Clamping Force Control of Electromechanical Brake Actuator Considering Contact Point between Friction Lining and Brake Disc

Abstract

1. Introduction

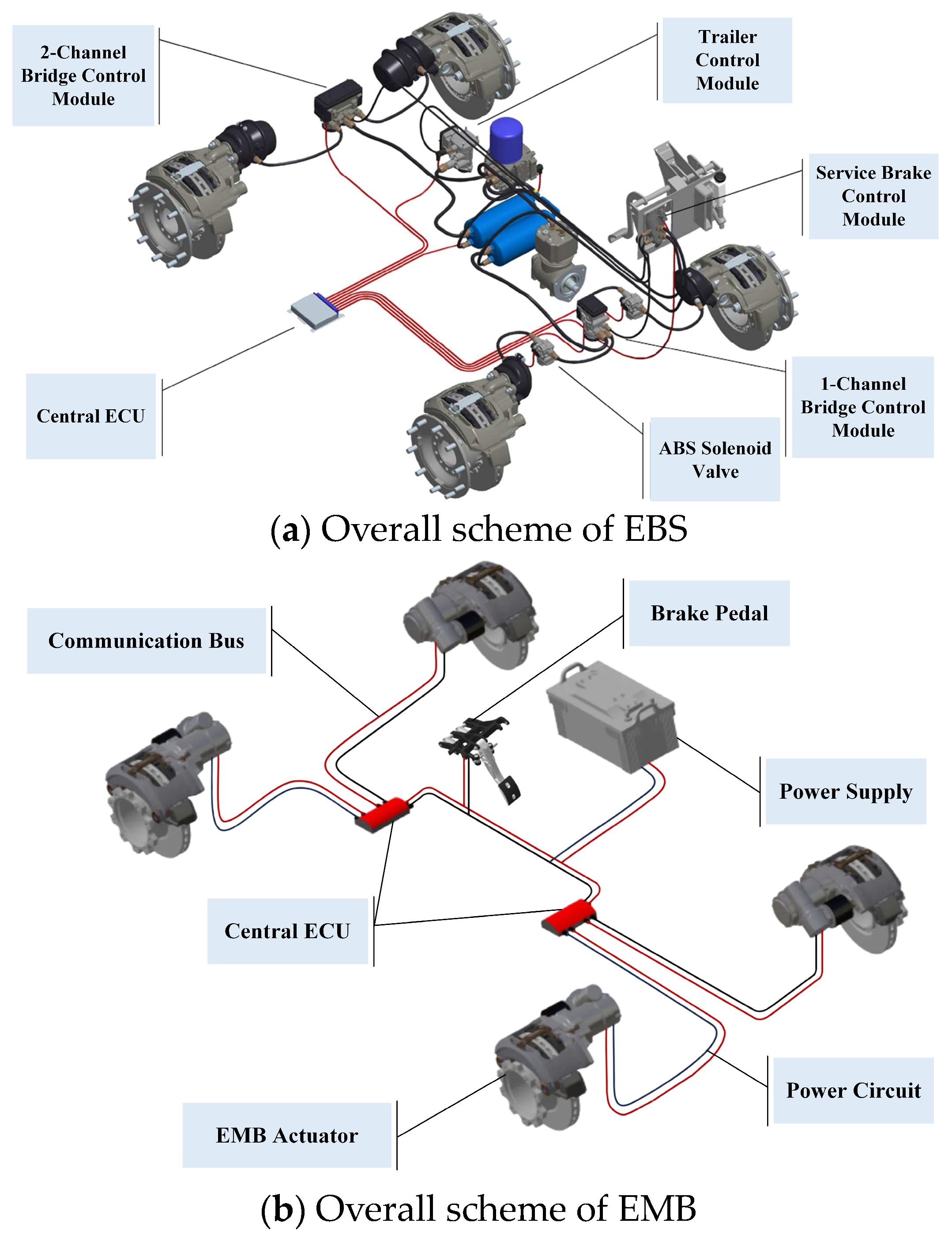

2. EMB Actuator Scheme for Commercial Vehicles

2.1. Braking Requirements for Commercial Vehicles

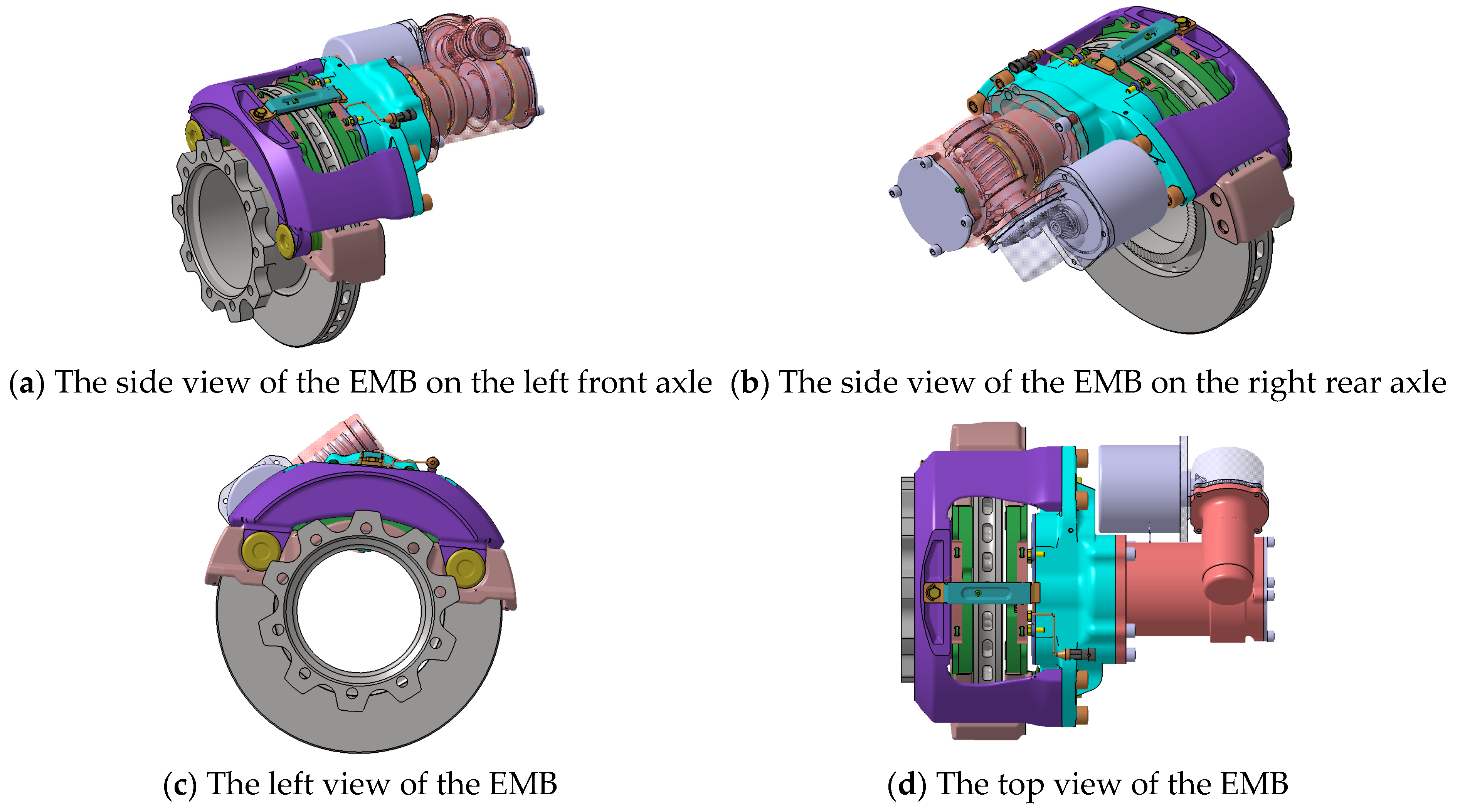

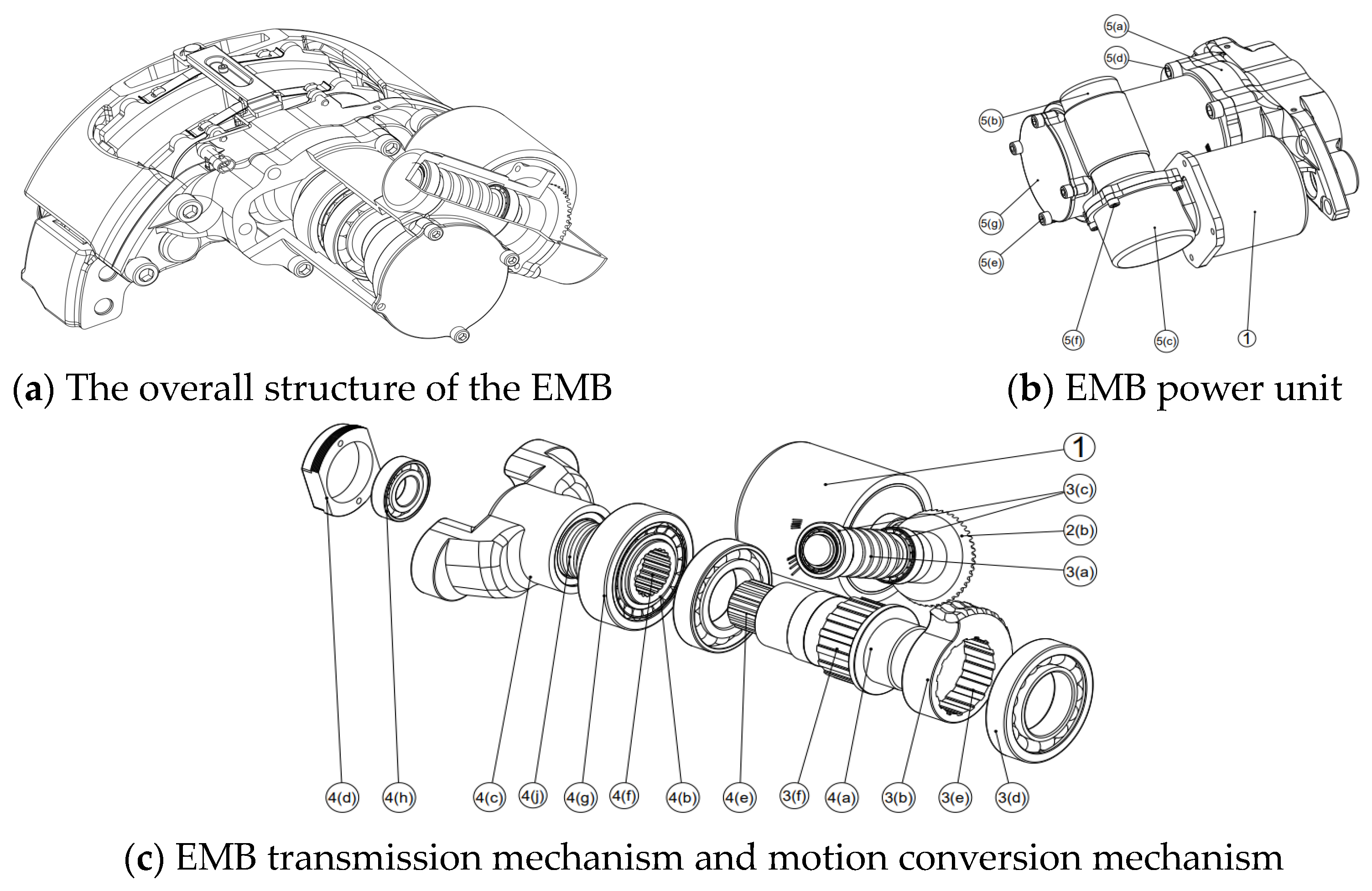

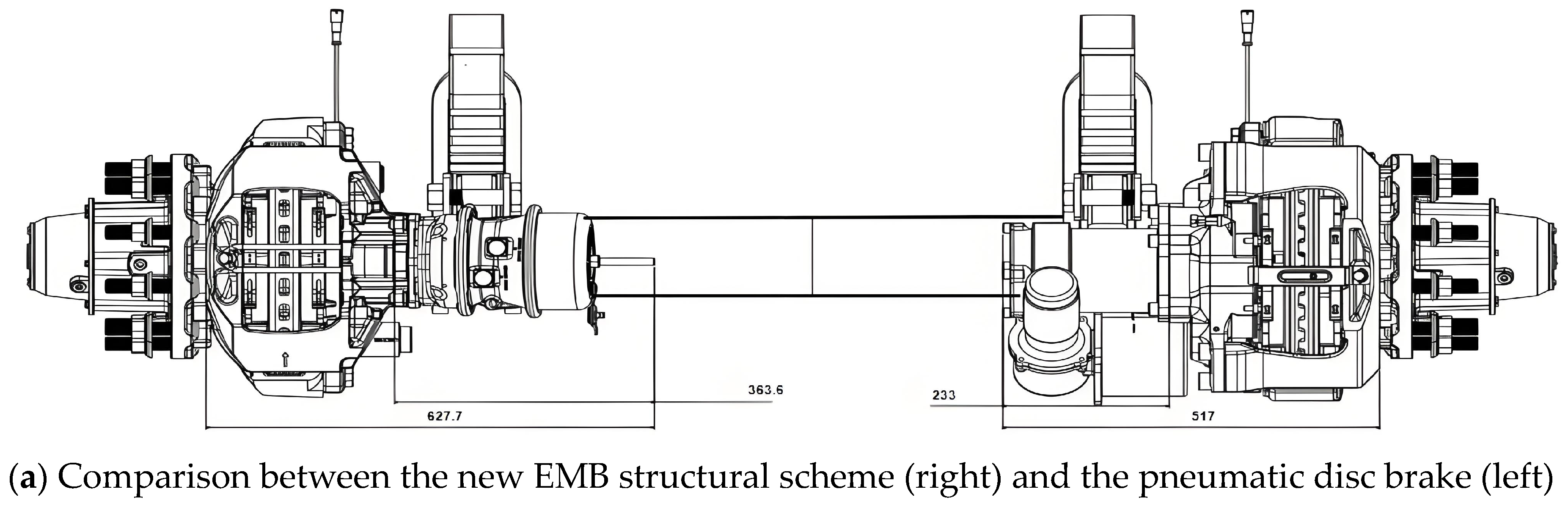

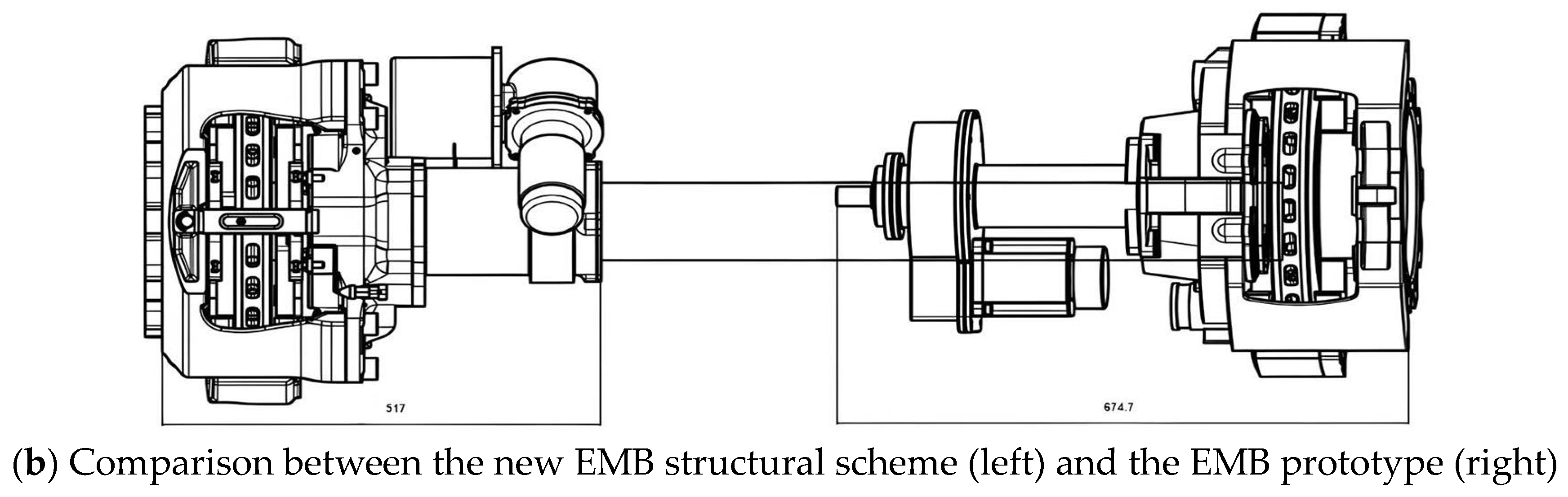

2.2. The Structure Scheme of the EMB Functional Prototype

2.3. The New Structural Scheme of the EMB

3. The Dynamics Model of the EMB Actuator

3.1. Control-Oriented Servo Motor Model

3.2. Transmission Mechanism Model

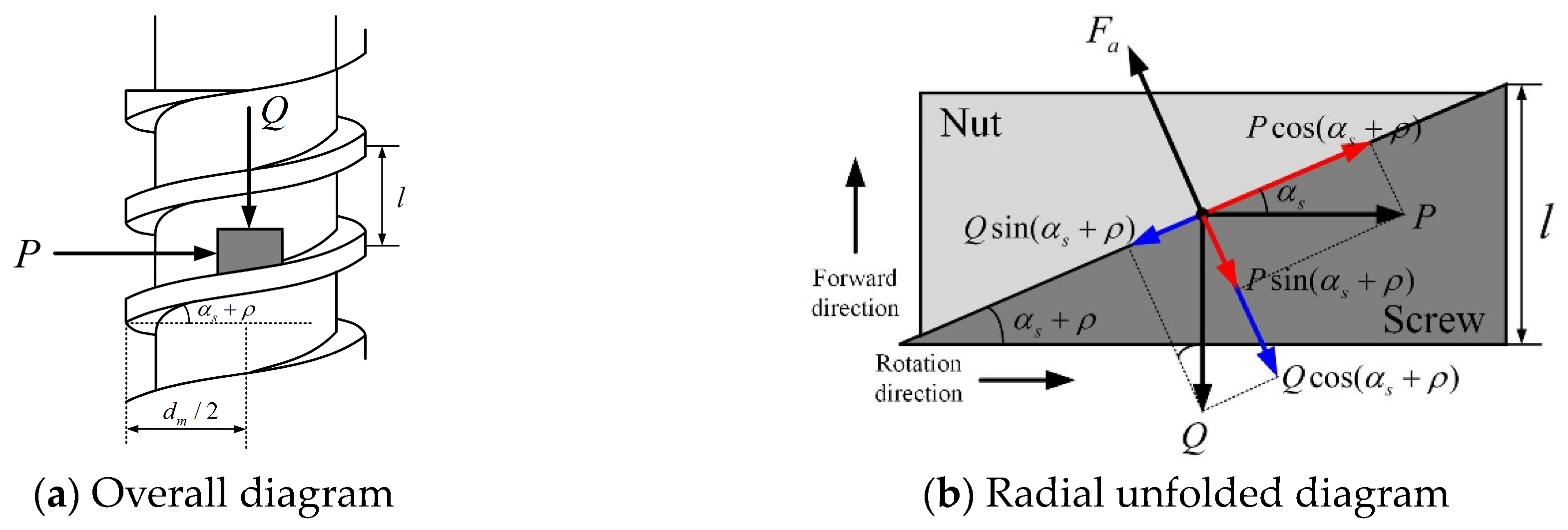

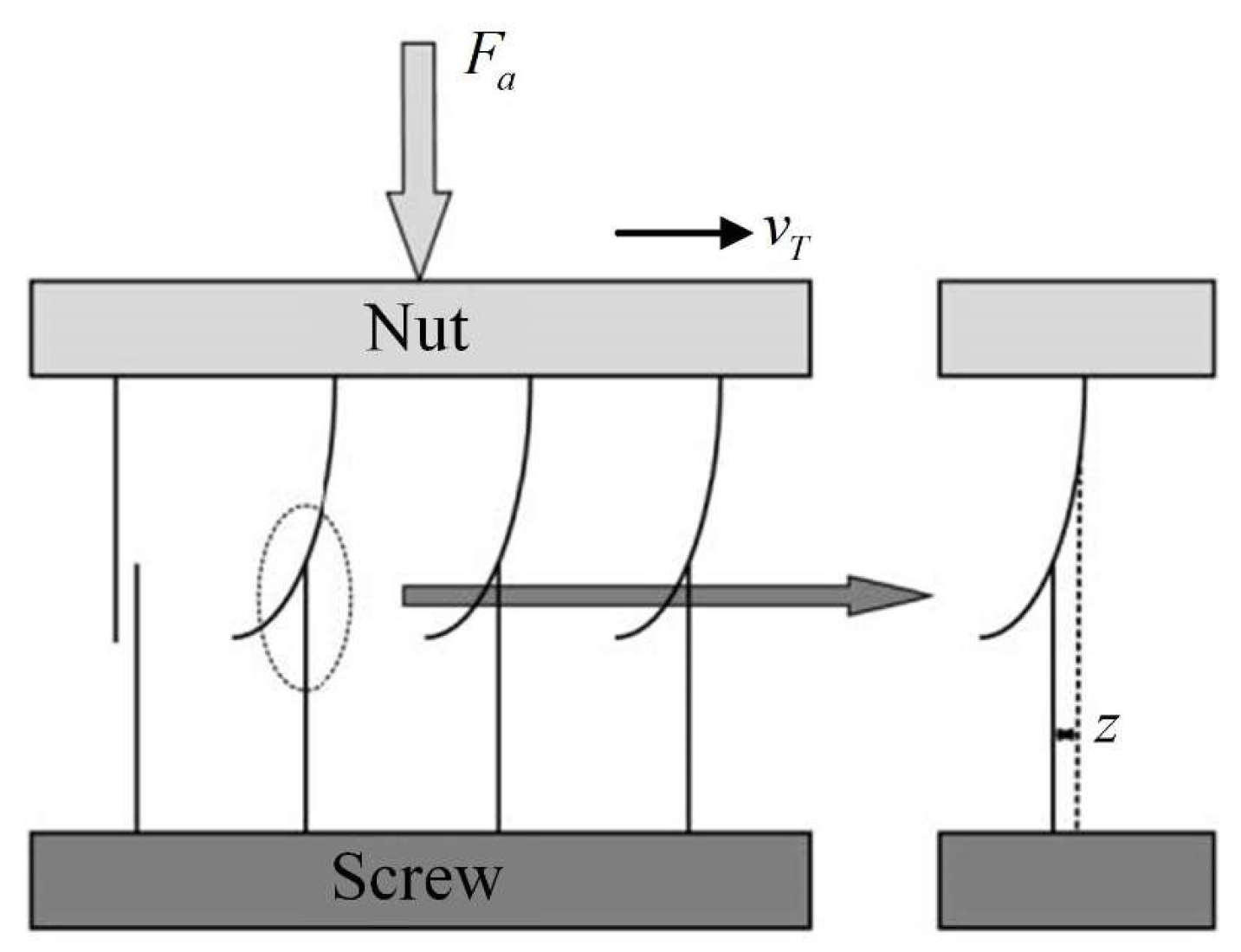

3.3. Conversion Mechanism Model

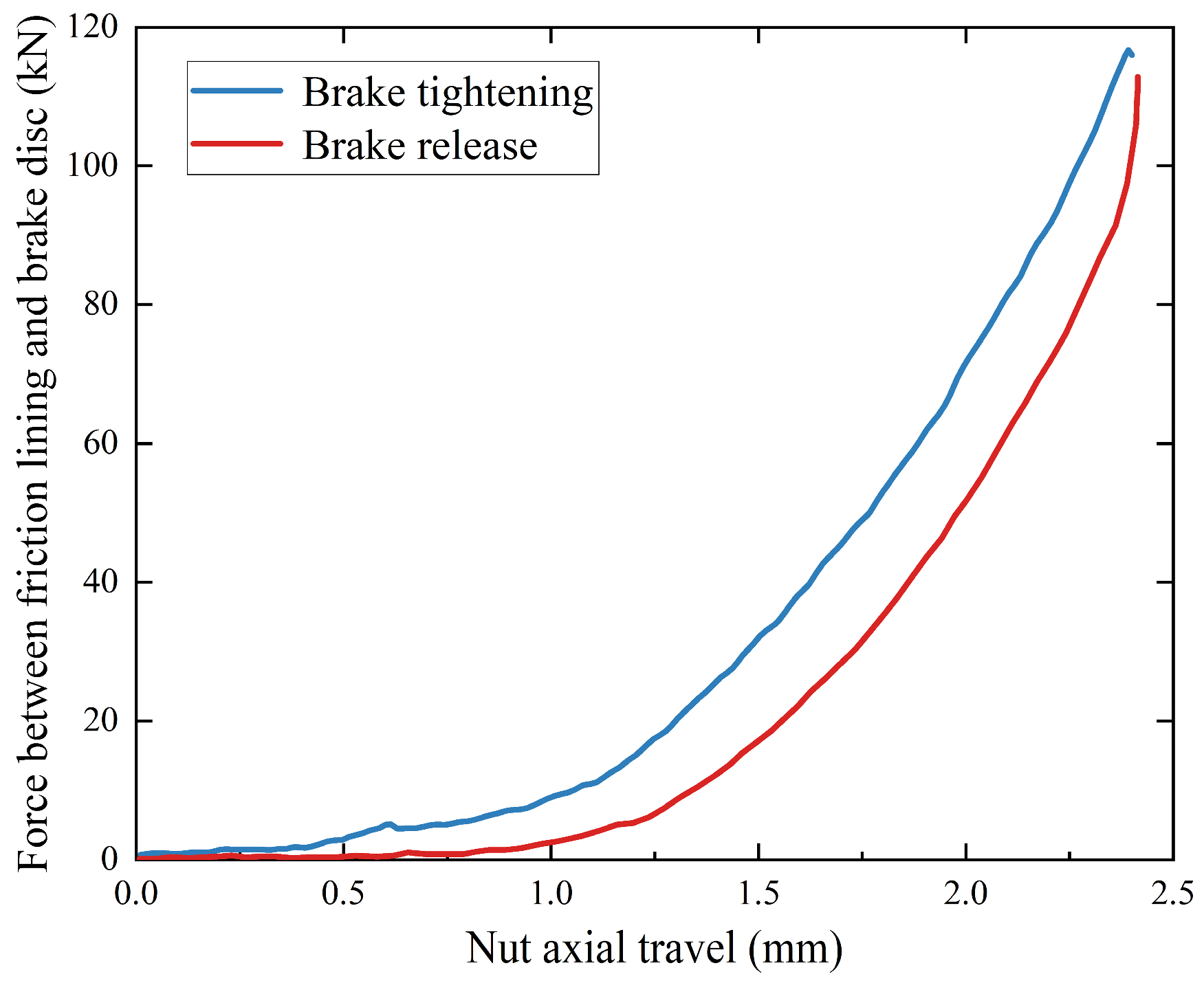

3.4. Friction Model

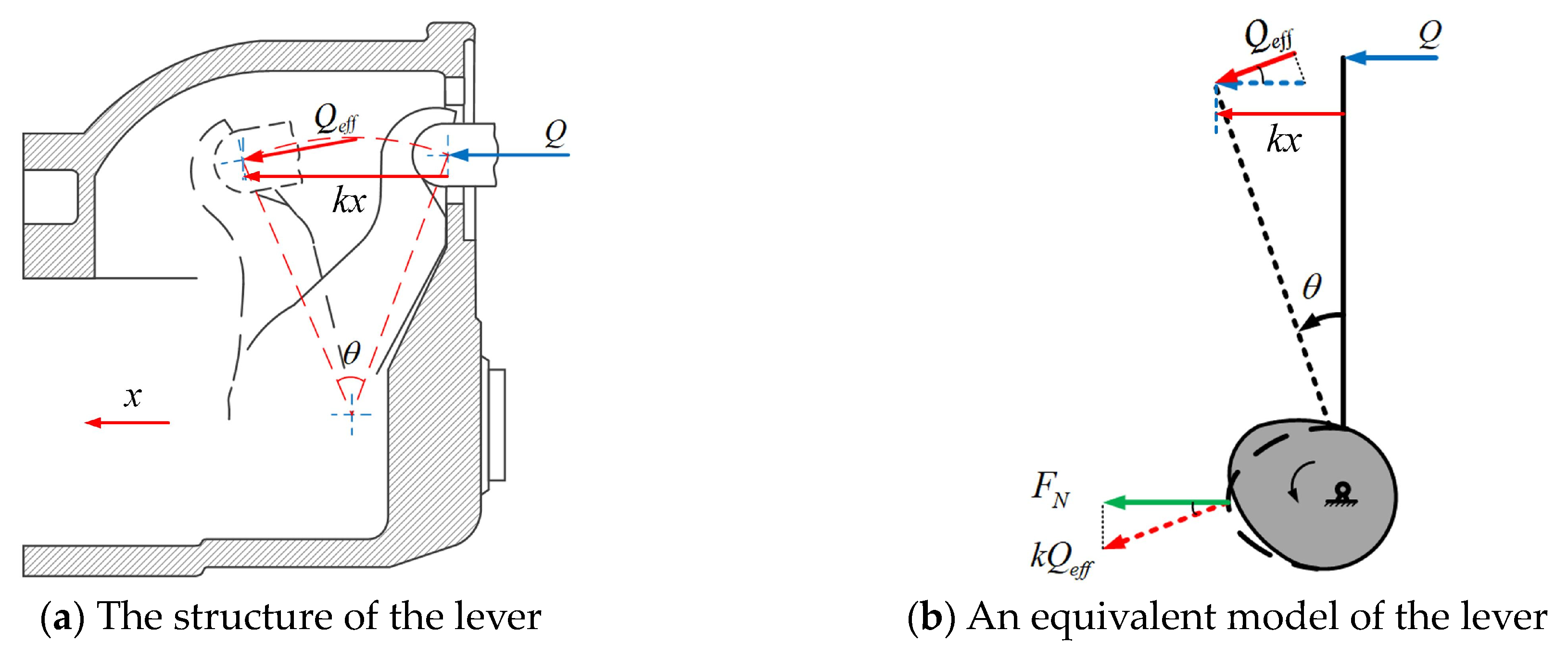

3.5. Caliper Model

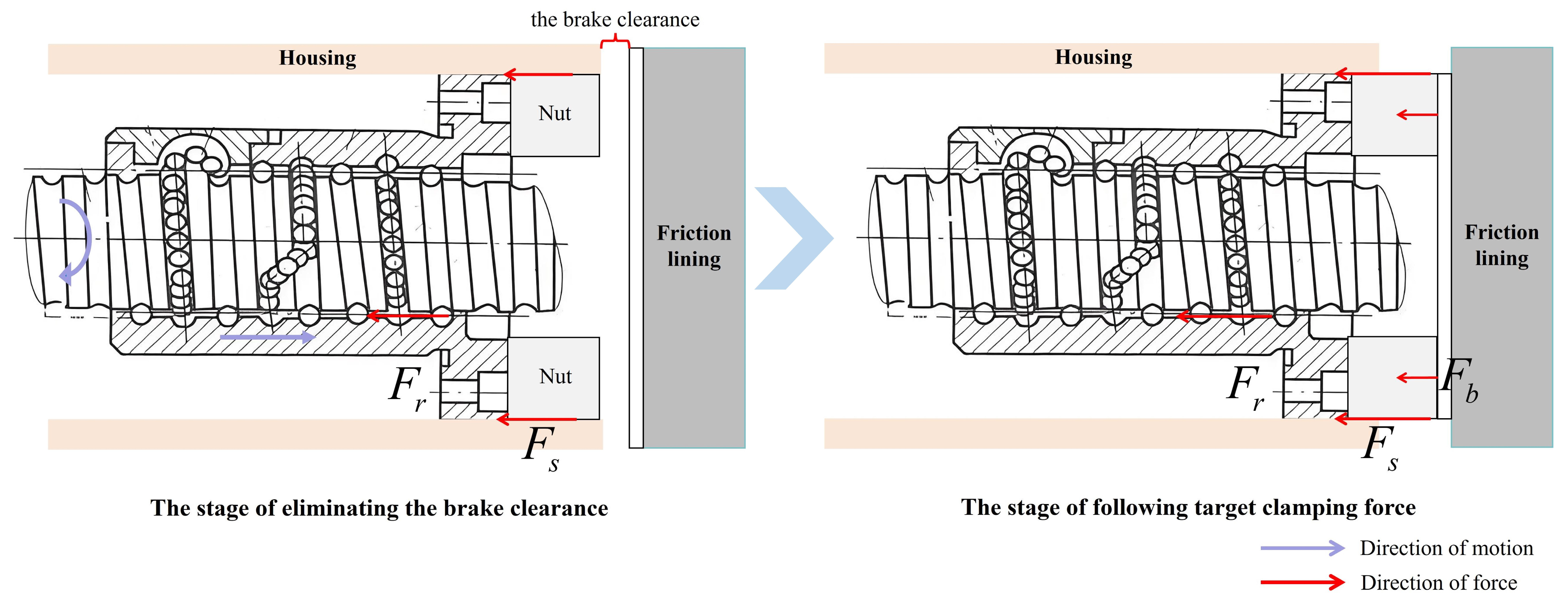

4. Clamping Force Control Strategy Considering Contact Point

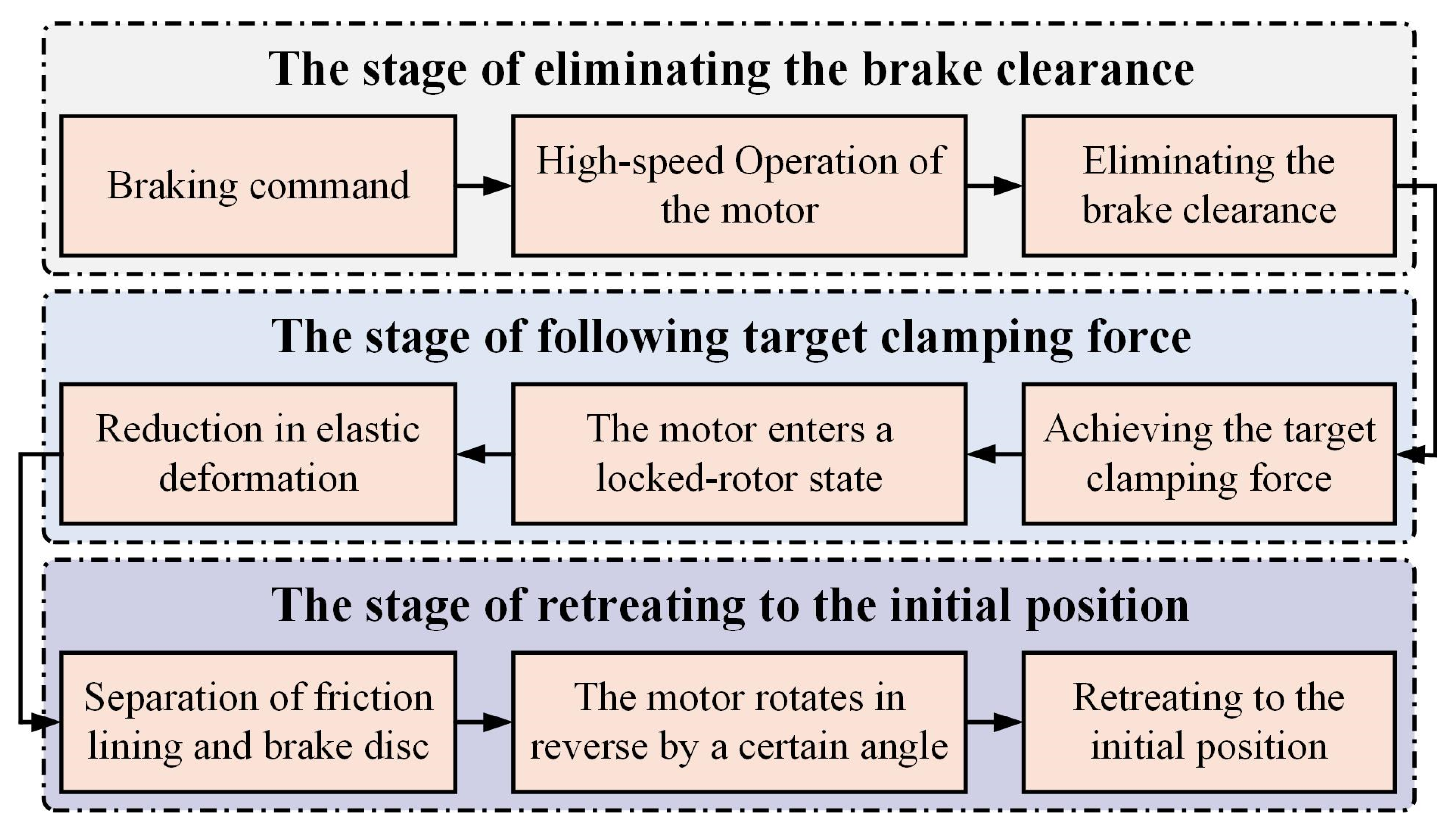

4.1. EMB Operation Process

- The stage of eliminating the brake clearance

- 2.

- The stage of following target clamping force

- 3.

- The stage of retreating to the initial position

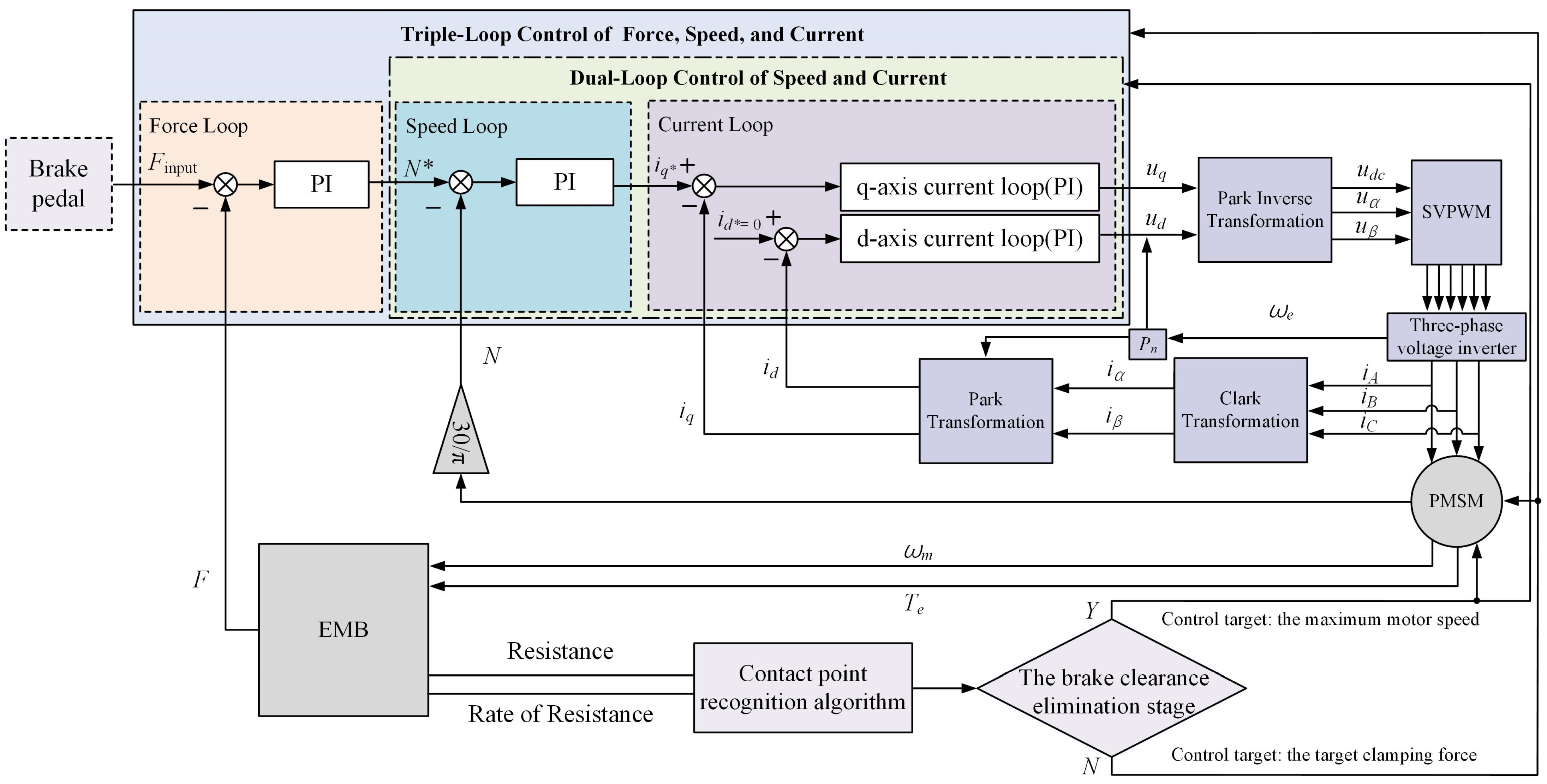

4.2. Clamping Force Control Architecture

4.3. Recognition of Contact Point between Friction Lining and Brake Disc Based on Fuzzy Logic Algorithm

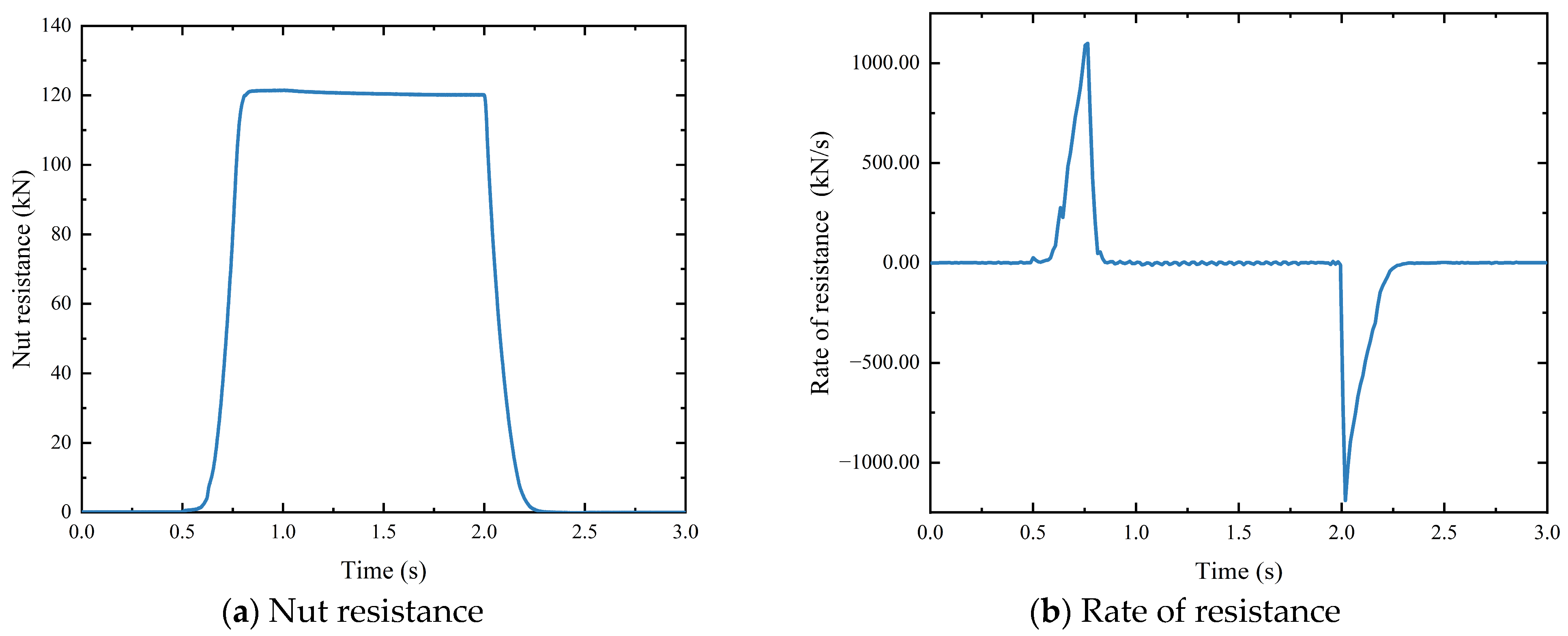

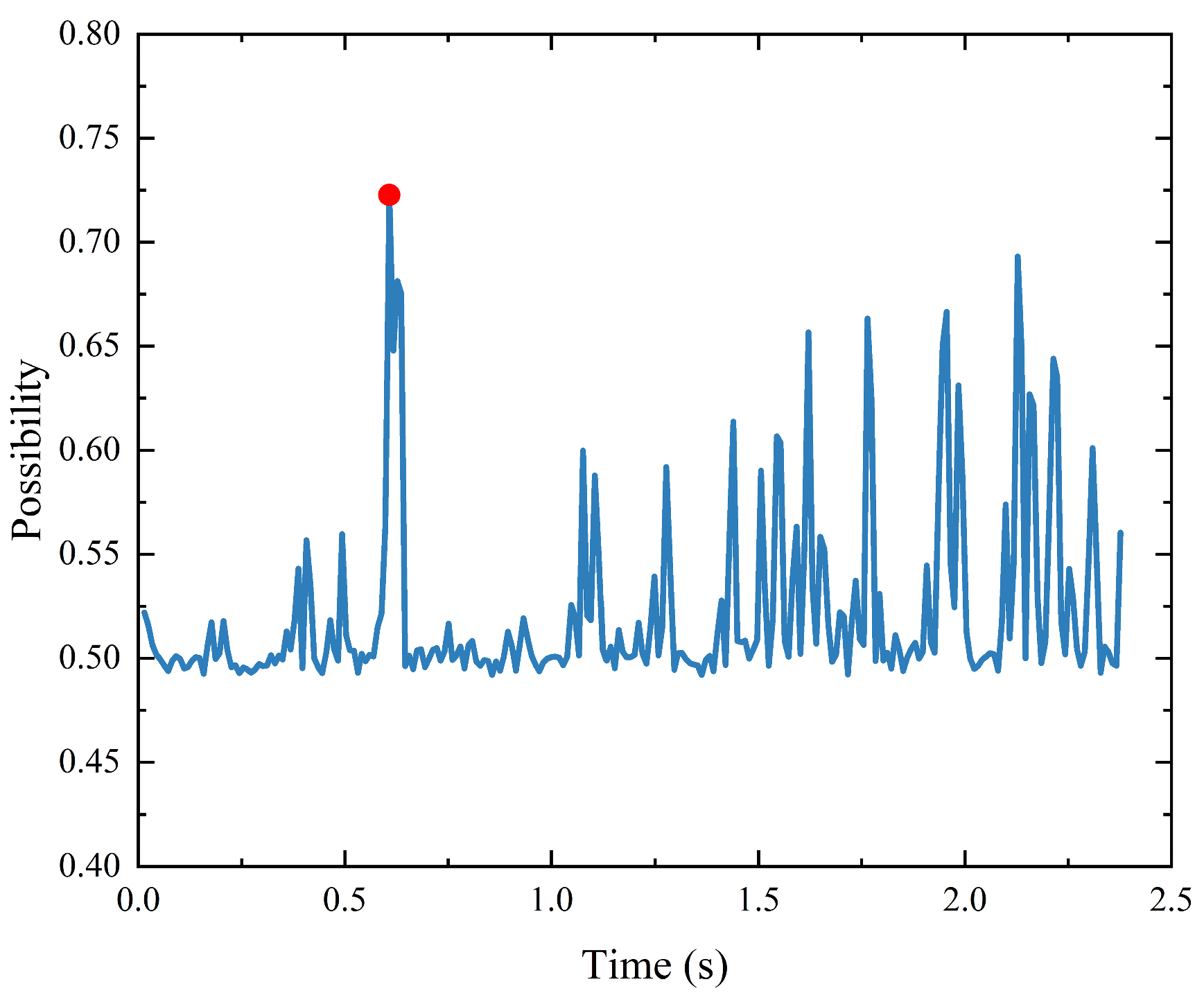

4.3.1. Principles of Contact Point Recognition

4.3.2. Contact Point Recognition Strategy

- Membership Function

- 2.

- Fuzzy Rules

4.4. Clamping Force Control Considering the Contact Point

4.4.1. Clamping Force and Motor Speed Loops: PI Algorithm

4.4.2. The Motor Current Loop

5. A Simulation Analysis of the Strategy

5.1. Contact Point Identification Method

5.2. Clamping Force Control Strategy

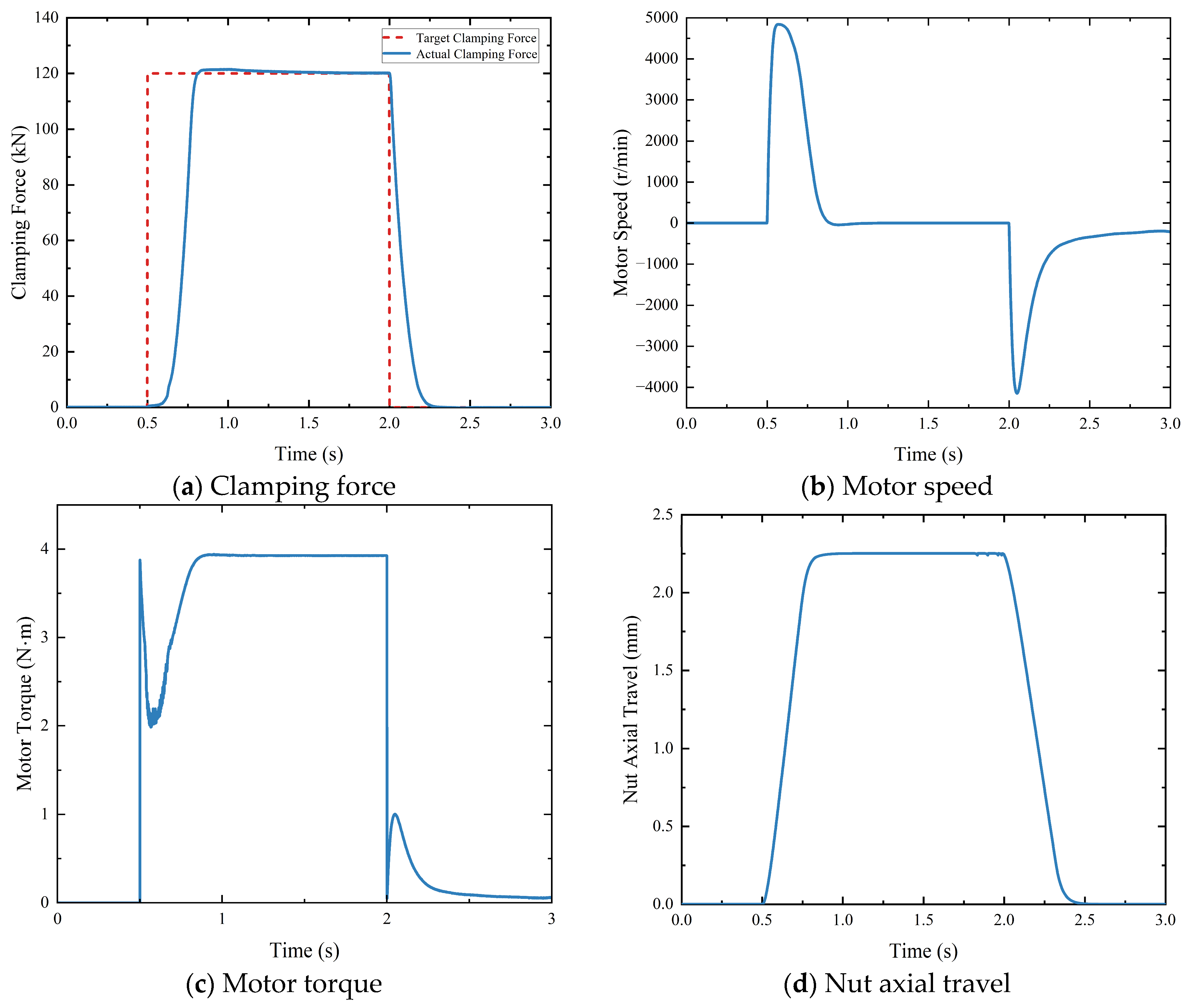

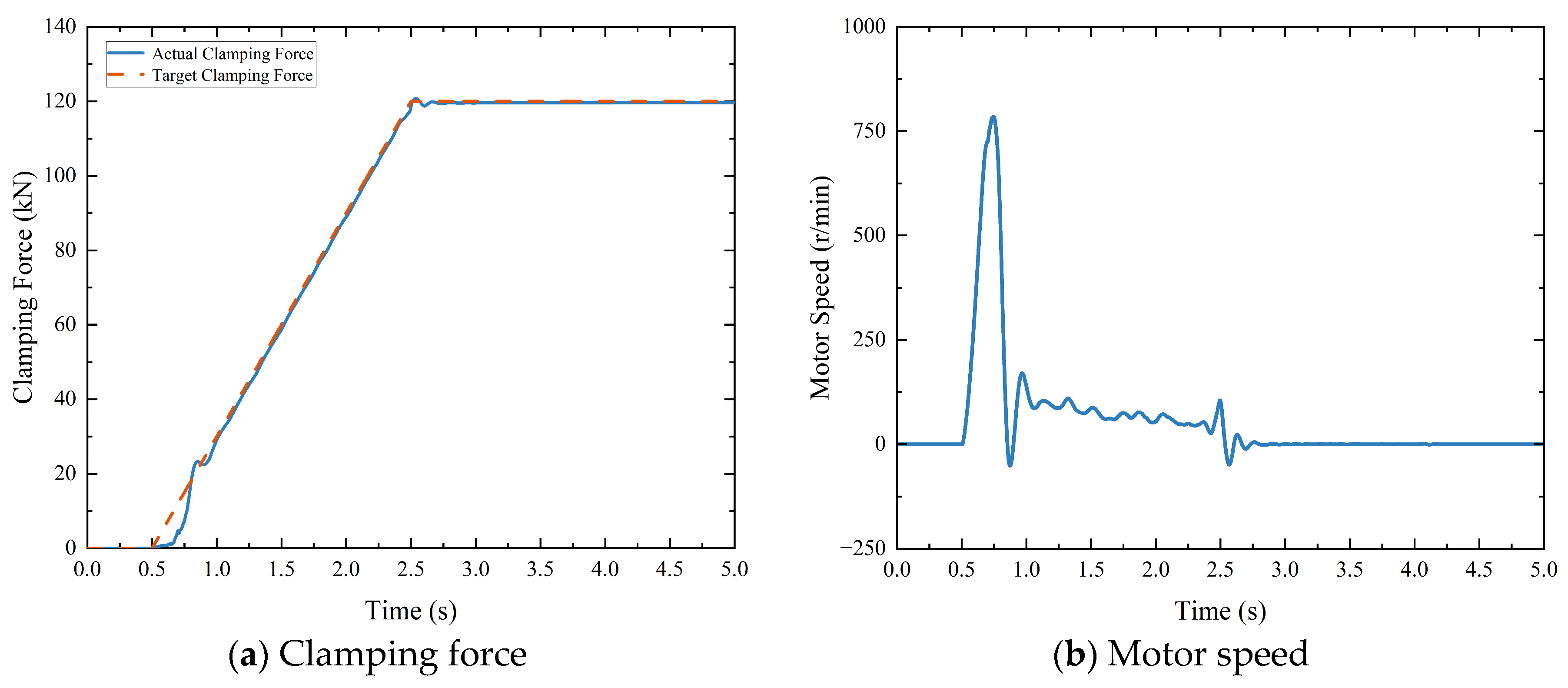

- Step signal of maximum clamping force

- 2.

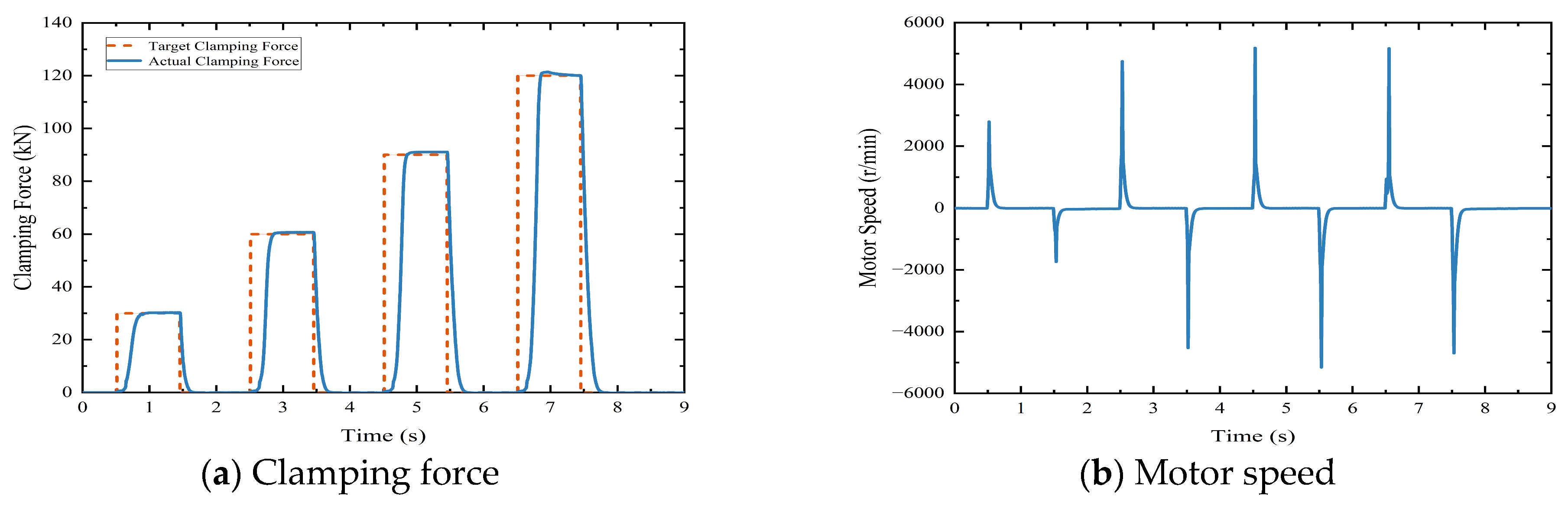

- Pulse signal of various amplitude analysis

- 3.

- Ramp signal

- 4.

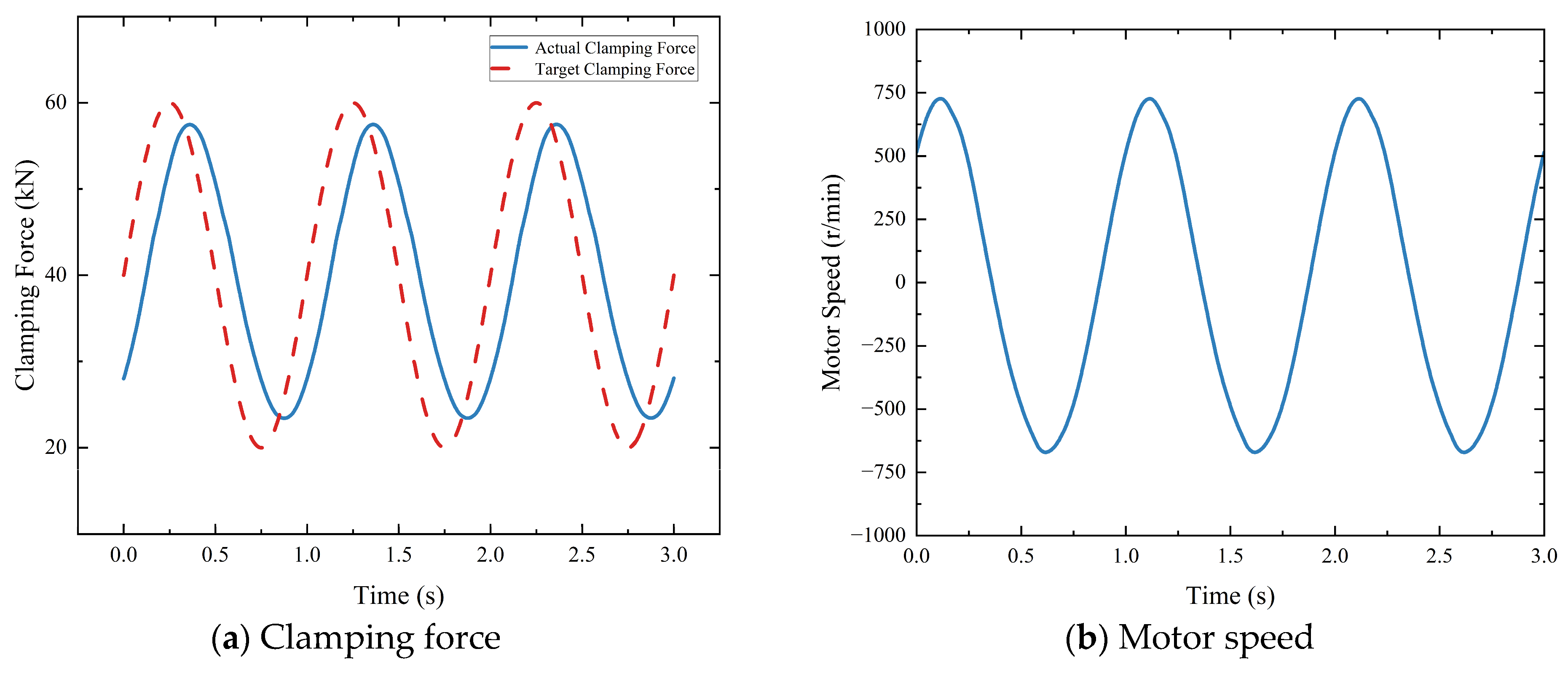

- Sinusoidal signal

6. Conclusions

- Compared with a mainstream pneumatic disc brake, the axial length of the EMB actuator proposed in this study is reduced by 17.6%.

- The contact point identification method can accurately identify the contact point between the friction lining and brake disc.

- The clamping force control strategy enables the EMB actuator to achieve the rapid response, accurate tracking, and stable maintenance of the target signal. Specifically, the time to eliminate brake clearance is 0.5 s, the maximum clamping force response is 0.3 s, and the steady-state error is less than 1 kN.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fang, Z.; Wang, J.; Liang, J.; Yan, Y.; Pi, D.; Zhang, H.; Yin, G. Authority Allocation Strategy for Shared Steering Control Considering Human-Machine Mutual Trust Level. IEEE Trans. Intell. Veh. 2023, 9, 1–14. [Google Scholar] [CrossRef]

- Xu, B.; Ban, X.J.; Bian, Y.; Li, W.; Wang, J.; Li, S.E.; Li, K. Cooperative Method of Traffic Signal Optimization and Speed Control of Connected Vehicles at Isolated Intersections. IEEE Trans. Intell. Transp. Syst. 2019, 20, 1390–1403. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, H.; He, R.; Chen, P.; Chen, H. A Mechatronic Brake Booster for Electric Vehicles: Design, Control, and Experiment. IEEE Trans. Veh. Technol. 2020, 69, 7040–7053. [Google Scholar] [CrossRef]

- Keller, F. Electromagnetic Wheel Brake Device. U.S. Patent US6536561 B1, 25 March 2003. [Google Scholar]

- Cao, C.-T.; Hofmann, D.; Vollert, H.; Nagel, W.; Foitzik, B.; Goetzelmann, B. Self-Boosting Electromechanical Friction Brake. EP 2057385A1, 13 May 2009. [Google Scholar]

- 2006-1-3196; The Electronic Wedge Brake-EWB. SAE International: Warrendale, PA, USA, 8 October 2006.

- 2007-1-866; Modeling and Control of a Single Motor Electronic Wedge Brake. SAE International: Warrendale, PA, USA, 16 April 2007.

- 2006-1-298; Simulation in the Development of the Electronic Wedge Brake. SAE International: Warrendale, PA, USA, 3 April 2006.

- Zhang, M.; Song, J. A Review of Electromechanical Brake (EMB) System. Mech. Sci. Technol. Aerosp. Eng. 2005, 24, 208–211. [Google Scholar]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the Development, Control Method and Application Prospect of Brake-by-Wire Actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef]

- Li, C.; Zhuo, G.; Tang, C.; Xiong, L.; Tian, W.; Qiao, L.; Cheng, Y.; Duan, Y. A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application. Sustainability 2023, 15, 4514. [Google Scholar] [CrossRef]

- Lars, S. A Method and Arrangement for Parking Braking at A Disc Brake. WO 2005/031184 A1, 7 April 2005. [Google Scholar]

- Li, J.; Wang, M.; He, R.; Zhang, J. A Design of Electromechanical Brake System Triple-Loop Controllers Using Frequency Domain Method Based on Bode Plote. In Proceedings of the Proceedings 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Changchun, China, 16–18 December 2011; IEEE: New York, NY, USA, 2011; pp. 795–798. [Google Scholar]

- Jo, C.; Hwang, S.; Kim, H. Clamping-force control for electromechanical brake. IEEE Trans. Veh. Technol. 2010, 59, 3205–3212. [Google Scholar] [CrossRef]

- Line, C.; Manzie, C.; Good, M.C. Electromechanical Brake Modeling and Control: From PI to MPC. IEEE Trans. Control Syst. Technol. 2008, 16, 446–457. [Google Scholar] [CrossRef]

- Saric, S.; Bab-Hadiashar, A.; Walt, J.V.D. Estimating Clamp Force for Brake-by-Wire Systems: Thermal Considerations. Mechatronics 2009, 19, 886–889. [Google Scholar] [CrossRef]

- Lindvai-Soos, D.; Horn, M. Modelling, Control & Implementation of an Electro-Mechanic Braking Force Actuator for HEV and EV. IFAC Proc. Vol. 2013, 46, 620–625. [Google Scholar]

- Park, G.; Choi, S.; Hyun, D. Clamping force estimation based on hysteresis modeling for electro-mechanical brakes. Int. J. Automot. Technol. 2017, 18, 883–890. [Google Scholar] [CrossRef]

- Chen, Q.; Lv, Z.; Tong, H.; Zeng, D.; Ouyang, L.; Liu, Q. Study on Multi-Closed Loop Control of Electro-Mechanical Braking for Electric Vehicles Based on Clamping Force. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023. [Google Scholar] [CrossRef]

- Eum, S.; Choi, J.; Park, S.-S.; Yoo, C.; Nam, K. Robust Clamping Force Control of an Electro-Mechanical Brake System for Application to Commercial City Buses. Energies 2017, 10, 220. [Google Scholar] [CrossRef]

- GB 12676-2014; Technical Requirements and Testing Methods for Commercial Vehicle and Trailer Braking Systems. Standards Press of China: Beijing, China, 2014.

- Kim, J.; Kwon, B.; Park, Y.; Cho, H.; Yi, K. A Control Strategy for Efficient Slip Ratio Regulation of a Pneumatic Brake System for Commercial Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 1546–1567. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Midgley, W.; Steffen, T. A Review of the State of the Art of Torque Ripple Minimization Techniques for Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Inform. 2024, 20, 1019–1031. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Wang, S. Precision loss modeling method of ball screw pair. Mech. Syst. Signal Process. 2020, 135, 106397. [Google Scholar] [CrossRef]

- Nguyen, A.-T.; Taniguchi, T.; Eciolaza, L.; Campos, V.; Palhares, R.; Sugeno, M. Fuzzy control systems: Past, present and future. IEEE Comput. Intell. Mag. 2019, 14, 56–68. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, F.; Liu, Z.; Zhang, Y.; Chen, C.L.P. Fixed-Time Fuzzy Control for a Class of Nonlinear Systems. IEEE Trans. Cybern. 2022, 52, 3880–3887. [Google Scholar] [CrossRef]

- Pan, M.; Wang, H.; Zhang, C.; Xu, Y. Fuzzy Control for Aircraft Engine: Dynamics Clustering Modeling, Compensation and Hardware-in-Loop Experimental Verification. Aerospace 2024, 11, 610. [Google Scholar] [CrossRef]

- Guo, P.; Li, Y.; Lin, Z.; Li, Y.; Su, P. Characterization and Calculation of Losses in Soft Magnetic Composites for Motors with SVPWM Excitation. Appl. Energy 2023, 349, 121631. [Google Scholar] [CrossRef]

- Yang, G.; Hussain, H.; Li, S.; Zhang, X.; Yang, J.; Lee, C.H.T. Design and Analysis of Universal Natural Fault-Tolerant SVPWM Strategy with Simplified Fault Diagnosis for Multiphase Motor Drives. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 4340–4354. [Google Scholar] [CrossRef]

- Arricale, V.M.; Genovese, A.; Tomar, A.S.; Kural, K.; Sakhnevych, A. Non-Linear Model of Predictive Control-Based Slip Control ABS Including Tyre Tread Thermal Dynamics. Appl. Mech. 2022, 3, 855–888. [Google Scholar] [CrossRef]

- Devika, K.; Sridhar, N.; Patil, H.; Subramanian, S.C. Delay Compensated Pneumatic Brake Controller for Heavy Road Vehicle Active Safety Systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 2333–2346. [Google Scholar] [CrossRef]

| Category | Parameters | Value | Unit |

|---|---|---|---|

| Vehicle Mass | Fully Loaded Mass | 10,080 | kg |

| Curb Mass | 7690 | kg | |

| Wheels | Maximum Braking Torque | 16,500 | |

| Effective Radius of Brake Disc | 173 | mm | |

| Rolling Radius of Wheel | 51 | mm | |

| Brakes | Brake Clearance (Single Side) | 0.3~0.6 | mm |

| Friction Coefficient | 0.4 | / |

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Stiffness coefficient | 0.001 | / | |

| Viscous damping coefficient | 0.001 | / | |

| Viscous friction coefficient | 0.001 | / | |

| Stribeck velocity | 0.8 | m/s | |

| Coulomb friction | 1 | N | |

| Static friction | 1.5 | N |

| Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Brake Tightening | −422.3 | 55.15 | 11.24 | 112.1 | 30.54 | 0 | 0 | 0 | |

| Brake Release | 63.39 | 3.911 | −23.25 | 43.14 | 7.137 | 142.2 | 49.03 | 12.55 |

| Resistance | Rate of Resistance | |||||||

|---|---|---|---|---|---|---|---|---|

| Ad | Bd | Cd | Dd | Ed | Fd | Gd | Hd | |

| Az | VL | VL | QL | QL | L | L | ML | ML |

| Bz | VL | QL | QL | L | L | ML | ML | M |

| Cz | QL | QL | L | L | ML | ML | M | M |

| Dz | QL | L | L | ML | ML | M | M | MG |

| Ez | L | L | ML | ML | M | M | MG | MG |

| Fz | L | ML | ML | M | M | MG | MG | MH |

| Gz | ML | ML | M | M | MG | MG | MH | MH |

| Hz | ML | M | M | MG | MG | MH | MH | H |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Wu, T.; Rong, J.; Yang, X.; Peng, J.; Chu, L. Clamping Force Control of Electromechanical Brake Actuator Considering Contact Point between Friction Lining and Brake Disc. Actuators 2024, 13, 345. https://doi.org/10.3390/act13090345

Meng Y, Wu T, Rong J, Yang X, Peng J, Chu L. Clamping Force Control of Electromechanical Brake Actuator Considering Contact Point between Friction Lining and Brake Disc. Actuators. 2024; 13(9):345. https://doi.org/10.3390/act13090345

Chicago/Turabian StyleMeng, Yang, Tong Wu, Jin Rong, Xiaojun Yang, Jing Peng, and Liang Chu. 2024. "Clamping Force Control of Electromechanical Brake Actuator Considering Contact Point between Friction Lining and Brake Disc" Actuators 13, no. 9: 345. https://doi.org/10.3390/act13090345

APA StyleMeng, Y., Wu, T., Rong, J., Yang, X., Peng, J., & Chu, L. (2024). Clamping Force Control of Electromechanical Brake Actuator Considering Contact Point between Friction Lining and Brake Disc. Actuators, 13(9), 345. https://doi.org/10.3390/act13090345