1. Introduction

The traditional use of 3D printing has been to create custom parts with intricate shapes including overhangs, recesses, and interleaved parts. More recently, 3D printing has been used to create kinematic mechanisms with gears, linkages [

1,

2] and machines that are powered by their natural dynamics and geometry [

3]. However, such passive machines and mechanisms have very little utility unless they are endowed with actuators. In this paper, we explore the use of 3D printing to create a pneumatic actuator and its utility on a legged robot.

The most straightforward technique of creating actuated robots is to first 3D print the individual components, assemble them, and then integrate electric motors (e.g., the humanoid poppy [

4]). A more subtle approach is to create 3D printed joints that are co-printed within the machine structure and embed actuators by stopping the print process [

5]. The benefit of this method is the elimination of the assembly process, thus saving time. However, the approach is more complicated: visual cues need to be set up to stop the printing process to embed actuators and joints need to be designed so that excess material around the joints can be easily removed post-printing. More recently, Maccurdy et al. [

6] created a non-assembly hexapod robot that included bellow actuators, gear pumps, and soft grippers, all of which were printed as a single integrated assembly using a multi-material printer. The gear pump forces the fluid through the transmission thus moving the robot legs in a predefined fashion to create forward movement.

There has been considerable research on creating actuators for soft robots. For example, Peele et al. [

7] have created a pneumatic bellow type actuator using stereolithography and fabricated an octopus tentacle. Tolley et al. [

8,

9] created a jumping robot with functionally graded stiffness that is rigid at the core and soft on its exterior. It is powered by an explosive reaction between butane and oxygen that generates a high thrust. Moog Inc. created a compact hydraulic actuator by using a 3D printer that can print metal. They have successfully integrated the hydraulic actuator with a two-stage servo control valve, position and pressure sensors, and onboard electronics [

10]. Wei [

11] created a pneumatic stepper motor which consists of a central fixed gear and an outer rotary gear. The three air cylinders on the outer side of the rotary gear are able to move the rotary gears either in steps or in a continuous mode. The actuator was used to create a robot that performed a pick and place operation.

Although 3D printing has been used to create soft pneumatic actuators where compressed air moves a springy surface to produce movement, conventional linear pneumatic actuators with sliding joints have not been investigated before and are the main novelty of this work. The fundamental challenges in creating such an actuator are achieving leak-proof, low friction, and a strong actuator that can withstand relatively high air pressure. We address these challenges by using the chemical treatment after 3D printing to achieve a strong and leak-proof cylinder, design of cylinder and the piston head to achieve a tight fit for the O-ring, supplementing plastic with metallic inserts in high-stress areas to improve durability, and the lubrication of surfaces to achieve low friction movement.

The paper is organized as follows. We present the actuator’s design and fabrication in

Section 2. Next, in

Section 3 we present the actuator’s testing and demonstration as a single leg hopping and jumping robot, and its incorporation into a legged robot inspired by Disney/Pixar Luxo lamp. The discussion is in

Section 4 followed by the conclusion in

Section 5.

2. Fabrication of the Pneumatic Actuator

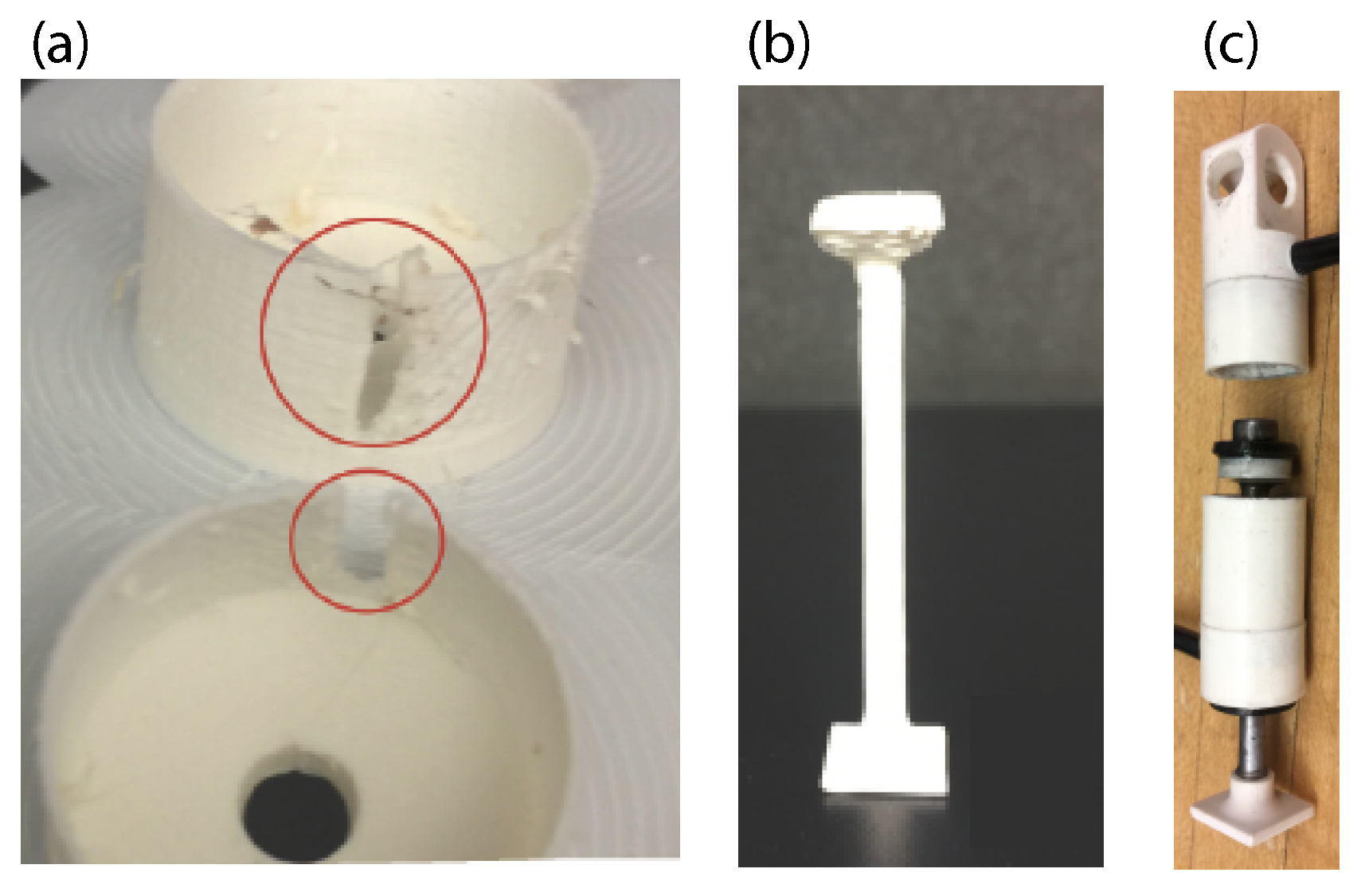

Figure 1a shows an exploded view of the different parts that constitute the actuator. The cylinder head (1), cylinder body (2), cylinder end cap (3), and piston head (5), all of which are 3D printed in the orientation shown in

Figure 2a. The piston rod (4), a galvanized steel bolt and the rubber O-ring (5) are off-the-shelf components. The Ultimaker 3 Extended, a hobby-grade Fused Deposition Modeling printer, was used to fabricate the 3D printed components. The print settings were chosen to allow for maximally dense printed components. The critical printer settings included: 100% infill density, extra-fine profile, layer height of

mm, and a printing temperature of 225

C. The complete assembly and fabricated actuator are shown in

Figure 1b,c respectively.

Our most successful 3D printed actuator had an overall size of cm, bore of cm, stroke of 2 cm, cylinder thickness of cm, mass of 12 gm, and a peak output force and power of 3 N and W, respectively, at an air supply pressure of 40 psi ( kPa).

2.1. Cylinder

The cylinder body, head, and end cap were 3D printed using ABS (Acrylonitrile Butadiene Styrene) as separate parts. In spite of printing with a fine resolution, the resulting parts have a rough surface finish leading to high friction and a presence of fine pores leading to air leakage. We resolved both of these issues by dipping individual cylinder components in acetone for a short period of time. Acetone is a solvent and has the ability to dissolve the ABS plastic [

12]. We have observed that if the ABS part is placed in the acetone for the correct amount of time, it dissolves just enough ABS to provide a smooth surface finish thus sealing the pores. The dipping time is critical as a very short period of time is inadequate while a long period of time would cause a substantial portion of ABS is dissolved, leading to loss of ABS plastic and therefore reducing material strength. More details on determining the optimum dip time is in

Section 2.5.

Figure 2b,c shows the surface finish of the different components before and after treatment, respectively.

Figure 3a,b shows a close of the surface finish before and after acetone treatment The head, body, and end cap were adhered using acrylic-based adhesive (Loctite, Henkel AG and Company, Düsseldorf, Germany).

2.2. Piston Rod

The piston rod is subject to significant compressive stresses during its operation. Our initial attempts at printing the piston rod led to actuator failure due to the breaking of the piston rod. We then used a galvanized steel bolt in place of the 3D printed one and it was found to be very durable.

2.3. Piston Head

One of the advantages of 3D printing is the ability to embed materials by stopping the print process. We used this feature to 3D print the piston head on the steel bolt as shown in

Figure 3b–d. First, we 3D printed a scaffold as shown in

Figure 3c. We used visual cues to stop the print process in order to place the steel bolt between the scaffolds. Note that the steel bolt is placed vertically with the bolt head at the top. Then, the piston head is printed on the bolt head using the scaffolds as support material as shown in

Figure 3d. Finally, the scaffolds are removed leaving the piston head on top of the steel bolt as shown in

Figure 3e. However, the process of embedding takes a long time and results in wastage of significant ABS plastic. We tried an alternate approach of first 3D printing the piston head. Then, we used an acrylic-based adhesive (Loctite, Henkel AG and Company) to attach the piston head to the piston. Loctite has an epoxy resin and a hardener that forms a strong bond between metal and plastic. The primary advantages of using Loctite are providing a bond as well as a seal, there is a marginal increase in the weight, and it provides a means for quick, yet strong assembly. After assembly, we then applied a waterproof grease (Danco, Inc., Irving, TX, USA) on the piston head and the inner surface of the cylinder to provide lubrication between the surfaces (see

Figure 3f).

2.4. Assembly between the Piston Head and Cylinder

We used a rubber O-ring (Danco, Inc., Irving, TX, USA) to provide a tight seal between the piston head and the cylinder. We created a groove in the middle of the 3D printed piston head. The diameter of the groove was slightly larger than the inner radius of the O-ring. The diameter of the cylinder was selected to have a compression squeeze of less than 5%, (an empirical choice used in O-ring applications). The compression squeeze is defined as the percentage difference between the original O-ring cross-section before installation and the final cross-section after installation. Our final design had a compression squeeze of

%. During O-ring installation design, a stretch greater than 5% is not recommended as it may lead to loss of seal compression. The final piston head and O-ring design are shown in

Figure 3f.

2.5. Improving Surface Finish, Reducing Air Leakage Through Acetone Treatment

The surface finish of the cylinder is rough because the cylinder is 3D printed in the axial direction along the length as concentric rings stacked on top of each other (see

Figure 4a). There is a single ring per layer and the thickness of each ring is equal to the size of the printer nozzle hole. Gravity helps to fuse the concentric layers together. However, occasionally these layers do not fuse properly leading to a defective print as shown in

Figure 4b. Furthermore,

Figure 4c shows a ring that separated from the cylinder. The lack of a strong contact between adjacent concentric rings is the main reason there is air leakage.

Acetone may be used to improve the surface finish of the rough surface. In addition, acetone should also help to fuse concentric rings more firmly thereby reducing air leakage. Acetone can dissolve ABS plastic and by controlling the dip time it is possible to ensure that the right amount of ABS is dissolved to provide a smooth surface without affecting structural integrity [

13]. Thus, it is critical to determine the correct dip time.

To determine the optimum dip time we prepared 7 identical cylinders. Each of these cylinders were dipped in acetone for different times, 0 s corresponding to no dipping in acetone, 1, 5, 10, 15, and 20 s as shown in

Figure 5a,b. One end of each cylinder was attached with tubing to a constant inlet pressure of compressed air ranging from 10 to 50 psi (

kPa to

kPa). At each interval of increasing the pressure by 10 psi (

kPa), the value of the pressure gauge also connected via tubing to the opposite end of the cylinder was recorded. The recorded values for the pressure differentials of the various combinations of treated specimens and inlet pressures are shown in

Figure 5c. It may be seen that as the inlet pressure is increased, the pressure loss increased. Also, as the treatment time increased, the pressure loss time decreased. At 15 and 20 s, there was no pressure loss. Based on this experiment, we chose the optimum dip time as 15 s as we noticed no pressure loss. The pressure loss may be attributed to the pores in the cylinder surface due to a lack of sufficiently dense filling with our hobby-grade printer.

4. Discussion

We have successfully demonstrated the development of miniature size, 3D printed linear pneumatic actuator, using a fused deposition modeling printer. We demonstrated both supported and unsupported vertical jumping of the actuator. Due to lightweight and high power capacity, the actuator achieved an average jump height of 2 stroke lengths and maximum jump height of 4 stroke lengths. Furthermore, we incorporated the actuator into a Disney/Pixar Luxo inspired lamp to demonstrate the actuator’s utility in legged robotic applications.

We compared our actuator with a hobby-grade pneumatic actuator by LEGO and an industrial-grade electric actuator by Faulhaber [

16]. We repeated the constrained rail test for the LEGO actuator.

Figure 10 compares the forces developed in the LEGO actuator and our 3D printed actuator for 2 different input air pressures of 20 psi (

kPa) and 40 psi (275 kPa). It is clear that our 3D printed actuator produces high output pressure than the LEGO actuator. Note that the forces shown are not repeatable due to two factors: (1) the lack of repeatable analog input to the valves by the Arduino due to its limited bandwidth, and (2) the bouncing off of the actuator after landing. We used values reported in the Faulhaber motor specification sheet for our comparison. The results are tabulated in

Table 1. The LEGO actuator and our actuator are comparable in both mass and size. However, our actuator produced

times the peak force, was about 2 times faster, and consequently had power of

times that of the LEGO actuator. The larger power in our actuator compared to the LEGO actuator may be attributed to the low sliding friction in our linear actuator. We achieved a smooth surface by acetone treatment followed by the application of lubricant on the inner surface as well as the piston head. In fact, when we tried to manually move the piston by hand, we found that the LEGO actuator needed substantially large force compared to our actuator, which is probably due to lack of enough lubrication at the piston-cylinder assembly. We believe that the LEGO actuator is produced from injection molding while our actuator is 3D printed. The LEGO actuator costs approximately USD

(market price) that includes the cost of materials, labor, and overhead. On the other hand, our 3D printed actuator requires material worth USD

(USD

for the steel bolt,

for 50 gm ABS, and

for the O-ring). Since our 3D printed actuator was hand-made versus the LEGO actuator which is mass-produced using injection molding, it is difficult to compare the two based on pricing. Our actuator was comparable in size to the Faulhaber electric motor. The peak power of our actuator was in the range of the continuous power output of the Faulhaber motor.

The surface treatment of ABS plastic performs three important functions. First, it seals the pores of the 3D printed actuator, thus preventing air leakage through the cylinder’s surface. Secondly, it produces a reduced friction surface, allowing for relatively smooth interface motion between the O-ring and the inner surface of the cylinder. Third, the cylinder surface is strengthened due to the acetone treatment. For example, the untreated actuator cylinder failed in the transverse direction when subjected to 70 psi ( kPa) pressure and a relatively low cycle rate. However, the cylinder that was acetone treated did not show any signs of failure at equivalent pressures. For our earlier prototypes, we used Polylactic Acid (PLA), which is the other dominant Fused Deposition Modeling (FDM) filament. Due to printer limitations, PLA, like ABS, produces parts with pores. Since acetone does not dissolve PLA, we were unable to seal the pores and thus unable to create a PLA-based 3D printed actuator.

An outstanding challenge in actuator design is to create a high power-to-weight actuator. The use of plastic material as the main fabrication material allows us to keep the design lightweight while capitalizing on the high force generation capability of compressed air. Furthermore, the use of acetone to smooth the surfaces and the use of waterproof grease on the inner surface of the cylinder provides a low friction surface. This reduces unnecessary losses and allows for high force and power generation. Although the strength of plastic can be an issue, we found that if the actuator is designed properly (i.e., sufficiently thick wall, avoiding kinks or corners to prevent stress concentration corners) and printed in the correct orientation, the actuator can be of sufficient strength. Another less exploited feature is the ability to stop the print process to embed sensors, motors, structural components, and fixtures that can provide additional functionality [

5]. We have exploited this feature by using a metallic piston rod, high stress-bearing part, in a fluidic actuator.

There is an increased drive towards creating designs that are 3D printed in a single pass without assembly. Our actuator does not fit this bill and requires substantial post-processing and manual assembly. In addition, the actuator also needed metal inserts (i.e., the piston) to be able to bear the high compressive forces experienced during its operation. However, our actuator is tiny and has the potential for the nontrivial addition of added sensors (e.g., position sensors). It is currently limited to simple On-Off type applications. Ultimately, adding high bandwidth position and force control will expand the utility of such an actuator (e.g., [

17]). In our experience, limitations of FDM based 3D printers such as low printer resolution, lack of isotropy of the finished parts, and poor quality control prevent the rapid prototyping of machines and mechanisms where high strength is desired.