’s actuation performances, as confirmed in the Section 3.6.

3.6. Electromechanical Characteristics

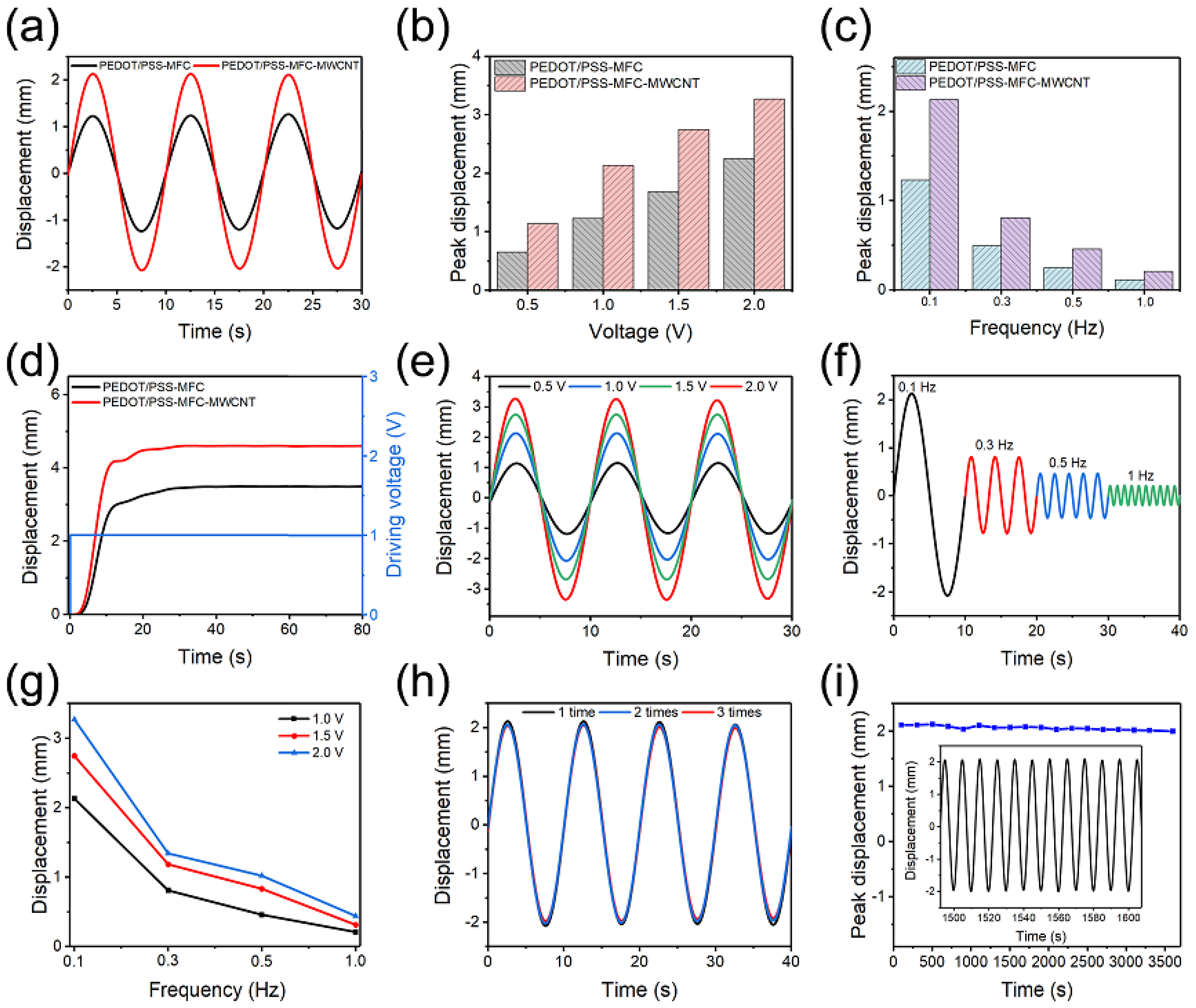

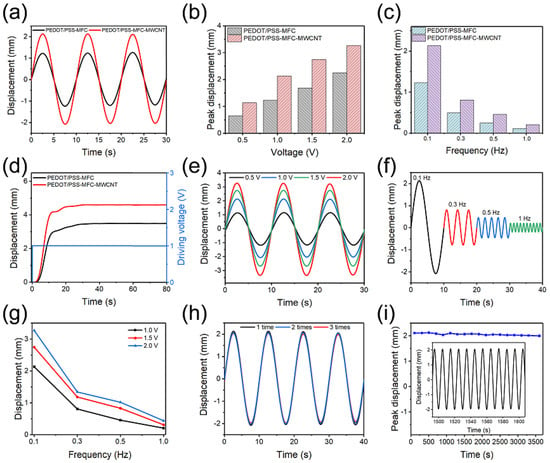

We evaluated the electromechanical characteristics of the prepared actuators in Figure 5. Figure 5a shows the actuation properties of the PEDOT/PSS-MFC and PEDOT/PSS-MFC-MWCNT actuators under an alternating sinusoidal voltage of ±1.0 V and a frequency of 0.1 Hz. The initial deformation slope and corresponding vertex displacement of the MWCNT-doped actuator are substantially higher than that without MWCNT. Specifically, in Figure 5b,c, the MWCNT-doped actuator displays a larger bending displacement under a given electric field. Similar results were observed in Figure 5d; the top displacement of the PEDOT/PSS-MFC-MWCNT actuator reached 4.6 mm at a direct current voltage of 1.0 V, while that of the PEDOT/PSS-MFC actuator measured 3.5 mm. The addition of MWCNT with nanopore structures and high conductivity to the PEDOT/PSS-MFC electrode improves the electrode’s available surface area for charge storage. Additionally, the conductivity of PEDOT/PSS-MFC film increases from an initial value of 33 S/cm to over 75 S/cm upon doping with MWCNT. To some extent, it enhances the actuator’s electrical conductivity and charging efficiency, which is beneficial to the electromechanical characteristics of the actuator.

Figure 5.

Electromechanical characteristics of PEDOT/PSS-MFC and PEDOT/PSS-MFC-MWCNT actuators. (a–d) Actuation properties of PEDOT/PSS-MFC and PEDOT/PSS-MFC-MWCNT actuators at (b) different sinusoidal voltages of ±0.5, ±1, ±1.5, and ±2.0 V, (c) applied frequencies of 1, 0.5, 0.3, and 0.1 Hz, and (d) a direct current voltage of 1.0 V. (e–g) The bending deformations of the PEDOT/PSS-MFC-MWCNT actuator are plotted as functions of the applied voltages and frequencies. (h) Reproducibility and (i) durability of the prepared PEDOT/PSS-MFC-MWCNT actuator.

The evaluation of the PEDOT/PSS-MFC-MWCNT actuators’ actuation properties in a range of electrical inputs is presented in Figure 5e–i. The actuation displacement obviously increases as the applied voltage grows under a constant frequency of 0.1 Hz (Figure 5e). The vertex displacement at 0.5, 1.0, 1.5, and 2.0 V were 1.1, 2.1, 2.8, and 3.3 mm, respectively. A capacitor-type ionic actuator’s actuation mechanism states (Figure 1d) that an increase in voltage causes a corresponding rise in the charge generated on the electrode. Accompanied by more hydrated cations in the Nafion flow to the cathode, it results in increased expansion and bending. Figure 5f,g show the peak displacement of the actuator increases from 0.2 to 2.1 mm as the frequency drops from 1 to 0.1 Hz at a constant voltage of 1.0 V because a lower frequency allows more time for the actuator bending.

More importantly, the actuation repeatability and durability are crucial characteristics for evaluating the electromechanical performances of the actuators. Figure 5h shows the PEDOT/PSS-MFC-MWCNT/Nafion actuator driving deformation with three sets of measurements at a sinusoidal voltage of ±1.0 V and a frequency of 0.1 Hz. Outstanding repeatability is verified by a high, consistent bending displacement of 2.1 ± 0.1 mm. Moreover, the peak displacement of the actuator as a function of actuation time is shown in Figure 5i. The PEDOT/PSS-MFC-MWCNT/Nafion actuator has a sustained vertex displacement of 2.1 mm and a long-term cyclic stability of 94% without any deterioration across 360 cycles, which is attributed to the PEDOT/PSS-MFC-MWCNT composite electrode membrane’s efficient charge transport ability, excellent film-forming electrodes, a high water-retaining capacity of hydrophilic MFC, high electrical conductivity with stretchability, and strong adhesion with Nafion via hot-pressing.

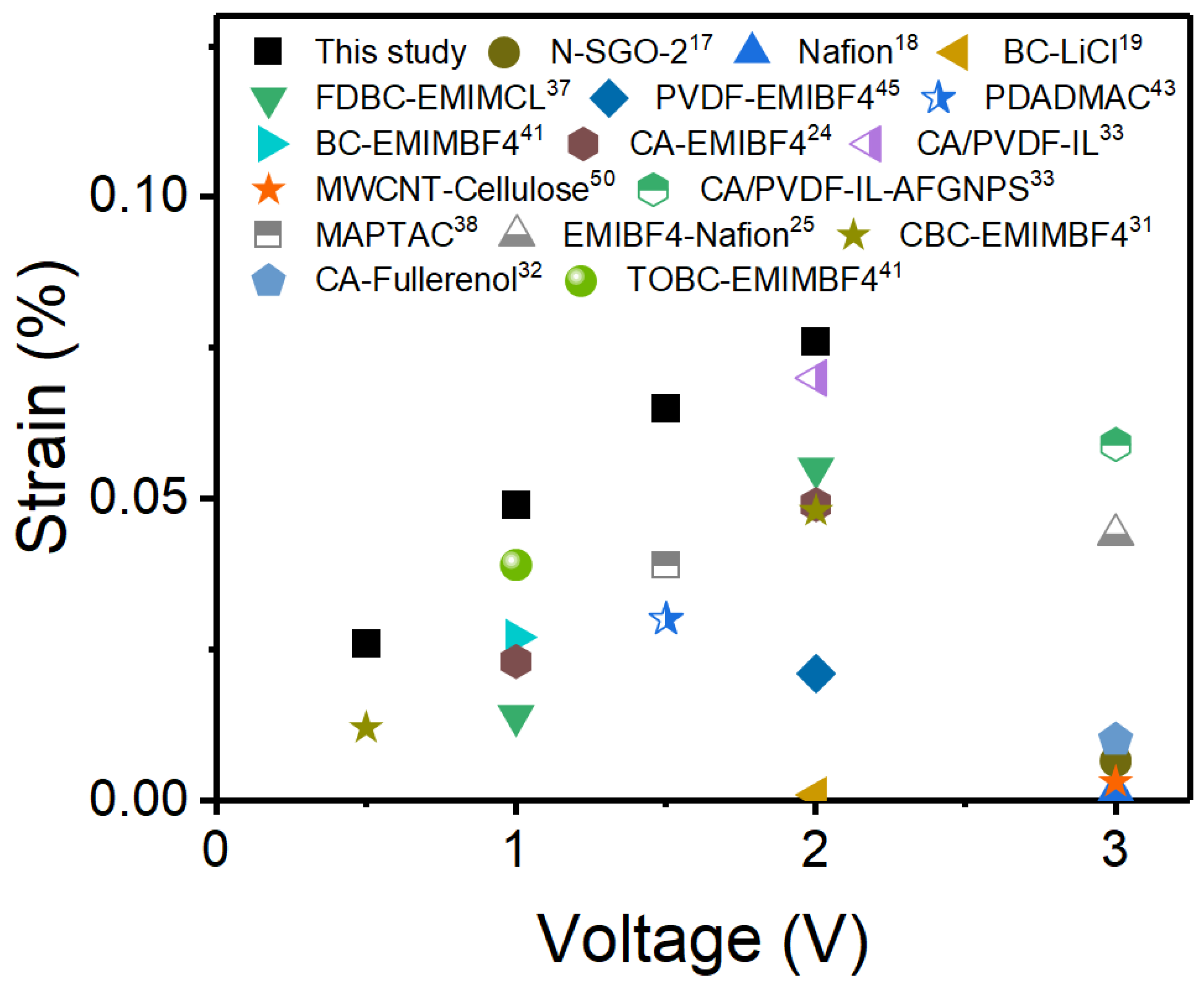

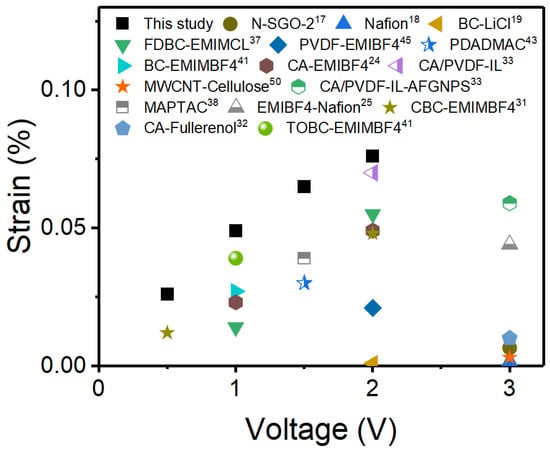

Furthermore, we comprehensively compared the actuation performances and fabrication methods of the proposed PEDOT/PSS-MFC-MWCNT/Nafion actuators with previously reported ionic soft actuators, as illustrated in Figure 6 and Table 1 [17,18,19,24,25,31,32,33,37,38,41,43,45,50]. However, the previously reported ionic actuators demonstrated low actuation performances with peak displacements not exceeding 4.0 mm and bending strains less than 0.07%. These limitations were primarily due to poor deformation capacity, weak interfacial adhesion, and insufficient water retention of the polyelectrolyte films. Moreover, the fabrication process was identified as a pivotal factor influencing the actuation performance. In contrast to the typically reported dip-coated, sputter-coated, or plated ionic actuators, the hot-pressed PEDOT/PSS-MFC-MWCNT actuators showed higher actuation characteristics. Specifically, the PEDOT/PSS-MFC-MWCNT actuators achieved a significantly higher bending strain of 0.076% at an applied voltage of 2.0 V and a frequency of 0.1 Hz, along with a peak displacement of 3.3 mm. The high-performance actuators can be attributed to several factors. The free-standing PEDOT/PSS-MFC- MWCNT electrode films offer excellent film-forming properties. The hydrophilic nature of MFC contributes to its exceptional water retention capacity, which is crucial for long-lasting and stability ionic actuation. High electrical conductivity and a large aspect ratio of MWCNTs, combined with its fast charge capability, contribute to the actuator’s response. Besides, the strong interactions and crosslinking of MFC, MWCNT, and PEDOT/PSS facilitate ion migration within the composite electrode, leading to the enhanced actuation performances. Furthermore, the hot-pressing method used in fabrication significantly enhances interfacial adhesion. The incorporation of MFC and MWCNT with a dense network structure and high specific surface further improves the contact surface between the PEDOT/PSS-MFC-MWCNT electrode film and Nafion film, leading to increased interface adhesion and, consequently, a more efficient and durable actuator.

Figure 6.

Comparative studies of the PEDOT/PSS-MFC-MWCNT actuator with the reported ionic actuators including N-SGO-2 [17], Nafion [18], BC-LiCl [19], CA-EMIBF4 [24], EMIBF4-Nafion [25], CBC-EMIMBF4 [31], CA-Fullerenol [32], CA/PVDF-IL-AFGNPS [33], CA/PVDF-IL [33], FDBC-EMIMCL [37], MAPTAC [38], BC-EMIMBF4 [41], TOBC-EMIMBF4 [41], PDADMAC [43], PVDF-EMIBF4 [45], MWCNT-Cellulose [50].

Table 1.

Comparative studies of the PEDOT/PSS-MFC-MWCNT actuator with the reported ionic actuators.

4. Applications

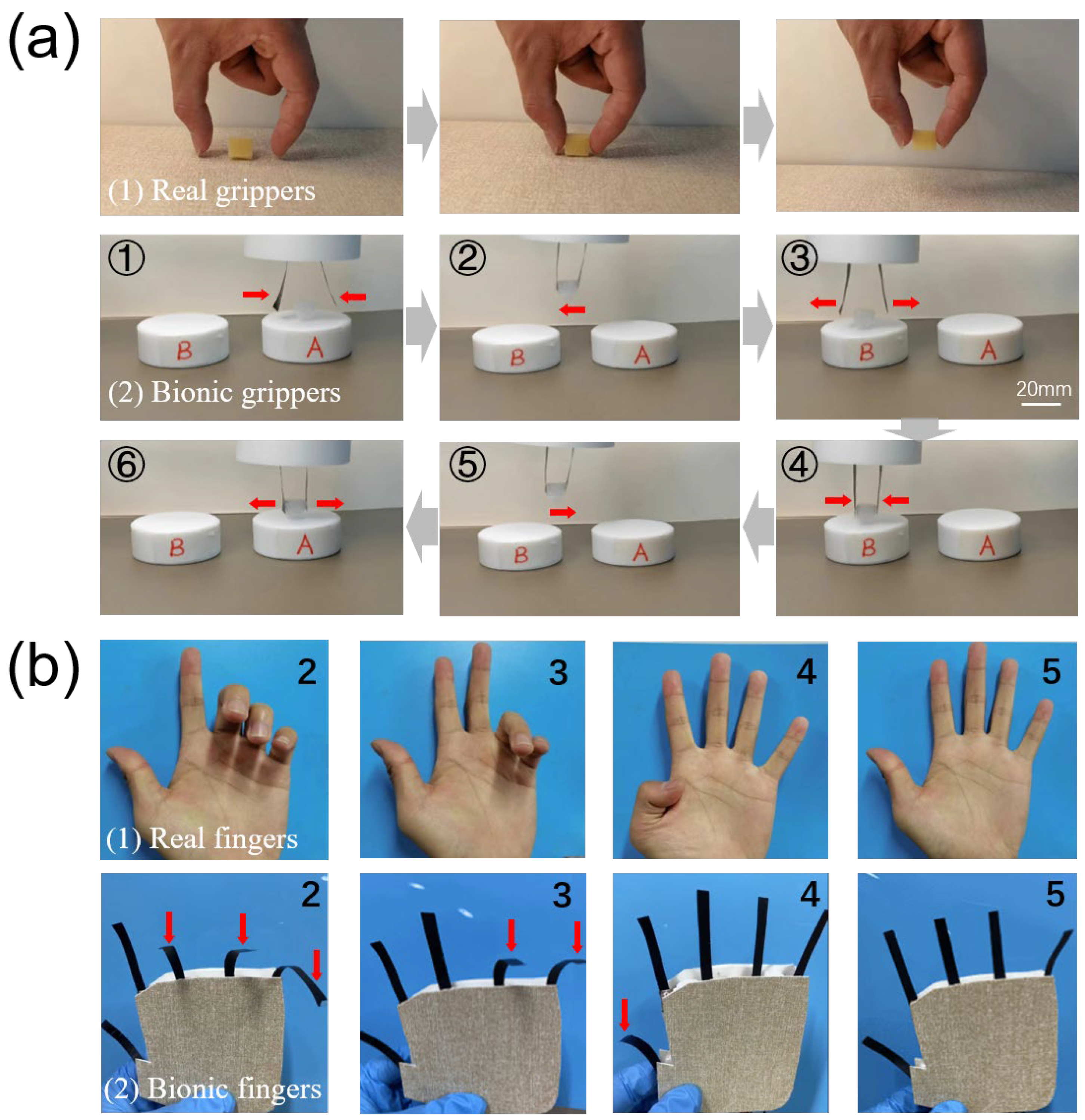

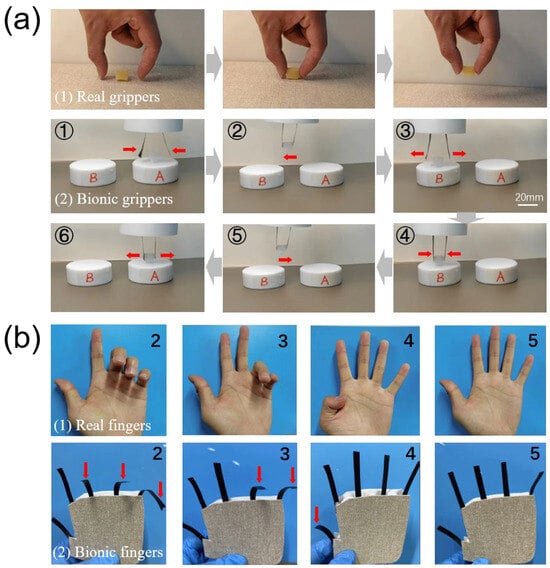

The promising applications of the PEDOT/PSS-MFC-MWCNT actuators in mimicking actual finger actions are presented in Figure 7. The bionic finger grasping and counting action is similar to that of actual fingers. A bionic gripper based on two actuators is shown in Figure 7a (Movie S1). The bionic gripper was capable of smoothly transferring a tiny sponge weighing 12 mg from position “a” to position “b” when applying voltages of ±2.0 V, which demonstrates the actuator-based bionic gripper’s ability to effectively grasp and finely manipulate an object in a small, constrained space. More interestingly, Figure 7b shows a biomimetic finger with five actuators for pointing and counting (Movie S2). The bionic fingers were fabricated with five PEDOT/PSS-MFC-MWCNT actuators to achieve counting from “2” to “5”. The finger counting characteristics of real fingers are simulated by switching the applied square wave voltage of 4 V to control the corresponding finger flexion and extension. Overall, the proposed PEDOT/PSS-MFC-MWCNT actuator demonstrates the great possibility of realizing the grasping, pointing, and counting actions of bionic fingers within a small or narrow space, which opens new possibilities for next-generation flexible manipulators and biomimetic soft robots or for using as effective active devices in micro-electromechanical systems.

Figure 7.

Simulation of actual fingers for grasping, pointing, and counting based on the PEDOT/PSS-MFC-MWCNT/Nafion actuators. (a) A bionic gripper based on two actuators grasps and transfers a tiny sponge from disk “A” to disk “B”. (b) Simulated actual fingers with five prepared actuators to achieve pointing and counting.

5. Conclusions

Herein, we developed advanced ionic electroactive soft actuators fabricated with free-standing MFC-reinforced MWCNT-doped PEDOT/PSS electrode films and a Nafion ion-exchange film via a hot-pressing method. We analyzed the prepared composite membranes’ morphology, chemical structure, crystallinity, mechanical properties, thermal stabilities, electrical conductivity, and electromechanical actuation characteristics with various electrical inputs (voltages: ±0.5, ±1, ±1.5, ±2, and ±3.0 V; frequencies: 1, 0.5, 0.3, and 0.1 Hz). The PEDOT/PSS-MFC-MWCNT film had high mechanical properties with a Young’s modulus of 448 MPa and a high electrical conductivity of 75 S/cm. The obtained PEDOT/PSS-MFC-MWCNT/Nafion actuators have a peak displacement of 2.1 mm at an applied voltage of 1.0 V, a frequency of 0.1 Hz, and a long-term cyclic stability of 94% with no degradation across 360 cycles due to the good film-forming PEDOT/PSS-MFC -MWCNT electrode, high electrical conductivity with stretchability, high hydrophilic MFC with excellent water retaining capacity, and strong interfacial adhesion between the composite electrodes and Nafion film via hot-pressing. Furthermore, we further verified the actuator’s potential applications as bionic fingers for grasping, pointing, and counting actions, which opens up new possibilities for next-generation micromanipulators and bionic soft robotics.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/act13060200/s1. Movie S1. A bionic gripper based on two PEDOT/PSS-MFC-MWCNT actuators is capable of smoothly transferring a tiny sponge from position “A” to position “B”. Movie S2. A biomimetic finger with five PEDOT/PSS-MFC-MWCNT actuators for pointing and counting from “2” to “5”.

Author Contributions

Conceptualization and Methodology: Y.W.; Formal analysis and investigation: F.W.; Data curation and writing—original draft preparation: Q.C.; Writing—review and editing: Y.W., F.W.; Funding acquisition: F.W.; Resources and Supervision: F.W., Q.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China [grant number: 52305327 and 12102393].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on reasonable request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nauber, R.; Goudu, S.; Goeckenjan, M.; Bornhauser, M.; Ribeiro, C.; Sanchez, M. Medical microrobots in reproductive medicine from the bench to the clinic. Nat. Commun. 2023, 14, 728. [Google Scholar] [CrossRef] [PubMed]

- Yoon, C. Advances in biomimetic stimuli responsive soft grippers. Nano Converg. 2019, 6, 20. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Wang, D.; Zhu, D.; Cao, S.; Wang, X.; Zhang, M. PiezoClimber: Versatile and self-transitional climbing soft robot with bioinspired highly directional footpads. Adv. Funct. Mater. 2024, 34, 2308384. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Z.; Liao, P.; Li, Y.; Qu, Y.; Zhang, Q.; Yang, M.; Chan, K.; Zhang, L.; Man, K.; et al. Biodegradable microrobots for DNA vaccine delivery. Adv. Healthc. Mater. 2023, 12, 2202921. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, Y.; Chen, H.; Law, J.; Pu, H.; Xie, S.; Duan, F.; Sun, Y.; Liu, N.; Yu, J. A magnetic multi-layer soft robot for on-demand targeted adhesion. Nat. Commun. 2024, 15, 644. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Han, C.; Liu, X.; Li, Z.; Liu, J.; Sun, Z. A highly flexible and stretchable ionic artificial muscle. Sens. Actuator A Phys. 2021, 332, 113190. [Google Scholar] [CrossRef]

- Kyle, E.; Paul, A.; Olaf, D. Recent advances in the 3D printing of ionic electroactive polymers and core ionomeric materials. Polym. Chem. 2022, 13, 456. [Google Scholar]

- Aivazyan, V.; Kholodkova, E.; Khmelnitskiy, I.; Alekseev, N.; Adamovich, D.; Parfenovich, S.; Trushlyakova, V.; Broyko, A. Ionic electroactive actuators and sensors with hybrid polymer-metal electrodes. J. Struct. Chem. 2024, 65, 267–280. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, B.; Liu, X.; Lan, T.; Huang, Y.; Zhang, Y.; Wu, D. High-performance electroionic artificial muscles boosted by superior ion transport with Ti3C2Tx MXene Cellulose nanocomposites for advanced 3D-motion actuation. Chem. Eng. J. 2023, 477, 147246. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Tian, A.; Huang, B. Fractal recognition and contact characteristics of ionic electroactive polymer interface based on microstructure analysis. Tribol. Int. 2023, 186, 108650. [Google Scholar] [CrossRef]

- Aabloo, A.; Luca, V.; Pasquale, G.; Graziani, S.; Gugliuzzo, C.; Johanson, U.; Marino, C.; Pollicino, A.; Puglisi, R. A new class of ionic electroactive polymers based on green synthesis. Sens. Actuator A Phys. 2016, 249, 32–44. [Google Scholar] [CrossRef]

- Terui, A.; Takenaka, R.; Kawaguchi, D.; Mino, A.; Nakazawa, Y.; Endo, H.; Iga, K.; Washio, M.; Oshima, A. Development of ionic polymer metal composite actuator by EB graft-polymerization. Radiat. Phys. Chem. 2023, 213, 111258. [Google Scholar] [CrossRef]

- Biswal, D.; Moharana, B.; Mohapatra, T. Bending response optimization of an ionic polymer-metal composite actuator using orthogonal array method. Mater. Today Proc. 2022, 49, 1550–1555. [Google Scholar] [CrossRef]

- Mehraeen, S.; Sadeghi, S.; Cebeci, F.; Papila, M.; Gürsel, S. Polyvinylidene fluoride grafted poly(styrene sulfonic acid) as ionic polymer-metal composite actuator. Sens. Actuator A Phys. 2018, 279, 157–169. [Google Scholar] [CrossRef]

- Ikeda, T. Gold nanowire mesh electrode for electromechanical device. Sci. Rep. 2023, 13, 16669. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhang, D.; Zhang, X.; Tian, A. Surface profile topography of ionic polymer metal composite based on fractal theory. Surf. 2021, 22, 100834. [Google Scholar] [CrossRef]

- Na, J.; Safari, M.; Moaven, S. Fabrication of SGO/Nafion-based IPMC soft actuators with sea anemone-like Pt electrodes and enhanced actuation performance. Carbon 2016, 100, 243. [Google Scholar]

- Yilmaz, O.C.; Sen, I.; Gurses, B.; Ozdemir, O.; Cetin, L.; Sarikanat, M.; Seki, Y.; Sever, K.; Altinkaya, E. The effect of gold electrode thicknesses on electromechanical performance of Nafion-based ionic polymer metal composite actuators. Compos. Part B. 2019, 165, 747. [Google Scholar] [CrossRef]

- Jeon, J.; Oh, I.; Kee, C.; Kim, S. Bacterial cellulose actuator with electrically driven bending deformation in hydrated condition. Sens. Actuators B Chem. 2010, 146, 307–313. [Google Scholar] [CrossRef]

- Yang, L.; Yang, Y.; Wang, H. Modeling and control of ionic polymer metal composite actuators: A review. Eur. Polym. J. 2023, 186, 111821. [Google Scholar] [CrossRef]

- Lee, S.; Hwang, L.; Lee, J.; Yang, T.; Jho, J.; Park, J. Multiday operable ionic polymer-metal composites prepared using a stacking method for practical actuator applications. Sens. Actuators B Chem. 2022, 372, 132616. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Yang, Y.; Zhang, D.; Tian, A. Highly flexible, large-deformation ionic polymer metal composites for artificial muscles: Fabrication, properties, applications, and prospects. Chem. Eng. J. 2023, 469, 143976. [Google Scholar] [CrossRef]

- Yu, F.; Ciou, J.; Chen, S.; Poh, W.; Chen, J.; Chen, J.; Haruethai, K.; Lv, J.; Gao, D.; Lee, P. Ionic covalent organic framework based electrolyte for fast-response ultra-low voltage electrochemical actuators. Nat. Commun. 2022, 13, 390. [Google Scholar] [CrossRef] [PubMed]

- Nan, M.; Wang, F.; Kim, S.; Li, H.; Jin, Z.; Bang, D.; Kim, C.; Park, J.; Choi, E. Ecofriendly high-performance ionic soft actuators based on graphene-mediated cellulose acetate. Sens. Actuators B Chem. 2019, 301, 127. [Google Scholar] [CrossRef]

- Kim, J.; Jeon, J.; Kim, H.; Lim, H.; Oh, I. Durable and water-floatable ionic polymer actuator with hydrophobic and asymmetrically laser-scribed reduced graphene oxide paper electrodes. ACS Nano. 2014, 8, 2986–2997. [Google Scholar] [CrossRef] [PubMed]

- Luqman, M.; Shaikh, H.; Anis, A.; Zahrani, A.; Hamidi, A.; Inamuddin, A. Platinum-coated silicotungstic acid-sulfonated polyvinyl alcohol-polyaniline based hybrid ionic polymer metal composite membrane for bending actuation applications. Sci. Rep. 2022, 12, 4467. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Zhou, Z.; Zhu, Z.; Huang, G.; Zhang, Z. Mechanical stimulation of cells with electroactive polymer-based soft actuators. Eur. Phys. J. Spec. Top. 2023, 232, 2695–2708. [Google Scholar] [CrossRef]

- Li, H.; Fan, M.; Yue, Y.; He, Q.; Yu, M.; Chen, G. Displacement response of ionic polymer metal composite actuator to asymmetric square waves in air operating. Sens. Actuator A Phys. 2020, 311, 112069. [Google Scholar] [CrossRef]

- Horiuchi, T.; Sugino, T.; Asaka, K. Elliptical-like cross-section ionic polymer-metal composite actuator for catheter surgery. Sens. Actuator A Phys. 2017, 267, 235–241. [Google Scholar] [CrossRef]

- James, D.C.; Tucker, H.; Kwang, J.; Kam, K.L. 3D-Printing and machine learning control of soft ionic polymer-metal composite actuators. Sci. Rep. 2019, 9, 17482. [Google Scholar]

- Wang, F.; Jeon, J.; Park, S.; Kee, C.; Kim, S.; Oh, I. Soft biomolecule actuator based on a highly functionalized bacterial cellulose nano-fiber network with carboxylic acid groups. Soft Matter. 2016, 12, 246–254. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Vadahanambi, S.; Kim, C.; Oh, I. Electrospun fullerenol-cellulose biocompatible actuators. Biomacromolecules. 2011, 6, 2048–2054. [Google Scholar] [CrossRef] [PubMed]

- Nan, M.; Bang, D.; Zheng, S.; Go, G.; Bobby, D.; Kim, S.; Li, H.; Kim, C.; Hong, A.; Wang, F.; et al. High-performance biocompatible nanobiocomposite artificial muscles based on ammonia-functionalized graphene nanoplatelets–cellulose acetate combined with PVDF. Sens. Actuat. B-Chem. 2020, 323, 128709. [Google Scholar] [CrossRef]

- Li, H.; Luo, R.; Hu, J.; Yang, K.; Du, B.; Zhou, S.; Zhou, X. Self-assembled gel-assisted preparation of high-performance hydrophobic PDMS @ MWCNTs /PEDOT:PSS composite aerogels for wearable piezoresistive sensors. J. Mater. Sci. Technol. 2024, 182, 22–32. [Google Scholar] [CrossRef]

- Monika; Pradhan, P.; Amrute, V.; Chanda, A. Structural and optical study of conducting polymer PEDOT:PSS and its composite with GO. Mater. Today Proc. 2023, 7, 123. [Google Scholar] [CrossRef]

- Jeon, Y.; Ko, Y.; Lee, S.; Jeong, M.; Lee, K.; Kwon, G.; Kim, J.; You, J. PEDOT:PSS/regenerated cellulose composite microelectrode for high-performance micro-supercapacitor. Appl. Surf. Sci. 2023, 636, 157806. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, J.; Kee, C.; Oh, I. Electro-active hybrid actuators based on freeze-dried bacterial cellulose and PEDOT:PSS. Smart Mater. Struct. 2013, 22, 085026. [Google Scholar] [CrossRef]

- Hara, Y.; Yamaguchi, Y. Development of a paper actuator with PEDOT:PSS thin-films as an electrode. Actuators 2014, 3, 285–292. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Gao, X.; Zou, T.; Deng, P.; Zhao, J.; Zhang, T.; Chen, Y.; He, L.; Shao, L.; et al. Carbon nanomaterials-PEDOT:PSS based electrochemical ionic soft actuators: Recent development in design and applications. Sens. Actuator A Phys. 2023, 354, 114277. [Google Scholar] [CrossRef]

- Wang, F.; Kong, Y.; Shen, F.; Wang, Y.; Wang, D.; Li, Q. High-performance microfibrillated cellulose-based low voltage electroactive ionic artificial muscles in bioinspired applications. Compos. Part. B-Eng. 2022, 228, 109436. [Google Scholar] [CrossRef]

- Kim, S.; Jeon, J.; Kim, H.; Kee, C.; Oh, I. High-fidelity bioelectronic muscular actuator based on graphene-mediated and TEMPO-oxidized bacterial cellulose. Adv. Funct. Mater. 2015, 25, 3560–3570. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, M.; Zhang, J.; Wang, S.; Cao, S.; Li, Y.; Hu, G.; Kong, D. Highly permeable and ultrastretchable liquid metal micromesh for skin-attachable electronics. ACS Mater. Lett. 2022, 4, 634–641. [Google Scholar] [CrossRef]

- Wu, Y.; Minamikawa, H.; Nakazumi, T.; Hara, Y. Actuation properties of paper actuators fabricated using PEDOT/PSS electrode films. J. Oleo Sci. 2020, 69, 1331–1337. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Li, Y.; Ren, M.; Ni, Q.; Hu, J.; Li, K.; Li, R. Soft actuators based on piezoelectric composites for nanoscale self-bending. Compos. Struct. 2023, 320, 117218. [Google Scholar] [CrossRef]

- Lu, L.; Liu, J.; Hu, Y.; Zhang, Y.; Randriamahazaka, H.; Chen, W. Highly stable air working bimorph actuator based on a graphene nanosheet/carbon nanotube hybridelectrode. Adv. Mater. 2012, 24, 4317–4321. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.; Lee, B. Microfibrillated cellulose film with enhanced mechanical and water-resistant properties by glycerol and hot-pressing treatment. Cellulose 2021, 28, 5693–5705. [Google Scholar] [CrossRef]

- Li, H.; Kulachenko, A.; Mathew, A.; Stoltz, R.; Sevastyanova, O. Enhancing the strength and flexibility of microfibrillated cellulose films from lignin-rich kraft pulp. ACS Sustain. Chem. Eng. 2023, 11, 16793–16805. [Google Scholar] [CrossRef]

- Mustaffa, M.; Azis, R.; Abdullah, N.; Ismail, I.; Ibrahim, I. An investigation of microstructural, magnetic and microwave absorption properties of multi walled carbon nanotubes/Ni0.5Zn0.5Fe2O4. Sci. Rep. 2019, 9, 15523. [Google Scholar] [CrossRef] [PubMed]

- Areerob, Y.; Hamontree, C.; Sricharoen, P.; Limchoowong, N.; Nijpanich, S.; Nachaithong, T.; Oh, W.; Pattarith, K. Synthesis of novel MoWO4 with ZnO nanoflowers on multi-walled carbon nanotubes for counter electrode application in dye-sensitized solar cells. Sci. Rep. 2022, 12, 12490. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.; Kim, J. Covalently bonded multi-walled carbon nanotubes-cellulose electro-active paper actuator. Sens. Actuator A Phys. 2009, 154, 73–78. [Google Scholar] [CrossRef]

- Wang, F.; Wang, L.; Wang, Y.; Wang, D. Highly bendable ionic electroactive polymer actuator based on carboxylated bacterial cellulose by doping with MWCNT. Appl. Phys. A. 2022, 128, 911. [Google Scholar] [CrossRef]

- Lertngim, A.; Phiriyawirut, M.; Wootthikanokkhan, J.; Yuwawech, K.; Sangkhun, W.; Kumnorkaew, P.; Muangnapoh, T. Preparation of surlyn films reinforced with cellulose nanofibres and feasibility of applying the transparent composite films for organic photovoltaic encapsulation. R. Soc. Open Sci. 2017, 4, 170972. [Google Scholar] [CrossRef] [PubMed]

- Aliabadi, M.; Chee, B.; Matos, M.; Cortese, Y.; Nugent, M.; Lima, T.; Magalhães, W.; Lima, G.; Firouzabadi, M. Microfibrillated cellulose films containing chitosan and tannic acid for wound healing applications. J. Mater. Sci. Mater. Med. 2021, 32, 67. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Zhang, M.; Liu, K.; Parit, M.; Jiang, Z.; Zhang, X.; Li, B.; Si, C. Conductive PEDOT:PSS/cellulose nanofibril paper electrodes for flexible supercapacitors with superior areal capacitance and cycling stability. Chem. Eng. J. 2022, 428, 131994. [Google Scholar] [CrossRef]

- Zhang, B.; Bu, X.; Wang, R.; Shi, J.; Chen, C.; Li, D. High mechanical properties of micro fibrillated cellulose/HDPE composites prepared with two different methods. Cellulose 2021, 28, 5449–5462. [Google Scholar] [CrossRef]

- Kozonoe, C.; Giudici, R.; Schmal, M. Ruthenium catalyst supported on multi-walled carbon nanotubes for CO oxidation. Mod. Res. Catal. 2021, 10, 73–91. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).