1. Introduction

The need for a sustainable power source for micro devices, autonomous underwater vehicles, drones, robotics, and remote sensor networks has placed an increasing emphasis on ambient energy harvesting devices that exhibit high converted energy density per cycle with improved efficiency [

1,

2,

3,

4,

5,

6]. Ambient energy may be one or more of the following sources: mechanical vibration, thermal fluctuations, or electromagnetic radiation. A multi-domain energy harvester is a harvester capable of generating a usable output electrical power in response to variations in ambient conditions. It is desirable if such a harvester could respond not only to low level inputs, but also to low frequency excitations. For instance, traditional mechanical energy harvesters are based on resonant cantilever designs utilizing the linear piezoelectric mode. However, as the most effective power conversion only occurs at the characteristic resonant frequency of the harvester, they are narrow band. Therefore, to harness broadband mechanical vibrations, a multimodal approach with multiple harvesters must be used. Another solution to broaden the bandwidth of the harvesters and maximize energy output is complex mechanical frequency up-conversion techniques, allowing for tuning the resonant frequency of the harvester to match the resonance of the excitation source frequency [

4].

However, we recently have demonstrated a giant electromechanical energy conversion in a non-resonant device capable of delivering an energy density per cycle nearly two orders of magnitude larger than traditional cantilever piezoelectric devices working in resonance mode [

7]. Moreover, the device is capable of low frequency energy conversion in the Hertz region and is not frequency-limited up to several kHz by the piezoelectric crystal-load impedance [

8]. This device is also capable of converting variations in environmental temperature to a usable electrical output [

9] and therefore can be considered a dual-domain harvester. It operates on a phase transition transduction principle in relaxor ferroelectric crystals that was first reported by Finkel, Benjamin, and Amin [

10] and was later utilized in a miniaturized class IV (flex-tensional) acoustic source [

11].

This electro-mechanical energy conversion was manifested during a ferroelectric-ferroelectric phase transformation in [011] cut domain engineered perovskite lead titanate-based relaxor ferroelectric single crystals with compositions near the morphotropic phase boundary (MPB) [

7,

8,

9]. It was found that under mechanical pre-stress, a relatively small oscillatory stress or electric field drives the material reversibly between the ferroelectric rhombohedral (F

R) and ferroelectric orthorhombic (F

O) states with a remarkably high polarization and strain jump induced at room temperature. This inter-ferroelectric phase transformation takes place via polarization rotation from the three-fold symmetry axes of the two rhombohedral macro-domain states to the two-fold symmetry axis of the mono-domain orthorhombic state. It is a consequence of the ultra-low energy barrier to stress- or electric field-induced inter-ferroelectric phase transformation due to the near degeneracy of the energy surface for lead indium niobate–lead magnesium niobate–lead titanate (PIN-PMN-PT) with a composition near the MPB [

12]. Since the mono-domain F

O state is unstable under free electric or elastic boundaries, it reverts back to its original F

R state upon the removal of stress or field. In this work, we have employed the same concept to design and build a non-resonant, magnetoelectric (ME) composite harvester. Magnetostrictively driven strain in this harvester generates sufficient critical stress to induce this phase transformation in mechanically biased single crystal with demonstrated high electromechanical energy conversion in broad range of frequencies [

7].

2. Magneto-Electric Harvester Architecture and Characterization

The ME hybrid harvester is comprised of a highly magnetostrictive Fe

81.4Ga

18.6 (Galfenol, from Etrema Products, Inc.) or Tb

xDy

1-xFe

2 (Terfenol-D) alloy and Pb(In

1/2Nb

1/2)O

3–Pb(Mg

1/3Nb

2/3)O

3–PbTiO

3 (PIN-PMN-PT) domain engineered relaxor ferroelectric single crystal under mechanical pre-stress. Commercially grown Bridgman PIN-PMN-PT single crystal with a nominal composition on the rhombohedral side of the MPB was selected to construct a magnetoelectric ME harvester. To determine the critical pre-stress, room temperature, quasi-static, harmonic compression–decompression scans of PMN-PMN-PT 4 × 4 × 12 mm

3 bars cut in the 32-mode geometry and poled along the [011] direction were conducted using 0.1 Hz cycles with a 50 MPa stress amplitude at different dc electric field levels from 0 to 0.5 MV/m.

Figure 1a depicts the stress-strain response of the crystal for different dc bias levels. A sharp strain change associated with a F

R-F

O phase transformation occurs for the zero field response near a critical stress of ~20 MPa on compression. Note the magnitude of the critical stress decreases upon increasing the dc bias level as shown in

Figure 1b for both the compression and decompression cycles.

Figure 1.

(a) Room temperature elastic response at various electric field bias and (b) stress-field stability region for [011] poled Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 (PIN-PMN-PT) samples, where FR and FO represent stable ferroelectric rhombohedral and ferroelectric orthorhombic states, respectively.

Figure 1.

(a) Room temperature elastic response at various electric field bias and (b) stress-field stability region for [011] poled Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 (PIN-PMN-PT) samples, where FR and FO represent stable ferroelectric rhombohedral and ferroelectric orthorhombic states, respectively.

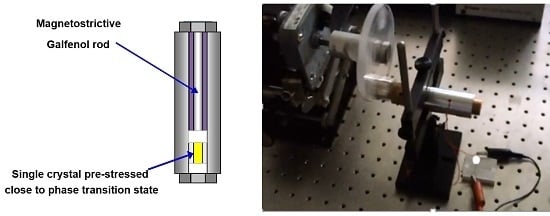

The hybrid system is designed to provide sufficient uniaxial stress in a pre-stressed piezocrystal with two specially machined stress-annealed Galfenol rods (with saturation magnetostriction ~300 × 10

−6) encapsulated with the crystal inside the aluminum case (

Figure 2a). The magnetostrictive Galfenol element’s frequency range is primarily limited by eddy currents. These Galfenol rods have been laminated to reduce eddy current losses and have been used to demonstrate operation in kHz range (private communication J.R. and Etrema Products, Inc).

Figure 2.

(a) Magnetoelectric harvester cross-section, showing the applied bipolar field direction. (b) Experimental setup showing the harvester in a solenoid coil.

Figure 2.

(a) Magnetoelectric harvester cross-section, showing the applied bipolar field direction. (b) Experimental setup showing the harvester in a solenoid coil.

When driven by a varying magnetic field, this hybrid ME device utilizes the strain in the laminated Galfenol rod to further stress the PIN-PMN-PT crystal, triggering the F

R-F

O phase transformation. The ME hybrid system is shown in

Figure 2a, and the experimental setup in

Figure 2b. Two polished ceramic (Macor©) spacers with insulating polyamide (Kapton) tape were used on both sides of the piezocrystal to avoid arc effects. To provide uniform and constant stress conditions for the PIN-PMN-PT, an elastomer (Polyurethane) spring was used for mechanically pre-stressing the piezocrystal close to a stress-induced F

R-F

O phase transformation (~17 MPa) using the bottom pre-loading screw (

Figure 2a). The end of one Galfenol rod is brought in intimate contact with the piezocrystal using an adjustable loading (top) screw allowing for the elimination of backlash to provide an additional magneto-mechanical stress. In this Galfenol rod, the stress annealing builds in about 30 MPa of internal compressive stress which is added to the applied pre-stress reducing the requirement for an externally applied pre-stress [

13,

14]. This additional magnetostriction-driven stress variation resulting from an applied magnetic field is sufficient to trigger the F

R-F

O phase transformation and consequent generation of voltage across [011] electrodes of the single crystal that is initially mechanically pre-stressed inside the aluminum case. Therefore, a direct magnetoelectric effect is realized here for direct energy conversion from a small ac magnetic field.

Figure 3a shows the magnetostrictive strain (λ)

vs. magnetic field (

H) curve and the piezomagnetic coefficient, dλ/d

H, for a stress annealed Galfenol rod with 20.7 MPa of pre-stress applied. The material is typically magnetically biased to operate in a quasi-linear regime of the device, with the vertical line representing an optimal magnetic bias point. This should correspond to the peak of the dλ/d

H of Galfenol as shown in

Figure 3a at ~200 Oe.

Figure 3.

(

a) Strain

vs. applied magnetic field and dλ/d

H for a stress-annealed Galfenol (Fe

81.6Ga

18.4) rod with 20.7 MPa of compressive pre-stress applied. The vertical line denotes a typical magnetic bias point. (

b) Voltage generated by the piezocrystal under the three different pre-stress conditions described in the text. (

c) Time dependence of the applied magnetic field, induced current and voltage from the crystal (V

crystal) in the PT region while driving with an ac magnetic field (setup shown in

Figure 2b).

Figure 3.

(

a) Strain

vs. applied magnetic field and dλ/d

H for a stress-annealed Galfenol (Fe

81.6Ga

18.4) rod with 20.7 MPa of compressive pre-stress applied. The vertical line denotes a typical magnetic bias point. (

b) Voltage generated by the piezocrystal under the three different pre-stress conditions described in the text. (

c) Time dependence of the applied magnetic field, induced current and voltage from the crystal (V

crystal) in the PT region while driving with an ac magnetic field (setup shown in

Figure 2b).

To demonstrate the working principle of this ME conversion in a wide range of frequencies and to characterize the output voltage generated via stress, an ac magnetic field with frequency 0.5–5 Hz was produced by the solenoid coil as shown in

Figure 2b using a current amplifier (Kepco Bipolar Operational Power Supply/Amplifier ±20 V, ±10 Amp) driven by a functional generator (Agilent 33220 A). We investigated three regimes corresponding to different pre-stress conditions: (i) when the crystal is pre-stressed below the F

R-F

O transition (linear mode with F

R phase); (ii) close to the transition for the stress-induced F

R-F

O nonlinear phase transformation (PT) region; and (iii) above critical stress sufficient to bring the crystal to F

O phase.

As the magnetic field is swept sinusoidally around a bias field, the Galfenol rod strains (see

Figure 3a) and stresses the piezocrystal, thus producing a voltage. The voltage generated across the [011] electrodes of the crystal (V

crystal) under the three different pre-stress conditions described above is illustrated in

Figure 3b. Away from the PT region, there is still some voltage produced due to the linear piezoelectric effect. This results in a magnetic field dependent induced voltage due to the large piezoelectric effect in PIN-PMN-PT, regardless of the level of pre-stress applied. When the crystal is in either the F

R or F

O phases, a slight increase in voltage occurs where the piezomagnetic coefficient (dλ/d

H) of Galfenol is maximum (right axis on

Figure 3a), taking into account some mechanical hysteresis due to the fixture as observed in

Figure 3b. However, when the crystal is situated at a critical stress near the phase transition, large and abrupt spikes in the voltage of around 50 V were observed in both the up and down magnetic field sweeps that can only result directly from the stress-induced phase transformation (see

Figure 3b). As shown in

Figure 1a,b, the hysteresis in the elastic response for F

R-F

O phase transformation is ~3 MPa. This stress variation should be less than that generated by the magnetostrictive strain in the Galfenol rods for an applied magnetic field created by the coil. It should be noted that Gao

et al. used similar circuitry with the viability to power low frequency ME magnetic sensors by using Metglas/PMN-PT laminates [

15].

The figure-of–merit (FOM) of the magnetic and electric energy conversion in the multi-domain harvester device that represents the efficiency of transduction between magnetic and electric fields is the ME coupling coefficient between the two phases denoted as

where

V is the generated voltage and

t is the thickness of the piezoelectric phase. By taking the derivative of the present magnetic field dependent voltage plots and normalizing by the thickness of the crystal, we can obtain the spontaneous values of

αME as a function of bias magnetic field. At 1 Hz applied field, the maximum ME coefficient was found to be 1.38, 1.34, and 82.9 V/(cm Oe) when PIN-PMN-PT is in the F

R phase, F

O phase, and near the F

R-F

O PT region, respectively. It is clear that the values of

αME are maximized when the crystal is near the phase transformation due to the large voltage spikes rising from this first-order phase transition and resulting large change in polarization. The value of

αME is an order of magnitude larger as compared to previous results in the literature (see review in Reference [

16]).

The potential for storing the harvested energy in an external capacitor was validated by placing the ME harvester in a coil supplying a time varying magnetic field up to 500 G. To optimize the response of the Galfenol rods, a magnetic field bias of 250 G was chosen. The time dependent magnetic field and the resulting time dependent current and voltage from the harvester are shown in

Figure 3c. For one period of the magnetic field, two voltage spikes corresponding to the F

R-F

O and F

O-F

R phase transformations are observed after rectification. An average peak power (P = V

2/R) of 2 mW was generated in a 1 MΩ load resistor. This power was then used to charge a 0.47 μF capacitor. The circuit diagram is shown in the inset of

Figure 4. The average charging rate was calculated from the slope of the time-dependent voltage over the capacitor (V

cap) shown in

Figure 4 to be 1.8, 1.6, and 3.2 V/s for a 1 Hz alternating magnetic field when PIN-PMN-PT is in the F

R phase, F

O phase, and near the F

R-F

O PT region, respectively. Thus we observe that the increased voltage, magneto-electric coupling and efficiency allow for a 1.8 times increase in charging rate.

Figure 4.

Voltage over a 0.47 μF capacitor versus time when the crystal is under various pre-stress conditions. Inset shows circuit diagram used to store voltage from the piezocrystal.

Figure 4.

Voltage over a 0.47 μF capacitor versus time when the crystal is under various pre-stress conditions. Inset shows circuit diagram used to store voltage from the piezocrystal.